Identifying Elastic Constants for PPS Technical Material When Designing and Printing Parts Using FDM Technology

Abstract

1. Introduction

- (a)

- As regards process: extrusion temperature, chamber temperature, printing speed, layer height, skin thickness of the printed part, the percentage and type of filling used, construction orientation regarding dimension, surface and functional capabilities related to the printed parts.

- (b)

- With respect to material: circularity and dimensional tolerance of 3D printing filaments, together with moisture content, surface roughness and internal porosity.

- (c)

- With reference to physical phenomena: room-temperature, nozzle diameter, and construction platform [3].

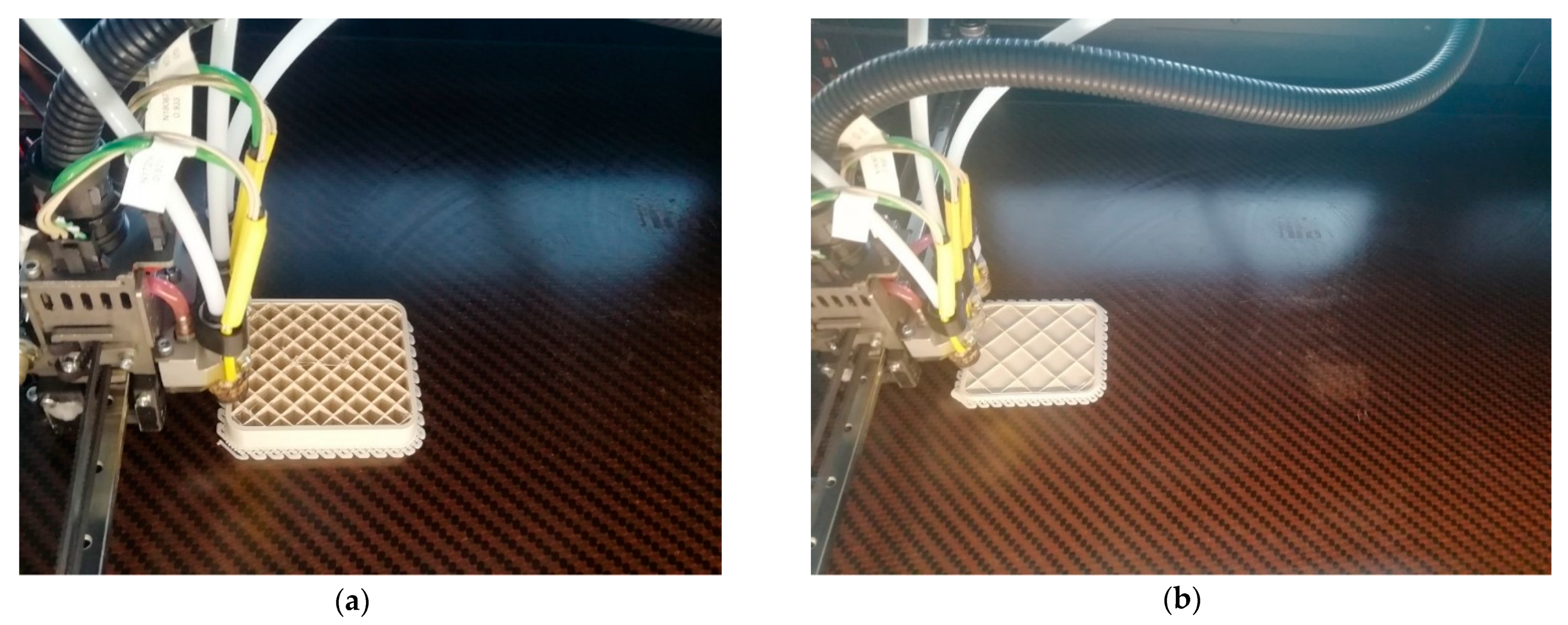

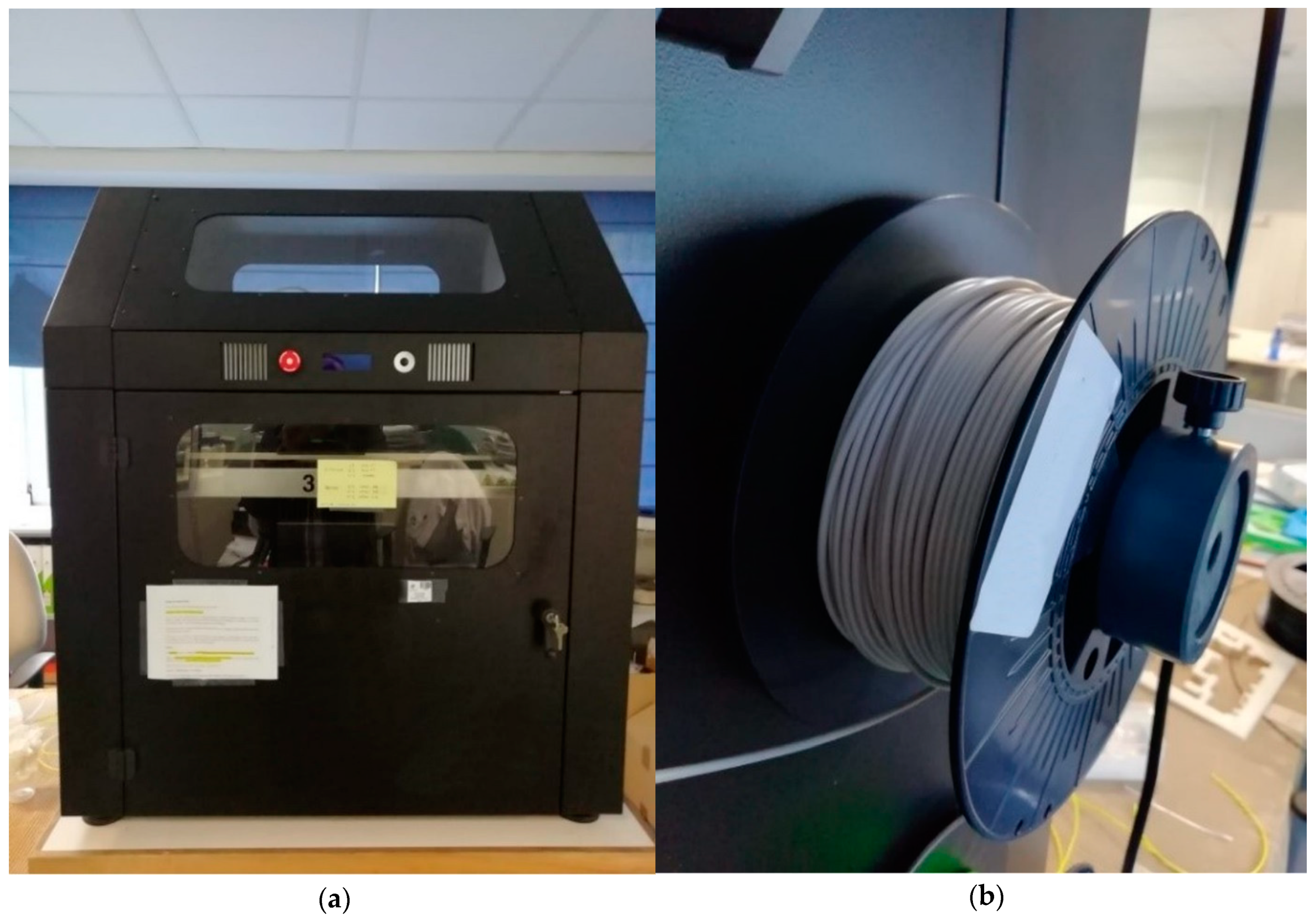

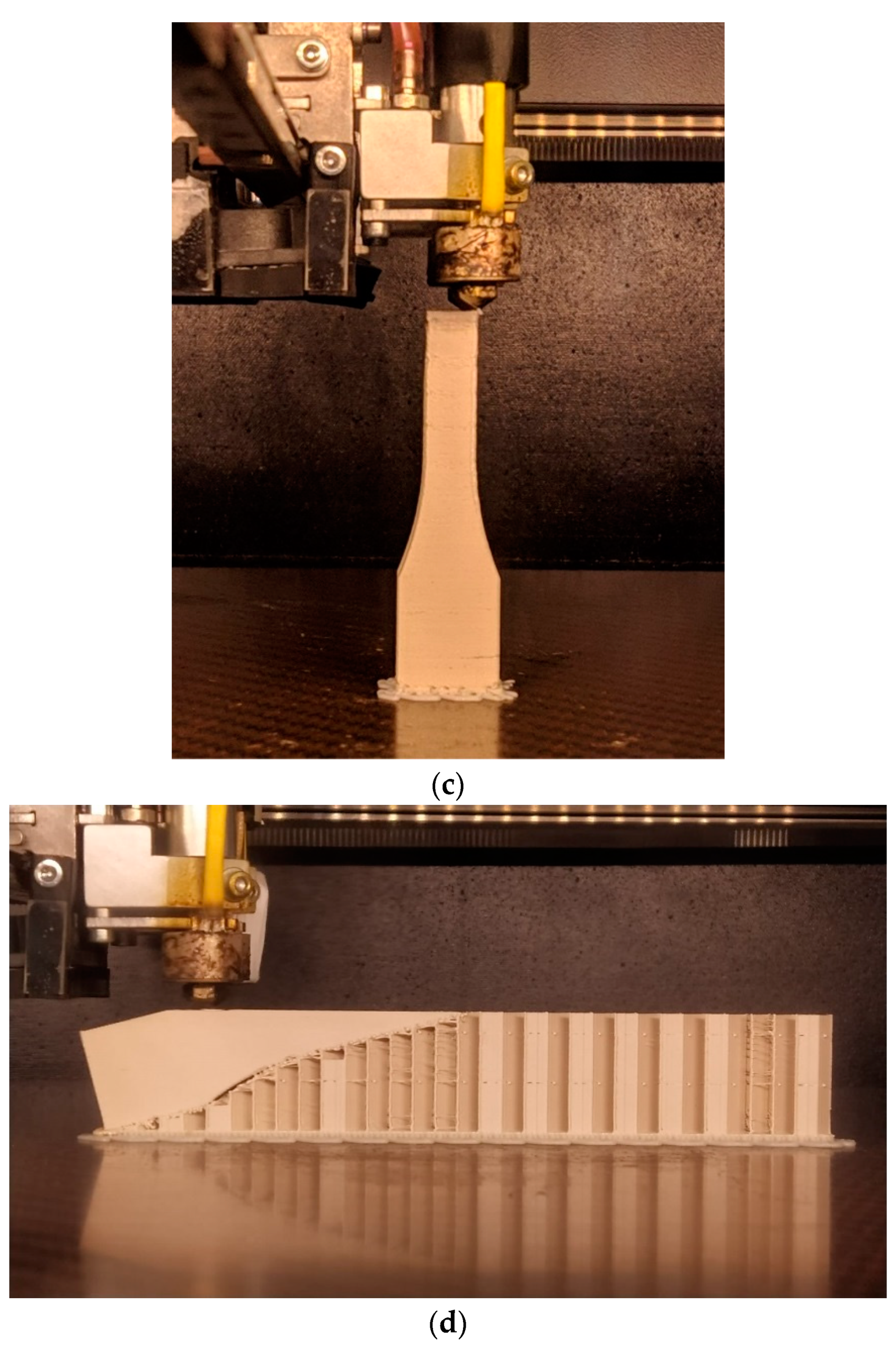

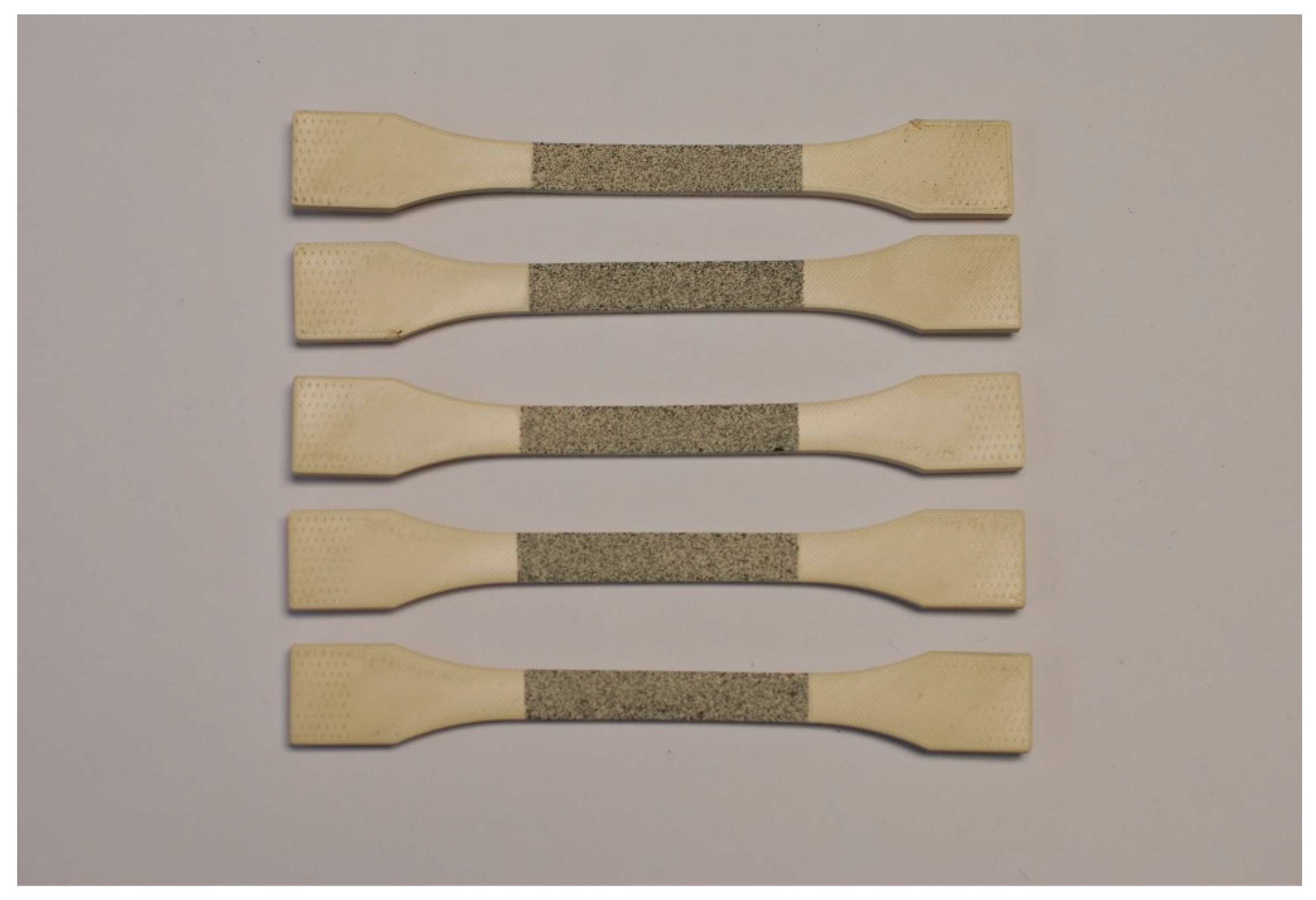

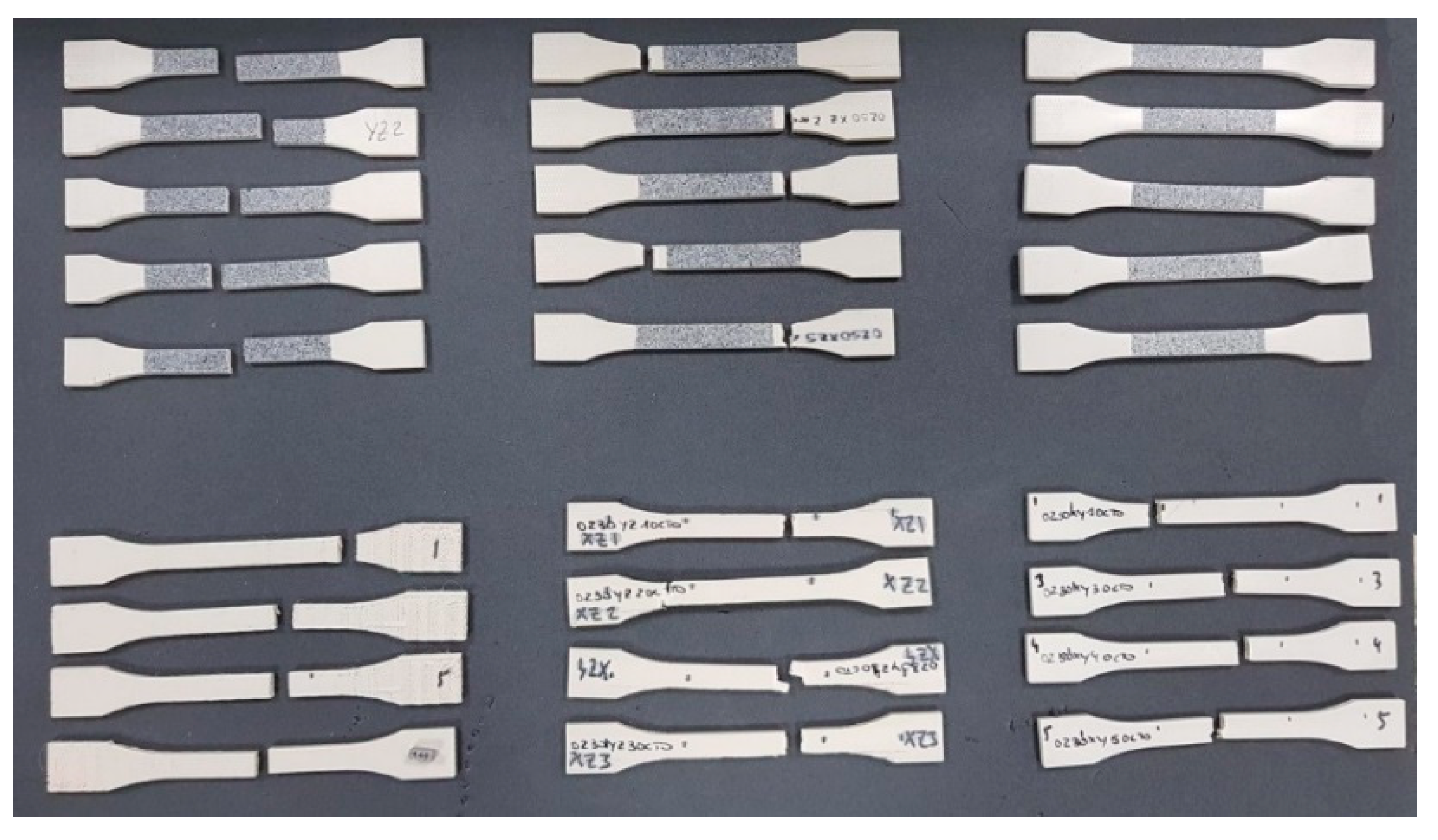

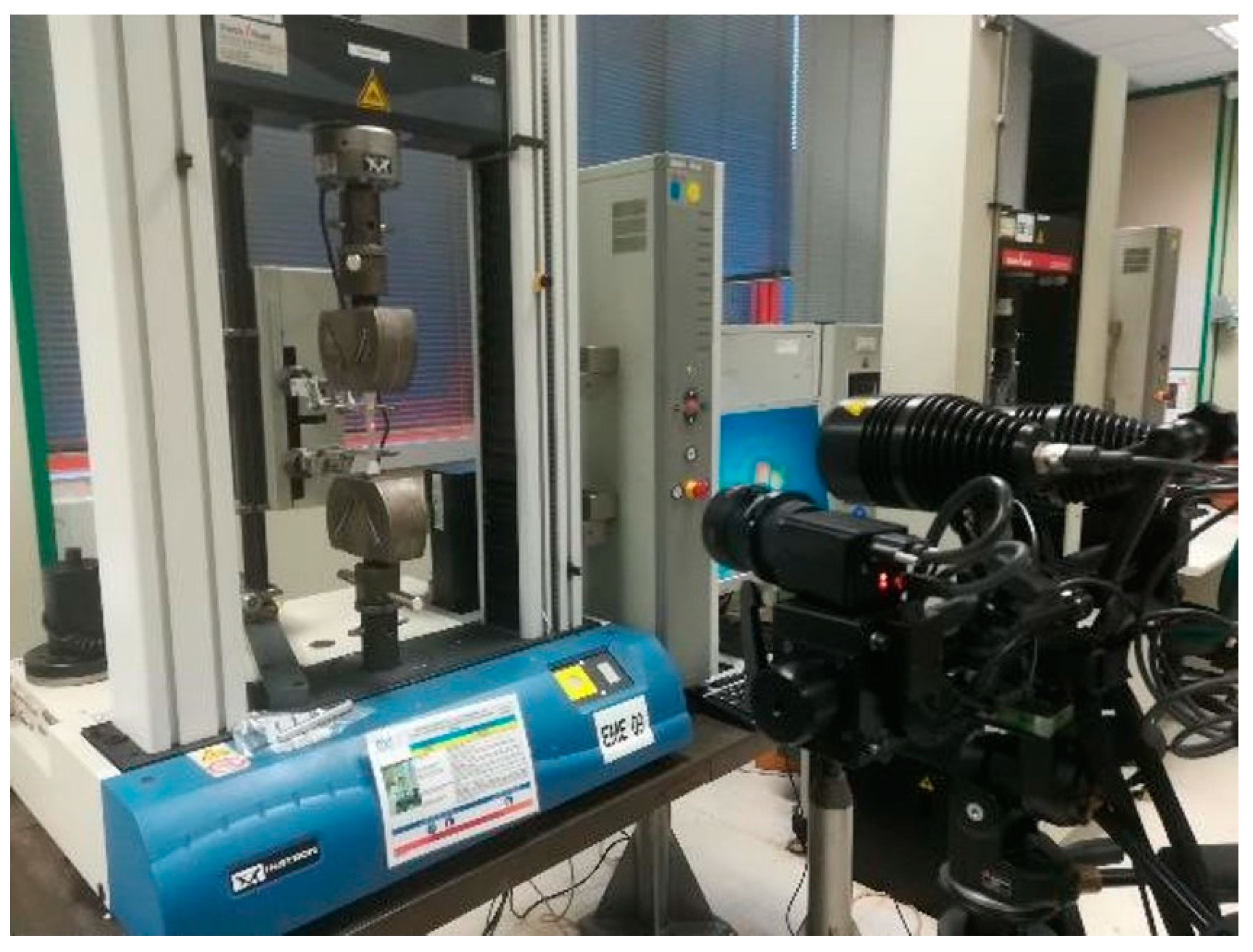

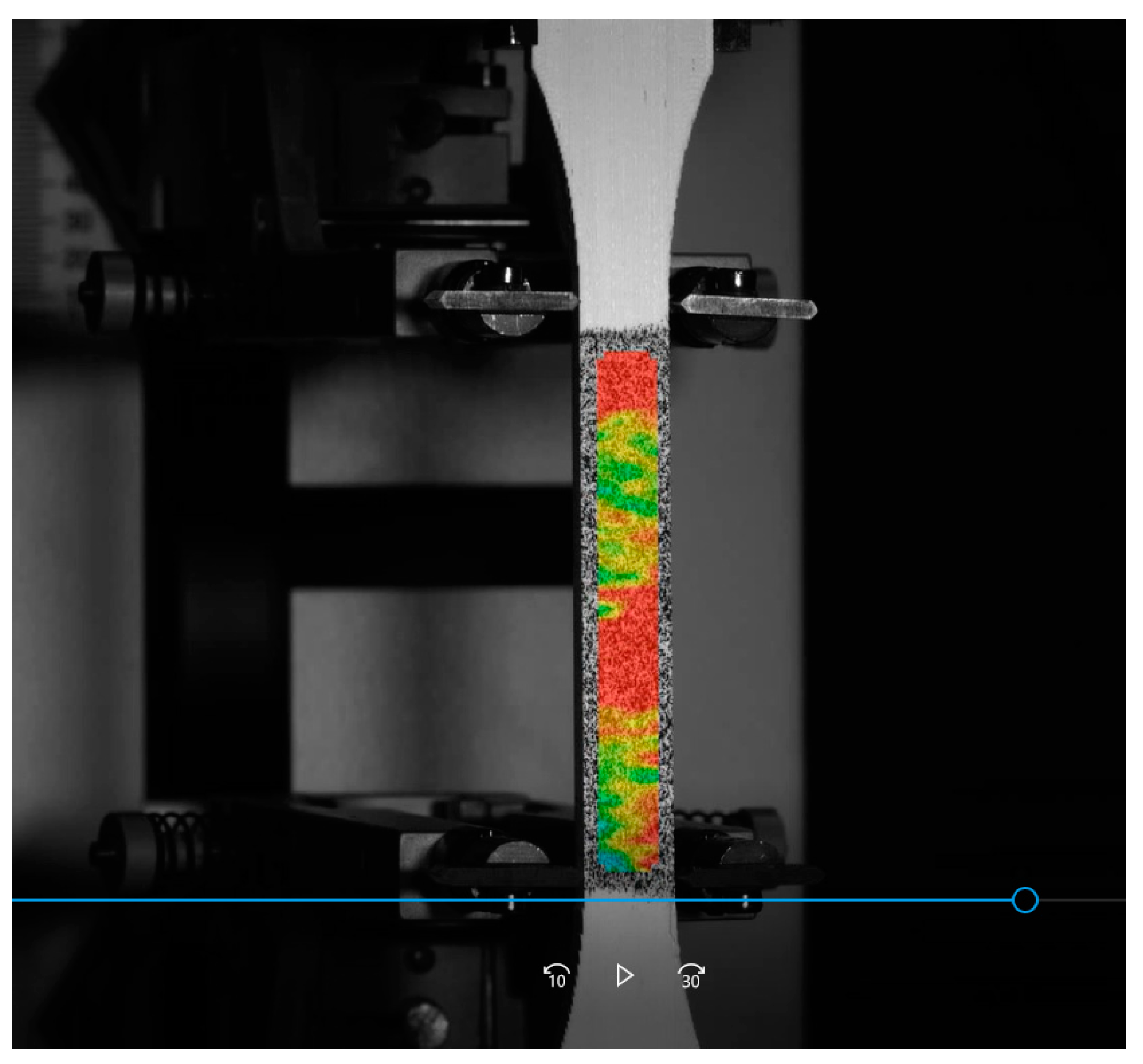

