An Efficient Computational Model for Magnetic Pulse Forming of Thin Structures

Abstract

:1. Introduction

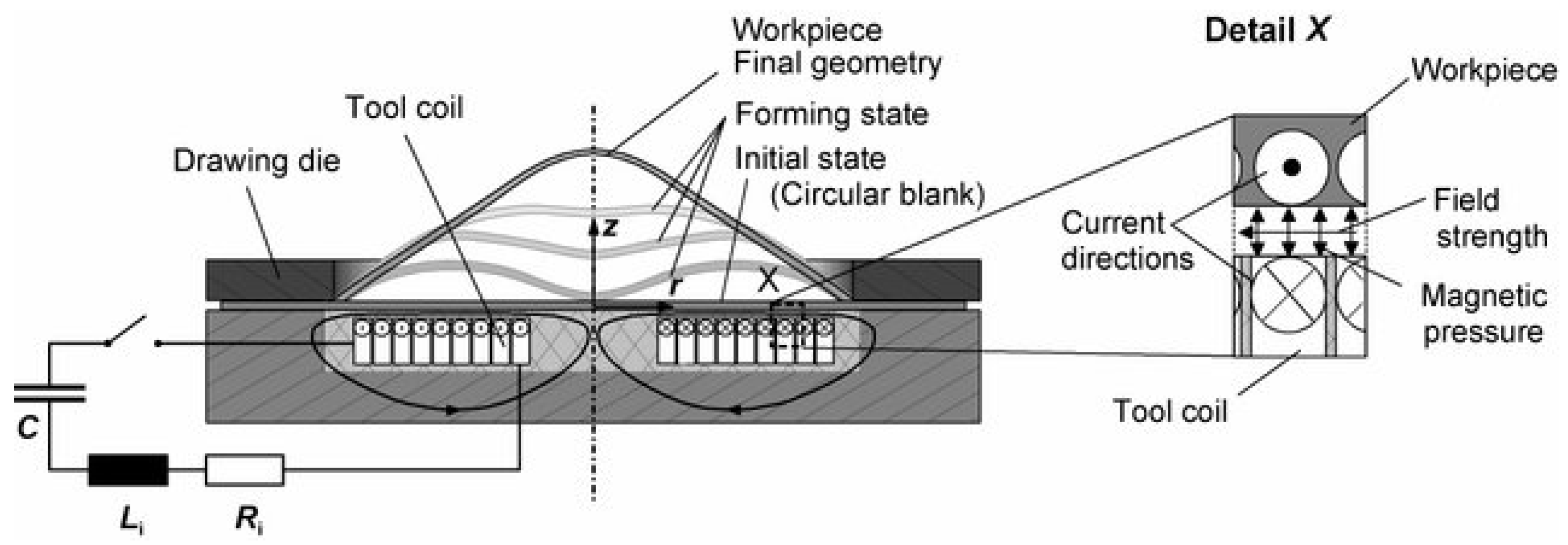

2. Modeling of the Magnetic Pulse Forming Process

2.1. Electromagnetic Model

2.1.1. Maxwell’S Equations and the Potential Formulation

| Electric field intensity | Electric flux intensity |

| Magnetic field intensity | Magnetic flux intensity |

| Electric charge density | Electric current density |

- Equation (1): (Maxwell Faraday) represents the electric induction due to a varying magnetic field.

- Equation (2): (Maxwell Ampere) represents the creation of a magnetic field due to a passing electric current.

- Equation (3): (Maxwell gauss) represents the conservation of electric charge in the material.

- Equation (4): Represents the conservation of the induced magnetic field in the material.

2.1.2. Weak Formulation and Discretization of Electromagnetic Problem

- Space of functions vanishing at the boundary .

- Space of vector functions with square-integrable curl.

- Inner products: The following notation for the inner product of the spaces will allow simplifying the notation for the weak forms.

2.2. Solid Mechanics Model

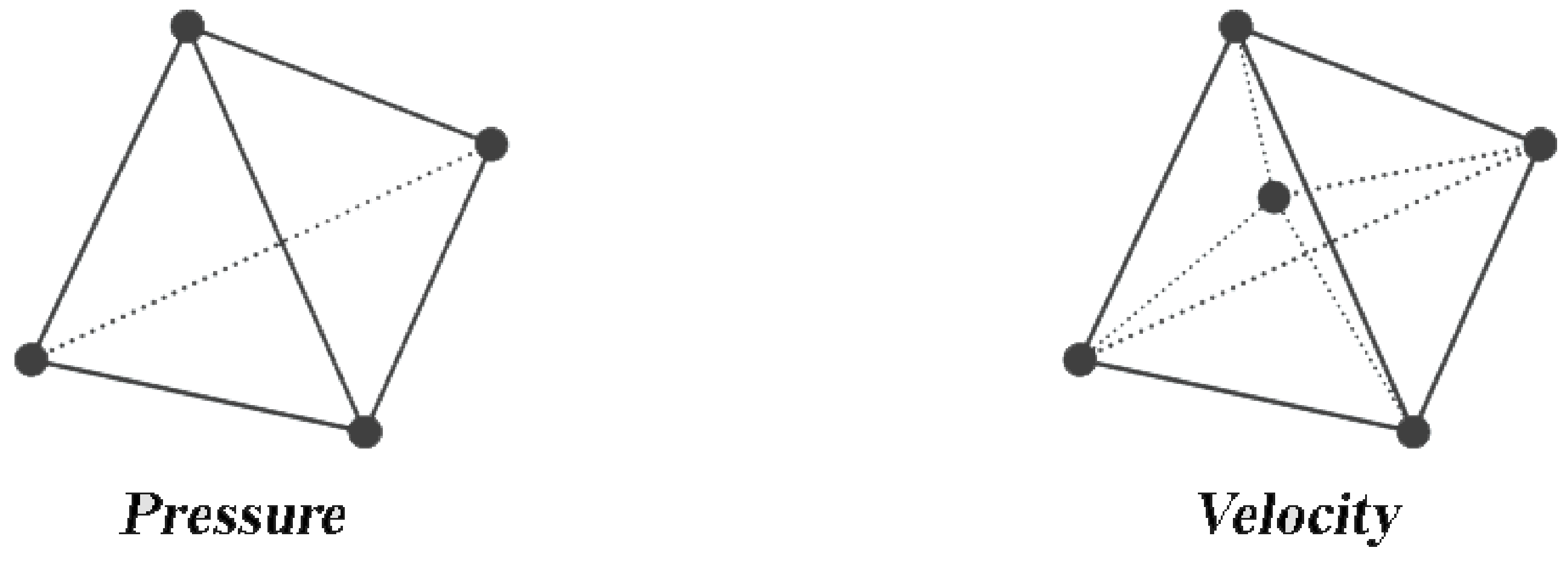

2.2.1. Mini Element Formulation

- : Free surface boundary.

- : Imposed external traction boundary.

- : Imposed external velocity boundary.

- : Contact condition on the boundary with other tools (rigid or deformable).

