Structural Integrity of Steel Pipeline with Clusters of Corrosion Defects

Abstract

:1. Introduction

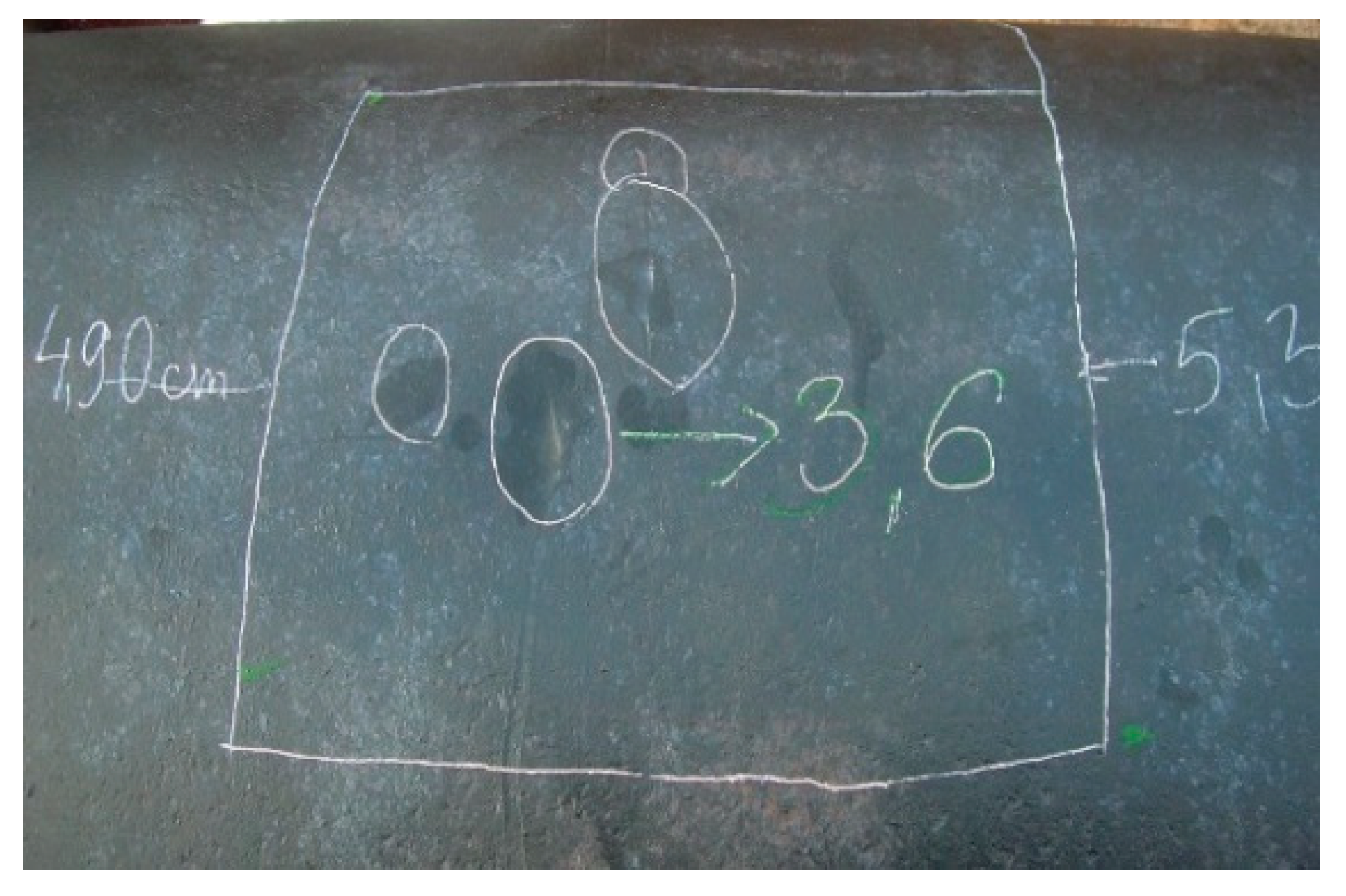

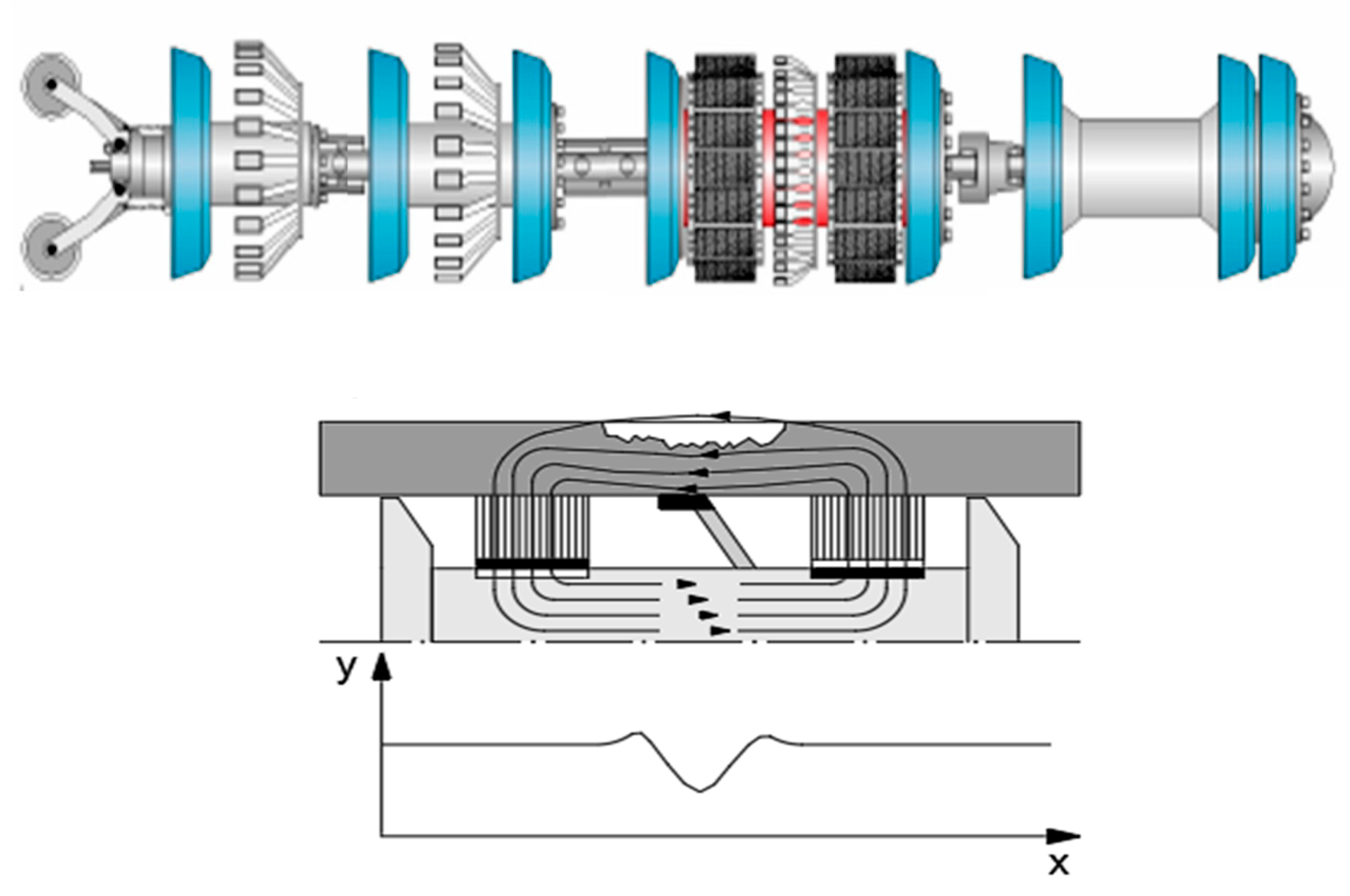

2. Clustering Rules for Tube Wall Metal Losses

2.1. Grouping Criteria for Volumetric Defect Colonies

- (a)

- longitudinal spacing along the pipe axis is less than sLi ≤ (sl)limand

- (b)

- circumferential spacing sci ≤ (sc)limwhere:sli—longitudinal spacing of each defect in the colony, [mm];sci—circumferential spacing of each anomaly in the group, [mm];D—tube outside diameter, [mm];t—pipe wall nominal thickness, [mm].