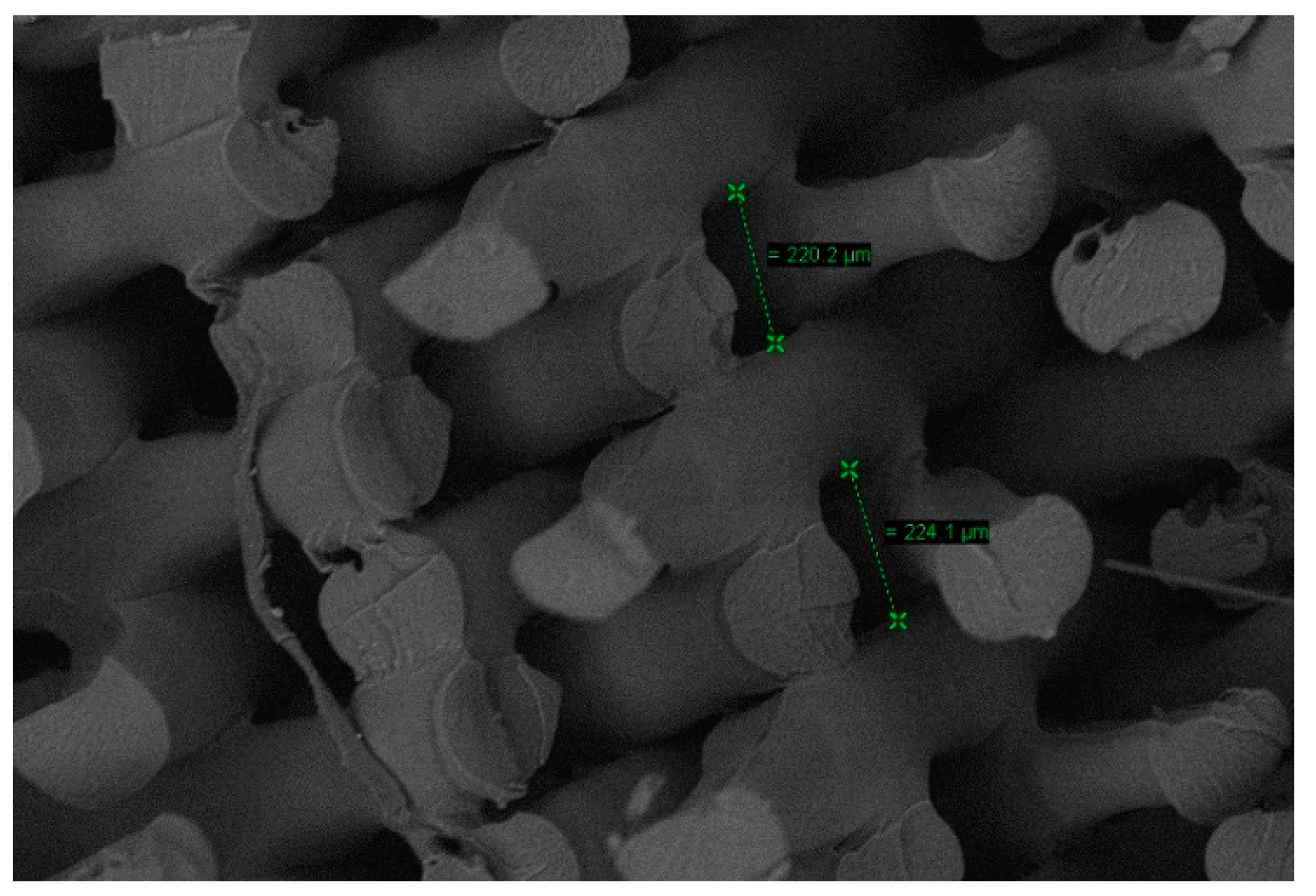

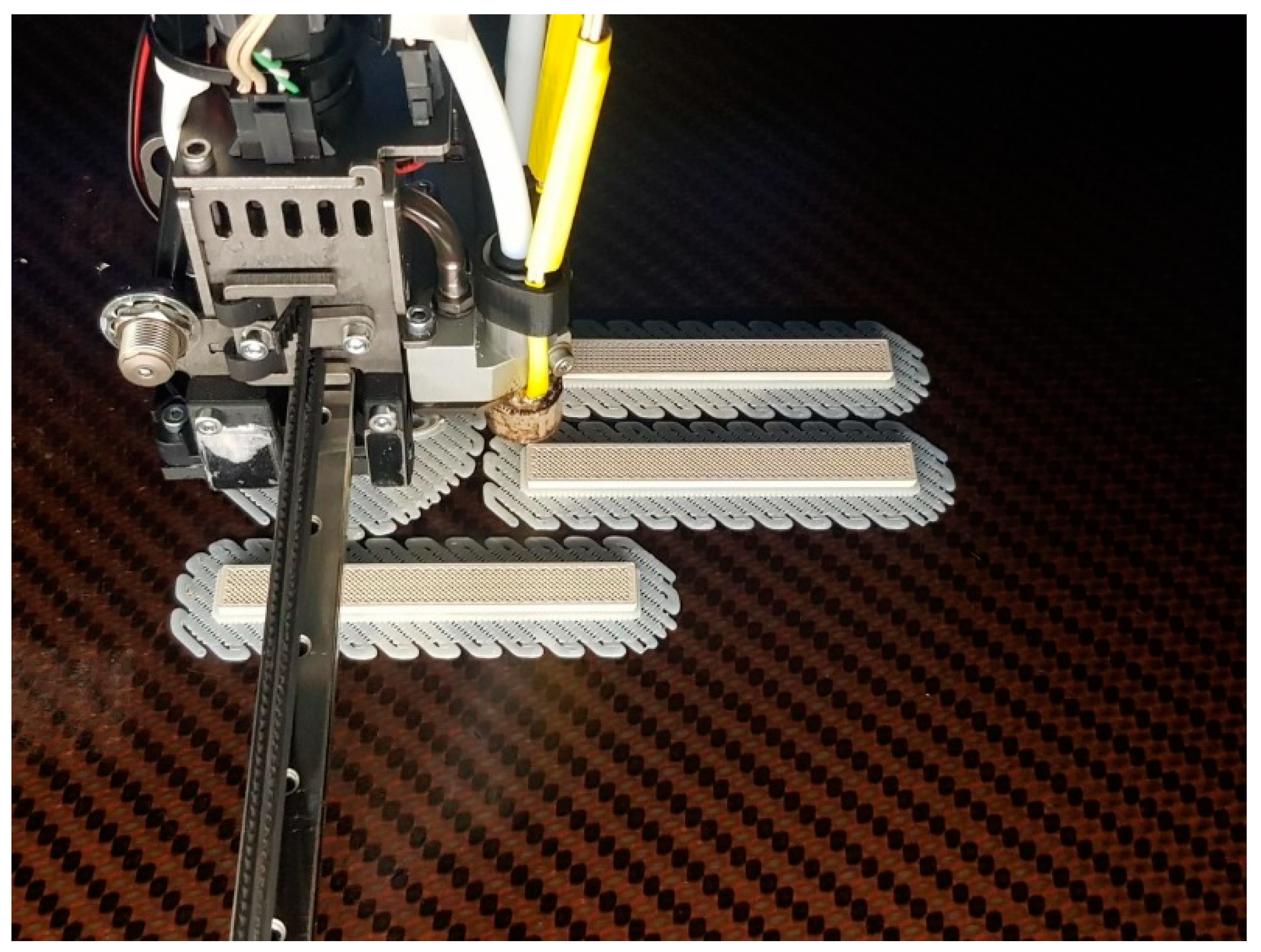

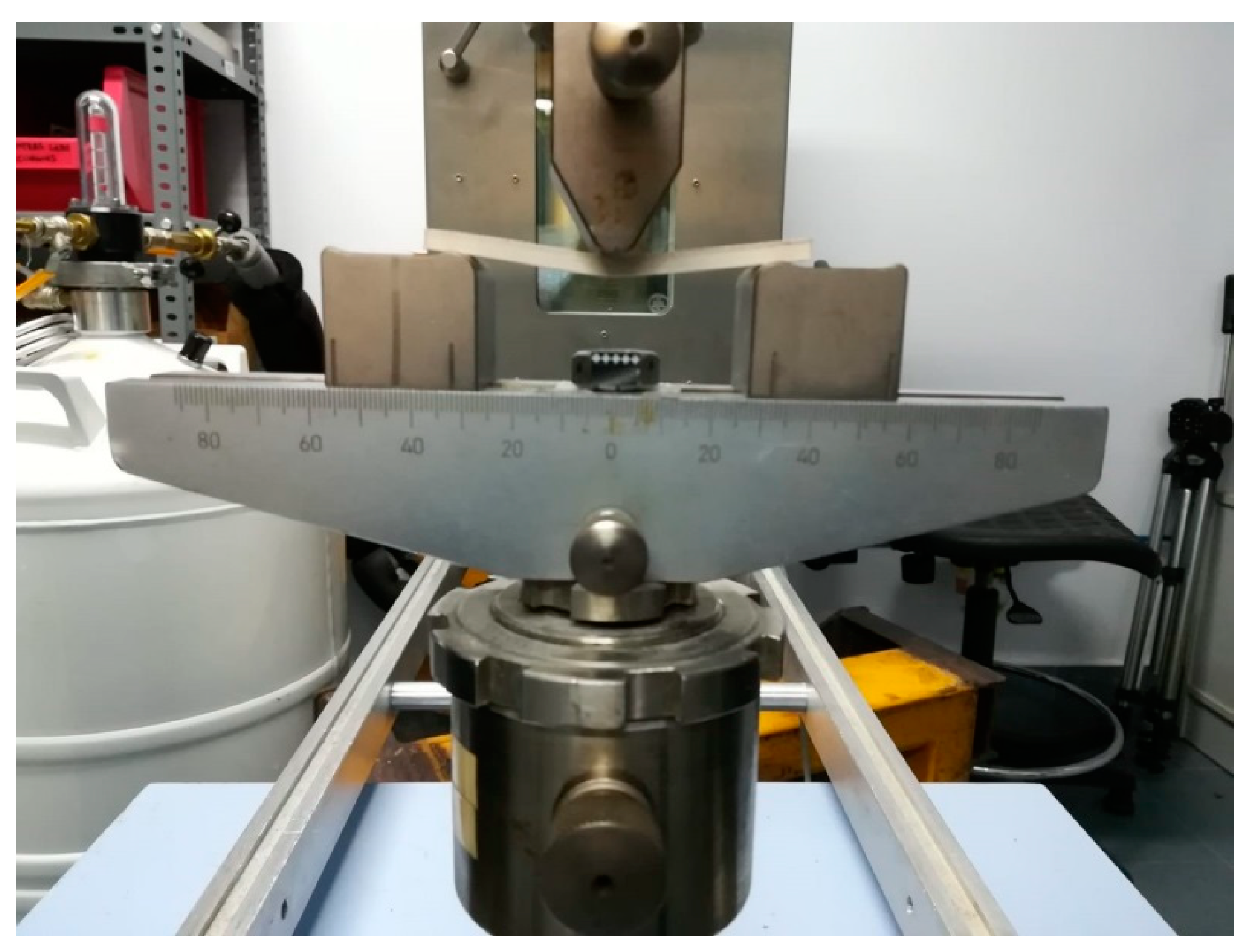

2. Materials and Methods

3. Results

3.1. Constitutive Relations

3.2. Tensile Tests

4. Discussion

4.1. Obtaining the Anisotropic Matrix

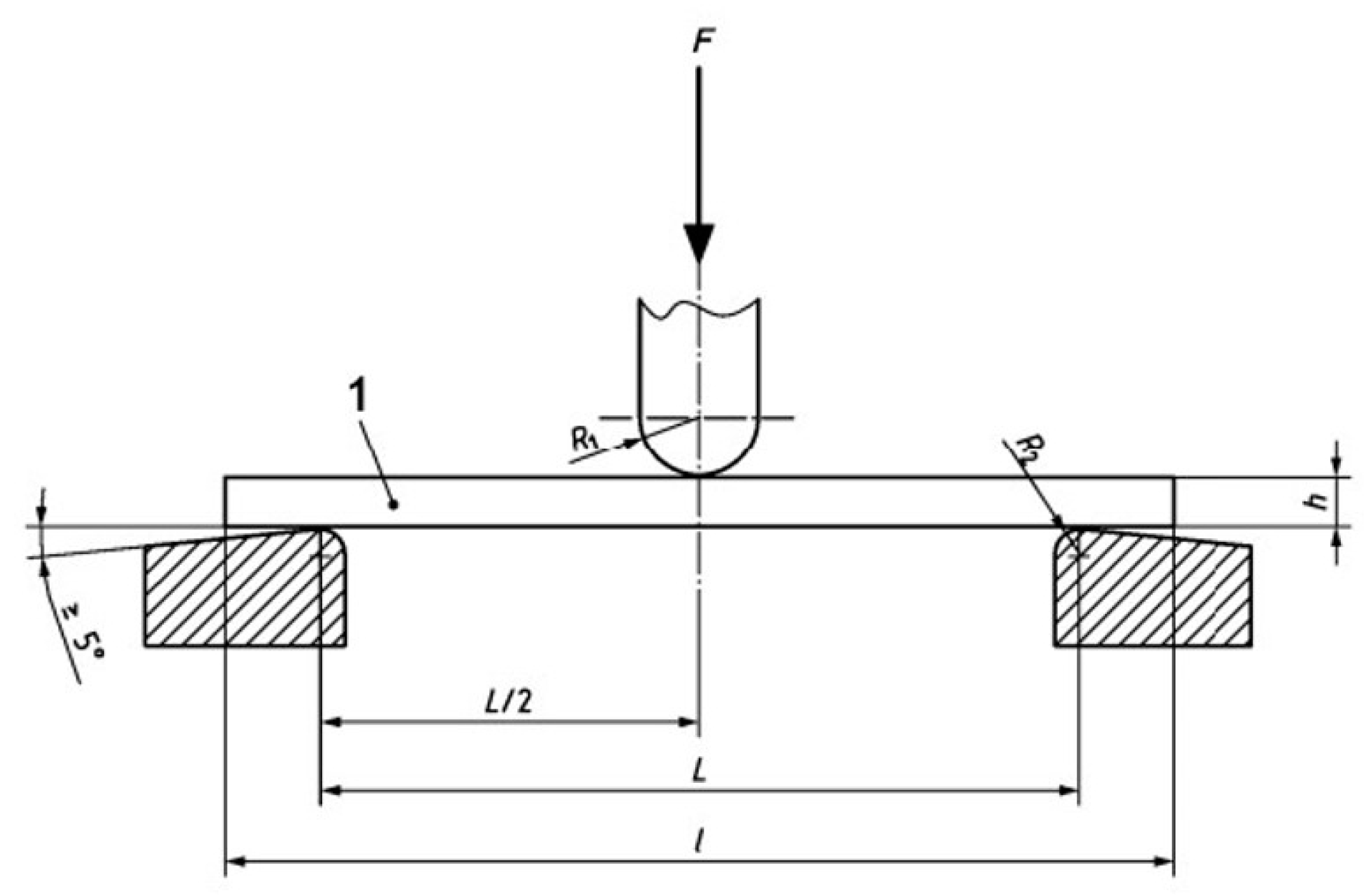

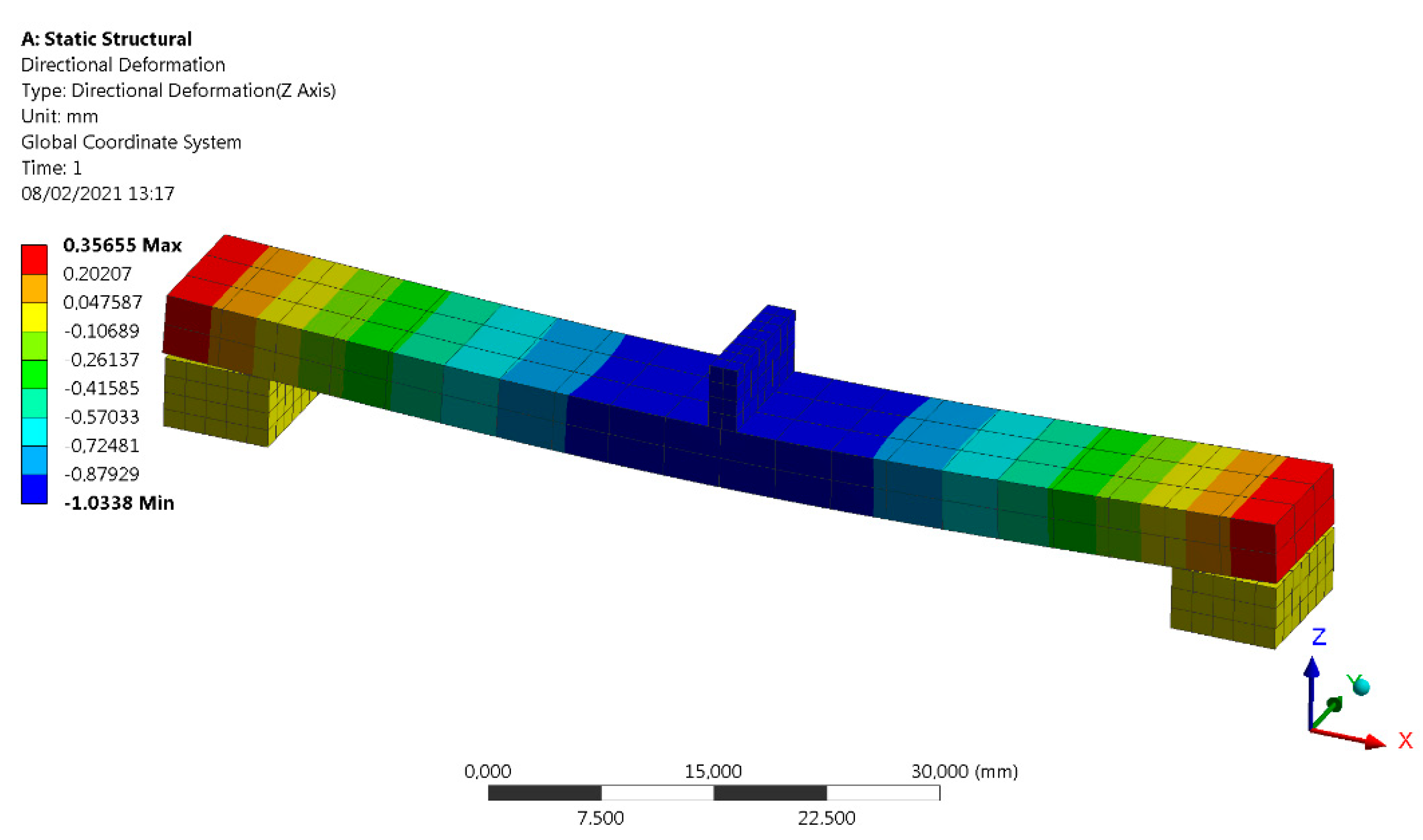

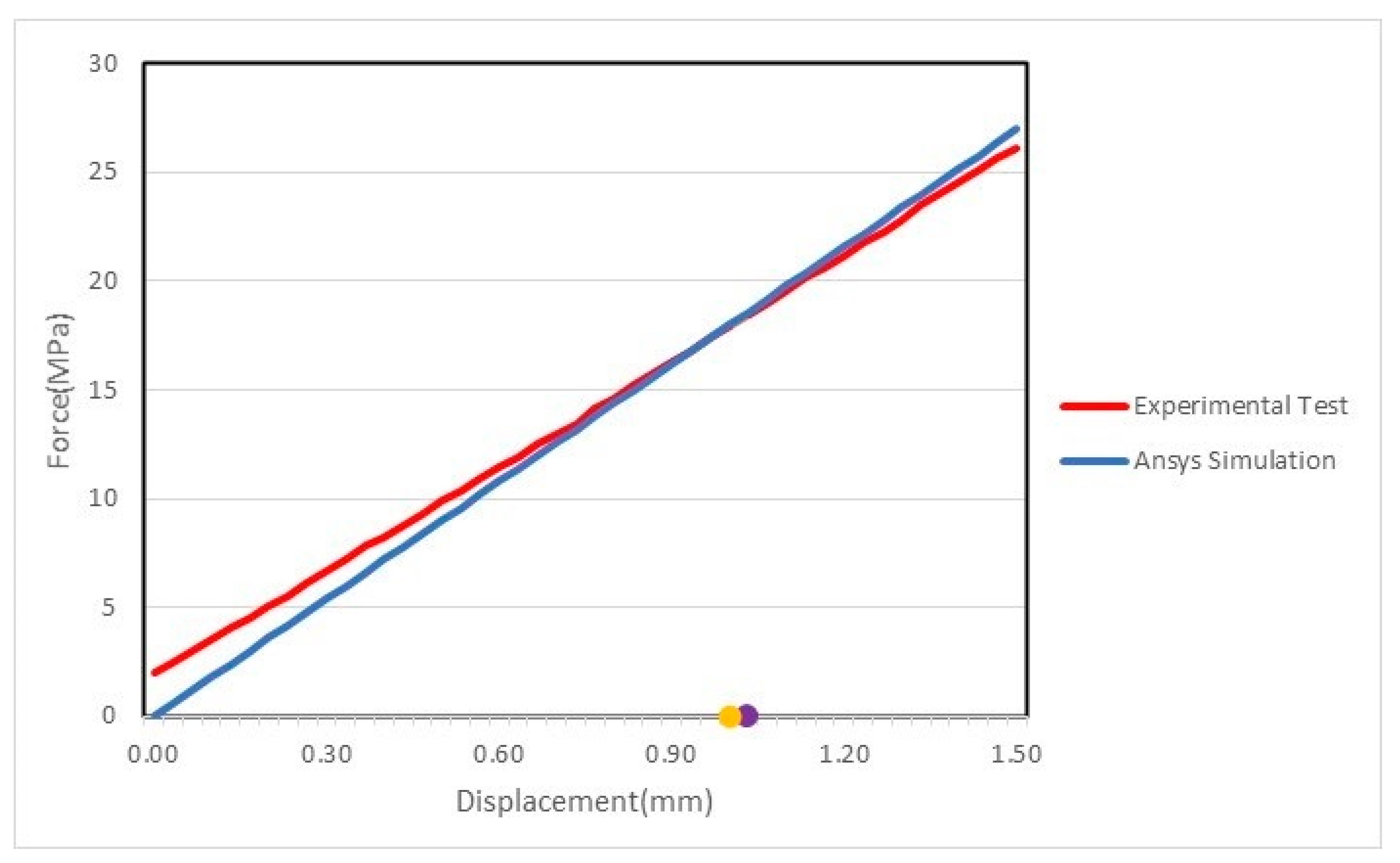

4.2. Validation by ANSYS Flexion Simulation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wong, K. Report on 3D Printing Industry Points to Softened Growth; Wohlers Report; Wohlers Associates Inc.: Fort Collins, CO, USA, 2017. [Google Scholar]

- Stratasys. FDM Design Handbook; Stratasys: Rehovot, Israel, 2010. [Google Scholar]

- Friedrich, B. Correlations between Influencing Parameters and Quality Properties of Components Produced by Fused Deposition Modeling. In Proceedings of the 51st CIRP Conference on Manufacturing Systems, Stockholm, Sweden, 16–18 May 2018; pp. 1214–1219. [Google Scholar]

