High and Low-Temperature Performance Evaluation and Microanalysis of SMCSBS Compound-Modified Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

3.1. Basic Technical Indexes of SMCSBS with Different SMC Content

3.2. Rotational Viscosity

3.2.1. Mixing Temperature and Compaction Temperature

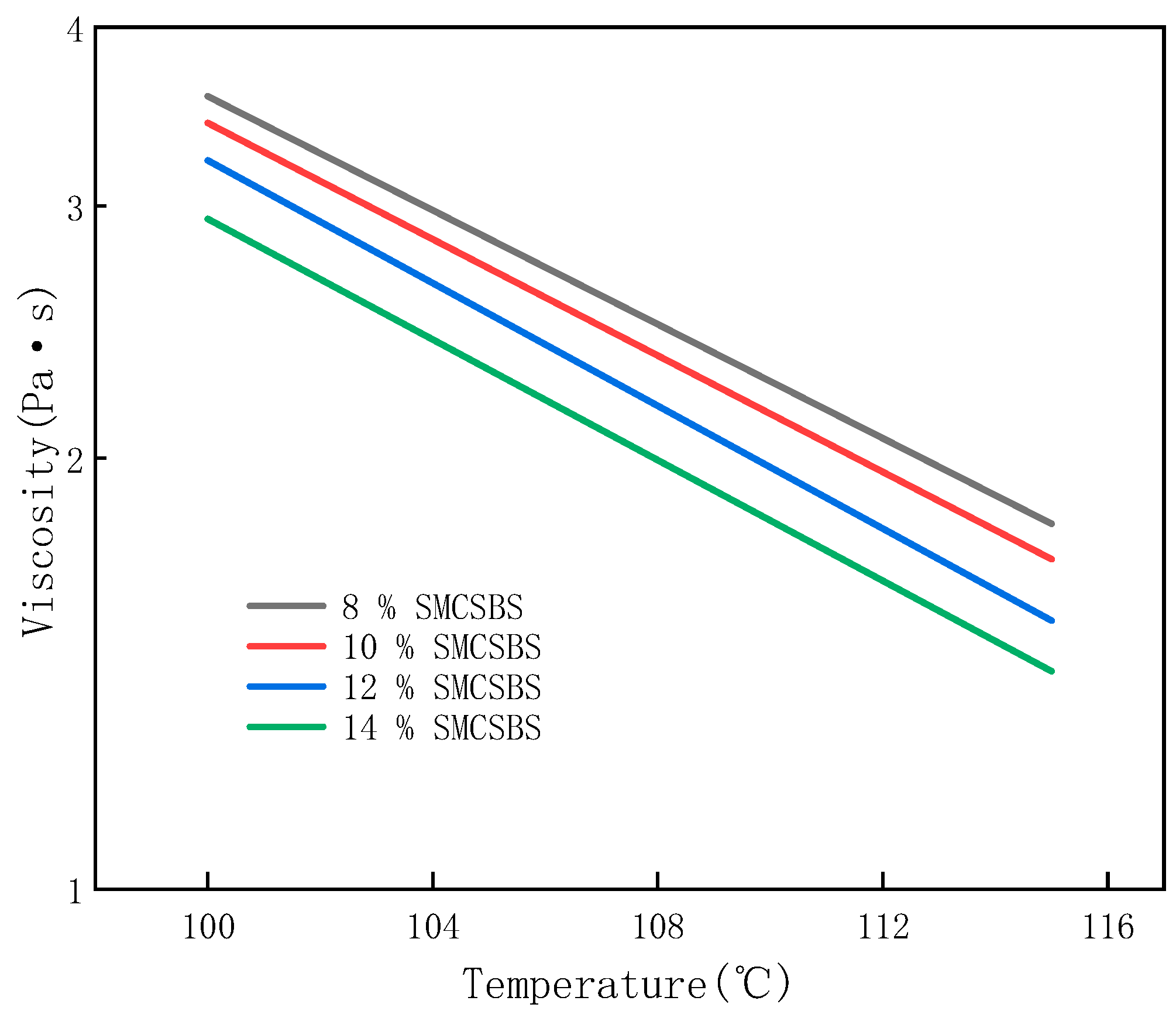

3.2.2. Viscous-Temperature Characteristics

3.3. High-Temperature Performance Analysis

3.3.1. Performance Grade (PG)

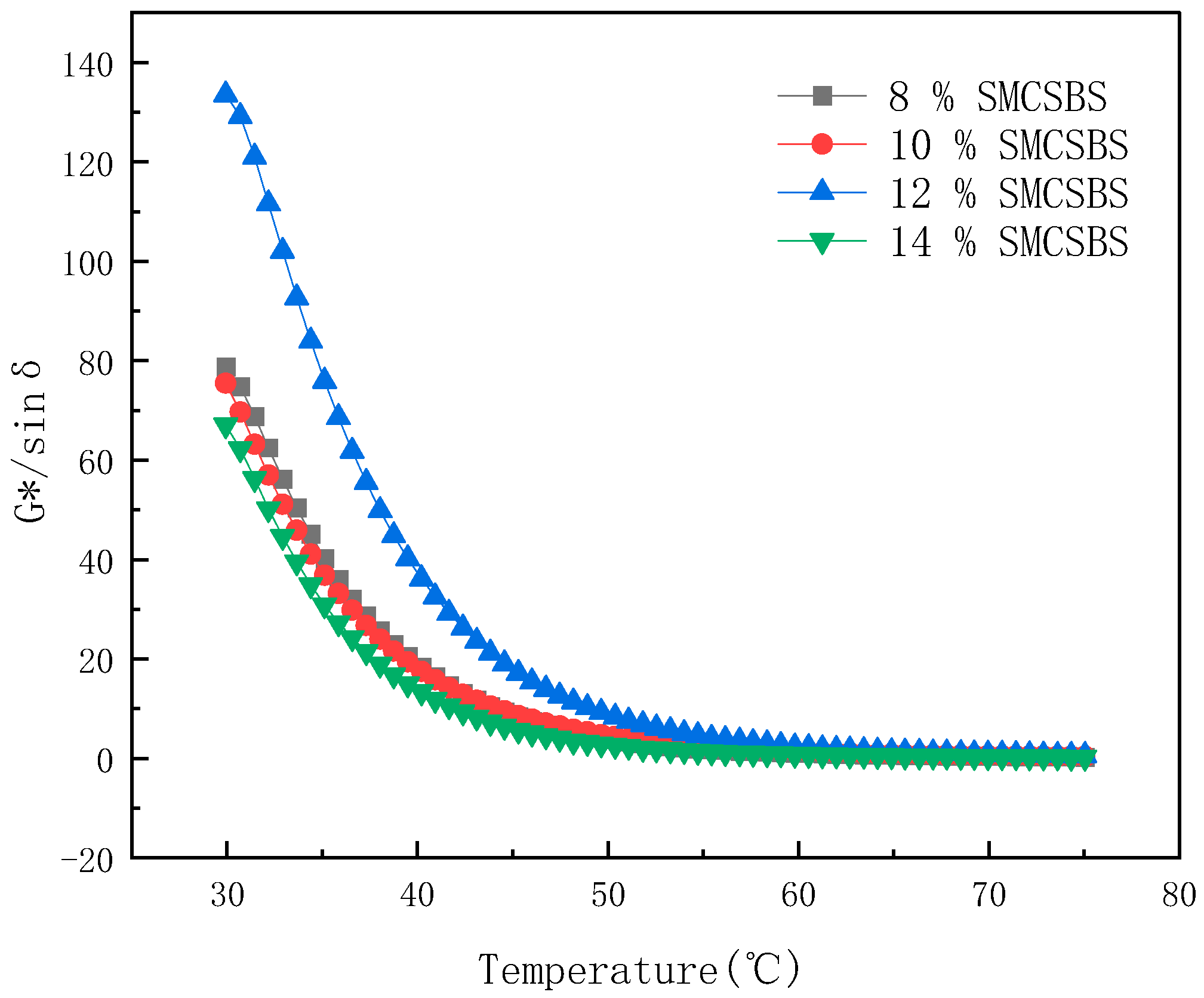

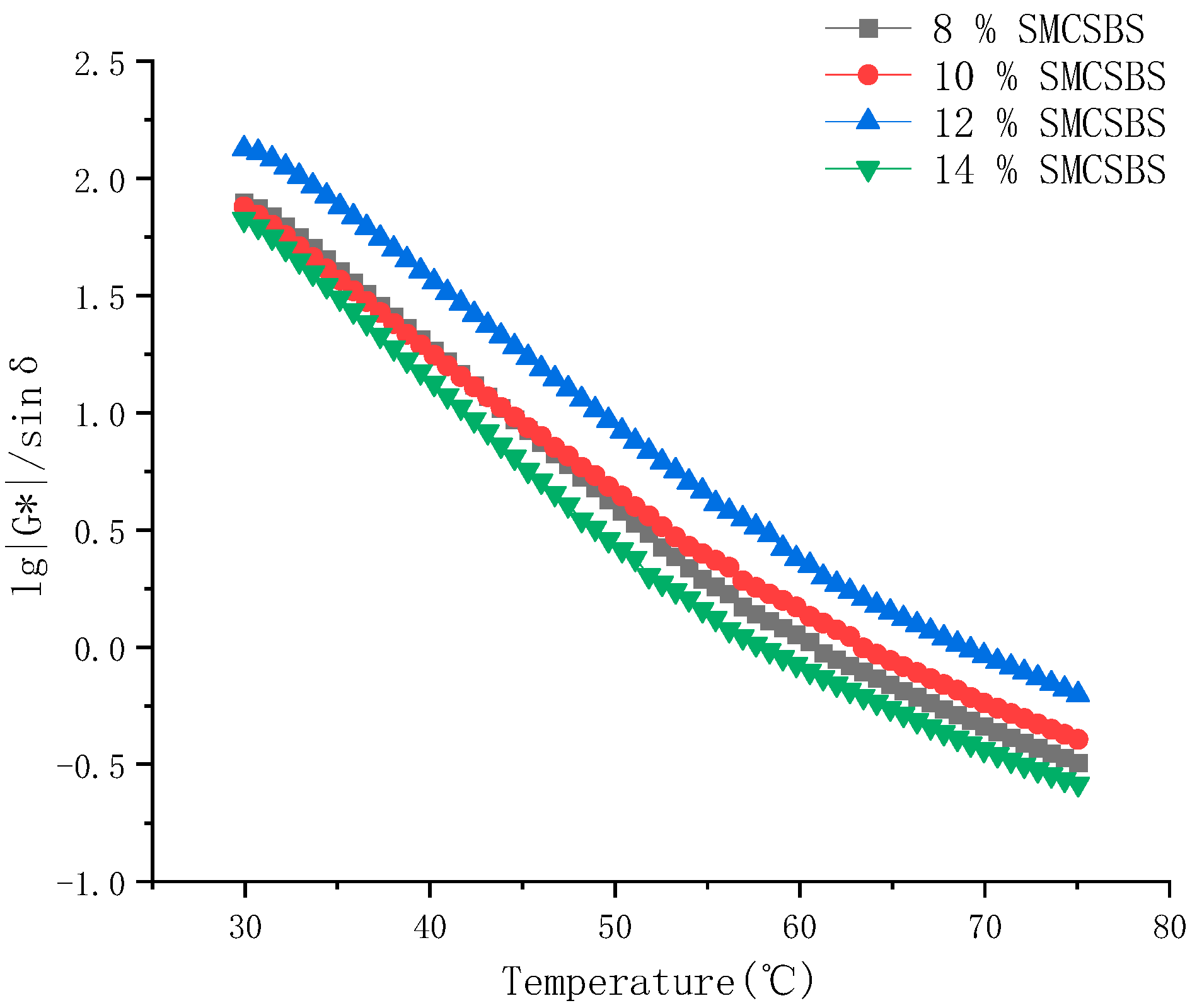

3.3.2. Analysis of the Rut Factor (G*/sinδ)

