Synergistic Effect of Screen-Printed Single-Walled Carbon Nanotubes and Phosphorylated Cellulose Nanofibrils on Thermophysiological Comfort, Thermal/UV Resistance, Mechanical and Electroconductive Properties of Flame-Retardant Fabric

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of PCNF-Based Dispersions and Acrylate-Based Pastes

2.3. Screen-Printing Process

2.4. Fabrics’ Washing and Drying

2.5. Fabric’s Analysis

3. Results

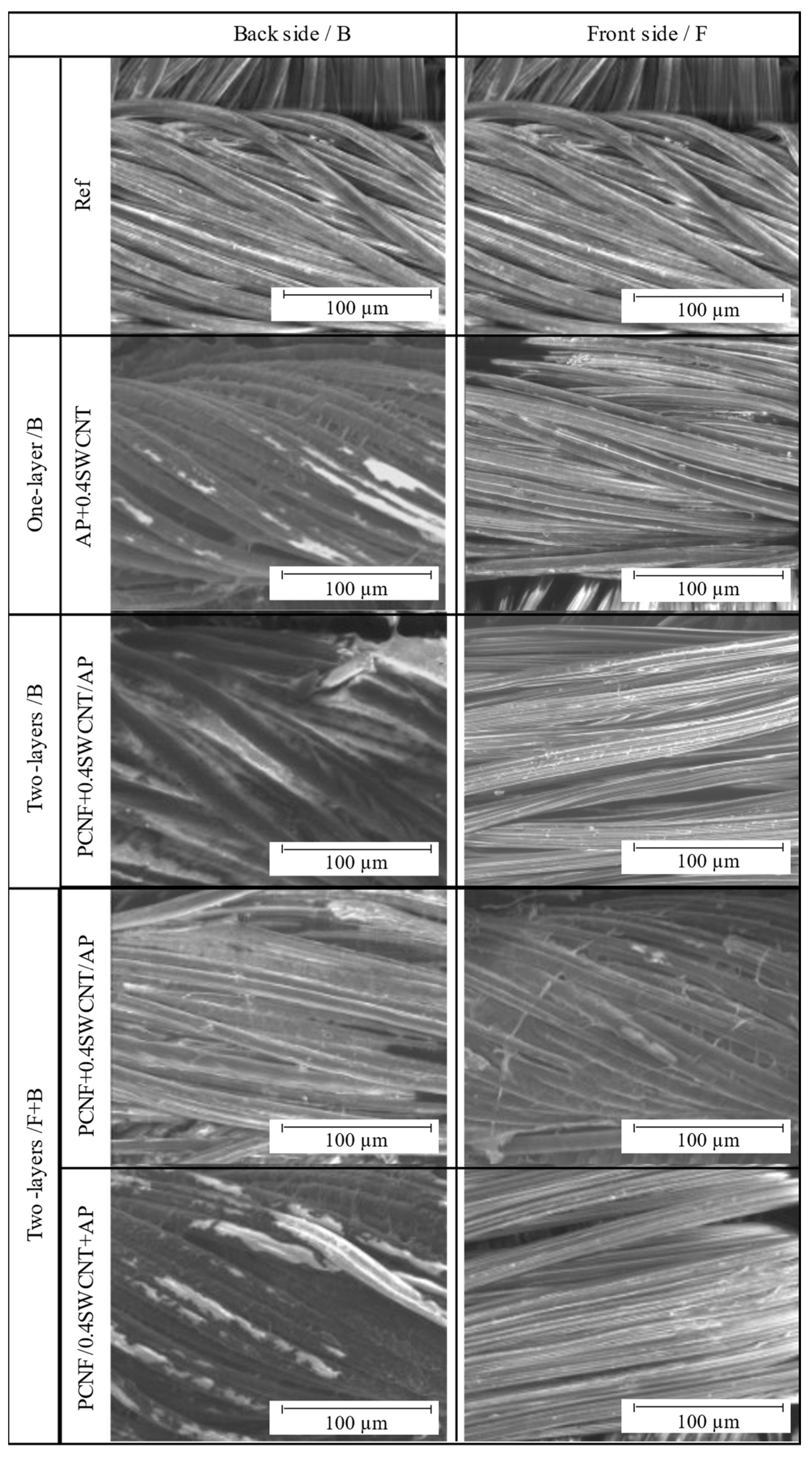

3.1. The Coating’s Patterning and Imprinting

