Comprehensive Machine Learning-Based Model for Predicting Compressive Strength of Ready-Mix Concrete

Abstract

1. Introduction

2. Research Significance

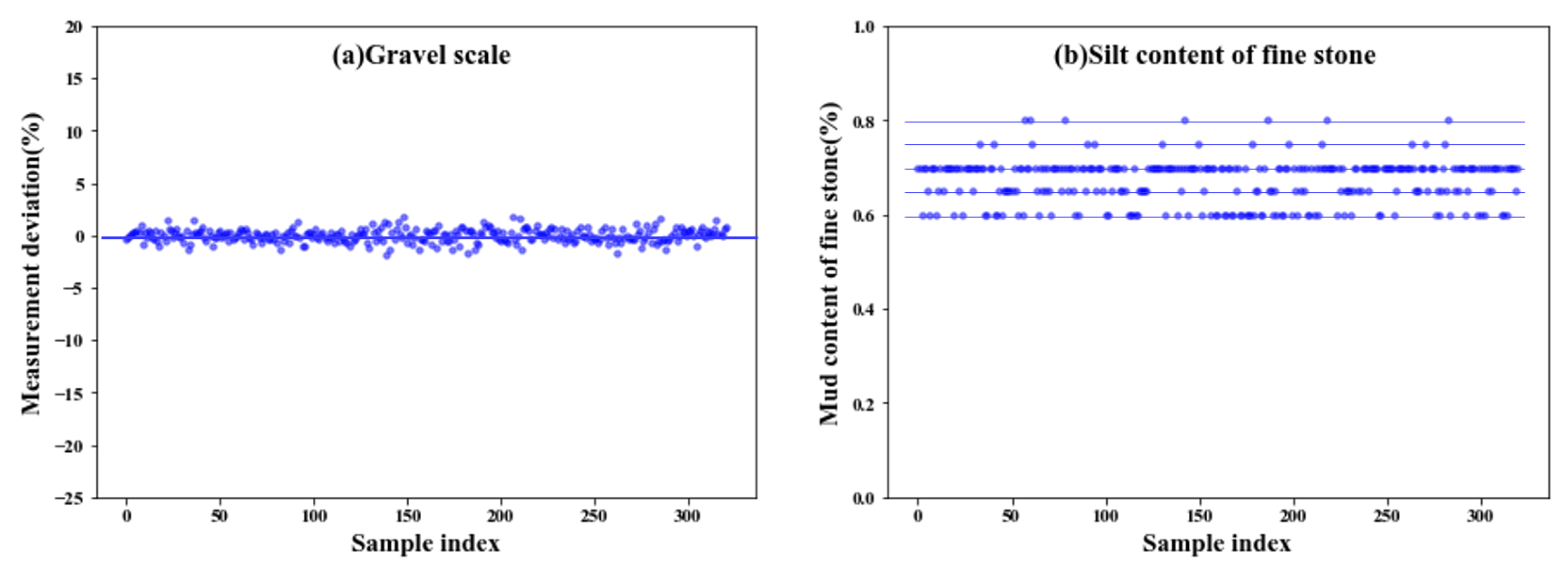

3. Data Collection and Pre-Processing

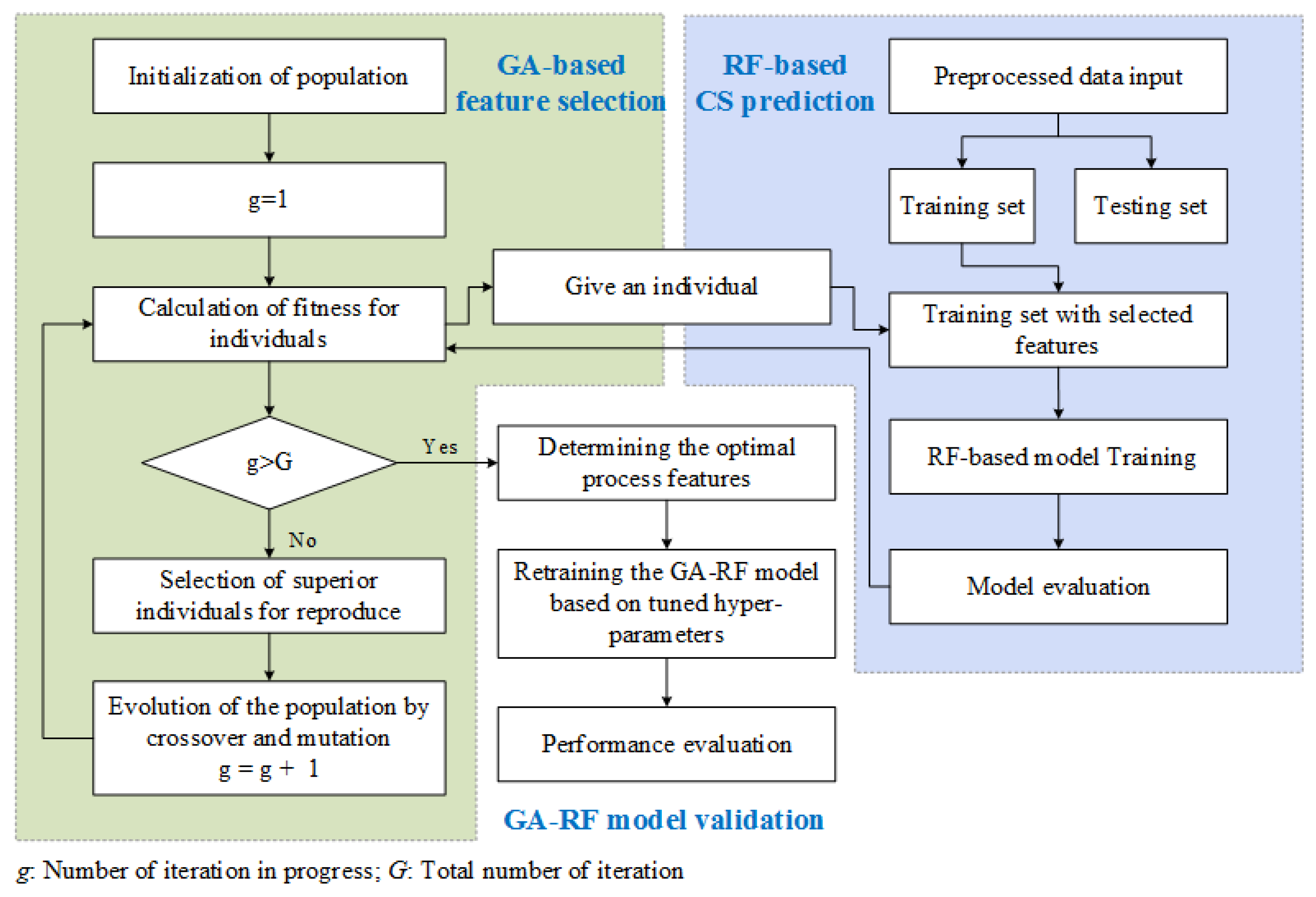

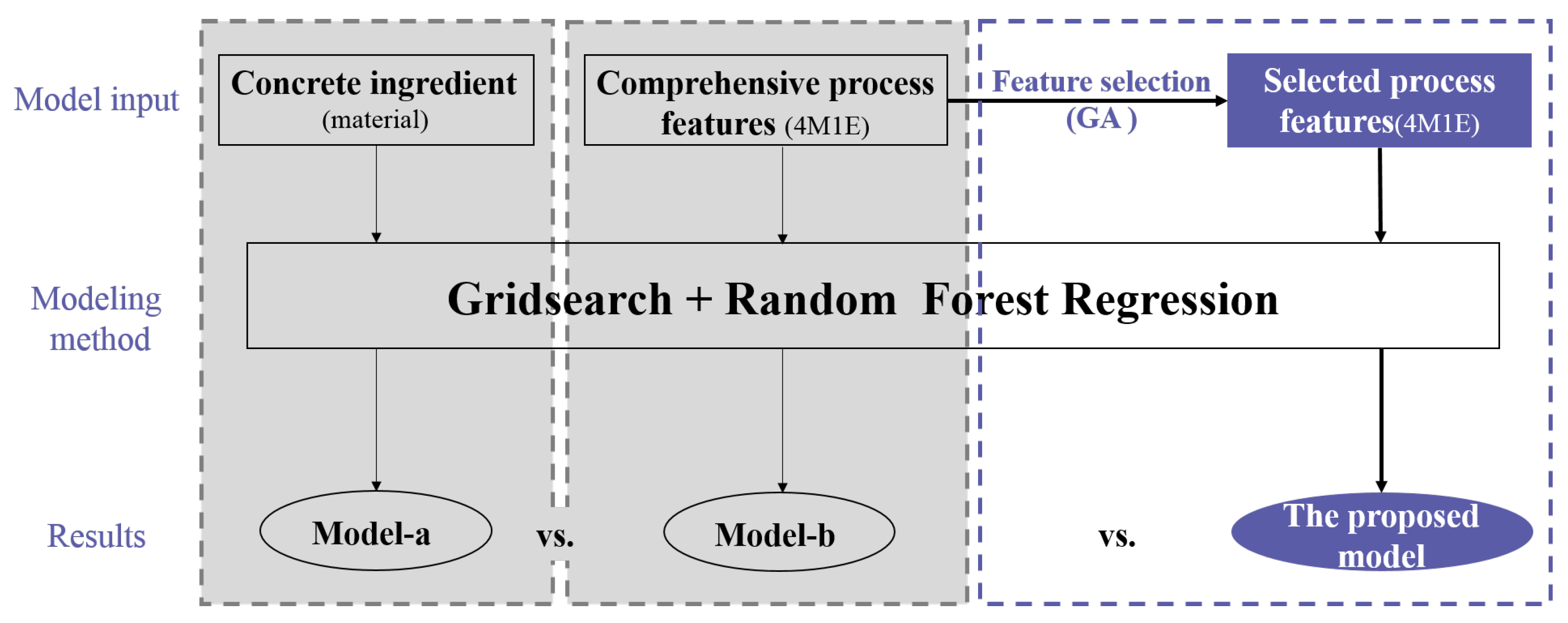

