Study on the Penetration Performance of a 5.8 mm Ceramic Composite Projectile

Abstract

:1. Introduction

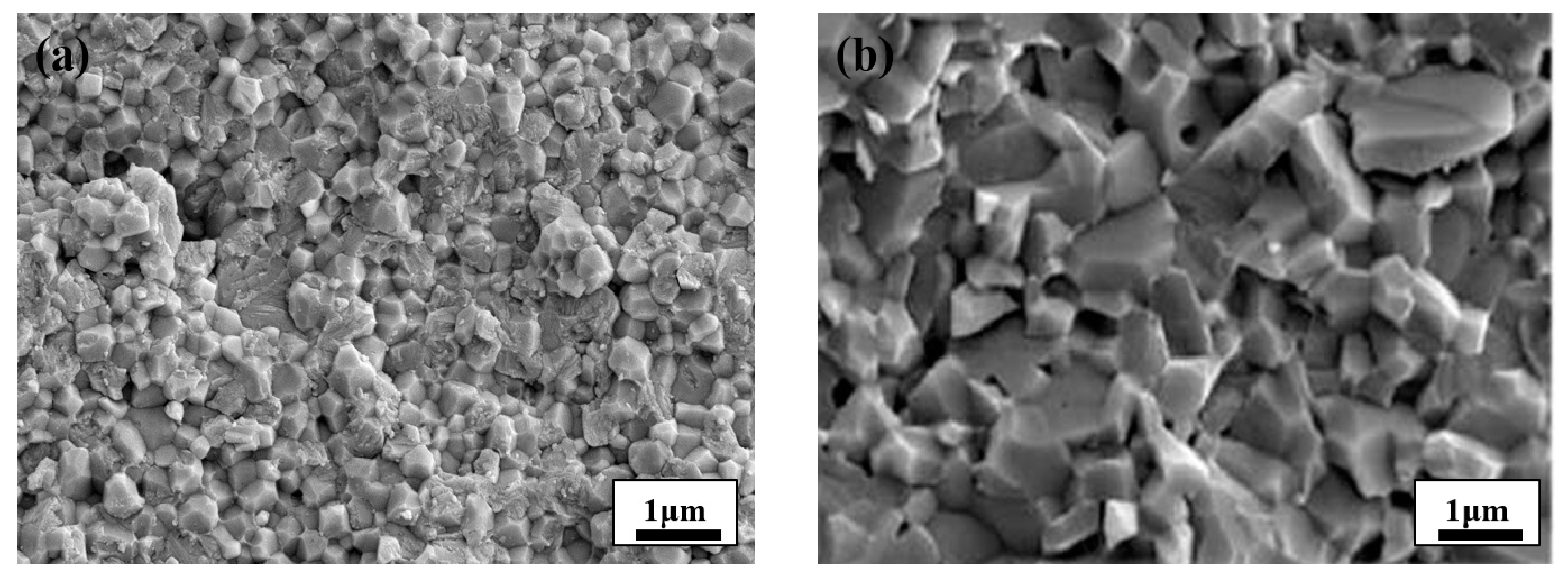

2. Experiment Preparation

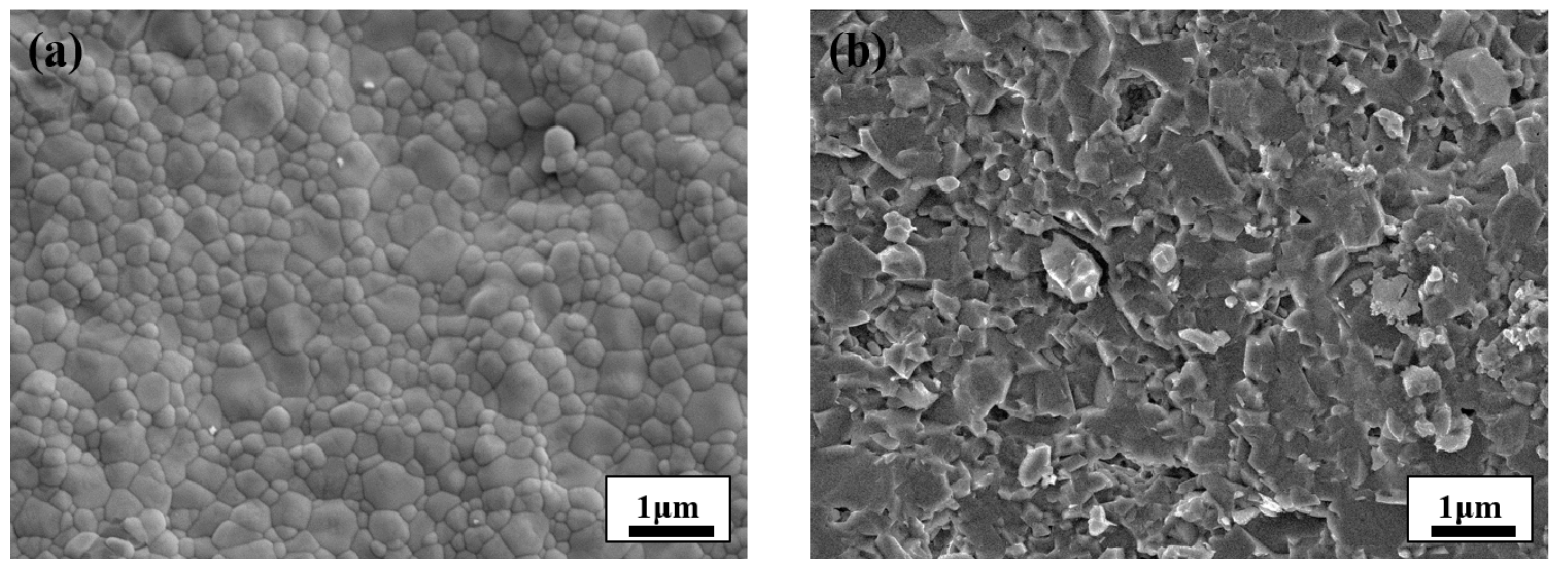

2.1. Material Preparation and Property Analysis

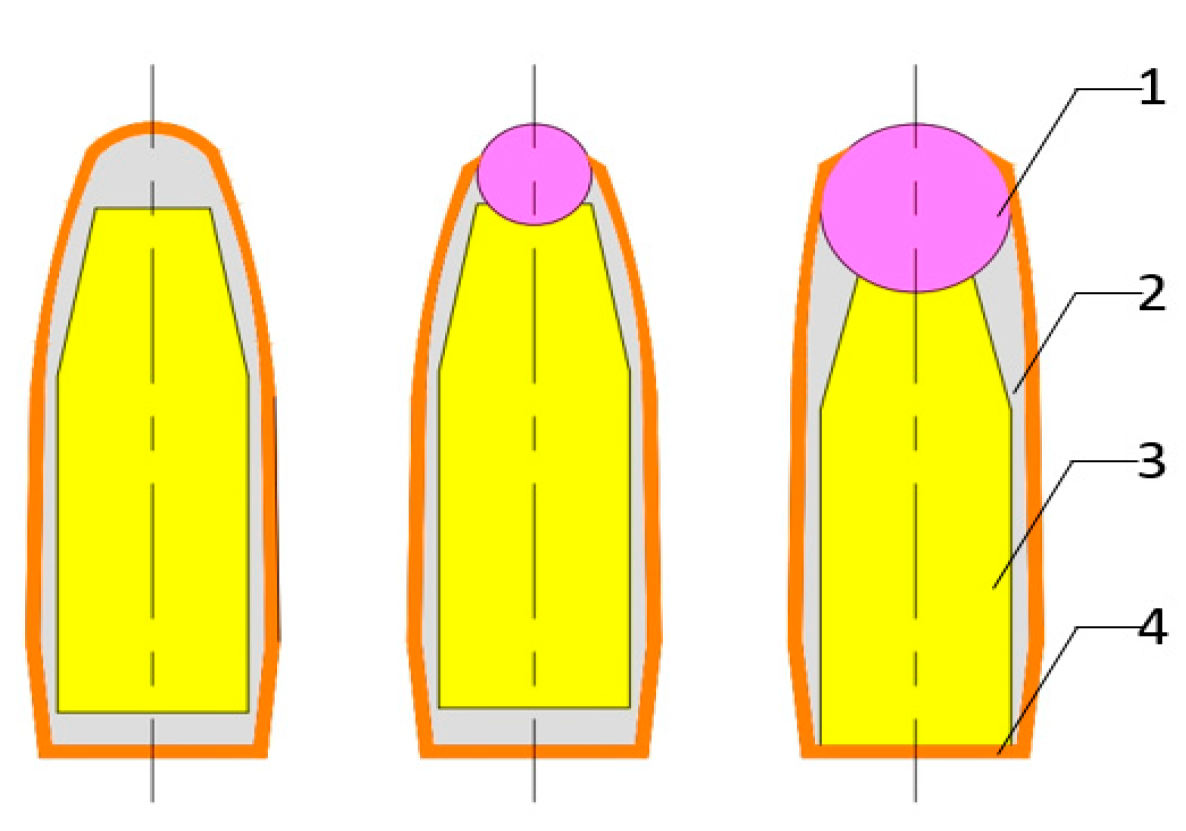

2.2. Depth-of-Penetration Experiment

3. Simulation Calculation

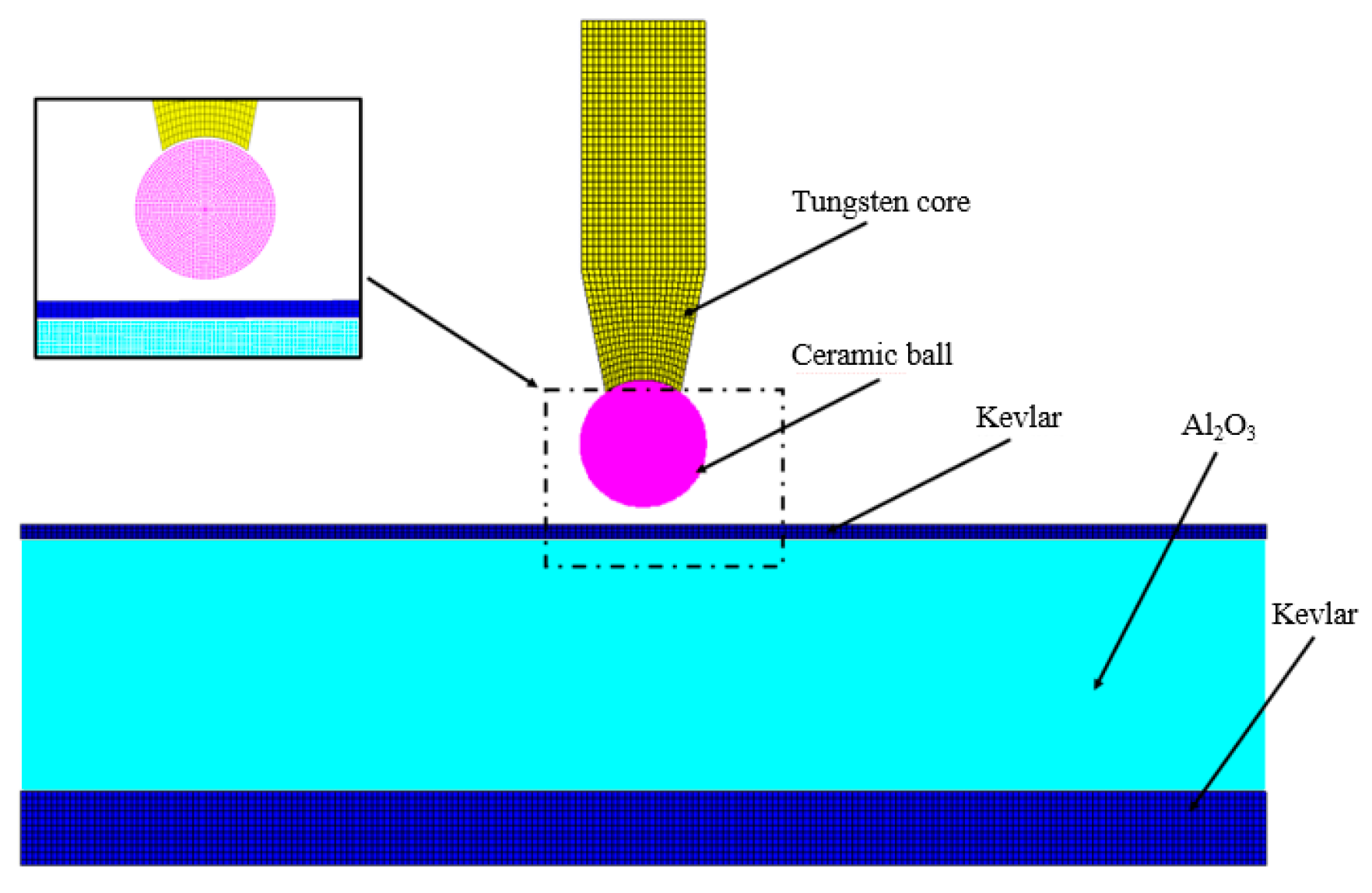

3.1. Simulation Model

3.2. Parameters of Materials

4. Results and Analysis

4.1. The Penetration of Armored Steel Target

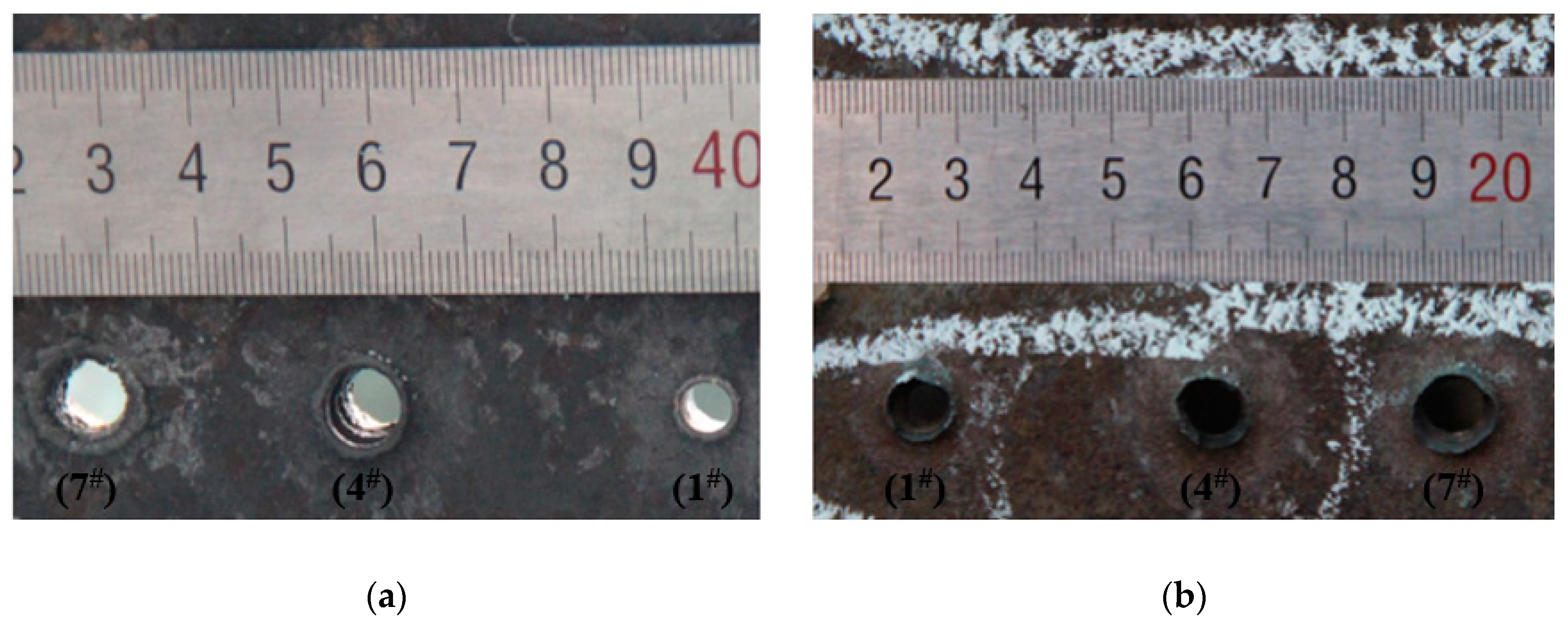

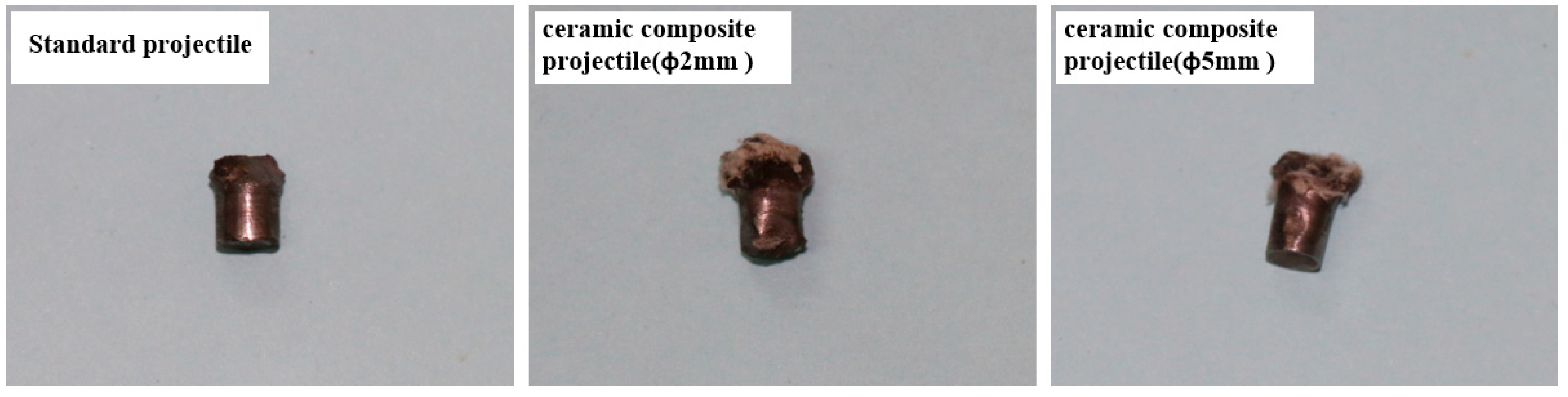

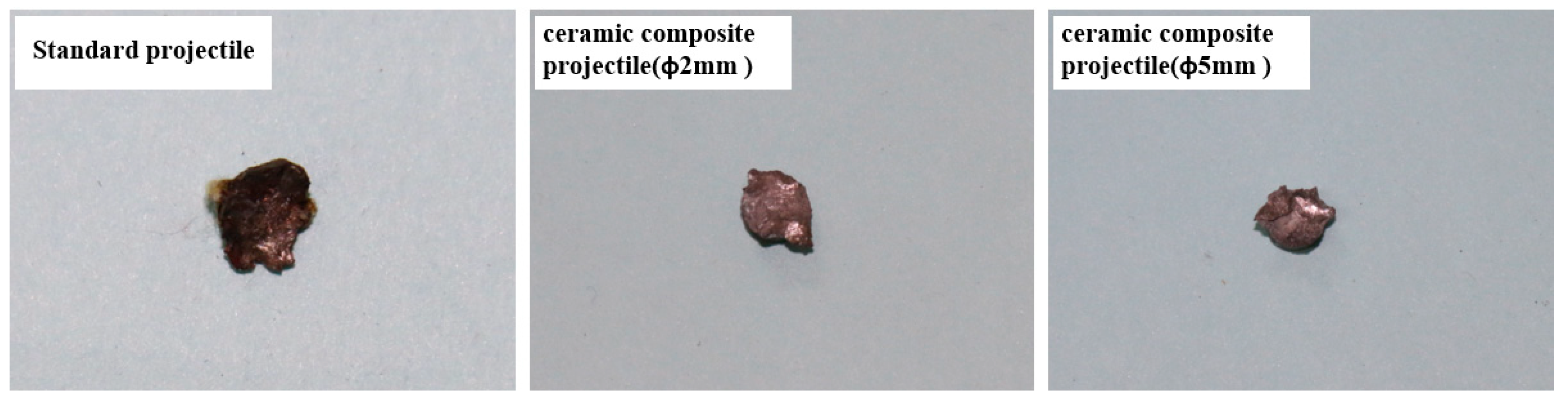

4.1.1. Test Results

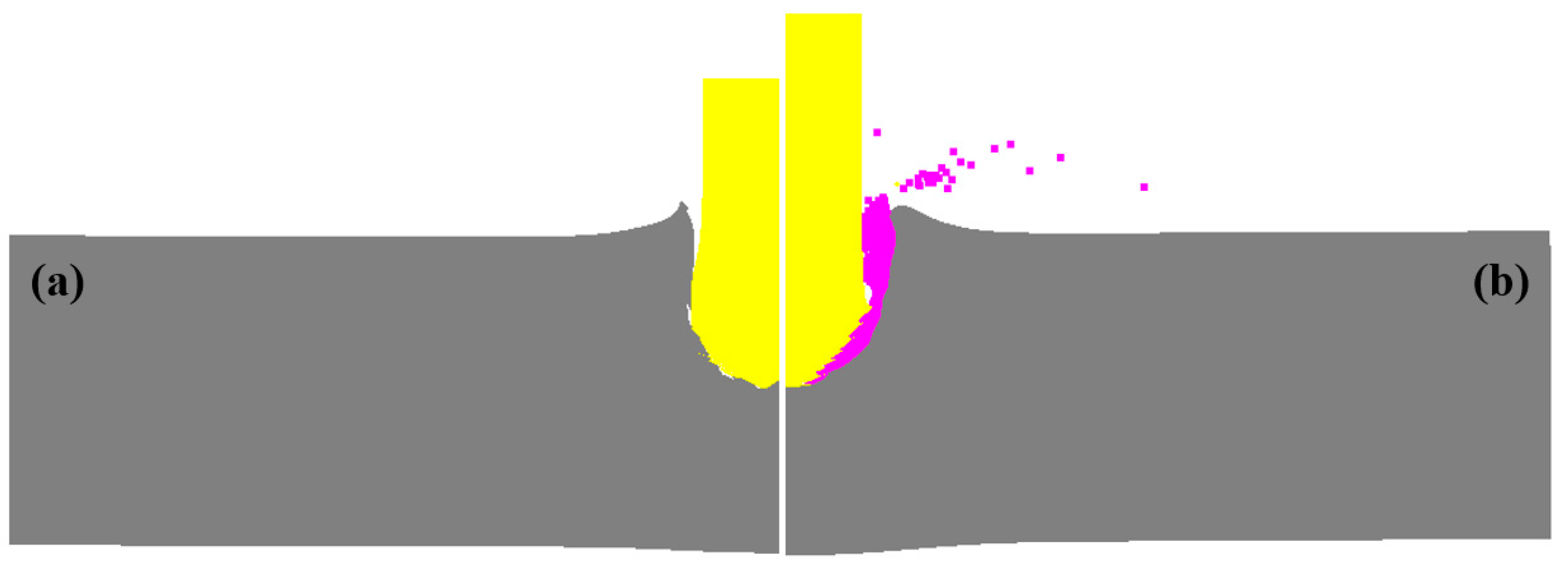

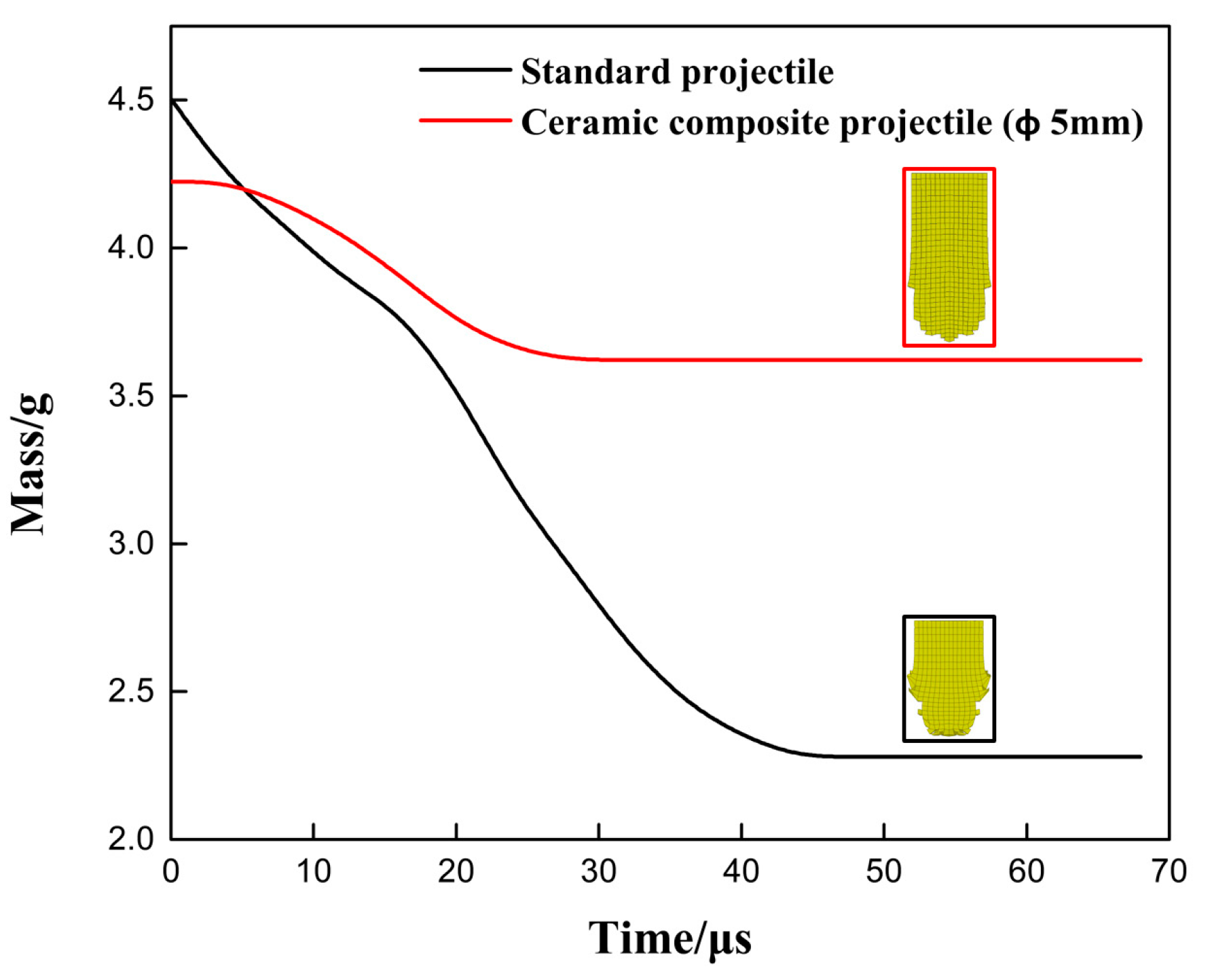

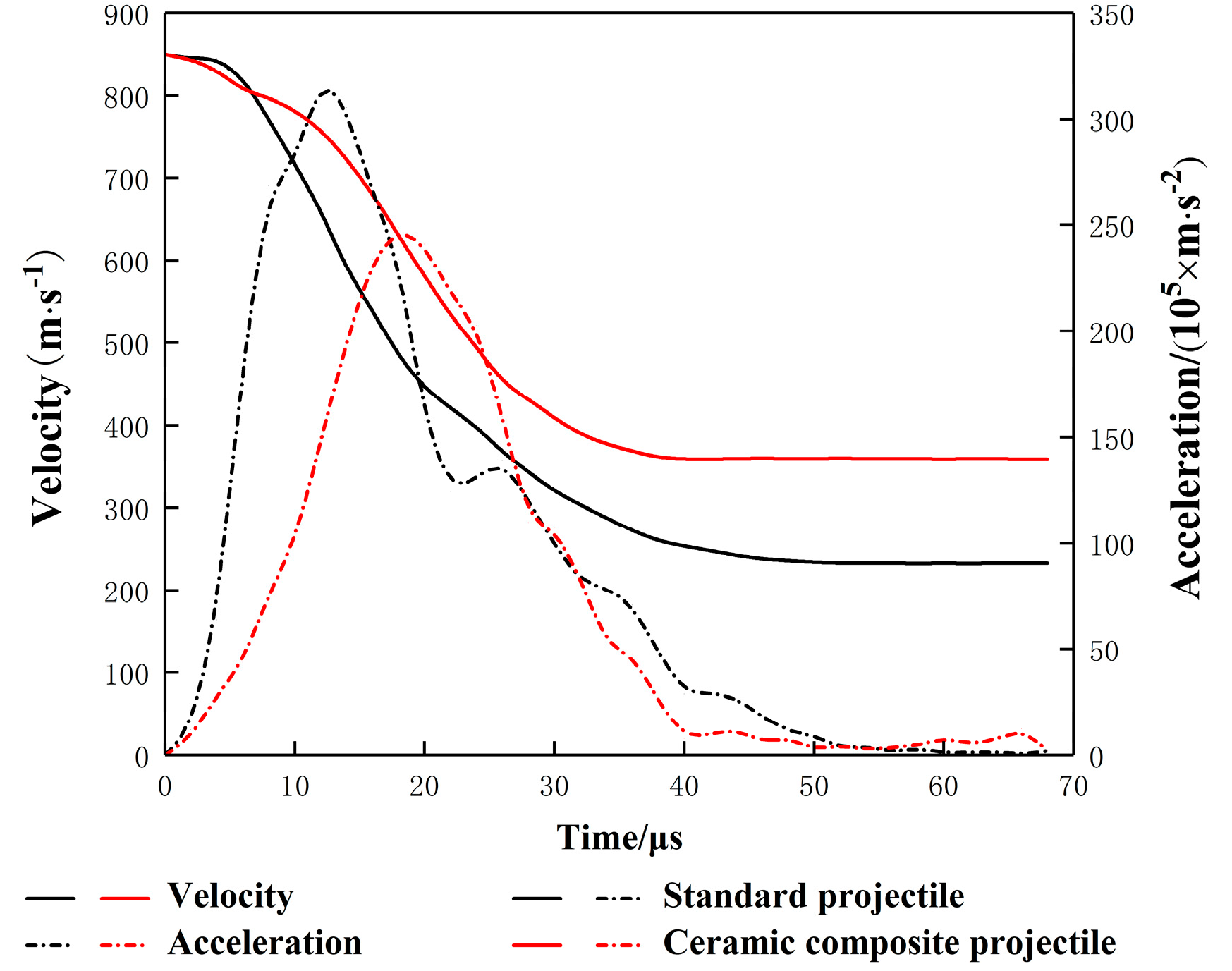

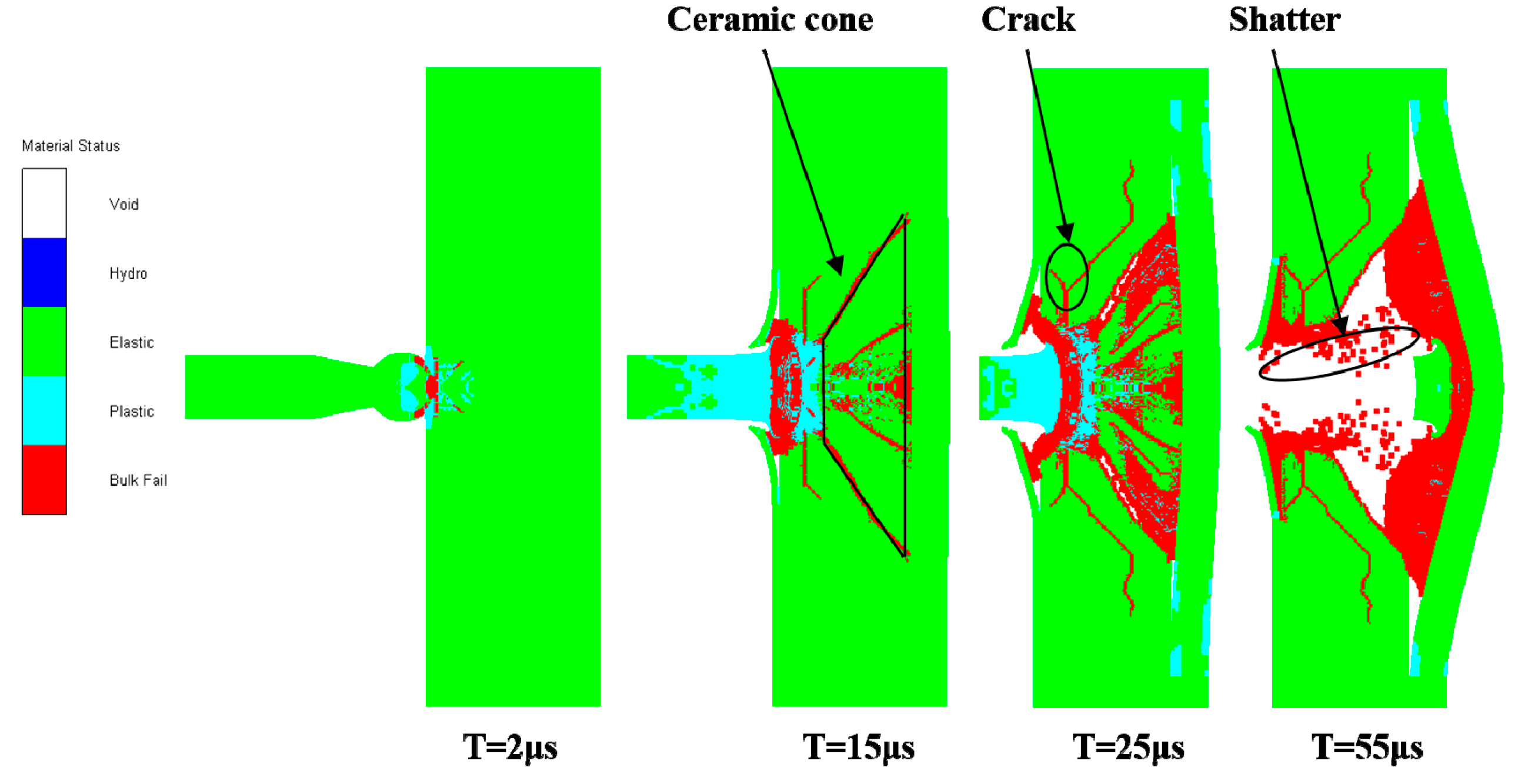

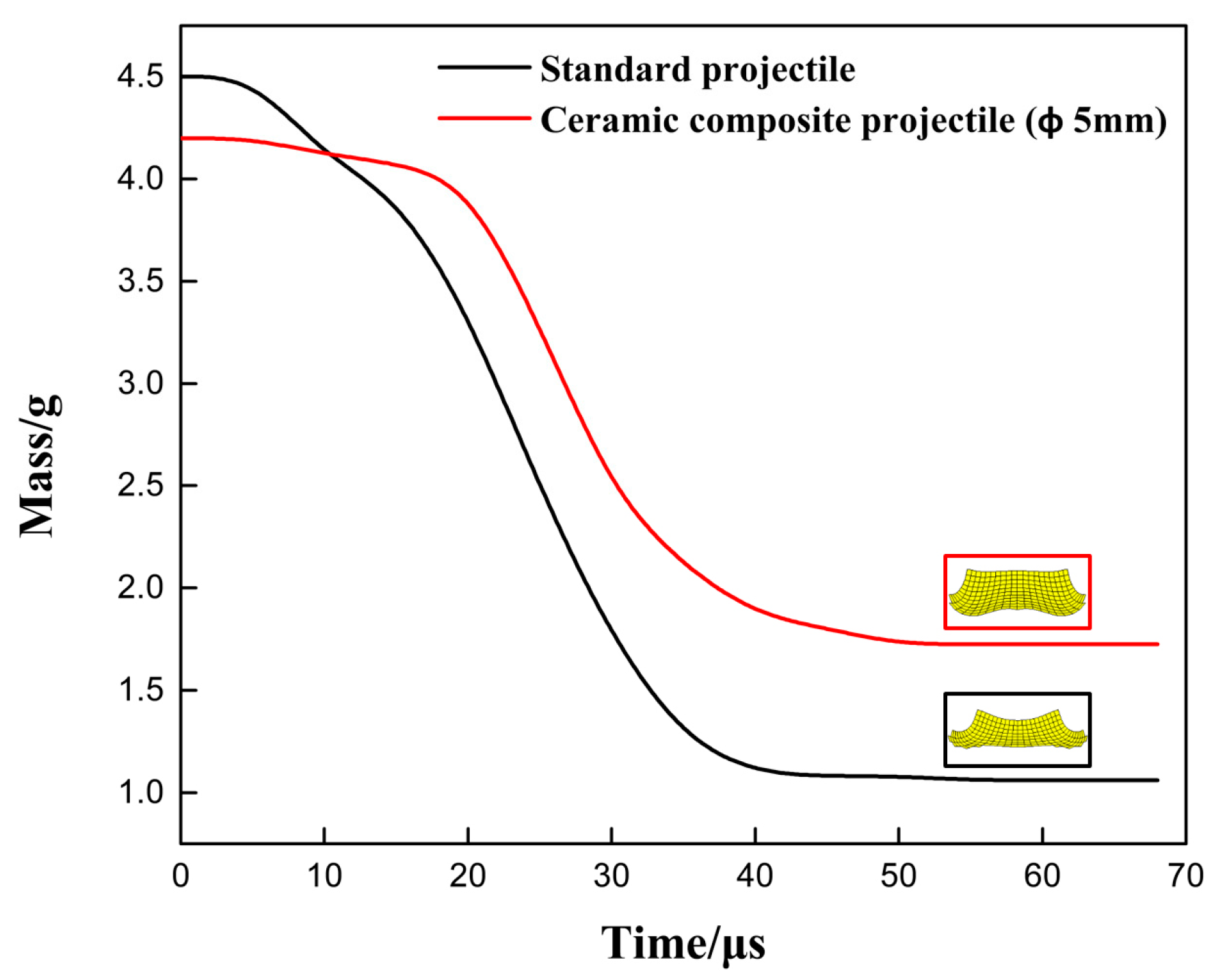

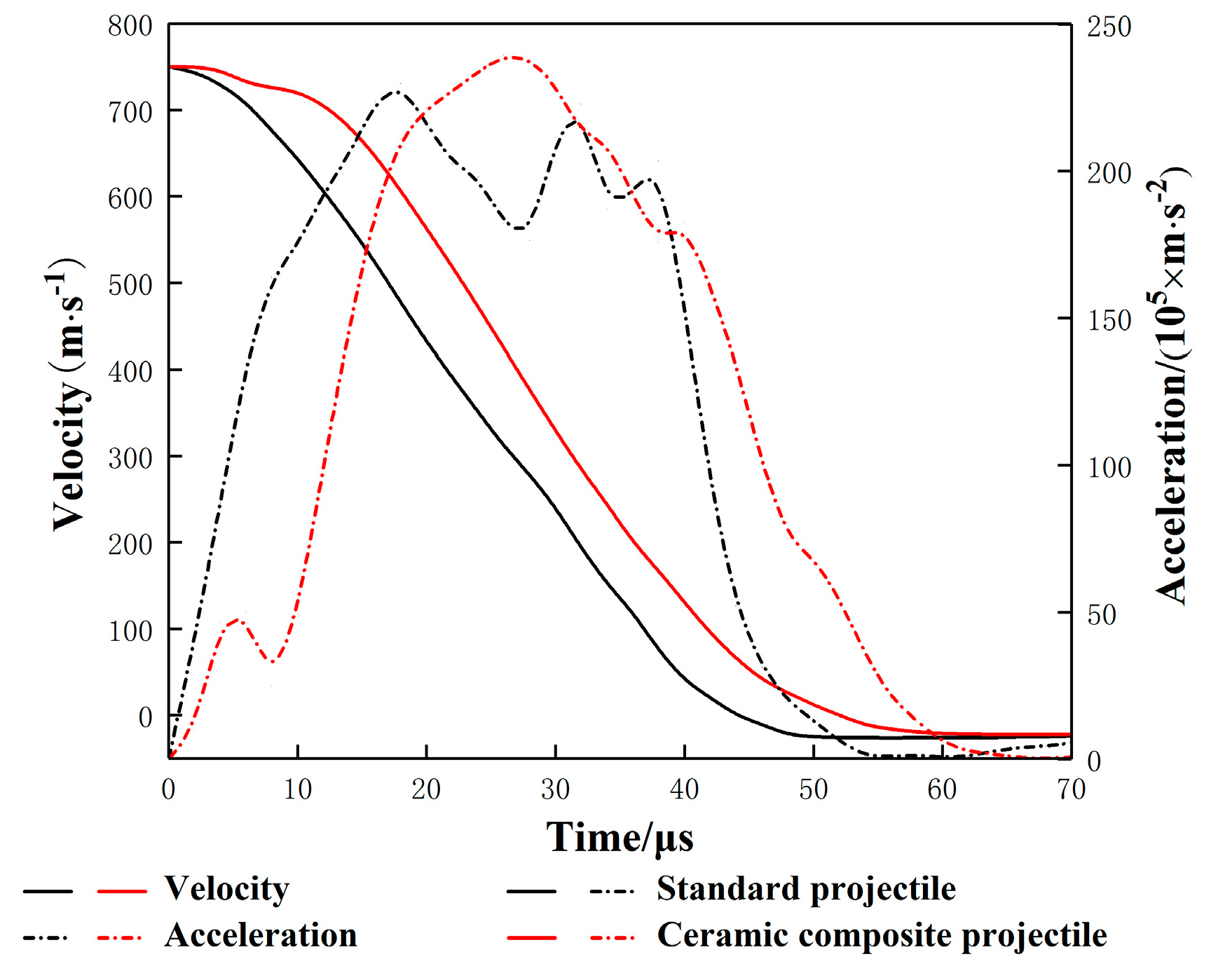

4.1.2. Simulation Analysis

