Traditional Artificial Neural Networks Versus Deep Learning in Optimization of Material Aspects of 3D Printing

Abstract

:1. Introduction

- Determining the structure of the technological process (sequences of technological operations and procedures): decision rules

- Building models of selecting materials, semi-finished products, tooling and their parameters, and settings: artificial neural networks (ANN) and decision trees (DT)

- Pre-processing (normalization, coding) of selected data used to build models: fuzzy logic, including ordered fuzzy numbers (OFN)

- Implementation of models for the selection of materials, semi-finished products, tools, devices, and parameters of their processing as a prototype expert system used to design the technological process: ANN

- Attempts to eliminate disturbances in the course of the planned technological process affecting product quality by means of the developed methodology and models of technological process supervision: process instability, exceeding warning and alarm values of monitored parameters by means of ANN and DT

- Predictive models, including for control and compensation of deformations (including thermal ones): ANN

- Ageing processes: ANN.

2. Theoretical Background

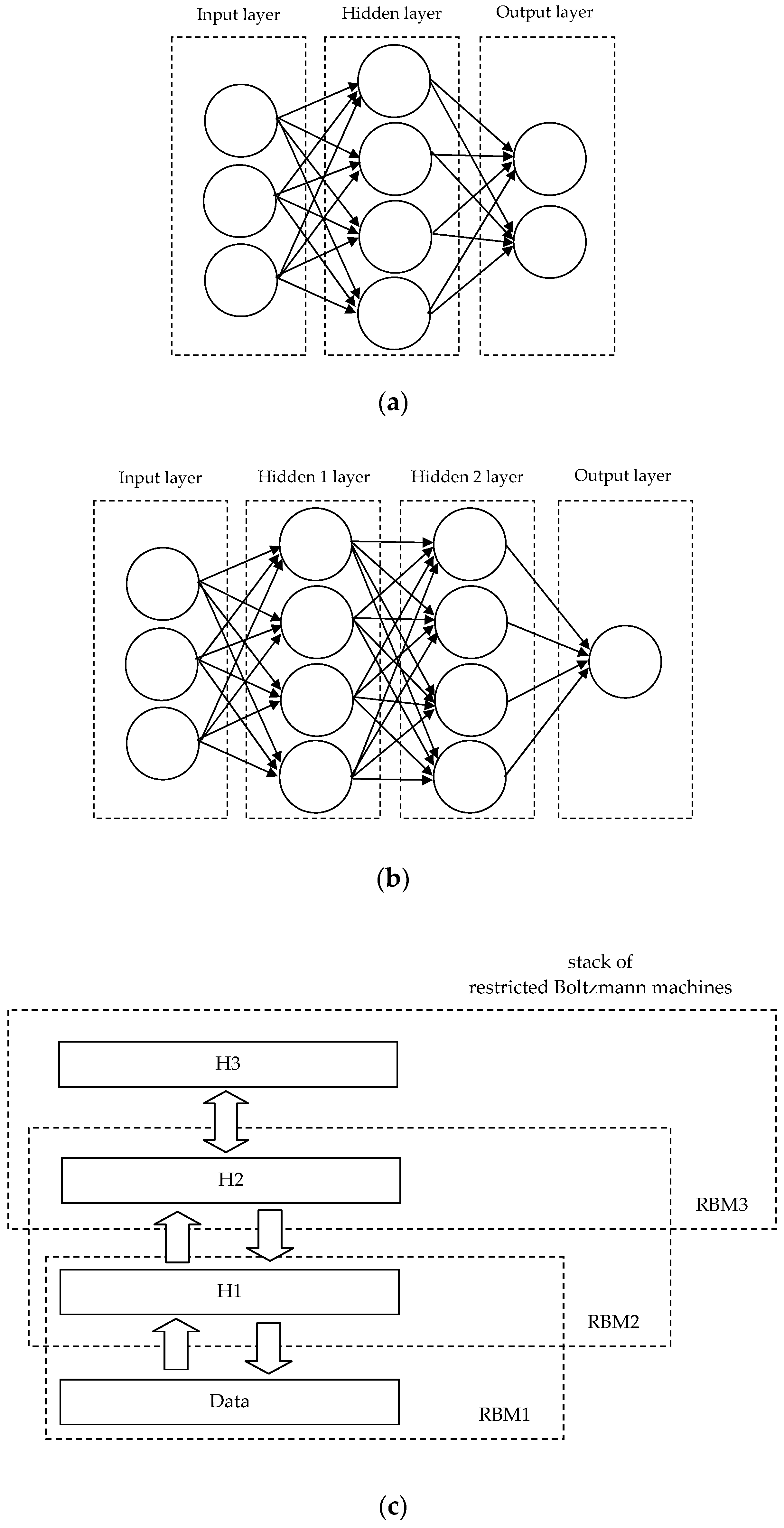

2.1. Deep Learning

- A significant reduction in hardware costs

- Drastically increased computing capabilities of processors (e.g., graphic processing units (GPUs)).

- Input layer

- Hidden layer

- The output layer.