2.2. Analytical Assessment of Interacting Defects

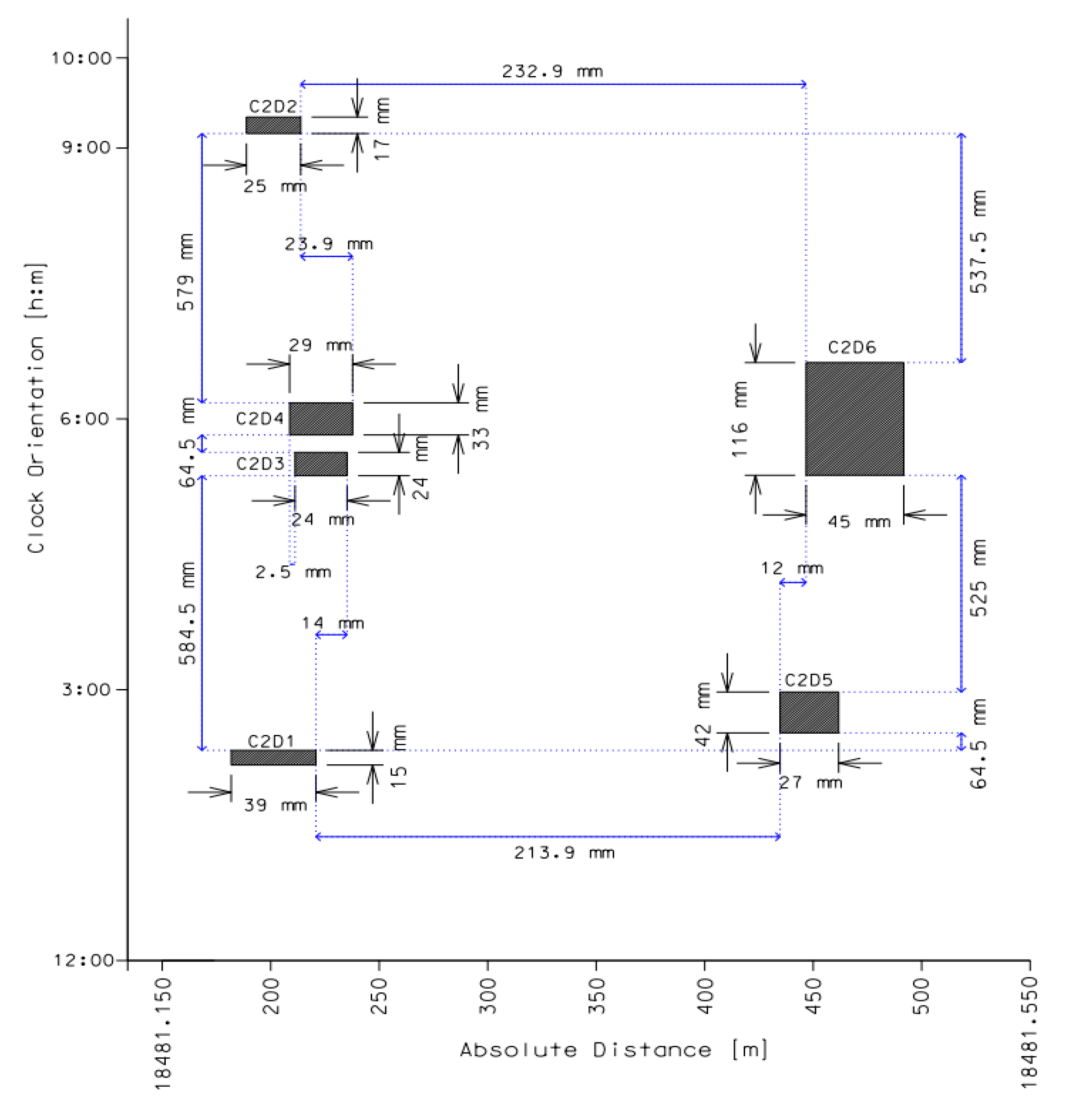

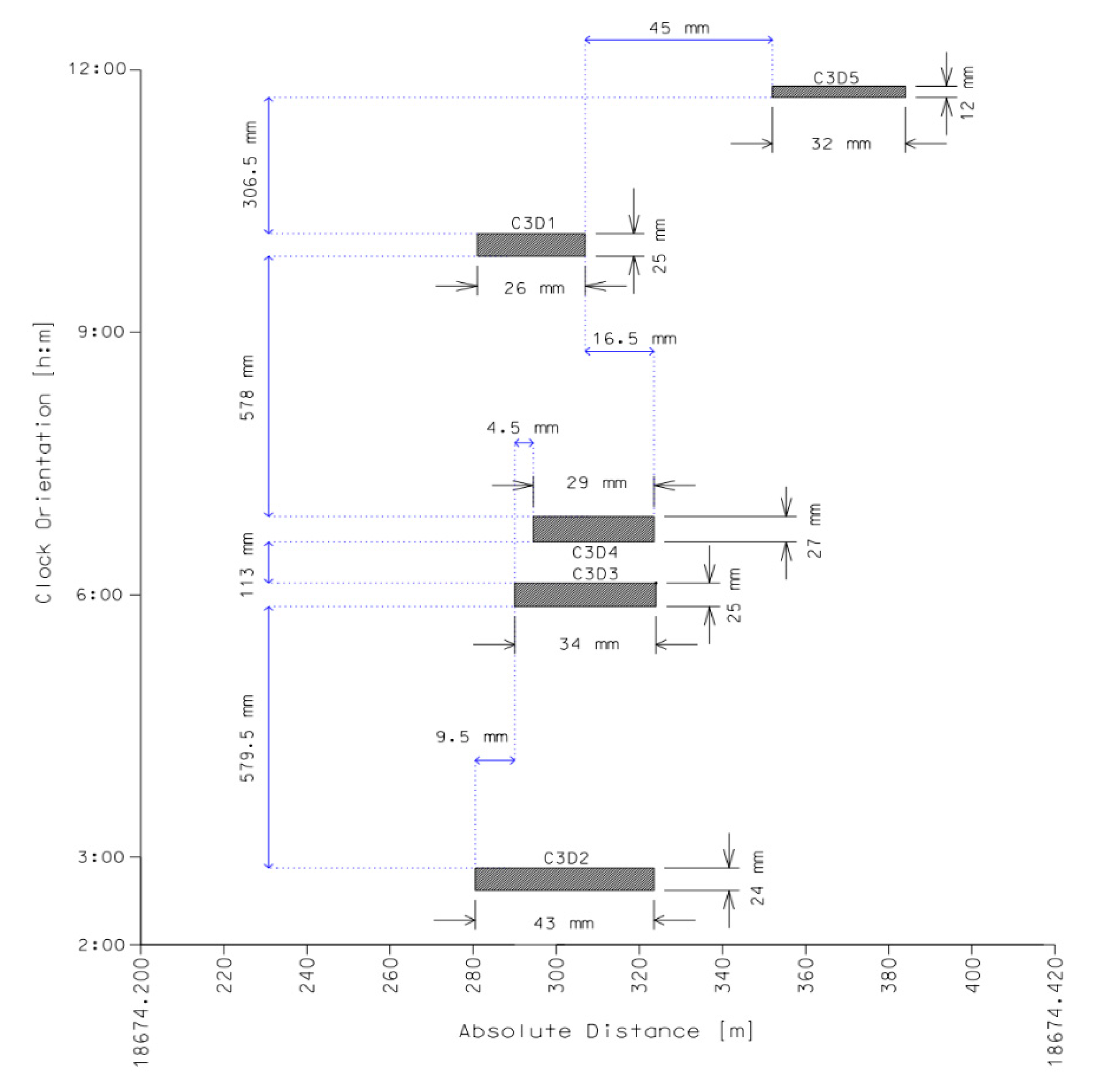

3. In-Line Inspection Indications Clustering

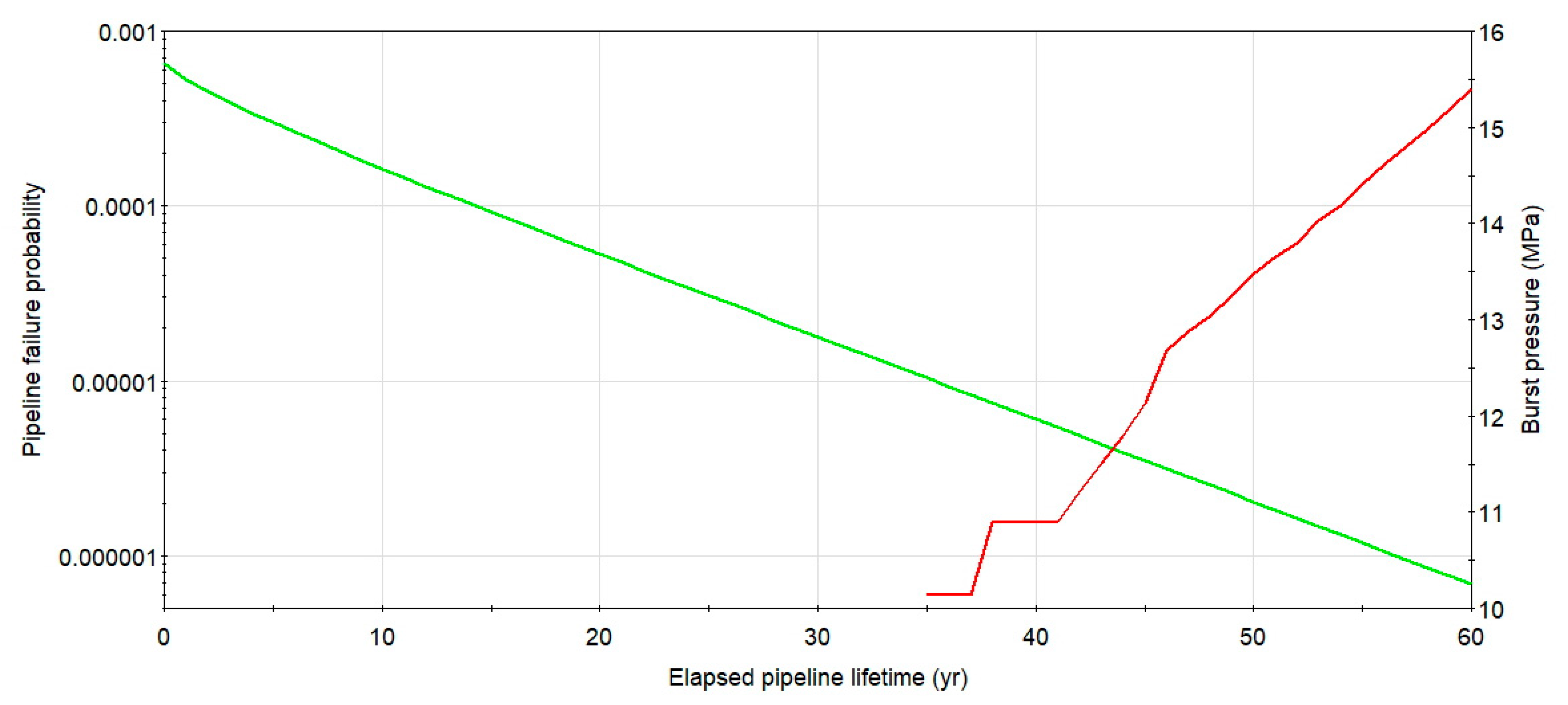

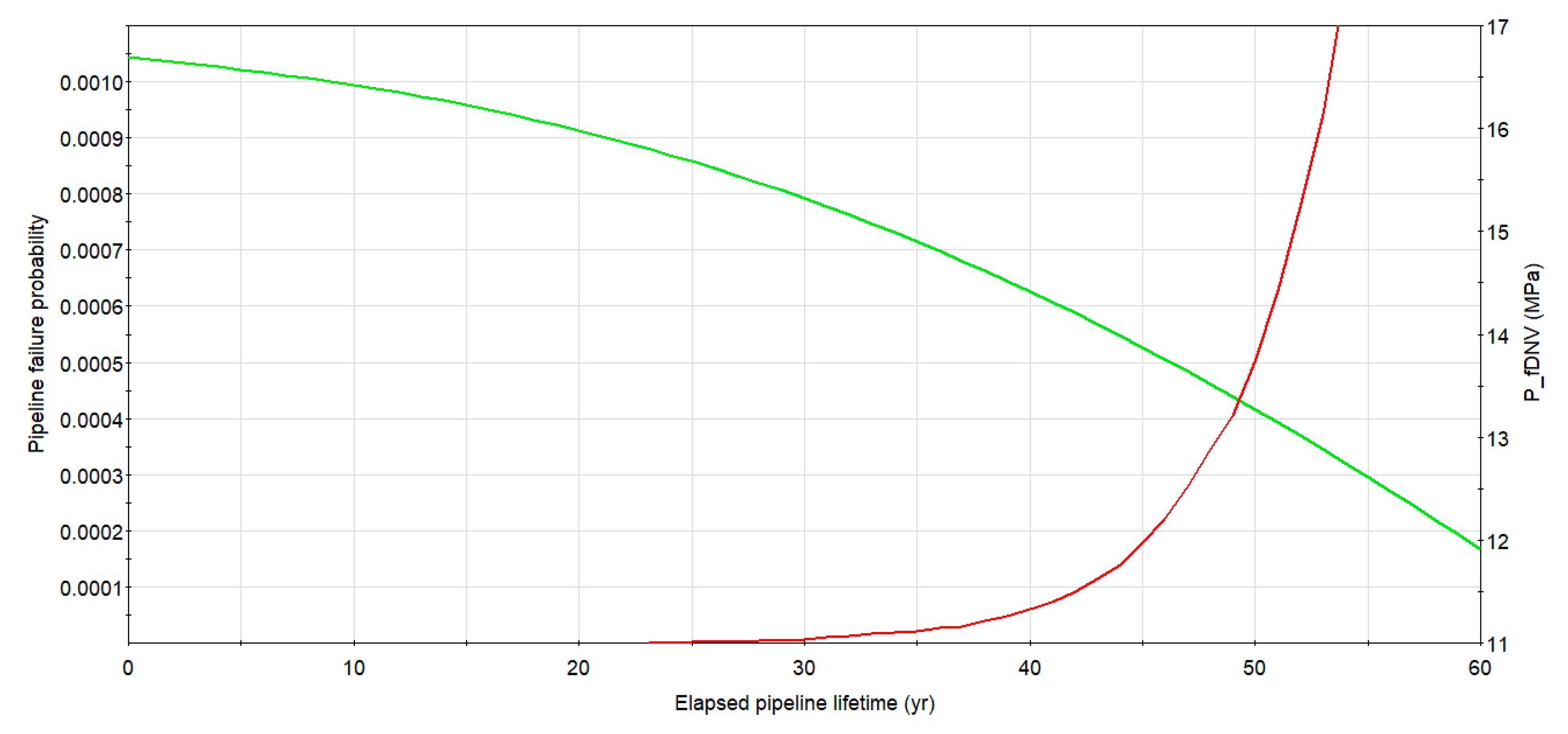

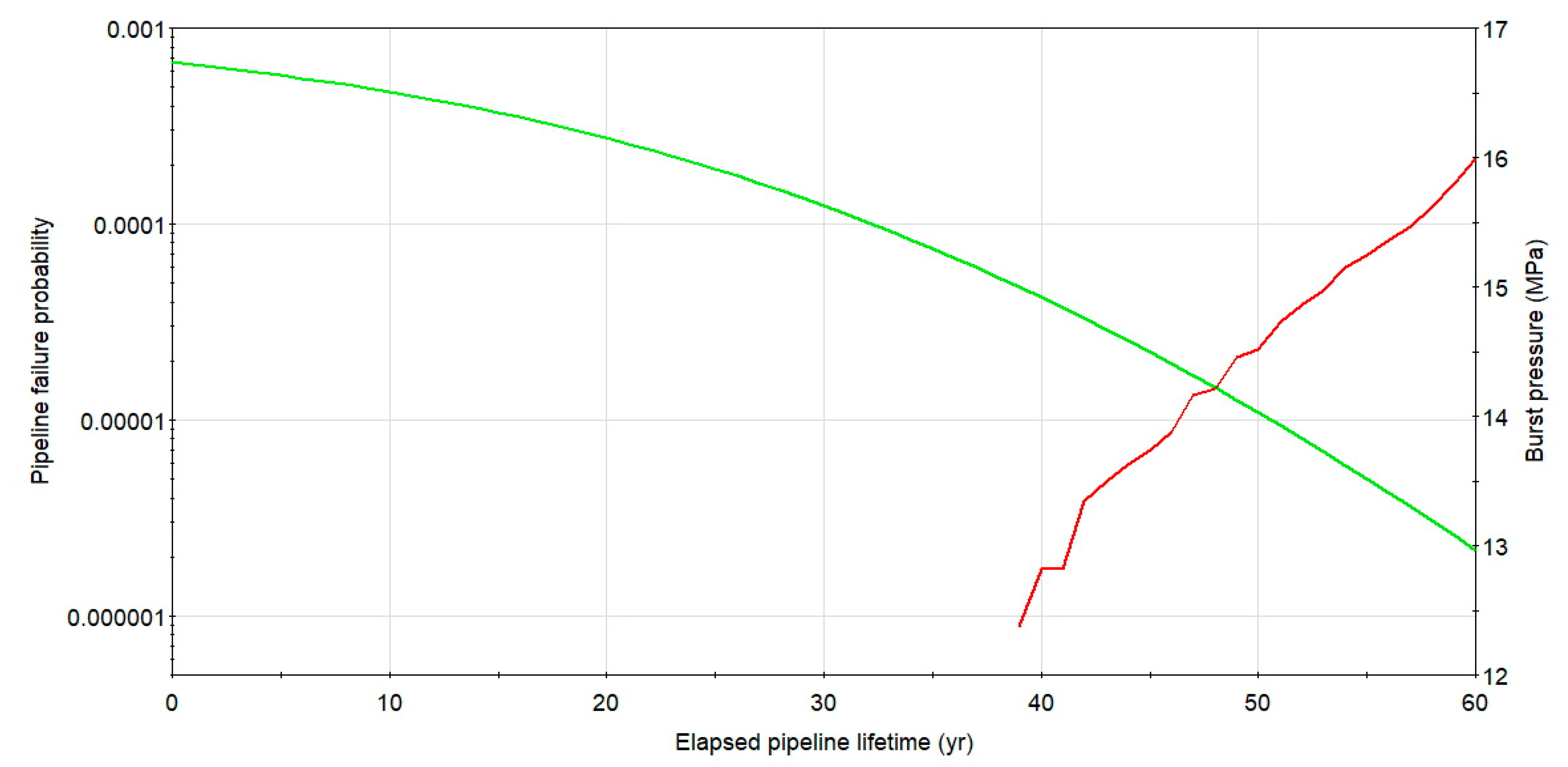

4. Probability of Pipeline Rupture

4.1. Calculation Methodology

4.2. Input Data for Structural Integrity Evaluation

5. Pipeline Structural Reliability Considering Flaws Grouping

