A Proposal to Improve the Effectiveness of the Deflection Control Method Provided by Eurocodes for Concrete, Timber, and Composite Slabs

Abstract

1. Introduction

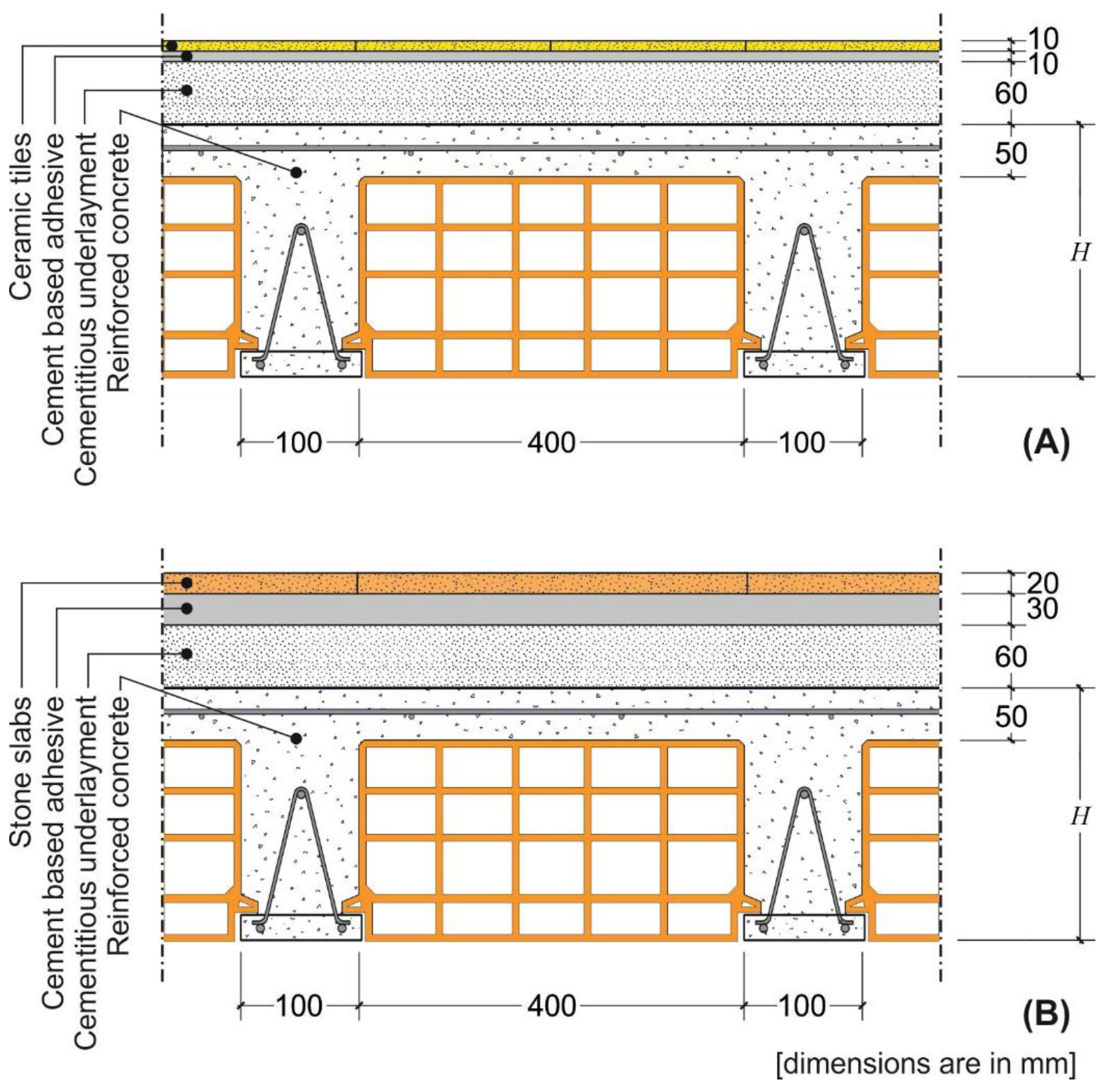

- rib (clay pot or hollow block) slab;

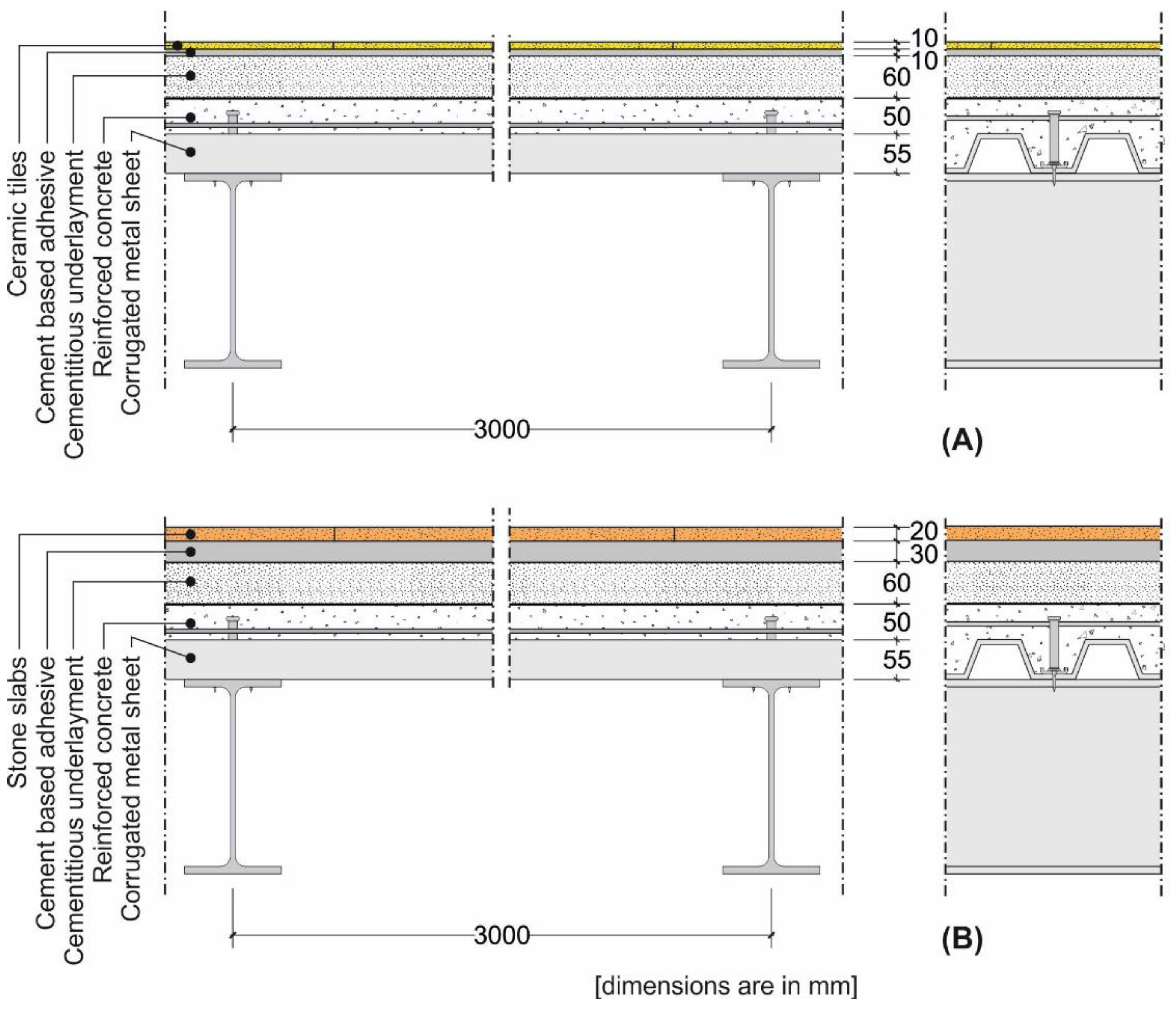

- composite steel–concrete slab;

- traditional slab made of timber beams and planks.

