Structural and Tribological Assessment of Biomedical 316 Stainless Steel Subjected to Pulsed-Plasma Surface Modification: Comparison of LPBF 3D Printing and Conventional Fabrication

Abstract

:1. Introduction

2. Materials and Methods

3. Results

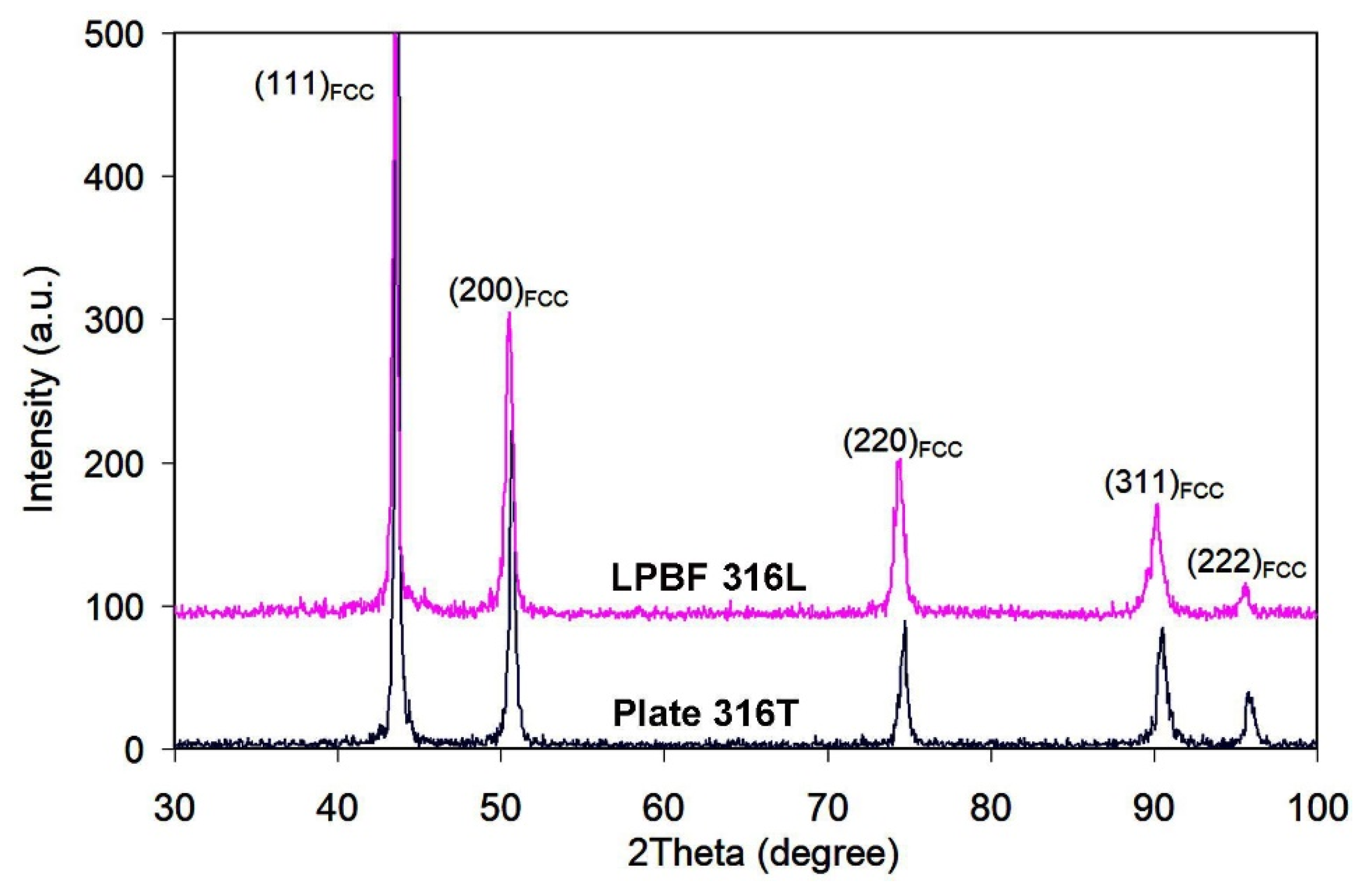

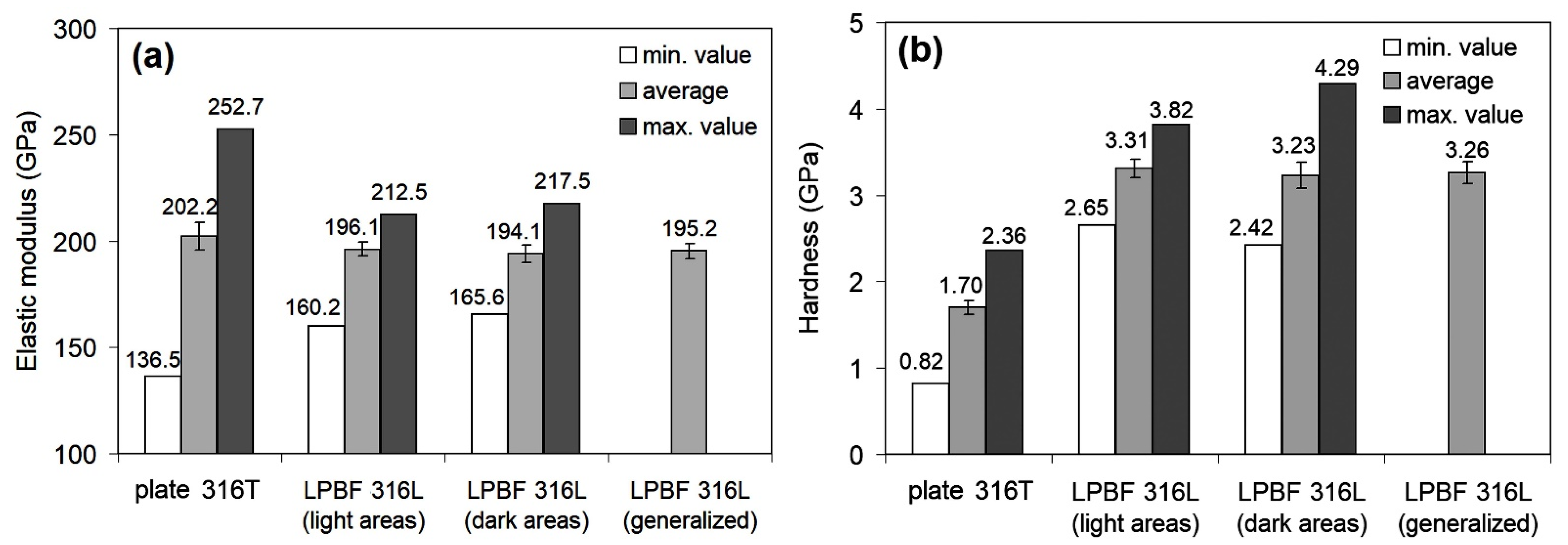

