Biopolymers and Biomaterials for Special Applications within the Context of the Circular Economy

Abstract

:1. Introduction

2. Smart Biopolymers for Special Applications

2.1. Polymers from Renewable Resources

2.1.1. Poly(Lactic Acid) PLA

2.1.2. Thermoplastic Starch TPS

2.1.3. Polyesters of Microbiological Origin—3-hydroxybutyrate (PHA), poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), and poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH)

2.1.4. Renewable Polyolefins

2.2. Polymers Derived from Fossil Raw Materials

2.2.1. Synthetic Aliphatic Polyesters

2.2.2. Synthetic Aliphatic–Aromatic Copolymers

2.3. Water-Soluble Polymers

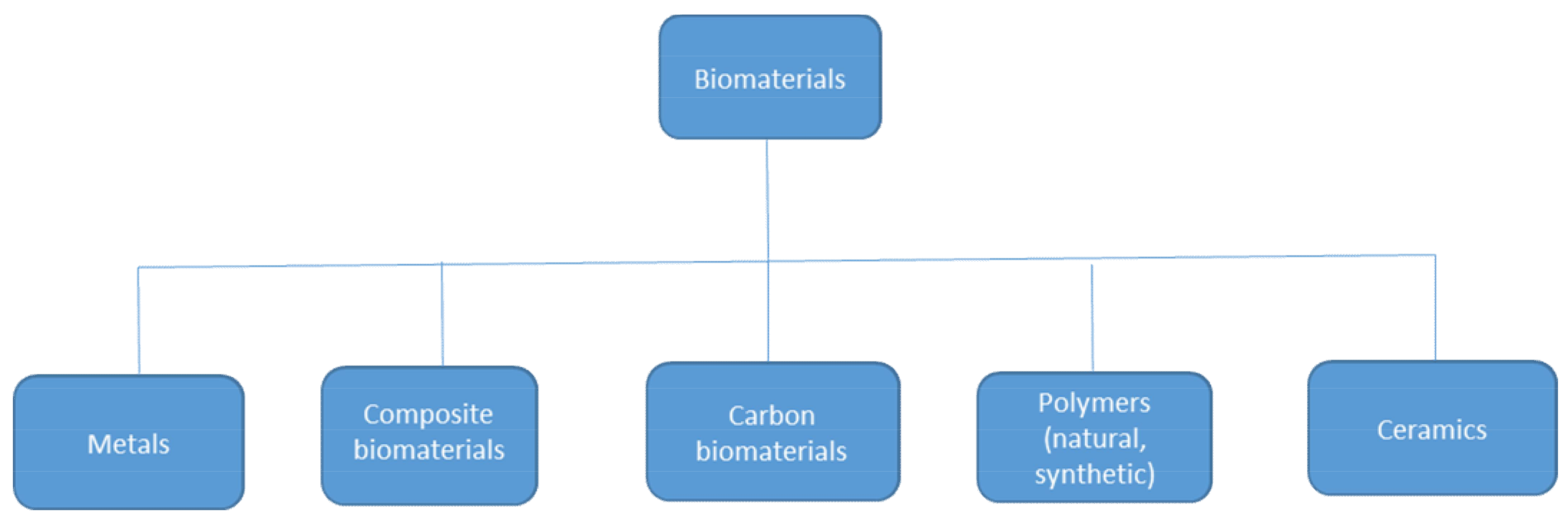

3. Biomaterials for Special Applications Based on Natural Polymers

4. Biomaterials Polymers in Łukasiewicz—IBWCh Applications

5. Future Directions of the Development of Biomaterials in the Medical Sector in Relation to the Circular Economy

6. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Matichescu, A.; Ardelean, L.C.; Rusu, L.-C.; Craciun, D.; Bratu, E.A.; Babucea, M.; Leretter, M. Advanced Biomaterials and Techniques for Oral Tissue Engineering and Regeneration—A Review. Materials 2020, 13, 5303. [Google Scholar] [CrossRef]

