Influence of Interlayer Temperature and Welding Sequence on the Temperature Distribution and Welding Residual Stress of the Saddle-Shaped Joint of Weldolet-Header Butt Welding

Abstract

:1. Introduction

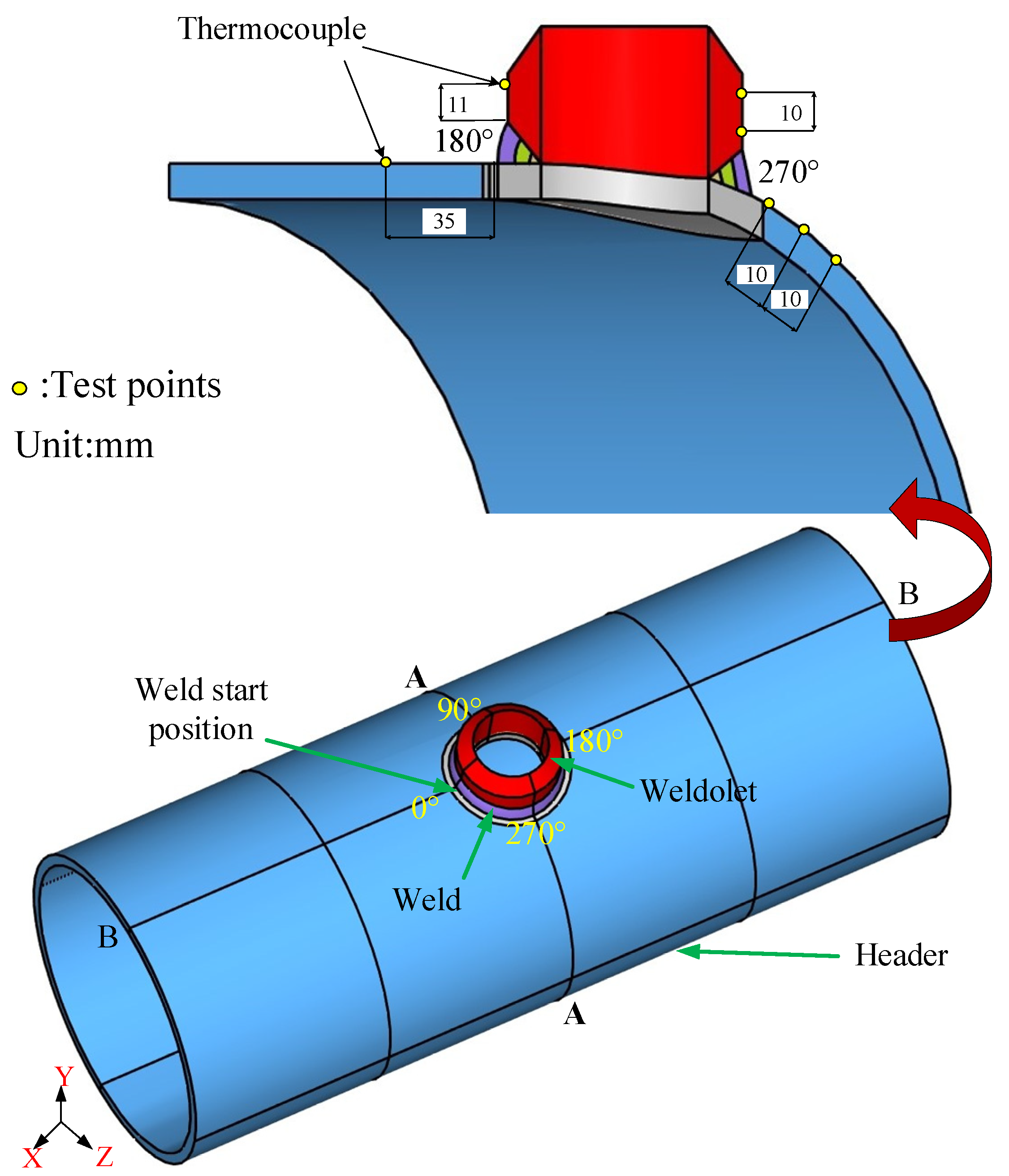

2. Experimental Procedure

3. Numerical Simulation

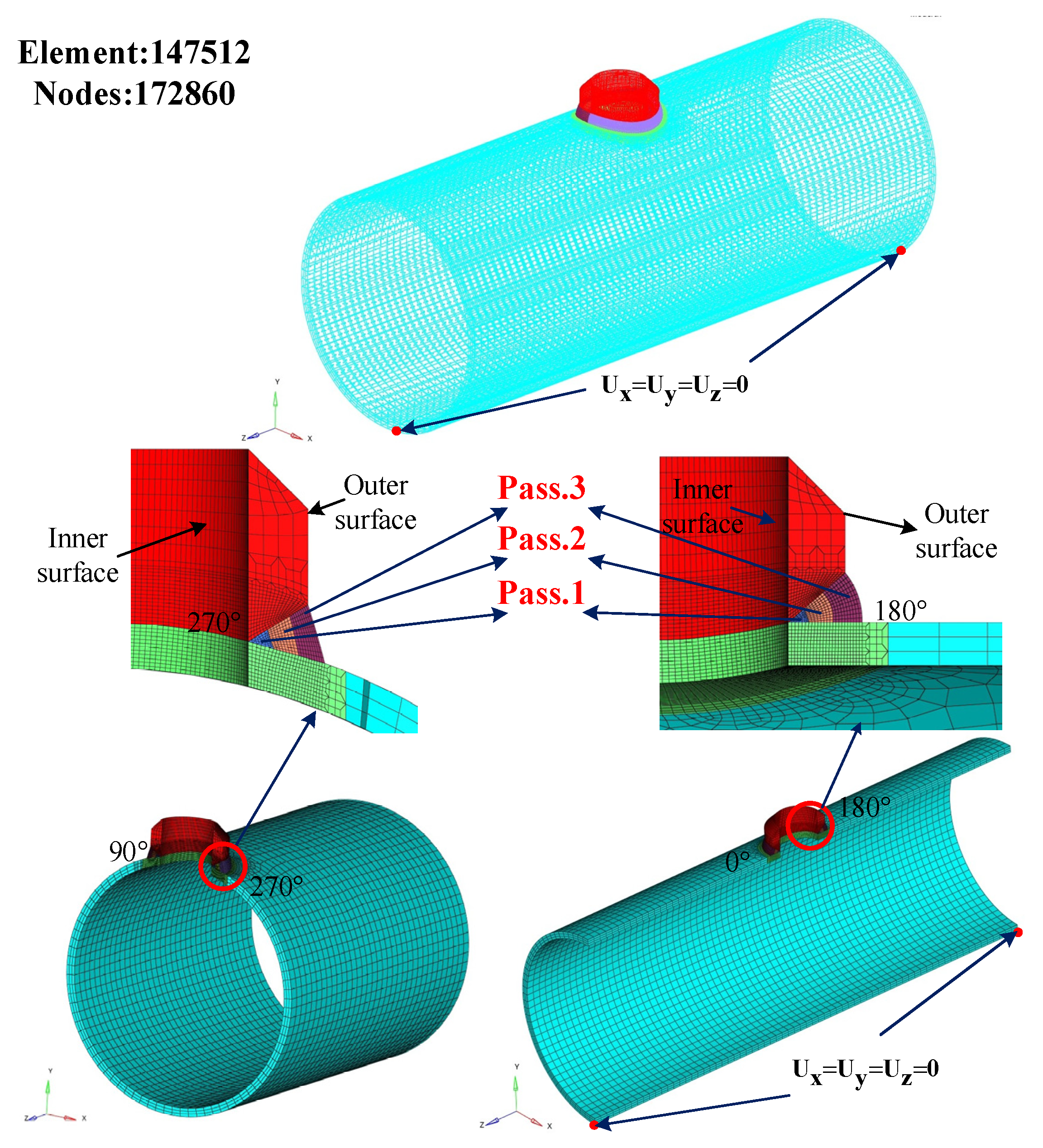