- reinforcement learning:

- Q-learning

- Deep Q-network

- Supervised learning:

- Regression (neural networks, decision trees, ensembles methods, linear, non-linear (GLM logistic)

- Classification (naive Bayes, k-nearest neighbors–kNN, discriminant analysis, support vector machines—SVM)

- Unsupervised learning:

- Autoencoders

- Clustering (k-means, hierarchical, neural, Gaussian, hidden) [4].

2.2. Optimization of Solutions

3. Materials and Methods

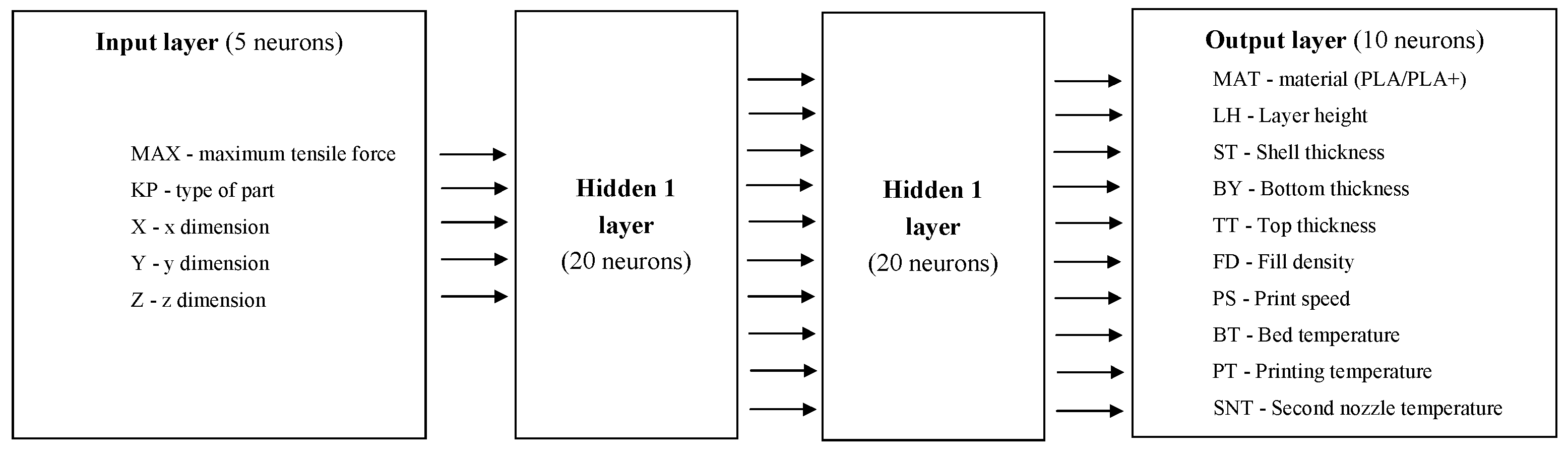

3.1. Data Analysis and Computational Model

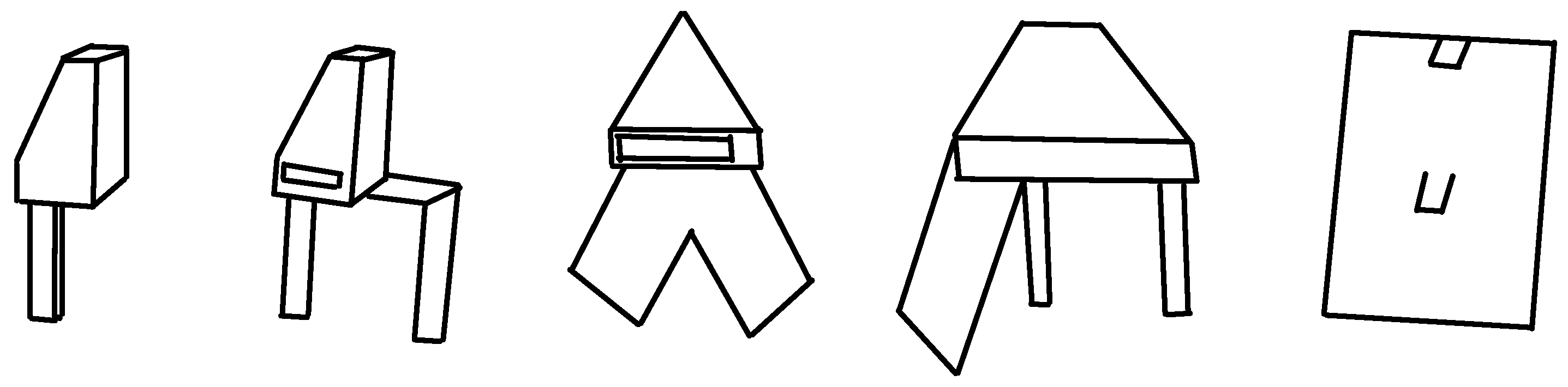

3.2. Analyzed Data Sets

- First, depending on the type of printer, the nozzle, the print bed or both move while the plastic is being extruded

- Simultaneously, the heated nozzle ejects molten plastic, and deposits it in thin layers, one on top of another, layer-by-layer, forming the shape of the whole 3D printed object

- The aforementioned filament layers fuse together due to the thermal fusion bonding occurring between the individual layers, to create a solid part (after cooling down).

