Electroplating Deposition of Bismuth Absorbers for X-ray Superconducting Transition Edge Sensors

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

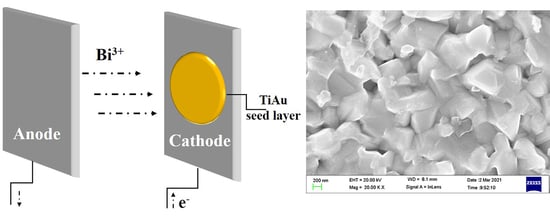

2.2. Electroplating Process

2.3. Characterization and Electrical Measurements

3. Results and Discussion

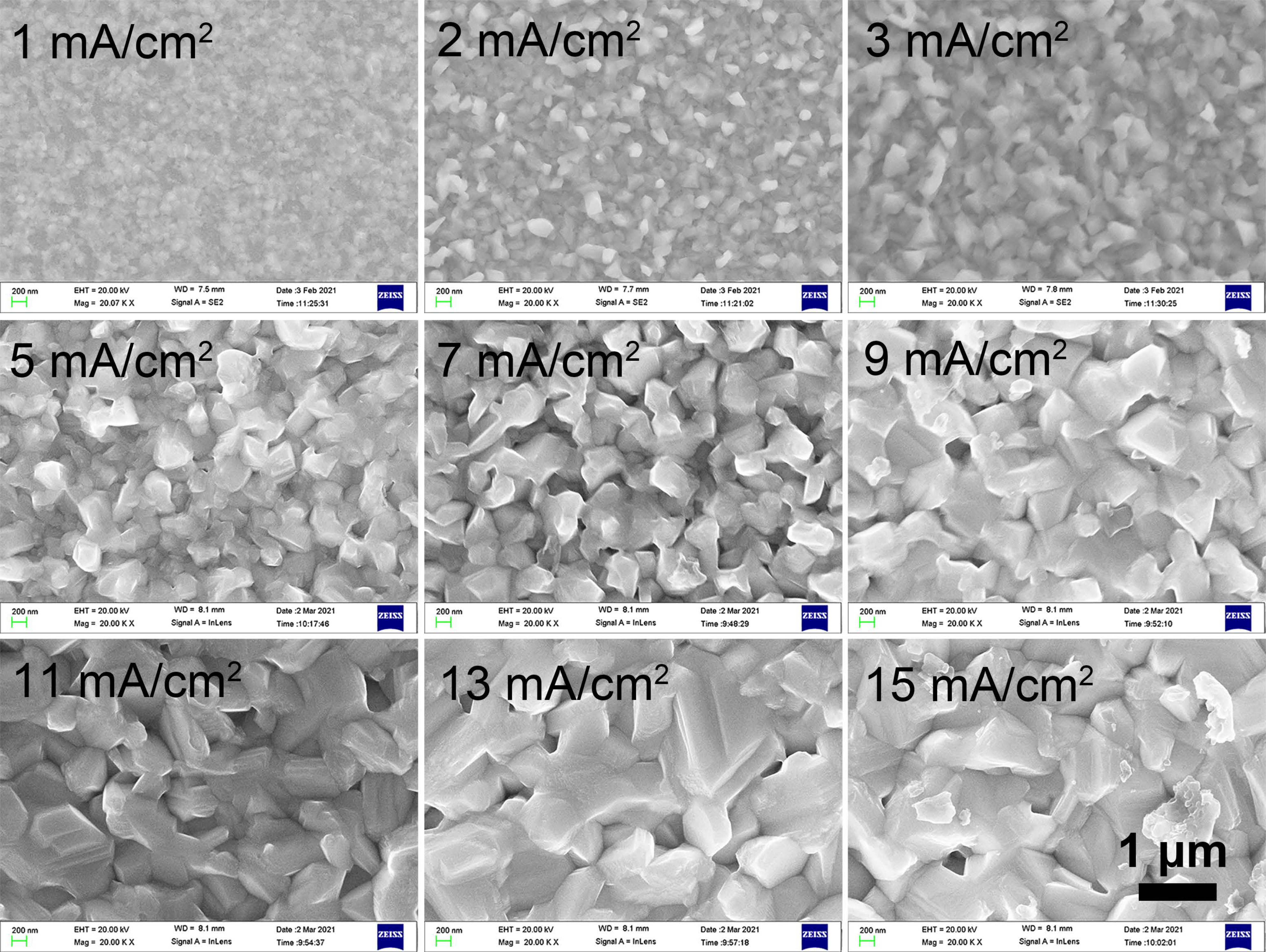