3.3.3. Critical Temperature

3.4. Low-Temperature Performance Analysis

3.4.1. Performance Grade (PG)

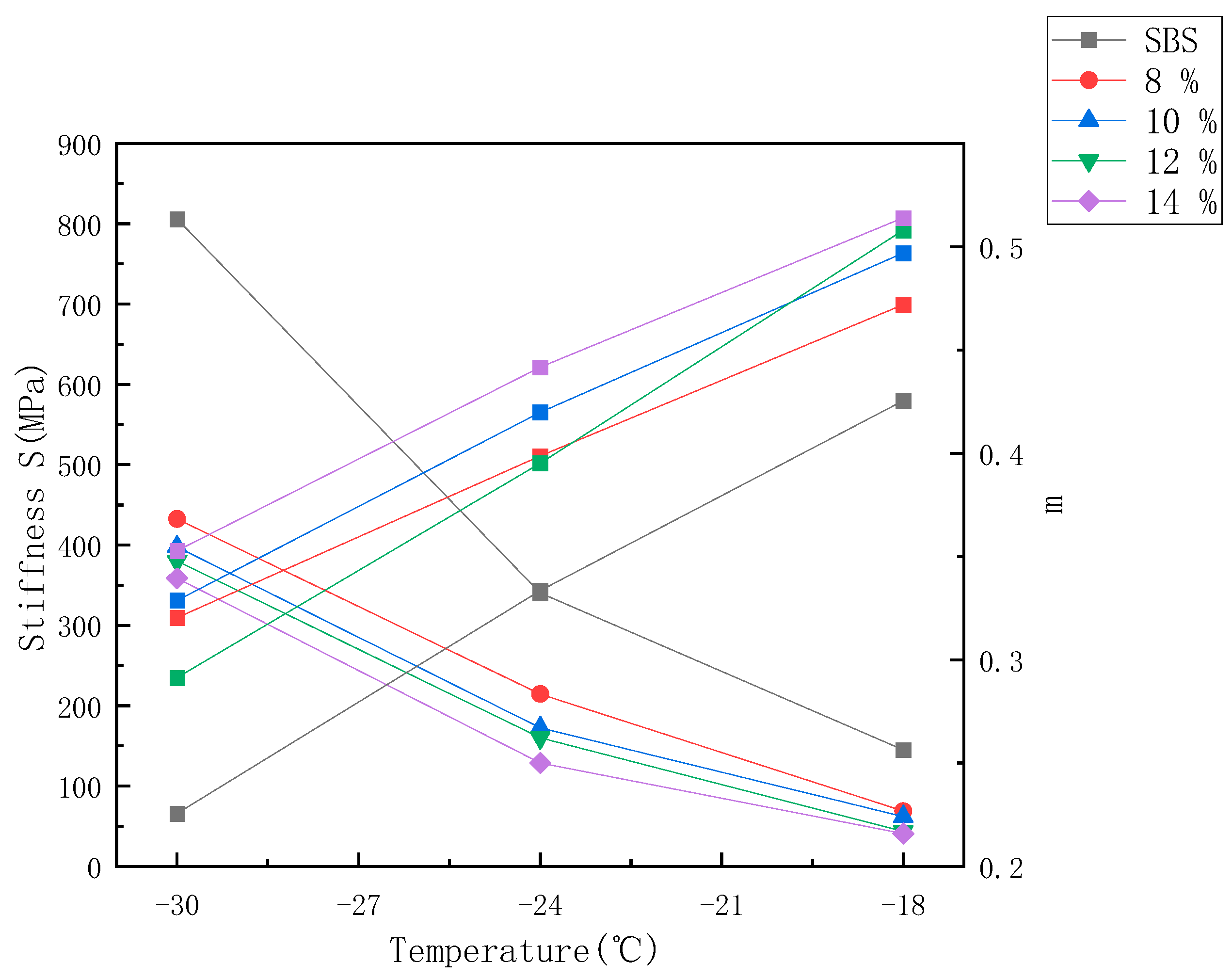

3.4.2. Creep Stiffness S and Creep Rate m

3.4.3. Crack Resistance Index m/S at Low Temperature

3.5. Micro Analysis

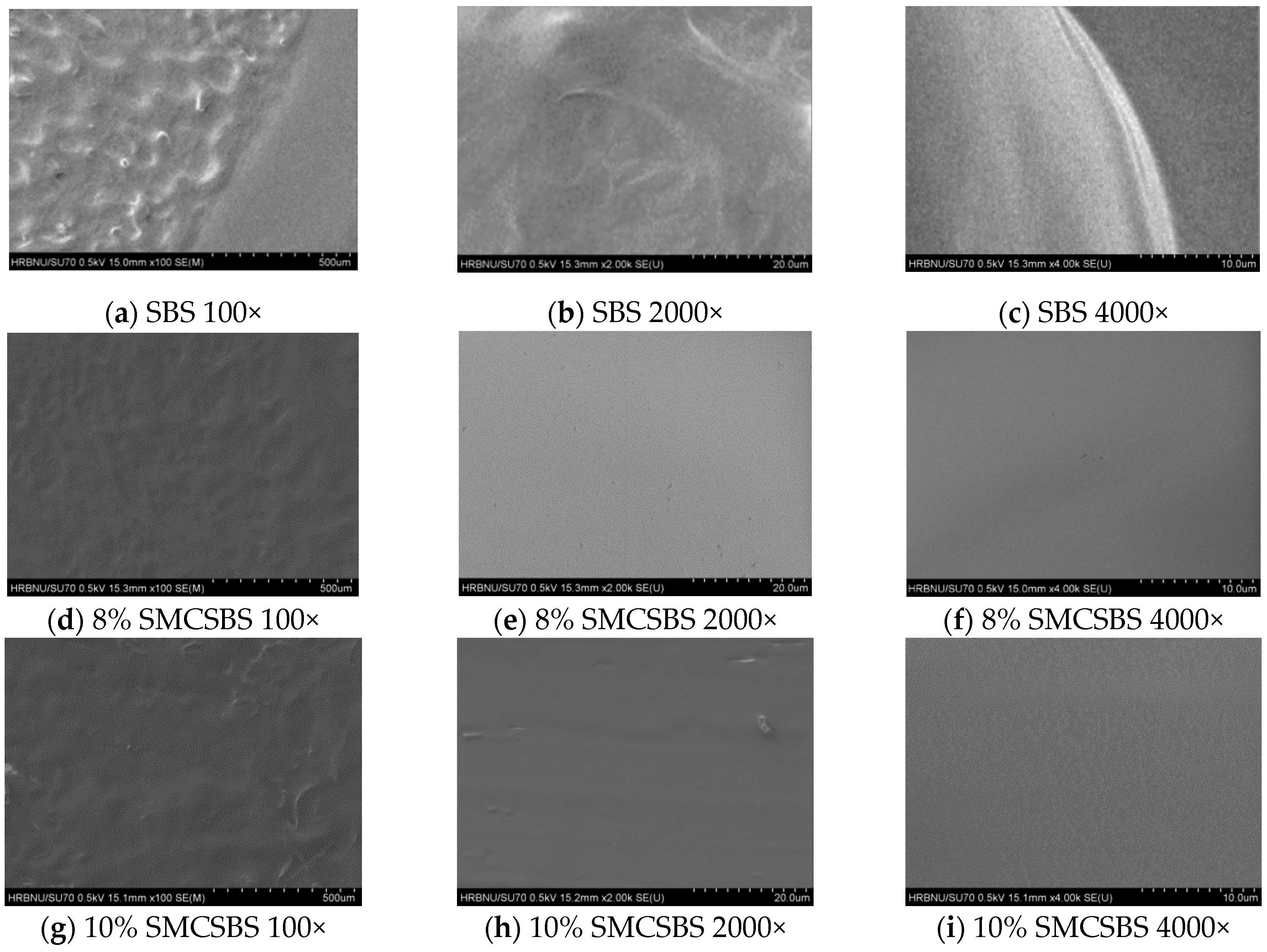

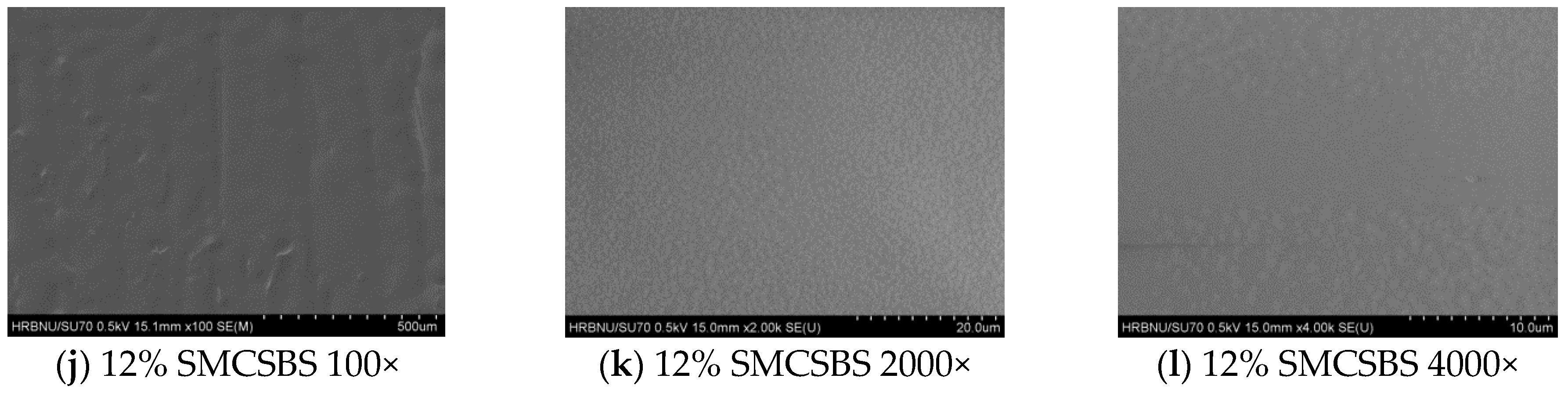

3.5.1. SEM

3.5.2. FITR

) exists in SMC [40]. The characteristic peak at 742–1035 cm−1 proves that there are a few end-group epoxy rings in the SMC, but the characteristic peaks such as the benzene ring basically disappear. This phenomenon should be caused by the volatilization of bisphenol A epoxy resin as a solvent.