- partition walls;

- floorings (of various type).

2. Bending Limit Imposed by Superstructures and Finishes

2.1. Partition Walls

2.2. Floorings

- carpet flooring (moquette);

- synthetic materials (usually rubber, PVC, or linoleum);

- resin;

- timber;

- stone (e.g., marble, granite, or sandstone);

- ceramic.

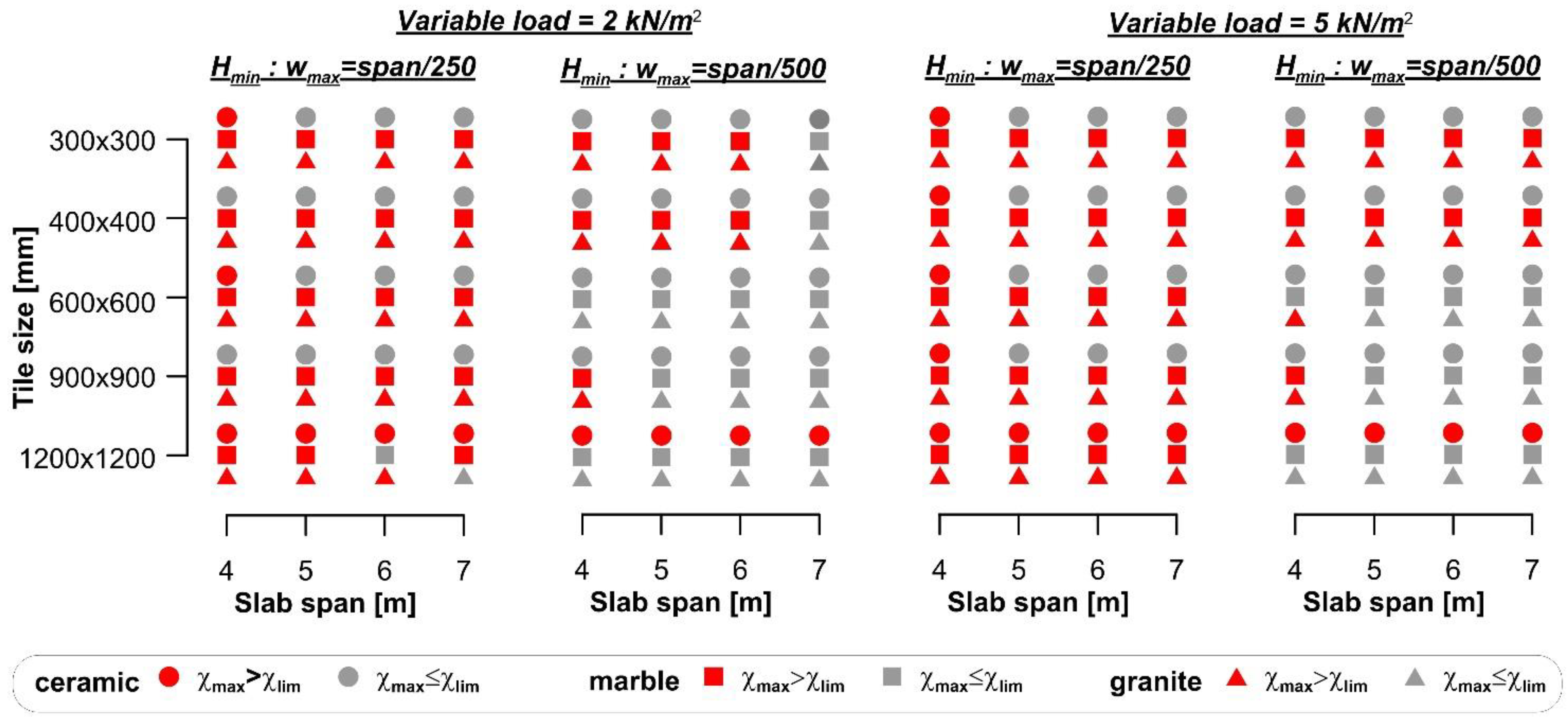

3. Limit Curvature Values

4. Comparison between the Eurocode Limits and the Performance Requirements of the Flooring

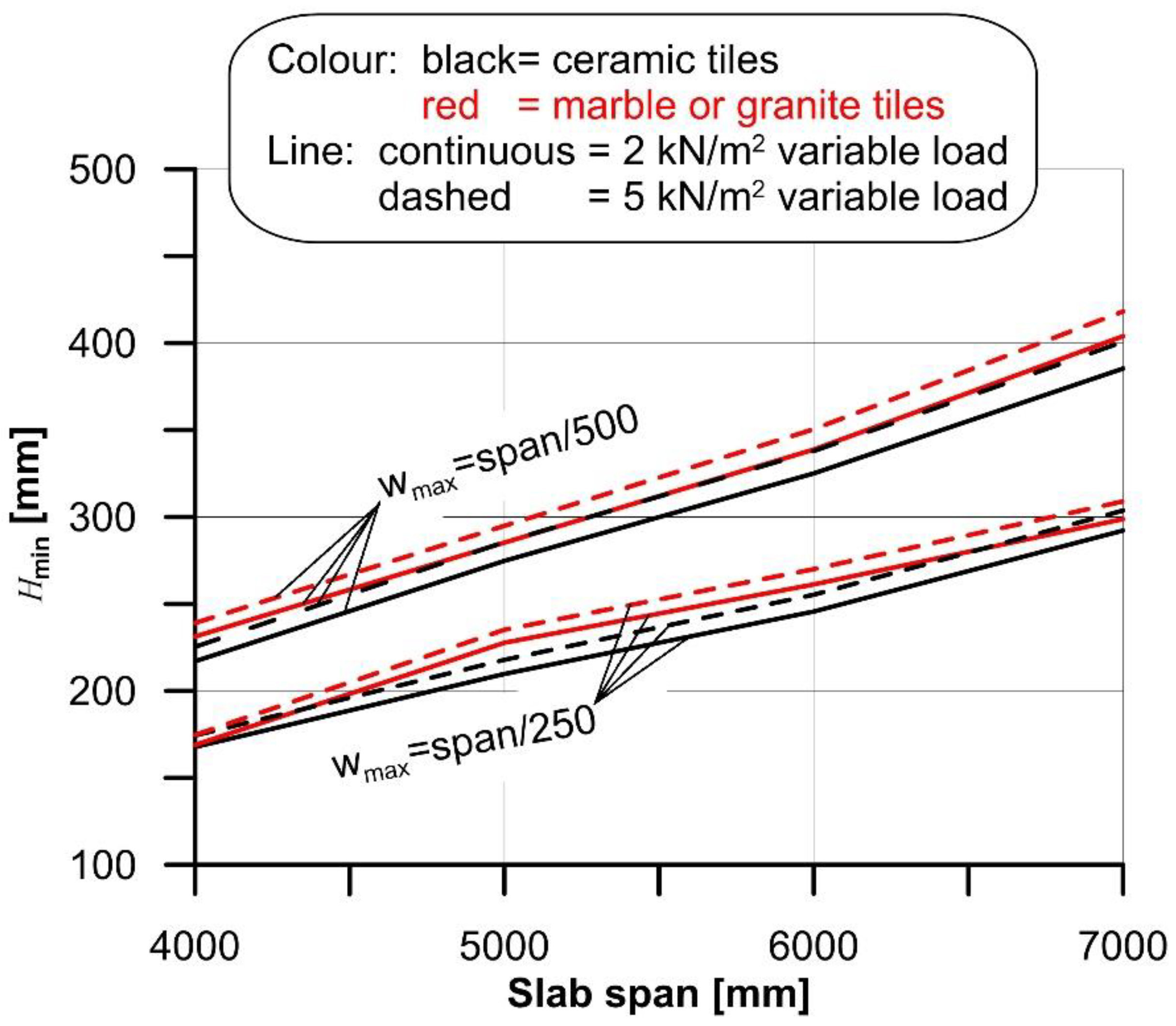

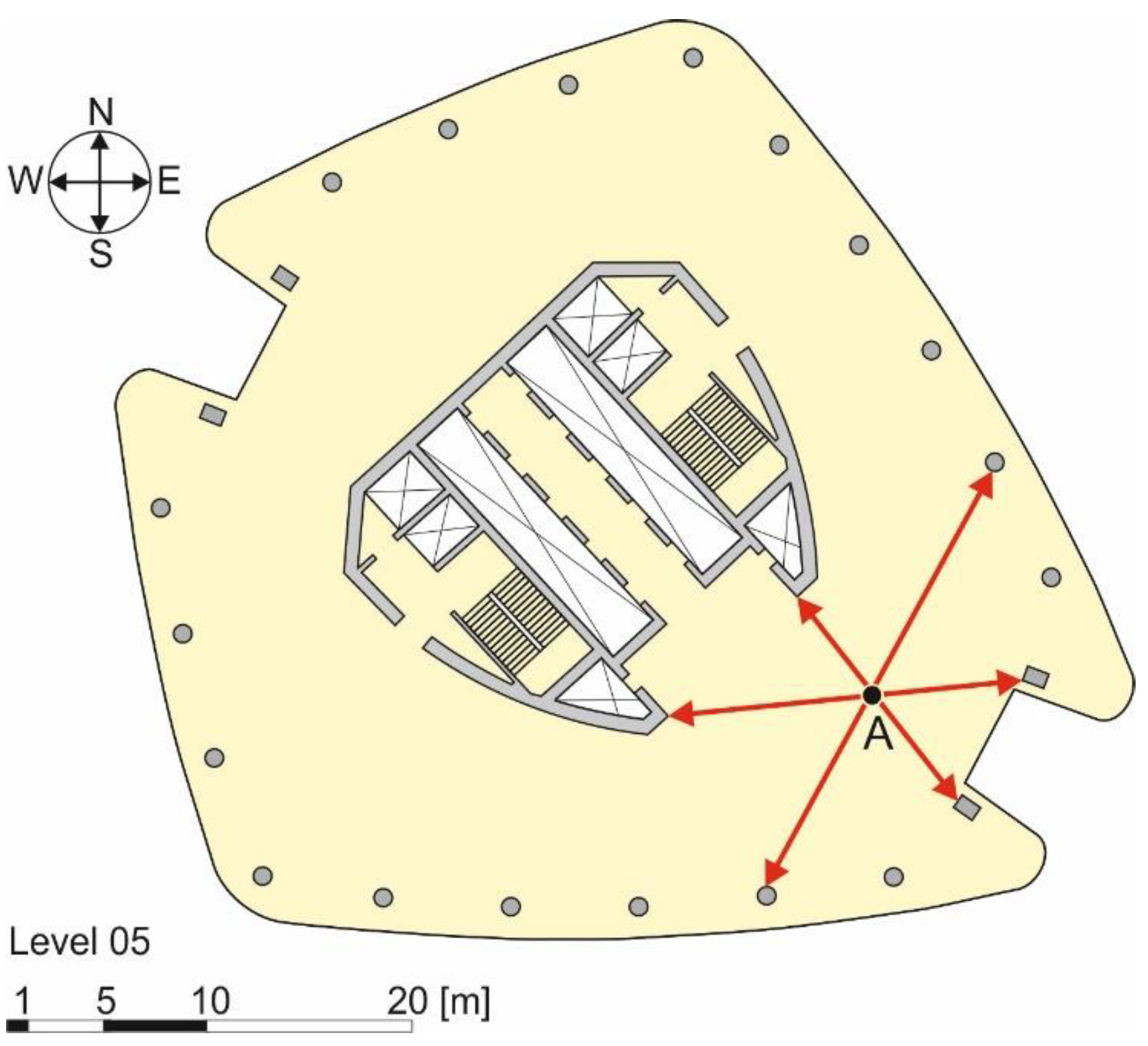

4.1. Rib and Clay Pot Slab

- “the appearance and general utility of the structure could be impaired when the calculated sag of a beam, slab or cantilever subjected to quasi-permanent loads exceeds span/250” [4];

- “deflections that could damage adjacent parts of the structure should be limited. For the deflection after construction, span/500 is normally an appropriate limit for quasi-permanent loads” [4].

- Determination of the self-weight of the member (slab).

- Determination of the cross-section cracking moment, where the tensile strength of concrete was computed according to Eurocode 2 [4].

- Identification of the structural element cracked segment (located at midspan) and of the two symmetrical uncracked segments (located at the supports).

- Computation of the second moment of area (J) of the reinforced concrete cross-section of each segment:

- 5.

- Determination of the sag w(H) under the quasi-permanent load.

- 6.

- Comparison of the sag w(H) with the limit wmax and determination of a new guess value of H, until the calculated sag matches the limit value.

