A Comparative Study between Polymer and Metal Additive Manufacturing Approaches in Investigating Stiffened Hexagonal Cells

Abstract

1. Introduction

2. Experimental Methodology

2.1. Selected Geometric Configurations

2.2. AM Technologies

2.3. Testing and Evaluation Procedures

3. Results and Discussion

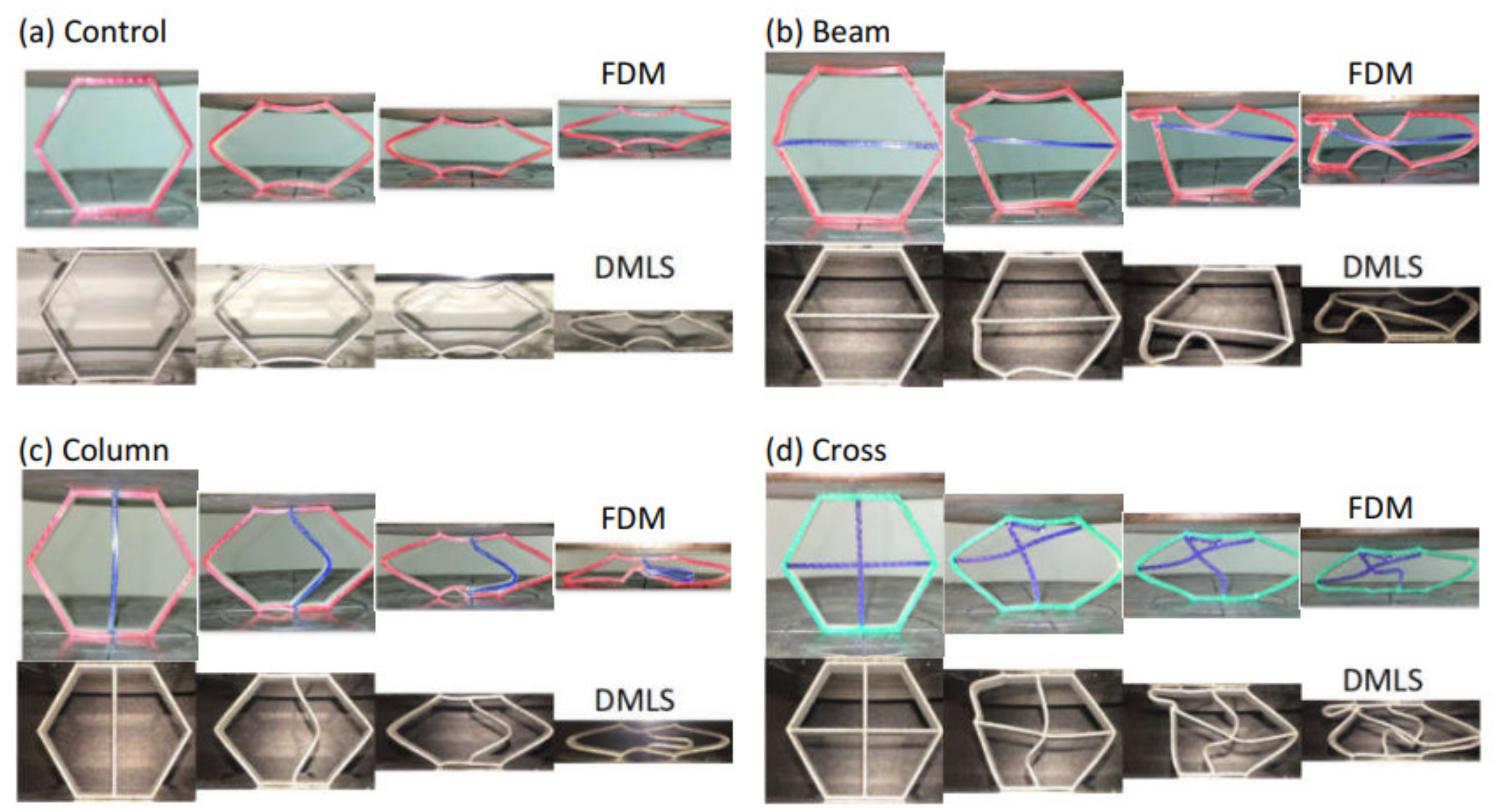

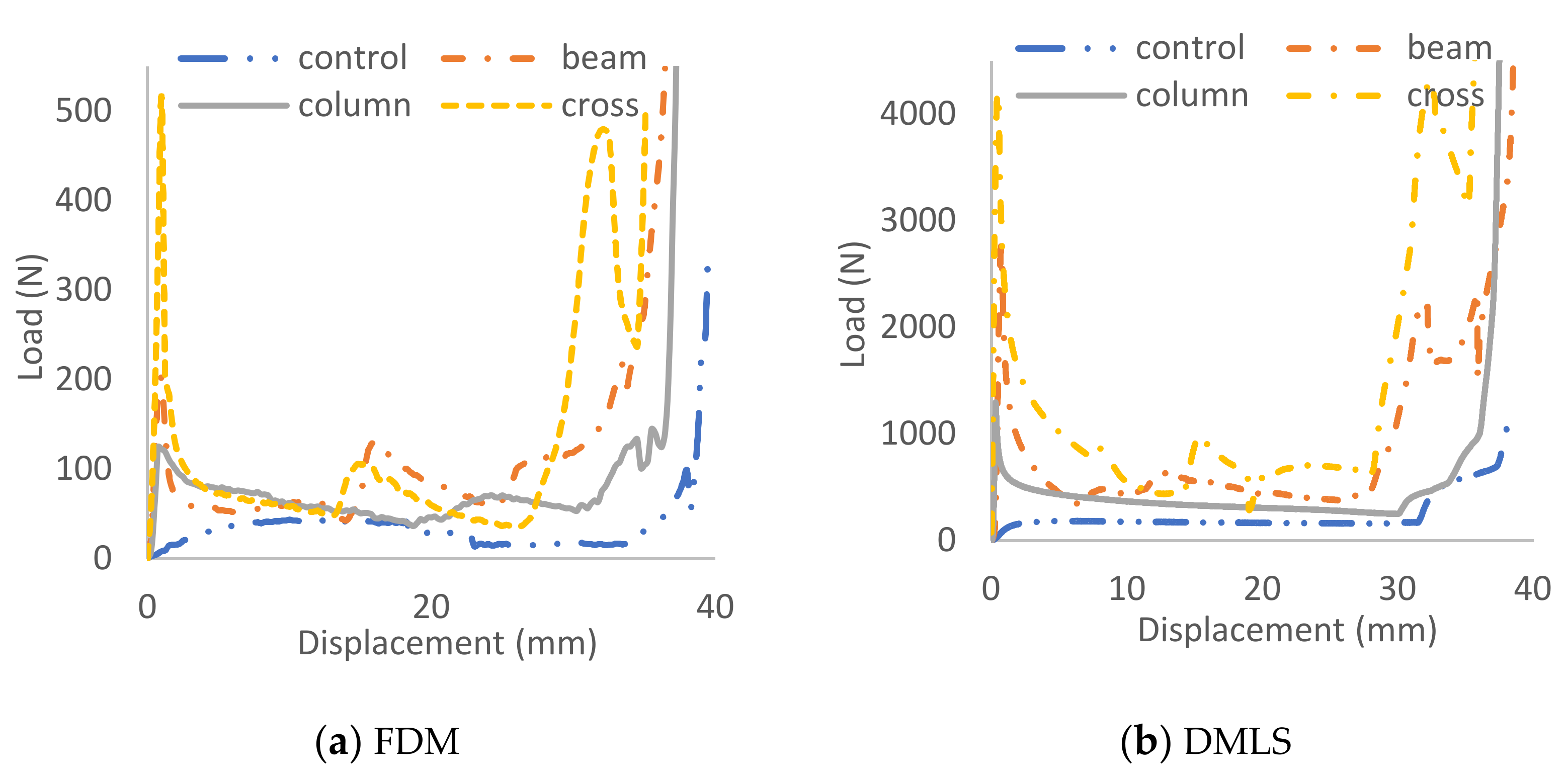

3.1. Comparative Analysis of Collapsing Behavior

3.2. Performance of Configurations

