The Plastic Deformation Mechanisms of hcp Single Crystals with Different Orientations: Molecular Dynamics Simulations

Abstract

1. Introduction

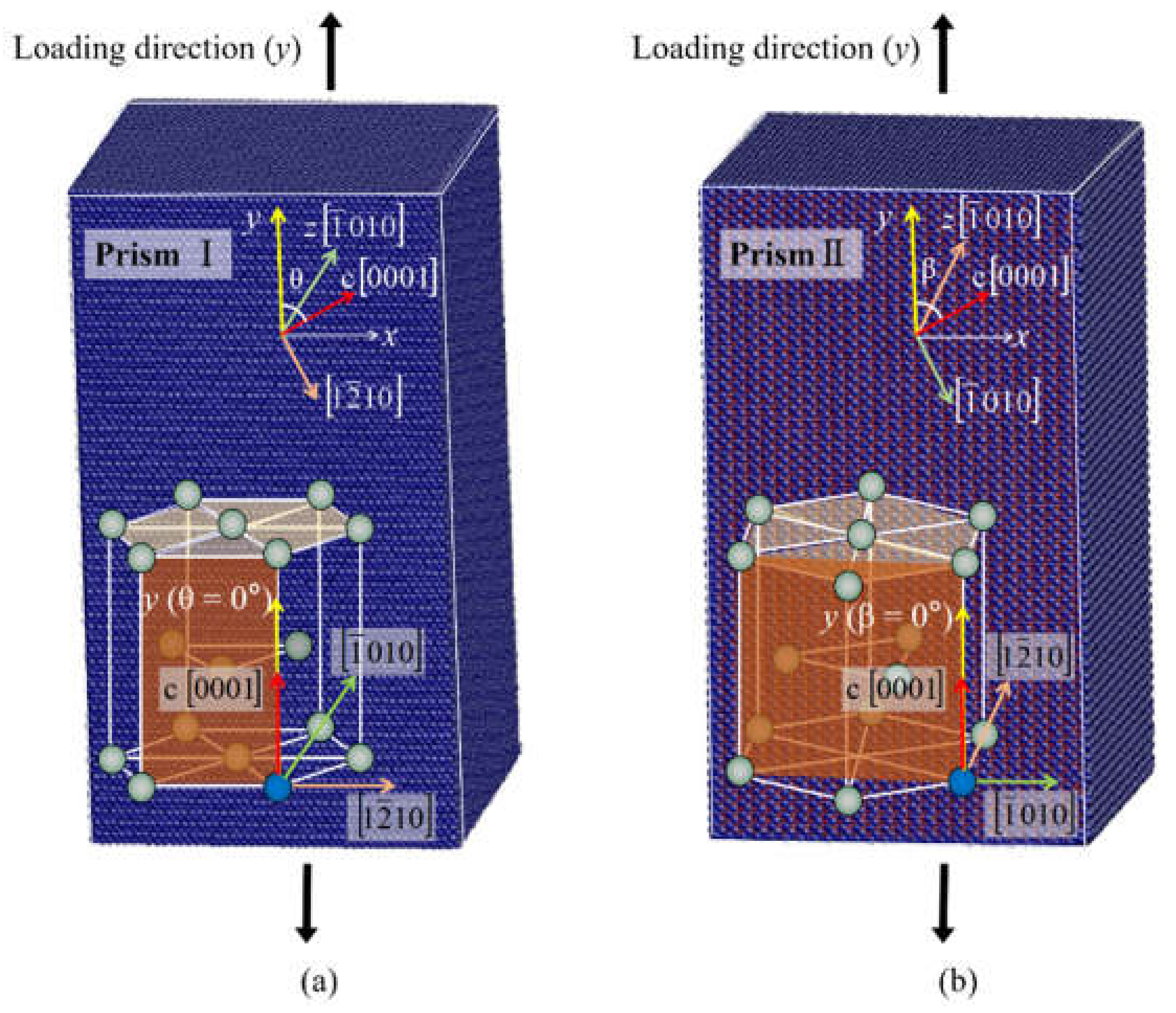

2. Simulation Method

3. Results and Discussion