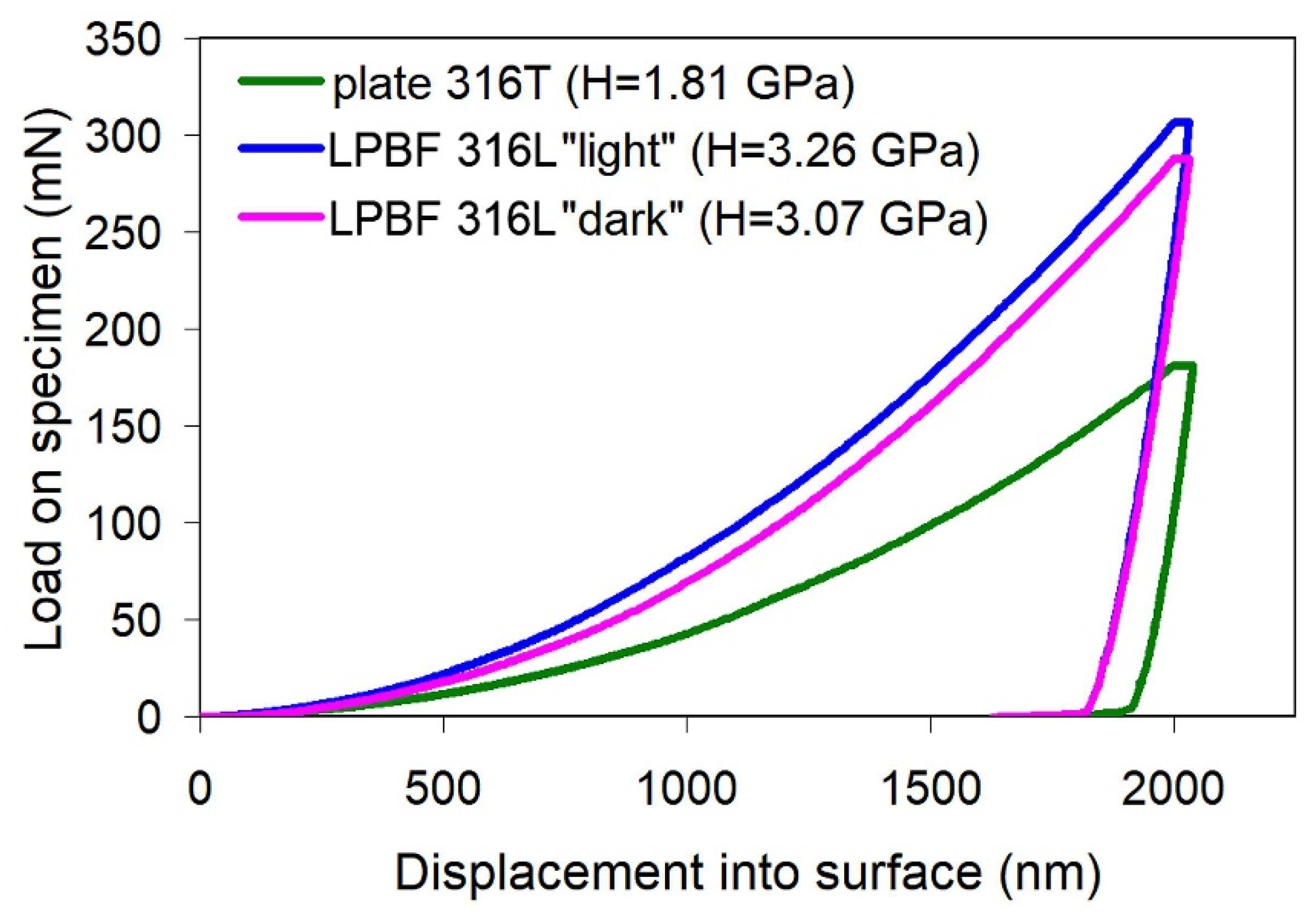

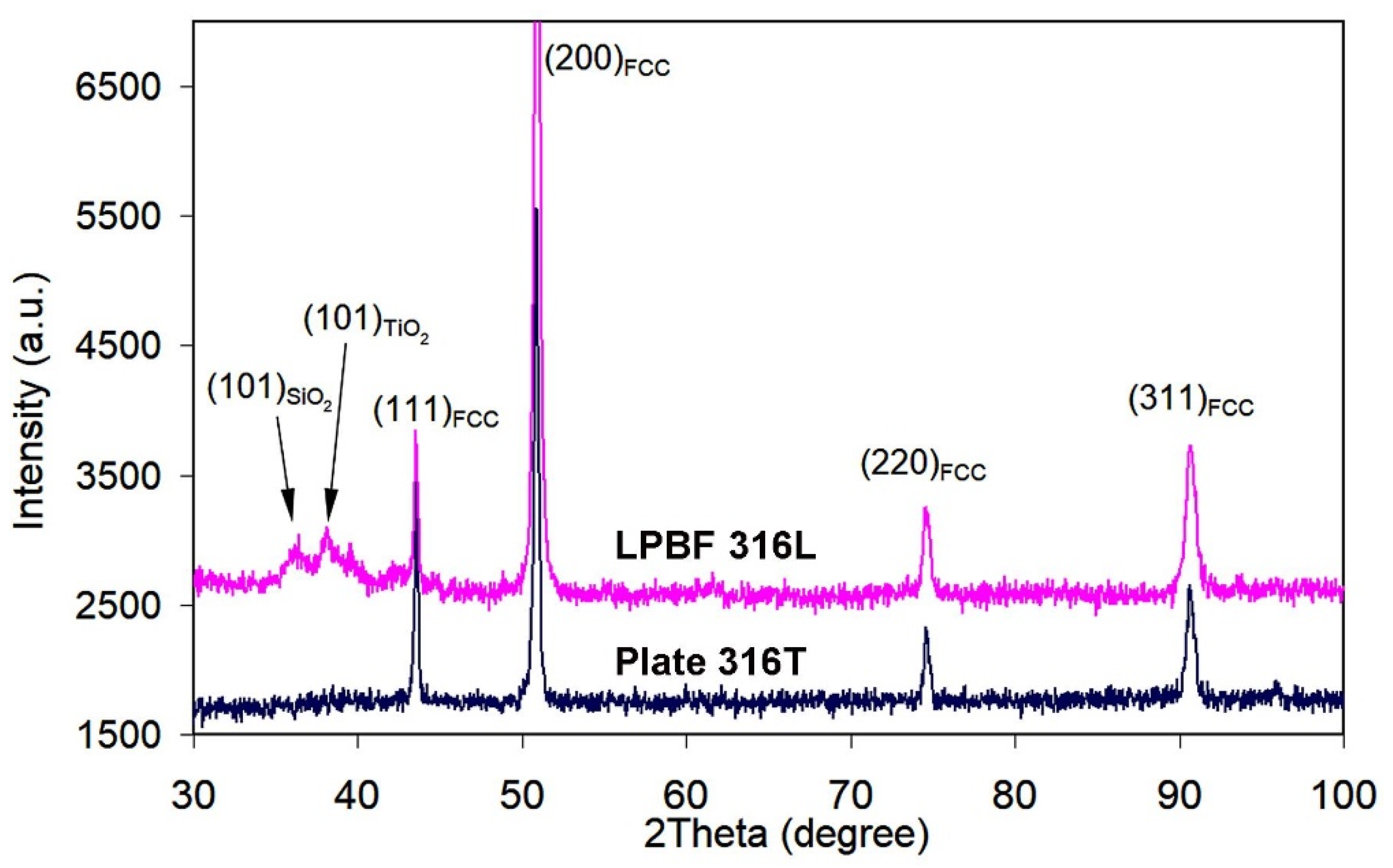

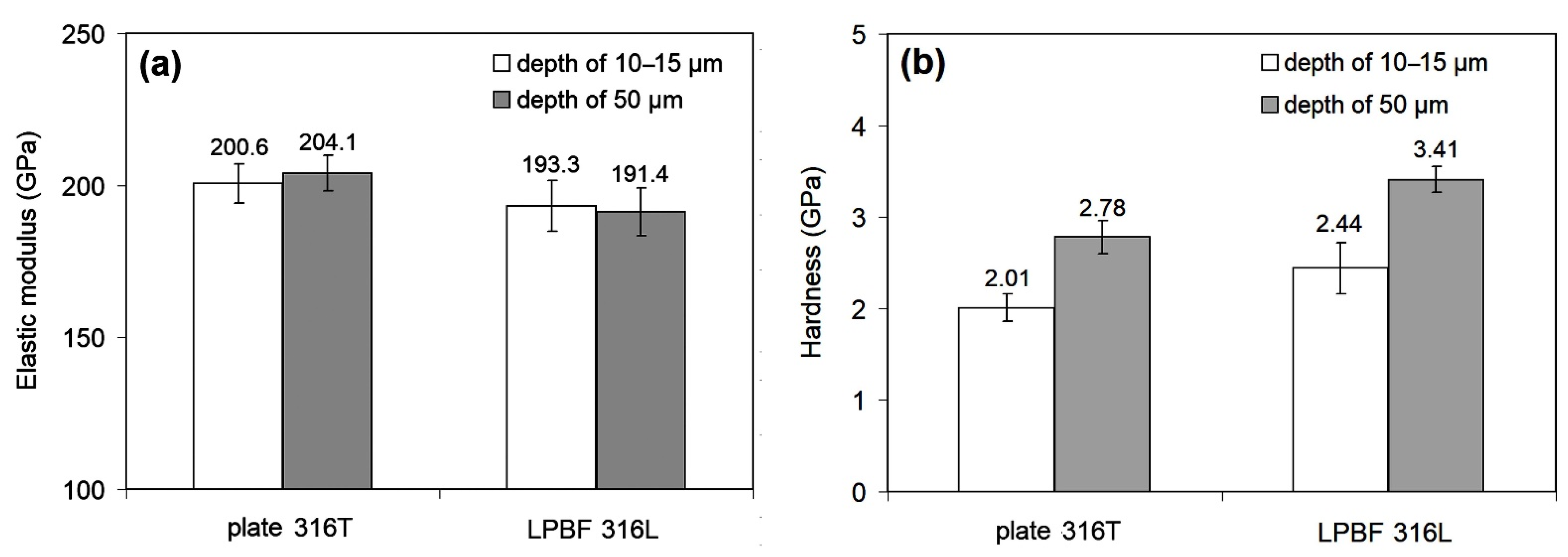

3.1. As-Received Microstructure and Nanoindentation Response

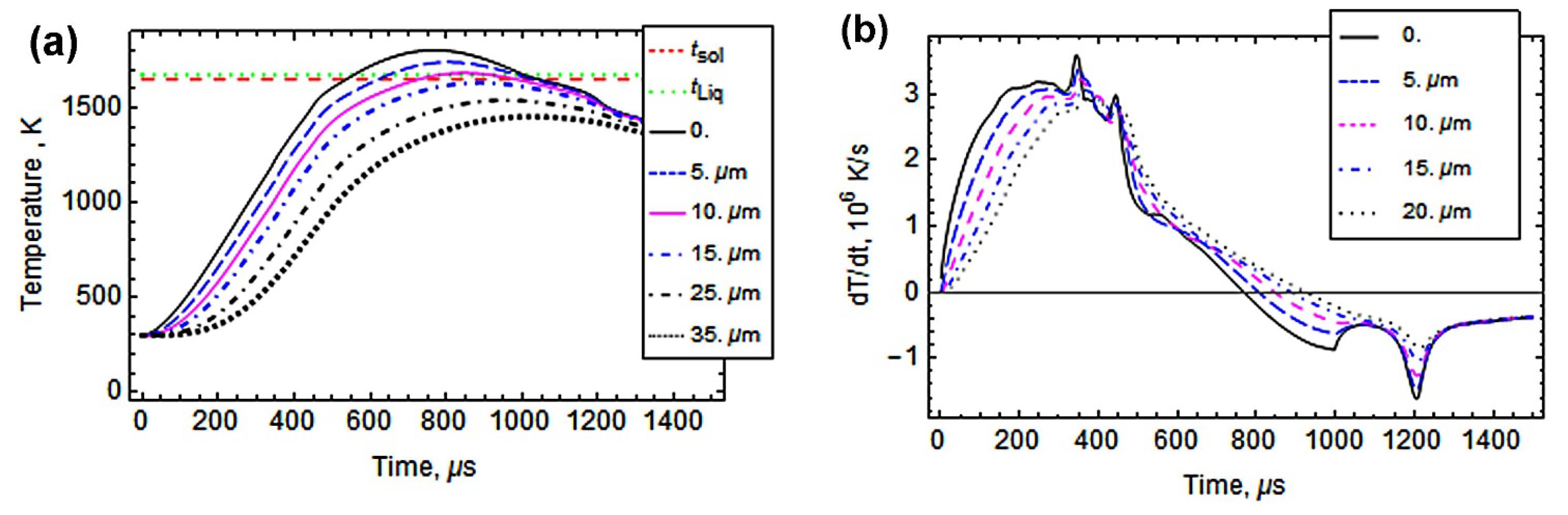

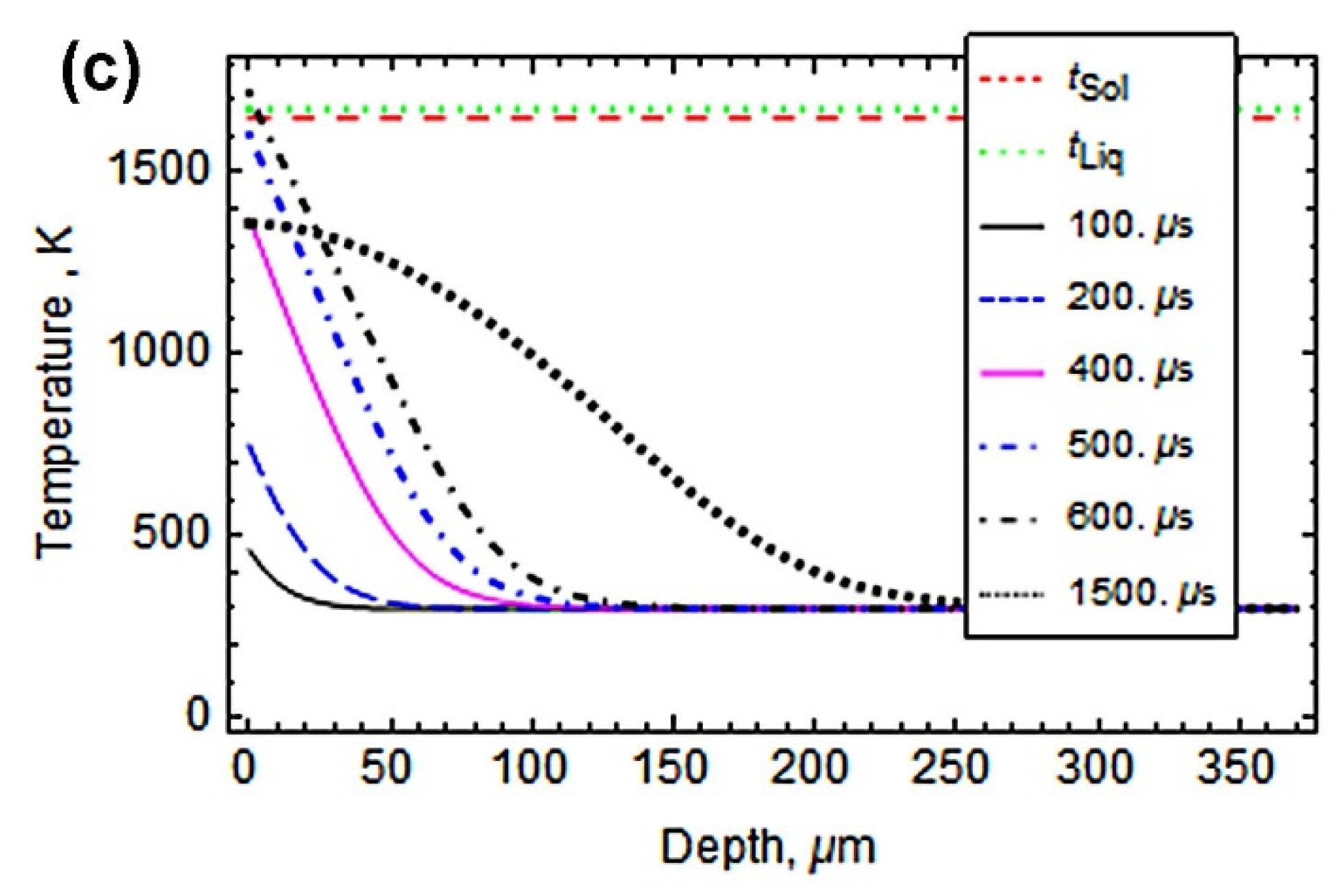

3.2. Plasma Heating Simulation

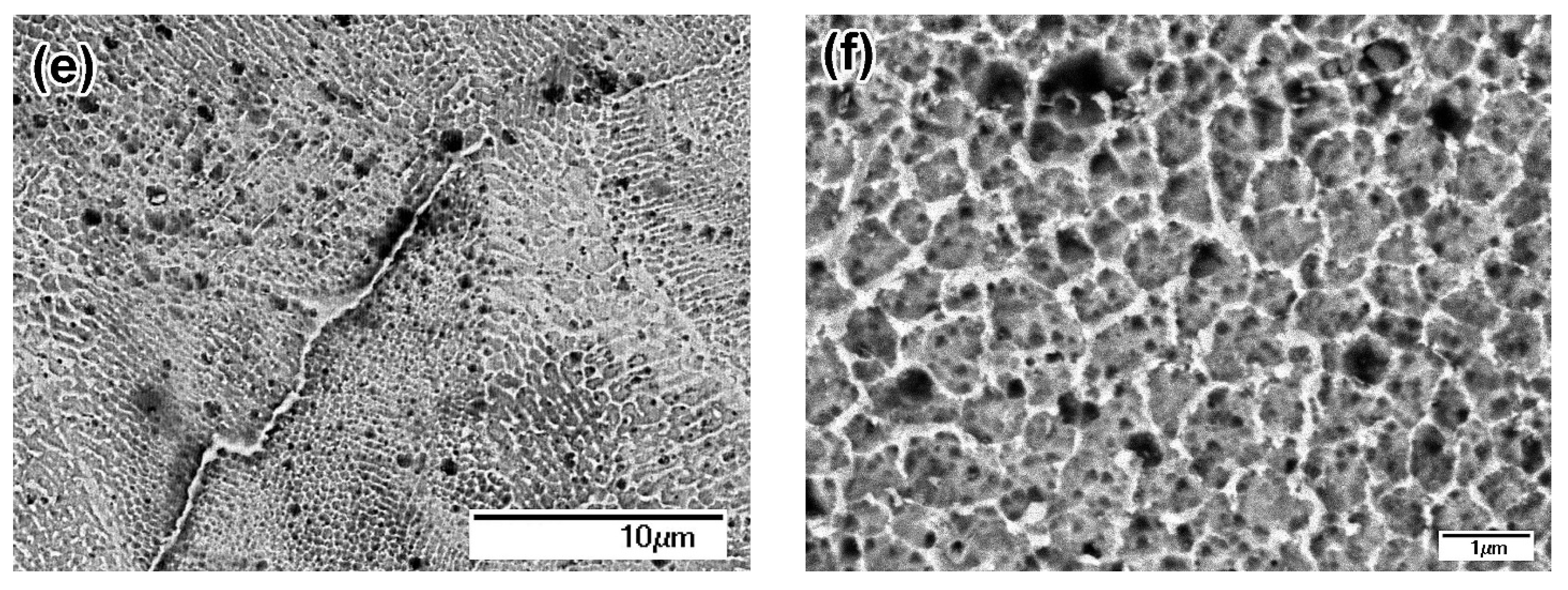