- Alonso-Goulart, V.; Carvalho, L.N.; Galante Marinho, A.L.; Lourenço de Oliveira, S.; de Aquino Pinto Palis, G.; Guerra Drumond Lage, H.; Lemos de Lima, I.; Duarte Guimarães, L.; Correia Peres, L.; Marques Silveira, M.; et al. Bio-Materials and Adipose-Derived Mesenchymal Stem Cells for Regenerative Medicine: A Systematic Review. Materials 2021, 14, 4641. [Google Scholar] [CrossRef]

- Sardon, H.; Dove, A.P. Plastics recycling with a difference. Science 2018, 360, 380–381. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Song, G.; Qu, S.; Dong, X.; Xu, M. Post-consumer packaging waste from express delivery in China. Resour. Conserv. Recycl. 2019, 144, 137–143. [Google Scholar] [CrossRef]

- Khatoon, N.; Jamal, A.; Ali, M.I. Lignin peroxidase isoenzyme: A novel approach to bio-degrade the toxic synthetic polymer waste. Environ. Technol. 2019, 40, 1366–1375. [Google Scholar] [CrossRef] [PubMed]

- Aguilar, A.; Twardowski, T.; Wohlgemuth, R. Bioeconomy for Sustaina-ble Development. Biotechnol. J. 2019, 14, 1800638–1800648. [Google Scholar] [CrossRef]

- Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment. Available online: https://eur-lex.europa.eu/eli/dir/2019/904/oj (accessed on 22 November 2021).

- Bachorz, M. www.igoz.org in the Knowledge Base Section. Available online: http://igoz.org/wp/wp-content/uploads/2017/04/Polska_droga_do_GOZ_IGOZ.pdf (accessed on 22 November 2021).

- Bruno, G.; Diglio, A.; Passaro, R.; Piccolo, C.; Quinto, I. Measuring spatial access to the recovery networks for WEEE: An in-depth analysis of the Italian case. Int. J. Prod. Econ. 2021, 240, 108210. [Google Scholar] [CrossRef]

- Favot, M.; Grassetti, L. E-waste collection in Italy: Results from an exploratory analysis. Waste Manag. 2017, 67, 222–231. [Google Scholar] [CrossRef]

- Krikke, H. Impact of closed-loop network configurations on carbon footprints: A case study in copiers. Resour. Conserv. Recycl. 2011, 55, 1196–1205. [Google Scholar] [CrossRef]

- Guang-Zhong, Y.; Xiao-Mei, Y. Biodegradable polymers: A cure for the planet, but a long way to go. J. Polym. Res. 2020, 27, 38–51. [Google Scholar]

- Li, Z.; Yang, J.; Loh, X.J. Polyhydroxyalkanoates: Opening doors for a sustainable future. NPG Asia Mater. 2016, 8, e265. [Google Scholar] [CrossRef]

- Boyandin, A.N.; Zhila, N.O.; Kiselev, E.G.; Volova, G. Constructing slow-release formulations of Metribuzin based on degradable poly(3-hydroxybutyrate). J. Agric. Food Chem. 2016, 64, 5625–5632. [Google Scholar] [CrossRef]

- Furtwengler, P.; Avérous, L. Renewable polyols for advanced polyurethane foams from diverse biomass resources. Polym. Chem. 2018, 9, 4258–4287. [Google Scholar] [CrossRef]

- Dai, J.; Styles, G.N.; Patti, A.F.; Saito, K. CuSO4/H2O2—Catalyzed lignin depolymerization under the irradiation of micro-waves. ACS Omega 2018, 3, 10433–10441. [Google Scholar] [CrossRef]

- Bangalore Ashok, R.P.; Oinas, P.; Lint-Inen, K.; Sarwar, G.; Kostiainen, M.A.; Österberg, M. Techno-economic assessment for the large-scale production of col-loidal lignin particles. Green Chem. 2018, 20, 4911–4919. [Google Scholar] [CrossRef] [Green Version]

- Ghaffar, S.H.; Fan, M. Lignin in straw and its applications as an adhesive. Int. J. Adhes. Adhes. 2014, 48, 92–101. [Google Scholar] [CrossRef]