3.2. Thickness, Mass Change, Dimensional Change and Air Permeability

3.3. Water-Vapour Resistance, Surface Wetting and Water Adsorption Capacity

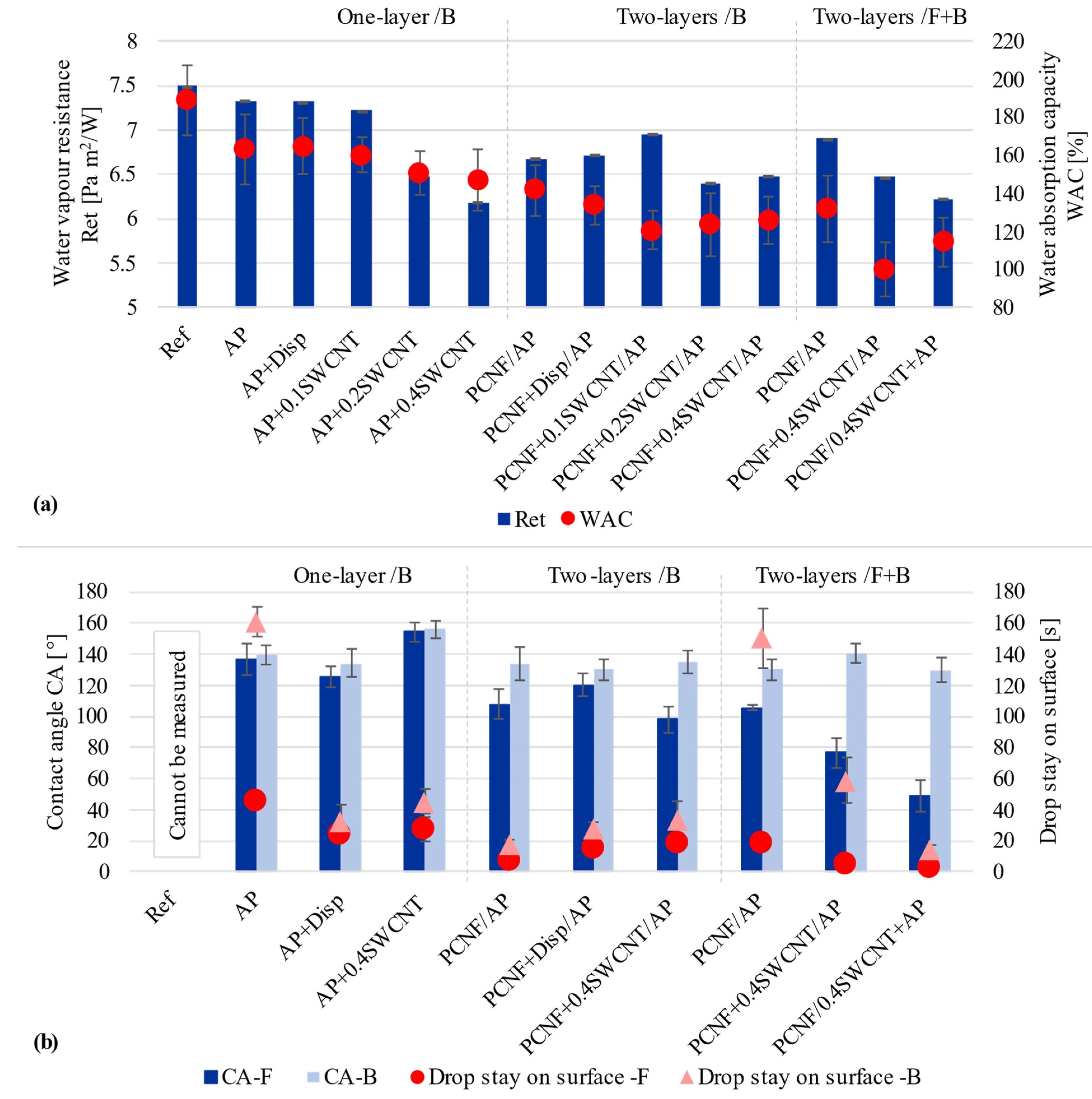

3.4. Thermal Resistance and Corresponding Cold-Warm Feeling Properties

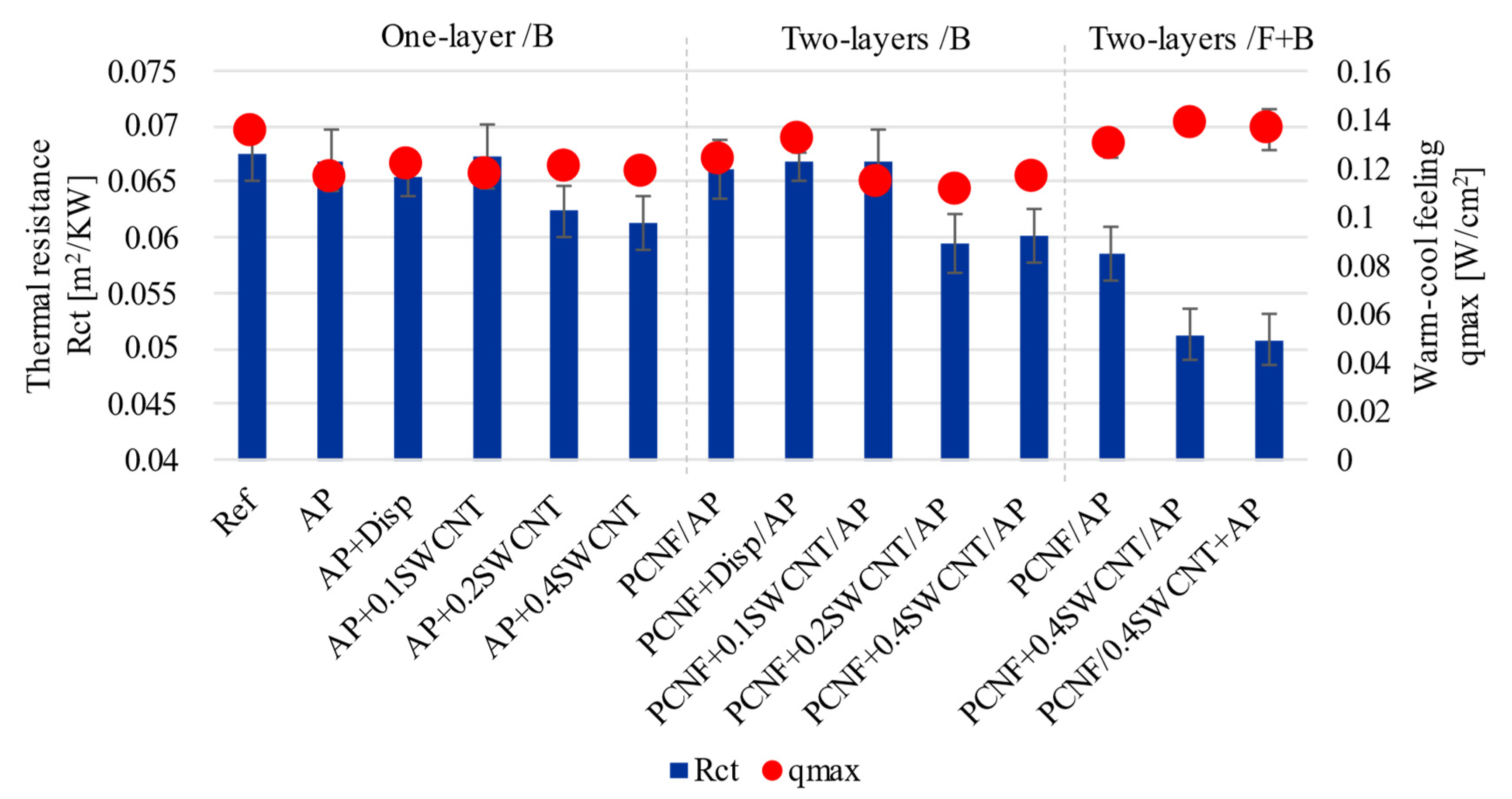

3.5. Thermal Stability and Flammability

3.6. UV Protection Properties

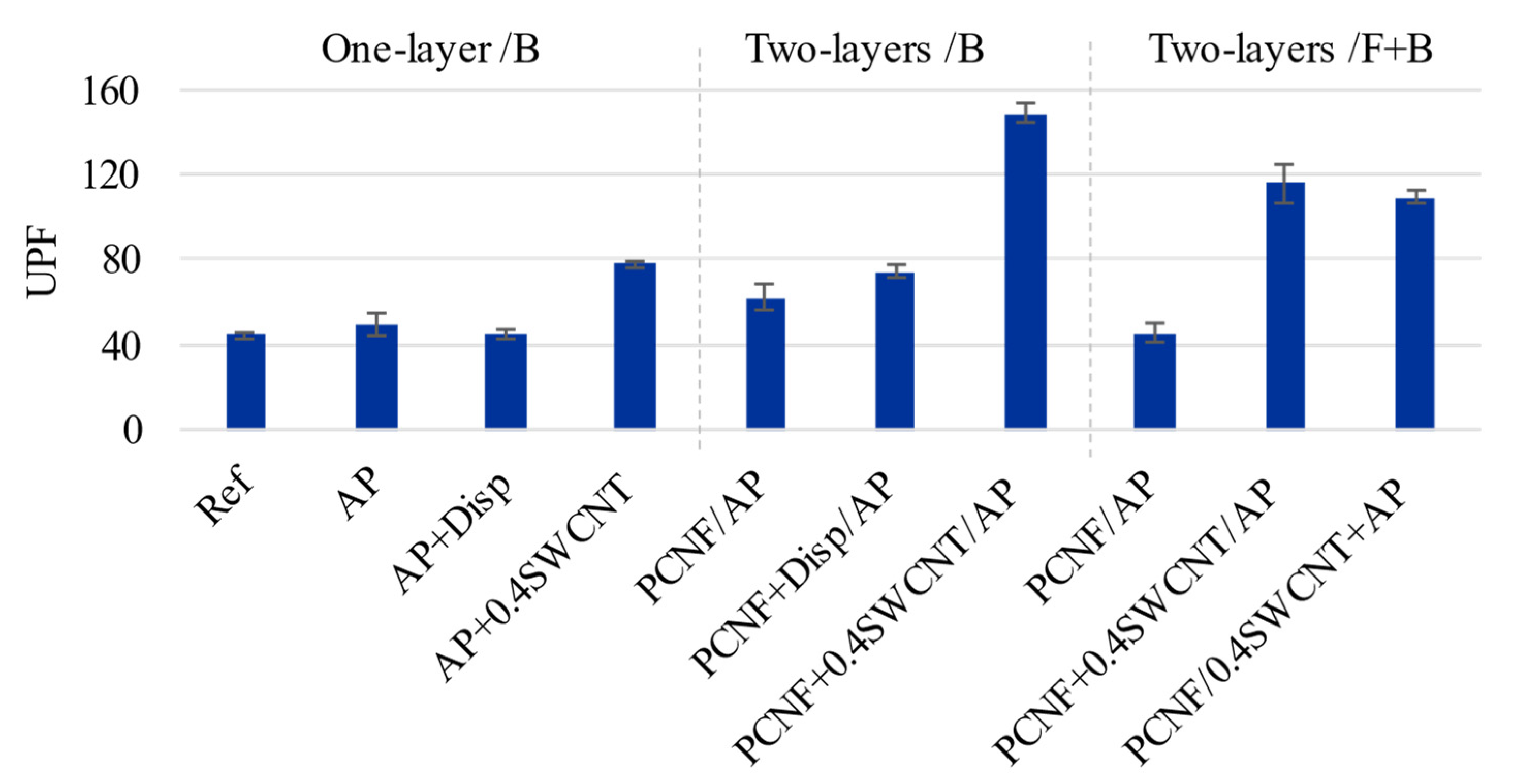

3.7. Electrical Conductivity

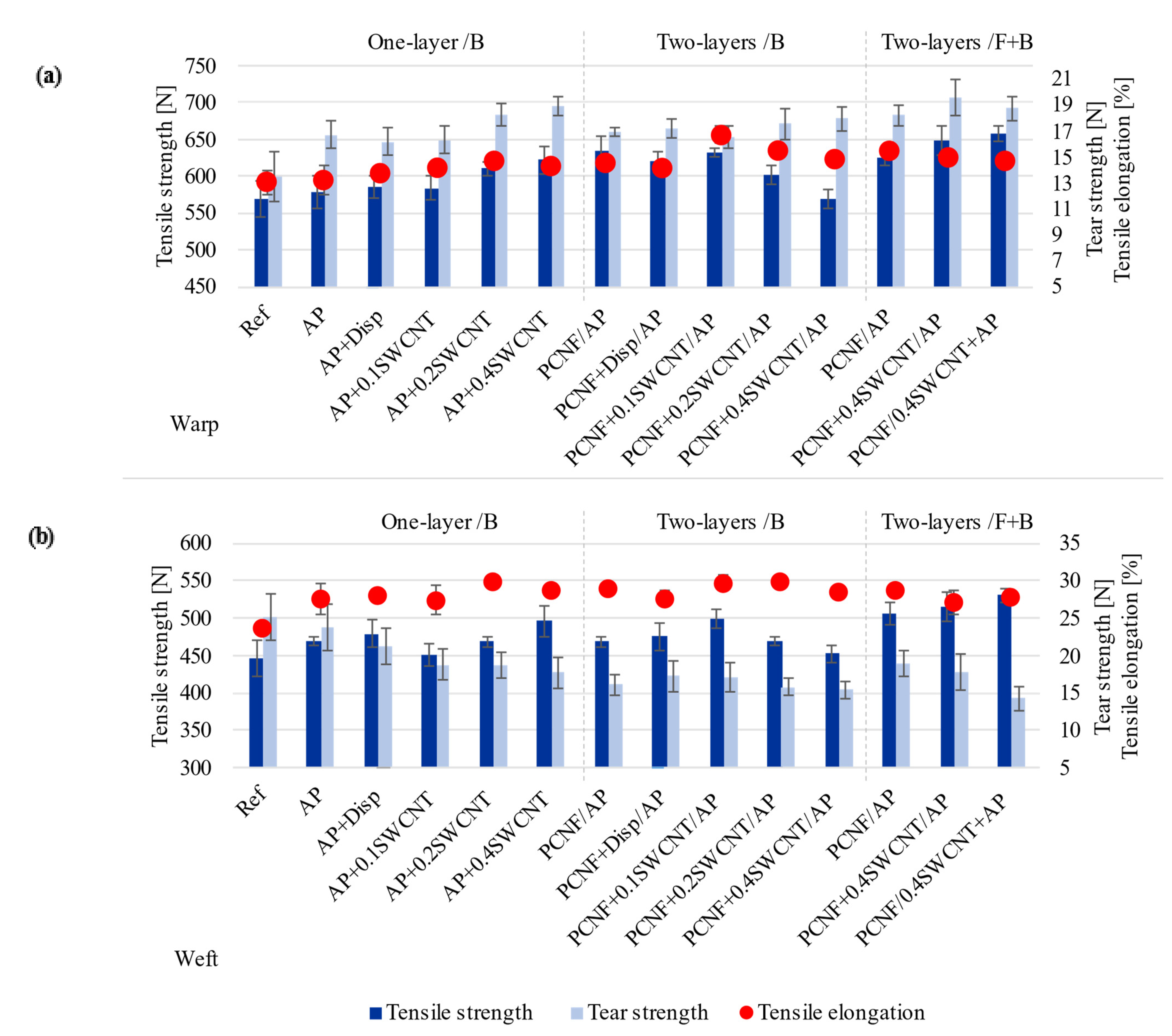

3.8. Tensile and Tear Strengths, and Breaking Elongation Properties