3.3. Testing Procedure

- The training set was used to identify systematic errors and network weights during their learning

- The testing set was used to calibrate, prevent network overtraining, and measure and compare the ANN and CNN performance.

3.4. Traditional Approach

- Back-propagation (BP) algorithm—a popular gradient-based local search optimization technique

- Naive initialization technique

- Neural network weights preset instead of setting the aforementioned scales to small random numbers to avoid a slow error convergence rate, being trapped at local minima, etc.

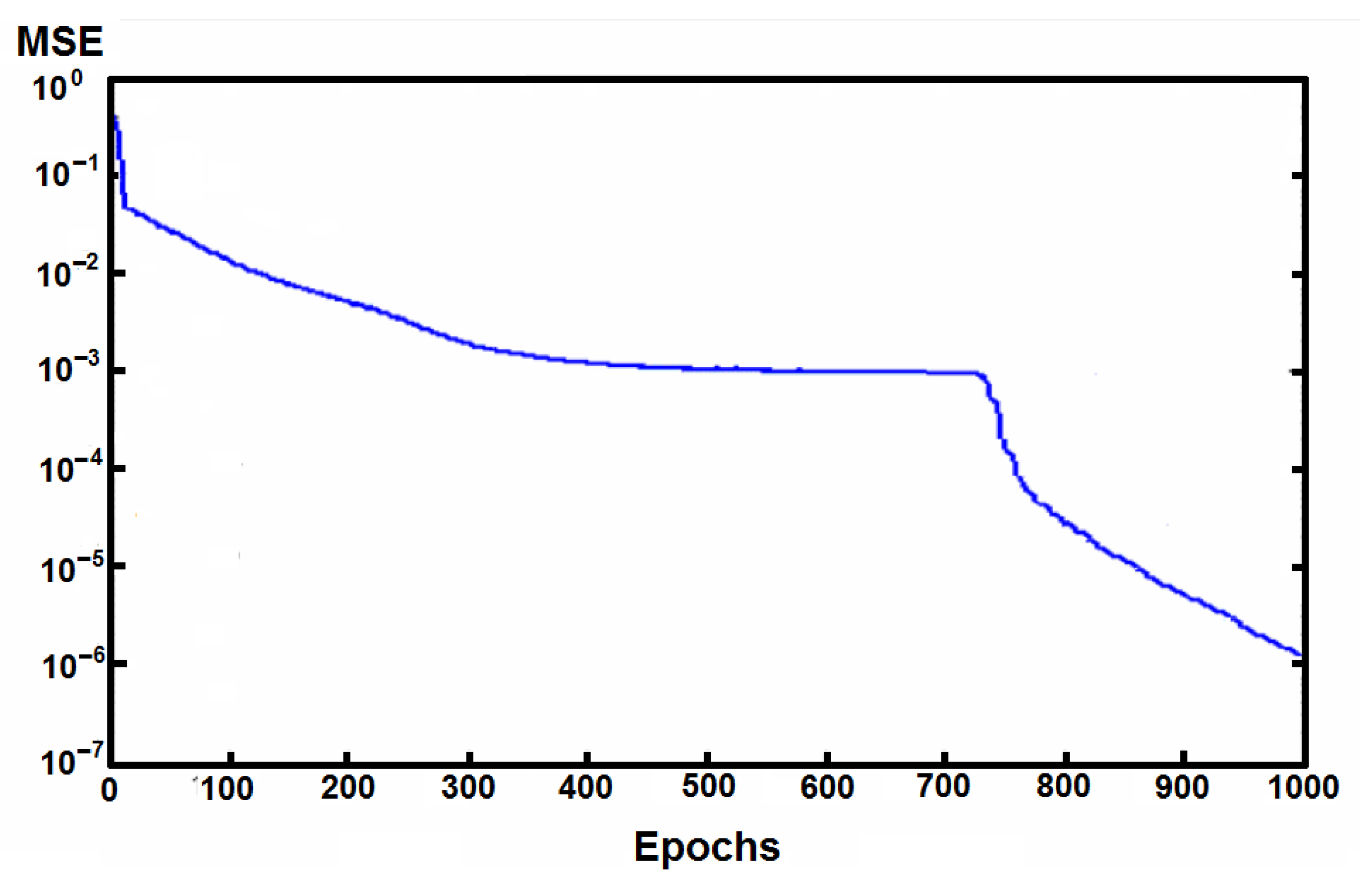

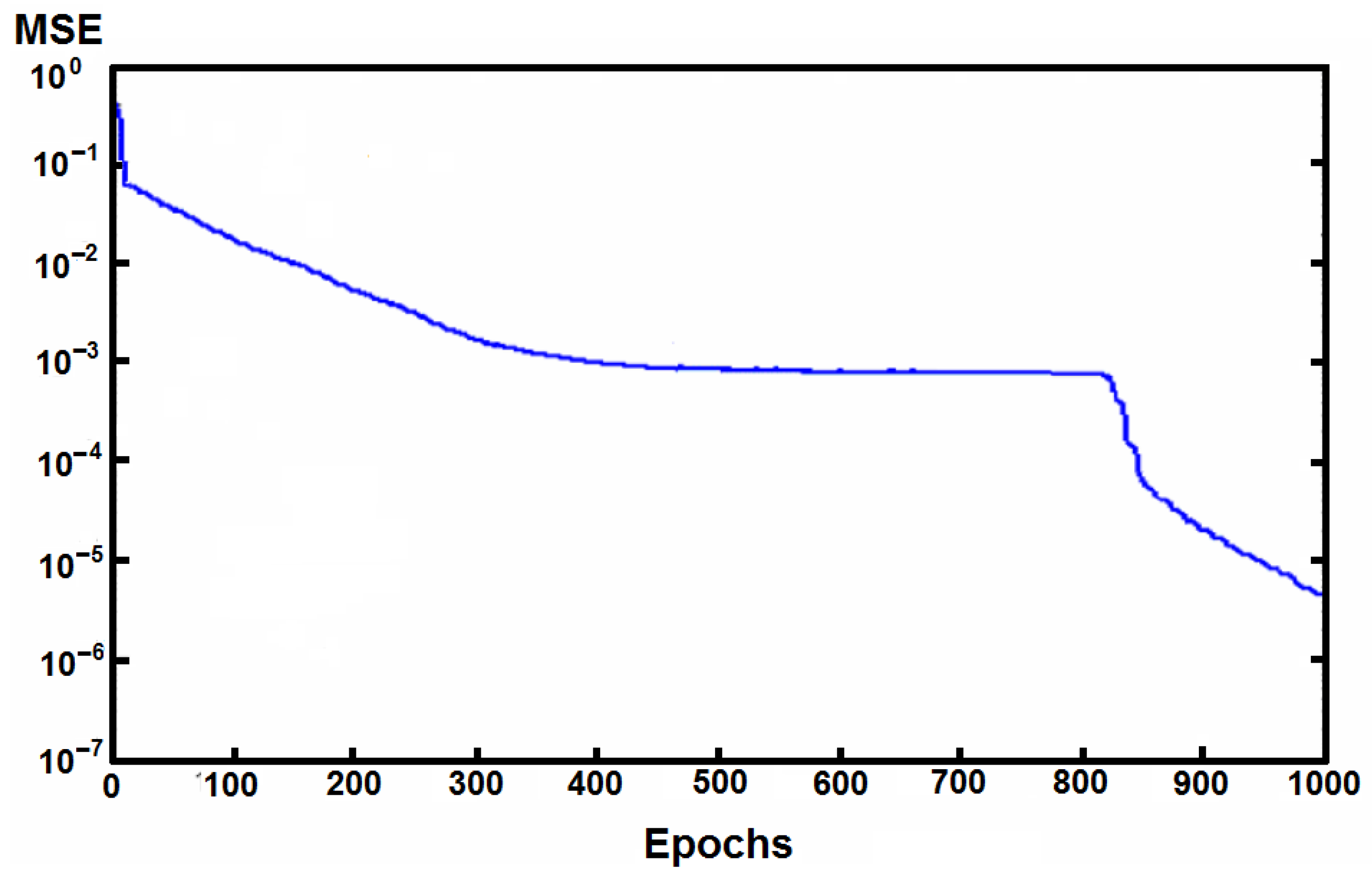

- Optimization of the connection weights of the MLP set to minimize the error function (i.e., average mean square error (MSE) between the target and actual outputs averaged over all training examples).

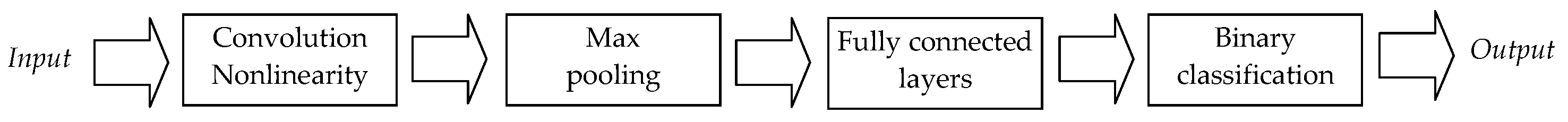

3.5. Deep Learning Approach

4. Results

5. Discussion

- 2D drawing

- 3D construction of the implant

- 3D printout for physical printing.

- We obtain the shape using technologies such as 3D scanning

- We use 3D DL to train a deep neural network for a specific task (printing an orthosis or a dental crown)—the CNN can learn the deformation function owing to the large amount of data used for training.

- We verify the performance of the neural network:

- Translation

- Scaling up

- Scaling down

- Rotation.

- The use of ultrasonic testing, filtering, DL, machine vision, and other technologies used to detect defects

- Classification of product defects into categories in different products

- Functions and characteristics of existing equipment used for defect detection, related to high precision, high positioning, fast detection, small objects, complex backgrounds, hidden object detection and object association

- And only then can DL methods be used to optimize production processes to avoid these defects [33].

6. Conclusions

- Experimental practices are time- and cost-intensive so the application of AI-based optimization may be a quicker and cheaper solution.

- PLA-based 3D printing can be optimized to successfully print a utility/functional part of an exoskeleton. Optimization powered by AI/ML can play a key role in the 3D printing process, increasing the efficiency and safety of the printed object (end product).