4.2. The Penetration of the Ceramic/Kevlar Composite Armor Target

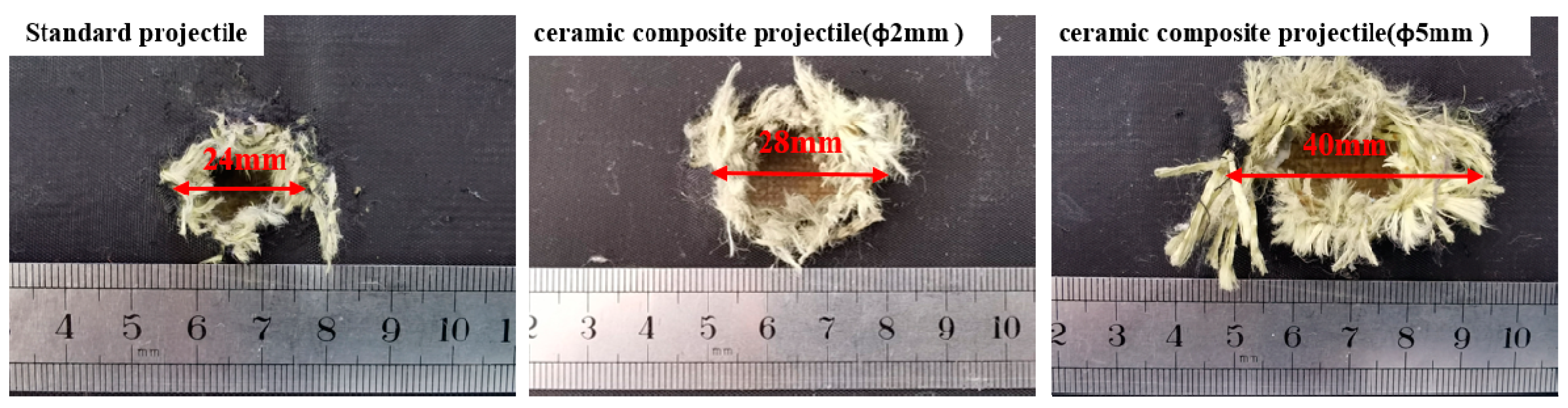

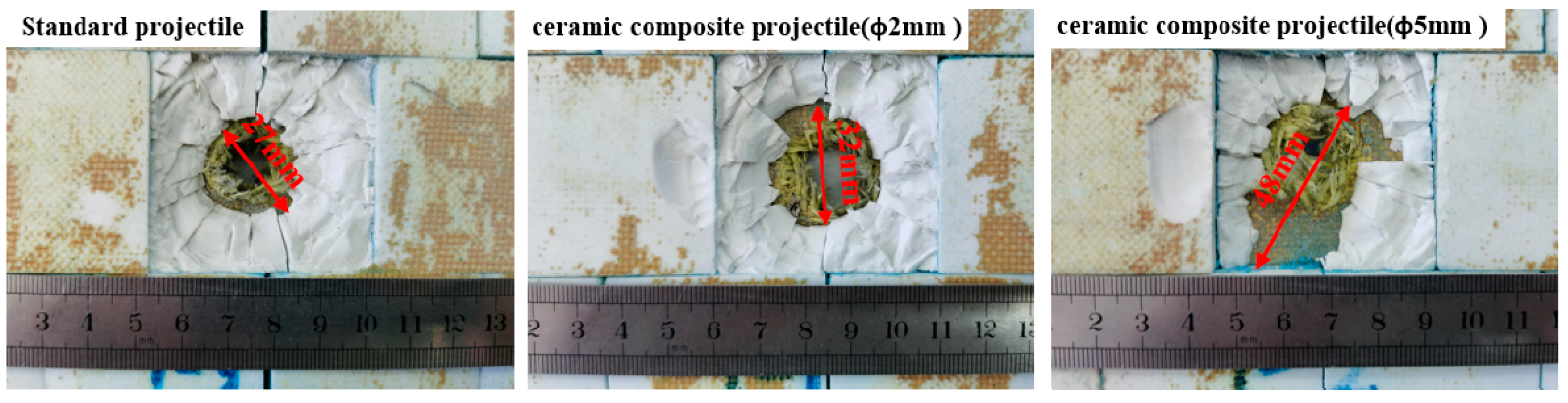

4.2.1. Test Results

4.2.2. Analysis of the Simulation Results

5. Impact Pressure Calculation Model for the Penetration of the Ceramic Composite Projectile into the Target

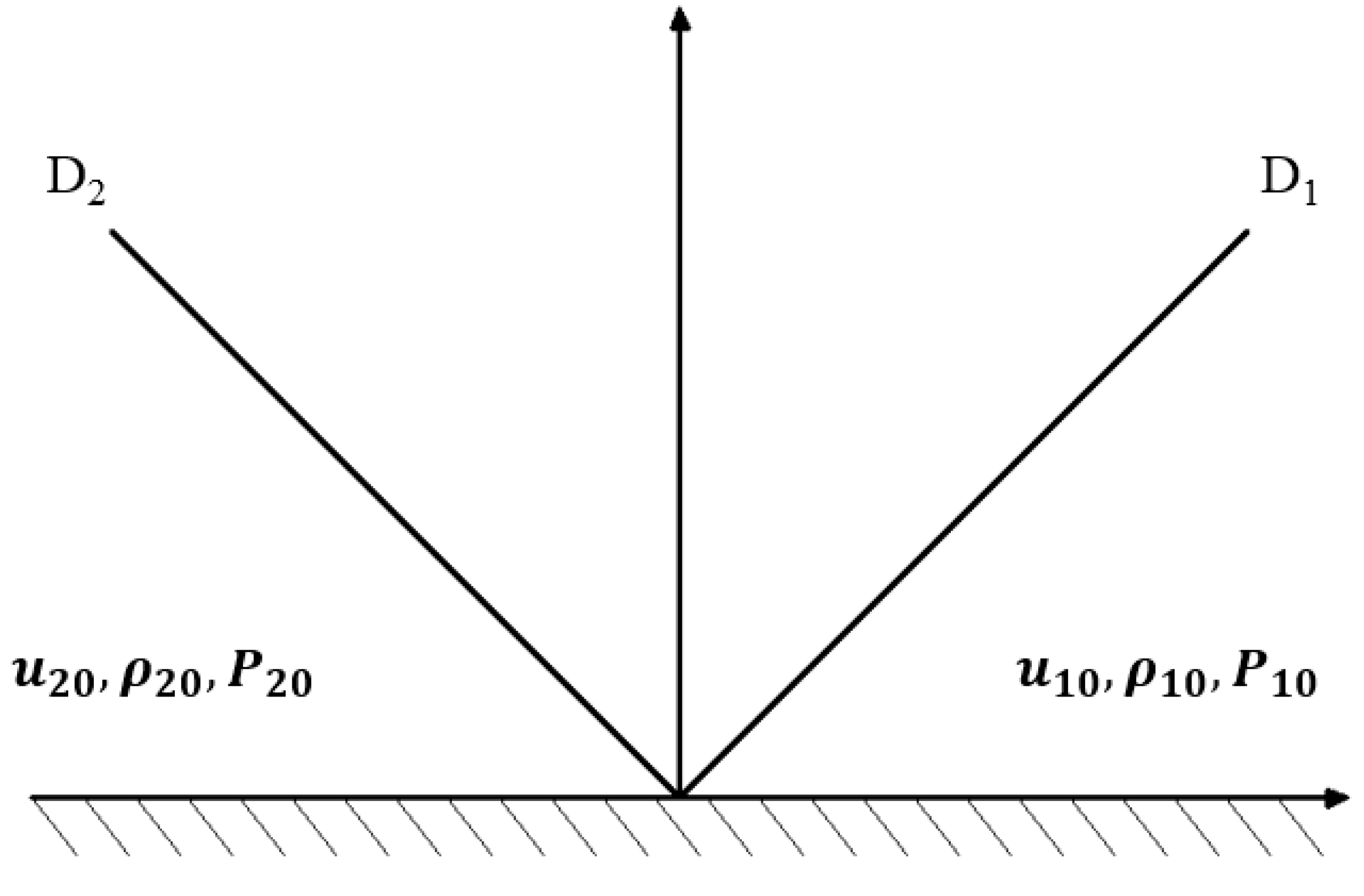

5.1. Basic Relational Expression

5.2. Shock Wave and Particle Velocity

5.3. Calculation Results

6. Conclusions

- (1)

- The ceramic composite projectile and standard projectile penetrated the armor steel target at the same velocity (850 m/s). The perforated areas of the ceramic composite projectiles (Ø5 mm & Ø2 mm) were 2.32 and 2.16 times larger, respectively, than that of standard projectile. The residual core masses of the two projectiles (Ø5 mm & Ø2 mm) were enhanced by 30.45% and 22.23%, respectively. The result showed that when penetrating RHA, the performance of the ceramic composite projectile was much better than that of the standard projectile.