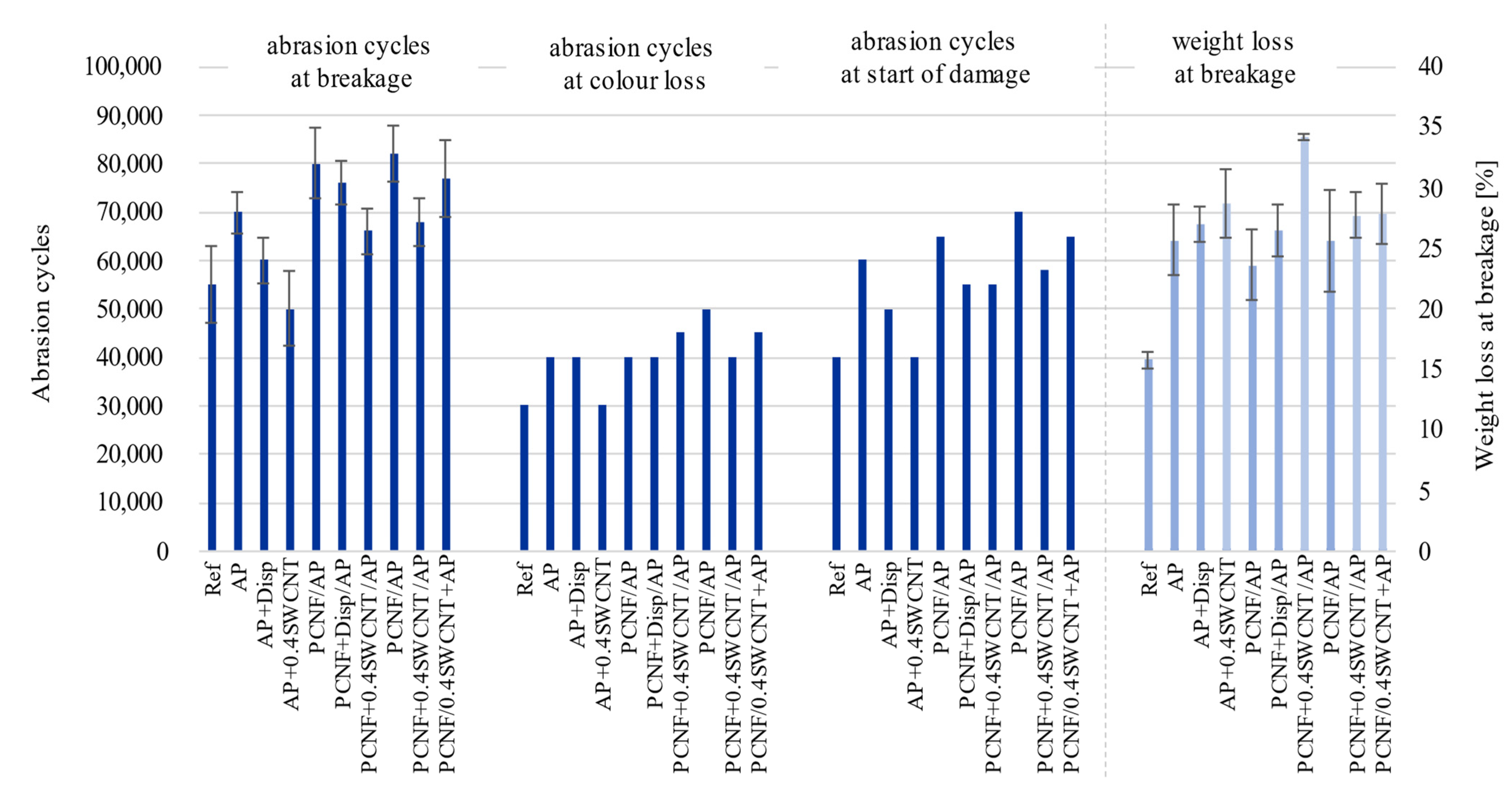

3.9. Abrasion Resistance Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Song, G.; Mandal, S.; Rossi, R.M. 4—Development of high performance thermal protective clothing. In Thermal Protective Clothing for Firefighters; Song, G., Mandal, S., Rossi, R.M., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 27–55. [Google Scholar]

- Norouzi, M.; Zare, Y.; Kiany, P. Nanoparticles as effective flame retardants for natural and synthetic textile polymers: Application, mechanism, and optimization. Polym. Rev. 2015, 55, 531–560. [Google Scholar] [CrossRef]

- Horrocks, A.R. Flame retardant challenges for textiles and fibres: New chemistry versus innovatory solutions. Polym. Degrad. Stab. 2011, 96, 377–392. [Google Scholar] [CrossRef]

- Rosace, G.; Trovato, V.; Colleoni, C.; Caldara, M.; Re, V.; Brucale, M.; Piperopoulos, E.; Mastronardo, E.; Milone, C.; de Luca, G.; et al. Structural and morphological characterizations of MWCNTs hybrid coating onto cotton fabric as potential humidity and temperature wearable sensor. Sens. Actuators B Chem. 2017, 252, 428–439. [Google Scholar] [CrossRef]

- Krucińska, I.; Skrzetuska, E.; Urbaniak-Domagala, W. Prototypes of carbon nanotube-based textile sensors manufactured by the screen printing method. Fibres Text. East. Eur. 2012, 91, 79–83. [Google Scholar]

- Grancarić, A.M.; Jerković, I.; Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive polymers for smart textile applications. J. Ind. Text. 2017, 48, 612–642. [Google Scholar] [CrossRef]