) exists in SMC [40]. The characteristic peak at 742–1035 cm−1 proves that there are a few end-group epoxy rings in the SMC, but the characteristic peaks such as the benzene ring basically disappear. This phenomenon should be caused by the volatilization of bisphenol A epoxy resin as a solvent.3.6. Study on Modification Mechanism of the SMCSBS

4. Conclusions

- The results show that the viscosity of the compound asphalt with SMC is sensitive to temperature change—8% SMCSBS viscosity has the lowest temperature sensitivity, while 12% SMCSBS viscosity is more sensitive to temperature changes, which is conducive to improving its workability. At the same time, careful handling should be paid attention to during construction;

- High-temperature performance of SMCSBS compound modified asphalt—the high-temperature performance of SMC compound asphalt with different content increases firstly with the increase of SMC content, and then the high-temperature performance decreases with the increase of SMC content. When the SMC content is 12%, the factor (G*/sinδ) was the highest;

- Low-temperature performance of SMCSBS compound modified asphalt—compared with SBS, the SMCSBS has a better low-temperature performance. The low-temperature performance of SMCSBS increases with the increase of SMC content, and the creep stiffness modulus S value of four kinds of composite asphalt with different content is 8% > 10% > 12% > 14%. The creep rate m value showed that the performance of SMCSBS with 12% content changed most obviously. However, with the increase of SMC content, the high-temperature performance gradually decreased. Therefore, the high and low-temperature performance of SMCSBS should be studied in combination;