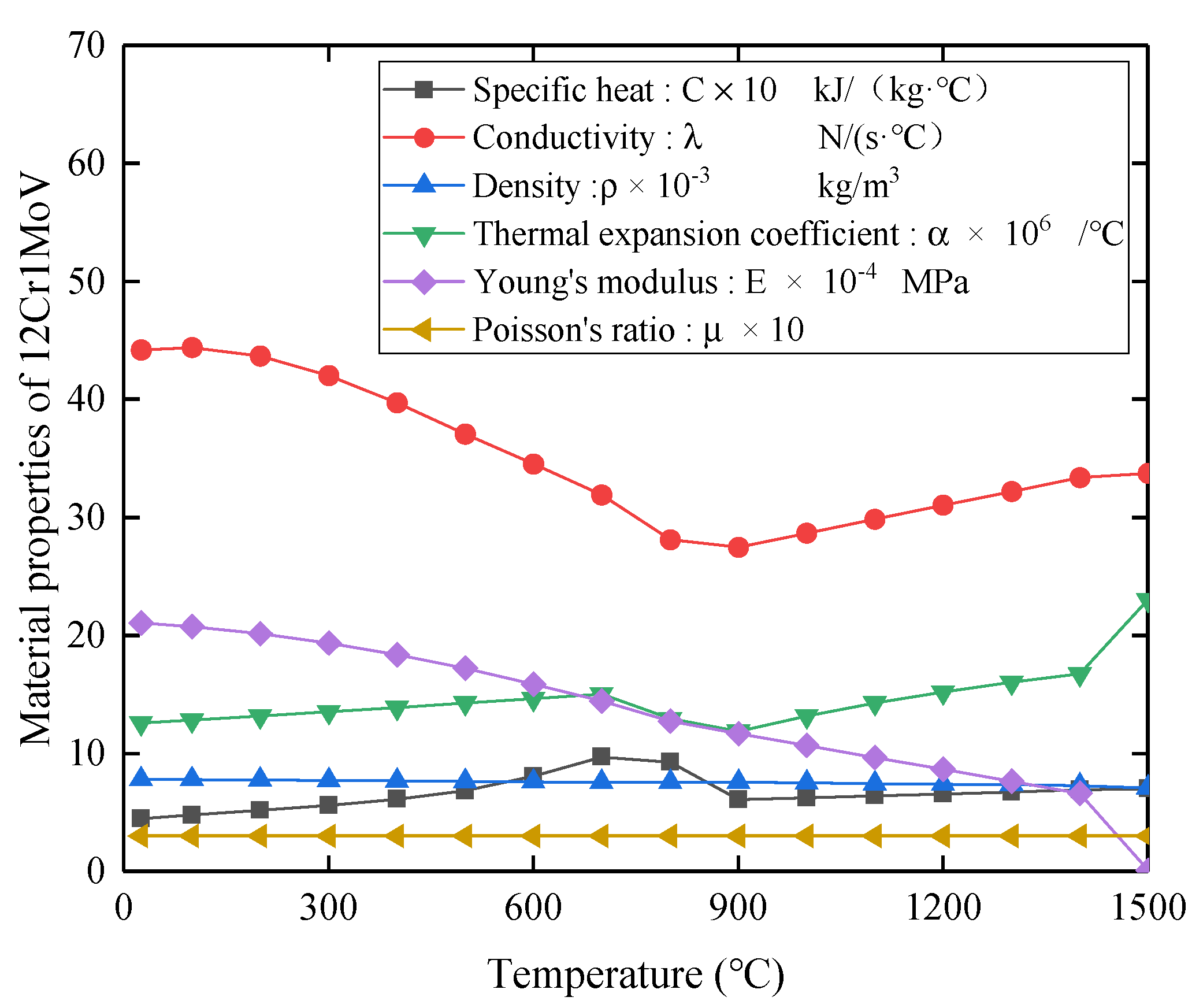

3.1. 3D Modeling and Meshing

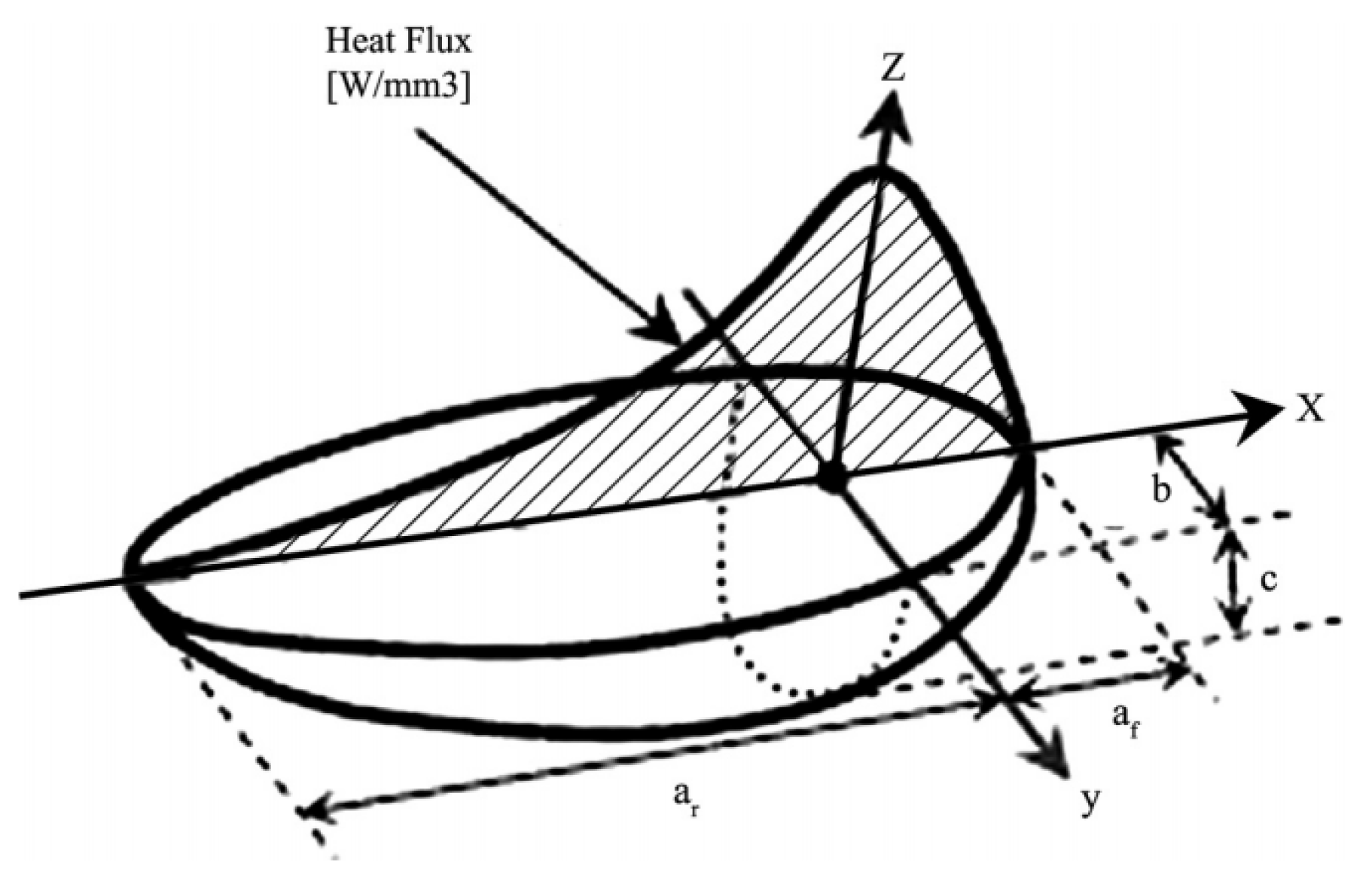