- Yu, Y.; Shang, L.; Guo, J.; Wang, J.; Zhao, Y. Design of capillary microfluidics for spinning cell-laden microfibers. Nat. Protoc. 2018, 13, 2557–2579. [Google Scholar] [CrossRef]

- Qin, Y.; Zhuang, Y.; Wu, Y.; Li, L. Quality evaluation of hot peppers stored in biodegradable poly(lactic acid)-based active packaging. Sci. Hortic. 2016, 202, 1–8. [Google Scholar] [CrossRef]

- Ma, W.; Zhang, M.; Liu, Z.; Huang, C.; Fu, G. Nature-inspired creation of a robust free-standing electrospun nanofibrous membranę for efficient oil–water separation. Environ. Sci. Nano J. 2018, 5, 2909–2920. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, M.; Liu, Y.; Li, R.; Wei, F.; Xiao, R.; Liu, H. 3D porous poly(l-lactic acid) foams composed of nanofibers, nanofibrous microsheaves and microspheres and their application in oil–water separation. J. Mater. Chem. A 2015, 3, 14054–14062. [Google Scholar] [CrossRef]

- Pérez-García, M.G.; Gutiérrez, M.C.; Mota-Morales, J.D.; Luna-Bárcenas, G.; del Monte, F. Synthesis of biodegradable macroporous poly(l-lactide)/poly(ε-caprolactone) blend using oil-in-eutectic-mixture high-internal-phase emulsions as template. ACS Appl. Mater. Interfaces 2016, 8, 16939–16949. [Google Scholar] [CrossRef]

- Honda, W.; Harada, S.; Arie, T.; Akita, S.; Takei, K. Flexible electronics: Wearable, human-interactive, health-monitoring, wireless devices fabricated by macroscale printing techniques. Adv. Funct. Mater. 2014, 24, 3298. [Google Scholar] [CrossRef]

- Messer, H.; Zinevich, A.; Alpert, P. Environmental monitoring by wireless communication networks. Science 2006, 312, 713. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grau, G.; Kitsomboonloha, R.; Swisher, S.L.; Kang, H.; Subramanian, V. Printed transistors on paper: Towards smart consumer product packaging. Adv. Funct. Mater. 2014, 24, 5067–5074. [Google Scholar] [CrossRef]

- Gao, X.; Huang, L.; Wang, B.; Xu, D.; Zhong, J.; Hu, Z.; Zhang, L.; Zhou, J. Natural materials assembled, biodegradable, and transparent paper-based electret Nanogenerator. ACS App. Mater. Interfaces 2016, 8, 35587–35592. [Google Scholar] [CrossRef] [PubMed]

- Mazurek, M.; Parzuchowski, P. Poli (Urethane Carbonate) Laboratory Exercise with Shape Memory. Available online: http://pparzuch.ch.pw.edu.pl/ids/mikro_SPB.pdf (accessed on 10 September 2021).

- Penczek, S.; Pretula, J.; Lewiński, P. Polymers from renewable resources, biodegradable polymers. Polimery 2013, 58, 835–846. (in Polish). [Google Scholar] [CrossRef]

- Global Markets for Advanced Wound Management Technologies 2021–2026. Available online: https://www.researchandmarkets.com/reports/5398506/global-markets-for-advanced-wound-management (accessed on 8 September 2021).

- Arif, M.M.; Khan, S.M.; Tanveer, N.G.; Gull, N.; Tabish, T.A.; Zia, S.; Khan, R.U.; Awais, S.M.; Butt, M.A. Polymer –based biomaterials for chronic wound management: Promises and challenges. Int. J. Pharm. 2021, 598, 120270–120284. [Google Scholar] [CrossRef]

- Mościcka, P.; Szewczyk, M.T.; Cwajda-Białasik, J. Modern dressings in the outpatient treatment of infected wounds. Chir. Po Dyplomie 2018, 3, 36–42. (In Polish) [Google Scholar]

- Głos Wielkoplski. Miraculous Dressing from Poznań—It Will Accelerate the Healing of Wounds. The Dressing Takes any Shape and Size! Available online:. Available online: https://gloswielkopolski.pl/cudowny-opatrunek-z-poznania-przyspieszygojenie-sie-ran-przybierze-kazdy-ksztalt-i-rozmiar/ar/663057 (accessed on 24 September 2012).