- In addition, the PG grades with different SMC content of 8%, 10%, 12%, and 14% are PG58-26, PG64-32, PG64-32, PG58-32, respectively, indicating that the SMCSBS has good low temperature and can meet the use requirements under poor low temperature and harsh conditions;

- In this paper, by means of microscopic analysis, SEM and FTIR results show that the SMC can give full play to its characteristics and can be evenly dispersed in the SBS asphalt, SMC is essentially a kind of surface active agent, by changing the surface tension and freeing the surface energy of asphalt molecules to achieve the purpose of reducing its viscosity and temperature; it also contains the curing agent of epoxy resin, crosslinking curing agent slowly after it is exposed to air to form a certain intensity.

Author Contributions

Funding

Conflicts of Interest

References

- Csanyi, L.H. Foamed Asphalt in Bituminous Paving Mixes. Highw. Res. Board. Bull. 1956, 10, 108–122. [Google Scholar]

- Lee, D.Y. Treating Marginal Aggregates and Soils with Foamed Asphalt. Assoc. Asph. Paving Technol. 1981, 50, 211–250. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). A Policy All Design Standards Interstate System; Standing Committee on Highways AASHTO Highway Subcommittee on Design Technical Committee on Geometric Design; AASHTO: Washington, DC, USA, 2005. [Google Scholar]

- Li, Z.K. The practice of warm-mix asphalt mixture technology in Europe. Sino-Foreign Highw. 2010, 30, 8–19. [Google Scholar]

- Jones, W. Warm Mix Asphalt Pavements: Technology of the Future? Asphalt 2004, 19, 8–11. [Google Scholar]

- Jia, Y. Warm-mix asphalt technology -- a technology worth thinking about. Asphalt 2012, 26, 65–69. [Google Scholar]

- Liu, Z.; Wu, S.; Chen, M.; Hu, D. Present situation and existing problems of warm mix asphalt mixture. Wuhan Univ. J. Nat. Sci. 2009, 31, 170–173. [Google Scholar]

- Buss, A.; Williams, R.C.; Schram, S. The influence of warm mix asphalt on binders in mixes that contain recycled asphalt materials. Constr. Build. Mater. 2015, 77, 50–58. [Google Scholar] [CrossRef]

- Hesami, S.; Roshani, H.; Hamedi, G.H.; Azarhoosh, A. Evaluate the mechanism of the effect of hydrated lime on moisture damage of warm mix asphalt. Constr. Build. Mater. 2013, 47, 935–941. [Google Scholar] [CrossRef]

- Wang, C.; Hao, P.; Fang, R.; Zhang, X.; Adhikari, S. Determination of the production temperature of warm mix asphalt by workability test. Constr. Build. Mater. 2013, 48, 1165–1170. [Google Scholar] [CrossRef]

- Qian, Q.; Farrar, M.J.; Pauli, A.T.; Adams, J.J. Morphology, thermal analysis and theology of Sasobit modified warm mix asphalt binders. Sci. Tech. Fuel. Energy 2014, 115, 416–425. [Google Scholar]

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of Warm Mix Asphalt containing Sasobit (R): State-of-the-art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Pasquini, E.; Giacomello, G.; Pasetto, M.; Canestrari, F. Laboratory evaluation of the effect of low—temperature application of warm-mix asphalts on interface shear strength. Constr. Build. Mater. 2015, 88, 56–63. [Google Scholar] [CrossRef]

- Sanchez-Alonso, E.; Vega-Zamanillo, A.; Calzada-Perez, M.A.; Castro-Fresno, D. Effect of warm additives on rutting and fatigue behaviour of asphalt mixtures. Constr. Build. Mater. 2013, 47, 240–244. [Google Scholar] [CrossRef]

- Ali, J.; Babak, G.; Meor, O.H.; Pamela, T. Selection of type of warm mix asphalt additive based on the theological properties of asphalt binders. J. Clean. Prod. 2015, 100, 89–106. [Google Scholar]

- Zhou, P.Y.; Cheng, Z.H.; Chen, L.L.; Zheng, S.P. Study on the influence of mixing temperature on related characteristics of warm-mix asphalt mixture. Sino-foreign Highw. 2017, 37, 236–240. [Google Scholar] [CrossRef]

- Tang, P.P.; Shen, A.Q.; Xiao, Z. Sensitivity Analysis of Temperature and Frequency of Warm Mix Asphalt Based on Rheological Properties. J. Highw. Transp. Res. Dev. 2016, 33, 7–12. [Google Scholar]

- Ma, Y.; He, Z.Y.; He, L.; Ling, T.Q. Aging characteristics and infrared spectroscopy analysis of warm-mix rubber modified asphalt. J. Highw. Transp. Res. Dev. 2015, 32, 13–18. [Google Scholar]