- Khosravania, M.R.; Zolfagharian, A. Fracture and load-carrying capacity of 3D-printed cracked components. Extreme Mech. Lett. 2020, 36. [Google Scholar] [CrossRef]

- Mohamed, A.O.; Masood, S.; Bhowmikb, J.L. Characterization and dynamic mechanical analysis on PC-ABS material processed by fused deposition modelling: And investigation through I-optimal response surface methodology. Measurement 2017, 107, 128–141. [Google Scholar] [CrossRef]

- Rodriguez, B.; Travieso-Rodriguez, J.A. Study on the Optimization of Manufacturing Parameters in a 3D Printer with FDM Technology; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Fernandez-Vicent, M.; Conejero, A.; Ferrándiz, S. Effect of Infill Parameters on Tensile Mechanical Behavior in Desktop 3D Printing and Additive Manufacturing. 3D Print. Addit. Manuf. 2016, 3, 183–192. [Google Scholar] [CrossRef]

- Luzanin, O.; Movrin, D. Effect of layer thickness, deposition angle and infill on maximun flexural force in FDM built specimens. J. Technol. Plast. 2014, 39, 1. [Google Scholar]

- Moshiur, R.K.; Reese, R.; Letcher, T. Mechanical Properties of additively manufactured peek components using fused deposition filament fabrication. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 3 November 2015. [Google Scholar]

- Ziemian, C.; Sharma, M.; Ziemian, S. Anisotropic Mechanical Properties of ABS Parts Fabricated by Fused Deposition Modelling. Mechanical Engineering; Gokcek, M., Ed.; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef]

- Xiaoyong, S. Experimental Analysis of High Temperature PEEK Materials on 3D Printing. In Proceedings of the 9th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Changsha, China, 14–15 January 2017. [Google Scholar]

- Riddick, J.C.; Haile, M.A.; Wahlde, R.V. Fractographic analysis of tensile failure of acrylonitrile-butadiene-styrene fabricated by fused deposition modelling. Addit. Manuf. 2016, 11, 49–59. [Google Scholar]