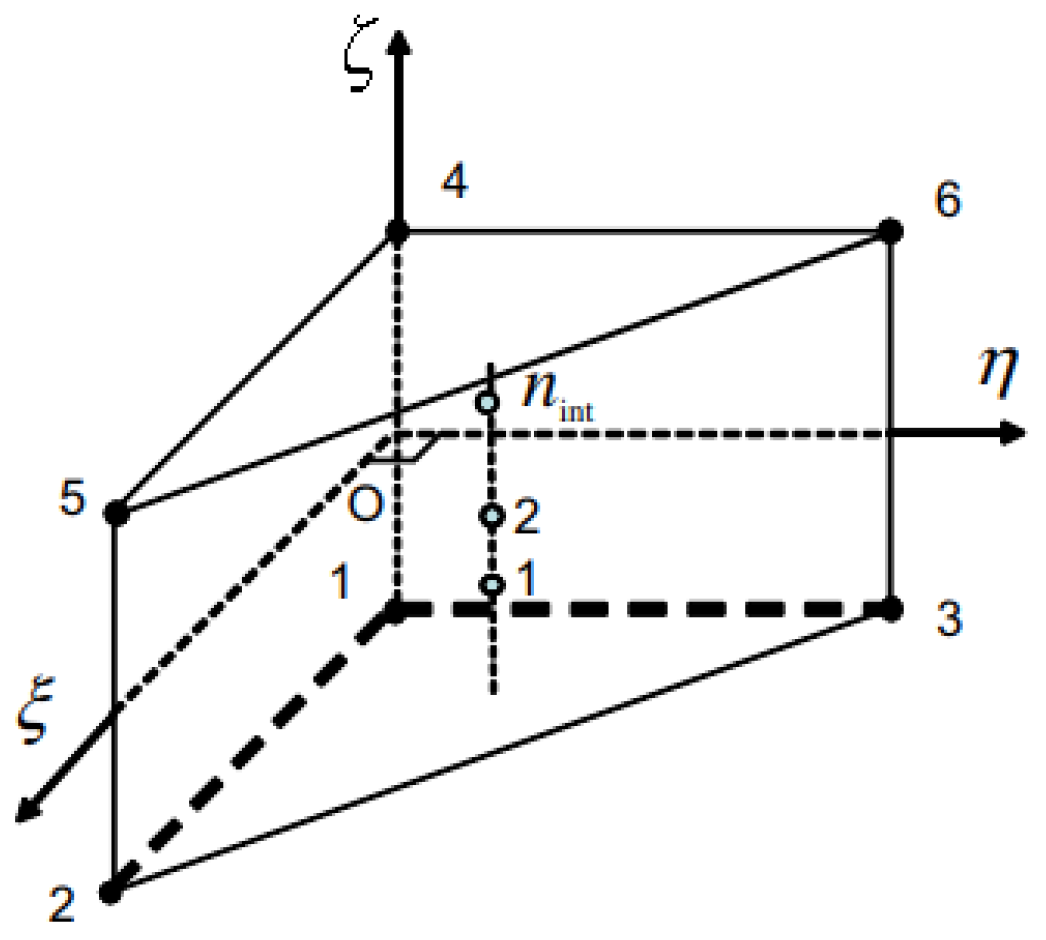

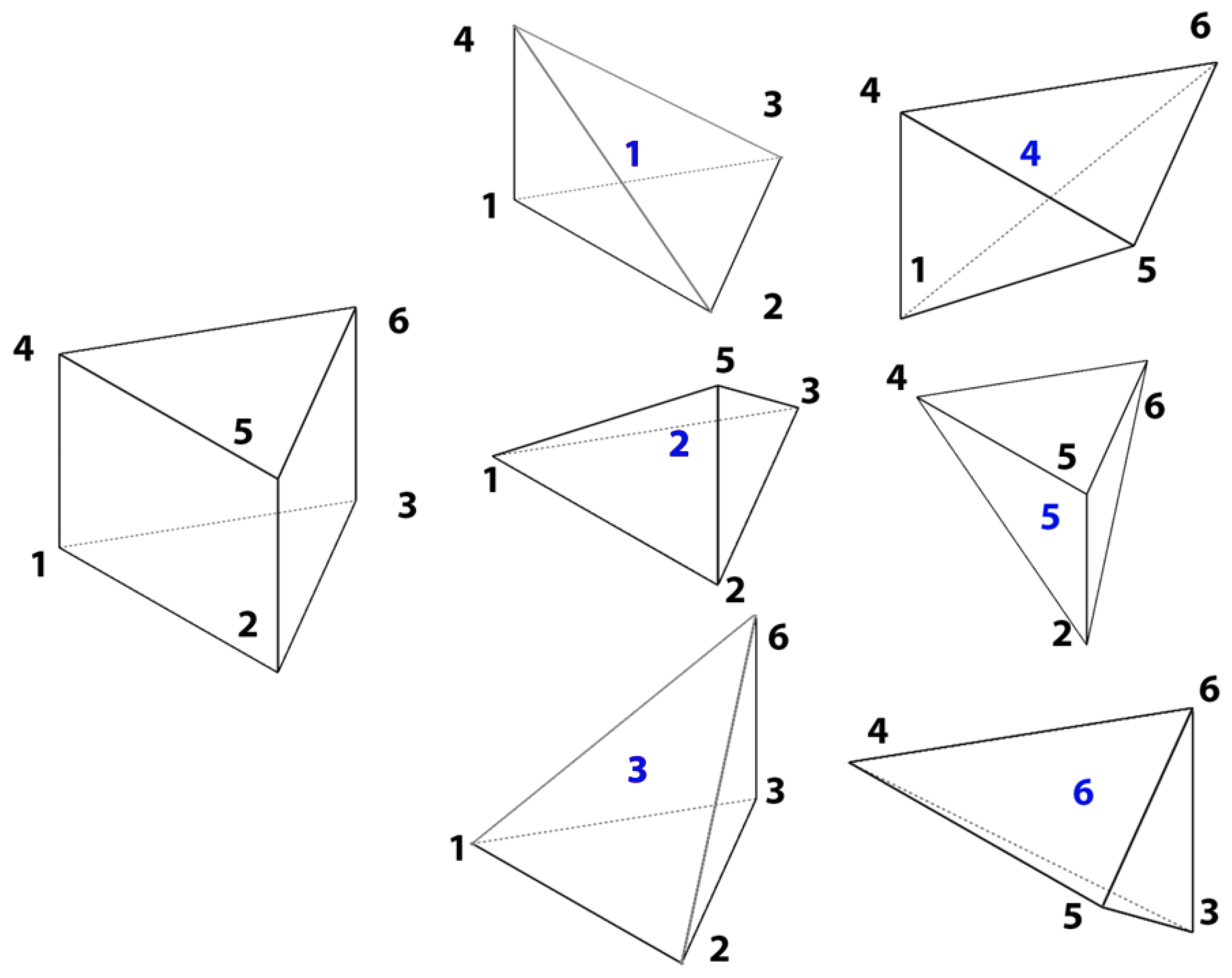

2.2.2. Shb Element Formulation

2.3. Numerical Implementation

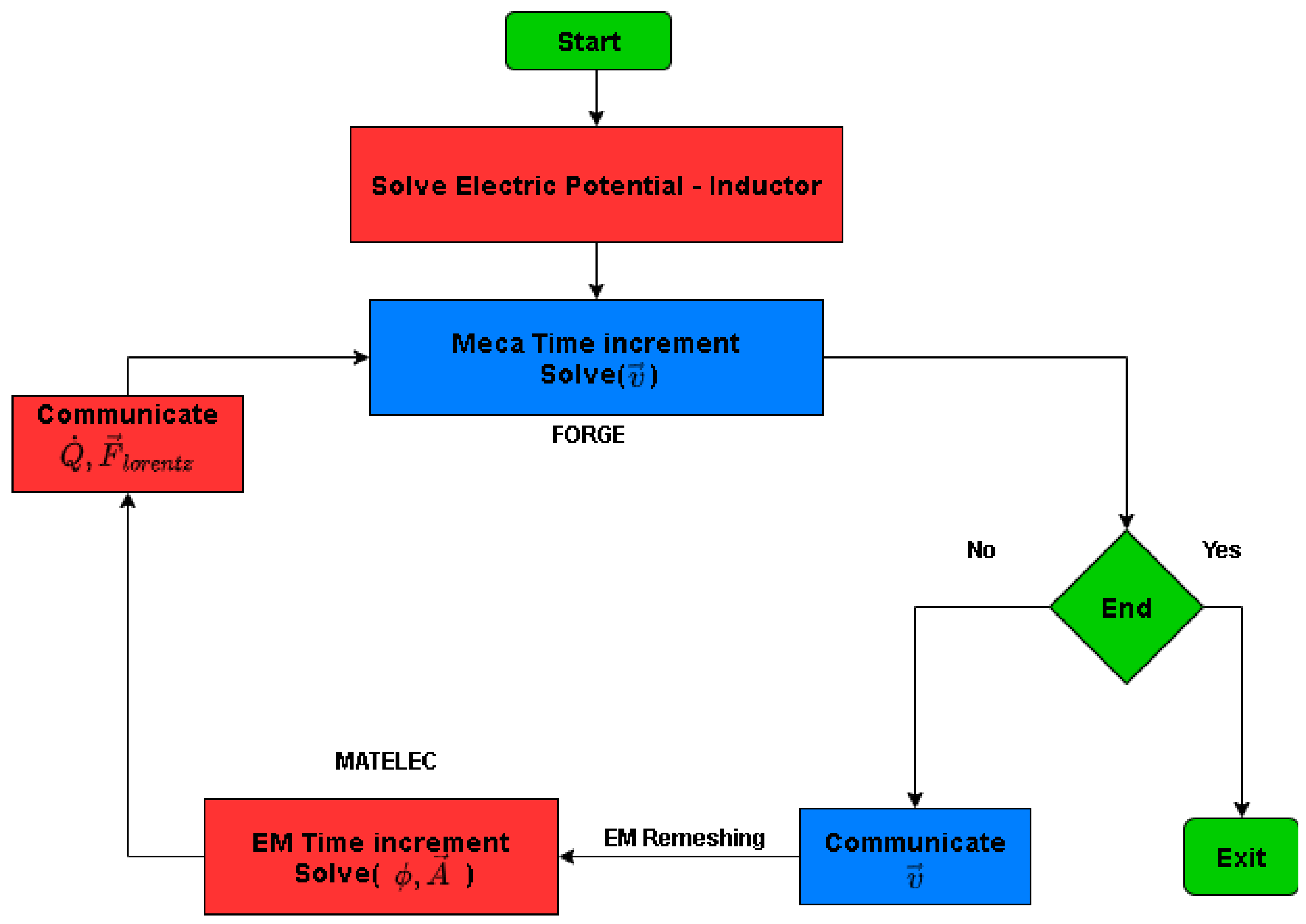

2.3.1. Coupling Algorithm

2.3.2. Shb Element Implementation Algorithm

3. Magnetic Pulse Forming Case Study