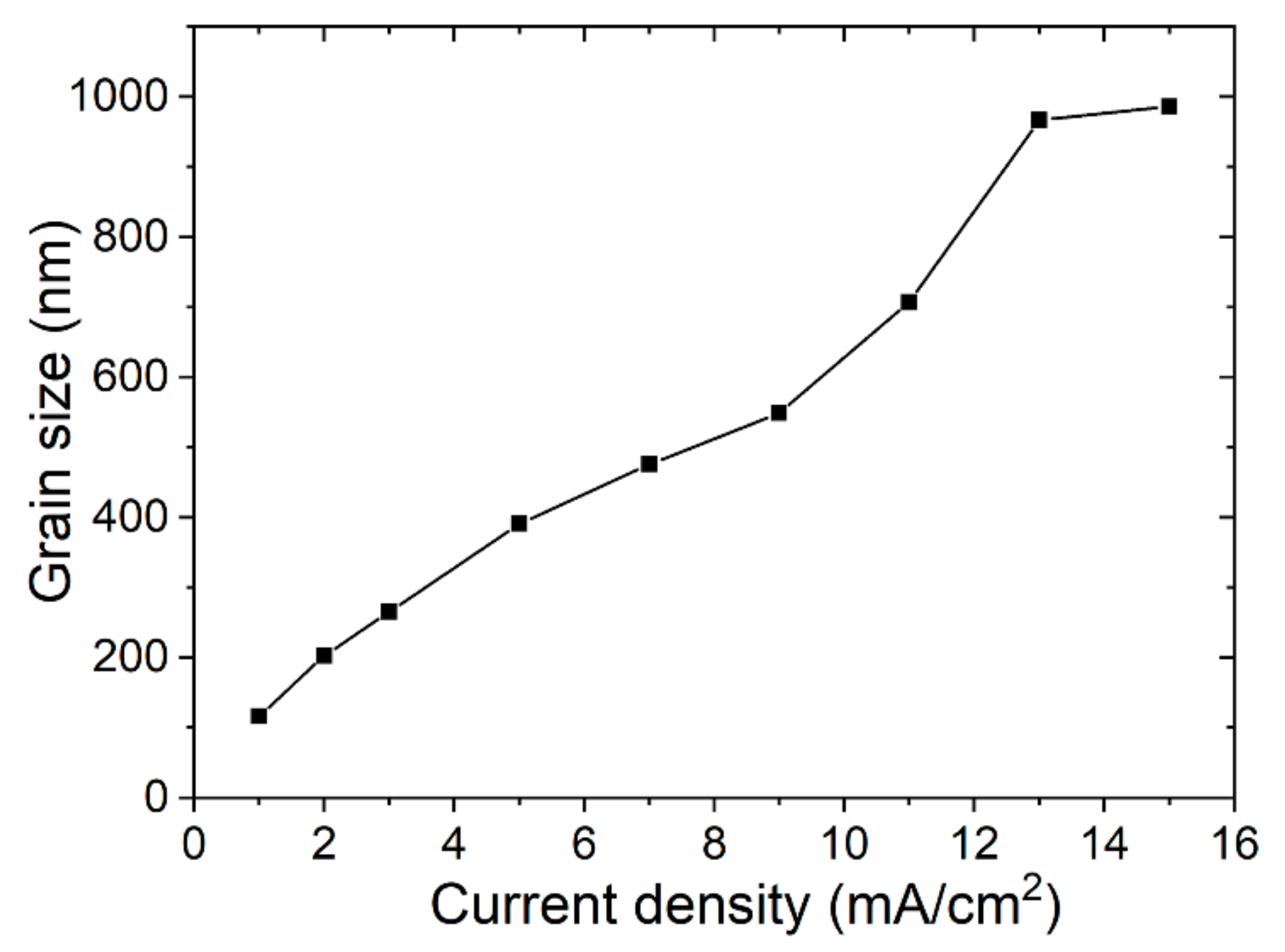

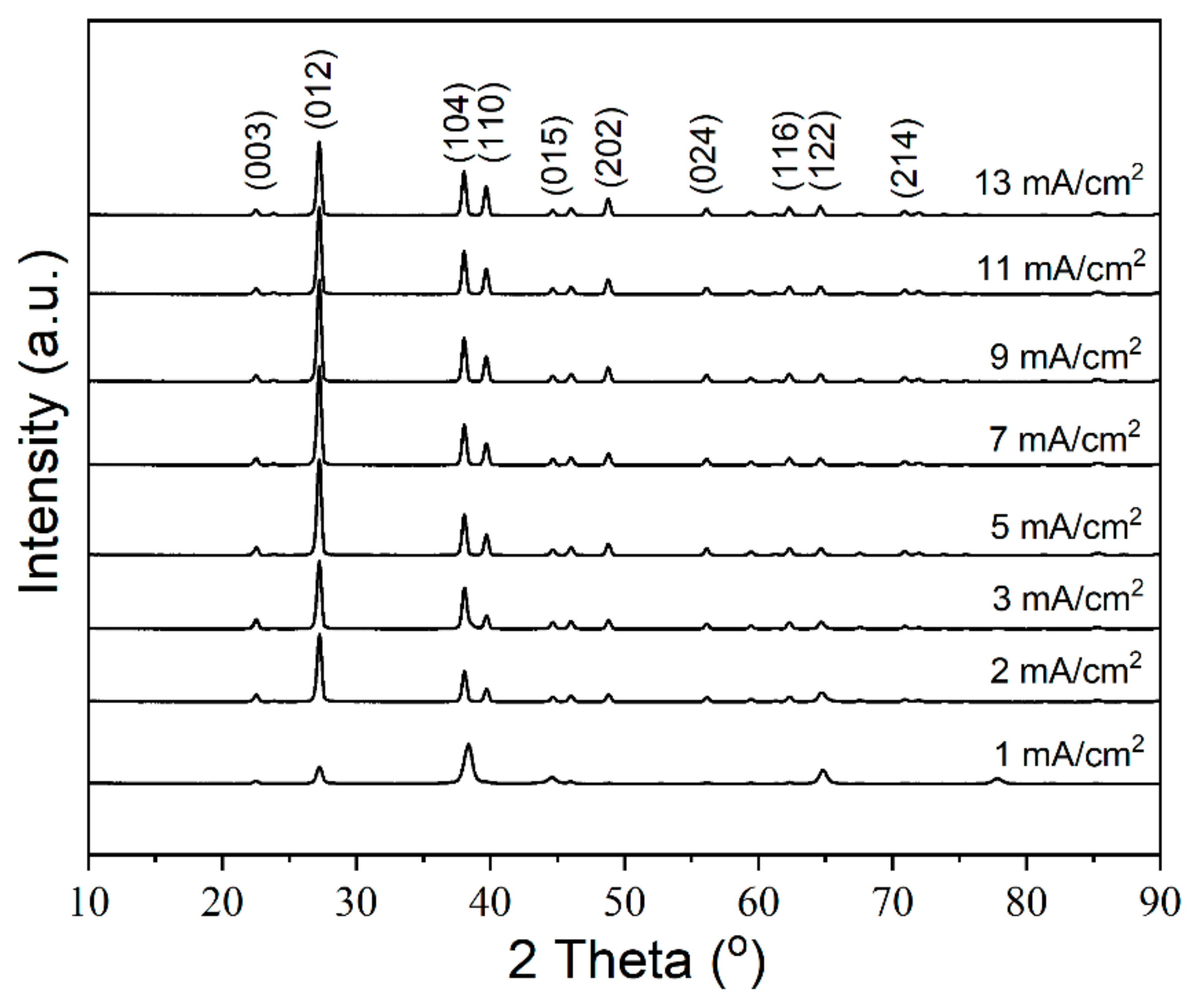

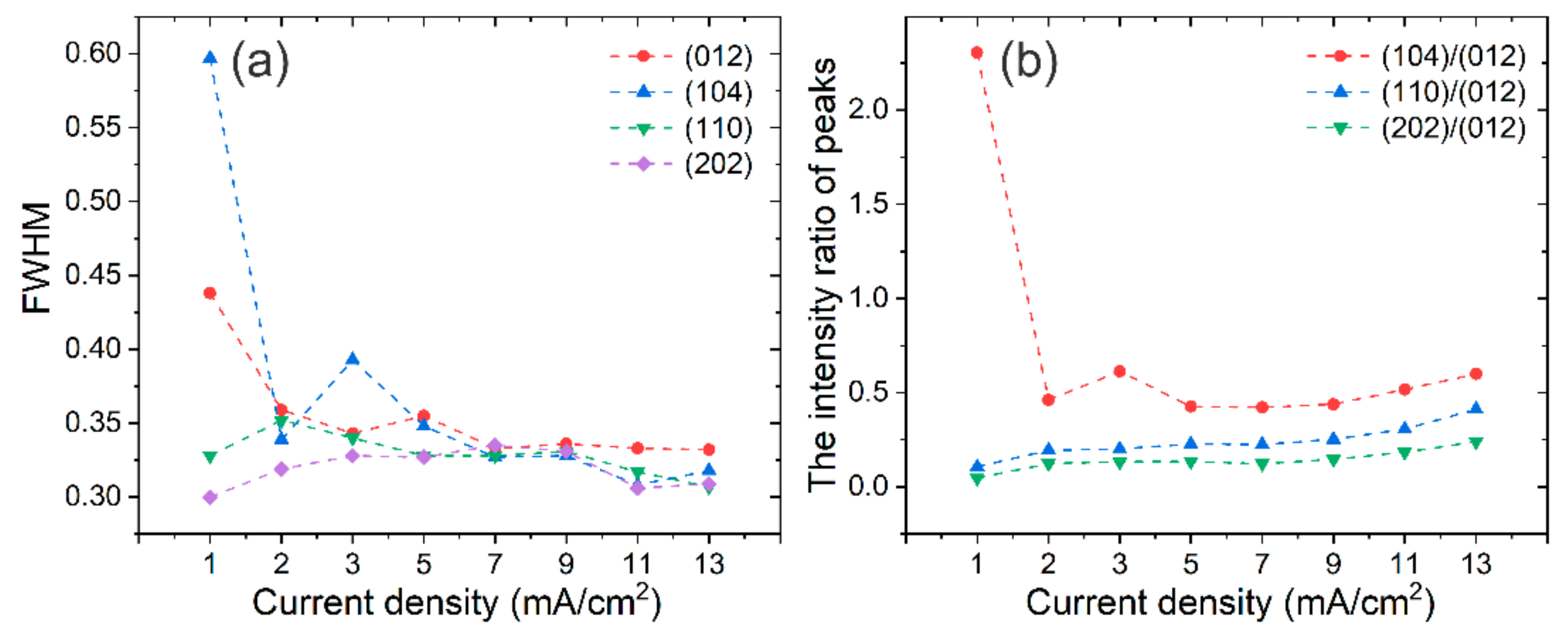

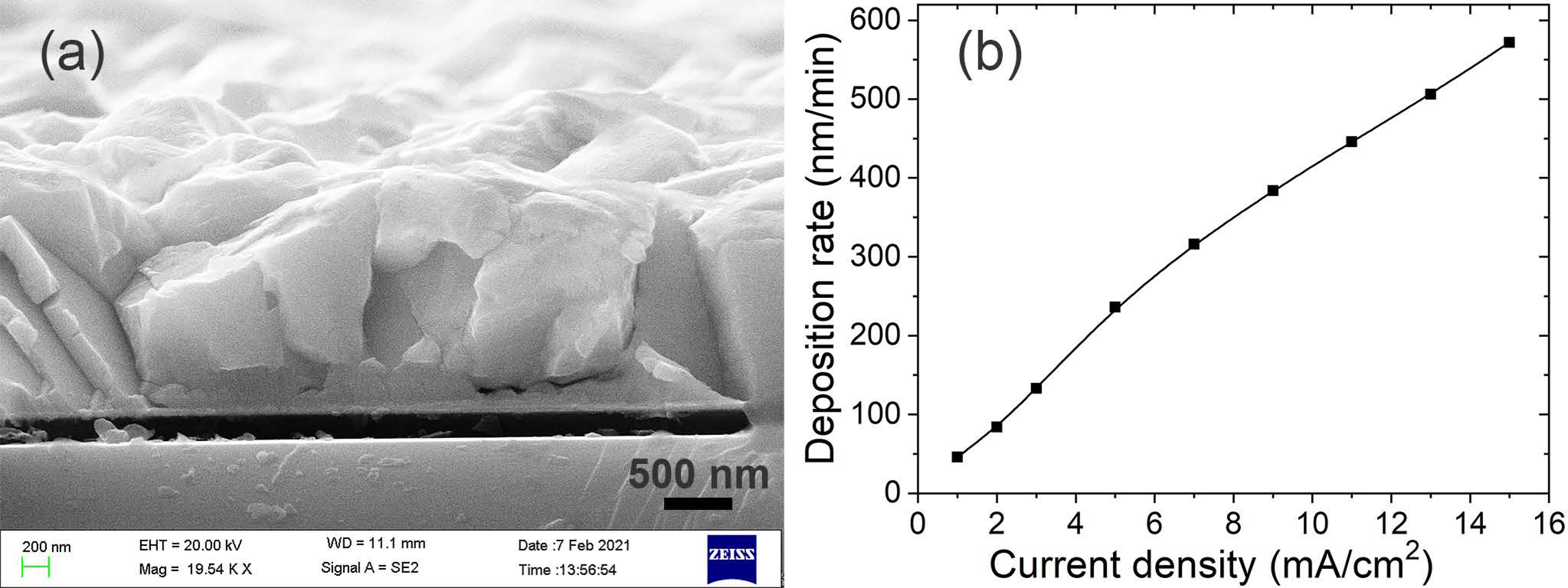

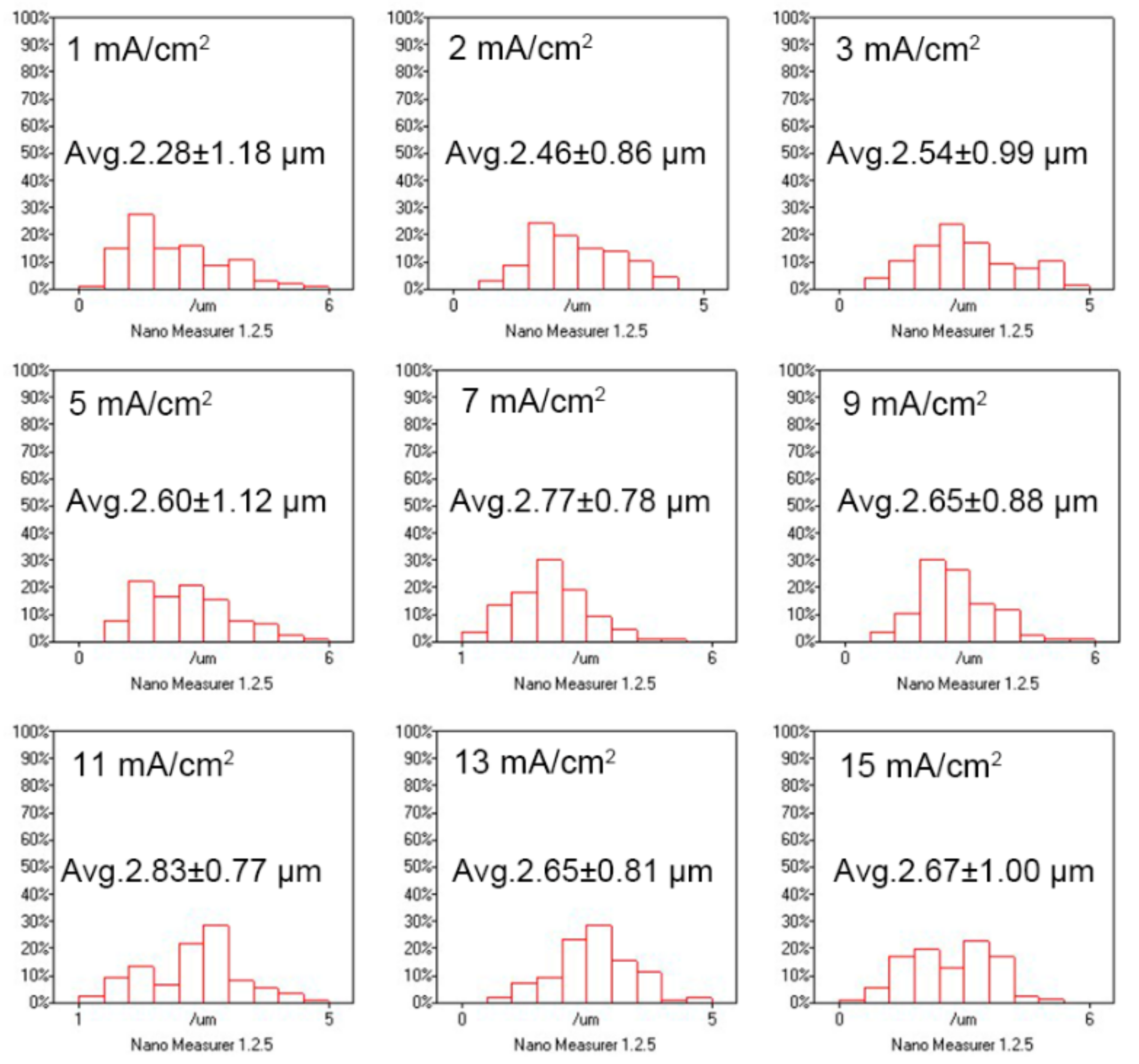

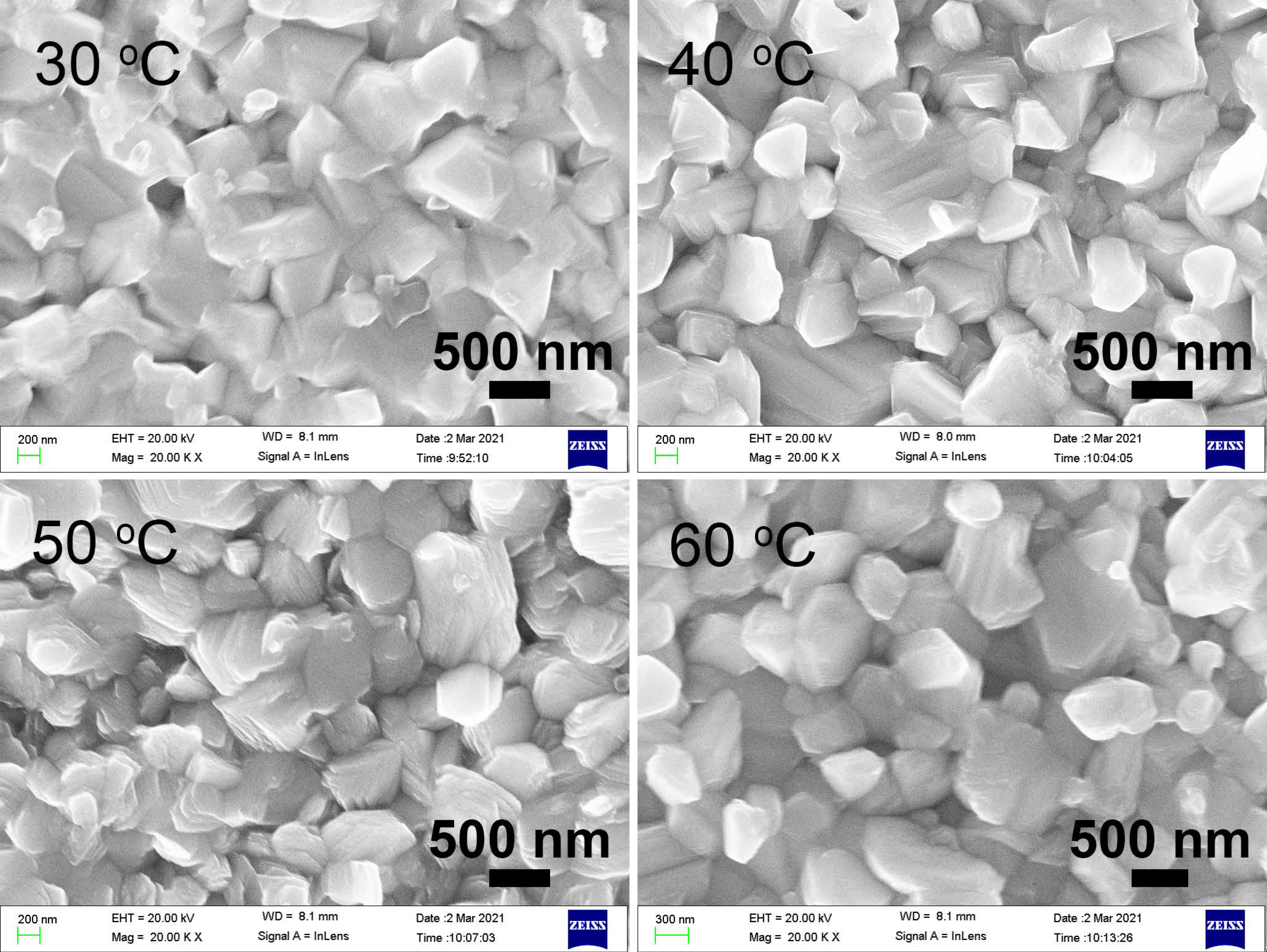

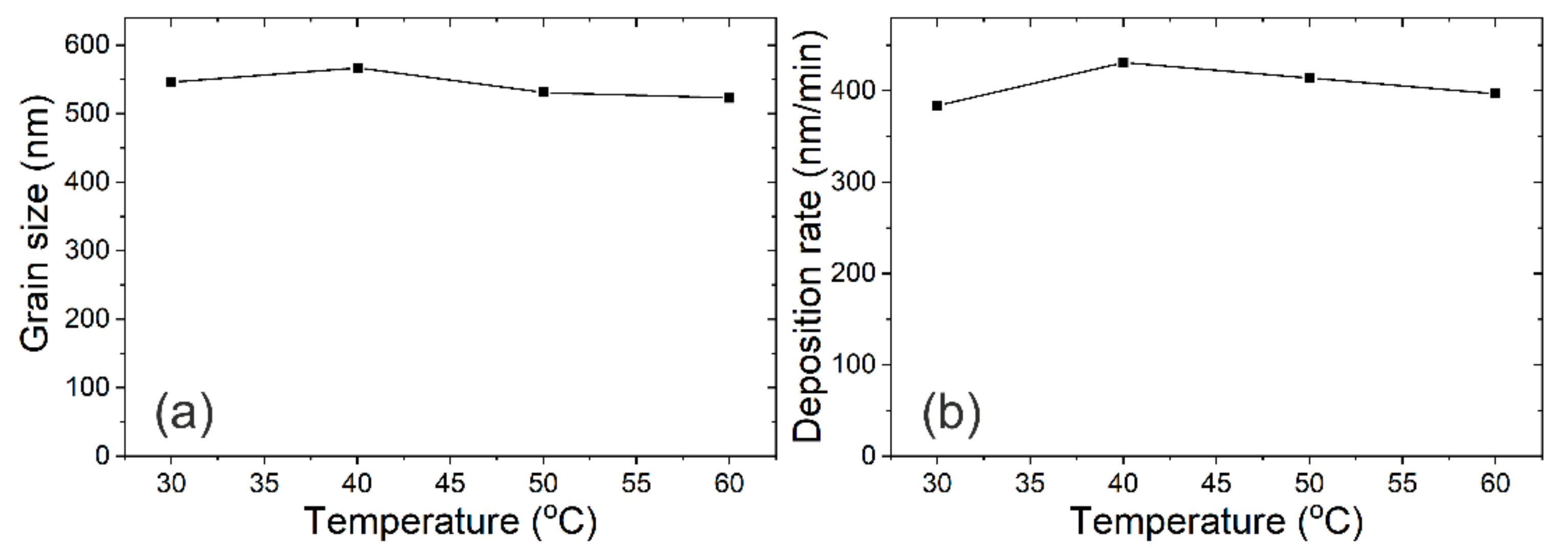

