Relationship between the Tensile Properties and Damping Capacity of Fe-22%Mn-12%Cr-4%Co-3%Ni-2%Si Alloys by Fatigue Stress

Abstract

1. Introduction

2. Materials and Methods

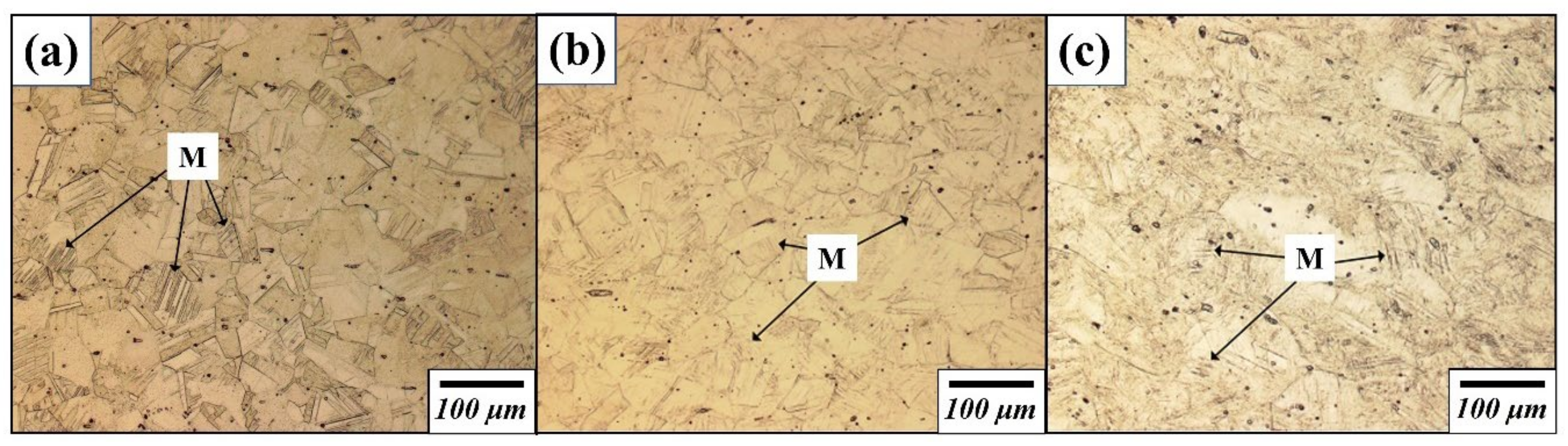

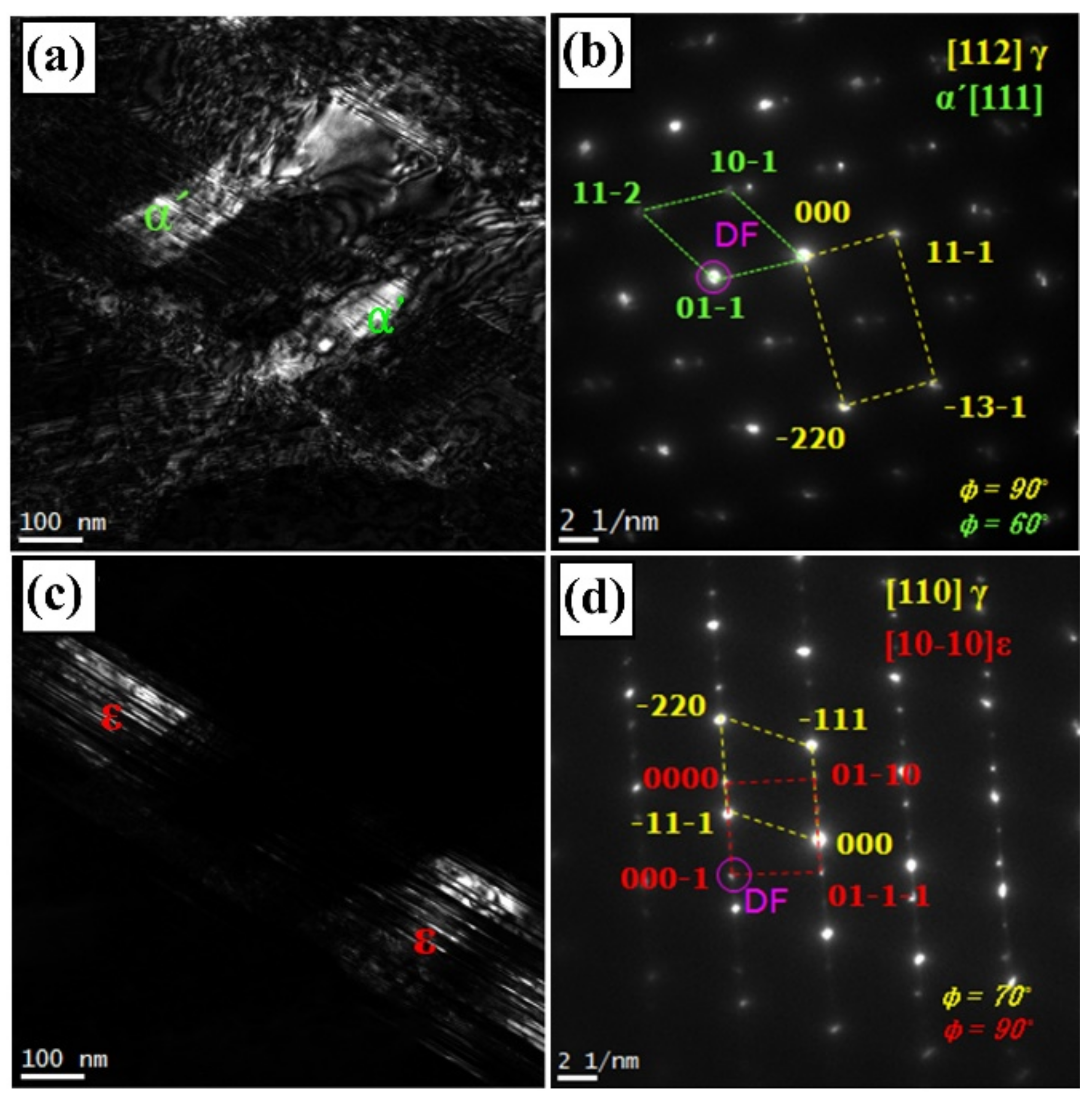

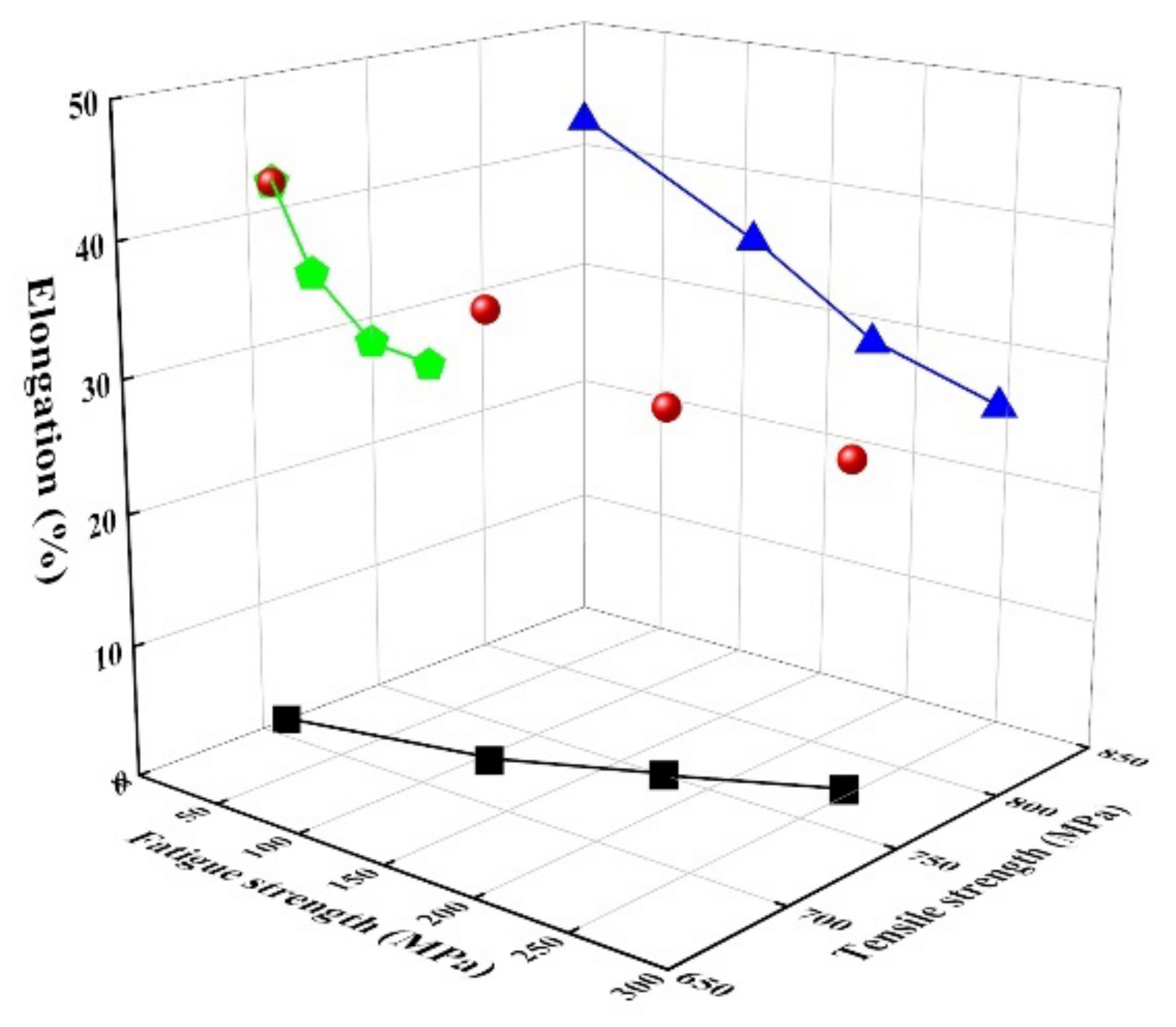

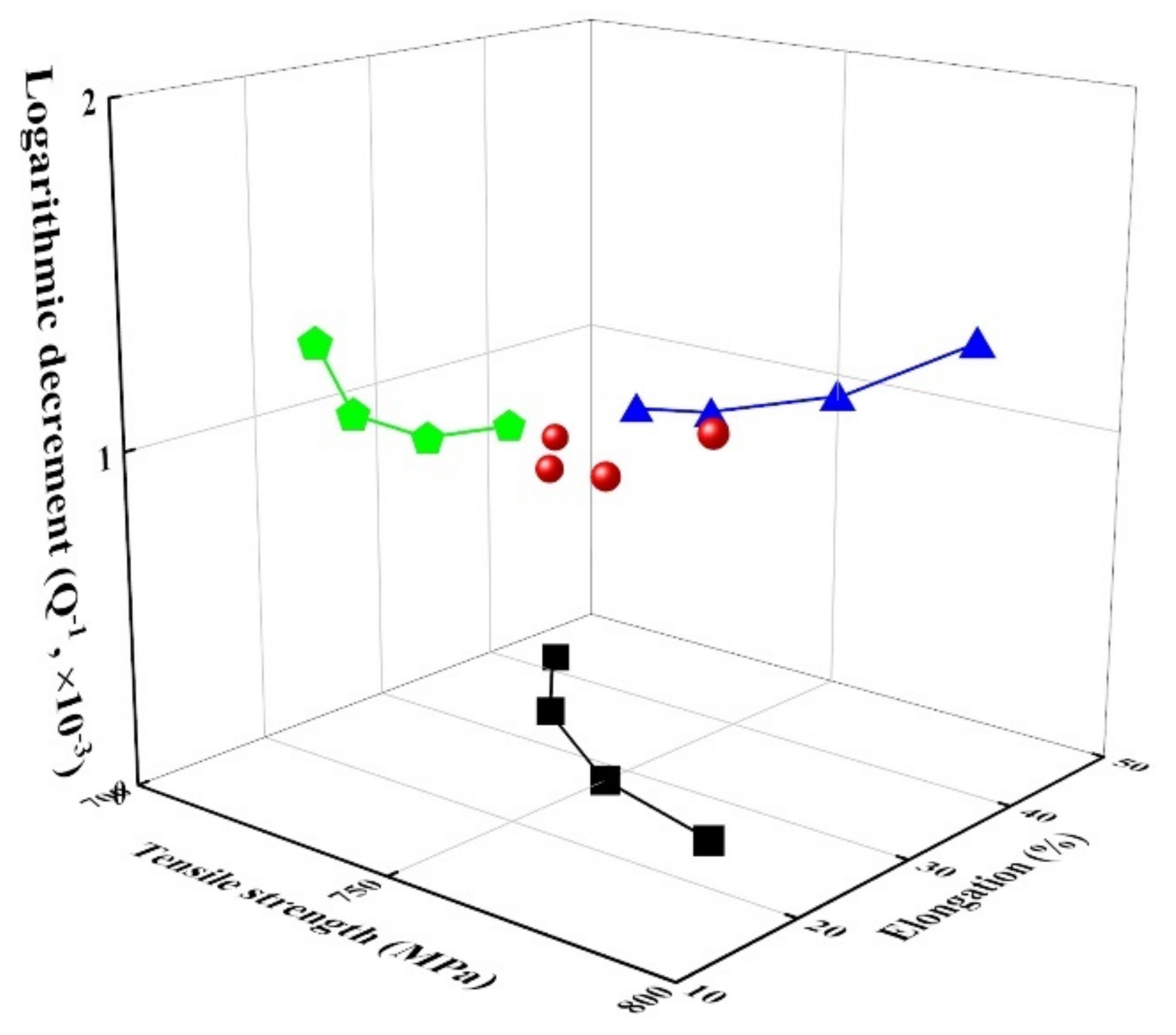

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, M.S.; Lee, Y.N.; Nam, K.W.; Kang, C.Y. Effect of Stress on the Damping Capacity of Damaged Damping Alloy under Fatigue Stress. Korean J. Mater. Res. 2018, 28, 583–589. [Google Scholar] [CrossRef]

- Jeong, S.; Kang, C.Y. Effect of Deformation Induced Martensite on Damping Capacity of Fe-26Mn-4Co-2Al Alloy. Korean J. Mater. Res. 2018, 26, 493–497. [Google Scholar] [CrossRef]