- (2)

- The ceramic composite projectile and standard projectile penetrated the ceramic/Kevlar composite armor at the same velocity (750 m/s). The former had a better effect on the Kevlar board and ceramic board. Besides, compared with standard projectile, the residual core masses of the ceramic composite projectiles (Ø5 mm & Ø2 mm) were enhanced by 12.4% and 3.6%, respectively. However, the three projectiles failed to penetrate through the ceramic/ Kevlar composite target. Therefore, the structure of the ceramic head shall be optimized.

- (3)

- Compared with the Ø2 mm ceramic composite projectile, the Ø5 mm ceramic projectile showed a much better penetration effect on the RHA and ceramic/Kevlar composite armor, which indicates that the larger the ceramic head, the better the penetration effect.

- (4)

- While penetrating the target, the ceramic composite projectile generated a larger instantaneous impact pressure than the standard projectile. The damage effect of the former was better than that of the latter.

- (5)

- Compared with the standard projectile, the ceramic composite projectile had a better penetration effect. Therefore, ZrO2 ceramic materials have a promising application prospect in projectile design in the field of armor-piercing penetration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Medvedovski, E. Ballistic performance of armor ceramics: Influence of design and structure. Part 1. Ceram. Int. 2010, 36, 2103–2115. [Google Scholar] [CrossRef]

- Chen, W.W.; Rajendran, A.M.; Song, B.; Nie, X. Dynamic fracture of ceramics in armor applications. J. Am. Ceram. Soc. 2007, 90, 1005–1018. [Google Scholar] [CrossRef]

- Medvedovski, E. Ballistic performance of armor ceramics: Influence of design and structure. Part 2. Ceram. Int. 2010, 36, 2117–2127. [Google Scholar] [CrossRef]