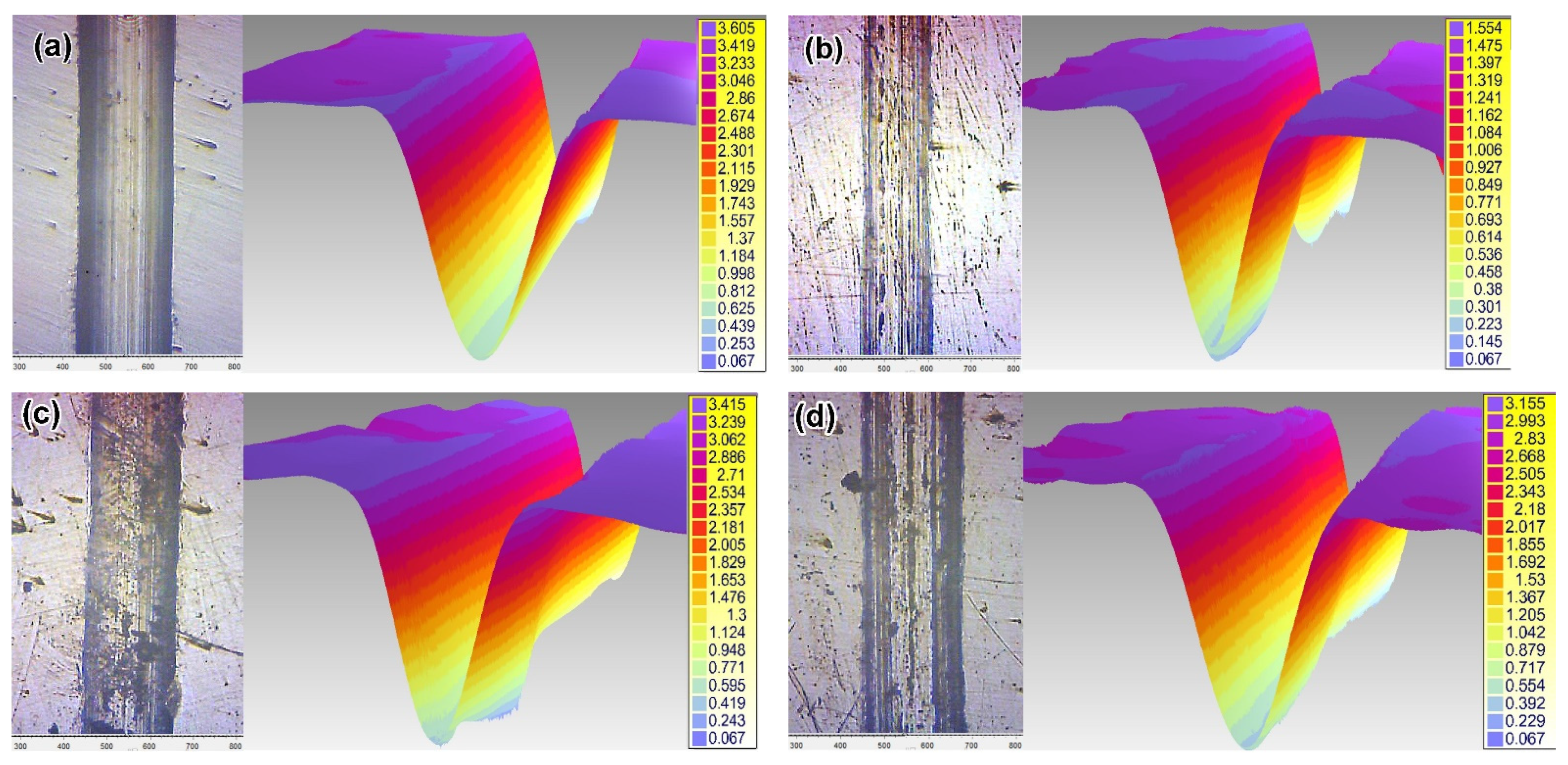

3.3. Microstructure and Properties after Pulsed-Plasma Treatment

4. Discussion

5. Conclusions

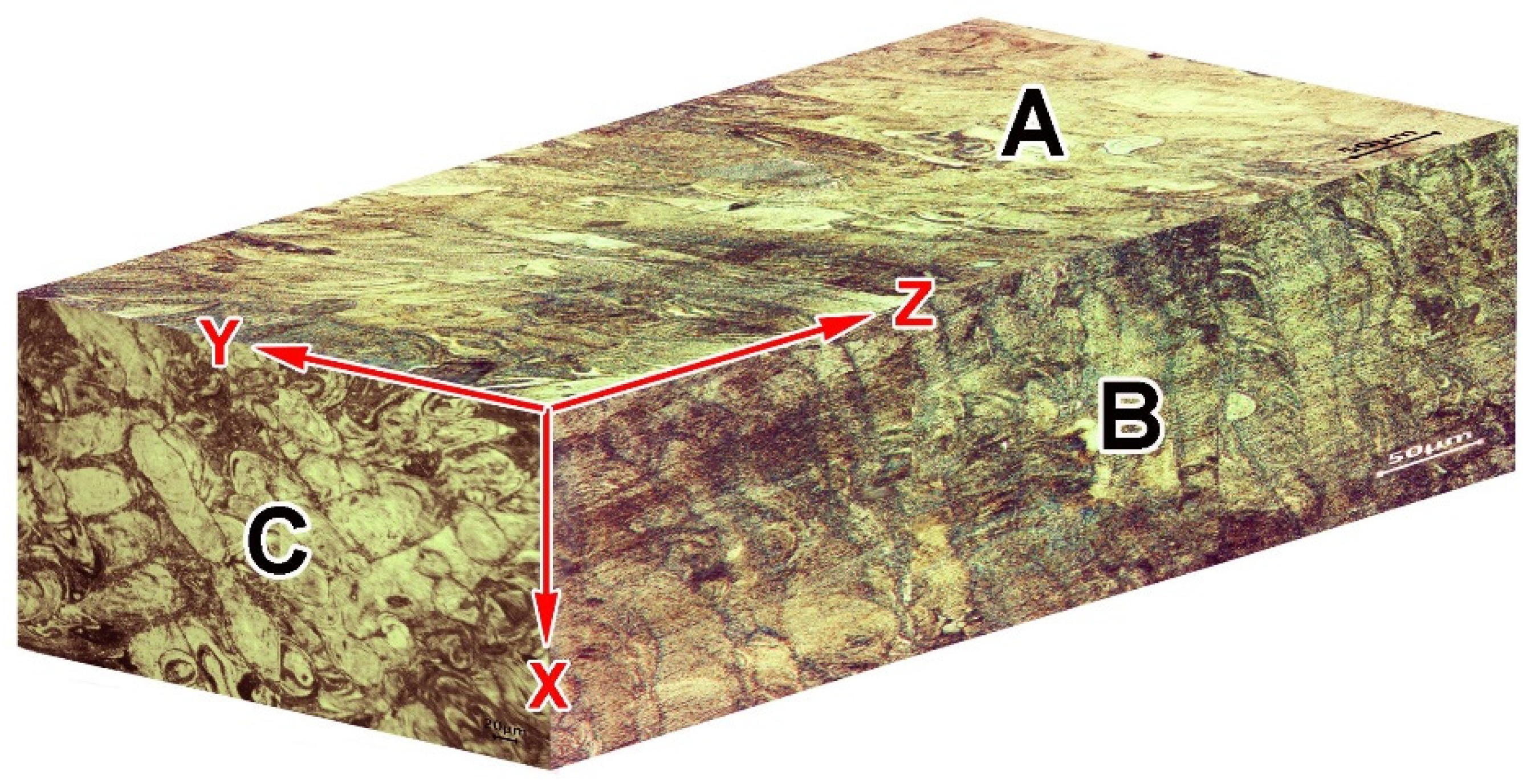

- LPBF-printed 316L steel features an inhomogeneous etched austenitic structure, presenting “fish-scale” or “drop-like” patterns depending on the observation plane. Additionally, the LPBF-printed 316L structure includes TiC carbides, Ti-based oxides, silicates and pores. LPBF 316L steel has almost the same elastic modulus and nearly double the hardness (mostly attributed to its fine structure and residual stresses), as compared with rolled 316T steel.