- Kang, C.Y.; Kim, S.H.; Jeong, G.S. Effect of Cold Working on the Tensile Strength of Fe-26Mn-4Co-2Al Damping Alloy. J. Tor. Soc. Power Syst. Eng. 2016, 20, 46–50. [Google Scholar] [CrossRef][Green Version]

- Kwon, M.K.; Kang, C.Y. Correlationship Between Tensile Properties and Damping Capacity of 316L Stainless Steel. Korean J. Mater. Res. 2014, 24, 1–5. [Google Scholar] [CrossRef]

- Son, D.U.; Kim, J.H.; Kim, I.S.; Miyahara, K.; Sung, J.H.; Kang, C.Y. Effect of ε Martensite on the Damping Capacity of Austenitic Stainless Steel. J. Korea Inst. Met. Mater. 2004, 42, 621–625. [Google Scholar]

- Birchon, D.E.; Bromly, D. Healey, Mechanism of Energy Dissipation in High-Damping-Capacity Manganese-Copper Alloys. Met. Sci. J. 1968, 2, 41–467. [Google Scholar] [CrossRef]

- Kommel, L. Microstructure and properties that change during hard cyclic visco-plastic deformation of bulk high purity niobium. Int. J. Refract. Hard Met. 2019, 79, 10–17. [Google Scholar] [CrossRef]

- Jee, K.K.; Jang, W.Y.; Baik, S.H.; Shin, M.C. Damping mechanism and application of Fe-Mn based alloys. Mater. Sci. Eng. A 1999, 273–275, 538–542. [Google Scholar] [CrossRef]

- Nagy, E.; Mertinger, V.; Tranta, F.; Solyom, J. Deformation Induced Martensite in Stainless Steel. Mater. Sci. Eng. A 2004, 378, 308–313. [Google Scholar] [CrossRef]

- Miller, R.L. A rapid X-ray method for the determination of retained austenite. Trans. ASM 1964, 57, 892–899. [Google Scholar]

- Shim, H.; Kang, C. Effect of thermo-mechanical treatment on the microstructure evaluation and mechanical properties of Fe-20Mn-12Cr-3Ni-3Si damping alloy. Materials 2019, 12, 1119. [Google Scholar] [CrossRef]

- Kitagawa, H.; Sohmura, T. An X-ray diffraction method for quantitative determination of retained austenite in the production line of metastable austenitic stainless steel. Trans. ISIJ 1983, 23, 543–549. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Kinetics of strain-induced martensitic nucleation. Metall. Trans. A 1975, 6, 791–795. [Google Scholar] [CrossRef]

- Stringfellow, R.G.; Parks, D.M.; Olson, G.B. A constitutive model for transformation plasticity accompanying strain-induced martensitic transformations in metastable austenitic steels. Acta Metall. Mater. 1992, 40, 1703–1710. [Google Scholar] [CrossRef]

- van Tol, R.T.; Kim, J.K.; Zhao, L.; Sietsma, J.; de Cooman, B.C. α’-Martensite formation in deep-drawn Mn-based TWIP steel. J. Mater. Sci. 2012, 47, 4845–4850. [Google Scholar] [CrossRef]