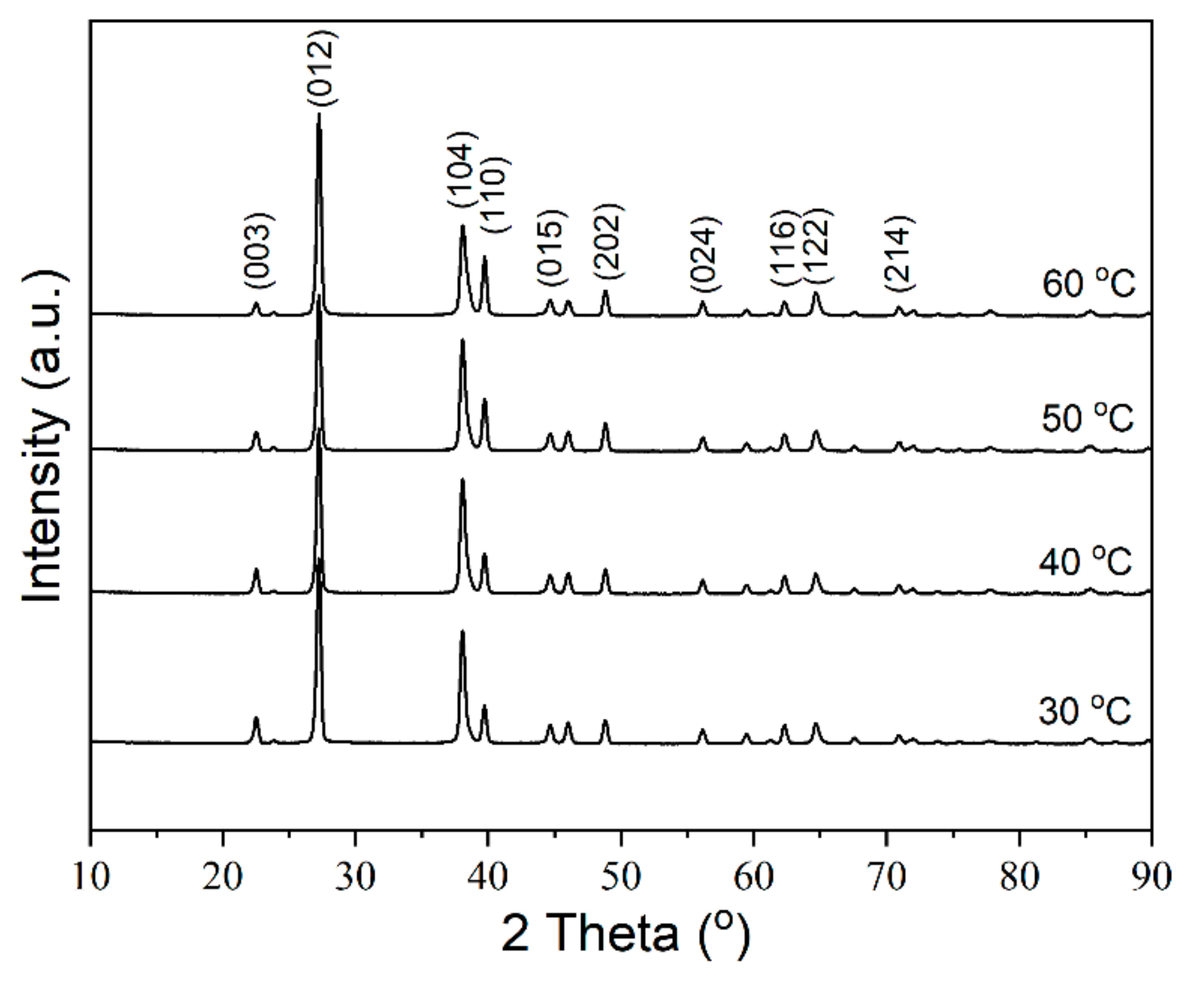

3.1. Morphology and Texture Study

3.2. XPS Study

3.3. Electrical Properties

3.4. X-ray Stopping Power

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Irwin, K.D.; Hilton, G.C. Transition-Edge Sensors. Top. Appl. Phys. 2005, 99, 63–150. [Google Scholar] [CrossRef]