4. The Proposed GA-RF Methodology for Concrete CS Prediction

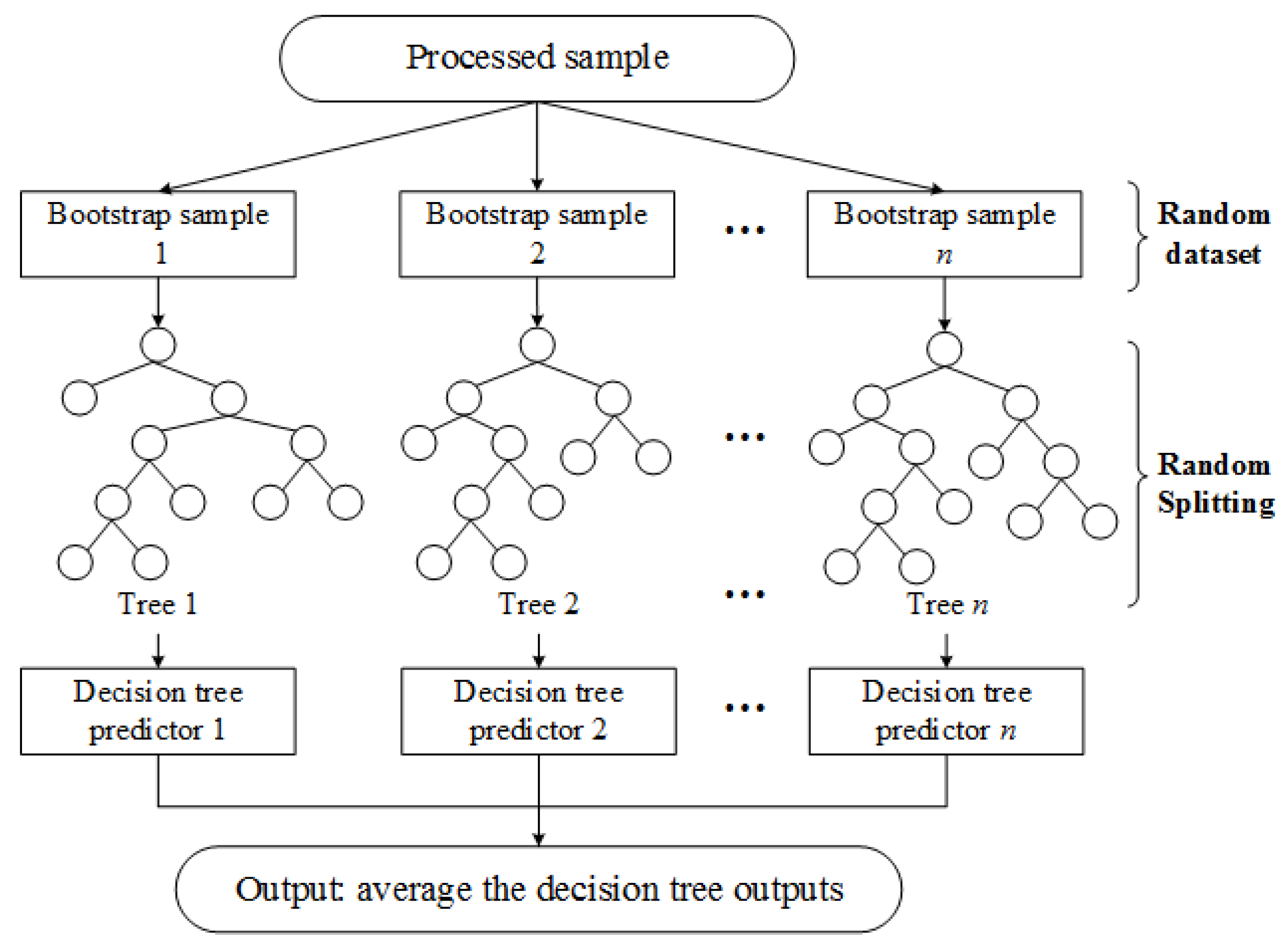

4.1. RF for Concrete CS Prediction

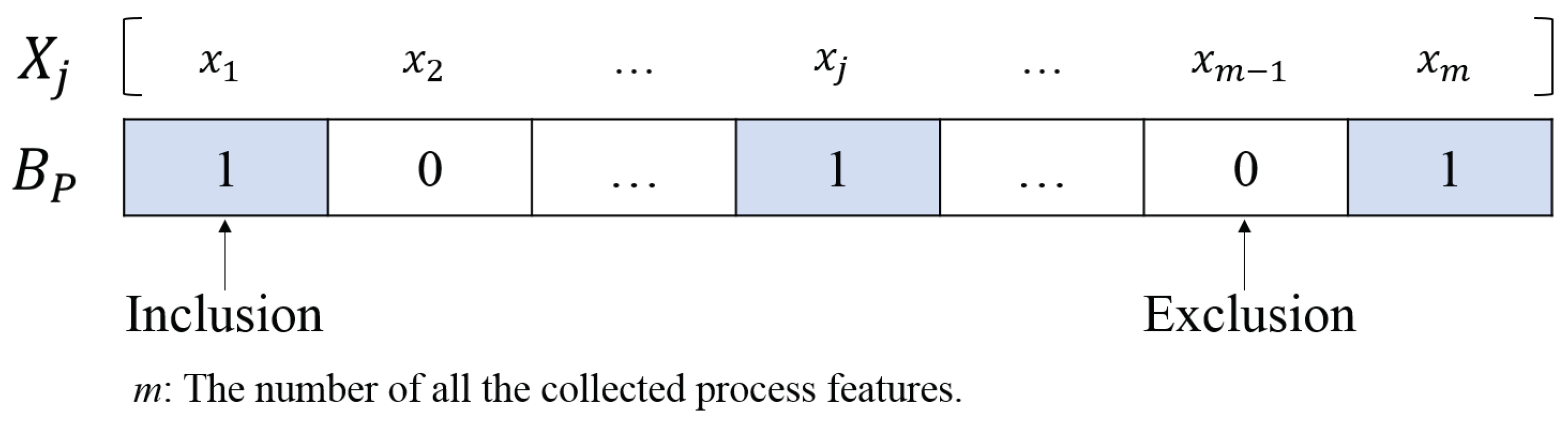

4.2. GA for Feature Selection

4.2.1. Initialization of Population

4.2.2. Calculation of Fitness for Individuals

4.2.3. Termination Condition Evaluation