- Natural Chitosan Sun—Polish Innovative Preparation, Which Is Worth Having at Hand, Especially in Summer. My Conversation with Dr. Eng. Grzegorz Gorczyca. Available online: http://www.kupujepolskieprodukty.pl/2017/06/chitozan-naturalny-sun-polski.html (accessed on 22 June 2017).

- The National Health Fund Is Looking for Money to Treat Poles. A New Tax as a Rescue. Available online: https://businessinsider.com.pl/firmy/zarzadzanie/pieniadze-w-budzecie-nfz-na-leczenie-polakow-w-2020-roku/hs3d9hj (accessed on 30 December 2019).

- Tolaimate, A.; Desbrieres, J.; Rhazi, M.; Alagui, A.; Vincendon, M.; Vottero, P. On the influence of deacetylation process on the physicochemical characteristics of chitosan from squid chitin. Polymers 2000, 41, 2463–2469. [Google Scholar] [CrossRef]

- Struszczyk, M.H. Chitin and Chitosan. Part I. Properties and production. Polimery 2002, 45, 316–323. [Google Scholar] [CrossRef]

- D’Ayala, G.G.; Malinconico, M.; Laurienzo, P. Marine derived polysaccharides for biomedical applications: Chemical modification approaches. Molecules 2008, 13, 2069–2106. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saravanakumar, G.; Jo, D.G.; Park, J.H. Polysaccharide-based nanoparticles: A versatile platform for drug delivery and biomedical imaging. Curr. Med. Chem. 2012, 19, 3212–3229. [Google Scholar] [CrossRef] [PubMed]

- Muzzarelli, R.A.A. Chitins and chitosans for the repair of wounded skin. Carbohydr. Polym. 2009, 77, 1–9. [Google Scholar] [CrossRef]

- Martau, G.A.; Mihai, M.; Vodnar, D.C. The Use of Chitosan, Alginate, and Pectin in the Biomedical and Food Sector-Biocompatibility, Bioadhesiveness, and Biodegradability. Polymers 2019, 11, 1837. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ifuku, S. Chitin and chitosan nanofibers: Preparation and chemical modifications. Molecules 2014, 19, 18367–18380. [Google Scholar] [CrossRef]

- Kucharska, M.; Sikora, M.; Brzoza-Malczeswka, K.; Owczarek, M. Antimicrobial Properties of Chitin and Chitosan. In Book Chitin and Chitosan: Properties and Application; van den Broek, L.A.M., Boeriu, C.G., Stevens, C.V., Eds.; Willey: Hoboken, NJ, USA, 2019; pp. 169–187. [Google Scholar]

- Maa, Z.; Garrido-Maestua, A.; Jeonga, K.C. Application, mode of action, and in vivo activity of chitosan and its micro and nanoparticles as antimicrobial agents: A review. Carbohydrate Polymers 2017, 176, 257–265. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Wang, C.; Li, C.; Qin, Y.; Wang, Z.; Yang, F.; Li, Z.; Wang, J. A functional chitosan-based hydrogel as a wound dressing and drug delivery system in the treatment of wound healing. RSC Adv. 2018, 8, 7533–7549. [Google Scholar] [CrossRef] [Green Version]

- Matica, M.A.; Aachmann, F.L.; Tøndervik, A.; Sletta, H.; Ostafe, V. Chitosan as a Wound Dressing Starting Material: Antimicrobial Properties and Mode of Action. Int. J. Mol. Sci. 2019, 20, 5889. [Google Scholar] [CrossRef] [Green Version]