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Witek, M.; Batura, A.; Orynyak, I.; Borodii, M. An integrated risk assessment of onshore gas transmission pipelines based on defect population. Eng. Struct. 2018, 173, 150–165. [Google Scholar] [CrossRef]

- Witek, M. Validation of in-line inspection data quality and impact on steel pipeline diagnostic intervals. J. Nat. Gas Sci. Eng. 2018, 56, 121–133. [Google Scholar] [CrossRef]

- Witek, M. Life cycle estimation of high pressure pipeline based on in-line inspection data. Eng. Fail. Anal. 2019, 104, 247–260. [Google Scholar] [CrossRef]

- Kong, F.T.; Wordu, A.H. Burst strength analysis of pressurized steel pipelines with corrosion and gouge defects. Eng. Fail. Anal. 2020, 108, 104347. [Google Scholar]

- Guillal, A.; Seghier, M.E.A.B.; Nourddine, A.; Correia, J.A.; Mustaffa, Z.B.; Trung, N.-T. Probabilistic investigation on the reliability assessment of mid- and high-strength pipelines under corrosion and fracture conditions. Eng. Fail. Anal. 2020, 118, 104891. [Google Scholar] [CrossRef]

- Liu, X.; Xia, M.; Bolati, D.; Liu, J.; Zheng, Q.; Zhang, H. An ANN-based failure pressure prediction method for buried high-strength pipes with stray current corrosion defect. Energy Sci. Eng. 2019, 8, 248–259. [Google Scholar] [CrossRef]

- Li, X.; Bai, Y.; Su, C.; Li, M. Effect of interaction between corrosion defects on failure pressure of thin wall steel pipeline. Int. J. Press. Vessel. Pip. 2016, 138, 8–18. [Google Scholar] [CrossRef]

- DNV-RP-F101. Det Norske Veritas Recommended Practice Corroded Pipelines; 2010; Available online: http://www.opimsoft.com/download/reference/rp-f101_2010-10.pdf (accessed on 8 February 2021).

