Heat Treatment of Cast and Cold Rolled Al–Yb and Al–Mn–Yb–Zr Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Initial State of the As-Cast and Cold Rolled Alloys

3.2. Isochronal Treatment of the Alloys

3.3. High Temperature Treatment of the Alloys

4. Conclusions

- (a)

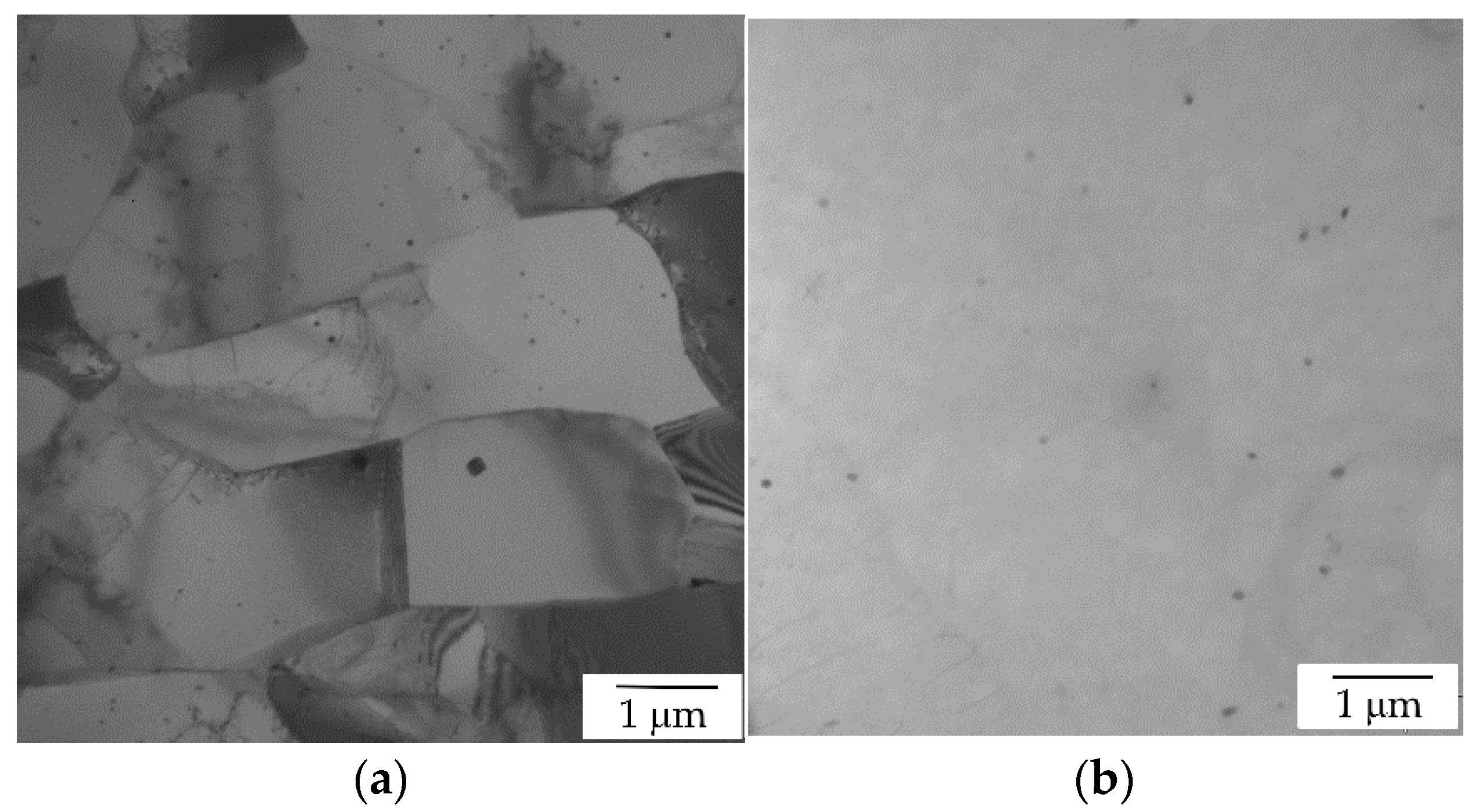

- The addition of manganese (Mn) and zirconium (Zr) to the AlYb alloy together with higher addition of Yb cause a grain refinement. The grain size of the alloys was approximately units of mm for the AlYb alloy and about tens of μm for the AlMnYbZr alloy. In the cold rolled materials, the deformation texture was noticed, but without a significant change in the grain size.