- Nechitailo, N.V.; Batra, R.C. Penetration/perforation of aluminum, steel and tungsten plates by ceramic rods. Comput. Struct. 1998, 66, 571–583. [Google Scholar] [CrossRef]

- Nechitailo, N.V. Advanced high-speed ceramic projectiles against hard targets. IEEE Trans. Magn. 2009, 45, 614–619. [Google Scholar] [CrossRef]

- Li, S.C.; Liu, W.; Chen, Z.G.; Yang, J.L. Research on Dynamic Property of ZrO_2 under High-speed Strike. J. Synth. Cryst. 2009, 38, 363–365. [Google Scholar] [CrossRef]

- Wang, W.Z.; Chen, Z.G.; Feng, S.S.; Zhao, T.Y. Experimental study on ceramic balls impact composite armor. Def. Technol. 2020, 16, 408–416. [Google Scholar] [CrossRef]

- Rui, L.; Wang, J.R.; Chen, Z.G.; Li, G.; Huo, Y.Y. Cratering effect of Tc composite projectile penetrating concrete target. Ordnance Mater. Sci. Eng. 2015, 38, 6–9. [Google Scholar] [CrossRef]

- Huang, D.Y.; Zhang, Y.Y.; Wang, J.R.; Wang, S.Z. A Study on Distance—Decay of Spherical Ceramic Fragments with Low Collateral Damage. J. Proj. Rocket. Missiles Guid. 2011, 31, 100–102. [Google Scholar] [CrossRef]