- Zhang, S.; Zhou, W. System reliability of corroding pipelines considering stochastic process-based models for defect growth and internal pressure. Int. J. Press. Vessels Pip. 2013, 111, 120–130. [Google Scholar] [CrossRef]

- Sahraoui, Y.; Khelif, R.; Chateauneuf, A. Maintenance planning under imperfect inspection of corroded pipelines. Int. J. Press. Vessel. Pip. 2013, 104, 76–82. [Google Scholar] [CrossRef]

- Li, S.-X.; Yu, S.-R.; Zeng, H.-L.; Li, J.-H.; Liang, R. Predicting corrosion remaining life of underground pipelines with a mechanically-based probabilistic model. J. Pet. Sci. Eng. 2009, 65, 162–166. [Google Scholar] [CrossRef]

- Pesinis, K.; Tee, K.F. Bayesian analysis of small probability incidents for corroding energy pipelines. Eng. Struct. 2018, 165, 264–277. [Google Scholar] [CrossRef]

- Witek, M. Gas transmission failure probability estimation and defect repairs activities based on in-line inspection data. Eng. Fail. Anal. 2016, 70, 255–272. [Google Scholar] [CrossRef]

- Adilson, C.; Benjamin, J.; Luiz, F.; Freire, R.; Vieira, D.; Divino, J.S. Interaction of corrosion defects in pipelines e Part. 1: Fundamentals. Int. J. Press. Vessel. Pip. 2016, 144, 56–62. [Google Scholar]

- Szteke, W.; Biłous, W.; Wasiak, J.; Hajewska, E.; Przyborska, M.; Wagner, T. Badania Wycinka Rury ze Stali G-355 z Gazociągu Po 15-Letniej Eksploatacji Część II.: Badania Metodami Niszczącymi. Available online: https://www.researchgate.net/publication/320798876_The_investigation_of_the_gas_pipeline_from_G355_steel_after_15-years_of_exploitation_Part_I_The_investigation_with_nondestructive_methods (accessed on 8 February 2021).

- Sahraoui, Y.; Chateauneuf, A. The effects of spatial variability of the aggressiveness of soil on system reliability of corroding underground pipelines. Int. J. Press. Vessel. Pip. 2016, 146, 188–197. [Google Scholar] [CrossRef]

| Defect № | Absolute Distance [m] | Relative Depth (d/t) [%] | Axial Length [mm] | Width [mm] | Clock Orientation [hour:min] |

|---|---|---|---|---|---|

| C1D1 | 393.611 | 17% | 44 | 27 | 12:30 |

| C1D2 | 393.623 | 22% | 20 | 26 | 03:30 |

| C1D3 | 393.629 | 25% | 21 | 30 | 07:45 |

| C1D4 | 393.635 | 20% | 23 | 36 | 04:15 |

| Defect № | Absolute Distance [m] | Relative Depth (d/t) [%] | Axial Length [mm] | Width [mm] | Clock Orientation [hour:min] |

|---|---|---|---|---|---|

| C2D1 | 18481.201 | 29% | 39 | 15 | 02:15 |

| C2D2 | 18481.201 | 25% | 25 | 17 | 09:15 |

| C2D3 | 18481.222 | 21% | 24 | 24 | 05:30 |

| C2D4 | 18481.222 | 31% | 29 | 33 | 06:00 |

| C2D5 | 18481.447 | 16% | 27 | 42 | 02:45 |

| C2D6 | 18481.468 | 19% | 45 | 116 | 06:00 |

| Defect № | Absolute Distance [m] | Relative Depth (d/t) [%] | Axial Length [mm] | Width [mm] | Clock Orientation [hour:min] |

|---|---|---|---|---|---|

| C3D1 | 18674.294 | 17% | 26 | 25 | 10:00 |

| C3D2 | 18674.302 | 22% | 43 | 24 | 02:45 |

| C3D3 | 18674.307 | 19% | 34 | 25 | 06:00 |

| C3D4 | 18674.309 | 22% | 29 | 27 | 06:45 |

| C3D5 | 18674.368 | 27% | 32 | 12 | 11:45 |

| Colony № | Defect № | Defect Depth [mm] | Axial Length [mm] | Burst Pressure [MPa] | Colony № |

|---|---|---|---|---|---|

| C1 | C1D2 | 2.42 | 20.0 | 17.875 | C1D2 |

| C1D4 | 2.20 | 23.0 | 17.868 | C1D4 | |

| C2 | C1D2 + C1D4 | 3.43 | 27.5 | 17.796 | C1D2 + C1D4 |

| C2D3 | 2.31 | 24.0 | 17.861 | C2D3 | |

| C3 | C2D4 | 3.41 | 29.0 | 17.784 | C2D4 |

| C2D3+ C2D4 | 5.10 | 29.0 | 17.666 | C2D3 + C2D4 |

| No. | Parameter | Unit | Mean Value | Uncertainty Coefficients | Distribution Type |

|---|---|---|---|---|---|

| 1. | Yield tensile strength (fy) | MPa | 370.6 | StD[fy] = 12.2 COV[fy] = 3.3 % | Lognormal |

| 2. | Ultimate tensile strength (fu) | MPa | 554.7 | StD[fu] = 19.4 COV[fu] = 3.5 % | Lognormal |

| 3. | Pipe wall thickness (t) | mm | 11.0 | StD[t] = 0.5 COV[t] = 4.5 % | Normal |

| 4. | Tube outside diameter (D) | mm | 711.0 | StD[D] = 20.3 COV[D] = 2.8 % | Normal |

| 5. | Maximum operating pressure (MOP) | MPa | 5.5 | s = 0.3 COV[MOP] = 5.5 % | Gumbel |

| 6. | Metal loss depth (d) | mm | defect specific | StD[d] = 0.6 COV[d] = 26.6 % | Normal |

| 7. | Flaw length (L) | mm | defect specific | StD[L] = 34.6 COV[L] = 76.9 % | Lognormal |

| 8. | Defect depth growth rate d(T) as a power law function with parameters cd, α. | mm/year | cd = 0.164, α = 0.78 | Parameters cd, α deterministic | Parameters cd, α deterministic |