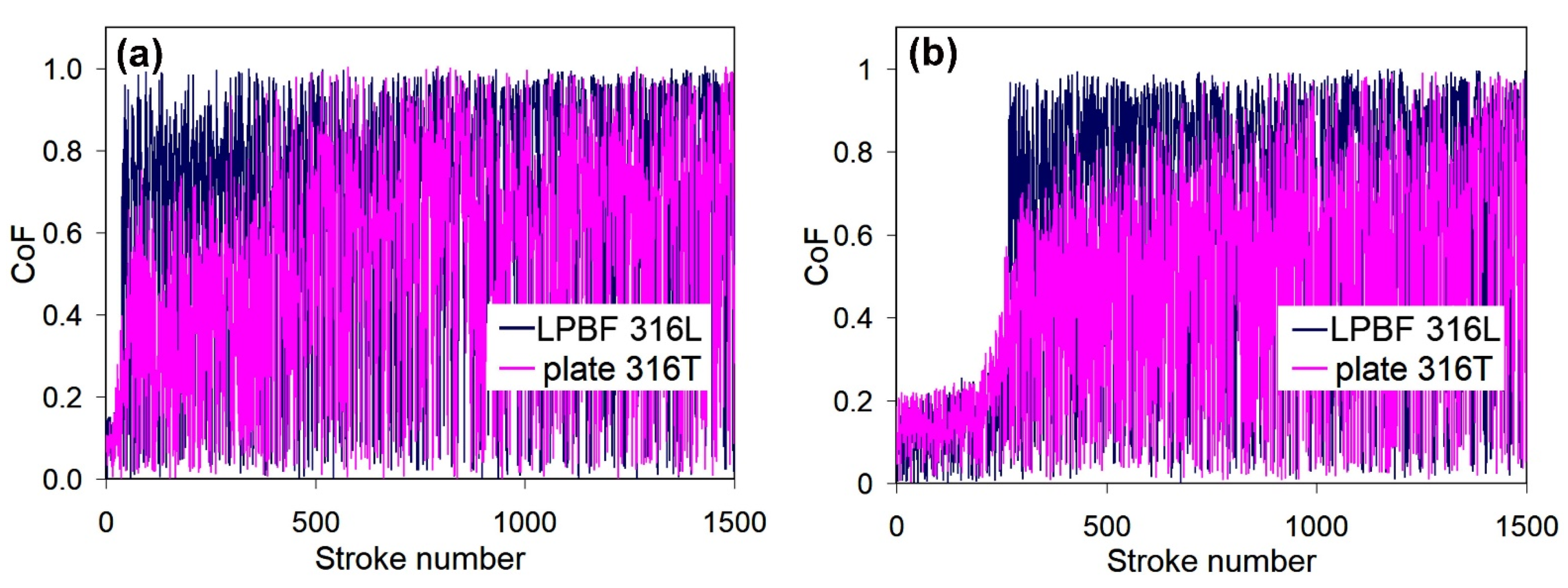

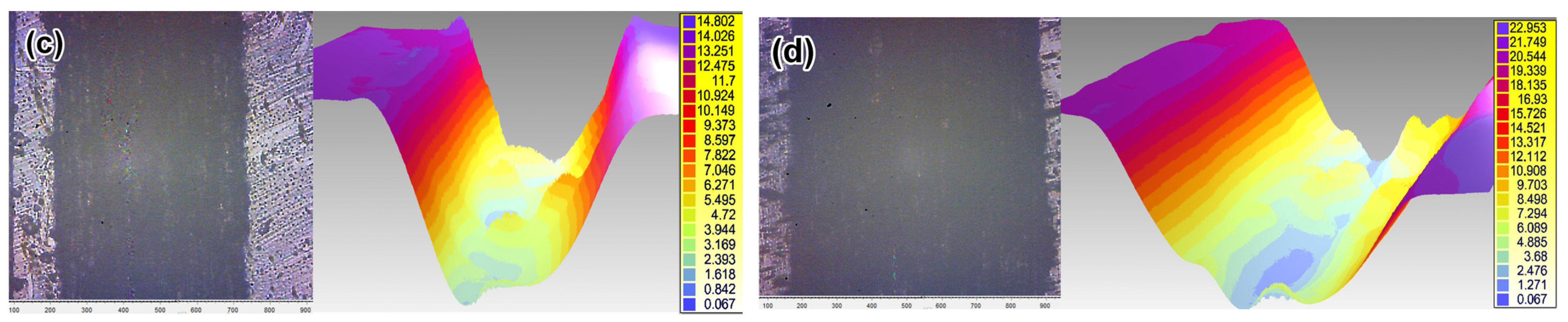

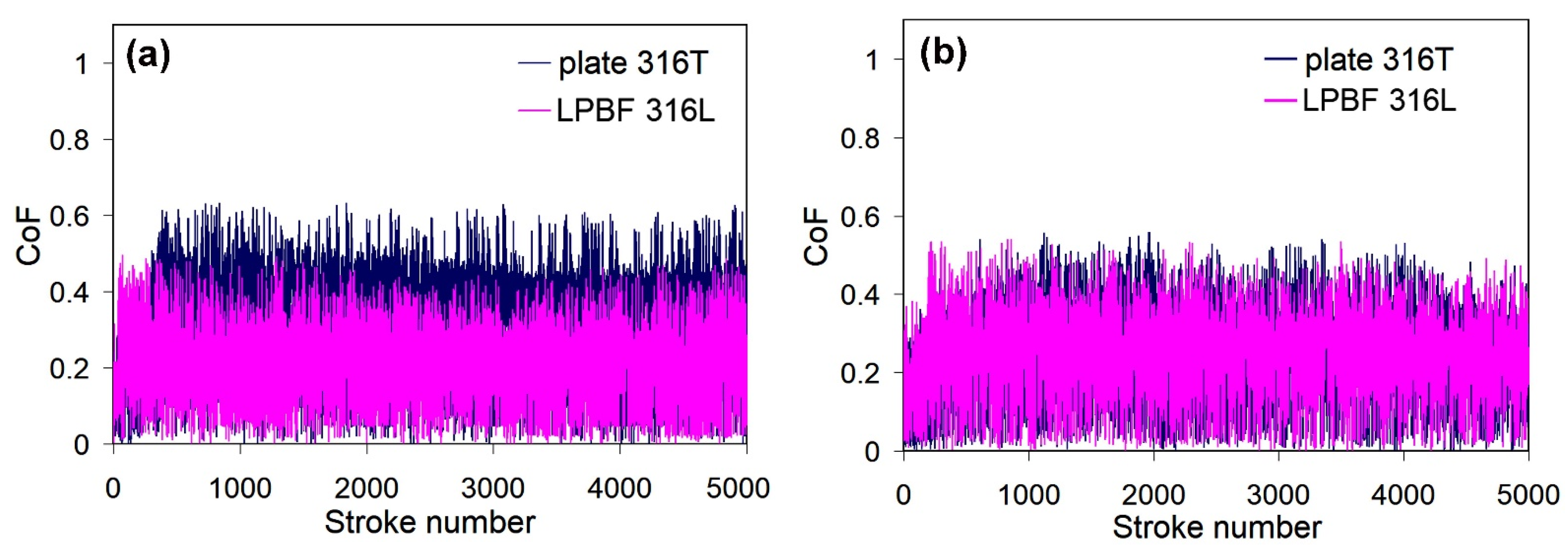

- Under dry sliding, LPBF 316L showed an inferior wear resistance and a slightly higher friction coefficient (CoF), as compared to rolled 316T, which is mainly attributed to the presence of porosity and coarse, non-metallic inclusions in its structure. Sliding in simulated body fluid (SBF) caused a significant decrease in the friction force. Under these conditions, LPBF 316L exhibited lower CoF and three-fold higher wear resistance, as compared to plate 316T, due to a higher hardness and enhanced surface formation of oxide films.

- PPT resulted in modification of the surface layer to a depth of 22–26 μm due to melting at a heating rate of up to 3.6 × 106 K⋅s−1, followed by solidification at a cooling rate of up to 1.6 × 106 K⋅s−1. The modified layer presents a cellular structure with refined cells of 0.3–0.7 μm (cross-section) in diameter, normally oriented to the surface. Plasma modification did not affect the elastic modulus of 316 steel. PPT simultaneously caused an increase in the hardness of the rolled steel, due to the transformation of the polygonal structure to a cellular grain structure. However, PPT did not affect the hardness of the LPBF-printed steel.

- Pulsed-plasma modification moderately improved the dry-sliding wear resistance of both LPBF 316L (due to elimination of porosity during surface melting) and plate 316T (due to an increase in hardness). PPT led to a slight decrease in the CoF of the wrought stainless steel, whereas it did not alter the CoF of the LPBF stainless steel.