- (b)

- The eutectic phase at (sub)grains boundaries was observed in both studied alloys in the initial as-cast state. This phase mainly consists of Yb and Fe in the AlYb alloy and mainly of Yb, Mn, Zr and additionally of Cu and Fe in the AlMnYbZr alloy.

- (c)

- TEM in the initial state of the AlYb AC and AlMnYbZr AC alloy proved secondary Al3Yb and Al3(Yb,Zr) phase particles with the L12 structure. Massive precipitation and/or coarsening of these secondary particles were observed in the alloys after treatment up to 330 °C and 540 °C.

- (d)

- The difference between the initial values of microhardness in AlYb and AlMnYbZr alloys is probably caused by a combination of the different grain size in the alloys and/or admixture hardening and/or the presence/volume fraction of Al3Yb and Al3(Yb,Zr) secondary particles. The positive influence of cold rolling was observed in both studied materials up to treatment at 390 °C. The decrease of microhardness in the cold rolled alloys in the range 390–450 °C is probably caused by recovery of dislocations and/or recrystallization in the AlYb alloy and by recovery of dislocations in the AlMnYbZr alloy. Almost no difference in microhardness values between cold rolled materials in different degrees (40% and 70%) after all steps of treatment was observed.

- (e)

- The decrease of relative resistivity (up to 420 °C in the as-cast AlYb alloy and up to 510 °C in the as-cast AlMnYbZr alloy) followed by an increase in resistivity were observed. More significant changes and even a double decrease in relative resistivity changes were observed in the cold rolled AlMnYbZr alloys. The decrease in the relative resistivity changes is likely caused by a combination of additional precipitation of secondary Al3Yb particles and/or recrystallization in the AlYb alloy. A double decrease in the cold rolled AlMnYbZr alloy is caused by precipitation of Al3Yb and by wrapping the Yb-rich core by Zr. The increase in the relative resistivity changes of the AlYb and AlMnYbZr alloys is connected to the dissolution of particles of the Al–Yb and Al–Yb–Zr system. Small addition of Mn (0.11 wt.%) has no influence of phase transformation.

- (f)

- No particles were observed in the AlYb alloy in contrast to AlMnYbZr alloy, where Fe, Yb and Cu-rich particles in size of μm were observed in grains boundaries after high temperature ageing at 625 °C/24 h.

- (g)

- The hardening effect with a double peak was observed in the temperature range 100–450 °C in the AlYb alloy after the high temperature ageing 625 °C/24 h. The first hardening peak (with maximum at ~150 °C) is connected to homogeneous precipitation of Al3Yb particles and the other (with maximum at ~270 °C) is connected to heterogeneous nucleation of the Al3Yb. A slight hardening effect in the temperature range of 330–570 °C with a maximum at 510 °C was observed after the high temperature ageing of the AlMnYbZr alloy, connected to the precipitation of Al3(Yb,Zr) particles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Dalen, M.E.; Karnesky, R.A.; Cabotaje, J.R.; Dunand, D.C.; Seidman, D.N. Erbium and ytterbium solubilities and diffusivities in aluminum as determined by nanoscale characterization of precipitates. Acta Mater. 2009, 57, 4081–4089. [Google Scholar] [CrossRef]

- Van Dalen, M.E.; Gyger, T.; Dunand, D.C.; Seidman, D.N. Effects of Yb and Zr microalloying additions on the microstructure and mechanical properties of dilute Al–Sc alloys. Acta Mater. 2011, 59, 7615–7626. [Google Scholar] [CrossRef]

- Tang, C.L.; Zhou, D.J. Precipitation hardening behavior of dilute binary Al−Yb alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 2326–2330. [Google Scholar] [CrossRef]

- Peng, G.; Chen, K.; Fang, H.; Chen, S. A study of nanoscale Al3(Zr,Yb) dispersoids structure and thermal stability in Al–Zr–Yb alloy. Mater. Sci. Eng. A 2012, 535, 311–315. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Butterworth and Co Ltd.: London, UK, 1976. [Google Scholar]