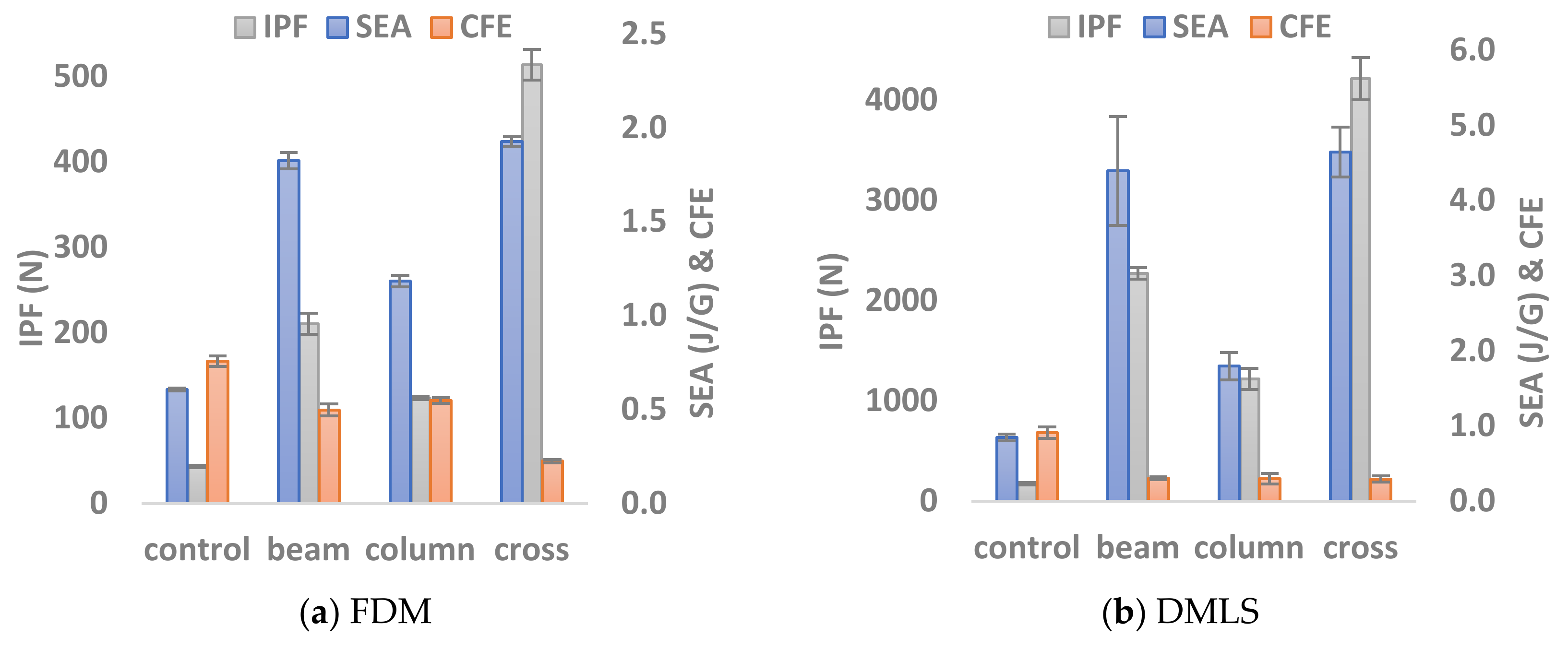

3.3. Cost-Effectiveness

4. Conclusions

- In general, the collapsing behavior of the configurations was similar between FDM and DMLS sets as well as the load-displacement trends.