- The DL-based approach will become the leader in 3D printing optimization as the complexity of the printed objects increases.

- Compared with the results from the traditional ANN approach, optimization based on DL decreased the calculating speed by up to 1.5 times with the same print quality, increased quality (both learning: 0.9577 and testing: 0.9721), decreased MSE (0.001), and a set of printing parameters not previously determined by trial and error was also identified.

- With the current complexity and type of computation, there is no need to combine two optimization solutions (traditional ANN and DL).

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mishra, C.; Gupta, D. Deep machine learning and neural networks: An Overview. IAES Int. J. Artif. Intell. 2017, 6, 66. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Macko, M. AI-optimized technological aspects of the material used in 3D printing processes for selected medical applications. Materials 2020, 13, 5437. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E. Digital twins in product lifecycle for sustainability in manufacturing and maintenance. Appl. Sci. 2021, 11, 31. [Google Scholar] [CrossRef]

- Walsh, J.; O’Mahony, N.; Campbell, S.; Carvalho, A.; Krpalkova, L.; Velasco-Hernandez, G.; Harapanahalli, S.; Riordan, D. Deep learning vs. traditional computer vision. In Science and Information Conference; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef] [Green Version]

- Nash, W.; Drummond, T.; Birbilis, N. A review of deep learning in the study of materials degradation. npj Mater. Degrad. 2018, 2, 37. [Google Scholar] [CrossRef]

- Bonaccorso, G. Machine Learning Algorithms Popular Algorithms for Data Science and Machine Learning, 2nd ed.; Packt Publishing Ltd.: Birmingham, UK, 2018. [Google Scholar]

- Mahony, N.O.; Murphy, T.; Panduru, K.; Riordan, D.; Walsh, J. Improving controller performance in a powder blending process using predictive control. In Proceedings of the 2017 28th Irish Signals and Systems Conference (ISSC), Killarney, Ireland, 20–21 June 2017; pp. 1–6. [Google Scholar]

- O’Mahony, N.; Murphy, T.; Panduru, K.; Riordan, D.; Walsh, J. Real-time monitoring of powder blend composition using near infrared spectroscopy. In Proceedings of the 2017 Eleventh International Conference on Sensing Technology (ICST), Sydney, Australia, 4–6 December 2017; pp. 1–6. [Google Scholar]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Martinez, J.L.; Damon, A.; Domingo, R.A.; Valero-Moreno, F.; Quiñones-Hinojosa, A. Retrosigmoid craniectomy and suprameatal drilling-3-dimensionally printed microneurosurgical simulation: 2-dimensional operative video. Oper. Neurosurg. 2021, 21, E355–E356. [Google Scholar] [CrossRef]

- Seok, J.; Yoon, S.; Ryu, C.H.; Kim, S.K.; Ryu, J.; Jung, Y.S. A personalized 3D-printed model for obtaining informed consent process for thyroid surgery: A randomized clinical study using a deep learning approach with mesh-type 3D modeling. J. Pers. Med. 2021, 11, 574. [Google Scholar] [CrossRef]

- Liu, X.; Fan, Y.; Li, S.; Chen, M.; Li, M.; Hau, W.K.; Zhang, H.; Xu, L.; Lee, A.P. Deep learning-based automated left ventricular ejection fraction assessment using 2D echocardiography. Am. J. Physiol. Heart Circ. Physiol. 2021, 321, H390–H399. [Google Scholar] [CrossRef]

- Fonseca, G.P.; Baer-Beck, M.; Fournie, E.; Hofmann, C.; Rinaldi, I.; Ollers, M.C.; van Elmpt, W.J.C.; Verhaegen, F. Evaluation of novel AI-based extended field-of-view CT reconstructions. Med. Phys. 2021, 48, 3583–3594. [Google Scholar] [CrossRef]

- Shi, L.; Li, B.; Kim, C.; Kellnhofer, P.; Matusik, W. Towards real-time photorealistic 3D holography with deep neural networks. Nature 2021, 591, 234–239. [Google Scholar] [CrossRef]

- Sivasankaran, S.; Jonnalagadda, S. Advances in controlled release hormonal technologies for contraception: A review of existing devices, underlying mechanisms, and future directions. J. Control. Release 2021, 330, 797–811. [Google Scholar] [CrossRef]

- Pan, Z.; Shen, Z.; Zhu, H.; Bao, Y.; Liang, S.; Wang, S.; Li, X.; Niu, L.; Dong, X.; Shang, X.; et al. Clinical application of an automatic facial recognition system based on deep learning for diagnosis of turner syndrome. Endocrine 2021, 72, 865–873. [Google Scholar] [CrossRef]

- Sanicola, H.W.; Stewart, C.E.; Mueller, M.; Ahmadi, F.; Wang, D.; Powell, S.K.; Sarkar, K.; Cutbush, K.; Woodruff, M.A.; Brafman, D.A. Guidelines for establishing a 3-D printing biofabrication laboratory. Biotechnol. Adv. 2020, 45, 107652. [Google Scholar] [CrossRef]