- Yi, R.C.; Wang, J.R.; Zan, S.D.; Chen, Z.G.; Hu, D.Q. Research on Penetration Performance of Non-penetrating Ceramic Bullet. Acta Armamentarii 2016, 37, 49–54. [Google Scholar]

- Li, B.; Wang, J.R.; Yin, L.K.; Chen, Z.G.; Yi, R.C.; Hu, D.Q. Performance of Low-penetration Ceramic Bullet Penetrating Aviation Organic Glass. Dandao Xuebao/J. Ballist. 2017, 29, 70–75. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, C.A. High Performance Multi Phase Composite Ceramics; Tsinghua University Press: Beijing, China, 2008; pp. 13–28. ISBN 978-7-302-16003-8. [Google Scholar]

- Claussen, N. Fracture Toughness of Al2O3 with an Unstabilized ZrO2 Dispersed Phase. J. Am. Ceram. Soc. 1976, 59, 49–51. [Google Scholar] [CrossRef]

- Wang, J.; Stevens, R. Zirconia-toughened alumina (ZTA) ceramics. J. Mater. Sci. 1989, 24, 3421–3440. [Google Scholar] [CrossRef]

- Kerkwijk, B.; Winnubst, L.; Mulder, E.J.; Verweij, H. Processing of homogeneous zirconia-toughened alumina ceramics with high dry-sliding wear resistance. J. Am. Ceram. Soc. 1999, 82, 2087–2093. [Google Scholar] [CrossRef]

- Hou, X.; Zhou, S.; Li, W.; Li, Y. Study on the effect and mechanism of zirconia on the sinterability of yttria transparent ceramic. J. Eur. Ceram. Soc. 2010, 30, 3125–3129. [Google Scholar] [CrossRef]

- Yang, J.L.; Xi, X.Q.; Huang, Y. Shrinkages during from Liquid to Solid in Colloidal Forming. Key Eng. Mater. 2007, 336–338, 2378–2381. [Google Scholar] [CrossRef]

- Yang, J.L.; Yu, J.L.; Huang, Y. Recent developments in gelcasting of ceramics. J. Eur. Ceram. Soc. 2011, 31, 2569–2591. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, J. Novel Colloidal Forming of Ceramics; Springer: Heidelberg, Germany, 2011. [Google Scholar]

- Evans, A.G.; Marshall, D.B.; Burlingame, N.H. Transformation Toughening in Ceramics. Adv. Ceram. 1981, 3, 202–216. [Google Scholar] [CrossRef]