3.1. The Initial Plastic Deformation Mechanisms of Mg, Zr, and Ti

3.2. Slips

3.3. Twinning

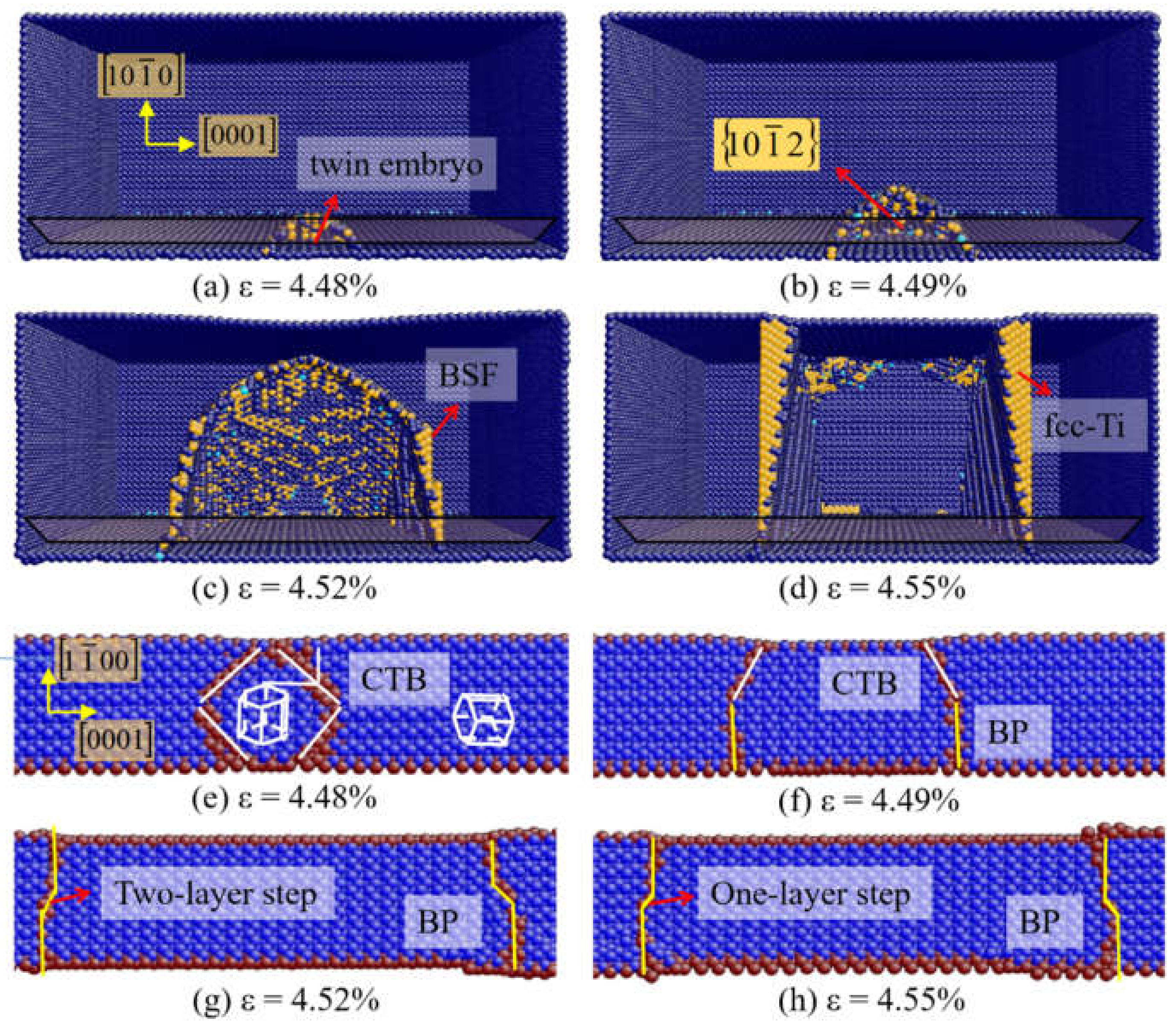

3.3.1. Twinning

3.3.2. Twinning

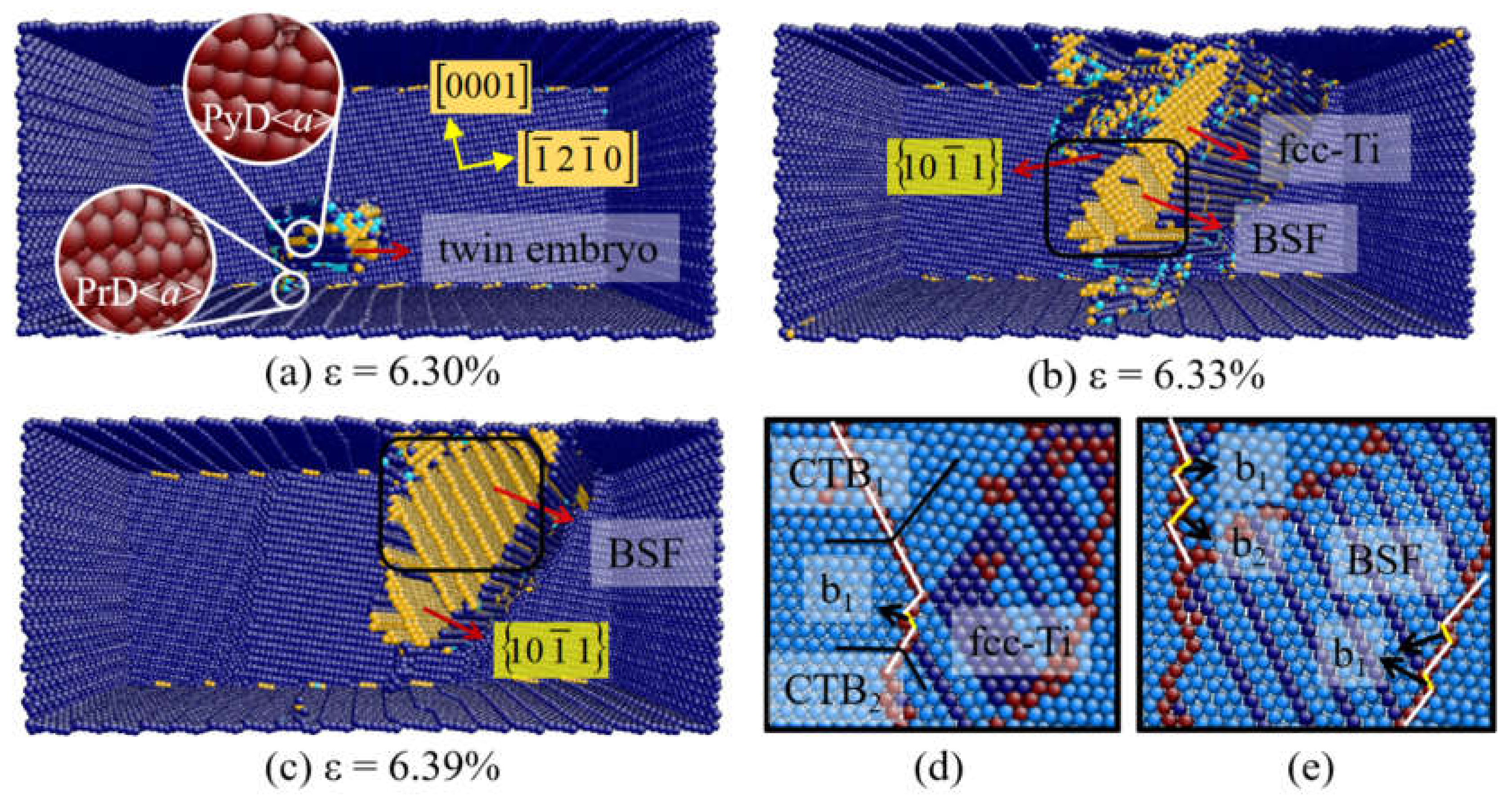

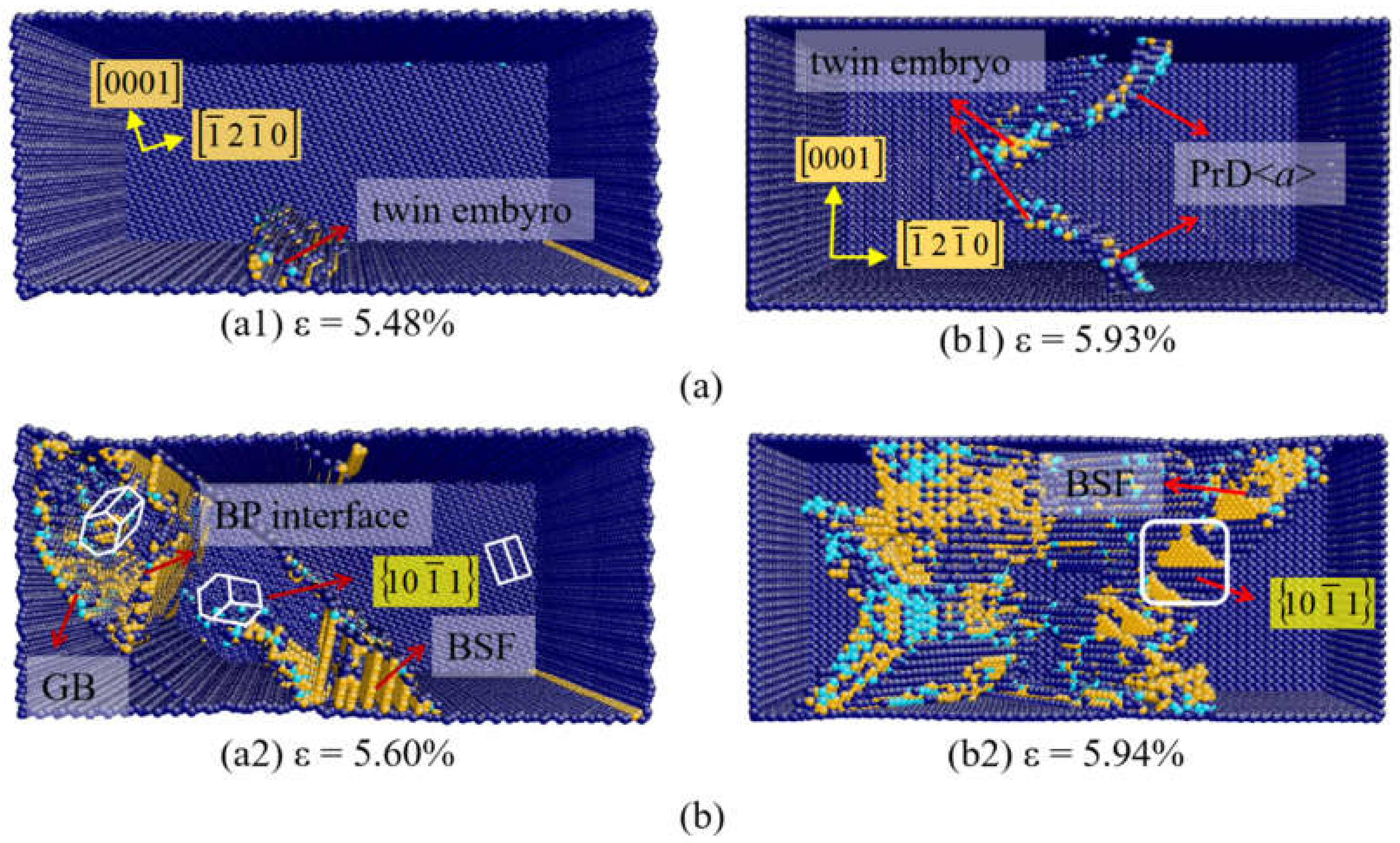