- PPT improved the SBF wear resistance of plate 316T and caused a decrease in the CoF of plate 316T. However, PPT decreased the SBF wear resistance of LPBF 316L, although it led to a decrease in the CoF of the LPBF steel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Harun, W.S.W.; Asri, R.I.M.; Romlay, F.R.M.; Sharif, S.; Jan, N.H.M.; Tsumori, F. Surface characterisation and corrosion behaviour of oxide layer for SLMed-316L stainless steel. J. Alloys Compd. 2018, 748, 1044–1052. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, S.; Gu, J.; Xiong, Q.; Duan, C.; Meng, X.; Fang, Y. Microstructure and wear properties of selective laser melting 316L. Mater. Chem. Phys. 2020, 254, 123487. [Google Scholar] [CrossRef]

- Wang, Z.W.; Li, Y.; Zhang, Z.H.; Zhang, S.Z.; Ren, P.; Qiu, J.X.; Wang, W.W.; Bi, Y.J.; He, Y.Y. Friction and wear behavior of duplex-treated AISI 316L steels by rapid plasma nitriding and (CrWAlTiSi)N ceramic coating. Results Phys. 2021, 24, 104132. [Google Scholar] [CrossRef]

- Ko, G.; Kim, W.; Kwon, K.; Lee, T.-K. The corrosion of stainless steel made by additive manufacturing: A review. Metals 2021, 11, 516. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Zeng, X. A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Kong, D.; Ni, X.; Dong, C.; Lei, X.; Zhang, L.G.; Man, C.; Yao, J.; Cheng, X.; Li, X. Bio-functional and anti-corrosive 3D printing 316L stainless steel fabricated by selective laser melting. Mater. Des. 2018, 152, 88–101. [Google Scholar] [CrossRef]

- Zheng, B.; Haley, J.C.; Yang, N.; Yee, J.; Terrassa, K.W.; Zhou, Y.; Lavernia, E.J.; Schoenung, J.M. On the evolution of microstructure and defect control in 316L SS components fabricated via directed energy deposition. Mater. Sci. Eng. A 2019, 764, 138243. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Romero, A.; Chacón, J.M.; Núñez, P.J.; García-Plaza, E.; Rodríguez, G.P. Additive manufacturing of 316L stainless-steel structures using fused filament fabrication technology: Mechanical and geometric properties. Rapid Prototyp. J. 2021, 27, 583–591. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Zhang, Z.; Chu, B.; Wang, L.; Lu, Z. Comprehensive effects of placement orientation and scanning angle on mechanical properties and behavior of 316L stainless steel based on the selective laser melting process. J. Alloys Compd. 2019, 791, 166–175. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Nie, M.; Chen, Y.; Yang, S.; Gao, N. Microstructure and corrosion performance of 316L stainless steel fabricated by Selective Laser Melting and processed through high-pressure torsion. J. Alloys Compd. 2018, 763, 360–375. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Yao, J.; Man, C.; Cheng, X.; Xiao, K.; Li, X. Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes. J. Mater. Sci. Technol. 2019, 35, 1499–1507. [Google Scholar] [CrossRef]

- Salman, O.O.; Gammer, C.; Chaubey, A.K.; Eckert, J.; Scudino, S. Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting. Mater. Sci. Eng. A 2019, 748, 205–212. [Google Scholar] [CrossRef]

- Garthe, K.-U.; Hoyer, K.-P.; Hagen, L.; Tillmann, W.; Schaper, M. Correlation between pre-and post-treatments of additively manufactured 316L parts and the resulting low cycle fatigue behavior. Rapid Prototyp. J. 2021. [Google Scholar] [CrossRef]

- Wiberg, A.; Persson, J.; Ölvander, J. An optimisation frame work for designs for additive manufacturing combining design, manufacturing and post-processing. Rapid Prototyp. J. 2021, 27, 90–105. [Google Scholar] [CrossRef]

- Sun, Y.; Haruman, E. Tribocorrosion behaviour of low temperature plasma carburised 316L stainless steel in 0.5MNaCl solution. Corros. Sci. 2011, 53, 4131–4140. [Google Scholar] [CrossRef]

- Zambrano, O.A.; Aguilar, Y.; Valdés, J.; Rodríguez, S.A.; Coronado, J.J. Effect of normal load on abrasive wear resistance and wear micromechanisms in FeMnAlC alloy and other austenitic steels. Wear 2016, 348–349, 61–68. [Google Scholar] [CrossRef]

- Li, M.H.; Yin, T.Y.; Wang, Y.Z.; Du, F.F.; Zou, X.Z.; Gregersen, H.; Wang, G.X. Study of biocompatibility of medical grade high nitrogen nickel-free austenitic stainless steel in vitro. Mater. Sci. Eng. C 2014, 43, 641–648. [Google Scholar] [CrossRef] [PubMed]

- Pertile, L.B.; Silva, P.M.S.; Peccin, V.B.; Peres, R.; Silveira, P.G.; Giacomelli, C.; Giacomelli, F.C.; Fredel, M.C.; Spinelli, A. In vivo human electrochemical properties of a NiTi-based alloy (Nitinol) used for minimally invasive implants. J. Biomed. Mater. Res. A 2009, 89a, 1072–1078. [Google Scholar] [CrossRef]

- Aliofkhazraei, M.; Taheri, P.; Rouhaghdam, A.S.; Dehghanian, C. Systematic study of nanocrystalline plasma electrolytic nitro carburising of 316L austenitic stainless steel for corrosion protection. J. Mater. Sci. Technol. 2007, 23, 665–671. [Google Scholar]

- Mechnik, V.A.; Bondarenko, N.A.; Kolodnitskyi, V.M.; Zakiev, V.I.; Zakiev, I.M.; Ignatovich, S.R.; Dub, S.N.; Kuzin, N.O. Formation of Fe-Cu-Ni-Sn-VN nanocrystalline matrix by vacuum hot pressing for diamond-containing composite. Mechanical and tribological properties. J. Superhard Mater. 2019, 41, 388–401. [Google Scholar] [CrossRef]

- Mashovets, N.S.; Pastukh, I.M.; Voloshko, S.M. Aspects of the practical application of titanium alloys after low temperature nitriding glow discharge in hydrogen-free-gas media. Appl. Surf. Sci. 2017, 392, 356–361. [Google Scholar] [CrossRef]

- Khyzhnyak, V.G.; Loskutova, T.V.; Kalashnikov, T.Y.; Mykolaychuk, O.I. Producing multilayer coatings from the gas phase with the participation of TiC and TiN compounds on the hard alloy VK8. J. Superhard Mater. 2018, 40, 170–178. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.L.; Baykara, M.Z.; Martini, A. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear—A review. Tribol. Int. 2021, 155, 106792. [Google Scholar] [CrossRef]

- Duriagina, Z.; Kulyk, V.; Kovbasiuk, T.; Vasyliv, B.; Kostryzhev, A. Synthesis of functional surface layers on stainless steels by laser alloying. Metals 2021, 11, 434. [Google Scholar] [CrossRef]

- Tepla, T.L.; Izonin, I.V.; Duriagina, Z.A.; Tkachenko, R.O.; Trostianchyn, A.M.; Lemishka, I.A.; Kulyk, V.V.; Kovbasyuk, T. Alloys selection based on the supervised learning technique for design of biocompatible medical materials. Arch. Mater. Sci. Eng. 2018, 93, 32–40. [Google Scholar] [CrossRef] [Green Version]

- García-León, R.A.; Martínez-Trinidad, J.; Campos-Silva, I.; Figueroa-López, U.; Guevara-Morales, A. Wear maps of borided AISI 316L steel under ball-on-flat dry sliding conditions. Mater. Lett. 2021, 282, 128842. [Google Scholar] [CrossRef]

- Li, B.; Wang, T.; Li, P.; Wang, S.; Wang, L. Selective laser melting of 316L stainless steel: Influence of Co-Cr-Mo-W addition on corrosion resistance. Metals 2021, 11, 597. [Google Scholar] [CrossRef]

- Kovaci, H.; Secer, Y. Improved tribological performance of AISI 316L stainless steel by a combined surface treatment: Surface texturing by selective laser melting and plasma nitriding. Surf. Coat. Technol. 2020, 400, 126178. [Google Scholar] [CrossRef]

- Aliofkhazraei, M.; Sabour Rouhaghdam, A.; Heydarzadeh, A. Strong relation between corrosion resistance and nanostructure of compound layer of treated 316 austenitic stainless steel. Mater. Charact. 2009, 60, 83–89. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Shimizu, K.; Pastukhova, T.V.; Chabak, Y.G.; Kusumoto, K.; Efremenko, A.V. Effect of bulk heat treatment and plasma surface hardening on the microstructure and erosion wear resistance of complex-alloyed cast irons with spheroidal vanadium carbides. J. Frict. Wear 2017, 38, 58–64. [Google Scholar] [CrossRef]