- Rajendran, A.M.; Kroupa, J.L. Impact damage model for ceramic materials. J. Appl. Phys. 1989, 66, 3560–3565. [Google Scholar] [CrossRef]

- Ravichandran, G.; Subhash, G. A micromechanical model for high strain rate behavior of ceramics. Int. J. Solids Struct. 1995, 32, 2627–2646. [Google Scholar] [CrossRef]

- Krishnan, K.; Sockalingam, S.; Bansal, S.; Rajan, S.D. Numerical simulation of ceramic composite armor subjected to ballistic impact. Compos. Part. B Eng. 2010, 41, 583–593. [Google Scholar] [CrossRef]

- Serjouei, A.; Chi, R.; Sridhar, I.; Tan, G.E.B. Empirical ballistic limit velocity model for bi-layer ceramic-metal armor. Int. J. Prot. Struct. 2015, 6, 509–527. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Vetiyatil, L.; Ahmad, S. The effect of hybridization on the ballistic impact behavior of hybrid composite armors. Compos. Part B Eng. 2015, 76, 300–319. [Google Scholar] [CrossRef]

- Chang, Z.L.; Zhao, W.L.; Zou, G.P.; Sun, H.Q. Simulation of the Lightweight Ceramic/Aluminum Alloy Composite Armor for Optimizing Component Thickness Ratios. Strength Mater. 2019, 51, 11–17. [Google Scholar] [CrossRef]

- Woodward, R.L.; Gooch, W.A.; O’Donnell, R.G.; Perciballi, W.J.; Baxter, B.J.; Pattie, S.D. A study of fragmentation in the ballistic impact of ceramics. Int. J. Impact Eng. 1994, 15, 605–618. [Google Scholar] [CrossRef]

- Sherman, D. Impact failure mechanisms in alumina tiles on finite thickness support and the effect of confinement. Int. J. Impact Eng. 2000, 24, 313–328. [Google Scholar] [CrossRef]

- Zhao, C.G. Wear of Engineering Mechanics; Ordnance Industry Press: Beijing, China, 1992; pp. 97–101. ISBN 7-80038-361-X. [Google Scholar]

- Tan, H. Experimental Shock Wave Physics Guidance; National Defense Industry Press: Beijing, China, 2007; pp. 72–83. ISBN 978-7-118-04949-7. [Google Scholar]

- Shockey, D.A.; Marchand, A.H.; Skaggs, S.R.; Cort, G.E.; Burkett, M.W.; Parker, R. Failure phenomenology of confined ceramic targets and impacting rods. Int. J. Impact Eng. 1990, 9, 263–275. [Google Scholar] [CrossRef]

| Materials | ρ/(g·cm−3) | G/Armor | HEL/Armor | A | B | C | M | N |

|---|---|---|---|---|---|---|---|---|

| ZrO2 Ceramic | 5.90 | 152 | 6.57 | 0.93 | 0.72 | 0.007 | 0.38 | 0.64 |

| Projectile Structure | Number | Projectile Mass/g | ZrO2 Ceramic Mass/g | Tungsten Core Mass/g | Initial Speed/(m/s) | Residual Core Mass/g | Damage of Armored Steel Target | ||

|---|---|---|---|---|---|---|---|---|---|

| Hole Entrance/mm | Hole Entrance Flange/mm | Hole Exit/mm | |||||||

| Standard projectile | 1 | 4.5 | - | 4.5 | 842 | 2.29 | Ø5.03 | Ø7.21 | Ø7.53 |

| 2 | 4.5 | - | 4.5 | 851 | 2.08 | Ø5.16 | Ø7.45 | Ø7.68 | |

| 3 | 4.5 | - | 4.5 | 846 | 2.21 | Ø5.06 | Ø7.19 | Ø7.61 | |

| ceramic composite projectile (Ø2 mm) | 4 | 4.5 | 0.03 | 4.47 | 848 | 3.26 | Ø7.52 | 11.3 × 12 | 8.98 × 7.96 |

| 5 | 4.5 | 0.03 | 4.47 | 842 | 3.19 | Ø7.36 | 10.6 × 11.2 | 8.68 × 8.16 | |

| 6 | 4.5 | 0.03 | 4.47 | 854 | 3.07 | Ø7.43 | 11.5 × 11.7 | 9.08 × 8.06 | |

| ceramic composite projectile (Ø5 mm) | 7 | 4.5 | 0.38 | 4.12 | 852 | 3.64 | Ø8.11 | Ø14.01 | 10.35 × 9.81 |

| 8 | 4.5 | 0.38 | 4.12 | 843 | 3.66 | Ø7.86 | Ø13.92 | 10.13 × 10.01 | |

| 9 | 4.5 | 0.38 | 4.12 | 844 | 3.52 | Ø7.93 | Ø13.68 | 10.26 × 9.97 | |

| Projectile Structure | Simulation | Test | ||||

|---|---|---|---|---|---|---|

| Hole Entrance/mm | Hole Exit/mm | Residual Core Mass/g | Hole Entrance/mm | Hole Exit/mm | Residual Core Mass/g | |

| Standard projectile | Ø5.09 | Ø7.59 | 2.28 | Ø5.06 | Ø7.19 | 2.21 |

| ceramic composite projectile (Ø5 mm) | Ø8.07 | Ø10.01 | 3.62 | Ø7.93 | 10.26×9.97 | 3.52 |

| Projectile Structure | Number | Full-Projectile Mass/g | ZrO2 Ceramic Mass/g | Tungsten Core Mass/g | Initial Speed/(m/s) | Residual Core Mass/g | Damage Effect |

|---|---|---|---|---|---|---|---|

| Standard projectile | 1 | 4.5 | - | 4.5 | 754 | 1.07 | Ceramic/Kevlar composite armor ceramic plate broken into large fragments. Kevlar bulges on the back. |

| 2 | 4.5 | - | 4.5 | 752 | 1.12 | ||

| 3 | 4.5 | - | 4.5 | 746 | 1.09 | ||

| Ceramic composite projectile (Ø2 mm) | 4 | 4.5 | 0.03 | 4.47 | 750 | 1.23 | Ceramic/Kevlar composite armor ceramic plate broken into small fragments. Kevlar bulges on the back. |

| 5 | 4.5 | 0.03 | 4.47 | 744 | 1.32 | ||

| 6 | 4.5 | 0.03 | 4.47 | 747 | 1.26 | ||

| Ceramic composite projectile (Ø5 mm) | 7 | 4.5 | 0.38 | 4.12 | 751 | 1.67 g | Ceramic/Kevlar composite armor ceramic plate broken into small fragments. Kevlar bulges on the back. |

| 8 | 4.5 | 0.38 | 4.12 | 753 | 1.62 | ||

| 9 | 4.5 | 0.38 | 4.12 | 746 | 1.59 |

| Name | RHA | Ceramic Target | Ceramic Composite Projectile | Standard Projectile |

|---|---|---|---|---|

| Density ρ/(kg/m3) | 7850 | 3630 | 16,000 | 17,600 |

| Material parameter α/(km/s) | 3.57 | 5.65 | 7.68 | 5.124 |

| Material parameter b | 1.92 | 1.65 | 1.65 | 1.233 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, K.; Feng, S.; Chen, Z.; Zhao, T.; Yin, L.; Fu, J. Study on the Penetration Performance of a 5.8 mm Ceramic Composite Projectile. Materials 2021, 14, 721. https://doi.org/10.3390/ma14040721

Ren K, Feng S, Chen Z, Zhao T, Yin L, Fu J. Study on the Penetration Performance of a 5.8 mm Ceramic Composite Projectile. Materials. 2021; 14(4):721. https://doi.org/10.3390/ma14040721

Chicago/Turabian StyleRen, Kai, Shunshan Feng, Zhigang Chen, Taiyong Zhao, Likui Yin, and Jianping Fu. 2021. "Study on the Penetration Performance of a 5.8 mm Ceramic Composite Projectile" Materials 14, no. 4: 721. https://doi.org/10.3390/ma14040721

APA StyleRen, K., Feng, S., Chen, Z., Zhao, T., Yin, L., & Fu, J. (2021). Study on the Penetration Performance of a 5.8 mm Ceramic Composite Projectile. Materials, 14(4), 721. https://doi.org/10.3390/ma14040721