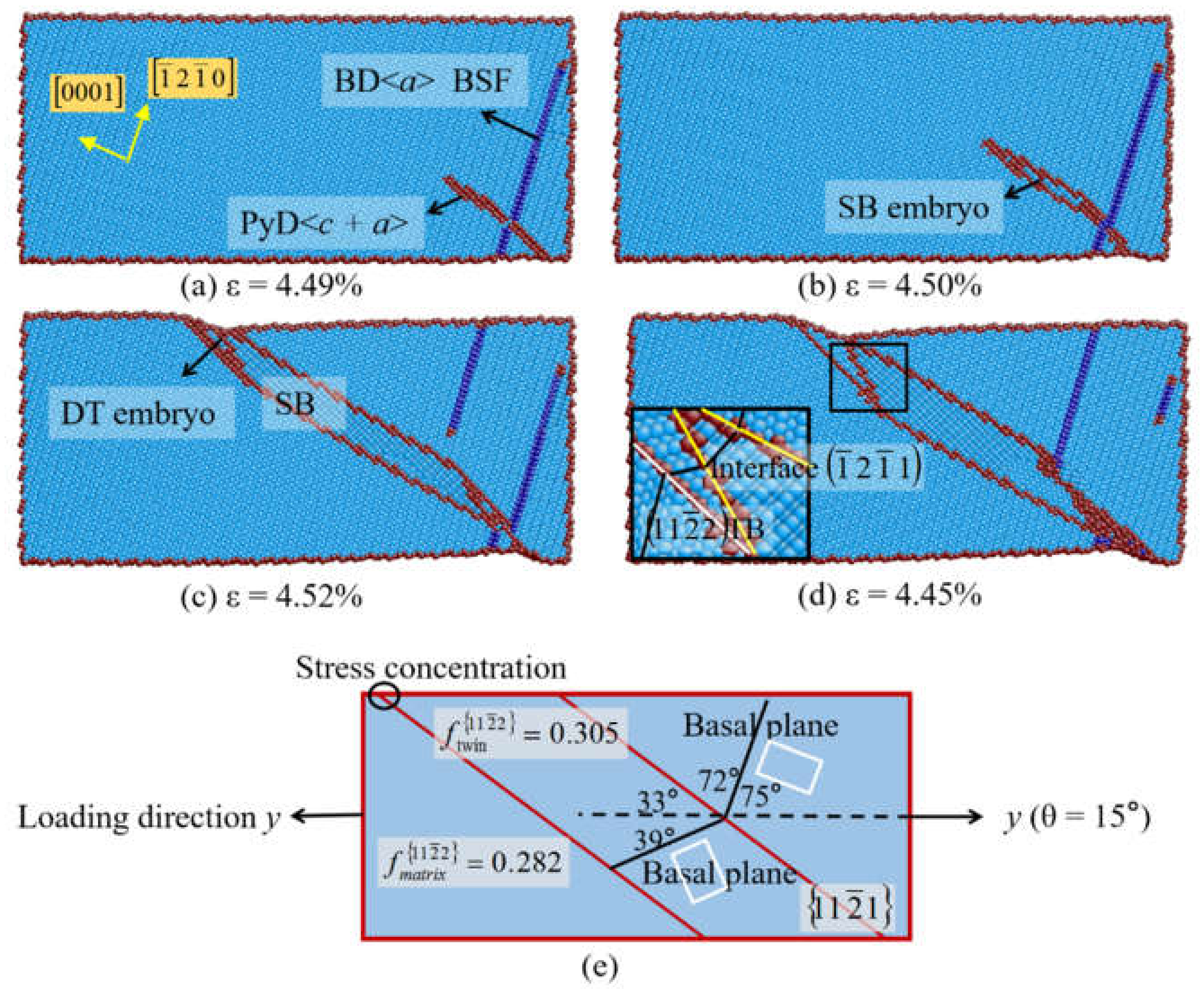

3.4. Double Twins (DTs)

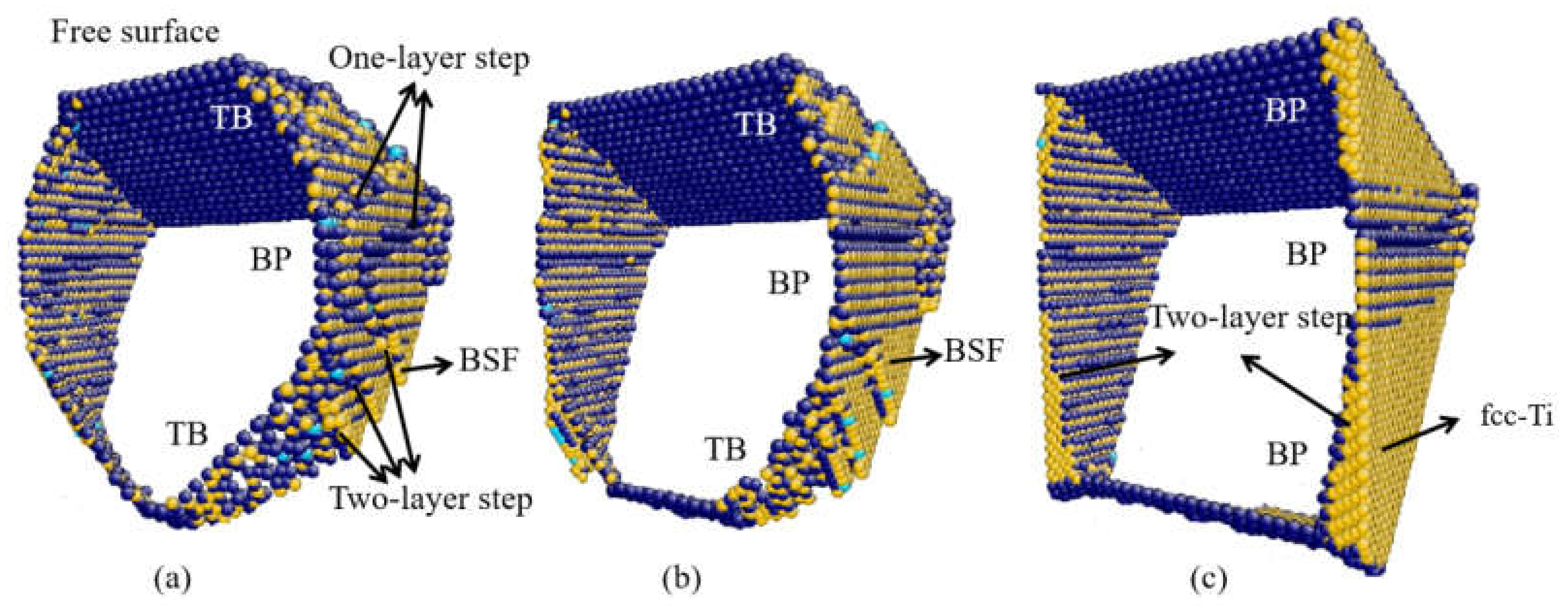

3.5. Phase Transformation

4. Discussion

5. Conclusions

- (1)

- The slips dominate the plasticity of hcp single crystals. The basal slip is preferred in Mg while the prism slip is favored in Ti and Zr, which are characterized by c/a ratio and the CRSS values. The slip mechanisms observed in our simulation match well with the comprehensive analysis of the Schmid factor and CRSS of slip systems.