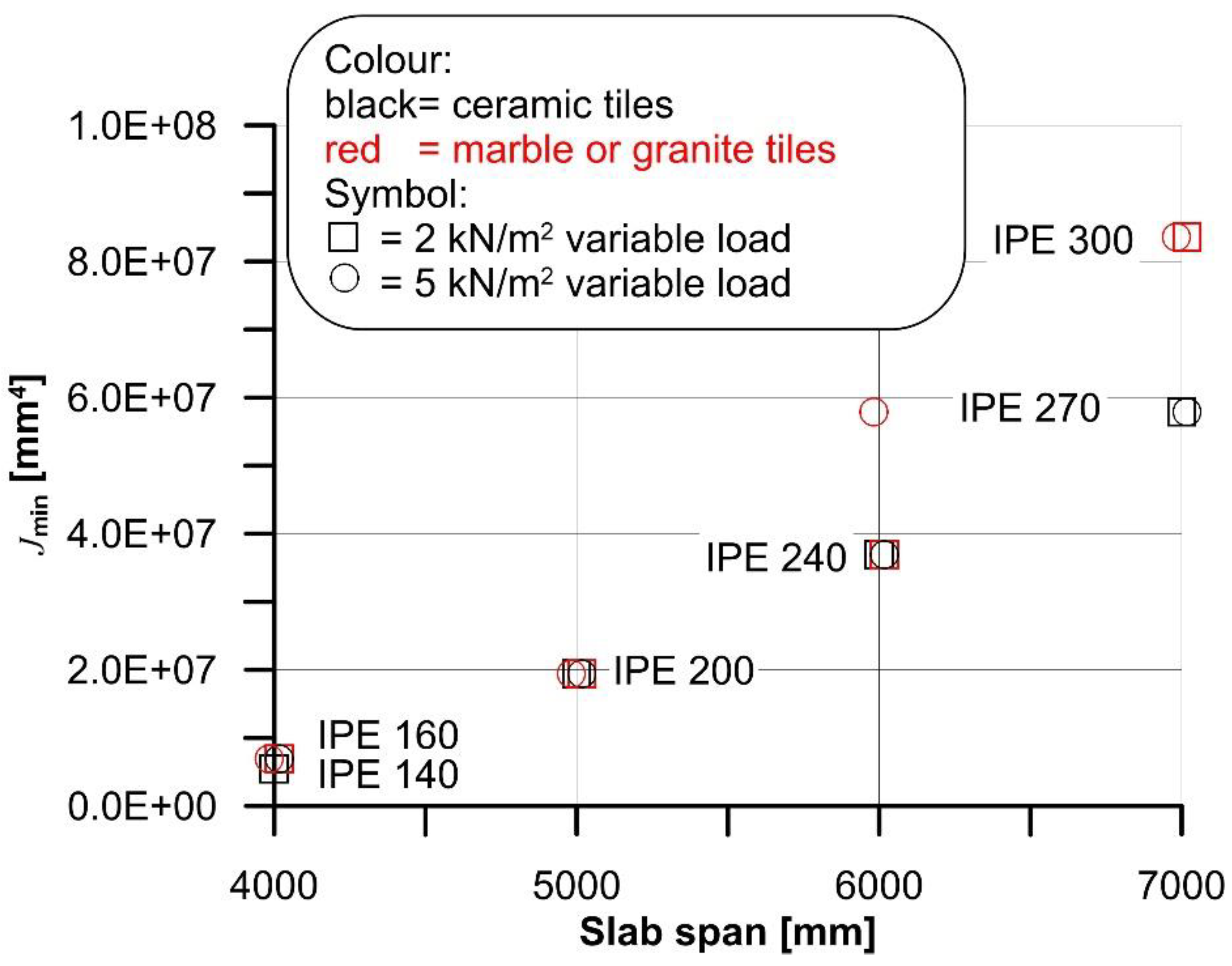

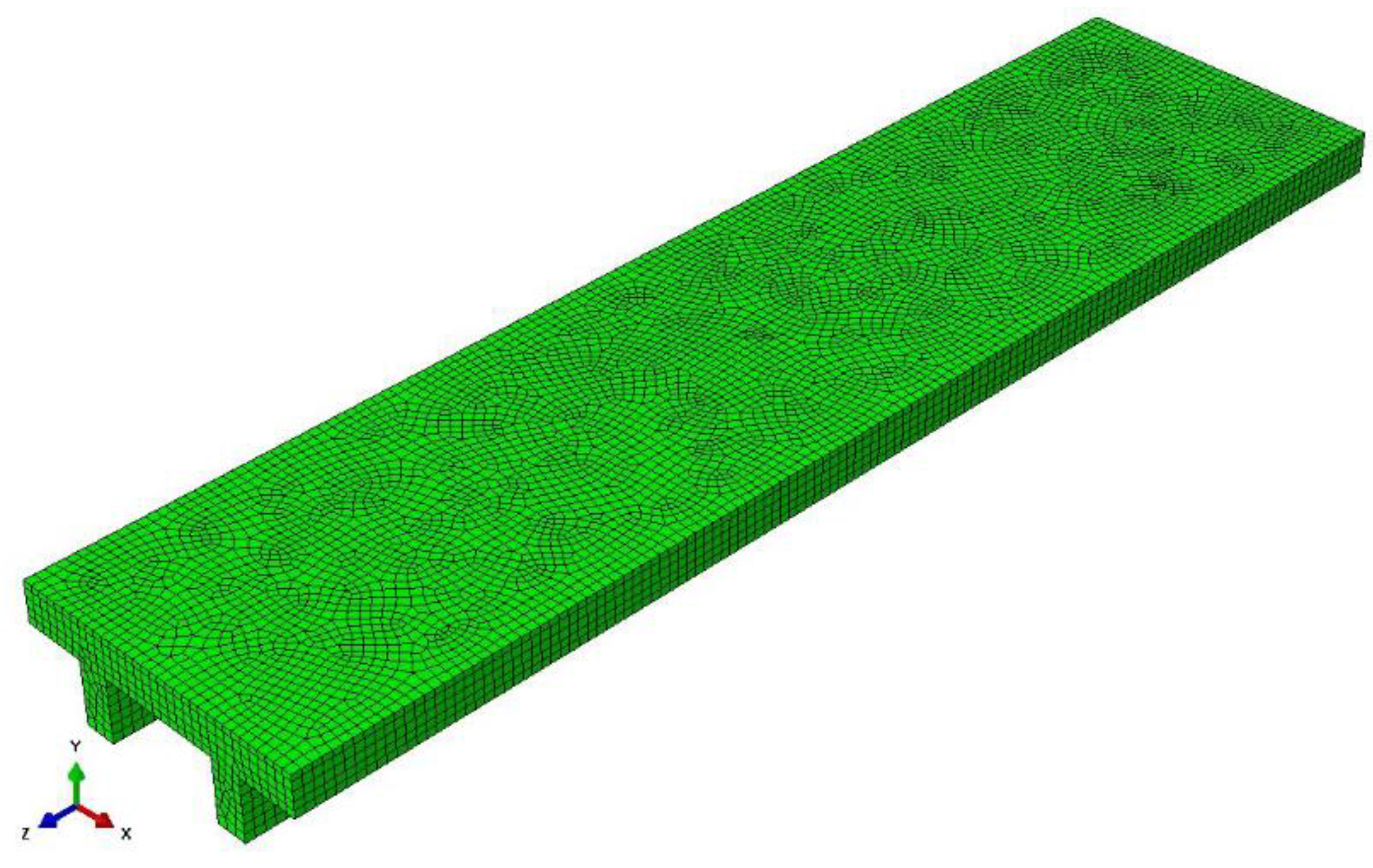

4.2. Composite Steel–Concrete Slab

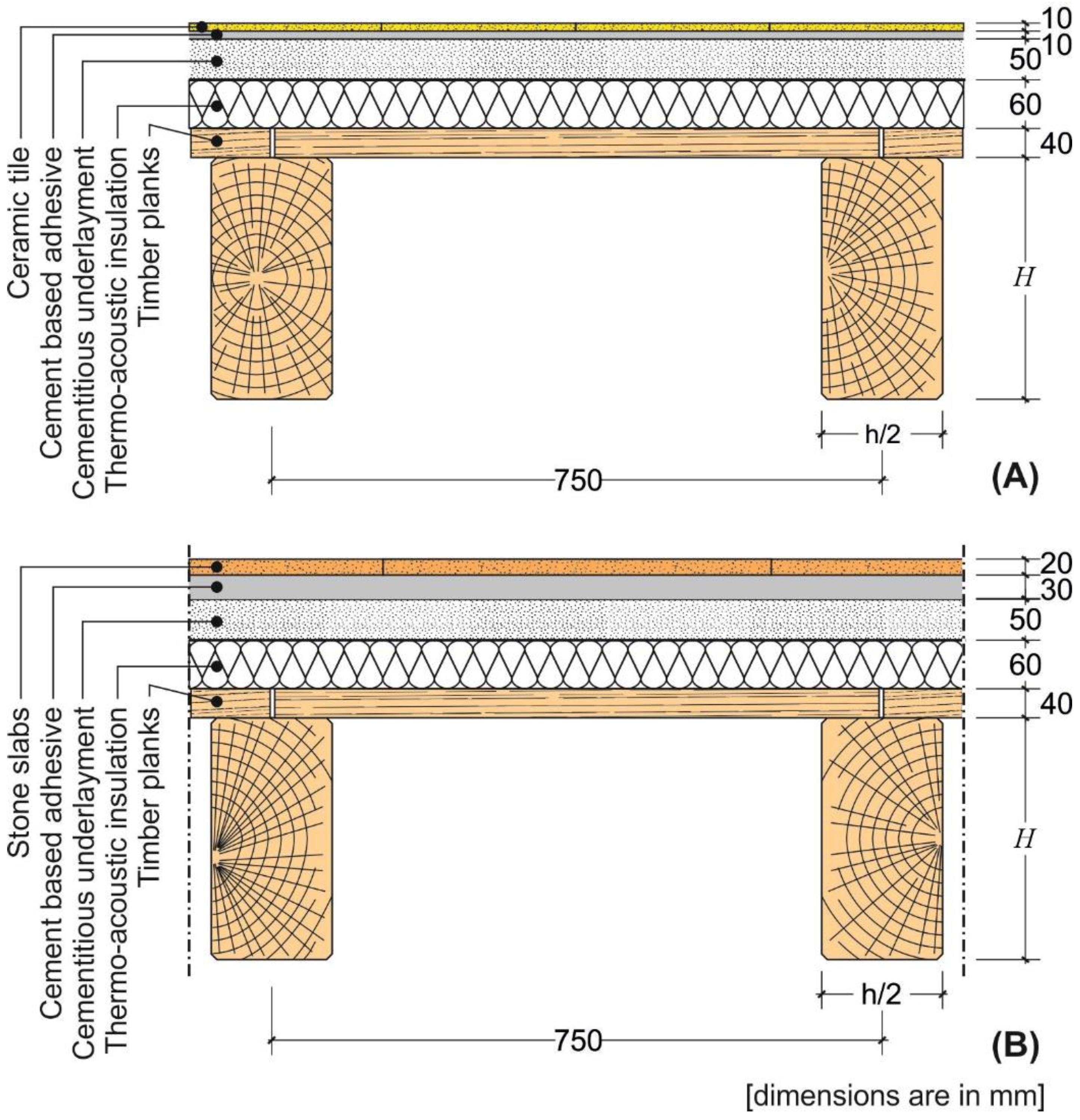

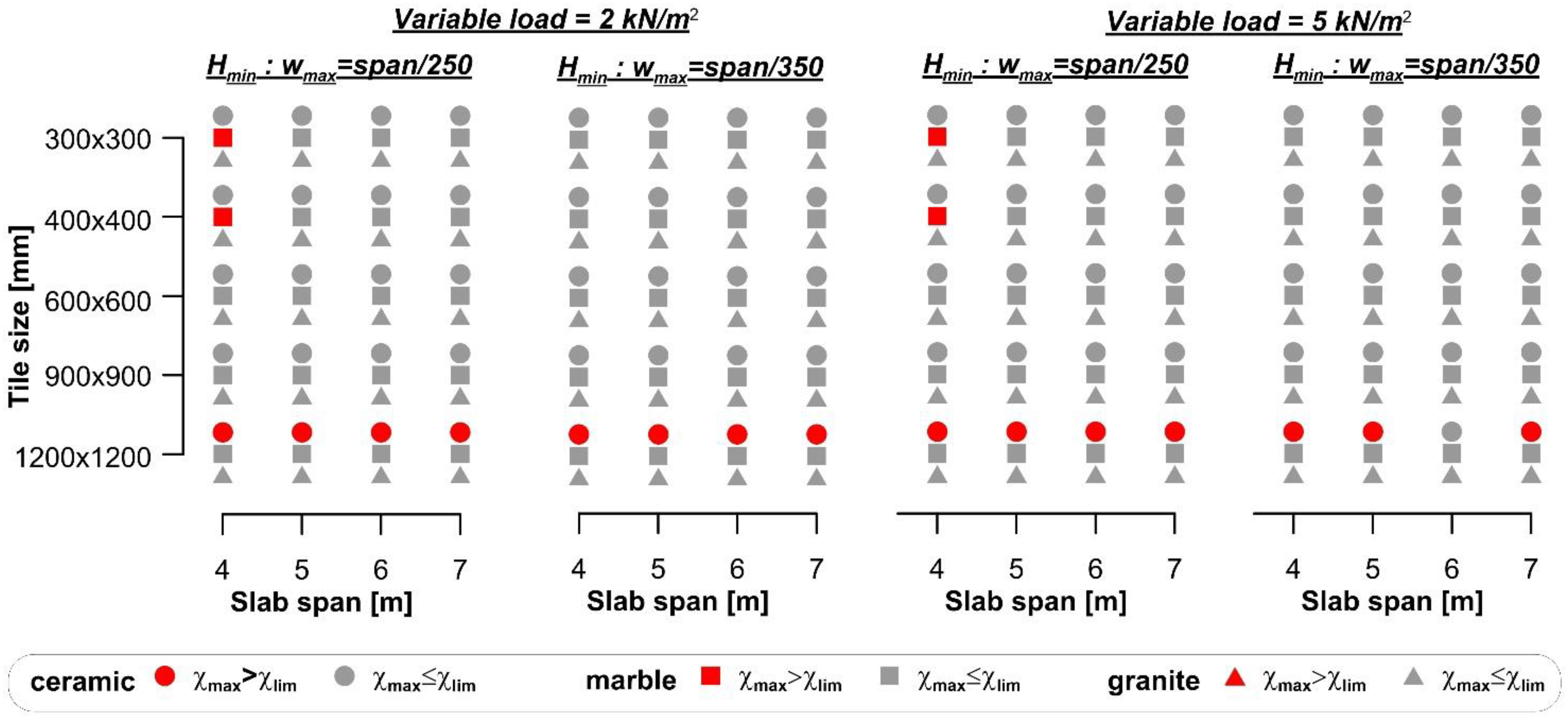

4.3. Traditional Slab Made of Timber Beams and Planks

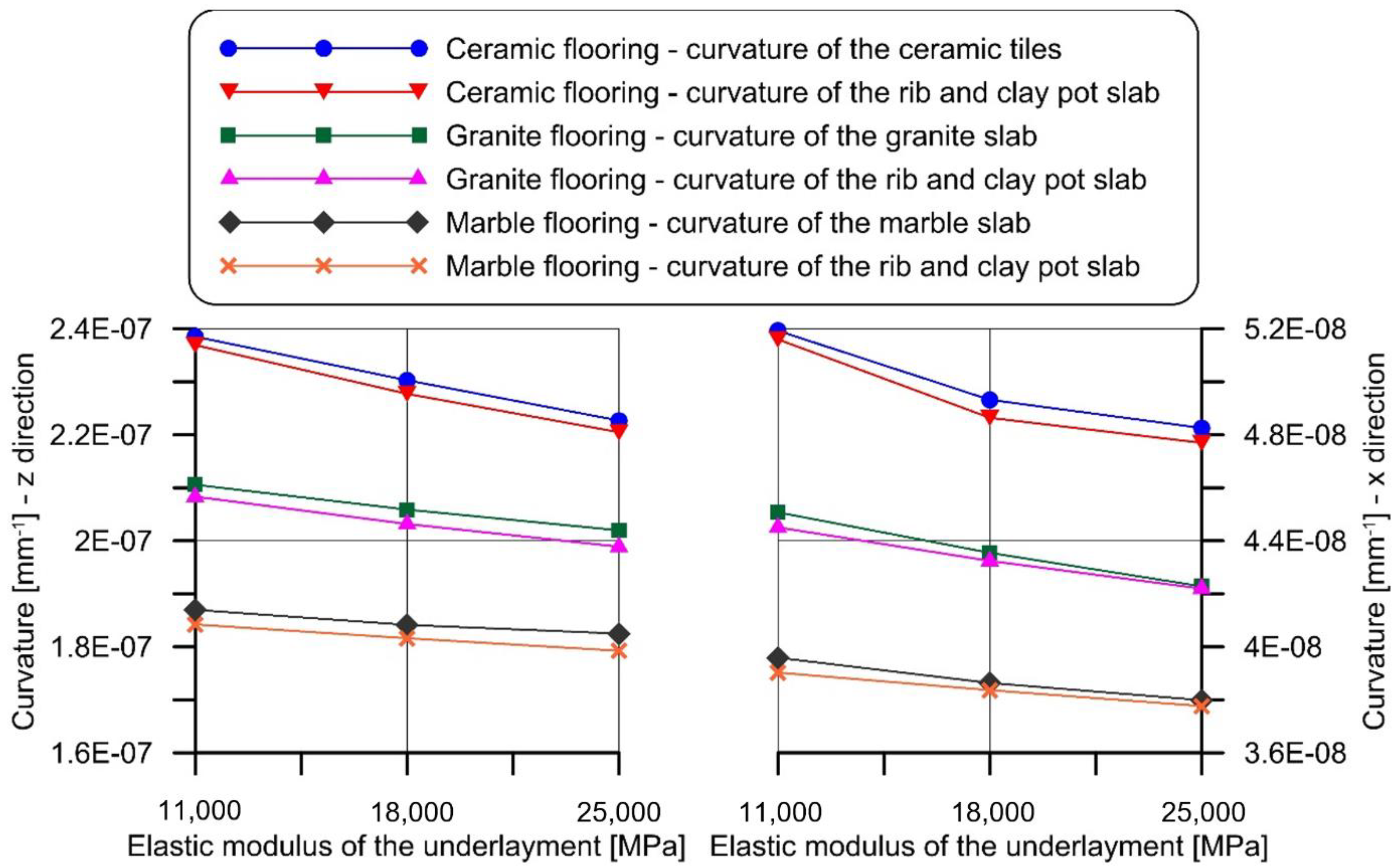

4.4. Effect of the Underlayment

5. Discussion

5.1. Curvature Control Method

5.2. Deflection Control Based on the Limit Curvature

6. Conclusions

- The deflection limit method adopted by the Eurocodes is complex and does not always guarantee the absence of damage to the floorings. Although the rules enforced by the Eurocodes for a reinforced concrete or a rib and clay pot slab were respected (except for tension stiffening that was neglected), up to 76.7% of the ceramic, marble, and granite floorings cracked. Furthermore, when dealing with a reinforced concrete or a rib and clay pot slab, the Eurocode 2 approach requires taking into account cracking, concrete creep, and tension stiffening, which make it extremely complex and hardly applicable for a professional engineer.