- Wu, W.; Geng, P.; Li, G. Influences of layer thickness and raster angle on mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS. Mater. Sci. 2015, 8, 5834–5846. [Google Scholar] [CrossRef] [PubMed]

- Zahng, P.; Liu, J.; To, A.C. Role of anisotropic properties on topology optimization of additive manufactured load bearing structures. Scr. Mater. 2017, 135, 148–152. [Google Scholar] [CrossRef]

- Jin, Y.; Du, J.; He, Y. Optimization of process planning for reducing material consumption in additive manufacturing. J. Manuf. Syst. 2017, 44, 65–78. [Google Scholar] [CrossRef]

- Leon-Medina, J.X.; Guzman, M.A.; Herrera, L. Manufacture of Beam Designs Obtained by Topological Optimization in a 3D Printer Applying FDM; Interdisciplinary Research; Grupo Dima-UN: Bogotá, Colombia, 2015. [Google Scholar]

- Fitzharris, E.R.; Watanabe, N.; Rosen, D.W. Effects of material properties on warpage in fused deposition modeling parts. Addit. Manuf. Technol. 2018, 95, 2059–2070. [Google Scholar] [CrossRef]

- Kibling, A.; Beneke, F.; Seul, T. Determination of Anisotropic Material Properties of Carbon-Fiber-Reinforced FDM Structures for Numerica Simulations. In Proceedings of the SPE ANTEC, Los Angeles, CA, USA, 8–10 May 2017. [Google Scholar]

- Koch, C.; Van Hulle, L.; Rudolth, N. Investigation of mechanical anisotropy of the fused filament fabrication process via customized tool path generation. Addit. Manuf. 2017, 16, 138–145. [Google Scholar] [CrossRef]

- Courter, B.; Savane, V.; Bi, J. Finite Element Simulation of Fused Deposition Modelling Process. In Proceedings of the NAFEMS World Congress 2017, Stockholm, Sweden, 11–13 June 2017. [Google Scholar]

- Afrose, F.; Masooss, H.; Nikzad, M. Effects of Build Orientations on Tensile Properties of PLA Material Processes by FDM. Adv. Mater. Res. 2014, 1044, 31–34. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, C.Y. Novel Mechanical models of tensile strengh and elastic property of FDM AM PLA materials: Experimental and theoretical analysis. Mater. Des. 2019, 181, 108089. [Google Scholar] [CrossRef]

- Farbman, D.; McCoy, C.D. Materials Testing of 3D printed and PLA samples to guide Mechanical Design. In Proceedings of the ASME 2016 International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016. [Google Scholar]

- Bertoldi, M.; Yardimci, C.; Pistor, S. Mechanical Characterization of Parts Processed via Fused Deposition; University of Illinois: Chicago, IL, USA, 1998. [Google Scholar]

- Stephen, W.T.; José, D.D.M. Composite Materials Design and Testing; Composites Design Group: San Diego, CA, USA, 2015. [Google Scholar]

- Cantrell, S.; Damian, R.; Gurnan, L. Experimental Characterization of the Mechanical Properties of 3D Printed ABS and Polycarbonate Parts. Adv. Opt. Methods Exp. Mech. 2016, 3, 89–105. [Google Scholar]

- Velaso, M.A.; Rodriguez, J.; Restrepo, D. Characterization of mechanical properties of parts in ABS based on FDM additive manufacturing process parameters. In Proceedings of the XXI National Congress of Mechanical Engineering, Elche, Spain, 2–4 August 2017. [Google Scholar]