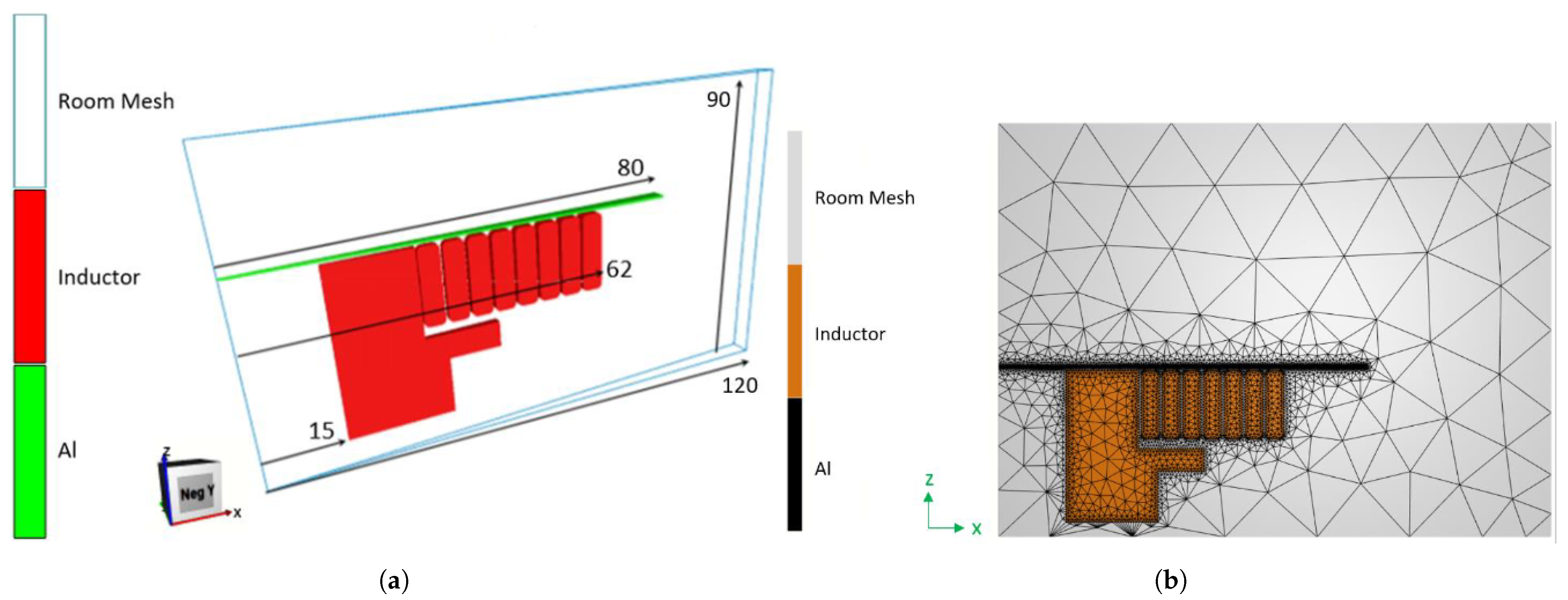

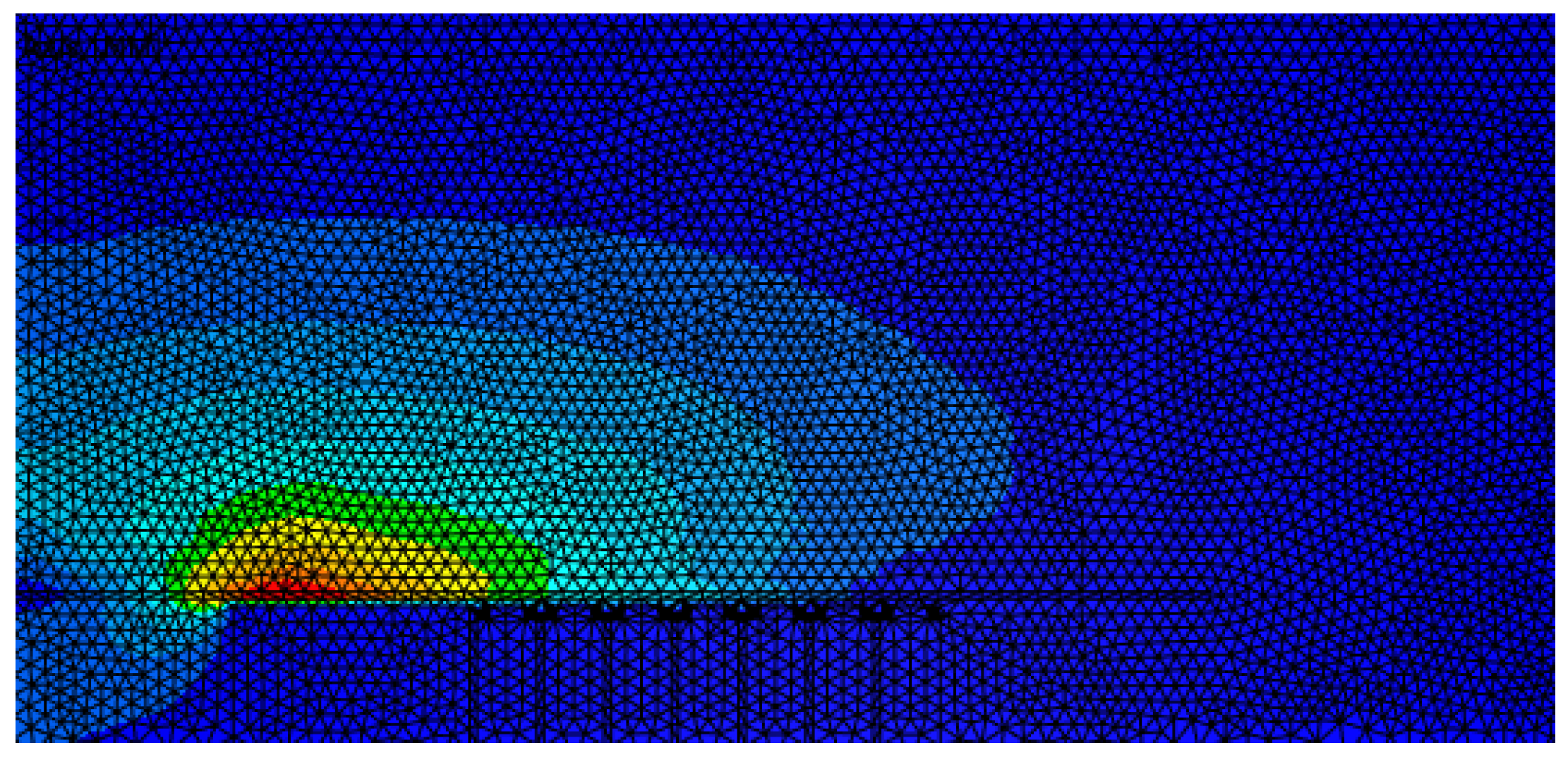

3.1. Electromagnetic Simulation Setup

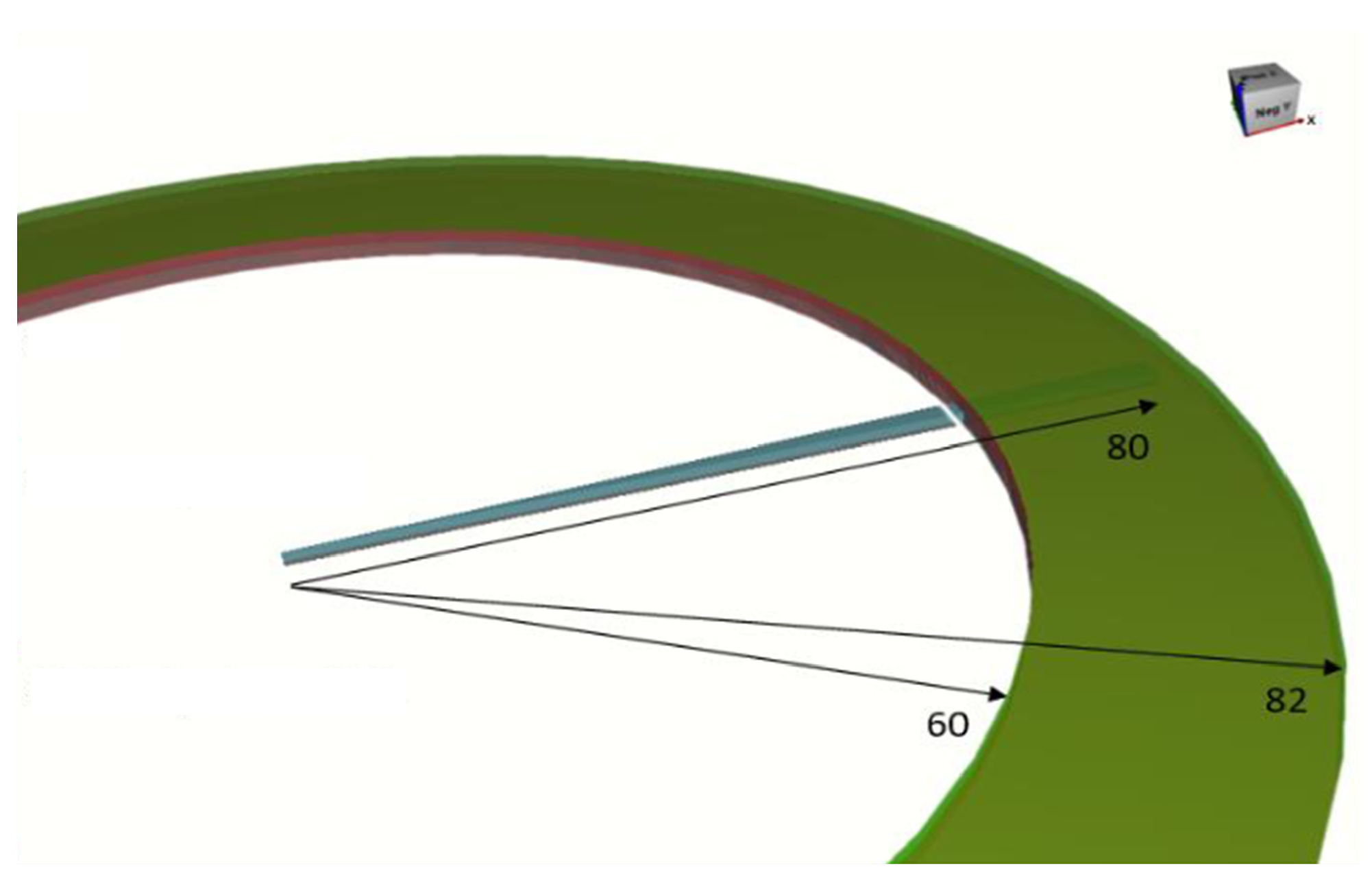

3.2. Mechanical Simulation Setup

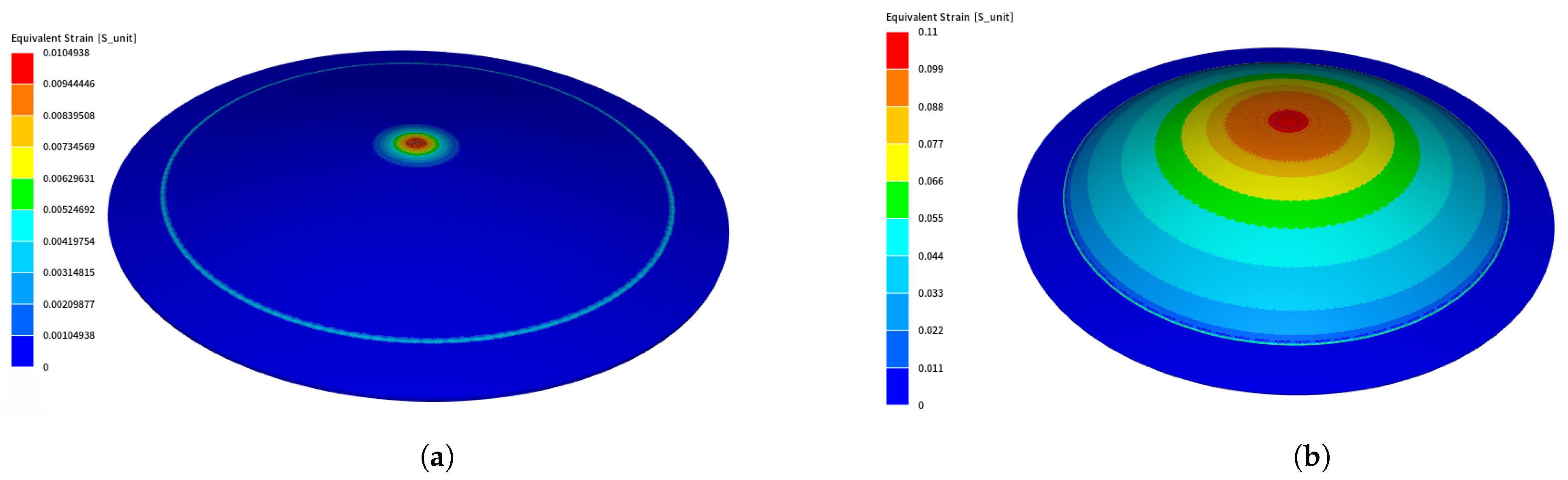

3.3. Results Overview

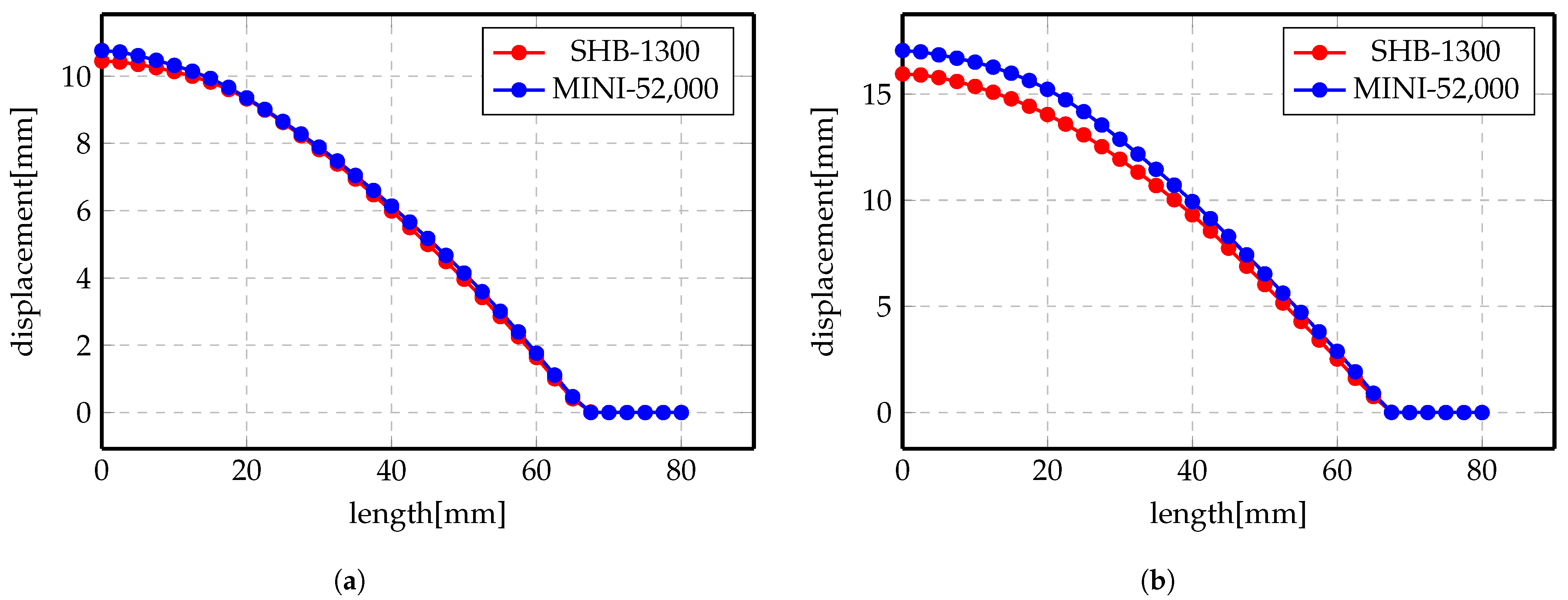