- The curvature control method is much simpler than the deflection control method adopted by the Eurocodes, since a direct verification on the curvature limits is performed. The curvature control method only requires a cross-section analysis, whereas the deflection control method requires the integration of curvature along the entire member axis.

- The curvature control method considers the constraint of the slab by computing the maximum curvature from the maximum service bending moment, calculated considering geometry, constraints, and intended use of the slab. Similarly, the limit imposed to the displacement in the deflection limit method seems independent from the constraints acting on the slab (it depends just on the span), which are accounted for in the computation of the maximum deflection.

- The curvature control method would allow for defining a general limit curvature value for floorings that could be adopted as minimum performance level in standards and would be able to guarantee the absence of flooring cracking. Furthermore, it appears promising for applications to specific problems arising with the use of innovative technologies, as in the case of bridge slabs reinforced with GFRP bars in which the design is controlled by the slab deformability rather than by its strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gilbert, R.I. The Serviceability Limit States in Reinforced Concrete Design. Procedia Eng. 2011, 14, 385–395. [Google Scholar]

- De Domenico, D.; Messina, D.; Recupero, A. A Combined Experimental-Numerical Framework for Assessing the Load-Bearing Capacity of Existing PC Bridge Decks Accounting for Corrosion of Prestressing Strands. Materials 2021, 14, 4914. [Google Scholar] [CrossRef]

- The Concrete Society. TR 58. Deflections in Concrete Slabs and Beams; The Concrete Society: Camberley, UK, 2019. [Google Scholar]

- European Committee for Standardization. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings—EN 1992-1-1; European Committeee for Standardization: Bruxelles, Belgium, 2010. [Google Scholar]

- Topolář, L.; Kocáb, D.; Šlanhof, J.; Schmid, P.; Daněk, P.; Nováček, J. Testing the Influence of the Material Bonding System on the Bond Strength of Large-Format Tiles Installed on Concrete Substrate under Mechanical Loading. Materials 2020, 13, 3200. [Google Scholar] [CrossRef]