- (2)

- When the basal and prismatic slips are restricted, the twinning is activated. The twinning is popularly observed in Mg, Zr, and Ti single crystals because of its low CRSS, which is usually accompanied with the BP transformation. The twins form in Mg and Ti, but not in Zr. The type II twins (SBs) appear in Mg, Zr, and Ti. Moreover, the DT in Mg and DT in Ti are observed, responsible for relaxing the local stress and strain concentration associated with the primary twin.

- (3)

- The stress-induced phase transformation from hcp to fcc structure in Ti is observed, which is achieved by the accumulation of BSFs. For samples with different orientations, the fcc phase can be nucleated at the defects or the free surface via the activation and successive glide of basal partial dislocations.

- (4)

- The lower CRSSs of slip and twinning in Mg result in the strength of Mg is much lower than that of Ti and Zr. Moreover, there are more types of plastic deformation mechanisms in Ti than in Mg and Zr. Multiple deformation mechanisms coordinate with each other, resulting in high strength and ductility of Ti.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Burke, E.C.; Hibbard, W.R. Plastic Deformation of Magnesium Single Crystals. JOM 1952, 4, 295–303. [Google Scholar] [CrossRef]

- Farenc, S.; Caillard, D.; Couret, A. An in situ study of prismatic glide in α titanium at low temperatures. Acta Metall. Mater. 1993, 41, 2701–2709. [Google Scholar] [CrossRef]

- Monnet, G.; Devincre, B.; Kubin, L.P. Dislocation study of prismatic slip systems and their interactions in hexagonal close packed metals: Application to zirconium. Acta Mater. 2004, 52, 4317–4328. [Google Scholar] [CrossRef]

- Tang, Y.; El-Awady, J.A. Formation and slip of pyramidal dislocations in hexagonal close-packed magnesium single crystals. Acta Mater. 2014, 71, 319–332. [Google Scholar] [CrossRef]

- Saidi, P.; Béland, L.K.; Yao, Z.; Daymond, M. Asymmetrical response of edge pyramidal dislocations in HCP zirconium under tension and compression: A molecular dynamics study. Comput. Mater. Sci. 2019, 170, 109183. [Google Scholar] [CrossRef]

- Yoo, M.H.; Morris, J.R.; Ho, K.M.; Agnew, S.R. Nonbasal deformation modes of HCP metals and alloys: Role of dislocation source and mobility. Metall. Mater. Trans. A 2002, 33, 813–822. [Google Scholar] [CrossRef]

- Jiwon, J.; Markus, A.; Ruth, K.; Daniel, K.; Ho, S.H. In-situ TEM observation of {1012} twin-dominated deformation of Mg pillars: Twinning mechanism, size effects and rate dependency. Acta. Mater. 2018, 158, 407–421. [Google Scholar]

- Chen, P.; Li, B.; Culbertson, D.; Jiang, Y. Contribution of extension twinning to plastic strain at low stress stage deformation of a Mg-3Al-1Zn alloy. Mater. Sci. Eng. A 2018, 709, 40–45. [Google Scholar] [CrossRef]

- Zu, Q.; Tang, X.Z.; Fu, H.; Peng, Q.M.; Guo, Y.F. The irrational shear of {1011} twinning in Mg. Materialia 2019, 5, 100239. [Google Scholar] [CrossRef]

- Ostapovets, A.; Serra, A. Review of Non-Classical Features of Deformation Twinning in hcp Metals and Their Description by Disconnection Mechanisms. Metals 2020, 10, 1134. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, P.; Liu, G.S.; Xiao, D.W.; Gong, M.Y.; Wang, J. Shock-induced two types of {1012} sequential twinning in Titanium. Acta. Mater. 2019, 165, 547–560. [Google Scholar] [CrossRef]

- Bao, L.; Zhang, Y.; Schuman, C.; LeComte, J.-S.; Philippe, M.-J.; Zhao, X.; Esling, C. Multiple twinning in pure hexagonal close-packed titanium. J. Appl. Crystallogr. 2013, 46, 1397–1406. [Google Scholar] [CrossRef]

- Ostapovets, A.; Serra, A. Slip dislocation and twin nucleation mechanisms in hcp metals. J. Mater. Sci. 2016, 52, 533–540. [Google Scholar] [CrossRef]

- Kou, Z.D.; Yang, Y.Y.; Huang, B.; Xian, L.; Li, P.T.; Zhao, G.M.; Zhang, W. Observing the dynamic {1011} twining process in pure Ti at atomic resolution. Scr. Mater. 2017, 139, 139–143. [Google Scholar] [CrossRef]

- Fu, Y.; Xiao, W.; Kent, D.; Dargusch, M.S.; Wang, J.; Zhao, X.; Ma, C. Ultrahigh strain hardening in a transformation-induced plasticity and twinning-induced plasticity titanium alloy. Scr. Mater. 2020, 187, 285–290. [Google Scholar] [CrossRef]

- Capolungo, L.; Marshall, P.; McCabe, R.; Beyerlein, I.; Tomé, C. Nucleation and growth of twins in Zr: A statistical study. Acta Mater. 2009, 57, 6047–6056. [Google Scholar] [CrossRef]

- Knezevic, M.; Zecevic, M.; Beyerlein, I.J.; Bingert, J.F.; McCabe, R.J. Strain rate and temperature effects on the selection of primary and secondary slip and twinning systems in HCP Zr. Acta Mater. 2015, 88, 55–73. [Google Scholar] [CrossRef]

- An, X.L.; Zhang, H.; Ni, S.; Ou, X.Q.; Liao, X.Z.; Song, M. Effects of temperature and alloying content on the phase transformation and {1011} twinning in Zr during rolling. J. Mater. Sci. Technol. 2020, 41, 76–80. [Google Scholar] [CrossRef]

- Hartt, W.H.; Reed-Hill, R.E. Internal deformation and fracture of second-order {1011}−{1012} twins in magnesium. Trans. Metall. Soc. AIME 1968, 242, 1127–1133. [Google Scholar]