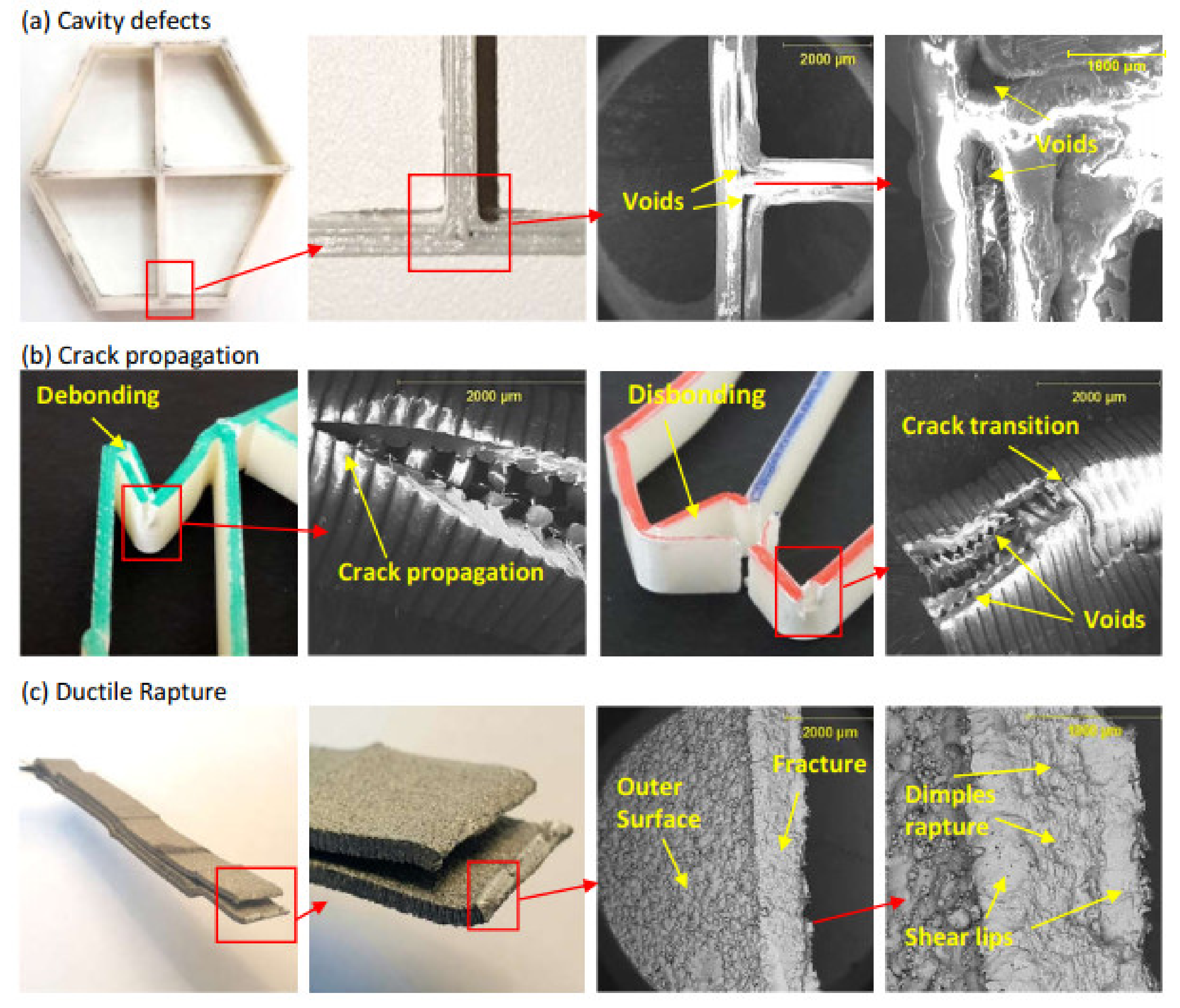

- The failure modes were different where crack propagation with progressive brittle fracture was dominant in FDM specimens while the DMLS specimens had excessive deformation with the ductile fractures.

- Material discontinuity defects and poor diffusion between building layers were observed at the structural joints produced by the FDM technique whereas the DMLS built seamless transitioning between the layers.