- European Committee for Standardization. Eurocode 4: Design of Composite Steel and Concrete Structures—Part 1-1: General Rules and Rules for Buildings—EN 1994-1-1; European Committeee for Standardization: Bruxelles, Belgium, 2009. [Google Scholar]

- European Committee for Standardization. Eurocode 5: Design of Timber Structures—Part 1-1: General-Common Rules and Rules for Buildings—EN 1995-1-1:2004+A1; European Committeee for Standardization: Bruxelles, Belgium, 2008. [Google Scholar]

- International Organization for Standardization. ISO 4356:1977 Bases for the Design of Structures—Deformations of Buildings at the Serviceability Limit States; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- European Committee for Standardization. Eurocode—Basis of Structural Design—EN 1990:2002; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- D’Antino, T.; Pisani, M.A. Influence of sustained stress on the durability of glass FRP. Constr. Build. Mater. 2018, 187, 474–486. [Google Scholar] [CrossRef]

- Meille, S.; Saâdaoui, M.; Reynaud, P.; Fantozzi, G. Mechanisms of crack propagation in dry plaster. J. Eur. Ceram. Soc. 2003, 23, 3105–3112. [Google Scholar] [CrossRef]

- Berardi, U.; Tronchin, L.; Manfren, M.; Nastasi, B. On the Effects of Variation of Thermal Conductivity in Buildings in the Italian Construction Sector. Energies 2018, 11, 872. [Google Scholar] [CrossRef]

- Kumar, S.; Arun Prakash, S.; Pandiyarajan, V.; Geetha, N.; Antony Aroul Raj, V.; Velraj, R. Effect of phase change material integration in clay hollow brick composite in building envelope for thermal management of energy efficient buildings. J. Build. Phys. 2020, 43, 351–364. [Google Scholar] [CrossRef]

- Masia, M.J.; Kleeman, P.W.; Melchers, R.E. Modeling Soil/Structure Interaction for Masonry Structures. J. Struct. Eng. 2004, 130, 641–649. [Google Scholar] [CrossRef]

- Brodsky, A.; Rabinovitch, O.; Yankelevsky, D.Z. Determination of the interaction between a masonry wall and a confining frame. Eng. Struct. 2018, 167, 214–226. [Google Scholar] [CrossRef]

- Besana Moquette. Available online: https://www.besanamoquette.com/ (accessed on 29 January 2020).

- Biagiotti, J.; Iannoni, A.; Lopez-Manchado, M.A.; Kenny, J.M. Cure characteristics, mechanical properties, and morphological studies of linoleum flour-filled NBR compounds. Polym. Eng. Sci. 2004, 44, 909–916. [Google Scholar] [CrossRef]

- Tian, N.; Ning, R.; Kong, J. Self-toughening of epoxy resin through controlling topology of cross-linked networks. Polymer 2016, 99, 376–385. [Google Scholar] [CrossRef]

- Kerakoll Design House. Available online: https://kerakolldesignhouse.com/ (accessed on 29 January 2020).

- Mapei Mapei—Adhesives, Sealants, Chemical Products for Building. Available online: https://www.mapei.com/en (accessed on 29 January 2020).

- Ayrilmis, N.; Buyuksari, U.; As, N. Bending strength and modulus of elasticity of wood-based panels at cold and moderate temperatures. Cold Reg. Sci. Technol. 2010, 63, 40–43. [Google Scholar] [CrossRef]

- Ruman, D.; Záborský, V.; Svoboda, T.; Kašičková, V.; Rodrová, V. Identifying the Characteristics of Laminated Wood Based on the Values of Deflection Measured during its Bending. BioResources 2017, 12, 2592–2608. [Google Scholar] [CrossRef][Green Version]

- Kaklis, K.; Maurigiannakis, S.; Agioutantis, Z.; Istantso, C. Influence of Specimen Shape on the Indirect Tensile Strength of Transversely Isotropic Dionysos Marble Using the Three-Point Bending Test. Strain 2009, 45, 393–399. [Google Scholar] [CrossRef]

- Garzonio, C.A.; Giovannini, P.; Cavallucci, F. Analyses of the physical parameters correlated to bending phenomena in marble slabs. In Proceedings of the 9th International Congress on Deterioration and Conservation of Stone, Venice, Italy, 19–24 June 2000; Fassina, V., Ed.; Elsevier Science B.V.: Amsterdam, The Netherlands, 2000; pp. 89–97, ISBN 978-0-444-50517-0. [Google Scholar]

- Liu, Z.; Shao, J. Strength Behavior, Creep Failure and Permeability Change of a Tight Marble Under Triaxial Compression. Rock Mech. Rock Eng. 2017, 50, 529–541. [Google Scholar] [CrossRef]

- Granitmarmi. Available online: https://www.granitmarmi.it/ (accessed on 29 January 2020).

- Sa.Ge.Van. Marmi. Available online: https://www.sagevanmarmi.com/ (accessed on 29 January 2020).

- FMG FMG Book. Available online: https://www.irisfmg.it/doc/cataloghi_catalogues/2general_fmg_standard_size.pdf (accessed on 29 January 2020).

- Secchiari, L. Stone Materials: The Techniques of Use in Advanced Façade Systems; Alinea Editrice s.r.l.: Florence, Italy, 2012; ISBN 978-88-6055-722-3. (In Italian) [Google Scholar]

- CEN. EN-14411:2016—Ceramic Tiles—Definition, Classification, Characteristics, Assessment and Verification of Constancy of Performance and Marking; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- CEN. EN ISO 10545 4:2019—Ceramic Tile. Part 4: Determination of Modulus of Rupture and Breaking Strength; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- Fragassa, C.; Ubertini, F.; Pavlovic, A.; Conti, P. Limits of Applicability of Regulations on Ceramics in the Case of Pirodeformed Elements; AIAS—Associazione Italiana per l’Analisi delle Sollecitazioni: Bologna, Italy, 2014; pp. 433–443. (In Italian) [Google Scholar]

- Hegedűsová, L.; Ceniga, L.; Dusza, J. Bending and Contact Strength of Monolithic Ceramic Materials. Int. J. Damage Mech. 2012, 21, 293–305. [Google Scholar] [CrossRef]

- FAP. FAP Tile Company: Quality Ceramic Floor and Wall Tiles Suppliers. Available online: https://www.fapceramiche.com/en/ (accessed on 29 January 2020).

- GranitiFiandre. Italian Floor Tiles, Porcelain Tile Flooring and Walls—Fiandre. Available online: http://www.granitifiandre.com/ (accessed on 29 January 2020).

- Ceramica Sant’Agostino. Porcelain Stoneware Floor and Wall Tiles. Available online: https://www.ceramicasantagostino.it/en/ (accessed on 29 January 2020).

- Ceramiche Refin. Porcelain Tiles|Floor Tile|Italian Ceramic Tile. Available online: https://www.refin-ceramic-tiles.com/ (accessed on 29 January 2020).