- Bratushka, S.N.; Tyurin, Y.; Kolisnichenko, O.V.; Mikhalev, A.D.; Tkachenko, R.Y.; Makhmudov, N.A.; Pshik, A.V.; Denisenko, R.; Yakushchenko, I.V. Structure and tribological characteristics of steel under melting by plasma flow and simultaneous Mo and W alloying. J. Frict. Wear 2012, 33, 22–33. [Google Scholar] [CrossRef]

- Chabak, Y.G.; Fedun, V.I.; Shimizu, K.; Efremenko, V.G.; Zurnadzhy, V.I. Phase-structural composition of coating obtained by pulsed plasma treatment using eroded cathode of T1 high speed steel. Probl. At. Sci. Technol. 2016, 4, 100–106. [Google Scholar]

- Yu, J.; Zhou, H.; Zhang, L.; Lu, L.; Lu, D. Microstructure and properties of modified layer on the 65Mn steel surface by pulse detonation-plasma technology. J. Mater. Eng. Perform. 2021. [Google Scholar] [CrossRef]

- Chabak, Y.G.; Pastukhova, T.V.; Efremenko, V.G.; Zurnadzhy, V.I.; Fedun, V.I.; Tsvetkova, E.V.; Dzherenova, A.V. Pulsedplasma surface modification of grey cast iron. J. Phys. Stud. 2020, 24, 2501. [Google Scholar] [CrossRef]

- Luo, J.; Chen, Y.; Xu, J.; Lu, D. Effect of plasma-pulses detonation treatment on microstructure and properties of the Ti-6Al-4V surface. Surf. Coat. Technol. 2019, 366, 164–169. [Google Scholar] [CrossRef]

- Chabak, Y.G.; Fedun, V.I.; Efremenko, V.G.; Pastukhova, T.V.; Efremenko, B.V. Plasma coating formation by the deposition of cathode material eroded through high-current pulsed discharge. Probl. At. Sci. Technol. 2019, 123, 167–174. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Chabak, Y.G.; Fedun, V.I.; Shimizu, K.; Pastukhova, T.V.; Petryshynets, I.; Zusin, A.M.; Kudinova, E.V.; Efremenko, B.V. Formation mechanism, microstructural features and dry-sliding behaviour of “Bronze/WC carbide” composite synthesised by atmospheric pulsed-plasma deposition. Vacuum 2021, 185, 110031. [Google Scholar] [CrossRef]

- Chabak, Y.G.; Efremenko, V.G.; Shimizu, K.; Lekatou, A.; Pastukhova, T.V.; Azarkhov, A.Y.; Zurnadzhy, V.I. Comparative analysis of the microstructural features of28wt.%Cr cast iron fabricated by pulsed plasma deposition and conventional casting. J. Mater. Eng. Perform. 2018, 27, 379–388. [Google Scholar] [CrossRef]

- Upadhyay, R.K.; Kumar, A. Scratch and wear resistance of additive manufactured 316L stainless steel sample fabricated by laser powder bed fusion technique. Wear 2020, 458–459, 203437. [Google Scholar] [CrossRef]

- Zhu, Y.; Zou, J.; Chen, X.; Yang, H. Tribology of selective laser melting processed parts: Stainless steel 316L under lubricated conditions. Wear 2016, 350–351, 46–55. [Google Scholar]

- Alvi, S.; Saeidi, K.; Akhtar, F. High temperature tribology and wear of selective laser melted (SLM) 316L stainless steel. Wear 2020, 448–449, 203228. [Google Scholar] [CrossRef]

- Bahshwan, M.; Myant, C.W.; Reddyhoff, T.; Pham, M.S. The role of microstructure on wear mechanisms and anisotropy of additively manufactured 316L stainless steel in dry sliding. Mater. Des. 2020, 196, 109076. [Google Scholar] [CrossRef]

- Kolyada, Y.E.; Fedun, V.I. Pulse electrothermal plasma accelerators and its application in scientific researches. Probl. At. Sci. Technol. 2015, 4, 325–330. [Google Scholar]

- Koljada, Y.E.; Fedun, V.I. Excitation of elastic pulses by powerful plasmoids in the acoustic waveguide. Probl. At. Sci. Technol. 2008, 4, 260–263. [Google Scholar]

- Kokubo, T.; Kushitani, H.; Sakka, S.; Kitsugi, T.; Yamamuro, T. Solutions able to reproduce in vivo surface-structure changes in bioactive glass-ceramic A-W. J. Biomed. Mater. Res. 1990, 24, 721–734. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wang, H.; Wu, Y.; Wang, H. Predicting the printability in selective laser melting with a supervised machine learningmethod. Materials 2020, 13, 5063. [Google Scholar] [CrossRef]

- Pichler, P.; Simonds, B.J.; Sowards, J.W.; Pottlacher, G. Measurements of thermophysical properties of solid and liquid NISTSRM 316L stainless steel. J. Mater. Sci. 2020, 55, 4081–4093. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mills, K.C.; Su, Y.; Li, Z.; Brooks, R.F. Equations for the calculation of the thermo-physical properties of stainless steel. ISIJ Int. 2004, 44, 1661–1668. [Google Scholar] [CrossRef] [Green Version]

- Wilthan, B.; Reschab, H.; Tanzer, R.; Schuetzenhoefer, W.; Pottlacher, G. Thermophysical properties of a chromium–nickel–molybdenum steel in the solid and liquid phases. Int. J. Thermophys. 2008, 29, 434–444. [Google Scholar] [CrossRef]

- Birnbaum, A.J.; Steuben, J.C.; Barrick, E.J.; Iliopoulos, A.P.; Michopoulos, J.G. Intrinsic strain aging, Σ3 boundaries, and origins of cellular substructure in additively manufactured 316L. Addit. Manuf. 2019, 29, 100784. [Google Scholar] [CrossRef]

- Sukhova, E.V. The effect of carbon content and cooling rate on the structure of boron-rich Fe–B–C alloys. Phys. Chem. Solid State 2020, 21, 355–360. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Bertoli, U.S.; MacDonald, B.E.; Schoenung, J.M. Stability of cellular microstructure in laser powder bed fusion of 316L stainless steel. Mater. Sci. Eng. A 2019, 739, 109–117. [Google Scholar] [CrossRef]

- Hlaváč, J. Melting temperatures of refractory oxides: PartI. Pure Appl. Chem. 1982, 54, 682–688. [Google Scholar] [CrossRef] [Green Version]

- Buketov, A.; Sapronov, O.; Brailo, M.; Stukhlyak, D.; Yakushchenko, S.; Buketova, N.; Sapronova, A.; Sotsenko, V. The use of complex additives for the formation of corrosion-and wear-resistant epoxy composites. Adv. Mater. Sci. Eng. 2019, 2019, 8183761. [Google Scholar] [CrossRef] [Green Version]

- Malinov, L.S.; Malysheva, I.E.; Klimov, E.S.; Kukhar, V.V.; Balalayeva, E.Y. Effect of particular combinations of quenching, tempering and carburization on abrasive wear of low-carbon manganese steels with metastable austenite. Mater. Sci. Forum 2019, 945, 574–578. [Google Scholar] [CrossRef]

- Ferreira, D.; Almeida, S.; Soares, R.; Juliani, L.; Bracarense, A.; Lins, V.; Junqueira, R. Synergism between mechanical wear and corrosion on tribocorrosion of a titanium alloy in a Ringer solution. J. Mater. Res. Technol. 2018, 8, 1593–1600. [Google Scholar] [CrossRef]

- Efremenko, B.; Belik, A.; Chabak, Y.; Halfa, H. Simulation of structure formation in the Fe–C–Cr–Ni–Si surfacing materials. East. Eur. J. Enterp. Technol. 2018, 2, 33–38. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.; Chen, K.; Xu, Z.; Li, D.Y. Effect of Ti addition on the sliding wear behavior of AlCrFeCoNi high-entropy alloy. Wear 2020, 462–463, 203493. [Google Scholar] [CrossRef]

- Khorasani, M.; Gibson, I.; Ghasemi, A.H.; Brandt, M.; Leary, M. On the role of wet abrasive centrifugal barrel finishing on surface enhancement and material removal rate of LPBF stainless steel 316L. J. Manuf. Process. 2020, 59, 523–534. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Mordyuk, B.N.; Dzhemelinskyi, V.V.; Lamikiz, A.; Prokopenko, G.I. Post-processingoftheInconel718 alloy parts fabricated by selective laser melting: Effects of mechanical surface treatments on surface topography, porosity, hardness and residual stress. Surf. Coat. Technol. 2020, 381, 125136. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Macera, L.; Veniali, F. Post-processing of complex SLM parts by barrel finishing. Appl. Sci. 2020, 10, 1382. [Google Scholar] [CrossRef] [Green Version]