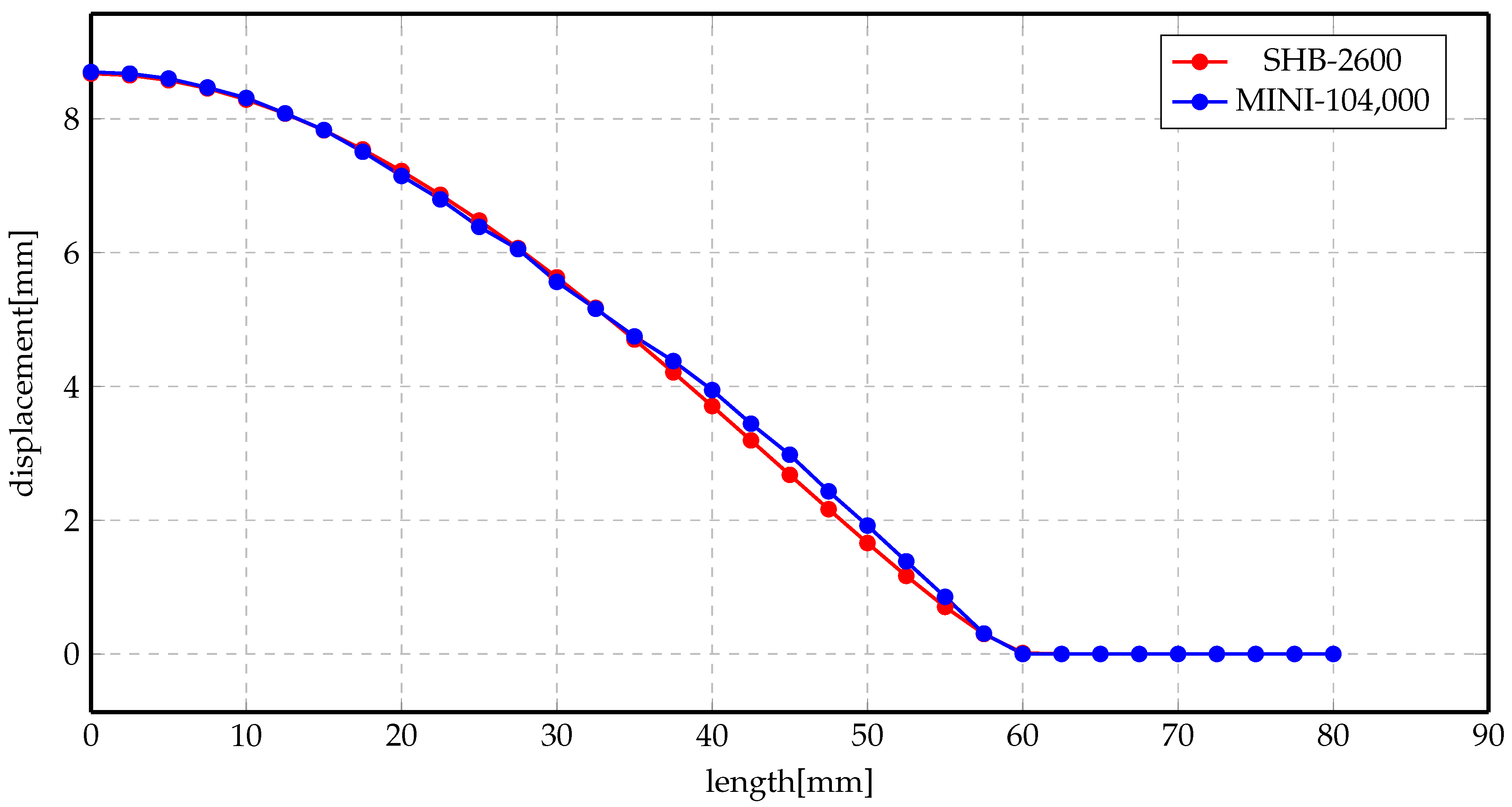

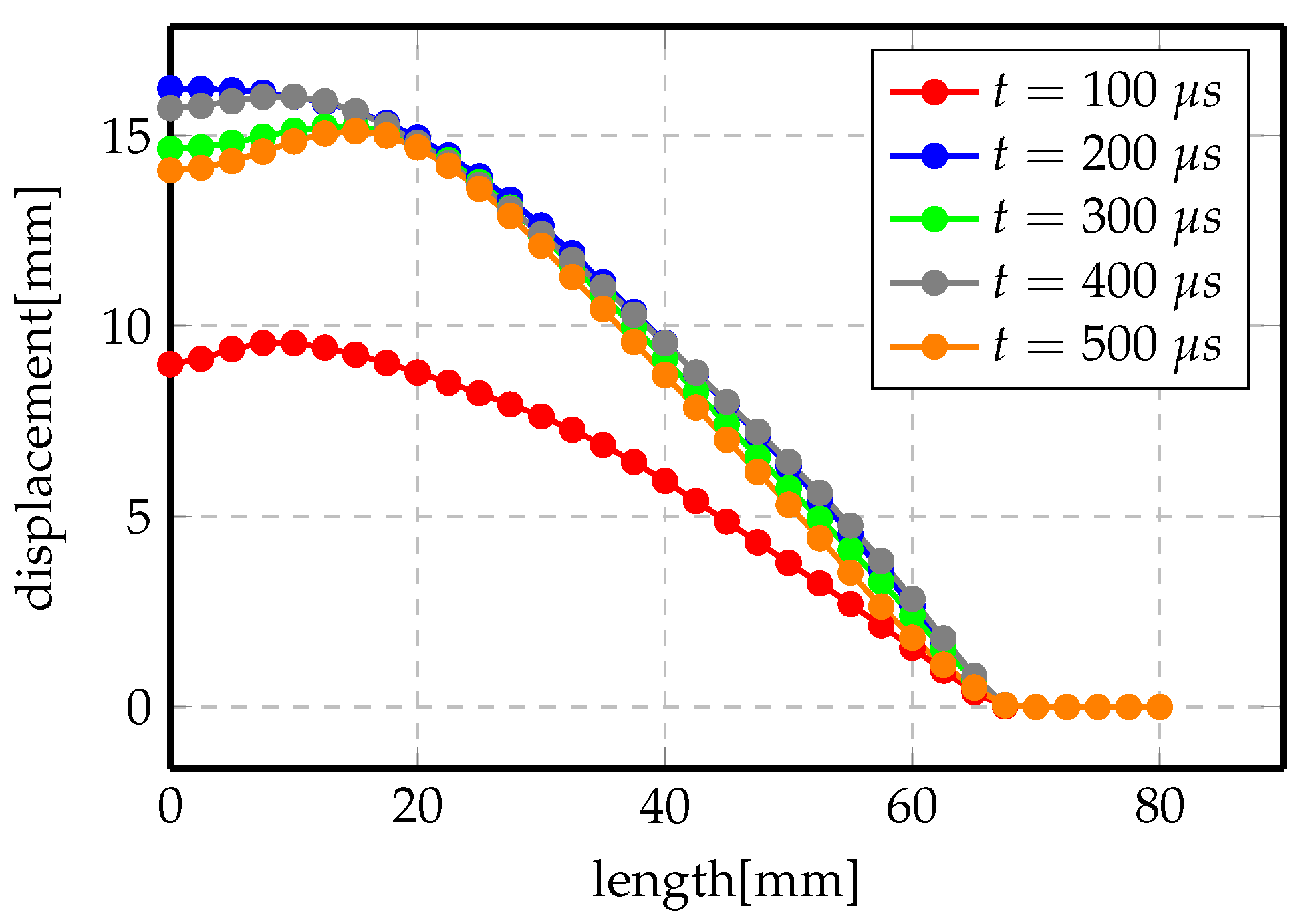

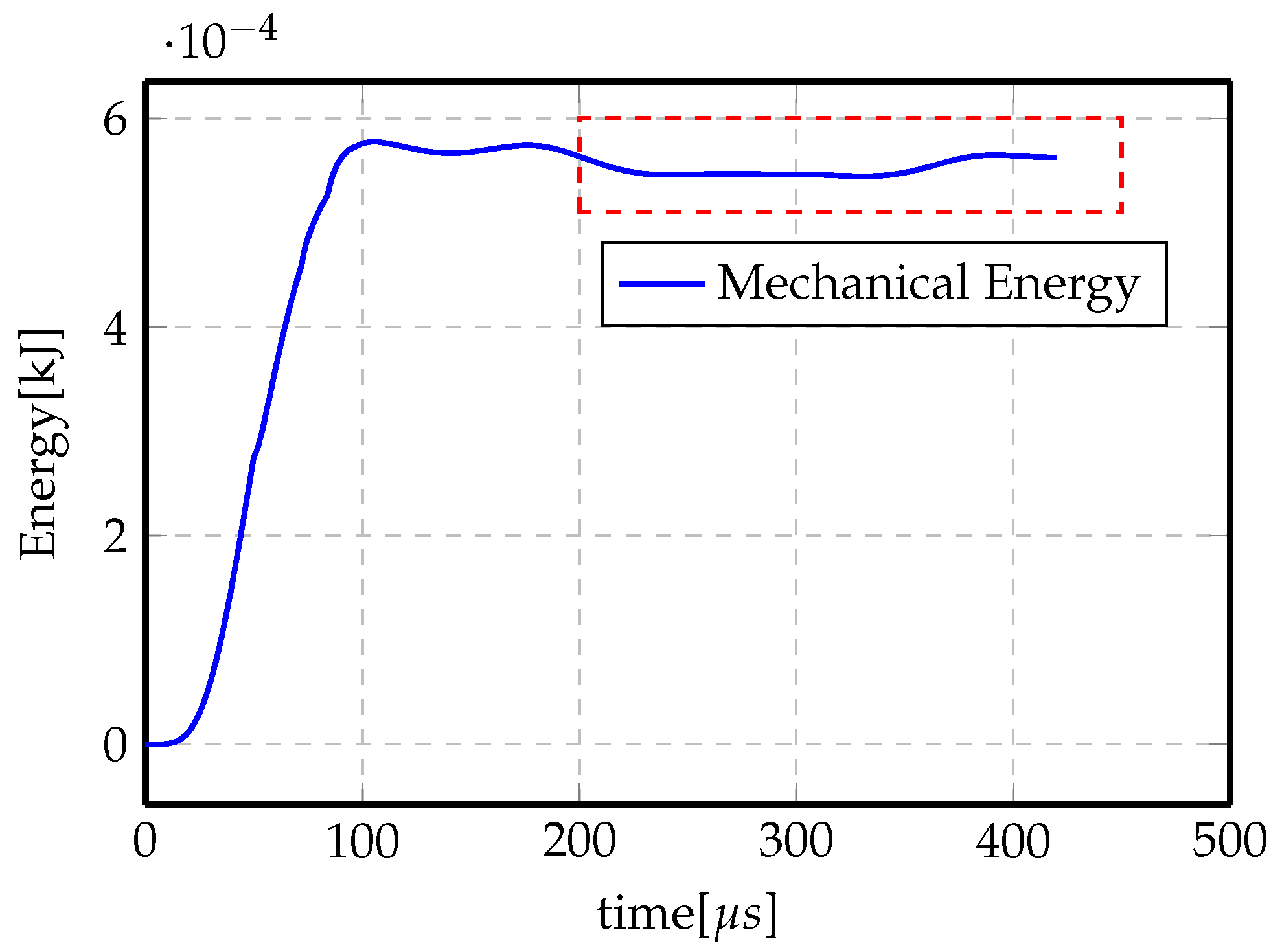

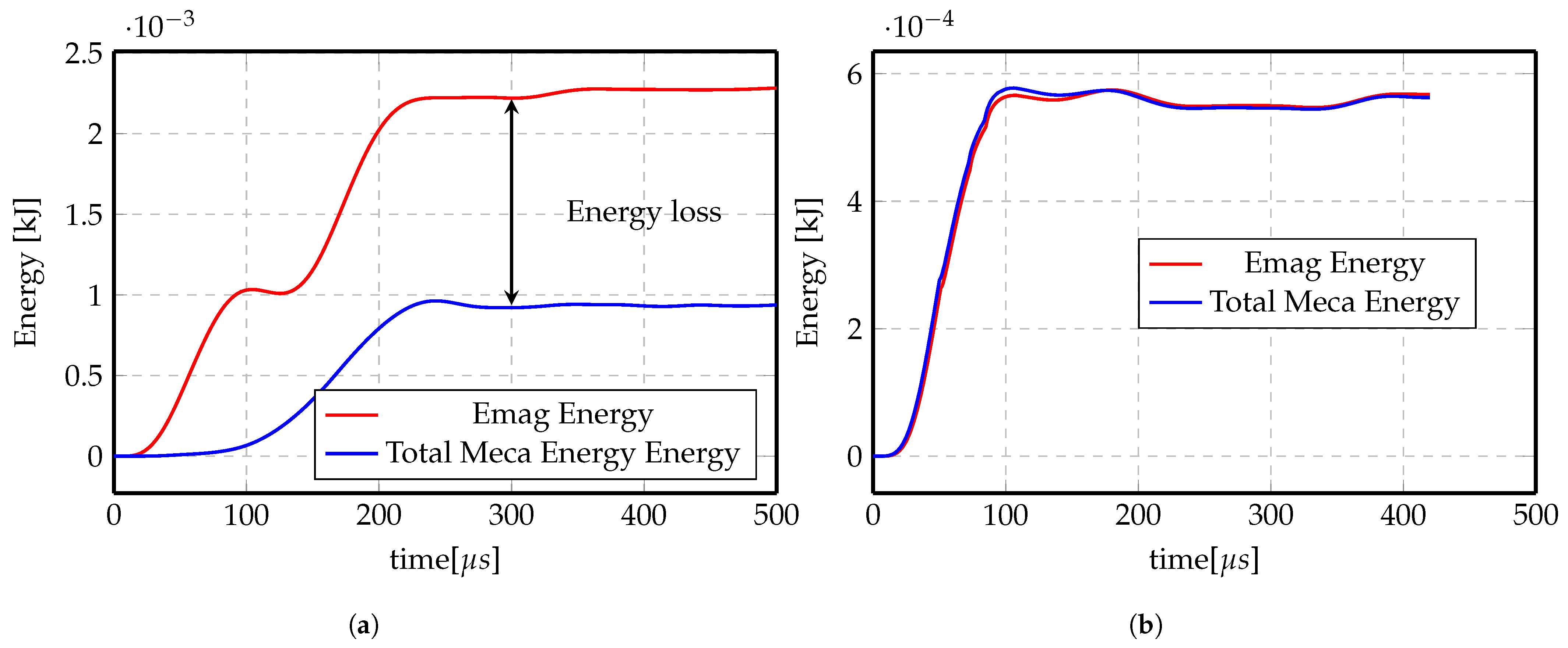

3.3.1. Direct Forming

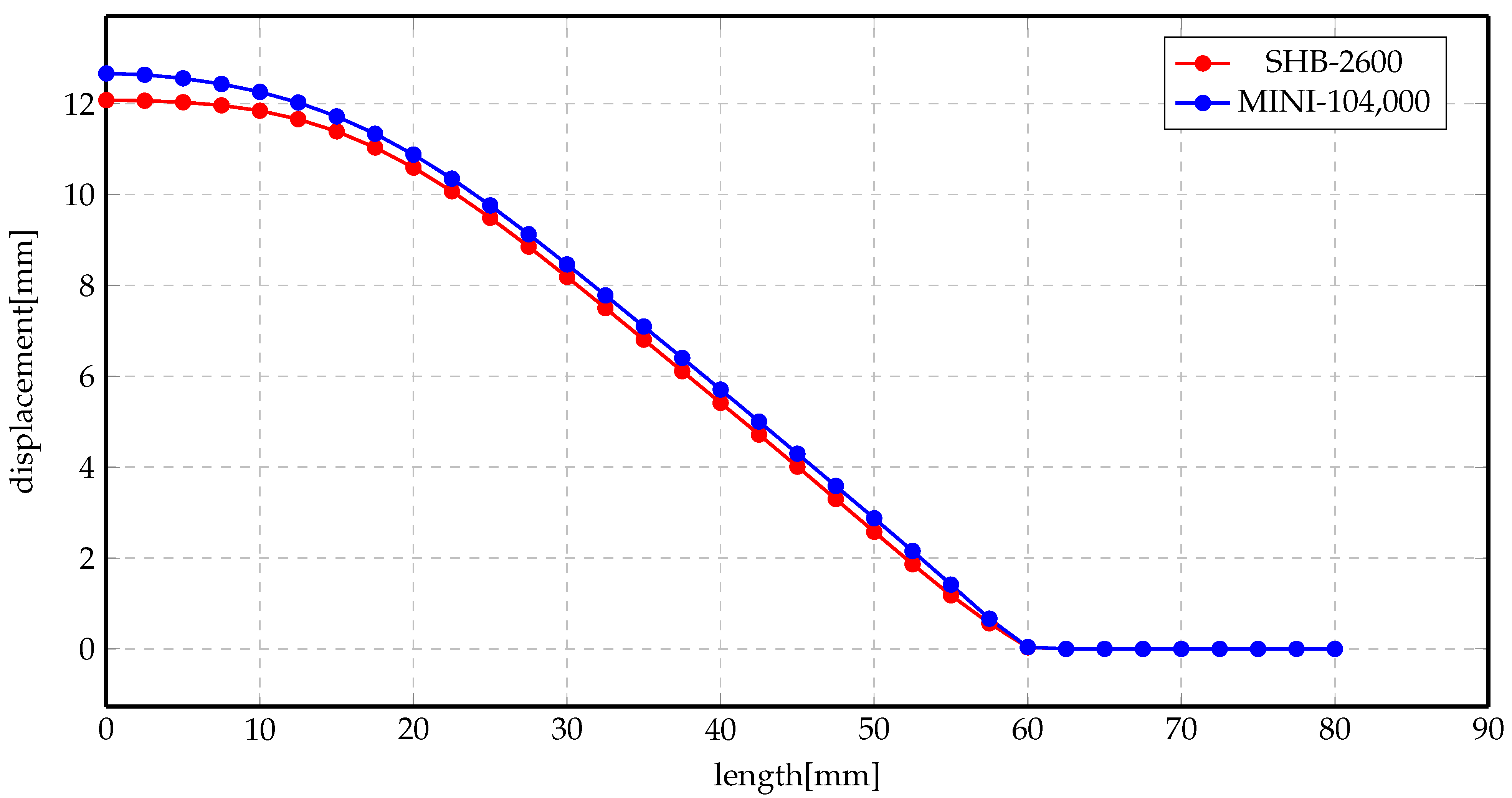

3.3.2. Indirect Forming

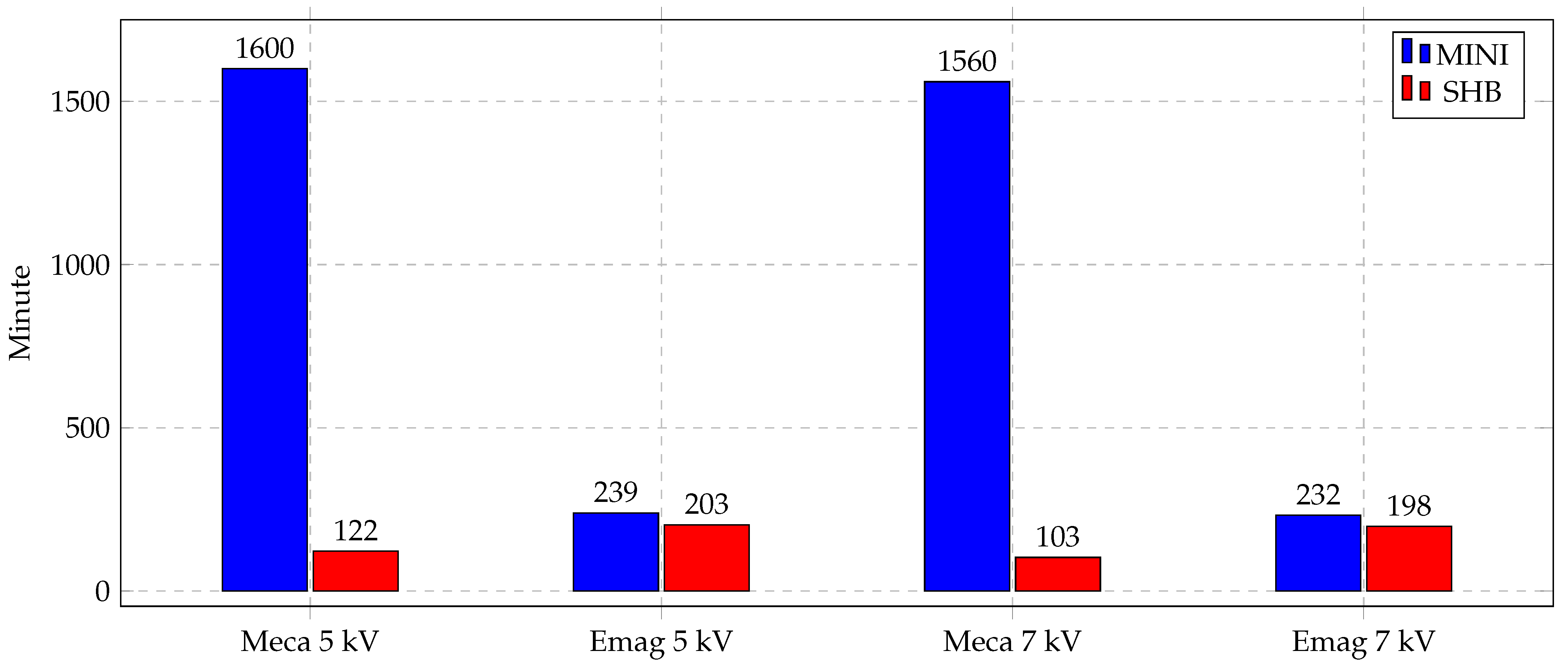

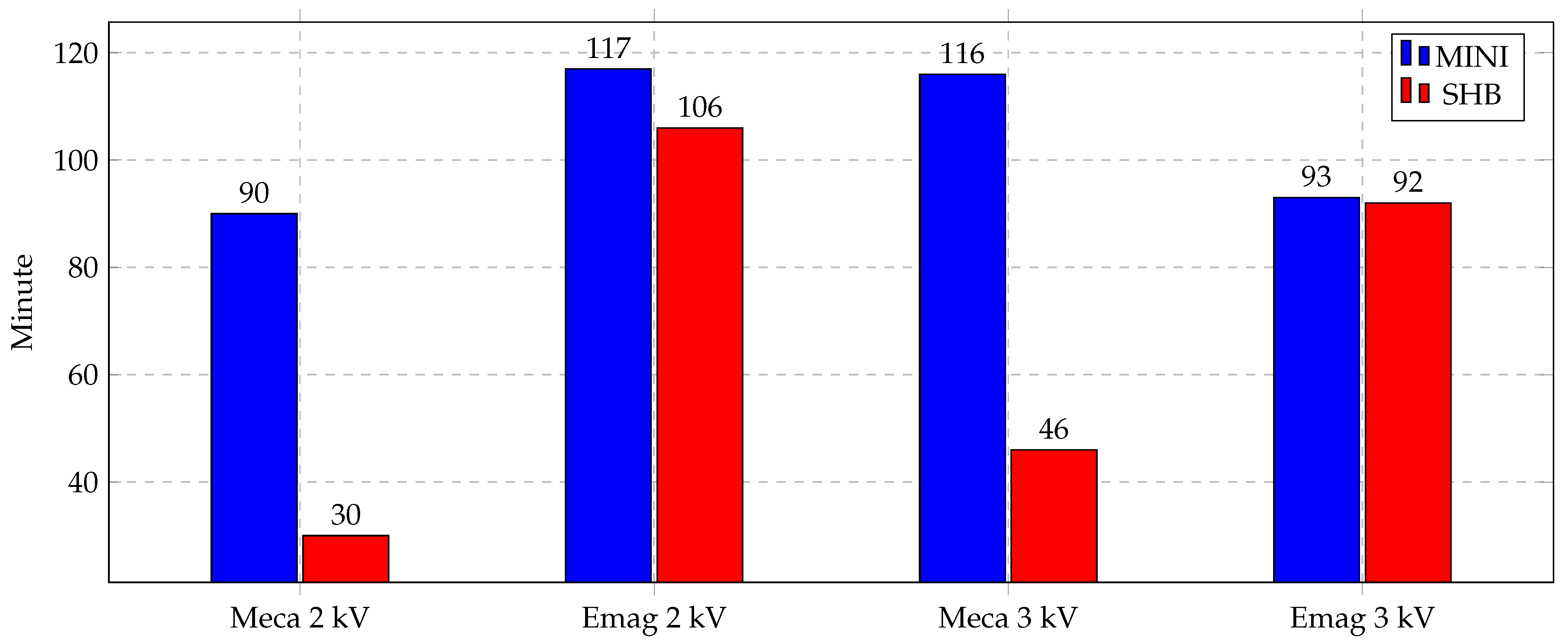