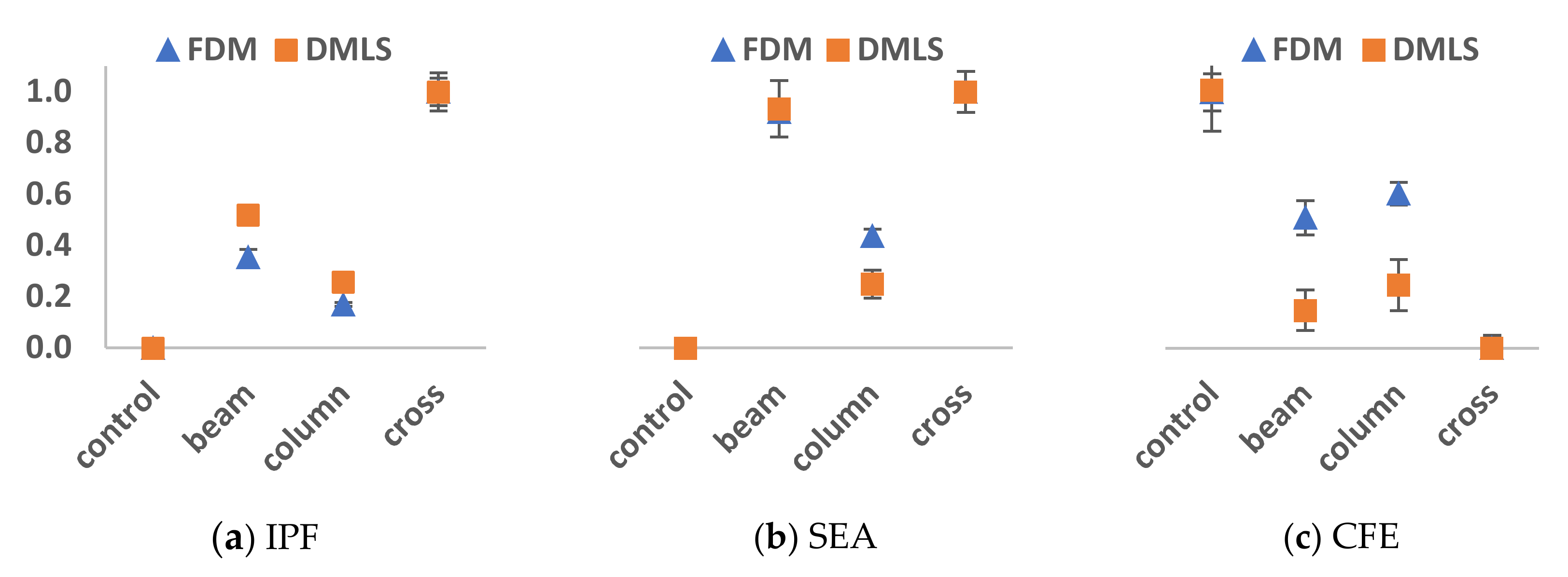

- Overall, similar conclusions were drawn from the performance parameters of both sets. The cross configuration has the highest IPF and SEA with the lowest CFE in both FDM and DMLS cases. In contrast, the coreless hexagonal cell had the highest CFE while the IPF was compensated.

- The FDM printing was 80% more time-efficient and 53.6% cheaper than the DMLS technique.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Li, V.C.-F.; Kuang, X.; Hamel, C.M.; Roach, D.; Deng, Y.; Qi, H.J. Cellulose nanocrystals support material for 3D printing complexly shaped structures via multi-materials-multi-methods printing. Addit. Manuf. 2019, 28, 14–22. [Google Scholar] [CrossRef]

- Bose, S.; Ke, D.; Sahasrabudhe, H.; Bandyopadhyay, A. Additive manufacturing of biomaterials. Prog. Mater. Sci. 2018, 93, 45–111. [Google Scholar] [CrossRef] [PubMed]

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 2132–2147. [Google Scholar] [CrossRef]

- Safai, L.; Cuellar, J.S.; Smit, G.; Zadpoor, A.A. A review of the fatigue behavior of 3D printed polymers. Addit. Manuf. 2019, 28, 87–97. [Google Scholar] [CrossRef]

- Ma, F.; Zhang, H.; Hon, K.; Gong, Q. An optimization approach of selective laser sintering considering energy consumption and material cost. J. Clean. Prod. 2018, 199, 529–537. [Google Scholar] [CrossRef]

- Mostafa, K.G.; Montemagno, C.; Qureshi, A.J. Strength to cost ratio analysis of FDM Nylon 12 3D Printed Parts. Procedia Manuf. 2018, 26, 753–762. [Google Scholar] [CrossRef]

- Duan, S.; Tao, Y.; Lei, H.; Wen, W.; Liang, J.; Fang, D. Enhanced out-of-plane compressive strength and energy absorption of 3D printed square and hexagonal honeycombs with variable-thickness cell edges. Extreme Mech. Lett. 2018, 18, 9–18. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Mohamed, A.; Laban, O.; Tarlochan, F.; Al Khatib, S.E.; Matar, M.S.; Mahdi, E. Experimental analysis of additively manufactured thin-walled heat-treated circular tubes with slits using AlSi10Mg alloy by quasi-static axial crushing test. Thin-Walled Struct. 2019, 138, 404–414. [Google Scholar] [CrossRef]

- Bates, S.R.G.; Farrow, I.R.; Trask, R.S. 3D printed polyurethane honeycombs for repeated tailored energy absorption. Mater. Des. 2016, 112, 172–183. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.; Tuck, C.; Ashcroft, I. Compressive failure modes and energy absorption in additively manufactured double gyroid lattices. Addit. Manuf. 2017, 16, 24–29. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, X.; Zhang, H. A review on functionally graded structures and materials for energy absorption. Eng. Struct. 2018, 171, 309–325. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.; Aremu, A.; Tuck, C.; Ashcroft, I.; Wildman, R.D.; Hague, R.J. A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting. Mater. Sci. Eng. A 2016, 670, 264–274. [Google Scholar] [CrossRef]

- Alkhatib, S.E.; Matar, M.S.; Tarlochan, F.; Laban, O.; Mohamed, A.S.; Alqwasmi, N. Deformation modes and crashworthiness energy absorption of sinusoidally corrugated tubes manufactured by direct metal laser sintering. Eng. Struct. 2019, 201, 109838. [Google Scholar] [CrossRef]

- Hosseinabadi, H.G.; Bagheri, R.; Gray, L.A.; Altstädt, V.; Drechsler, K. Plasticity in polymeric honeycombs made by photo-polymerization and nozzle based 3D-printing. Polym. Test. 2017, 63, 163–167. [Google Scholar] [CrossRef]

- ASTM, E9Standard Test Methods of Compression Testing of Metallic Materials at Room TemperatureASTM International: West Conshohocken, PA, USA, 2000.