- Yu, H.Y.; Leng, Z.; Zhou, Z.Y.; Shih, K.; Xiao, F.; Gao, Z. Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. J. Clean. Prod. 2017, 141, 336–345. [Google Scholar] [CrossRef]

- Liu, S.J.; Zhou, S.B.; Peng, A.H. Analysis of moisture susceptibility of foamed warm mix asphalt based on cohesion, adhesion, bond strength, and morphology. J. Clean. Prod. 2020, 277, 123334. [Google Scholar] [CrossRef]

- Tan, Y.R.; Zhang, H.Y.; Cao, D.W.; Xia, L.; Du, R.J.; Shi, Z.Q.; Dong, R.; Wang, X.H. Study on cohesion and adhesion of high-viscosity modified asphalt. Int. J. Tran. Sci. Tech. 2019, 8, 394–402. [Google Scholar]

- Tan, Y.Q.; Zhang, L.; Xu, H.N. Evaluation of low-temperature performance of asphalt paving mixtures. Cold. Reg. Sci. Technol. 2012, 70, 107–112. [Google Scholar] [CrossRef]

- Sun, Z.G. Application of SMC room temperature modified asphalt mixture in highway maintenance in Qingyang area. J. Highw. Tran. Res. Dev. 2018, 12, 8–10. [Google Scholar]

- Zhao, L.N. Application of SMC Modified Asphalt at Room Temperature on G312 Line. Manag. Tech. SME. 2017, 8, 184–185. [Google Scholar]

- Qu, H.W. Application of SMC Modified Asphalt at Room Temperature in Highway Overlay Engineering. Shanxi Constr. 2016, 42, 166–167. [Google Scholar]

- Chu, J.F.; Wang, S.J.; Jin, M.H.; Zhou, X.H.; Lei, Q.R. Study on the strength formation process and influencing factors of SMC normal temperature asphalt mixture. J. Highw. Tran. Res. Dev. 2015, 8, 68–70. [Google Scholar]

- Luo, H.Y.; Li, Z.K.; Zheng, P.F.; Ouyang, C.F.; Qiu, Y.J. Analysis of road performance, mechanism and environmental protection benefit of SMC room temperature modifier. J. Build. Mater. 2020, 23, 1144–1152. [Google Scholar]

- Liang, Q.L. Research on the performance of high RAP content SMC room temperature recycled asphalt mixture. West. Commun. Tech 2020, 5, 10–13. [Google Scholar]

- Wang, J.J. Road performance analysis of AC-13 asphalt mixture at room temperature. Urban. Roads Br. Flood Control. 2019, 8, 211–213. [Google Scholar]

- Miao, L.; Yang, T.; Guan, H.X. Experimental Research on the High-Temperature Performance, Low-Temperature Performance, and Water Stability of Tuff Asphalt Mixture. J. Highw. Tran. Res. Dev. (English Ed.) 2016, 10, 1–7. [Google Scholar]

- Xing, X.Y.; Chen, S.H.; Li, Y.; Pei, J.Z.; Zhang, J.P.; Wen, Y.; Li, R.; Cui, S.C. Effect of different fibers on the properties of asphalt mastics. Constr. Build. Mater. 2020, 262, 120005. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, H.L.; Li, C.J.; Jia, W.; Lai, F. The effects of hollow glass microsphere modification on the road performances and thermal performance of asphalt binder and mixture. Constr. Build. Mater. 2019, 30, 64–75. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 2003, 182, 32–39. [Google Scholar] [CrossRef]

- Gao, K.K.; Chen, F.; Kuai, H.D.; Yang, Z.X.; Si, Y.; Huo, Z.Q. Laboratory Experimental Research on Foamed Warm Mix Asphalt Mixture Road Property. IOP Conf. Ser. Mater. Sci. Eng. 2020, 774, 012072. [Google Scholar] [CrossRef]

- Thives, L.P.; Guisi, E. Asphalt mixtures emission and energy consumption: A review. Renew. Sust. Energ. Rev. 2017, 72, 473–484. [Google Scholar] [CrossRef]

- Zhang, H.T.; Gong, M.Y.; Gao, D.D.; Yang, T.; Huang, Y.L. Comparative analysis of mechanical behavior of composite modified asphalt mixture based on PG technology. Constr. and Build. Mater. 2020, 259, 119771. [Google Scholar] [CrossRef]

- Chebil, S.; Chaala, A.; Roy, C. Use of softwood bark charcoal as a modifier for road bitumen. Fuel 2000, 79, 671–683. [Google Scholar] [CrossRef]

- Wang, L.; Li, J.; Gui, W.M. Effffect of Surfactant on High- and Low-Temperature Performances of Warm-Mixed Crumb Rubber Modifified Asphalt. Mater. Rep. 2019, 33, 986–990. [Google Scholar]