- Zalutskaya, O.I.; Kontseyoy, V.G.; Karamishev, N.I.; Ryabov, V.R. Zalutskii II Dopovidi Akademii Nauk Ukrains’koi RSR, Seriya A: Fiziko-Tekhnichni ta Matematichni Nauki; Ukraine; 1970; pp. 751–753. [Google Scholar]

- Palenzona, A.J. The ytterbium-aluminum system. J. Less. Common Met. 1972, 29, 289. [Google Scholar] [CrossRef]

- Kononenko, V.I.; Golubev, S.V. Al-M (M = La, Ce, Pr, Nd, Sm, Eu, Yb, Sc, Y) Phase Diagrams. Russ. Metall. 1990, 2, 197. [Google Scholar]

- Massalski, T.B. Binary Alloy Phase Diagrams; ASM International: Materials Park, OH, USA, 1990. [Google Scholar]

- Meng, F.G.; Zhang, L.G.; Liu, H.S.; Liu, L.B.; Jin, Z.P. Thermodynamic optimization of the Al–Yb binary system. J. Alloys Compds. 2008, 452, 279. [Google Scholar] [CrossRef]

- Barkov, R.Y.; Yakovtseva, O.A.; Mamzurina, O.I.; Loginova, I.S.; Medvedeva, S.V.; Proviryakov, A.S.; Mikhaylovskaya, A.V.; Pozdniakov, A.V. Effect of Yb on the Structure and Properties of an Electroconductive Al–Y–Sc Alloy. Phys. Met. 2020, 121, 604–609. [Google Scholar] [CrossRef]

- Karnesky, R.A.; Van Dalen, M.E.; Dunand, D.C.; Seidman, D.N. Effects of substituting rare-earth elements for scandium in a precipitation-strengthened Al–0.08 at. %Sc alloy. Scr. Mater. 2006, 55, 437. [Google Scholar] [CrossRef]

- Nie, Z.; Jin, T.; Fu, J.; Xu, G.; Yang, J.; Zhou, J.; Zuo, T. Research on Rare Earth in Aluminum. Mater. Sci. Forum 2002, 1731, 396–402. [Google Scholar] [CrossRef]

- Fang, H.; Chen, K.; Zhang, Z.; Zhu, C. Effect of Yb additions on microstructures and properties of 7A60 aluminum alloy. Trans. Nonferrous Met. Soc. China 2008, 18, 28–32. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, K.; Fang, H.; Qi, X.; Liu, G. Effect of Yb Addition on Strength and Fracture Toughness of Al-Zn-Mg-Cu-Zr Aluminum Alloy. Trans. Nonferrous Met. Soc. China 2008, 18, 1037–1042. [Google Scholar] [CrossRef]

- Song, M.; Wu, Z.; He, Y. Effects of Yb on the mechanical properties and microstructures of an Al–Mg alloy. Mater. Sci. Eng. A 2008, 497, 519–523. [Google Scholar] [CrossRef]

- Marquis, E.A.; Dunand, D.C. Model for creep threshold stress in precipitation-strengthened alloys with coherent particles. Scr. Mater. 2002, 47, 503–508. [Google Scholar] [CrossRef] [Green Version]

- Karnesky, R.A.; Seidman, D.N.; Dunand, D.C. Creep of Al-Sc Microalloys with Rare-Earth Element Additions. Mater. Sci. Forum 2006, 519–521, 1035–1040. [Google Scholar] [CrossRef]

- Knipling, K.E.; Dunand, D.C.; Seidman, D.N. Precipitation evolution in Al-Zr and Al-Zr-Ti alloys during aging at 450–600 °C. Acta Mater. 2008, 56, 1182–1195. [Google Scholar] [CrossRef]

- Fujikawa, S.I. Impurity Diffusion of Scandium in Aluminium. Defect Dif. Forum 1997, 115, 143–147. [Google Scholar] [CrossRef]