- Peng, Q.; Sun, Y.; Ge, B.; Fu, H.; Zu, Q.; Tang, X.; Huang, J. Interactive contraction nanotwins-stacking faults strengthening mechanism of Mg alloys. Acta Mater. 2019, 169, 36–44. [Google Scholar] [CrossRef]

- Zhou, P.; Xu, S.; Xiao, D.W.; Jiang, C.L.; Hu, Y.; Wang, J. Shock-induced {1121}−{1122} double twinning in titanium. Int. J. Plast. 2019, 112, 194–205. [Google Scholar] [CrossRef]

- Raabe, D.; Sander, B.; Friák, M.; Ma, D.; Neugebauer, J. Theory-guided bottom-up design of β-titanium alloys as biomaterials based on first principles calculations: Theory and experiments. Acta Mater. 2007, 55, 4475–4487. [Google Scholar] [CrossRef]

- Wawner, F.E.; Lawless, K.R. Epitaxial growth of titanium thin films. J. Vac. Sci. Technol. 1969, 6, 588–590. [Google Scholar] [CrossRef]

- Jankowski, A.F.; Wall, M.A. Formation of face-centered cubic titanium on a Ni single crystal and in Ni/Ti multilayers. J. Mater. Res. 1994, 9, 31–38. [Google Scholar] [CrossRef]

- Van Heerden, D.; Josell, D.; Shechtman, D. The formation of f.c.c. titanium in titanium-aluminum multilayers. Acta Mater. 1996, 44, 297–306. [Google Scholar] [CrossRef]

- Yang, J.X.; Zhao, H.L.; Gong, H.R.; Song, M.; Ren, Q.Q. Proposed mechanism of HCP→FCC phase transition in titanium through first principles calculation and experiments. Sci. Rep. 2018, 8, 1992. [Google Scholar] [CrossRef]

- Zu, Q.; Guo, Y.; Yao, X. Surface and orientation effects on stress-induced hcp-fcc phase transformation in Ti nanopillars. Appl. Surf. Sci. 2020, 509, 145234. [Google Scholar] [CrossRef]

- Ren, J.; Liu, X.; Lei, Q.; Wang, Q.; Zhang, X.; Zhang, X.; Lu, X.; Xue, H.; Ding, Y. Deformation Behavior of Pure Titanium with a Rare HCP/FCC Boundary: An Atomistic Study. Mater. Res. 2020, 23, 1015901980. [Google Scholar] [CrossRef]

- Zu, Q.; Guo, Y.; Xu, S.; Tang, X.-Z.; Wang, Y.-S. Molecular Dynamics Simulations of the Orientation Effect on the Initial Plastic Deformation of Magnesium Single Crystals. Acta Met. Sin. Engl. Lett. 2016, 29, 301–312. [Google Scholar] [CrossRef]

- Pathak, S.; Kalidindi, S.R.; Mara, N.A. Investigations of orientation and length scale effects on micromechanical responses in polycrystalline zirconium using spherical nanoindentation. Scr. Mater. 2016, 113, 241–245. [Google Scholar] [CrossRef]

- Battaini, M.; Pereloma, E.; Davies, C. Orientation Effect on Mechanical Properties of Commercially Pure Titanium at Room Temperature. Met. Mater. Trans. A 2007, 38, 276–285. [Google Scholar] [CrossRef]

- An, M.; Su, M.; Deng, Q.; Song, H.; Wang, C.; Shang, Y. Anisotropic plasticity of nanocrystalline Ti: A molecular dynamics simulation. Chin. Phys. B 2020, 29, 046201. [Google Scholar] [CrossRef]

- Sun, D.Y.; Mendelev, M.I.; Becker, C.A.; Kudin, K.; Haxhimali, T.; Asta, M.; Hoyt, J.J.; Karma, A.; Srolovitz, D.J. Crystal-melt interfacial free energies in hcp metals: A molecular dynamics study of Mg. Phys. Rev. B 2006, 73, 024116. [Google Scholar] [CrossRef]

- Mendelev, M.I.; Ackland, G.J. Development of an interatomic potential for the simulation of phase transformations in zirconium. Philos. Mag. Lett. 2007, 87, 349–359. [Google Scholar] [CrossRef]

- Ackland, G.J. Temperature dependence in interatomic potentials and an improved potential for Ti. J. Phys. Conf. Ser. 2012, 402, 012001. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Reed, T.M.; Gubbins, K.E. Applied Statistical Mechanics; McCraw-Hill: New York, NY, USA, 1973. [Google Scholar]

- McQuarrie, D.A. Statistical Mechanics; Harper and Row: New York, NY, USA, 1976. [Google Scholar]

- Goldstein, H. Classical Mechanic; Addison-Wesley: Boston, MA, USA, 1980. [Google Scholar]

- Li, J. AtomEye: An efficient atomistic configuration viewer. Model. Simul. Mater. Sci. Eng. 2003, 11, 173–177. [Google Scholar] [CrossRef]

- Ackland, G.J.; Jones, A.P. Applications of local crystal structure measures in experiment and simulation. Phys. Rev. B 2006, 73, 054104. [Google Scholar] [CrossRef]

- Faken, D.; Jónsson, H. Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 1994, 2, 279–286. [Google Scholar] [CrossRef]

- Lane, N.J.; Simak, S.I.; Mikhaylushkin, A.S.; Abrikosov, I.A.; Hultman, L.; Barsoum, M.W. First-principles study of dislocations in hcp metals through the investigation of the {1121} twin boundary. Phys. Rev. B 2011, 84, 184101. [Google Scholar] [CrossRef]

- Minonishi, Y.; Ishioka, S.; Koiwa, M.; Mobozumi, S. The structure of {1121} twin boundaries in HCP crystals. Phys. Status Solidi A 1982, 71, 253–258. [Google Scholar] [CrossRef]