- Zheng, X.W.; Xu., W.Y.; Feng., H.M.; Cao., K. High and Low Temperature Performance and Fatigue Properties of Silica Fume/SBS Compound Modified Asphalt. Adv. Mater. Sci. Eng. 2018, 8, 1–8. [Google Scholar]

- Liu, H.H. The Synthesis and Application Study of Crystalline Resin Used in SMC; Wuhan University of Technology: Hubei, China, 2007. [Google Scholar]

- Guo, N.N. Synthesis of a new cyclic ether quaternary ammonium cationic surfactant under ultrasonic condition. Petrochemical Tech. 2018, 47, 95–99. [Google Scholar]

| Indexes | Unit | Results | Technical Indicators 1 |

|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 84 | 80~100 |

| Softening Point | °C | 49 | 44 |

| Ductility (15 °C) | cm | >100 | 100 |

| Indexes | Unit | Results | Technical Indicators 2 |

|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 90 | 80~100 |

| Softening Point | °C | 50 | 45 |

| Ductility (15 °C) | cm | >100 | 100 |

| Indexes | Unit | Results | Technical Indicators 3 |

|---|---|---|---|

| Appearance | - | A brown viscous liquid | - |

| Density | g/cm3 | 0.92 | 0.8~1.0 |

| Flash point, not less than | °C | 92 | 170 |

| Rubber hydrocarbon content, not less than | % | 93 | 85 |

| Volatile organic benzene content, not more than | % | 0.01 | 0.1 |

| SMC Content/% | 25 °C Penetration/0.1 mm | Softening Point °C | 5 °C Ductility | 35 °C Viscosity/Pa·s | |||

|---|---|---|---|---|---|---|---|

| Average | Standard Deviation | Average | Standard Deviation | Average | Standard Deviation | ||

| 8 | 191 | 0.211 | 74 | 0.050 | 89.7 | 0.531 | 1662.34 |

| 10 | 228 | 0.325 | 56.5 | 0.400 | >100 | 0 | 671.29 |

| 12 | 248 | 0.561 | 55 | 0.636 | >100 | 0 | 373.73 |

| Additive Content (%) | Temperatures (°C) | |

|---|---|---|

| Mixing Temperature (M) | Compaction Temperature (°C) | |

| SBS | 165–170 | 150–155 |

| 8% SMCSBS | 120.27–118.26 | 114.75–112.74 |

| 10% SMCSBS | 118.98–117.01 | 113.56–111.59 |

| 12% SMCSBS | 116.72–114.86 | 111.60–109.73 |

| 14% SMCSBS | 115.11–113.21 | 109.89–107.99 |

| Specimens | Absolute Value of m | n |

|---|---|---|

| 8% SMCSBS | 3.13394 | 8.46664 |

| 10% SMCSBS | 3.2235 | 8.69367 |

| 12% SMCSBS | 3.45191 | 9.2766 |

| 14% SMCSBS | 3.44914 | 9.2625 |

| Type | Specimens | PG (°C) |

|---|---|---|

| Pure | SBS | 64–28 |

| SMC Compound Modified Asphalt | 8% SMCSBS | 58–34 |

| 10% SMCSBS | 64–34 | |

| 12% SMCSBS | 64–34 | |

| 14% SMCSBS | 58–34 |

| Contents | Relation | R2 | Standard Deviations | Variation Coefficient | Critical Temperature/°C |

|---|---|---|---|---|---|

| 8% SMCSBS | y = −0.05586x + 3.48612 | 0.98456 | 0.00089 | 1.14673 | 62.41 |

| 10% SMCSBS | y = −0.05173x + 3.32187 | 0.98915 | 0.00069 | 1.36044 | 64.22 |

| 12% SMCSBS | y = −0.05485x + 3.74342 | 0.99165 | 0.00064 | 0.85154 | 68.25 |

| 14% SMCSBS | y = −0.05521x + 3.32741 | 0.97700 | 0.00108 | 1.74475 | 60.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; He, D. High and Low-Temperature Performance Evaluation and Microanalysis of SMCSBS Compound-Modified Asphalt. Materials 2021, 14, 771. https://doi.org/10.3390/ma14040771

Sun Y, He D. High and Low-Temperature Performance Evaluation and Microanalysis of SMCSBS Compound-Modified Asphalt. Materials. 2021; 14(4):771. https://doi.org/10.3390/ma14040771

Chicago/Turabian StyleSun, Yu, and Dongpo He. 2021. "High and Low-Temperature Performance Evaluation and Microanalysis of SMCSBS Compound-Modified Asphalt" Materials 14, no. 4: 771. https://doi.org/10.3390/ma14040771

APA StyleSun, Y., & He, D. (2021). High and Low-Temperature Performance Evaluation and Microanalysis of SMCSBS Compound-Modified Asphalt. Materials, 14(4), 771. https://doi.org/10.3390/ma14040771