- Karim, N.; Afroj, S.; Leech, D.; Abdelkader, A.M. Flexible and Wearable Graphene-Based E-Textiles. In Oxide Electronics; Ray, A.K., Ed.; John Wiley and Sons, Inc.: London, UK, 2021; pp. 21–49. [Google Scholar]

- Knittel, D.; Schollmeyer, E. Electrically high-conductive textiles. Synth. Met. 2009, 159, 1433–1437. [Google Scholar] [CrossRef]

- Wang, Y.; Weng, G.J. Electrical Conductivity of Carbon Nanotube- and Graphene-Based Nanocomposites. In Micromechanics and Nanomechanics of Composite Solids; Meguid, S.A., Weng, G.J., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 123–156. [Google Scholar]

- Abbas, A.; Zhao, Y.; Zhou, J.; Wang, X.; Lin, T. Improving thermal conductivity of cotton fabrics using composite coatings containing graphene, multiwall carbon nanotube or boron nitride fine particles. Fibers Polym. 2013, 14, 1641–1649. [Google Scholar] [CrossRef]

- Mondal, S.; Hu, J. A novel approach to excellent UV protecting cotton fabric with functionalized MWNT containing water vapor permeable PU coating. J. Appl. Polym. Sci. 2007, 103, 3370–3376. [Google Scholar] [CrossRef]

- Jhon, Y.I.; Kim, C.; Seo, M.; Cho, W.J.; Lee, S.; Jhon, Y.M. Tensile characterization of single-walled carbon nanotubes with helical structural defects. Sci. Rep. 2016, 6, 20324. [Google Scholar] [CrossRef] [Green Version]

- Cui, J.; Zhou, S. Highly conductive and ultra-durable electronic textiles via covalent immobilization of carbon nanomaterials on cotton fabric. J. Mater. Chem. C 2018, 6, 12273–12282. [Google Scholar] [CrossRef]

- Shahidi, S.; Moazzenchi, B. Carbon nanotube and its applications in textile industry—A review. J. Text. Inst. 2018, 109, 1653–1666. [Google Scholar] [CrossRef]

- Rahman, M.J.; Mieno, T. Conductive cotton textile from safely functionalized carbon nanotubes. J. Nanomater. 2015, 16, 978484. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, J.; Wang, R.; Lu, H.; Li, L.; Kong, Y.; Qi, K.; Xin, J.H. Artificial lotus leaf structures from assembling carbon nanotubes and their applications in hydrophobic textiles. J. Mater. Chem. C 2007, 17, 1071–1078. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Qi, K.; Xin, J.H. Functionalization of cotton with carbon nanotubes. J. Mater. Chem. C 2008, 18, 3454–3460. [Google Scholar] [CrossRef]

- Li, G.; Wang, H.; Zheng, H.; Bai, R. A facile approach for the fabrication of highly stable superhydrophobic cotton fabric with multi-walled carbon nanotubes-azide polymer composites. Langmuir ACS J. Surf. Colloids 2010, 26, 7529–7534. [Google Scholar] [CrossRef]

- Nafeie, N.; Montazer, M.; Nejad, N.H.; Harifi, T. Electrical conductivity of different carbon nanotubes on wool fabric: An investigation on the effects of different dispersing agents and pretreatments. Colloids Surf. A Physicochem. Eng. Asp. 2016, 497, 81–89. [Google Scholar] [CrossRef]

- Lin, J.-H.; Lin, Z.-I.; Pan, Y.-J.; Hsieh, C.-T.; Lee, M.-C.; Lou, C.-W. Manufacturing techniques and property evaluations of conductive composite yarns coated with polypropylene and multi-walled carbon nanotubes. Compos. A Appl. Sci. Manuf. 2016, 84, 354–363. [Google Scholar] [CrossRef]

- Lin, Z.-I.; Lou, C.-W.; Pan, Y.-J.; Hsieh, C.-T.; Huang, C.-H.; Huang, C.-L.; Chen, Y.-S.; Lin, J.-H. Conductive fabrics made of polypropylene/multi-walled carbon nanotube coated polyester yarns: Mechanical properties and electromagnetic interference shielding effectiveness. Compos. Sci. Technol. 2017, 141, 74–82. [Google Scholar] [CrossRef]

- Xue, C.-H.; Wu, Y.; Guo, X.-J.; Liu, B.-Y.; Wang, H.-D.; Jia, S.-T. Superhydrophobic, flame-retardant and conductive cotton fabrics via layer-by-layer assembly of carbon nanotubes for flexible sensing electronics. Cellulose 2020, 27, 3455–3468. [Google Scholar] [CrossRef]

- Mahmoudifard, M.; Safi, M. Novel study of carbon nanotubes as UV absorbers for the modification of cotton fabric. J. Text. Inst. 2012, 103, 893–899. [Google Scholar] [CrossRef]

- Lee, T.-W.; Han, M.; Lee, S.-E.; Jeong, Y.G. Electrically conductive and strong cellulose-based composite fibers reinforced with multiwalled carbon nanotube containing multiple hydrogen bonding moiety. Compos. Sci. Technol. 2016, 123, 57–64. [Google Scholar] [CrossRef]

- Kokol, V.; Vivod, V.; Peršin, Z.; Kamppuri, T.; Dobnik-Dubrovski, P. Screen-printing of microfibrillated cellulose for an improved moisture management, strength and abrasion resistant properties of flame-resistant fabrics. Cellulose 2021, 28, 6663–6678. [Google Scholar] [CrossRef]