3.4. Simulation Time

4. Discussion

4.1. Final Forming Time

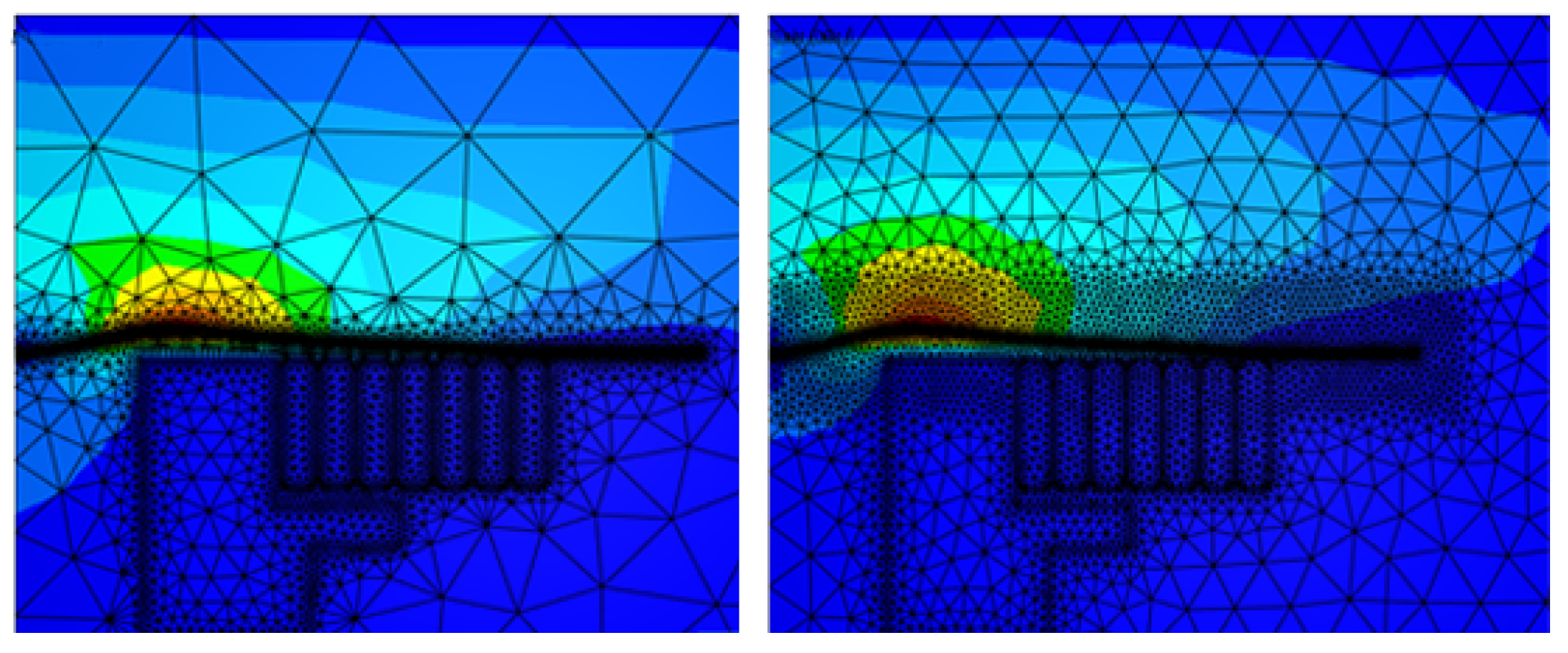

4.2. Remeshing of Electromagnetic Domain Mesh

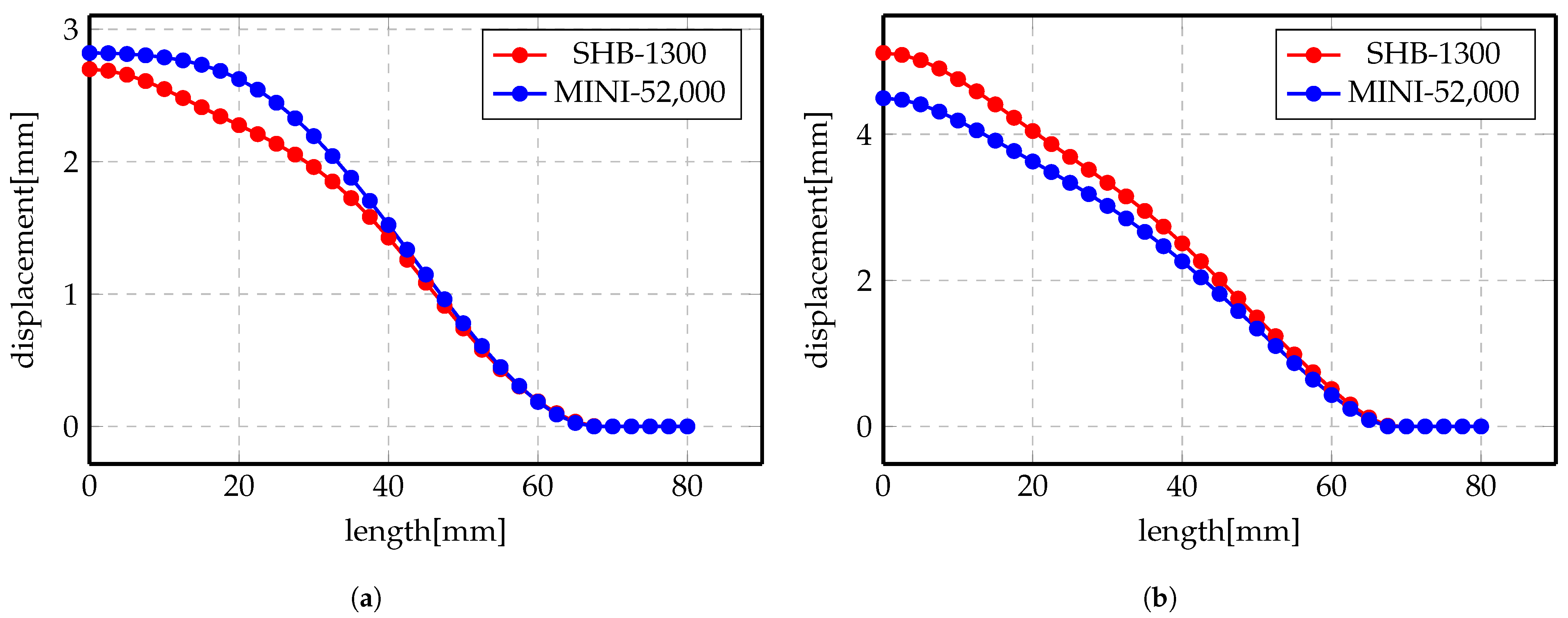

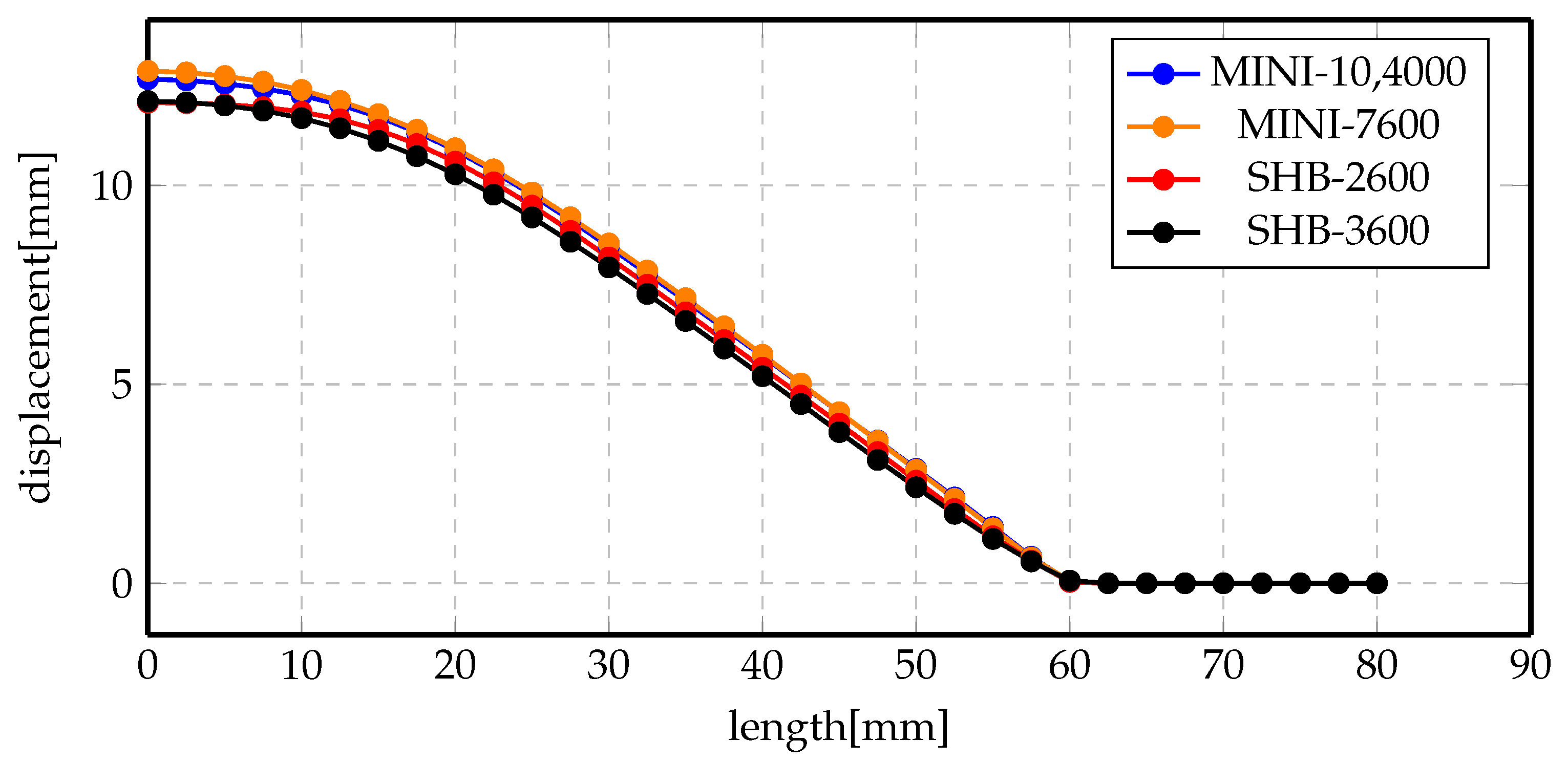

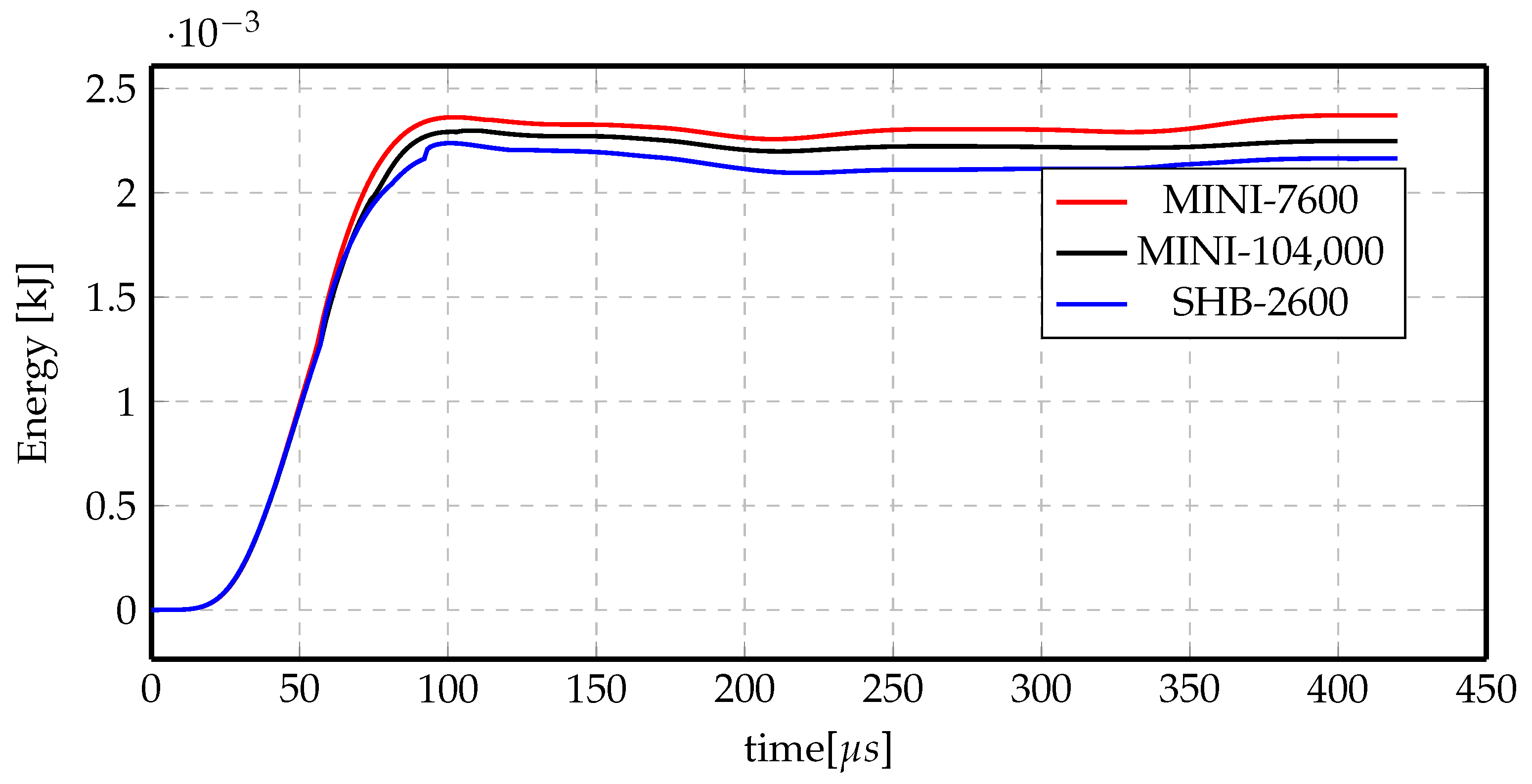

4.3. Effect of Mechanical Mesh Refinement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Mynors, D.J.; Zhang, B. Applications and capabilities of explosive forming. J. Mater. Process. Technol. 2002, 125, 1–25. [Google Scholar] [CrossRef]

- Rohatgi, A.; Stephens, E.V.; Davies, R.W.; Smith, M.T.; Soulami, A.; Ahzi, S. Electro-hydraulic forming of sheet metals: Free-forming vs. conical-die forming. J. Mater. Process. Technol. 2012, 212, 1070–1079. [Google Scholar] [CrossRef]

- Zittel, G. A Historical Review of High Speed Metal Forming; Institute für Forming Technology-Technical Universityät: Dortmund, Germany, 2010. [Google Scholar]