- Wiśniewska-Wrona, M.; El Fray, M. Functional Three-Component Polymeric Biocomposites for the Treatment of Bedsores in Progress on Chemistry and Application of Chitin and its Derivatives PCACD; Jaworska, M.M., Ed.; Polish Chitin Society: Lodz, Poland, 2018; Volume 23. [Google Scholar]

- Kiyozumi, K.; Kanatani, Y.; Ishihara, M.; Saitoh, D.; Shimizu, J.; Yura, H.; Suzuki, S.; Okada, Y.; Kikuchi, M. The effect of chitosan hydrogel containing DMEM/F12 medium on full-thickness skin defects after deep dermal burn. Burns 2007, 33, 642–648. [Google Scholar] [CrossRef]

- NHS Forth Valley. Wound Managament Formulary. Available online: https://nhsforthvalley.com.pdf (accessed on 4 April 2019).

- Tricol Biomedical Inc. Available online: http://www.hemcon.com (accessed on 14 September 2021).

- Alam, H.B.; Burris, D.; DaCorta, J.A.; Rhee, P. Hemorrhage Control in the Battlefield: Role of New Hemostatic Agents. Mil. Med. 2005, 170, 1–63. Available online: https://pubmed.ncbi.nlm.nih.gov/15724857/ (accessed on 15 January 2005). [CrossRef] [Green Version]

- Niekraszewicz, A. Chitosan medical dressings. Fibres Text. East. Eur. 2005, 13, 16–18. [Google Scholar]

- Wiśniewska-Wrona, M.; El Fray, M. Physicochemical and functional properties of polymer biocomposites. Polimery 2019, 64, 23–33. [Google Scholar] [CrossRef]

- Pighinelli, L.; Kucharska, M.; Wiśniewska-Wrona, M.; Gruchała, B.; Brzoza-Malczewska, K. Biodegradation study of microcrystalline chitosan and microcrystalline chitosan/B-TCP complex composites. Int. J. Mol. Sci. 2012, 13, 7617–7628. [Google Scholar] [CrossRef]

- Kucharska, M.; Niekraszewicz, A.; Wiśniewska-Wrona, M.; Brzoza-Malczewska, K. Dressing Sponges Made of Chitosan and Chitosan-Alginate Fibrids. Fibres Text. East. Eur. 2008, 3, 109–113. [Google Scholar]

- Marcol, W.; Larysz-Brysz, M.; Kucharska, M.; Niekraszewicz, A.; Ślusarczyk, W.; Kotulska, K.; Właszczuk, P.; Właszczuk, A.; Jedrzejowska-Szypulka, H.; Lewin-Kowalik, J. Reduction of post-traumatic neuroma and epineural scar formation in rat sciatic nerve by application of microcrystallic chitosan. Microsurgery 2011, 3, 642–649. [Google Scholar] [CrossRef]

- Właszczuk, A.; Marcol, W.; Kucharska, M.; Wawro, D.; Palen, P.; Lewin-Kowalik, J. Poly(D, L-Lactide-Co-Glycolide) Tubes With Multifilament Chitosan Yarn or Chitosan Sponge Core in Nerve Regeneration. J. Oral Maxillofac. Surg. 2016, 74, 2327–2374. [Google Scholar] [CrossRef]

- Lopez, O.; Garcia, M.A.; Villar, M.A.; Gentili, A.; Rodriguez, M.S.; Albertengo, L. Thermo-compression of biodegradable thermoplastic corn starch films containing chitin and chitosan. LWT Food Sci. Technol. 2014, 57, 106–115. [Google Scholar] [CrossRef]

- Dang, K.M.; Yoksan, R. Development of thermoplastic starch blown film by incorporating plasticized chitosan. Carbohydr. Polym. 2015, 115, 575–581. [Google Scholar] [CrossRef] [PubMed]

- Chenni, A.; Djidjelli, H.; Boukerrou, A.; Grohens, Y.; Saulnier, B. Thermomechanical and acidic treatments to improve plasticization and properties of chitosan films: A comparative study of acid types and glycerol effects. Mater. Test. 2018, 60, 93–101. [Google Scholar] [CrossRef]