- Tile Council of North America (TCNA). Handbook for Ceramic, Glass, and Stone Tile Installation; Tile Council of North America Inc.: Anderson, SC, USA, 2017. [Google Scholar]

- de Sousa, R.; Sousa, H. Analysis of reinforcement techniques for partition walls subjected to vertical deformations of concrete slabs. In Proceedings of the XII International Conference on Structural Repair and Rehabilitation, Porto, Portugal, 26 October 2016. [Google Scholar]

- Abreu, M.; Leitao, V.; Lucas, J.C. Modelling the Behaviour of Ceramic Tile Coverings; Colegio Oficial de Ingenieros Superiores Industriales: Castellón, Spain, 2004; Volume 3, pp. 3–17. [Google Scholar]

- Diolaiti, E. Physical-Mechanical Characterizations of Large Format Ceramic Tiles. Master’s Thesis, Alma Mater Studiorum (University of Bologna), Bologna, Italy, 2016. (In Italian). [Google Scholar]

- CEN. EN 771-1:2011+A1:2015—Specification for Masonry Units. Part 1: Clay Masonry Units; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- Toniolo, G.; Di Prisco, M. Reinforced Concrete Design: To Eurocode 2; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- European Committee for Concrete. CEB FIP Manual of Buckling and Instability. Bulletin 123; CEB FIP: Paris, France, 1977. [Google Scholar]

- Gilbert, R.I.; Ranzi, G. Time-Dependent Behaviour of Concrete Structures; Spon Press: London, UK, 2010. [Google Scholar]

- Pisani, M.A. Strength of FRP RC sections after long-term loading. Struct. Eng. Mech. 2003, 15, 345–365. [Google Scholar] [CrossRef]

- Bradford, M.A. Generic modelling of composite steel–concrete slabs subjected to shrinkage, creep and thermal strains including partial interaction. Eng. Struct. 2010, 32, 1459–1465. [Google Scholar] [CrossRef]

- Federation Internationale du Beton. Fib Model Code for Concrete Structures 2010; Ernst & Sohn GmbH & Co.: Lausanne, Switzerland, 2013; ISBN 978-3-433-03061-5. [Google Scholar]

- European Committeee for Standardization. Eurocode 3: Design of Steel Structures—Part 1-1: General Rules and Rules for Buildings—EN 1993-1-1; European Committeee for Standardization: Bruxelles, Belgium, 2006. [Google Scholar]

- Ministero delle Infrastrutture e dei Trasporti. Norme Tecniche per le Costruzioni; MIT: Rome, Italy, 2018. [Google Scholar]

- Gere, J.M.; Timoshenko, S.P. Mechanics of Materials, 2nd ed.; Brooks/Cole Engineering Div: Monterey, CA, USA, 1984; ISBN 978-0-534-03099-5. [Google Scholar]

- Forest Products Laboratory. Mechanical properties of wood. In Wood Handbook—Wood as an Engineering Material; Department of Agricolture, Forest Service: Madison, WI, USA, 1999; p. 463. [Google Scholar]

- Simulia. Abaqus 6.14 Extended Functionality Online Documentation. Available online: http://130.149.89.49:2080/v6.14/ (accessed on 15 January 2016).

- Fermacel-Sottofondi. Available online: https://www.fermacell.it/Sottofondi (accessed on 29 January 2020).

- Knauf. Available online: http://www.knauf.it/Default.aspx (accessed on 29 January 2020).

- Laterlite. Available online: https://www.laterlite.com/ (accessed on 29 January 2020).

- Saint-Gobain Weber. Available online: https://www.it.weber/ (accessed on 29 January 2020).

- CEN. prEN 13813:2017 E—Screed Material and Floor Screeds—Screed Material—Properties and Requirements; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- Jankowiak, T.; Lodygowsky, T. Identification of parameters of concrete damage plasticity constitutive model. Found. Civ. Environ. Eng. 2005, 6, 53–69. [Google Scholar]

- de Borst, R.; Groen, A.E. Computational strategies for standard soil plasticity models. In Modeling in Geomechanics; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2000; pp. 23–50. [Google Scholar]

- Reinhardt, H.W.; Cornelissen, H.; Hordijk, D.A. Tensile Tests and Failure Analysis of Concrete. J. Struct. Eng. 1986, 112, 2462–2477. [Google Scholar] [CrossRef]

- Marí, A.; Bairán, J.-M.; Oller, E.; Duarte, N. Modeling serviceability performance and ultimate capacity of corroded reinforced and prestressed concrete structures. Struct. Concr. 2021, 1–10. [Google Scholar] [CrossRef]

| Size [mm] | s [mm] | S [N] | |

|---|---|---|---|

| 300 × 300 | 9.5 | 750 | 4.03 |

| 400 × 400 | 9.5 | 900 | 4.84 |

| 600 × 600 | 10 | 900 | 4.15 |

| 900 × 900 | 10 | 1000 | 4.61 |

| 1200 × 1200 | 20 | 1200 | 6.91 |

| Size [mm] | s [mm] | f [MPa] | |

|---|---|---|---|

| 300 × 300 | 20 | 12 | 0.85 |

| 400 × 400 | 20 | 12 | 0.85 |

| 600 × 600 | 20 | 35 | 2.49 |

| 900 × 900 | 30 | 35 | 1.66 |

| 1200 × 1200 | 30 | 50 | 2.37 |

| Size [mm] | s [mm] | f [MPa] | |

|---|---|---|---|

| 300 × 300 | 20 | 12 | 1.18 |

| 400 × 400 | 20 | 12 | 1.18 |

| 600 × 600 | 20 | 25 | 2.47 |

| 900 × 900 | 30 | 25 | 1.64 |

| 1200 × 1200 | 30 | 35 | 2.30 |

| Material | Elastic Modulus [GPa] | Poisson’s Ratio |

|---|---|---|

| Concrete | 32 | 0.20 |

| Underlayment 1 (cementitious) | 11 | 0.20 |

| Underlayment 2 (cementitious) | 18 | 0.20 |

| Underlayment 3 (cementitious) | 25 | 0.20 |

| Flooring: ceramic tiles | 60 | 0.28 |

| Flooring: marble tiles | 132 | 0.25 |

| Flooring: granite tiles | 90 | 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Antino, T.; Pisani, M.A. A Proposal to Improve the Effectiveness of the Deflection Control Method Provided by Eurocodes for Concrete, Timber, and Composite Slabs. Materials 2021, 14, 7627. https://doi.org/10.3390/ma14247627

D’Antino T, Pisani MA. A Proposal to Improve the Effectiveness of the Deflection Control Method Provided by Eurocodes for Concrete, Timber, and Composite Slabs. Materials. 2021; 14(24):7627. https://doi.org/10.3390/ma14247627

Chicago/Turabian StyleD’Antino, Tommaso, and Marco Andrea Pisani. 2021. "A Proposal to Improve the Effectiveness of the Deflection Control Method Provided by Eurocodes for Concrete, Timber, and Composite Slabs" Materials 14, no. 24: 7627. https://doi.org/10.3390/ma14247627

APA StyleD’Antino, T., & Pisani, M. A. (2021). A Proposal to Improve the Effectiveness of the Deflection Control Method Provided by Eurocodes for Concrete, Timber, and Composite Slabs. Materials, 14(24), 7627. https://doi.org/10.3390/ma14247627