- Sato, K.; Ichinose, M.; Hirotsu, Y.; Inoue, Y. Effect of deformation induced phase transformation and twinning on the mechanical properties of austenitic Fe-Mn-Al alloys. ISIJ Int. 1989, 29, 868–877. [Google Scholar] [CrossRef]

- Grunes, R.L.; D’Antonio, C.; Mukherjee, K. A study of α′ martensite nucleation in the iron15% Mn alloy. Mater. Sci. Eng. 1972, 9, 1–6. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part I. General concepts and the FCC→HCP transformation. Metall. Trans. A 1976, 7, 1897–1904. [Google Scholar]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steel: A review of the microstructure properties relationships. Curr. Opin. Solid St. M. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Giles, P.M.; Marder, A.R. The effect of composition on the pressure-induced HCP (ε) transformation in iron. Met. Trans. 1971, 2, 1371–1378. [Google Scholar]

- Li, J.C.; Zhao, M.; Jiang, Q. Alloy design of FeMnSiCrNi shape memory alloys related to stacking fault energy. Metall. Mater. Trans. A 2000, 31, 581–584. [Google Scholar] [CrossRef]

- Tian, Y.; Borgenstam, A.; Hedström, P. A microstructural investigation of athermal and deformation-induced martensite in Fe-Cr-Ni alloys. Mater. Today Proc. 2015, 2, 687–690. [Google Scholar]

- Choi, Y.; Dong, Z.; Li, W.; Schonecker, S.; Kim, H.; Kwon, S.; Vitos, L. Predicting the stacking fault energy of austenitic Fe-Mn-Al (Si) alloys. Mater. Design 2020, 187, 108392. [Google Scholar] [CrossRef]

- Lu, S.; Hu, Q.M.; Johansson, B.; Vitos, L. Stacking fault energies of Mn, Co and Nb alloyed austenitic stainless steels. Acta Mater. 2011, 59, 5728–5734. [Google Scholar] [CrossRef]

- Wei, D.; Li, X.; Heng, W.; Koizumi, Y.; He, F.; Choi, W.-M.; Lee, B.-J.; Kim, H.S.; Kato, H.; Chiba, A. Novel Co-rich high entropy alloys with superior tensile properties. Mater. Res. Lett. 2019, 7, 82–88. [Google Scholar] [CrossRef]

- Seo, Y.; Lee, Y.; Choi, C. Effect of deformation on damping capacity and microstructure of Fe-22%Mn-8%Co alloy. Mater. Trans. 2005, 46, 1274–1277. [Google Scholar] [CrossRef][Green Version]

- Mizubayashi, H.; Murayama, S.; Tanimoto, H. Feasibility study of high-strength and high damping materials by means of hydrogen internal friction in amorphous alloys. J. Alloy. Compd. 2002, 330, 389–392. [Google Scholar]

| C | N | P | S | Mn | Cr | Co | Ni | Si | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.01 | 0.1 | 0.01 | 0.01 | 22 | 12 | 4 | 3 | 2 | 0.3 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Lee, M.-S.; Kim, J.-S. Relationship between the Tensile Properties and Damping Capacity of Fe-22%Mn-12%Cr-4%Co-3%Ni-2%Si Alloys by Fatigue Stress. Materials 2021, 14, 7160. https://doi.org/10.3390/ma14237160

Kim J-H, Lee M-S, Kim J-S. Relationship between the Tensile Properties and Damping Capacity of Fe-22%Mn-12%Cr-4%Co-3%Ni-2%Si Alloys by Fatigue Stress. Materials. 2021; 14(23):7160. https://doi.org/10.3390/ma14237160

Chicago/Turabian StyleKim, Jae-Hwan, Myong-Soo Lee, and Jong-Sig Kim. 2021. "Relationship between the Tensile Properties and Damping Capacity of Fe-22%Mn-12%Cr-4%Co-3%Ni-2%Si Alloys by Fatigue Stress" Materials 14, no. 23: 7160. https://doi.org/10.3390/ma14237160

APA StyleKim, J.-H., Lee, M.-S., & Kim, J.-S. (2021). Relationship between the Tensile Properties and Damping Capacity of Fe-22%Mn-12%Cr-4%Co-3%Ni-2%Si Alloys by Fatigue Stress. Materials, 14(23), 7160. https://doi.org/10.3390/ma14237160