- Clouet, E. Screw dislocation in zirconium: An ab initio study. Phys. Rev. B 2012, 86, 144104. [Google Scholar] [CrossRef]

- Moskalenko, V.A.; Natsik, V.D.; Kovaleva, V.N. The role of Peierls relief in the low-temperature plasticity of pure α-Ti. Low Temp. Phys. 2005, 31, 907–914. [Google Scholar] [CrossRef]

- Yin, B.; Wu, Z.; Curtin, W. Comprehensive first-principles study of stable stacking faults in hcp metals. Acta Mater. 2017, 123, 223–234. [Google Scholar] [CrossRef]

- Caillard, D.; Gaumé, M.; Onimus, F. Glide and cross-slip of a-dislocations in Zr and Ti. Acta Mater. 2018, 155, 23–34. [Google Scholar] [CrossRef]

- Chapuis, A.; Liu, Q. Investigating the temperature dependency of plastic deformation in a Mg-3Al-1Zn alloy. Mater. Sci. Eng. A 2018, 725, 108–118. [Google Scholar] [CrossRef]

- Wu, Z.; Yin, B.; Curtin, W. Energetics of dislocation transformations in hcp metals. Acta Mater. 2016, 119, 203–217. [Google Scholar] [CrossRef]

- Jones, I.; Hutchinson, W. Stress-state dependence of slip in Titanium-6Al-4V and other H.C.P. metals. Acta Met. 1981, 29, 951–968. [Google Scholar] [CrossRef]

- Kwon, J.; Brandes, M.; Phani, P.S.; Pilchak, A.; Gao, Y.; George, E.; Pharr, G.; Mills, M. Characterization of deformation anisotropies in an α-Ti alloy by nanoindentation and electron microscopy. Acta Mater. 2013, 61, 4743–4756. [Google Scholar] [CrossRef]

- Beyerlein, I.; Tomé, C. A dislocation-based constitutive law for pure Zr including temperature effects. Int. J. Plast. 2008, 24, 867–895. [Google Scholar] [CrossRef]

- Yang, H.; Li, H.; Ma, J.; Wei, D.; Chen, J.; Fu, M. Temperature dependent evolution of anisotropy and asymmetry of α-Ti in thermomechanical working: Characterization and modeling. Int. J. Plast. 2020, 127, 102650. [Google Scholar] [CrossRef]

- Chen, P.; Wang, F.; Li, B. Transitory phase transformations during {1012} twinning in titanium. Acta. Mater. 2019, 171, 65–78. [Google Scholar] [CrossRef]

- Zu, Q.; Tang, X.; Zhang, H.; Guo, Y. Double twin-like crystalline reorientations in Mg single crystals: Molecular dynamics simulations. Comput. Mater. Sci. 2018, 150, 265–272. [Google Scholar] [CrossRef]

- Zhou, B.; Sui, M.L. High density stacking faults of {1011} compression twin in magnesium alloys. J. Mater. Sci. Technol. 2019, 35, 2263–2268. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, Q.W.; Li, B. Non-dislocation-mediated basal stacking faults inside {1011} twins. Scr. Mater. 2017, 141, 85–88. [Google Scholar] [CrossRef]

- Gong, M.Y.; Xu, S.; Xie, D.Y. Steps and {1121} secondary twinning associated with {1121} twin in titanium. Acta Mater. 2019, 164, 776–787. [Google Scholar] [CrossRef]

- Hirth, J.; Pond, R. Steps, dislocations and disconnections as interface defects relating to structure and phase transformations. Acta Mater. 1996, 44, 4749–4763. [Google Scholar] [CrossRef]

- Qian, X.; Zeng, Y.; Jiang, B.; Dou, Y.; Shi, O.; Quan, G.; Li, B.; Pan, F. Study on mechanical behaviors and theoretical critical shear strength of cold-rolled AZ31 alloy with different Li additions. Mater. Sci. Eng. A 2019, 742, 241–254. [Google Scholar] [CrossRef]

- Ojha, A.; Sehitoglu, H. Critical Stresses for Twinning, Slip, and Transformation in Ti-Based Shape Memory Alloys. Shape Mem. Superelast. 2016, 2, 180–195. [Google Scholar] [CrossRef]

- Westlake, D. Precipitation strengthening in crystals of zirconium-hydrogen alloys containing oxygen as an impurity. Acta Met. 1964, 12, 1373–1380. [Google Scholar] [CrossRef]

- Suwas, S.; Gottstein, G.; Kumar, R. Evolution of crystallographic texture during equal channel angular extrusion (ECAE) and its effects on secondary processing of magnesium. Mater. Sci. Eng. A 2007, 471, 1–14. [Google Scholar] [CrossRef]

- Sattari, M.; Holt, R.; Daymond, M. Variant selection and transformation texture in zirconium alloy Excel. J. Nucl. Mater. 2014, 453, 120–123. [Google Scholar] [CrossRef]

- Zhang, Z.; Eakins, D.E.; Dunne, F.P. On the formation of adiabatic shear bands in textured HCP polycrystals. Int. J. Plast. 2016, 79, 196–216. [Google Scholar] [CrossRef]

| θ (°) | Mg [26] (c/a = 1.623) | Zr (c/a = 1.593) | Ti (c/a = 1.588) |

|---|---|---|---|

| 0 (c-axis) | PyD <c + a>, BD <a>, BSF, T3, BP | PyD <c + a>, BD <a>, BSF, T3, BP | T3, BP, BSF, fcc-Ti |