- Ferchow, J.; Baumgartner, H.; Klahn, C.; Meboldt, M. Model of surface roughness and material removal using abrasive flow machining of selective laser melted channels. Rapid Prototyp. J. 2020, 26, 1165–1176. [Google Scholar] [CrossRef]

- Singh, G.; Kumar, H.; Kumar Kansal, H.; Srivastava, A. Effects of chemically assisted magnetic abrasive finishing process parameters on material removal of Inconel 625 tubes. Procedia Manuf. 2020, 48, 466–473. [Google Scholar] [CrossRef]

- KarthickRaaj, R.; Vijay Anirudh, P.; Karunakaran, C.; Kannan, C.; Jahagirdar, A.; Joshi, S.; Balan, A.S.S. Exploring grinding and burnishing as surface post-treatment options for electron beam additive manufactured Alloy 718. Surf. Coat. Technol. 2020, 397, 126063. [Google Scholar] [CrossRef]

- Chuecade Bruijn, A.; Gómez-Gras, G.; Pérez, M.A. On the effect upon the surface finish and mechanical performance of ballburnishing process on fused filament fabricated parts. Addit. Manuf. 2021, 46, 102133. [Google Scholar] [CrossRef]

- Hasib, M.T.; Ostergaard, H.E.; Li, X.; Kruzic, J.J. Fatigue crack growth behavior of laser powder bed fusion additive manufactured Ti-6Al-4V: Roles of post heat treatment and build orientation. Int. J. Fatigue 2021, 142, 105955. [Google Scholar] [CrossRef]

| Process | Equipment | Energy Source | Surface Power Density, Wt⋅m−2 | Working Atmosphere | Working Parameters |

|---|---|---|---|---|---|

| LPBF | ProX DMP 320 | Fiber laser (1070 nm, beam diameter: 0.5 mm) | 25.5 × 108 | Argon (1.5–4.0 bar) | Layer thickness: 30–60μm, printing accuracy: ±50 μm |

| PPT | Electrothermal axial plasma accelerator | Capacitive energy storage | 6 × 108 | Air | Charging voltage: 4.5 kV, pulse duration: 1 ms, distance to the target: 50 mm, pulse number: 1. |

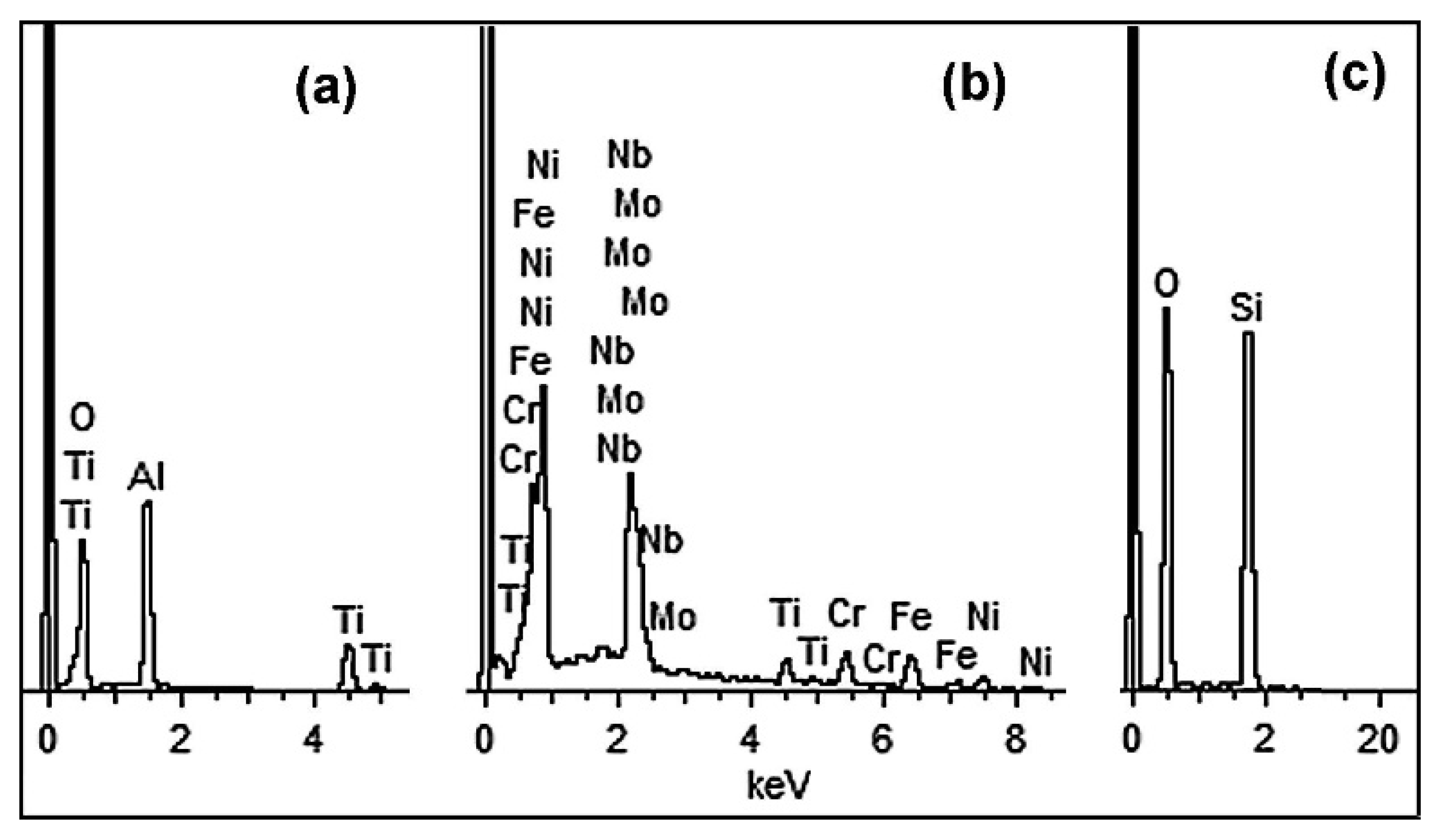

| Phase | O | Si | Ti | Nb | Mo | Al | Cr | Fe | Ni |

|---|---|---|---|---|---|---|---|---|---|

| (Ti,Al)O2 | 38.5 | - | 38.8 | - | - | 22.7 | - | - | - |

| (Nb,Ti,Mo)C | - | - | 5.6 | 21.2 | 7.4 | - | 10.4 | 23.3 | 32.1 |

| SiO2 | 47.0 | 53.0 | - | - | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chabak, Y.; Efremenko, B.; Petryshynets, I.; Efremenko, V.; Lekatou, A.G.; Zurnadzhy, V.; Bogomol, I.; Fedun, V.; Kovaľ, K.; Pastukhova, T. Structural and Tribological Assessment of Biomedical 316 Stainless Steel Subjected to Pulsed-Plasma Surface Modification: Comparison of LPBF 3D Printing and Conventional Fabrication. Materials 2021, 14, 7671. https://doi.org/10.3390/ma14247671

Chabak Y, Efremenko B, Petryshynets I, Efremenko V, Lekatou AG, Zurnadzhy V, Bogomol I, Fedun V, Kovaľ K, Pastukhova T. Structural and Tribological Assessment of Biomedical 316 Stainless Steel Subjected to Pulsed-Plasma Surface Modification: Comparison of LPBF 3D Printing and Conventional Fabrication. Materials. 2021; 14(24):7671. https://doi.org/10.3390/ma14247671

Chicago/Turabian StyleChabak, Yuliia, Bohdan Efremenko, Ivan Petryshynets, Vasily Efremenko, Angeliki G. Lekatou, Vadym Zurnadzhy, Iurii Bogomol, Victor Fedun, Karol Kovaľ, and Tatiana Pastukhova. 2021. "Structural and Tribological Assessment of Biomedical 316 Stainless Steel Subjected to Pulsed-Plasma Surface Modification: Comparison of LPBF 3D Printing and Conventional Fabrication" Materials 14, no. 24: 7671. https://doi.org/10.3390/ma14247671

APA StyleChabak, Y., Efremenko, B., Petryshynets, I., Efremenko, V., Lekatou, A. G., Zurnadzhy, V., Bogomol, I., Fedun, V., Kovaľ, K., & Pastukhova, T. (2021). Structural and Tribological Assessment of Biomedical 316 Stainless Steel Subjected to Pulsed-Plasma Surface Modification: Comparison of LPBF 3D Printing and Conventional Fabrication. Materials, 14(24), 7671. https://doi.org/10.3390/ma14247671