- El-Shafei, A.M.; Adel, A.M.; Ibrahim, A.A.; Al-Shemy, M.T. Dual functional jute fabric biocomposite with chitosan and phosphorylated nano-cellulose (antimicrobial and thermal stability). Int. J. Biol. Macromol. 2019, 124, 733–741. [Google Scholar] [CrossRef]

- Thomas, B.; Raj, M.C.; Joy, J.; Moores, A.; Drisko, G.L.; Sanchez, C. Nanocellulose, a versatile green platform: From biosources to materials and their applications. Chem. Rev. 2018, 118, 11575–11625. [Google Scholar] [CrossRef]

- ISO. Textiles—Woven Fabrics—Determination of Mass per Unit Length and Mass per Unit Area; ISO 3801:1977; ISO: Geneva, Switzerland, 1977. [Google Scholar]

- ISO. Textiles—Determination of Thickness of Textiles and Textile Products; ISO 5084:1996; ISO: Geneva, Switzerland, 1996. [Google Scholar]

- CEN. Textiles—Woven Fabrics—Construction—Methods of Analysis—Part 2: Determination of Number of Threads per Unit Length; EN 1049-2:1993; CEN: Geneva, Switzerland, 1993. [Google Scholar]

- ISO. Textiles—Domestic Washing and Drying Procedures for Textile Testing; ISO 6330:2012; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- ISO. Textiles—Standard Atmospheres for Conditioning and Testing; ISO 139:2005; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- ISO. Textiles—Determination of the Permeability of Fabrics to Air; ISO 9237:1995; ISO: Geneva, Switzerland, 1995. [Google Scholar]

- ASTM. Surface Wettability and Absorbency of Sheeted Materials Using an Automated Contact Angle Tester; ASTM D5725-99:2008; ASTM: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ISO. Textiles—Physiological Effects—Measurement of Thermal and Water-Vapour Resistance under Steady-State Conditions (Sweating Guarded-Hotplate Test); ISO 11092:2014; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- ISO. Protective Clothing—Protection against Flame—Method of Test for Limited Flame Spread; ISO 15025:2016; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- CEN. Textiles—Solar UV Protective Properties—Part 1: Method of Test for Apparel Fabrics; CEN 13758-1:2001; CEN: Geneva, Switzerland, 2001. [Google Scholar]

- ISO. Textiles—Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method; ISO 13934-1:2013; ISO: Geneva, Switzerland, 2013. [Google Scholar]

- ISO. Textiles—Tear Properties of Fabrics—Part 2: Determination of Tear Force of Trouser-Shaped Test Specimens (Single Tear Method); ISO 13937-2:2000; ISO: Geneva, Switzerland, 2000. [Google Scholar]

- ISO. Textiles—Determination of the Abrasion Resistance of Fabrics by the Martindale Method—Part 2: Determination of Specimen Breakdown; ISO 12947-2:2016; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- ISO. Textiles—Determination of the Abrasion Resistance of Fabrics by the Martindale Method—Part 3: Determination of Mass Loss; ISO 12947-3:1998; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- ISO. Textiles—Determination of the Abrasion Resistance of Fabrics by the Martindale Method—Part 4: Assessment of Appearance Change; ISO 12947-4:1998; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- Huang, J. Thermal parameters for assessing thermal properties of clothing. J. Therm. Biol. 2006, 31, 461–466. [Google Scholar] [CrossRef]

- El Messiry, M.; El Ouffy, A.; Issa, M. Microcellulose particles for surface modification to enhance moisture management properties of polyester, and polyester/cotton blend fabrics. Alex. Eng. J. 2015, 54, 127–140. [Google Scholar] [CrossRef] [Green Version]

- Kwon, S.-o.; Kim, J.; Moon, M.-W.; Park, C.H. Nanostructured superhydrophobic lyocell fabrics with asymmetric moisture absorbency: Moisture managing properties. Text. Res. J. 2016, 87, 807–815. [Google Scholar] [CrossRef]

- Havenith, G. Clothing and Thermoregulation. In Textiles and Skin; Elsner, P., Hatch, K., Wigger-Alberti, W., Eds.; Karger: Basel, Switzerland, 2003; Volume 31, pp. 35–49. [Google Scholar]

- Ashraf, M.; Siyal, M.; Nazir, A.; Rehman, A. Single-step antimicrobial and moisture management finishing of pc fabric using zno nanoparticles. Autex Res. J. 2016, 17, 259–262. [Google Scholar] [CrossRef]

- Das, B.; Das, A.; Kothari, V.; Fanguiero, R.; Araújo, M. Moisture transmission through textiles. Part I: Processes involved in moisture transmission and the factors at play. Autex Res. J. 2007, 7, 100–110. [Google Scholar]

- Kwon, S.-o.; Ko, T.-J.; Yu, E.; Kim, J.; Moon, M.-W.; Park, C.H. Nanostructured self-cleaning lyocell fabrics with asymmetric wettability and moisture absorbency (Part I). RSC Adv. 2014, 4, 45442–45448. [Google Scholar] [CrossRef]