4.2.4. Evolution of the Population

4.3. GA-RF Model Validation

5. Results and Discussion

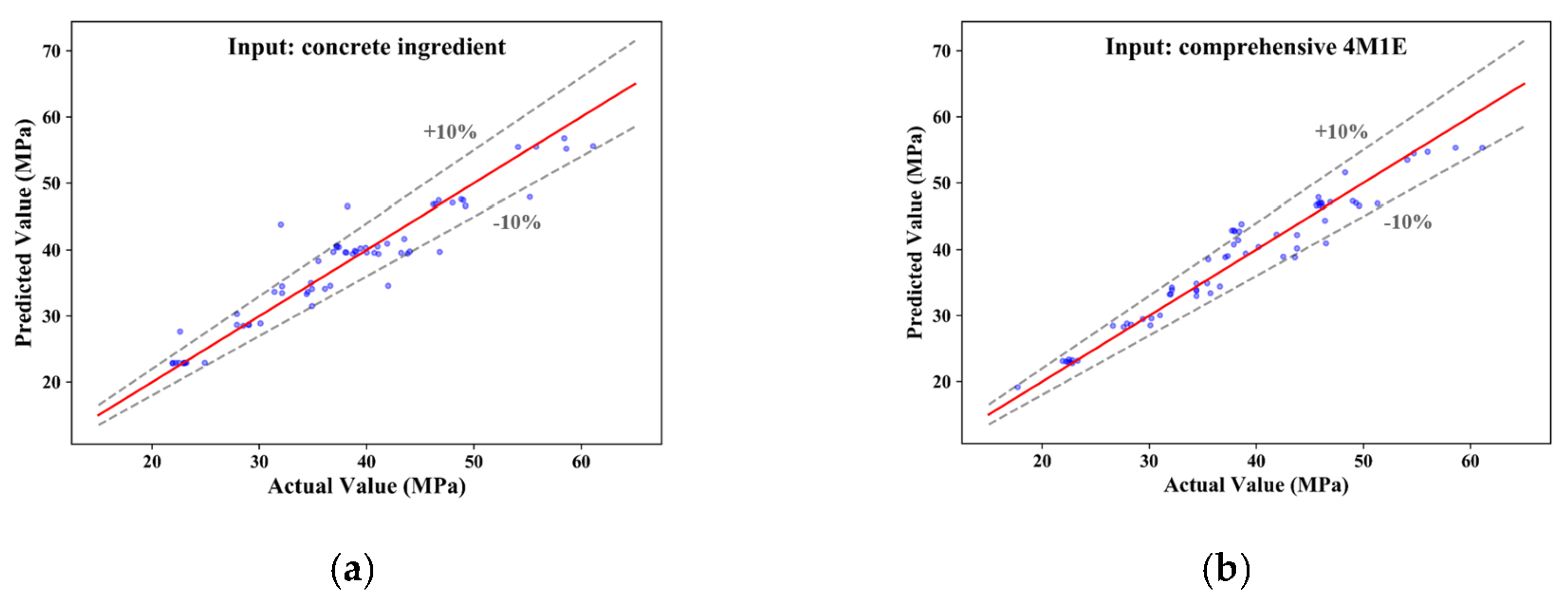

5.1. Result Comparison between the Concrete Ingredient Modeling and the Comprehensive 4M1E Modeling

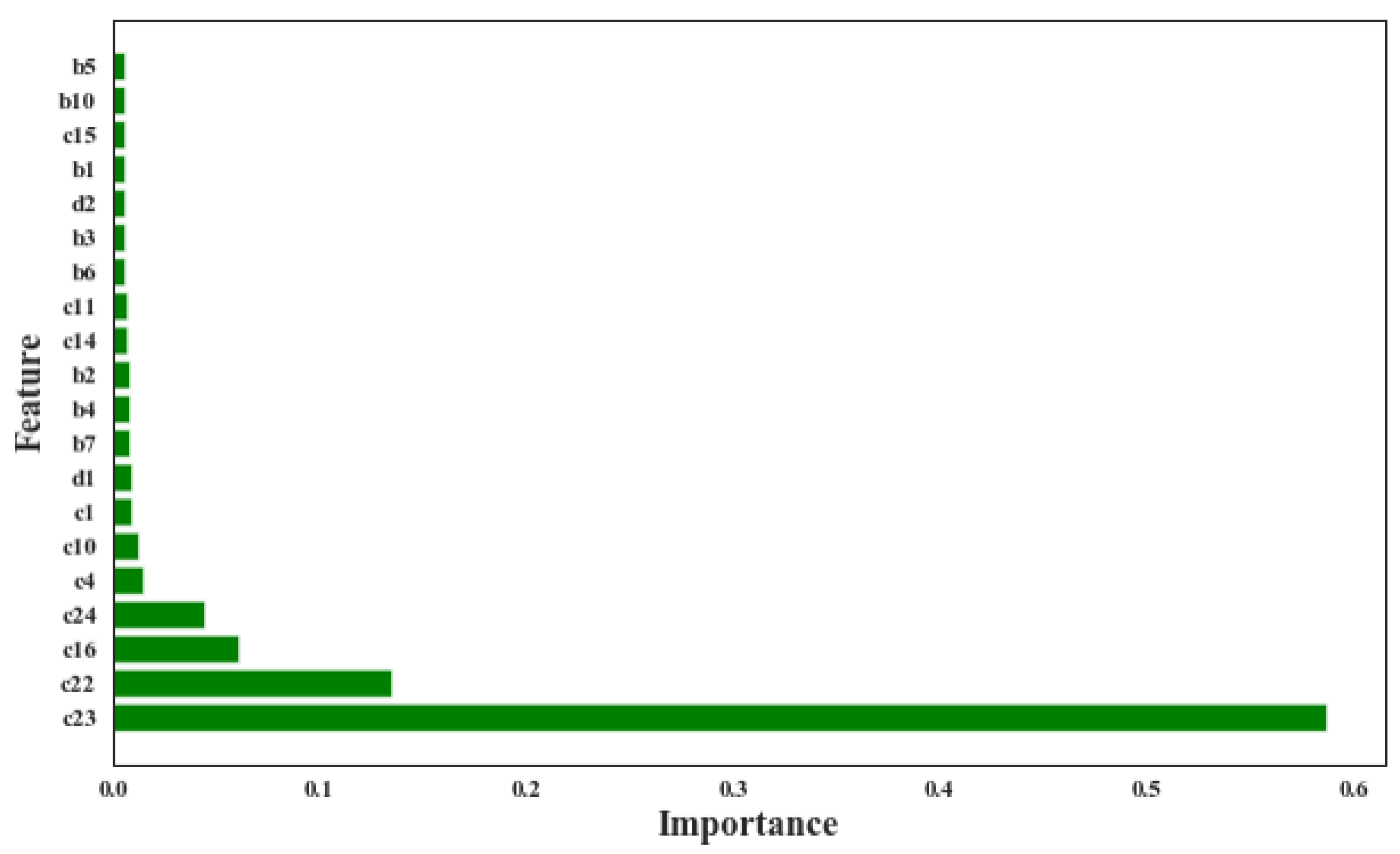

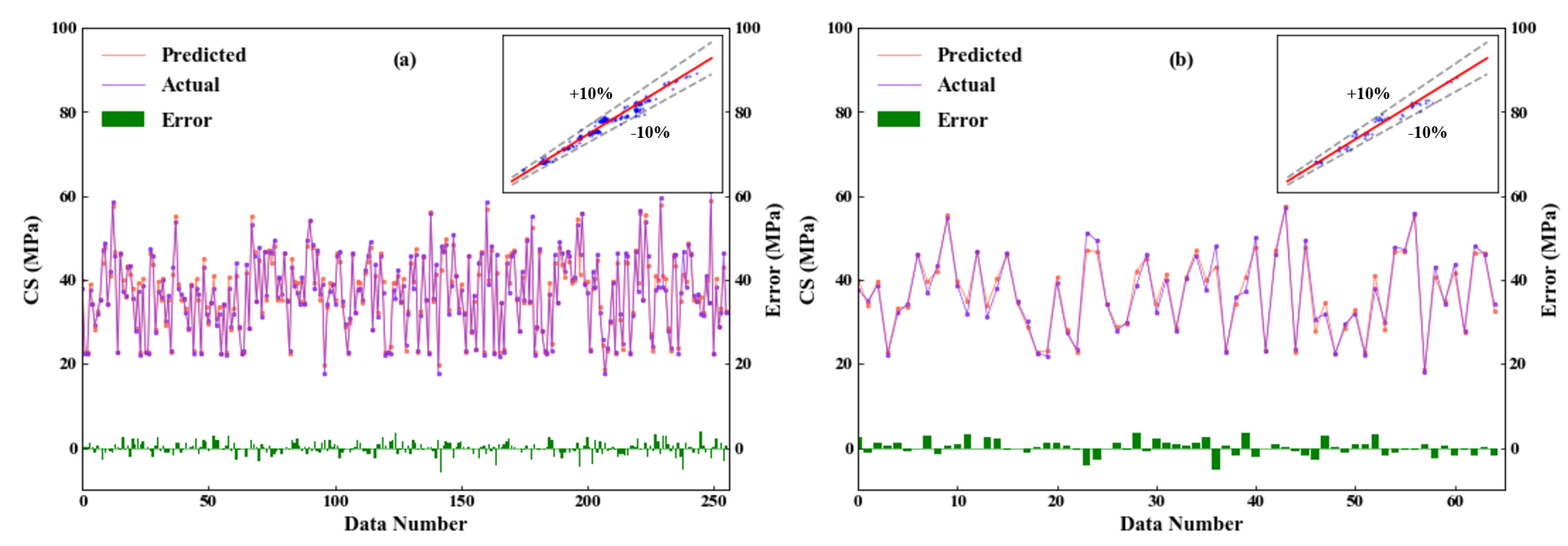

5.2. Result Comparison between the Comprehensive 4M1E Modeling and 4M1E Modeling with Feature Selection

5.3. Comparison with Other Methodologies

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Detailed Introduction to the RF Modeling Technique

References

- Bhanja, S.; Sengupta, B. Investigations on the compressive strength of silica fume concrete using statistical methods. Cem. Concr. Res. 2002, 32, 1391–1394. [Google Scholar] [CrossRef]

- Zain, M.F.M.; Abd, S.M. Multiple Regression Model for Compressive Strength Prediction of High Performance Concrete. J. Appl. Sci. 2009, 9, 155–160. [Google Scholar] [CrossRef]