- Khezri, M.; Bradford, M.A.; Vrcelj, Z. Application of RKP-FSM in the buckling and free vibration analysis of thin plates with abrupt thickness changes and internal supports. Int. Numer. Methods Eng. 2015. [Google Scholar] [CrossRef]

| Material | Resistance to XZ Axis Traction | Resistance to ZX Axis Traction | Module to XZ Axis Tensile | Module to ZX Axis Tensile | Resistance to XZ Flex | Resistance to ZX Flex | Module to XZ Flex | Module to ZX Flex | Elongation to XZ Axis Breakage | Elongation to ZX Axis Breakage | Vitreous Transition Temperature |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ULTEM 1010 | 64 MPa | 42 MPa | 2.770 MPa | 2.200 MPa | 144 MPa | 77 MPa | 2.820 MPa | 2.230 MPa | 3.3% | 2% | 215 °C |

| ULTEM 9085 | 47 MPa | 33 MPa | 2150 MPa | 2270 MPa | 112 MPa | 68 MPa | |||||

| PPSF | 55 MPa | 2.100 MPa | 110 MPa | 2.300 MPa | 250 MPa | 5.8% | 2.2% | 186 °C | |||

| PC-ISO | 57 MPa | 2.000 MPa | 90 MPa | 2.200 MPa | 4% | 230 °C | |||||

| PC-ABS | 41 MPa | 1.900 MPa | 68 MPa | 1.900 MPa | 6% | 161 °C | |||||

| PC | 40 MPa | 30 Mpa | 1.944 MPa | 1958 MPa | 89 MPa | 68 MPa | 2.006 MPa | 1.800 MPa | 2.2% | 2% | 125 °C |

| Nylon 12 | 32 MPa | 26 Mpa | 1.282 MPa | 1138 MPa | 67 MPa | 61 MPa | 1.276 MPa | 1.180 MPa | 2.4% | 2.7% | 161 °C |

| Nylon 6 | 49.3 MPa | 28.9 Mpa | 2.232 MPa | 1817 MPa | 97.2 MPa | 82 MPa | 2.196 MPa | 1.879 MPa | 2.3% | 1.7% | |

| ASA | 29 MPa | 27 Mpa | 2.010 MPa | 1950 MPa | 60 MPa | 48 MPa | 1.870 MPa | 1.630 MPa | 2% | 2% | 108 °C |

| ABS-M30i | 36 Mpa | 2.400 MPa | 61 MPa | 2.300 MPa | 4% | 108 °C | |||||

| ABS-M30 | 31 MPa | 26 Mpa | 2.230 MPa | 2180 MPa | 60 MPa | 48 MPa | 2.060 MPa | 1.760 MPa | 7% | 2% | 108 °C |

| ABSi | 37 MPa | 1.920 MPa | 62 MPa | 1.920 MPa | 4.4% | 116 °C |

| PPS Mechanical Properties | |||

|---|---|---|---|

| Type | Test Method | Imperial | Metric |

| Tensile Modulus | ASTM D638 | 285144.2 psi | 1966 MPa |

| Yield Point | ASTM D639 | 39.7% | 39.7% |

| Tensile Elongation at Yield | ASTM D640 | 2.8% | 2.8% |

| Tensile Strneght Ultimate | ASTM D641 | 5018.306 psi | 34.6Mpa |

| Tensile Elongation at Break | ASTM D642 | 7.4% | 7.4% |

| Parameter | Value |

|---|---|

| Room conditions | 23 °C and 40% HR |

| Universal test machine | Zwick/Roell |

| Load shell | 10 kN |

| Test speed | 2 mm/min |

| Distance between jaws | 119 mm |

| DIC system | GOM-ARAMIS |

| DIC volume analysis | 125 × 100 mm |

| DIC distance | 845 mm |

| DIC sampling frequency | 1 Hz |

| Young’s Modulus | Value (Gpa) | Poisson’s Coefficient | Value | Shear Modulus | Value (Gpa) | Tensile Strength | Value (Mpa) |

|---|---|---|---|---|---|---|---|

| ET(flat) | 1.38 | νTT | 0.40 | GTT(flat) | 0.49 | σT(flat) | 29.2 |

| ET(edge) | 1.58 | νLT | 0.39 | GTT(edge) | 0.56 | σT(edge) | 32.3 |

| EL | 1.60 | νTL | 0.40 | GLT | 0.67 | σL | 15.41 |

| Young’s Modulus | Value (Gpa) | Poisson’s Coefficient | Value | Shear Modulus | Value (Gpa) | Tensile Strength | Value (Mpa) |

|---|---|---|---|---|---|---|---|

| ET(average) | 1.48 | νTT | 0.4 | GTT(average) | 0.52 | σT(average) | 30.8 |

| EL | 1.60 | νLT | 0.39 | GLT | 0.67 | σL | 15.41 |

| νTL | 0.40 |

| Elastic Coefficient | Value |

|---|---|

| ET | 1.48 GPa |

| EL | 1.60 GPa |

| νTT | 0.40 |

| νLT | 0.39 |

| GLT | 0.67 GPa |

| Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Time | Force | Displacement | Force | Displacement | Force | Displacement | Force | Displacement | Force | Displacement |

| seg | N | mm | N | mm | N | mm | N | mm | N | mm |

| 0 | 2.026 | 0.000 | 2.002 | 0.000 | 2.027 | 0.000 | 2.127 | 0.000 | 2.0011 | 0.0000 |

| 10 | 7.234 | 0.333 | 7.484 | 0.333 | 7.068 | 0.332 | 7.137 | 0.332 | 7.2551 | 0.3333 |

| 20 | 12.506 | 0.667 | 12.867 | 0.667 | 12.325 | 0.666 | 12.744 | 0.666 | 12.6871 | 0.6667 |

| 25 | 15.201 | 0.833 | 15.606 | 0.833 | 15.077 | 0.832 | 15.455 | 0.832 | 15.3430 | 0.8333 |

| 30 | 17.907 | 1.000 | 18.543 | 1.000 | 17.845 | 0.999 | 18.293 | 0.999 | 18.1246 | 1.0000 |

| 31 | 18.427 | 1.033 | 19.170 | 1.033 | 18.347 | 1.032 | 18.750 | 1.032 | 18.7516 | 1.0334 |

| 40 | 23.508 | 1.333 | 24.257 | 1.333 | 23.427 | 1.332 | 23.855 | 1.332 | 23.7171 | 1.3333 |

| 45 | 26.160 | 1.500 | 27.130 | 1.500 | 26.274 | 1.499 | 26.737 | 1.499 | 26.4891 | 1.5000 |

| Elastic Coefficient | Value |

|---|---|

| Ex | 1.48 GPa |

| Ey | 1.48 GPa |

| Ez | 1.6 GPa |

| νxy | 0.40 |

| νyz | 0.40 |

| νxz | 0.40 |

| Gxy | 0.52 GPa |

| Gyz | 0.67 GPa |

| Gxz | 0.67 GPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Retolaza, J.; Ansola, R.; Gómez, J.L.; Díez, G. Identifying Elastic Constants for PPS Technical Material When Designing and Printing Parts Using FDM Technology. Materials 2021, 14, 1123. https://doi.org/10.3390/ma14051123

Retolaza J, Ansola R, Gómez JL, Díez G. Identifying Elastic Constants for PPS Technical Material When Designing and Printing Parts Using FDM Technology. Materials. 2021; 14(5):1123. https://doi.org/10.3390/ma14051123

Chicago/Turabian StyleRetolaza, Jone, Rubén Ansola, Jose Luis Gómez, and Gorka Díez. 2021. "Identifying Elastic Constants for PPS Technical Material When Designing and Printing Parts Using FDM Technology" Materials 14, no. 5: 1123. https://doi.org/10.3390/ma14051123

APA StyleRetolaza, J., Ansola, R., Gómez, J. L., & Díez, G. (2021). Identifying Elastic Constants for PPS Technical Material When Designing and Printing Parts Using FDM Technology. Materials, 14(5), 1123. https://doi.org/10.3390/ma14051123