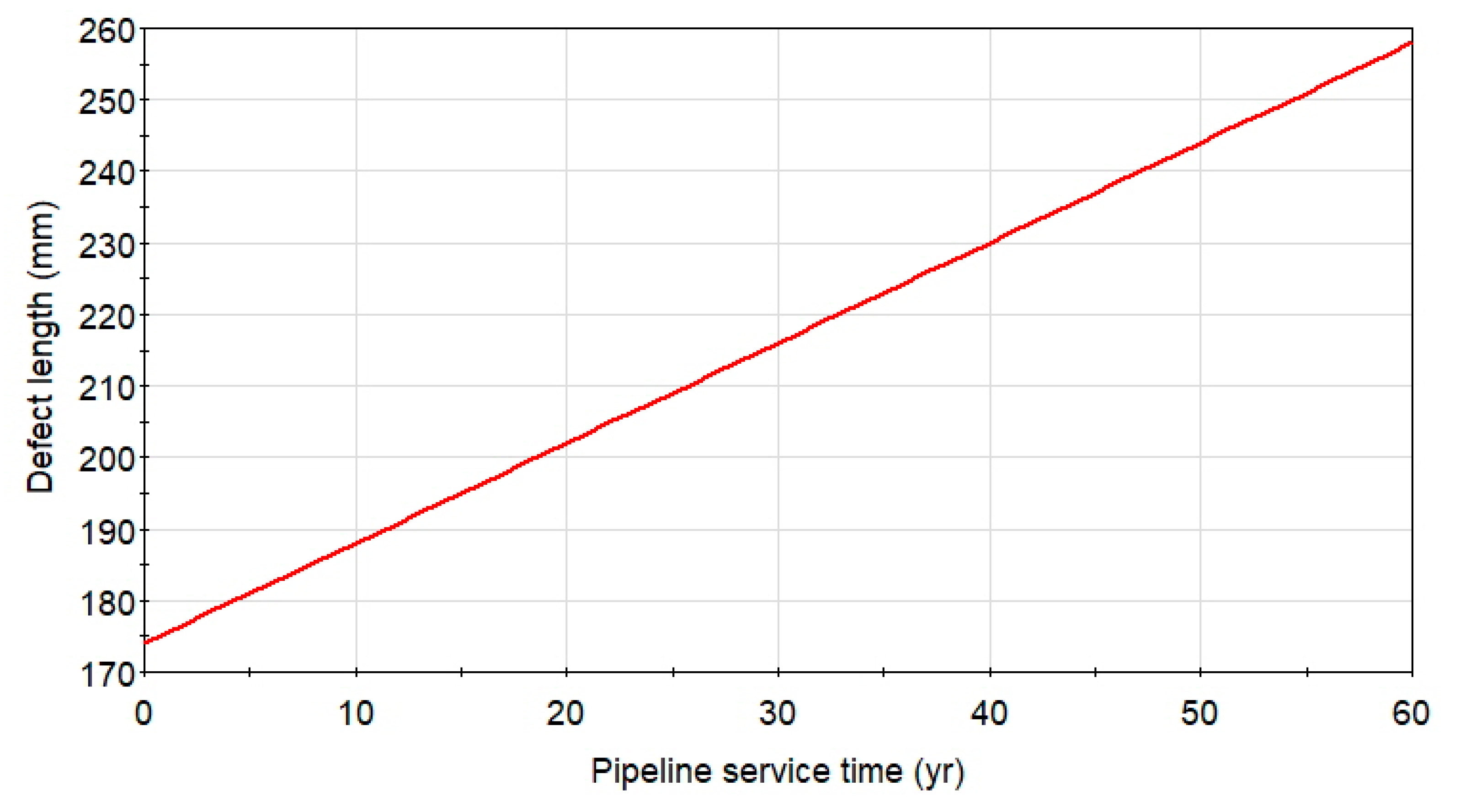

| 9. | Metal loss length growth rate L(T) as a power law function with parameters cl. | mm/year | cl = 1.4 | Parameter cl deterministic | Parameter cl deterministic |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Witek, M. Structural Integrity of Steel Pipeline with Clusters of Corrosion Defects. Materials 2021, 14, 852. https://doi.org/10.3390/ma14040852

Witek M. Structural Integrity of Steel Pipeline with Clusters of Corrosion Defects. Materials. 2021; 14(4):852. https://doi.org/10.3390/ma14040852

Chicago/Turabian StyleWitek, Maciej. 2021. "Structural Integrity of Steel Pipeline with Clusters of Corrosion Defects" Materials 14, no. 4: 852. https://doi.org/10.3390/ma14040852

APA StyleWitek, M. (2021). Structural Integrity of Steel Pipeline with Clusters of Corrosion Defects. Materials, 14(4), 852. https://doi.org/10.3390/ma14040852