- Feng, D.; Ren, X.; Li, J. Softened Damage-Plasticity Model for Analysis of Cracked Reinforced Concrete Structures. J. Struct. Eng. Asce 2018, 144, 04018044. [Google Scholar] [CrossRef]

- Feng, D.; Wang, Z.; Wu, G. Progressive collapse performance analysis of precast reinforced concrete structures. Struct. Des. Tall Spec. Build. 2019, 28. [Google Scholar] [CrossRef]

- Sobhani, J.; Najimi, M.; Pourkhorshidi, A.R.; Parhizkar, T. Prediction of the compressive strength of no-slump concrete: A comparative study of regression, neural network and ANFIS models. Constr. Build. Mater. 2010, 24, 709–718. [Google Scholar] [CrossRef]

- Chou, J.; Chiu, C.; Farfoura, M.; Altaharwa, I.A. Optimizing the Prediction Accuracy of Concrete Compressive Strength Based on a Comparison of Data-Mining Techniques. J. Comput. Civ. Eng. 2011, 25, 242–253. [Google Scholar] [CrossRef]

- Al-Shamiri, A.K.; Yuan, T.F.; Kim, J.H. Non-Tuned Machine Learning Approach for Predicting the Compressive Strength of High-Performance Concrete. Materials 2020, 13, 1023. [Google Scholar] [CrossRef] [PubMed]

- Cheng, M.; Chou, J.; Roy, A.F.; Wu, Y. High-performance Concrete Compressive Strength Prediction using Time-Weighted Evolutionary Fuzzy Support Vector Machines Inference Model. Autom. Constr. 2012, 28, 106–115. [Google Scholar] [CrossRef]

- Cheng, M.; Firdausi, P.M.; Prayogo, D. High-performance concrete compressive strength prediction using Genetic Weighted Pyramid Operation Tree (GWPOT). Eng. Appl. Artif. Intell. 2014, 29, 104–113. [Google Scholar] [CrossRef]

- Aiyer, B.G.; Kim, D.; Karingattikkal, N.; Samui, P.; Rao, P.R.M. Prediction of Compressive Strength of Self-Compacting Concrete using Least Square Support Vector Machine and Relevance Vector Machine. Ksce J. Civ. Eng. 2014, 18, 1753–1758. [Google Scholar] [CrossRef]

- Behnood, A.; Behnood, V.; Gharehveran, M.M.; Alyamac, K.E. Prediction of the compressive strength of normal and high-performance concretes using M5P model tree algorithm. Constr. Build. Mater. 2017, 142, 199–207. [Google Scholar] [CrossRef]

- Yu, Y.; Li, W.; Li, J.; Nguyen, T.N. A novel optimised self-learning method for compressive strength prediction of high performance concrete. Constr. Build. Mater. 2018, 184, 229–247. [Google Scholar] [CrossRef]

- Feng, D.; Liu, Z.; Wang, X.; Chen, Y.; Chang, J.; Wei, D.; Jiang, Z. Machine learning-based compressive strength prediction for concrete: An adaptive boosting approach. Constr. Build. Mater. 2020, 230, 117000. [Google Scholar] [CrossRef]

- Dantas, A.T.A.; Leite, M.B.; Nagahama, K.D.J. Prediction of compressive strength of concrete containing construction and demolition waste using artificial neural networks. Constr. Build. Mater. 2013, 38, 717–722. [Google Scholar] [CrossRef]

- Duan, Z.; Kou, S.; Poon, C.S. Prediction of compressive strength of recycled aggregate concrete using artificial neural networks. Constr. Build. Mater. 2013, 40, 1200–1206. [Google Scholar] [CrossRef]

- Nikoo, M.; Moghadam, F.T.; Sadowski, L. Prediction of Concrete Compressive Strength by Evolutionary Artificial Neural Networks. Adv. Mater. Sci. Eng. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Naderpour, H.; Rafiean, A.H.; Fakharian, P. Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J. Build. Eng. 2018, 16, 213–219. [Google Scholar] [CrossRef]

- Hadzima-Nyarko, M.; Nyarko, E.K.; Ademović, N.; Miličević, I.; Kalman Šipoš, T. Modelling the influence of waste rubber on compressive strength of concrete by artificial neural networks. Materials 2019, 12, 561. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Zhang, J.; Gu, Y.; Huang, Y.; Sun, Y.; Ma, G. Prediction of permeability and unconfined compressive strength of pervious concrete using evolved support vector regression. Constr. Build. Mater. 2019, 207, 440–449. [Google Scholar] [CrossRef]

- Khademi, F.; Akbari, M.; Jamal, S.M. Prediction of concrete compressive strength using ultrasonic pulse velocity test and artificial neural network modeling. Rrm 2016, 46, 343–350. [Google Scholar]

- Sadowski, L.; Nikoo, M.; Nikoo, M. Concrete compressive strength prediction using the imperialist competitive algorithm. Comput. Concr. 2018, 22, 355–363. [Google Scholar]

- Ly, H.B.; Pham, B.T.; Dao, D.V.; Le, V.M.; Le, L.M.; Le, T.T. Improvement of ANFIS model for prediction of compressive strength of manufactured sand concrete. Appl. Sci. 2019, 9, 3841. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, G.; Huang, Y.; Sun, J.; Aslani, F.; Nener, B. Modelling uniaxial compressive strength of lightweight self-compacting concrete using random forest regression. Constr. Build. Mater. 2019, 210, 713–719. [Google Scholar] [CrossRef]

- Benaicha, M.; Burtschell, Y.; Alaoui, A.H. Prediction of compressive strength at early age of concrete-Application of maturity. J. Build. Eng. 2016, 6, 119–125. [Google Scholar] [CrossRef]