| 10 | SB | PyD <c + a>, SB | PyD <c + a>, SB |

| 15 | SB | PyD <c + a>, SB | BD <a>, BSF, PyD <c + a>, SB,DT |

| 32.1 | SB | BD <a>, BSF | BD <a>, BSF |

| 43.3 | PrD <a>, BD <a>, BSF | PrD <a>, BD <a>, BSF | BD <a>, BSF |

| 51.6 | PrD <a>, BD <a>, BSF | PrD <a>, BD <a>, BSF | BD <a>, BSF |

| 70 | PrD <a>, T1, BSF, BP, GB | PrD <a> | PrD <a>, PyD <a>,T1,BSF,fcc-Ti |

| 75 | PrD <a>, T1, BSF, BP, GB | PrD <a> | PrD <a>, PyD <a>,T1,BSF,fcc-Ti |

| 80 | T1, BSF, BP, GB | PrD <a> | PrD <a>, PyD <a>,T1,BSF,fcc-Ti |

| 90 | T1, BSF, BP, GB | PrD <a> | PrD <a>, PyD <a>,T1,BSF,fcc-Ti |

| β (°) | Mg (c/a = 1.623) | Zr (c/a = 1.593) | Ti (c/a = 1.588) |

|---|---|---|---|

| 0 (c-axis) | PyD <c + a>, BD <a>, BSF, T3, BP | PyD <c + a>, BD <a>, BSF, T3, BP | T3, BP, BSF, fcc-Ti |

| 10 | BD <a>, BSF, PyD <c + a>, SB | PyD <c + a>, SB | BD <a>, BSF, PyD <c + a>, SB,DT |

| 15 | BD <a>, BSF, PyD <c + a>, SB | PyD <c + a>, BD <a>, BSF | BD <a>, BSF,fcc-Ti |

| 28.6 | BD <a>, BSF | PyD <c + a>, BD <a>, BSF | BD <a>, BSF,fcc-Ti |

| 35.9 | BD <a>, BSF | PyD <c + a>, BD <a>, BSF | PyD <c + a>,fcc-Ti, BP |

| 47.4 | BD <a>, BSF | BD <a>, BSF, PrD <a>, PyD <c + a> | BD <a>, BSF,fcc-Ti |

| 55.4 | BD <a>, BSF | BD <a>, BSF, PrD <a>, PyD <c + a> | BD <a>, BSF,fcc-Ti |

| 58.6 | BD <a>, BSF | BD <a>, BSF, PrD <a>, PyD <c + a> | BD <a>, BSF,fcc-Ti |

| 70 | T1,BSF, BP, GB | PyD <c + a>, PrD <a> | PrD <a>, BD <a>, BSF |

| 75 | PrD <a>,T1,BSF | PyD <c + a>, PrD <a> | PrD <a>, BD <a>, BSF |

| 80 | PrD <a>,T1,BSF | PyD <c + a>, PrD <a> | PrD <a> |

| 90 | PrD <a>,T1,BSF | PyD <c + a>, PrD <a> | PrD <a> |

| Loading Direction (θ) | BD <a> | PrD <a> | PyD <c + a> | PyD <c + a> (SB) | ||||

|---|---|---|---|---|---|---|---|---|

| Mg | Zr | Ti | Mg | Zr | Ti | |||

| 0 | 0 | 0 | 0.401 | 0.404 | 0.404 | 0.281 | 0.286 | 0.286 |

| 15 | 0.25 | 0.029 | 0.493 | 0.493 | 0.493 | 0.451 | 0.453 | 0.454 |

| 32.1 | 0.450 | 0.122 | 0.468 | 0.466 | 0.466 | 0.495 | 0.494 | 0.493 |

| 51.6 | 0.487 | 0.266 | 0.288 | 0.284 | 0.283 | 0.469 | 0.464 | 0.464 |

| 70 | 0.321 | 0.382 | 0.436 | 0.435 | 0.434 | 0.481 | 0.480 | 0.484 |

| 90 | 0 | 0.433 | 0.400 | 0.405 | 0.405 | 0.282 | 0.286 | 0.287 |

| Loading Direction (β) | BD <a> | PrD <a> | PyD <c + a> | PyD <c + a> (SB) | ||||

|---|---|---|---|---|---|---|---|---|

| Mg | Zr | Ti | Mg | Zr | Ti | |||

| 0 | 0 | 0 | 0.401 | 0.404 | 0.404 | 0.281 | 0.286 | 0.286 |

| 10 | 0.125 | 0.013 | 0.469 | 0.470 | 0.470 | 0.388 | 0.388 | 0.392 |

| 28.6 | 0.365 | 0.099 | 0.442 | 0.440 | 0.438 | 0.470 | 0.470 | 0.472 |

| 55.4 | 0.399 | 0.293 | 0.394 | 0.389 | 0.390 | 0.388 | 0.386 | 0.387 |

| 70 | 0.278 | 0.382 | 0.480 | 0.479 | 0.477 | 0.383 | 0.383 | 0.386 |

| 90 | 0 | 0.433 | 0.401 | 0.405 | 0.405 | 0.211 | 0.214 | 0.216 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.-C.; Tang, X.-Z.; Mao, Y.; Guo, Y.-F. The Plastic Deformation Mechanisms of hcp Single Crystals with Different Orientations: Molecular Dynamics Simulations. Materials 2021, 14, 733. https://doi.org/10.3390/ma14040733

Ma Z-C, Tang X-Z, Mao Y, Guo Y-F. The Plastic Deformation Mechanisms of hcp Single Crystals with Different Orientations: Molecular Dynamics Simulations. Materials. 2021; 14(4):733. https://doi.org/10.3390/ma14040733

Chicago/Turabian StyleMa, Zhi-Chao, Xiao-Zhi Tang, Yong Mao, and Ya-Fang Guo. 2021. "The Plastic Deformation Mechanisms of hcp Single Crystals with Different Orientations: Molecular Dynamics Simulations" Materials 14, no. 4: 733. https://doi.org/10.3390/ma14040733

APA StyleMa, Z.-C., Tang, X.-Z., Mao, Y., & Guo, Y.-F. (2021). The Plastic Deformation Mechanisms of hcp Single Crystals with Different Orientations: Molecular Dynamics Simulations. Materials, 14(4), 733. https://doi.org/10.3390/ma14040733