- Laban, O.; Gowid, S.; Mahdi, E.; Musharavati, F. Experimental investigation and artificial intelligence-based modeling of the residual impact damage effect on the crashworthiness of braided Carbon/Kevlar tubes. Compos. Struct. 2020, 243, 112247. [Google Scholar] [CrossRef]

- Laban, O.; Mahdi, E. Energy Absorption Capability of Cotton Fiber/Epoxy Composite Square and Rectangular Tubes. J. Nat. Fibers 2016, 13, 726–736. [Google Scholar]

- Gu, J.; Yang, S.; Gao, M.; Jing, B.; Zhai, Y.; Ding, J. Micropore evolution in additively manufactured aluminum alloys under heat treatment and inter-layer rolling. Mater. Des. 2020, 186, 108288. [Google Scholar] [CrossRef]

- Kerekes, T.W.; Lim, H.; Joe, W.Y.; Yun, G.J. Characterization of process–deformation/damage property relationship of fused deposition modeling (FDM) 3D-printed specimens. Addit. Manuf. 2019, 25, 532–544. [Google Scholar]

- Uddin, S.Z.; Murr, L.E.; Terrazas, C.A.; Morton, P.; Roberson, D.A.; Wicker, R.B. Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing. Addit. Manuf. 2018, 22, 405–415. [Google Scholar] [CrossRef]

- Materialise. Materialise Magics, version Magics SG+STL Editor Software for Additive Manufacturing; Materialise: Leuven, Belgium, 2021. [Google Scholar]

- CADimensions Inc. CatalystEX, version 4.2, Software to convert STL output into 3D modeling print paths; CADimensions Inc.: East Syracuse, NY, USA, 2017. [Google Scholar]

| Mechanical Property | ABS (P430) | AlSi10Mg (HT) |

|---|---|---|

| Specific gravity | 1.04 | 2.67 |

| Ultimate tensile strength | 33 MPa | 350 MPa |

| Yield strength | 31 MPa | 230 MPa |

| Modulus of elasticity | 2.2 GPa | 60 GPa |

| Failure strain | 6% | 11% |

| Machine Parameters | Value | Material Composition | |||

|---|---|---|---|---|---|

| Element | wt.% | Element | wt.% | ||

| Laser Power | 370 W | Al | Balance | Ni | ≤0.05 |

| Laser scanning speed | 1.3 m/s | Si | 9.0–11.0 | Pb | ≤0.05 |

| Layer thickness | 30 μm | Fe | ≤0.55 | Zn | ≤0.10 |

| Beam diameter | 0.1 mm | Cu | ≤0.05 | Sn | ≤0.05 |

| Hatch spacing | 0.19 mm | Mn | ≤0.45 | Ti | ≤0.15 |

| Powder size | 45 ± 10 µm | Mg | 0.2–0.45 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laban, O.; Mahdi, E.; Samim, S.; Cabibihan, J.-J. A Comparative Study between Polymer and Metal Additive Manufacturing Approaches in Investigating Stiffened Hexagonal Cells. Materials 2021, 14, 883. https://doi.org/10.3390/ma14040883

Laban O, Mahdi E, Samim S, Cabibihan J-J. A Comparative Study between Polymer and Metal Additive Manufacturing Approaches in Investigating Stiffened Hexagonal Cells. Materials. 2021; 14(4):883. https://doi.org/10.3390/ma14040883

Chicago/Turabian StyleLaban, Othman, Elsadig Mahdi, Samahat Samim, and John-John Cabibihan. 2021. "A Comparative Study between Polymer and Metal Additive Manufacturing Approaches in Investigating Stiffened Hexagonal Cells" Materials 14, no. 4: 883. https://doi.org/10.3390/ma14040883

APA StyleLaban, O., Mahdi, E., Samim, S., & Cabibihan, J.-J. (2021). A Comparative Study between Polymer and Metal Additive Manufacturing Approaches in Investigating Stiffened Hexagonal Cells. Materials, 14(4), 883. https://doi.org/10.3390/ma14040883