- Ullom, J.N.; Bennett, D.A. Review of superconducting transition-edge sensors for X-ray and gamma-ray spectroscopy. Supercond. Sci. Technol. 2015, 28, 084003. [Google Scholar] [CrossRef]

- Gottardi, L.; Nagayashi, K. A Review of X-ray Microcalorimeters Based on Superconducting Transition Edge Sensors for Astrophysics and Particle Physics. Appl. Sci. 2021, 11, 3793. [Google Scholar] [CrossRef]

- Hummatov, R.; Adams, J.S.; Bandler, S.R.; Barlis, A.; Beaumont, S.; Chang, M.P.; Chervenak, J.A.; Datesman, A.M.; Eckart, M.E.; Finkbeiner, F.M.; et al. Quantum Efficiency Study and Reflectivity Enhancement of Au/Bi Absorbers. J. Low Temp. Phys. 2020, 199, 393–400. [Google Scholar] [CrossRef]

- Yoon, W.; Adams, J.S.; Bandler, S.R.; Betancourt-Martinez, G.L.; Chiao, M.P.; Chang, M.P.; Chervenak, J.A.; Datesman, A.; Eckart, M.E.; Ewin, A.J.; et al. Design and Performance of Hybrid Arrays of Mo/Au Bilayer Transition-Edge Sensors. IEEE Trans. Appl. Supercond. 2017, 27, 1–5. [Google Scholar] [CrossRef]