- Kuang, X.; Cheung, J.P.; Wu, H.; Dokos, S.; Zhang, T. MRI-SegFlow: A novel unsupervised deep learning pipeline enabling accurate vertebral segmentation of MRI images. Annu. Int. Conf. IEEE Eng. Med. Biol. Soc. 2020, 2020, 1633–1636. [Google Scholar]

- Lu, L.; Dao, M.; Kumar, P.; Ramamurty, U.; Karniadakis, G.E.; Suresh, S. Extraction of mechanical properties of materials through deep learning from instrumented indentation. Proc. Natl. Acad. Sci. USA 2020, 117, 7052–7062. [Google Scholar] [CrossRef] [Green Version]

- Tripodi, N.; Kelly, K.; Husaric, M.; Wospil, R.; Fleischmann, M.; Johnston, S.; Harkin, K. The impact of three-dimensional printed anatomical models on first-year student engagement in a block mode delivery. Anat. Sci. Educ. 2020, 13, 769–777. [Google Scholar] [CrossRef]

- Licci, M.; Thieringer, F.M.; Guzman, R.; Soleman, J. Development and validation of a synthetic 3D-printed simulator for training in neuroendoscopic ventricular lesion removal. Neurosurg. Focus. 2020, 48, E18. [Google Scholar] [CrossRef] [Green Version]

- Mussi, E.; Mussa, F.; Santarelli, C.; Scagnet, M.; Uccheddu, F.; Furferi, R.; Volpe, Y.; Genitori, L. Current practice in preoperative virtual and physical simulation in neurosurgery. Bioengineering 2020, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- Tanner, J.A.; Jethwa, B.; Jackson, J.; Bartanuszova, M.; King, T.S.; Bhattacharya, A.; Sharma, R. A three-dimensional print model of the pterygopalatine fossa significantly enhances the learning experience. Anat. Sci. Educ. 2020, 13, 568–580. [Google Scholar] [CrossRef]

- Luo, Y.; Mengu, D.; Yardimci, N.T.; Rivenson, Y.; Veli, M.; Jarrahi, M.; Ozcan, A. Design of task-specific optical systems using broadband diffractive neural networks. Light Sci. Appl. 2019, 8, 112. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Chen, X.; Lv, S.; Zhang, Y.; Long, H.; Yang, K.; Qi, S.; Zhang, W.; Wang, J. Application of 3D printing in the construction of burr hole ring for deep brain stimulation implants. J. Vis. Exp. 2019, 151, e59560. [Google Scholar] [CrossRef]

- Martín Noguerol, T.; Paulano-Godino, F.; Martín-Valdivia, M.T.; Menias, C.O.; Luna, A. Strengths, weaknesses, opportunities, and threats analysis of artificial intelligence and machine learning applications in radiology. J. Am. Coll. Radiol. 2019, 16, 1239–1247. [Google Scholar] [CrossRef]

- Cairns, D.R.; Curtis, R.; Sierros, K.A.; Bolyard, J.J. Taking professional development from 2D to 3D: Design-based learning, 2D modeling, and 3D fabrication for authentic standards-aligned lesson plans. Interdiscip. J. Probl. Based Learn. 2018, 12, 8. [Google Scholar] [CrossRef]

- Shen, Z.; Shang, X.; Zhao, M.; Dong, X.; Xiong, G.; Wang, F.Y. A learning-based framework for error compensation in 3D printing. IEEE Trans. Cybern. 2019, 49, 4042–4050. [Google Scholar] [CrossRef]

- Luo, X.; Mori, K.; Peters, T.M. Advanced endoscopic navigation: Surgical big data, methodology, and applications. Annu. Rev. Biomed. Eng. 2018, 20, 221–251. [Google Scholar] [CrossRef]

- Kim, K.; Kim, S.; Jeon, J.S. Visual estimation of bacterial growth level in microfluidic culture systems. Sensors 2018, 18, 447. [Google Scholar] [CrossRef] [Green Version]

- Szymanik, B.; Psuj, G.; Hashemi, M.; Lopato, P. Detection and identification of defects in 3D-printed dielectric structures via thermographic inspection and deep neural networks. Materials 2021, 14, 4168. [Google Scholar] [CrossRef]

- Wen, H.; Huang, C.; Guo, S. The application of convolutional neural networks (CNNs) to recognize defects in 3D-printed parts. Materials 2021, 14, 2575. [Google Scholar] [CrossRef]

- Yang, J.; Li, S.; Wang, Z.; Dong, H.; Wang, J.; Tang, S. Using deep learning to detect defects in manufacturing: A comprehensive survey and current challenges. Materials 2020, 13, 5755. [Google Scholar] [CrossRef]

- Jiang, Z.; Hu, J.; Marrone, B.L.; Pilania, G.; Yu, X. A deep neural network for accurate and robust prediction of the glass transition temperature of polyhydroxyalkanoate homo and copolymers. Materials 2020, 13, 5701. [Google Scholar] [CrossRef]

- Shin, H.K.; Ahn, Y.H.; Lee, S.H.; Kim, H.Y. Automatic concrete damage recognition using multi-level attention convolutional neural network. Materials 2020, 13, 5549. [Google Scholar] [CrossRef]