- Matet, M.; Heuzey, M.C.; Ajji, A.; Sarazin, P. Plasticized chitosan/polyolefin films produced by extrusion. Carbohydr. Polym. 2015, 117, 177–184. [Google Scholar] [CrossRef]

- Kucharska, M.; Niekraszewicz, A.; Struszczyk, M.; Gruchała, B.; Brzoza-Malczewska, K. Surgical Mesh and a Method of Producing a Composite Surgical Mesh. Poland Patent (In Polish). PL211,673B1, 29 June 2012. [Google Scholar]

- Niekraszewicz, A.; Kucharska, M.; Wawro, D.; Struszczyk, M.H.; Kopias, K.; Rogaczewska, A. Development of a Manufacturing Method for Surgical Meshes Modified by Chitosan. Fibres Text. East. Eur. 2007, 15, 105–109. [Google Scholar]

- Brzoza-Malczewska, K.; Kucharska, M.; Wiśniewska-Wrona, M.; Guzińska, K.; Ulacha-Bacciarelli, A. Modified Cellulose Products for Application in Hygiene and Dressing Materials—Part I. Fibres Text. East. Eur. 2015, 23, 126–132. [Google Scholar] [CrossRef]

- Brzoza-Malczewska, K.; Kucharska, M.; Wiśniewska-Wrona, M.; Kaźmierczak, D.; Jóźwicka, J.; Pałys, B. Modified Cellulosic Products for Application in Hygiene and Dressing Materials—Part II. Fibres Text. East. Eur. 2015, 23, 124–128. [Google Scholar] [CrossRef]

- Wawro, D.; Stęplewski, W.; Brzoza-Malczewska, K.; Święszkowski, W. Collagen-Modified Chitosan Fibres Intended for Scaffolds. Fibres Text. East. Eur. 2012, 20, 32–39. [Google Scholar]

- Pandey, V.; Haider, T.; Jain, P.; Gupta, P.N.; Soni, V. Silk as a leading-edge biological macromolecule for improved drug delivery. J. Drug Deliv. Sci. Technol. 2020, 55, 101294–101363. [Google Scholar] [CrossRef]

- Kumar, S.S.D.; Houreld, N.N.; Abrahamse, H. Biopolymer-based composites for medical applications. In Encyclopedia of Renewable and Sustainable Materials; Hashmi, S., Choudhary, I.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 20–28. [Google Scholar]

- Bondaruk, J. Vision of the Future of Metropolitan Public Services in the Upper Silesian Metropolitan Area; Główny Instytut Górnictwa: Katowice, Poland, 2011. (In Polish) [Google Scholar]

- Zhang, J.; Shishatskaya, E.I.; Volova, T.G.; Ferrira da Silva, L.; Chen, G.-Q. Polyhydroxyalkanoates (PHA) for therapeutic applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2018, 86, 144–150. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziuba, R.; Kucharska, M.; Madej-Kiełbik, L.; Sulak, K.; Wiśniewska-Wrona, M. Biopolymers and Biomaterials for Special Applications within the Context of the Circular Economy. Materials 2021, 14, 7704. https://doi.org/10.3390/ma14247704

Dziuba R, Kucharska M, Madej-Kiełbik L, Sulak K, Wiśniewska-Wrona M. Biopolymers and Biomaterials for Special Applications within the Context of the Circular Economy. Materials. 2021; 14(24):7704. https://doi.org/10.3390/ma14247704

Chicago/Turabian StyleDziuba, Radosław, Magdalena Kucharska, Longina Madej-Kiełbik, Konrad Sulak, and Maria Wiśniewska-Wrona. 2021. "Biopolymers and Biomaterials for Special Applications within the Context of the Circular Economy" Materials 14, no. 24: 7704. https://doi.org/10.3390/ma14247704

APA StyleDziuba, R., Kucharska, M., Madej-Kiełbik, L., Sulak, K., & Wiśniewska-Wrona, M. (2021). Biopolymers and Biomaterials for Special Applications within the Context of the Circular Economy. Materials, 14(24), 7704. https://doi.org/10.3390/ma14247704