- Miniussi, A.R.; Adams, J.S.; Bandler, S.R.; Chervenak, J.A.; Datesman, A.M.; Eckart, M.E.; Ewin, A.J.; Finkbeiner, F.M.; Kelley, R.L.; Kilbourne, C.A.; et al. Performance of an X-ray Microcalorimeter with a 240 μm Absorber and a 50 μm TES Bilayer. J. Low Temp. Phys. 2018, 193, 337–343. [Google Scholar] [CrossRef]

- Patel, U.; Divan, R.; Gades, L.; Guruswamy, T.; Yan, D.; Quaranta, O.; Miceli, A. Development of Transition-Edge Sensor X-ray Microcalorimeter Linear Array for Compton Scattering and Energy Dispersive Diffraction Imaging. J. Low Temp. Phys. 2020, 199, 384–392. [Google Scholar] [CrossRef]

- Marcel, L.v.d.B.; Daniel, T.C.; Alex, L.; Mark, F.C.; Troy, W.B., Jr.; Matthias, A.F.; Simon, E.L. High-resolution hard X-ray and gamma-ray spectrometers based on superconducting absorbers coupled to superconducting transition edge sensors. Proc. SPIE 2000, 4140, 436–444. [Google Scholar]

- Irimatsugawa, T.; Hatakeyama, S.; Ohno, M.; Takahashi, H.; Otani, C.; Maekawa, T. High Energy Gamma-Ray Spectroscopy Using Transition-Edge Sensor With a Superconducting Bulk Tantalum Absorber. IEEE Trans. Appl. Supercond. 2015, 25, 1–3. [Google Scholar] [CrossRef]

- Ridder, M.L.; Khosropanah, P.; Hijmering, R.A.; Suzuki, T.; Bruijn, M.P.; Hoevers, H.F.C.; Gao, J.R.; Zuiddam, M.R. Fabrication of Low-Noise TES Arrays for the SAFARI Instrument on SPICA. J. Low Temp. Phys. 2016, 184, 60–65. [Google Scholar] [CrossRef]

- Damayanthi, R.M.T.; Ohno, M.; Hatakeyama, S.; Takahashi, H.; Otani, C. Development of Bulk Superconducting-Absorber Coupled Transition-Edge Sensor Detectors for Positron Annihilation Spectroscopy. IEEE Trans. Appl. Supercond. 2013, 23, 2100304. [Google Scholar] [CrossRef]

- Hatakeyama, S.; Ohno, M.; Damayanthi, R.M.T.; Takahashi, H.; Kuno, Y.; Maehata, K.; Otani, C.; Takasaki, K. Development of Hard X-Ray and Gamma-Ray Spectrometer Using Superconducting Transition Edge Sensor. IEEE Trans. Appl. Supercond. 2013, 23, 2100804. [Google Scholar] [CrossRef]

- Taralli, E.; Gottardi, L.; Nagayoshi, K.; Ridder, M.; Visser, S.; Khosropanah, P.; Akamatsu, H.; van der Kuur, J.; Bruijn, M.; Gao, J.R. Characterization of High Aspect-Ratio TiAu TES X-ray Microcalorimeter Array Under AC Bias. J. Low Temp. Phys. 2020, 199, 80–87. [Google Scholar] [CrossRef]

- Nagayoshi, K.; Ridder, M.L.; Bruijn, M.P.; Gottardi, L.; Taralli, E.; Khosropanah, P.; Akamatsu, H.; Visser, S.; Gao, J.R. Development of a Ti/Au TES Microcalorimeter Array as a Backup Sensor for the Athena/X-IFU Instrument. J. Low Temp. Phys. 2020, 199, 943–948. [Google Scholar] [CrossRef]

- Gades, L.M.; Cecil, T.W.; Divan, R.; Schmidt, D.R.; Ullom, J.N.; Madden, T.J.; Yan, D.; Miceli, A. Development of Thick Electroplated Bismuth Absorbers for Large Collection Area Hard X-ray Transition Edge Sensors. IEEE Trans. Appl. Supercond. 2017, 27, 1–5. [Google Scholar] [CrossRef]

- Yan, D.; Divan, R.; Gades, L.M.; Kenesei, P.; Madden, T.J.; Miceli, A.; Park, J.-S.; Patel, U.M.; Quaranta, O.; Sharma, H.; et al. Microstructure Analysis of Bismuth Absorbers for Transition-Edge Sensor X-ray Microcalorimeters. J. Low Temp. Phys. 2018, 193, 225–230. [Google Scholar] [CrossRef]

- Yan, D.; Divan, R.; Gades, L.M.; Kenesei, P.; Madden, T.J.; Miceli, A.; Park, J.-S.; Patel, U.M.; Quaranta, O.; Sharma, H.; et al. Eliminating the non-Gaussian spectral response of X-ray absorbers for transition-edge sensors. Appl. Phys. Lett. 2017, 111, 192602. [Google Scholar] [CrossRef]

- Chervenak, J.A.; Adams, J.M.; Bailey, C.N.; Bandler, S.; Brekosky, R.P.; Eckart, M.E.; Ewin, A.E.; Finkbeiner, F.M.; Kelley, R.L.; Kilbourne, C.A.; et al. Fabrication of Microstripline Wiring for Large Format Transition Edge Sensor Arrays. J. Low Temp. Phys. 2012, 167, 547–553. [Google Scholar] [CrossRef][Green Version]

- Brown, A.D.; Bandler, S.R.; Brekosky, R.; Chervenak, J.A.; Figueroa-Feliciano, E.; Finkbeiner, F.; Iyomoto, N.; Kelley, R.L.; Kilbourne, C.A.; Porter, F.S.; et al. Absorber Materials for Transition-Edge Sensor X-ray Microcalorimeters. J. Low Temp. Phys. 2008, 151, 413–417. [Google Scholar] [CrossRef]