- Machrowska, A.; Szabelski, J.; Karpiński, R.; Krakowski, P.; Jonak, J.; Jonak, K. Use of deep learning networks and statistical modeling to predict changes in mechanical parameters of contaminated bone cements. Materials 2020, 13, 5419. [Google Scholar] [CrossRef]

- Liu, Y.; Yuan, Y.; Balta, C.; Liu, J. A light-weight deep-learning model with multi-scale features for steel surface defect classification. Materials 2020, 13, 4629. [Google Scholar] [CrossRef]

- Nunez, I.; Marani, A.; Nehdi, M.L. Mixture optimization of recycled aggregate concrete using hybrid machine learning model. Materials 2020, 13, 4331. [Google Scholar] [CrossRef]

- Zazoum, B.; Triki, E.; Bachri, A. Modeling of mechanical properties of clay-reinforced polymer nanocomposites using deep neural network. Materials 2020, 13, 4266. [Google Scholar] [CrossRef]

- Thomas, A.; Durmaz, A.R.; Straub, T.; Eberl, C. Automated quantitative analyses of fatigue-induced surface damage by deep learning. Materials 2020, 13, 3298. [Google Scholar] [CrossRef]

- Rojek, I.; Jagodziński, M. Hybrid artificial intelligence system in constraint based scheduling of integrated manufacturing erp systems. In Hybrid. Artificial Intelligent Systems; Lecture Notes in Computer Science, 7209; Corchado, E., Snášel, V., Abraham, A., Woźniak, M., Graña, M., Cho, S.B., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 229–240. [Google Scholar] [CrossRef]

- Rojek, I. Neural networks as prediction models for water intake in water supply system. In Artificial Intelligence and Soft Computing—ICAISC 2008, Proceedings of the ICAISC 2008, Zakopane, Poland, 22–26 June 2008; Lecture Notes in Computer Science, 5097; Rutkowski, L., Tadeusiewicz, R., Zadeh, L.A., Zurada, J.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1109–1119. [Google Scholar] [CrossRef]

- Rojek, I.; Kowal, M.; Stoic, A. Predictive compensation of thermal deformations of ball screws in CNC machines using neural networks. Teh. Vjesn. 2017, 24, 1697–1703. [Google Scholar] [CrossRef] [Green Version]

- Rojek, I.; Kujawinska, A.; Hamrol, A.; Rogalewicz, M. Artificial neural networks as a means for making process control charts user friendly. In Intelligent Systems in Production Engineering and Maintenance—ISPEM 2017, Proceedings of the ISPEM 2017, Wrocław, Poland, 28–29 September 2017; Advances in Intelligent Systems and Computing, 637; Burduk, A., Mazurkiewicz, D., Eds.; Springer: Cham, Switzerland, 2018; pp. 168–178. [Google Scholar] [CrossRef]

- Dostatni, E.; Rojek, I.; Hamrol, A. The use of machine learning method in concurrent ecodesign of products and technological processes. In Advances in Manufacturing. Lecture Notes in Mechanical Engineering; Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M., Eds.; Springer: Cham, Switzerland, 2018; pp. 321–330. [Google Scholar] [CrossRef]

- Erps, T.; Foshey, M.; Luković, M.K.; Shou, W.; Goetzke, H.H.; Dietsch, H.; Stoll, K.; von Vacano, B.; Matusik, W. Accelerated discovery of 3D printing materials using data-driven multiobjective optimization. Sci. Adv. 2021, 7, eabf7435. [Google Scholar] [CrossRef]

- Verma, D.; Dong, Y.; Sharma, M.; Chaudhary, A.K. Advanced processing of 3D printed biocomposite materials using artificial intelligence. Mater. Manuf. Process. 2021, 36, 1–21. [Google Scholar] [CrossRef]