- Barkov, R.Y.; Mikhaylovskaya, A.V.; Yakovtseva, O.A.; Loginova, I.S.; Prosviryakov, A.S.; Pozdniakov, A.V. Effects of thermomechanical treatment on the microstructure, precipitation strengthening, internal friction, and thermal stability of Al-Er-Yb-Sc alloys with good electrical conductivity. J. Alloys Compd. 2021, 855. [Google Scholar] [CrossRef]

- Gao, Z.; Li, H.; Liu, J.; Lu, X.; Ou, Y. Effects of Ytterbium and Zirconium on precipitation evolution and coarsening resistance in aluminum during isothermal aging. J. Alloys Compd. 2014, 592, 100–104. [Google Scholar] [CrossRef]

- Kodetová, V.; Vlach, M.; Kudrnová, H.; Leibner, M.; Málek, J.; Cieslar, M.; Bajtošová, L.; Harcuba, P.; Neubert, V. Annealing effects in commercial aluminium hot-rolled 7075(-Sc-Zr) alloys. J. Therm. Anal. Calorim. 2020, 142, 1613–1623. [Google Scholar] [CrossRef]

- Vlach, M.; Stulíková, I.; Smola, B.; Žaludová, N.; Černá, J. Phase transformations in isochronally annealed mould-cast and cold-rolled Al–Sc–Zr-based alloy. J. Alloys Compd. 2010, 492, 143–148. [Google Scholar] [CrossRef]

- Vo, N.Q.; Bayansan, D.; Sanaty-Zadeh, A.; Ramos, E.H.; Dunand, D.C. Effect of Yb microadditions on creep resistance of a dilute Al-Er-Sc-Zr alloy. Materialia 2018, 4, 65–69. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, K.; Wen, S.; Huang, H.; Wang, W.; Zhu, Z.; Nie, Z.; Zhou, D. Determination of Er and Yb solvuses and trialuminide nucleation in Al–Er and Al–Yb alloys. J. Alloys Compd. 2014, 590, 526–534. [Google Scholar] [CrossRef]

- Cahn, J.W. Nucleation on Dislocations. Acta Metall. 1957, 5, 169. [Google Scholar] [CrossRef]

| Alloy | HV 0.1 |

|---|---|

| AlYb AC | 26 ± 1 |

| AlYb CR40 | 40 ± 3 |

| AlYb CR70 | 37 ± 2 |

| AlMnYbZr AC | 33 ± 1 |

| AlMnYbZr CR40 | 42 ± 1 |

| AlMnYbZr CR70 | 43 ± 1 |

| Alloy | HV 0.1 |

|---|---|

| AlYb AC | 26 ± 1 |

| AlYb HT | 25 ± 1 |

| AlMnYbZr AC | 33 ± 1 |

| AlMnYbZr HT | 26 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kodetová, V.; Vlach, M.; Bajtošová, L.; Leibner, M.; Kudrnová, H.; Málek, J.; Mára, V.; Cieslar, M.; Zikmund, S. Heat Treatment of Cast and Cold Rolled Al–Yb and Al–Mn–Yb–Zr Alloys. Materials 2021, 14, 7122. https://doi.org/10.3390/ma14237122

Kodetová V, Vlach M, Bajtošová L, Leibner M, Kudrnová H, Málek J, Mára V, Cieslar M, Zikmund S. Heat Treatment of Cast and Cold Rolled Al–Yb and Al–Mn–Yb–Zr Alloys. Materials. 2021; 14(23):7122. https://doi.org/10.3390/ma14237122

Chicago/Turabian StyleKodetová, Veronika, Martin Vlach, Lucia Bajtošová, Michal Leibner, Hana Kudrnová, Jaroslav Málek, Vladimír Mára, Miroslav Cieslar, and Sebastien Zikmund. 2021. "Heat Treatment of Cast and Cold Rolled Al–Yb and Al–Mn–Yb–Zr Alloys" Materials 14, no. 23: 7122. https://doi.org/10.3390/ma14237122

APA StyleKodetová, V., Vlach, M., Bajtošová, L., Leibner, M., Kudrnová, H., Málek, J., Mára, V., Cieslar, M., & Zikmund, S. (2021). Heat Treatment of Cast and Cold Rolled Al–Yb and Al–Mn–Yb–Zr Alloys. Materials, 14(23), 7122. https://doi.org/10.3390/ma14237122