- Moral-Vico, J.; Casañ-Pastor, N.; Camón, A.; Pobes, C.; Jáudenes, R.M.; Strichovanec, P.; Fàbrega, L. Microstructure and electrical transport in electrodeposited Bi films. J. Electroanal. Chem. 2019, 832, 40–47. [Google Scholar] [CrossRef]

- Sandnes, E.; Williams, M.E.; Bertocci, U.; Vaudin, M.D.; Stafford, G.R. Electrodeposition of bismuth from nitric acid electrolyte. Electrochim. Acta 2007, 52, 6221–6228. [Google Scholar] [CrossRef]

- Fàbrega, L.; Camón, A.; Costa-Krämer, J.L.; Pobes, C.; Parra-Borderías, M.; Fernández-Martínez, I.; Jáudenes, R.; Cereceda, P.; Ceballos, M.T.; Barcons, X.; et al. Towards Mo/Au based TES detectors for Athena/X-IFU. Proc. SPIE 2014, 9144, 91445P. [Google Scholar] [CrossRef]

- Lien, C.-H.; Hu, C.-C.; Tsai, Y.-D.; Wong, D. Preferred Orientation Control of Bi Deposits Using Experimental Strategies. J. Electrochem. Soc. 2012, 159, D260–D264. [Google Scholar] [CrossRef]

- Cereceda-Company, P.; Costa-Krämer, J.L. Electrochemical Growth of Bismuth for X-ray Absorbers. J. Electrochem. Soc. 2018, 165, D167–D182. [Google Scholar] [CrossRef]

- Sun, Y.; Gleber, S.-C.; Jacobsen, C.; Kirz, J.; Vogt, S. Optimizing detector geometry for trace element mapping by X-ray fluorescence. Ultramicroscopy 2015, 152, 44–56. [Google Scholar] [CrossRef]

- Qin, X.; Sui, C.; Di, L. Influence of substrate temperature on the morphology and structure of bismuth thin films deposited by magnetron sputtering. Vacuum 2019, 166, 316–322. [Google Scholar] [CrossRef]

- O’Brien, B.; Plaza, M.; Zhu, L.Y.; Perez, L.; Chien, C.L.; Searson, P.C. Magnetotransport Properties of Electrodeposited Bismuth Films. J. Phys. Chem. C 2008, 112, 12018–12023. [Google Scholar] [CrossRef]

- Fedotov, A.; Shendyukov, V.; Tsybulskaya, L.; Perevoznikov, S.; Dong, M.; Xue, X.; Feng, X.; Sayyed, M.I.; Zubar, T.; Trukhanov, A.; et al. Electrodeposition conditions-dependent crystal structure, morphology and electronic properties of Bi films. J. Alloy. Compd. 2021, 887, 161451. [Google Scholar] [CrossRef]

- Shu, Y.; Hu, W.; Liu, Z.; Shen, G.; Xu, B.; Zhao, Z.; He, J.; Wang, Y.; Tian, Y.; Yu, D. Coexistence of multiple metastable polytypes in rhombohedral bismuth. Sci. Rep. 2016, 6, 20337. [Google Scholar] [CrossRef]

- Rajamani, A.R.; Jothi, S.; Kumar, M.D.; Srikaanth, S.; Singh, M.K.; Otero-Irurueta, G.; Ramasamy, D.; Datta, M.; Rangarajan, M. Effects of Additives on Kinetics, Morphologies and Lead-Sensing Property of Electrodeposited Bismuth Films. J. Phys. Chem. C 2016, 120, 22398–22406. [Google Scholar] [CrossRef]

- Yan, D.; Weber, J.; Morgan, K.; Wessels, A.; Bennett, D.; Pappas, C.; Mates, J.; Gard, J.; Becker, D.; Fowler, J.; et al. Transition-Edge Sensor Optimization for Hard X-ray Applications. IEEE Trans. Appl. Supercond. 2021, 31, 2100505. [Google Scholar] [CrossRef]

| Temperature (°C) | 30 | 40 | 50 | 60 |

|---|---|---|---|---|

| Average (Ω/R) | 1.1234 | 0.9800 | 0.9600 | 1.0302 |

| Stopping Power | 2 μm Bi | 3 μm Bi | 4 μm Bi | 5 μm Bi |

|---|---|---|---|---|

| 10 keV | 12.691% | 23.855% | 31.524% | 40.300% |

| 15.6 keV | 12.091% | 19.868% | 24.808% | 30.689% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Li, J.; Xu, X.; Wang, Z.; Guo, S.; Jiang, Z.; Gao, H.; Zhong, Q.; Zhong, Y.; Zeng, J.; et al. Electroplating Deposition of Bismuth Absorbers for X-ray Superconducting Transition Edge Sensors. Materials 2021, 14, 7169. https://doi.org/10.3390/ma14237169

Chen J, Li J, Xu X, Wang Z, Guo S, Jiang Z, Gao H, Zhong Q, Zhong Y, Zeng J, et al. Electroplating Deposition of Bismuth Absorbers for X-ray Superconducting Transition Edge Sensors. Materials. 2021; 14(23):7169. https://doi.org/10.3390/ma14237169

Chicago/Turabian StyleChen, Jian, Jinjin Li, Xiaolong Xu, Zhenyu Wang, Siming Guo, Zheng Jiang, Huifang Gao, Qing Zhong, Yuan Zhong, Jiusun Zeng, and et al. 2021. "Electroplating Deposition of Bismuth Absorbers for X-ray Superconducting Transition Edge Sensors" Materials 14, no. 23: 7169. https://doi.org/10.3390/ma14237169

APA StyleChen, J., Li, J., Xu, X., Wang, Z., Guo, S., Jiang, Z., Gao, H., Zhong, Q., Zhong, Y., Zeng, J., & Wang, X. (2021). Electroplating Deposition of Bismuth Absorbers for X-ray Superconducting Transition Edge Sensors. Materials, 14(23), 7169. https://doi.org/10.3390/ma14237169