- Noman, M.; Petru, M.; Amor, N.; Louda, P. Thermophysiological comfort of zinc oxide nanoparticles coated woven fabrics. Sci. Rep. 2020, 10, 21080. [Google Scholar] [CrossRef]

- Wang, T.; Xu, X.; Ren, Y.; Qin, S.; Sui, X.; Wang, L. Kinetics of thermal degradation of viscose fiber and fire retardant viscose fiber. J. Eng. Fibers Fabr. 2014, 9, 38–46. [Google Scholar] [CrossRef] [Green Version]

- Linda, A.; Demšar, A.; Varga, K. Termična Analiza Ognjevarnih Vlaken: Diplomsko Delo. Bachelor‘s Thesis, Faculty of Natural Sciences and Engineering, University of Ljubljana, Ljuljana, Slovenia, 2016. [Google Scholar]

- Horrocks, A.R. 9—Smart Flame Retardant Textile Coatings and Laminates. In Smart Textile Coatings and Laminates, 2nd ed.; Smith, W.C., Ed.; Woodhead Publishing: Cambridge, UK, 2019; Volume 2, pp. 205–236. [Google Scholar]

- Tokarska, M.; Frydrysiak, M.; Zięba, J. Electrical properties of flat textile material as inhomegeneous and anisotropic structure. J. Mater. Sci. Mater. Electron. 2013, 24, 5061–5068. [Google Scholar] [CrossRef] [Green Version]

- Tseghai, G.B.; Malengier, B.; Nigusse, A.; Van Langenhove, L. Development and Evaluation of Resistive Pressure Sensors from Electro-Conductive Textile Fabric. In Proceedings of the The Second International Forum on Textiles for Graduate Students (IFTGS); Tianjin Polytechnic University: Tianjin, China, 2018. [Google Scholar]

- Giovanelli, D.; Farella, E. Force sensing resistor and evaluation of technology for wearable body pressure sensing. J. Sens. 2016, 2016, 9391850. [Google Scholar] [CrossRef] [Green Version]

- Euler, L.; Guo, L.; Persson, N.-K. Textile electrodes: Influence of knitting construction and pressure on the contact impedance. Sensors 2021, 21, 1578. [Google Scholar] [CrossRef]

- Palanisamy, S.; Tunáková, V.; Malengier, B.; Karthik, D.; Langenhove, L.; Militký, J. Development of the Force Sensitive Resistors Using Polypyrrole Coated Cotton Woven Fabric for Pressure Sensing Application. In Proceedings of the 22nd International Conference STRUTEX, 4 December 2018, Liberec, Czech Republic, 5–7 December 2018; Technical University of Liberec: Liberec, Czech Republic, 2018; pp. 52–55. [Google Scholar]

- Krifa, M. Electrically conductive textile materials—Application in flexible sensors and antennas. Textiles 2021, 1, 12. [Google Scholar] [CrossRef]

- Tokarska, M. Characterization of electro-conductive textile materials by its biaxial anisotropy coefficient and resistivity. J. Mater. Sci. Mater. Electron. 2019, 30, 4093–4103. [Google Scholar] [CrossRef] [Green Version]

- Hebeish, A.A.; El-Gamal, M.A.; Said, T.S.; El-Hady, R.A.M.A. Major factors affecting the performance of ESD-protective fabrics. J. Text. Inst. 2010, 101, 389–398. [Google Scholar] [CrossRef]

- Riaz, S.; Ashraf, M.; Hussain, T.; Hussain, M.T.; Rehman, A.; Javid, A.; Iqbal, K.; Basit, A.; Aziz, H. Functional finishing and coloration of textiles with nanomaterials. Color. Technol. 2018, 134, 327–346. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolar, T.; Kokol, V. Synergistic Effect of Screen-Printed Single-Walled Carbon Nanotubes and Phosphorylated Cellulose Nanofibrils on Thermophysiological Comfort, Thermal/UV Resistance, Mechanical and Electroconductive Properties of Flame-Retardant Fabric. Materials 2021, 14, 7238. https://doi.org/10.3390/ma14237238

Kolar T, Kokol V. Synergistic Effect of Screen-Printed Single-Walled Carbon Nanotubes and Phosphorylated Cellulose Nanofibrils on Thermophysiological Comfort, Thermal/UV Resistance, Mechanical and Electroconductive Properties of Flame-Retardant Fabric. Materials. 2021; 14(23):7238. https://doi.org/10.3390/ma14237238

Chicago/Turabian StyleKolar, Tjaša, and Vanja Kokol. 2021. "Synergistic Effect of Screen-Printed Single-Walled Carbon Nanotubes and Phosphorylated Cellulose Nanofibrils on Thermophysiological Comfort, Thermal/UV Resistance, Mechanical and Electroconductive Properties of Flame-Retardant Fabric" Materials 14, no. 23: 7238. https://doi.org/10.3390/ma14237238

APA StyleKolar, T., & Kokol, V. (2021). Synergistic Effect of Screen-Printed Single-Walled Carbon Nanotubes and Phosphorylated Cellulose Nanofibrils on Thermophysiological Comfort, Thermal/UV Resistance, Mechanical and Electroconductive Properties of Flame-Retardant Fabric. Materials, 14(23), 7238. https://doi.org/10.3390/ma14237238