| Parameter | Unit |

|---|---|

| Material choice (PLA/PLA+) | - |

| Layer height | mm |

| Shell thickness | mm |

| Bottom thickness | mm |

| Top thickness | mm |

| Fill density | % |

| Print speed | mm/s |

| Bed temperature | °C |

| Printing temperature | °C |

| Second nozzle temperature | °C |

| NS | AH | AO |

|---|---|---|

| 5-20-10 | Sigmoid | Sigmoid |

| NS | AH1 | AH2 | AO |

|---|---|---|---|

| 5-20-20-10 | Sigmoid | Sigmoid | Linear |

| Network Name | Quality (Learning) | QUALITY (Testing) |

|---|---|---|

| MLP 5-20-10 | 0.9471 | 0.9676 |

| CNN 5-20-20-10 | 0.9577 | 0.9721 |

| Network Name | (R)MSE |

|---|---|

| MLP 5-18-10 | 0.01 |

| CNN 5-20-20-10 | 0.001 |

| Parameter | Optimal Value |

|---|---|

| Layer height [mm] | 0.2 |

| Shell thickness [mm] | 1.2 |

| Bottom thickness [mm] | 2 |

| Top thickness [mm] | 2 |

| Fill density [%] | 40 |

| Print speed [mm/s] | 70 |

| Bed temperature [°C] | 55 |

| Printing temperature [°C] | 215 |

| Second nozzle temperature [°C] | 220 |

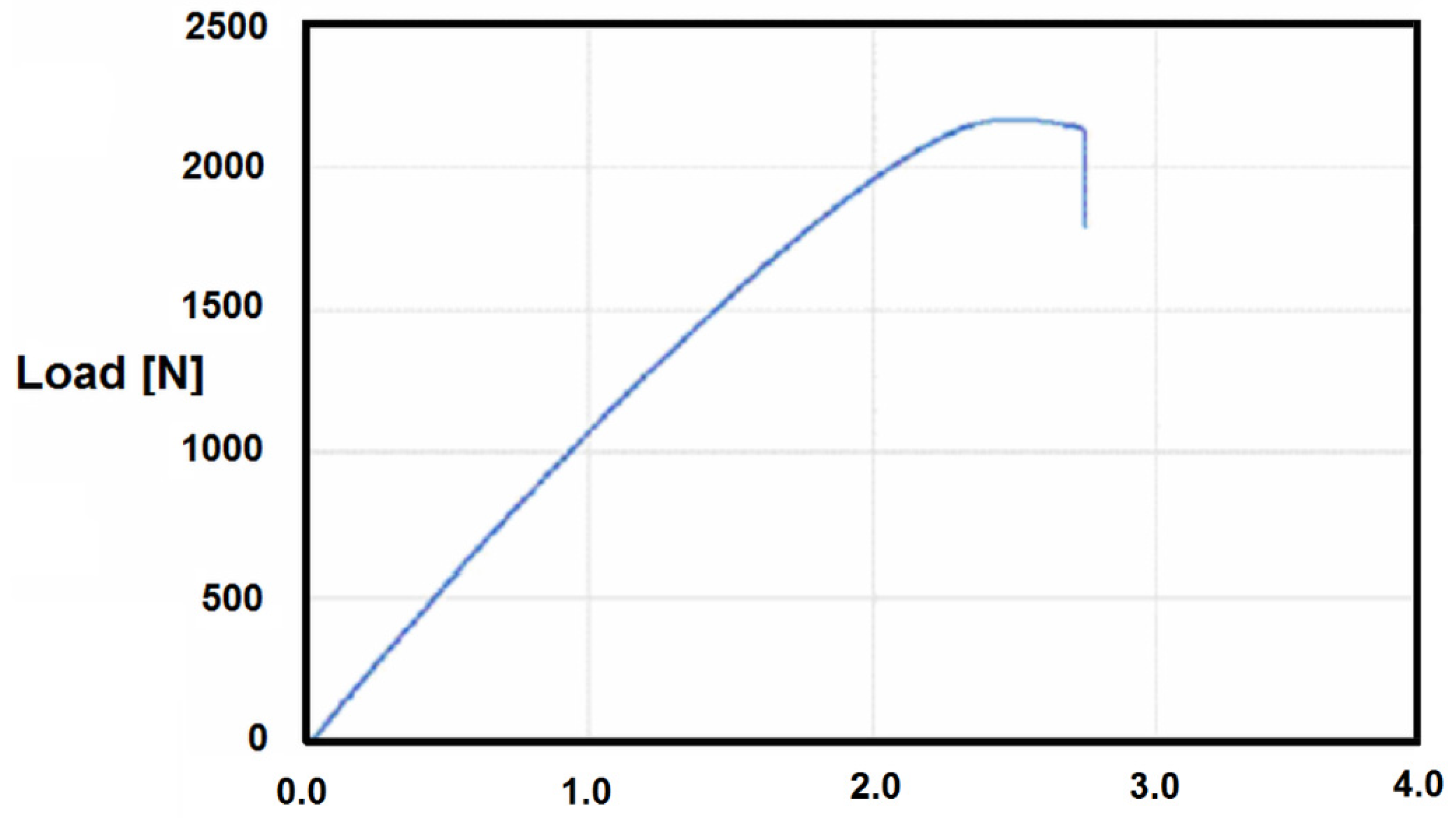

| Maximum tensile force [N] | 2112.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojek, I.; Mikołajewski, D.; Kotlarz, P.; Tyburek, K.; Kopowski, J.; Dostatni, E. Traditional Artificial Neural Networks Versus Deep Learning in Optimization of Material Aspects of 3D Printing. Materials 2021, 14, 7625. https://doi.org/10.3390/ma14247625

Rojek I, Mikołajewski D, Kotlarz P, Tyburek K, Kopowski J, Dostatni E. Traditional Artificial Neural Networks Versus Deep Learning in Optimization of Material Aspects of 3D Printing. Materials. 2021; 14(24):7625. https://doi.org/10.3390/ma14247625

Chicago/Turabian StyleRojek, Izabela, Dariusz Mikołajewski, Piotr Kotlarz, Krzysztof Tyburek, Jakub Kopowski, and Ewa Dostatni. 2021. "Traditional Artificial Neural Networks Versus Deep Learning in Optimization of Material Aspects of 3D Printing" Materials 14, no. 24: 7625. https://doi.org/10.3390/ma14247625

APA StyleRojek, I., Mikołajewski, D., Kotlarz, P., Tyburek, K., Kopowski, J., & Dostatni, E. (2021). Traditional Artificial Neural Networks Versus Deep Learning in Optimization of Material Aspects of 3D Printing. Materials, 14(24), 7625. https://doi.org/10.3390/ma14247625