- Kwon, S.H.; Jang, K.P.; Bang, J.; Lee, J.H.; Kim, Y.Y. Prediction of concrete compressive strength considering humidity and temperature in the construction of nuclear power plants. Nucl. Eng. Des. 2014, 275, 23–29. [Google Scholar] [CrossRef]

- Atici, U. Prediction of the strength of mineral admixture concrete using multivariable regression analysis and an artificial neural network. Expert Syst. Appl. 2011, 38, 9609–9618. [Google Scholar] [CrossRef]

- Mao, Y.; Xu, T. Research of 4M1E’s effect on engineering quality based on structural equation model. Syst. Eng. Procedia 2011, 1, 213–220. [Google Scholar]

- Pyon, C.U.; Lee, M.J.; Park, S.C. Decision support system for service quality management using customer knowledge in public service organization. Expert Syst. Appl. 2009, 36, 8227–8238. [Google Scholar] [CrossRef]

- Xu, Z.; Dang, Y.; Munro, P. Knowledge-driven intelligent quality problem-solving system in the automotive industry. Adv. Eng. Inform. 2018, 38, 441–457. [Google Scholar] [CrossRef]

- Zhou, H.; Zhao, Y.; Shen, Q.; Yang, L.; Cai, H. Risk assessment and management via multi-source information fusion for undersea tunnel construction. Autom. Constr. 2020, 111, 103050. [Google Scholar] [CrossRef]

- Zhao, F.; Wu, J.; Zhao, Y.; Ji, X.; Zhou, L.; Sun, Z. A machine learning methodology for reliability evaluation of complex chemical production systems. RSC Adv. 2020, 10, 20374–20384. [Google Scholar] [CrossRef]

- Chen, C.; Zhou, L.; Ji, X.; He, G.; Dai, Y.; Dang, Y. Adaptive Modeling Strategy Integrating Feature Selection and Random Forest for Fluid Catalytic Cracking Processes. Ind. Eng. Chem. Res. 2020, 59, 11265–11274. [Google Scholar] [CrossRef]

- Maldonado, S.; Weber, R. A wrapper method for feature selection using Support Vector Machines. Inf. Sci. 2009, 179, 2208–2217. [Google Scholar] [CrossRef]

- Yap, B.W.; Ibrahim, N.; Hamid, H.A.; Rahman, S.A.; Fong, S. Feature selection methods: Case of filter and wrapper approaches for maximising classification accuracy. Pertanika J. Sci. Technol. 2018, 26, 329–340. [Google Scholar]

- Ekbal, A.; Saha, S. Joint model for feature selection and parameter optimization coupled with classifier ensemble in chemical mention recognition. Knowl.-Based Syst. 2015, 85, 37–51. [Google Scholar] [CrossRef]

- Sakri, S.B.; Rashid, N.A.; Zain, Z.M. Particle Swarm Optimization Feature Selection for Breast Cancer Recurrence Prediction. IEEE Access 2018, 6, 29637–29647. [Google Scholar] [CrossRef]

- Svetnik, V.; Liaw, A.; Tong, C.; Wang, T. Application of Breiman’s Random Forest to Modeling Structure-Activity Relationships of Pharmaceutical Molecules. In International Workshop on Multiple Classifier Systems; Springer: Berlin/Heidelberg, Germany, 2004; pp. 334–343. [Google Scholar]

- Han, Q.; Gui, C.; Xu, J.; Lacidogna, G. A generalized method to predict the compressive strength of high-performance concrete by improved random forest algorithm. Constr. Build. Mater. 2019, 226, 734–742. [Google Scholar] [CrossRef]

- Li, Y.; Zou, C.; Berecibar, M.; Naninimaury, E.; Chan, J.C.; Den Bossche, P.V.; Van Mierlo, J.; Omar, N. Random forest regression for online capacity estimation of lithium-ion batteries. Appl. Energy 2018, 232, 197–210. [Google Scholar] [CrossRef]

- de Matos, P.R.; Prudencio, L.R., Jr.; Pilar, R.; Gleize, P.J.P.; Pelisser, F. Use of recycled water from mixer truck wash in concrete: Effect on the hydration, fresh and hardened properties. Constr. Build. Mater. 2020, 230, 116981. [Google Scholar] [CrossRef]

- Sandrolini, F.; Franzoni, E. Waste wash water recycling in ready-mixed concrete plants. Cem. Concr. Res. 2001, 31, 485–489. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Lahouar, A.; Slama, J.B.H. Hour-ahead wind power forecast based on random forests. Renew. Energy 2017, 109, 529–541. [Google Scholar] [CrossRef]