- Dowell, E.H.; Hall, K.C. Modeling of fluid-structure interaction. Annu. Rev. Fluid Mech. 2001, 33, 445–490. [Google Scholar] [CrossRef]

- Keyes, D.E.; McInnes, L.C.; Woodward, C.; Gropp, W.; Myra, E.; Pernice, M.; Bell, J.; Brown, J.; Clo, A.; Connors, J.; et al. Multiphysics simulations: Challenges and opportunities. Int. J. High Perform. Comput. Appl. 2013, 27, 4–83. [Google Scholar] [CrossRef] [Green Version]

- Singhal, A.; Sahu, S.A.; Chaudhary, S. Liouville-Green approximation: An analytical approach to study the elastic waves vibrations in composite structure of piezo material. Compos. Struct. 2018, 184, 714–727. [Google Scholar] [CrossRef]

- Alves Z, J.R.; Bay, F. Magnetic pulse forming: Simulation and experiments for high-speed forming processes. Adv. Mater. Process. Technol. 2015, 1, 560–576. [Google Scholar] [CrossRef] [Green Version]

- Psyk, V.; Risch, D.; Kinsey, B.L.; Tekkaya, A.E.; Kleiner, M. Electromagnetic forming—A review. J. Mater. Process. Technol. 2011, 211, 787–829. [Google Scholar] [CrossRef]

- Psyk, V.; Beerwald, C.; Henselek, A.; Homberg, W.; Brosius, A.; Kleiner, M. Integration of electromagnetic calibration into the deep drawing process of an industrial demonstrator part. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch SZ, Switzerland, 2007; Volume 344, pp. 435–442. [Google Scholar]

- Unger, J.; Stiemer, M.; Schwarze, M.; Svendsen, B.; Blum, H.; Reese, S. Strategies for 3D simulation of electromagnetic forming processes. J. Mater. Process. Technol. 2008, 199, 341–362. [Google Scholar] [CrossRef]

- Fenton, G.K.; Daehn, G.S. Modeling of electromagnetically formed sheet metal. J. Mater. Process. Technol. 1998, 75, 6–16. [Google Scholar] [CrossRef]

- Imbert, J.; Winkler, S.; Worswick, M.; Oliveira, D.; Golovashchenko, S. Numerical modeling of an electromagnetic corner fill operation. In Proceedings of the NUMIFORM, Columbus, OH, USA, 13–17 June 2004; pp. 1833–1839. [Google Scholar]

- Schinnerl, M.; Schoberl, J.; Kaltenbacher, M.; Lerch, R. Multigrid methods for the three-dimensional simulation of nonlinear magnetomechanical systems. IEEE Trans. Magn. 2002, 38, 1497–1511. [Google Scholar] [CrossRef]

- Heyliger, P.; Reddy, J. A higher order beam finite element for bending and vibration problems. J. Sound Vib. 1988, 126, 309–326. [Google Scholar] [CrossRef]

- Simo, J.C.; Armero, F. Geometrically non-linear enhanced strain mixed methods and the method of incompatible modes. Int. J. Numer. Methods Eng. 1992, 33, 1413–1449. [Google Scholar] [CrossRef]

- Simo, J.; Armero, F.; Taylor, R. Improved versions of assumed enhanced strain tri-linear elements for 3D finite deformation problems. Comput. Methods Appl. Mech. Eng. 1993, 110, 359–386. [Google Scholar] [CrossRef]

- Belytschko, T.; Bindeman, L.P. Assumed strain stabilization of the eight node hexahedral element. Comput. Methods Appl. Mech. Eng. 1993, 105, 225–260. [Google Scholar] [CrossRef]

- Liu, W.K.; Guo, Y.; Tang, S.; Belytschko, T. A multiple-quadrature eight-node hexahedral finite element for large deformation elastoplastic analysis. Comput. Methods Appl. Mech. Eng. 1998, 154, 69–132. [Google Scholar] [CrossRef]

- Reese, S.; Wriggers, P.; Reddy, B. A new locking-free brick element technique for large deformation problems in elasticity. Comput. Struct. 2000, 75, 291–304. [Google Scholar] [CrossRef]

- Trinh, V.D.; Abed-Meraim, F.; Combescure, A. A new assumed strain solid-shell formulation “SHB6” for the six-node prismatic finite element. J. Mech. Sci. Technol. 2011, 25, 2345. [Google Scholar] [CrossRef] [Green Version]

- Abed-Meraim, F.; Combescure, A. An improved assumed strain solid–shell element formulation with physical stabilization for geometric non-linear applications and elastic–plastic stability analysis. Int. J. Numer. Methods Eng. 2009, 80, 1640–1686. [Google Scholar] [CrossRef] [Green Version]

- Reese, S. A large deformation solid-shell concept based on reduced integration with hourglass stabilization. Int. J. Numer. Methods Eng. 2007, 69, 1671–1716. [Google Scholar] [CrossRef]

- L’Eplattenier, P.; Çaldichoury, I. Update on the electromagnetism module in LS-DYNA. In Proceedings of the 12th LS-DYNA Users Conference, Detroit, MI, USA, 3–5 June 2012. [Google Scholar]

- Brebbia, C.A.; Dominguez, J. Boundary Elements: An Introductory Course; WIT Press: The New Forest, UK, 1994. [Google Scholar]

- Bahmani, M.A.; Niayesh, K.; Karimi, A. 3D Simulation of magnetic field distribution in electromagnetic forming systems with field-shaper. J. Mater. Process. Technol. 2009, 209, 2295–2301. [Google Scholar] [CrossRef]

- Nédélec, J.C. A new family of mixed finite elements in R3. Numer. Math. 1986, 50, 57–81. [Google Scholar] [CrossRef]

- Alves Zapata, J. Magnetic Pulse Forming Processes: Computational Modelling and Experimental Validation. Ph.D. Thesis, Ecole Nationale Supérieure des Mines de Paris, Paris, France, 2016. [Google Scholar]

- Reese, S.; Svendsen, B.; Stiemer, M.; Unger, J.; Schwarze, M.; Blum, H. On a new finite element technology for electromagnetic metal forming processes. Arch. Appl. Mech. 2005, 74, 834–845. [Google Scholar] [CrossRef]

- Arnold, D.N.; Brezzi, F.; Fortin, M. A stable finite element for the stokes equations. Calcolo 1984, 21, 337–344. [Google Scholar] [CrossRef]

- Mahmoud, M.; Bay, F.; Mũnoz, D.P. An efficient multiphysics solid shell based finite element approach for modeling thin sheet metal forming processes. Finite Elem. Anal. Des. 2021, 198, 103645. [Google Scholar] [CrossRef]

- Bay, F.; Zapata, J.R.A. Computational modelling for electromagnetic forming processes. In Proceedings of the International Scientific Colloquium Modelling for Electromagnetic Processing-MEP 2014, Hannover, Germany, 16–19 September 2014; pp. 259–264. [Google Scholar]

- Bay, F.; Jeanson, A.C.; Zapata, J.A. Electromagnetic forming processes: Material behaviour and computational modelling. Procedia Eng. 2014, 81, 793–800. [Google Scholar] [CrossRef] [Green Version]

- Svendsen, B.; Chanda, T. Continuum thermodynamic formulation of models for electromagnetic thermoinelastic solids with application in electromagnetic metal forming. Contin. Mech. Thermodyn. 2005, 17, 1–16. [Google Scholar] [CrossRef]

- Chari, M.; Konrad, A.; Palmo, M.; D’angelo, J. Three-dimensional vector potential analysis for machine field problems. IEEE Trans. Magn. 1982, 18, 436–446. [Google Scholar] [CrossRef]

- Biro, O.; Preis, K. On the use of the magnetic vector potential in the finite-element analysis of three-dimensional eddy currents. IEEE Trans. Magn. 1989, 25, 3145–3159. [Google Scholar] [CrossRef]

- Brezzi, F.; Fortin, M. Mixed and Hybrid Finite Element Methods; Springer Science & Business Media: Berlin, Germany, 2012; Volume 15. [Google Scholar]

- Fayolle, S. Etude de la Modélisation de la Pose et de la Tenue Mécanique des Assemblages par Déformation Plastique. Ph.D. Thesis, Ecole Nationale Supérieure des Mines de Paris, Paris, France, 2009. [Google Scholar]

- Risch, D.; Beerwald, C.; Brosius, A.; Kleiner, M. On the significance of the die design for electromagnetic sheet metal forming. In Proceedings of the 1st International Conference on High Speed Forming, Dortmund, Germany, 31 March–1 April 2004; pp. 191–200. [Google Scholar]

- Jeanson, A.C.; Avrillaud, G.; Mazars, G.; Bay, F.; Massoni, E.; Jacques, N.; Arrigoni, M. Identification du comportement mécanique dynamique de tubes d’aluminium par un essai d’expansion électromagnétique. In CSMA 2013-11ème Colloque National en Calcul des Structures; HAL: Giens, France, 2013. [Google Scholar]

- Johnson, J.R.; Taber, G.A.; Daehn, G.S. Constitutive relation development through the FIRE test. In Proceedings of the 4th International Conference on High Speed Forming, Columbus, OH, USA, 9–10 March 2010; pp. 295–306. [Google Scholar]

| Property | Value |

|---|---|

| Electrical resistivity of Al () | |

| Electrical resistivity of Steel () | |

| Relative magnetic permeability of Al () | 1 |

| Relative magnetic permeability of Steel () | 1 |

| Magnetic permeability in vacuum () | |

| Machine parameters | |

| ; ; | |

| Time step |

| Property | Al | Steel |

|---|---|---|

| Elastic modulus (E) | ||

| Poisson ratio () | ||

| A | ||

| B | ||

| C | ||

| n |

| Al | Steel | |

|---|---|---|

| Steel | Sliding | |

| 3D manipulator (matrix) | Bilateral sticking | Bilateral sticking |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmoud, M.; Bay, F.; Muñoz, D.P. An Efficient Computational Model for Magnetic Pulse Forming of Thin Structures. Materials 2021, 14, 7645. https://doi.org/10.3390/ma14247645

Mahmoud M, Bay F, Muñoz DP. An Efficient Computational Model for Magnetic Pulse Forming of Thin Structures. Materials. 2021; 14(24):7645. https://doi.org/10.3390/ma14247645

Chicago/Turabian StyleMahmoud, Mohamed, François Bay, and Daniel Pino Muñoz. 2021. "An Efficient Computational Model for Magnetic Pulse Forming of Thin Structures" Materials 14, no. 24: 7645. https://doi.org/10.3390/ma14247645

APA StyleMahmoud, M., Bay, F., & Muñoz, D. P. (2021). An Efficient Computational Model for Magnetic Pulse Forming of Thin Structures. Materials, 14(24), 7645. https://doi.org/10.3390/ma14247645