| Input | Variable | Unit | Variable | Unit |

|---|---|---|---|---|

| Man | a: work shifts | - | a: age | year |

| a: seniority | month | |||

| Machine | b: gravel scale | % | b: coarse sand scale | % |

| b: fine stone scale | % | b: powder scale 1 | % | |

| b: powder scale 2 | % | b: additives scale 1 | % | |

| b: additives scale 2 | % | b: tap water scale | % | |

| b: recycled water scale | % | b: stable current value | A | |

| Material | c: cement content | - | c: compressive strength of cement | MPa |

| c: cement paste fluidity | mm | c: slag powder content | - | |

| c: fluidity ratio | - | c: activity index of slag powder | % | |

| c: fly ash content | - | c: fineness of fly ash | % | |

| c: water demand ratio of fly ash | % | c: activity index of fly ash | % | |

| c: fine stone content | - | c: silt content of fine stone | % | |

| c: gravel content | - | c: silt content of gravel | % | |

| c: aggregate water-content | % | c: fine sand content | - | |

| c: fineness modulus of fine sand | - | c: silt content of fine sand | % | |

| c: coarse sand content | - | c: fineness modulus of coarse sand | - | |

| c: silt content of coarse sand | % | c: tap water content | - | |

| c: recycled water content | - | c: superplasticizer content | - | |

| c: expansive agent content | - | |||

| Method | d: water-cement ratio | - | d: sand ratio | - |

| d: design strength | MPa | |||

| Environment | e: Minimum temperature | e: maximum temperature | ||

| e: average temperature | e: relative humidity | % |

| Variable | Unit | No | Range | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | ... | 321 | ||||

| Input | a | - | 0 | 1 | ... | 1 | 0, 1 |

| ... | ... | ... | ... | ... | ... | ... | |

| a | month | 60 | 14 | ... | 24 | 12–60 | |

| b | % | −0.095 | 0.2083 | ... | 0.0417 | −1.80–1.84 | |

| ... | ... | ... | ... | ... | ... | ... | |

| b | A | 64.94 | 65.67 | ... | 69.81 | 35.1–76.3 | |

| c | - | 0.1305 | 0.1533 | ... | 0.1407 | 0.07–0.17 | |

| ... | ... | ... | ... | ... | ... | ... | |

| c | - | 0.0153 | 0.016 | ... | 0.016 | 0–0.016 | |

| d | - | 0.6071 | 0.4396 | ... | 0.4278 | 0.41–1.14 | |

| ... | ... | ... | ... | ... | ... | ... | |

| d | MPa | 50 | 45 | ... | 40 | 15–50 | |

| e | 19.4 | 19.9 | ... | 22.8 | 5.9–27.5 | ||

| ... | ... | ... | ... | ... | ... | ... | |

| e | % | 85 | 78 | ... | 68 | 38–98 | |

| Output | s | MPa | 49.4 | 45.8 | ... | 43.5 | 17.7–61.1 |

| Terms in Biology | Genetic Algorithm (GA) in Feature Selection |

|---|---|

| Gene | Binary variables indicating the inclusion or exclusion of a process feature from the following five aspects (man, machine, material, method, environment) |

| Chromosome | A vector consists of the whole set of genes for the concrete production process |

| Crossover | Exchange of variables between two parent individuals at randomly selected sites |

| Mutation | Change the selection state of variables at randomly selected sites |

| Fitness | Performance evaluation of RF model |

| Input | Performance Measures | ||||

|---|---|---|---|---|---|

| R | MAE(MPa) | RMSE(MPa) | MAPE | ||

| model-a | 0.9564 | 2.081 | 3.079 | 0.0551 | 0.998 |

| model-b | 0.9707 | 1.846 | 2.428 | 0.0475 | 0.582 |

| Input | Performance Measures | ||||

|---|---|---|---|---|---|

| R | MAE(MPa) | RMSE(MPa) | MAPE | ||

| model-a | 0.9564 | 2.081 | 3.079 | 0.0551 | 0.998 |

| model-b | 0.9707 | 1.846 | 2.428 | 0.0475 | 0.582 |

| the proposed model | 0.9821 | 1.429 | 1.824 | 0.0394 | 0.395 |

| Model | Performance Measures | Feature-Selected | ||||

|---|---|---|---|---|---|---|

| R | MAE (MPa) | RMSE (MPa) | MAPE | |||

| RF | 0.9707 | 1.846 | 2.428 | 0.0475 | 0.528 | 44 |

| GA-ANN | 0.9619 | 2.155 | 2.686 | 0.0631 | 0.531 | 21 |

| GA-SVR | 0.9708 | 1.919 | 2.327 | 0.0541 | 0.408 | 18 |

| GA-MLR | 0.9723 | 1.821 | 2.246 | 0.0521 | 0.425 | 20 |

| GA-RF | 0.9821 | 1.429 | 1.824 | 0.0394 | 0.395 | 20 |

| PCA-RF | 0.9167 | 2.587 | 3.862 | 0.0797 | 1.275 | 9 |

| GRA-RF | 0.9724 | 1.835 | 2.343 | 0.0468 | 0.508 | 17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Zhou, L.; He, G.; Ji, X.; Dai, Y.; Dang, Y. Comprehensive Machine Learning-Based Model for Predicting Compressive Strength of Ready-Mix Concrete. Materials 2021, 14, 1068. https://doi.org/10.3390/ma14051068

Xu J, Zhou L, He G, Ji X, Dai Y, Dang Y. Comprehensive Machine Learning-Based Model for Predicting Compressive Strength of Ready-Mix Concrete. Materials. 2021; 14(5):1068. https://doi.org/10.3390/ma14051068

Chicago/Turabian StyleXu, Jiajia, Li Zhou, Ge He, Xu Ji, Yiyang Dai, and Yagu Dang. 2021. "Comprehensive Machine Learning-Based Model for Predicting Compressive Strength of Ready-Mix Concrete" Materials 14, no. 5: 1068. https://doi.org/10.3390/ma14051068

APA StyleXu, J., Zhou, L., He, G., Ji, X., Dai, Y., & Dang, Y. (2021). Comprehensive Machine Learning-Based Model for Predicting Compressive Strength of Ready-Mix Concrete. Materials, 14(5), 1068. https://doi.org/10.3390/ma14051068