3.2. Heat Source Model and Thermal Analysis

3.3. Mechanical Analysis

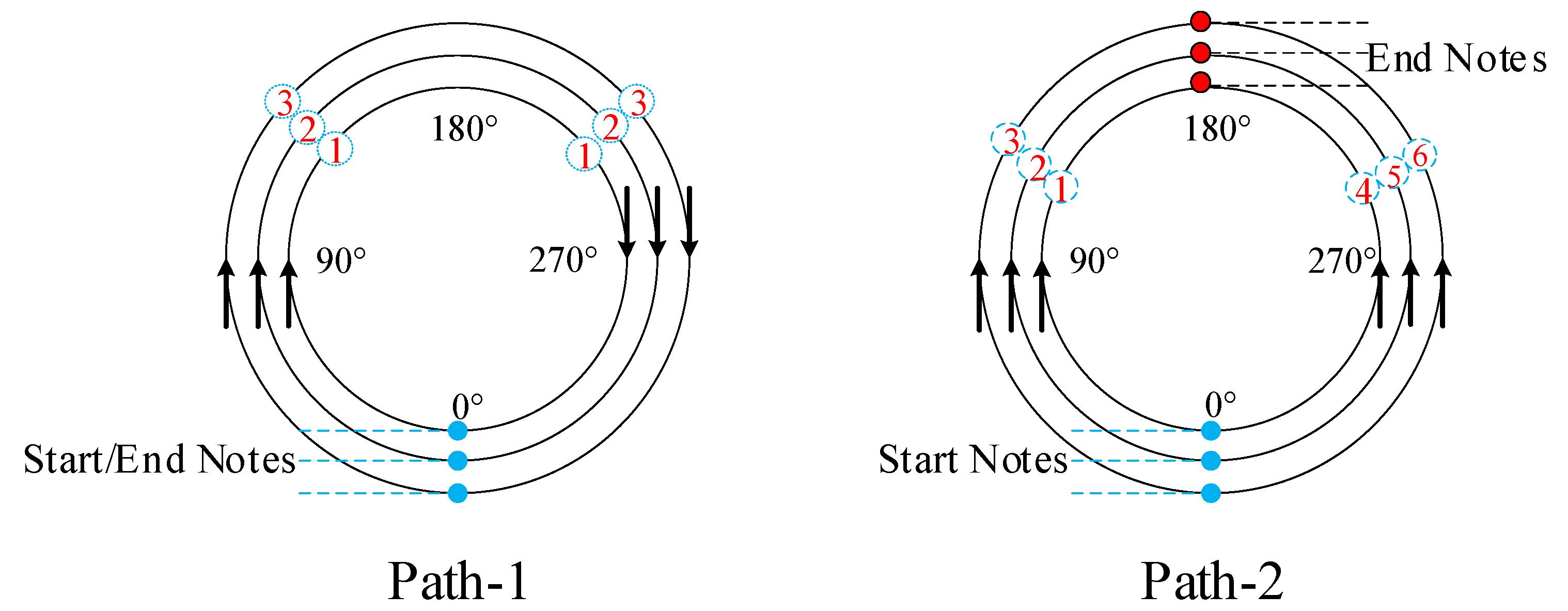

3.4. Simulation Cases

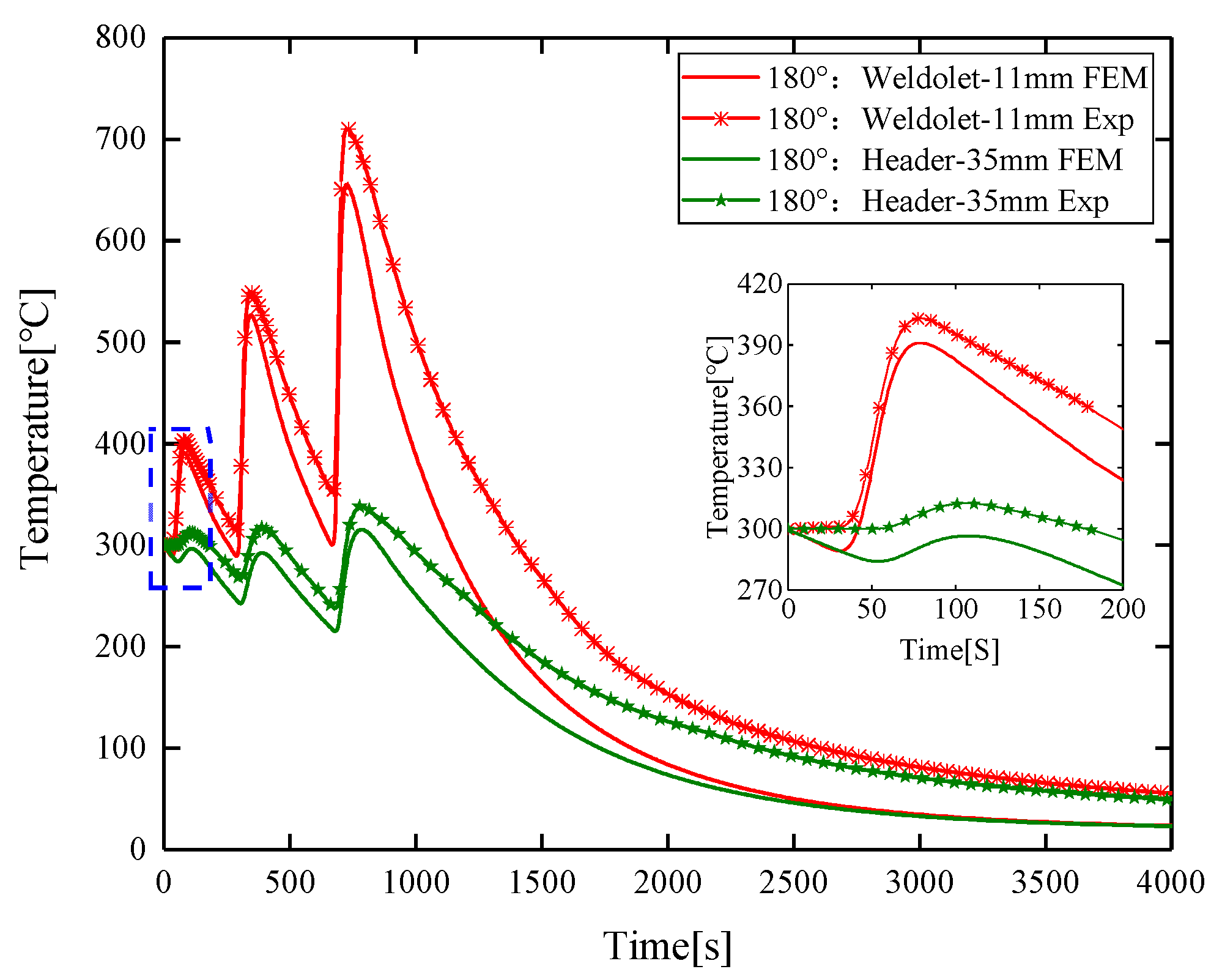

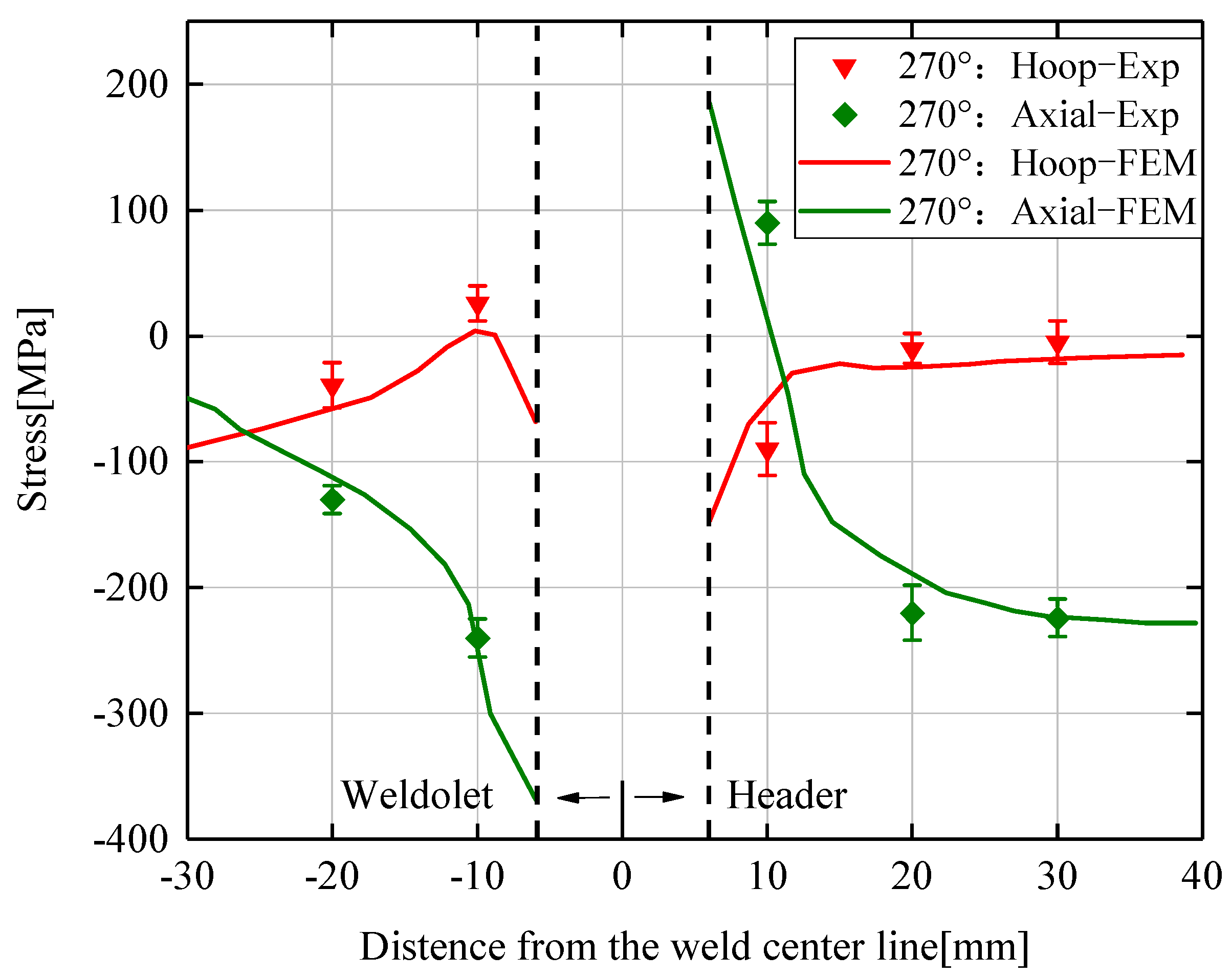

4. Experimental Validation of the Numerical Simulation Model

5. Results and Discussion

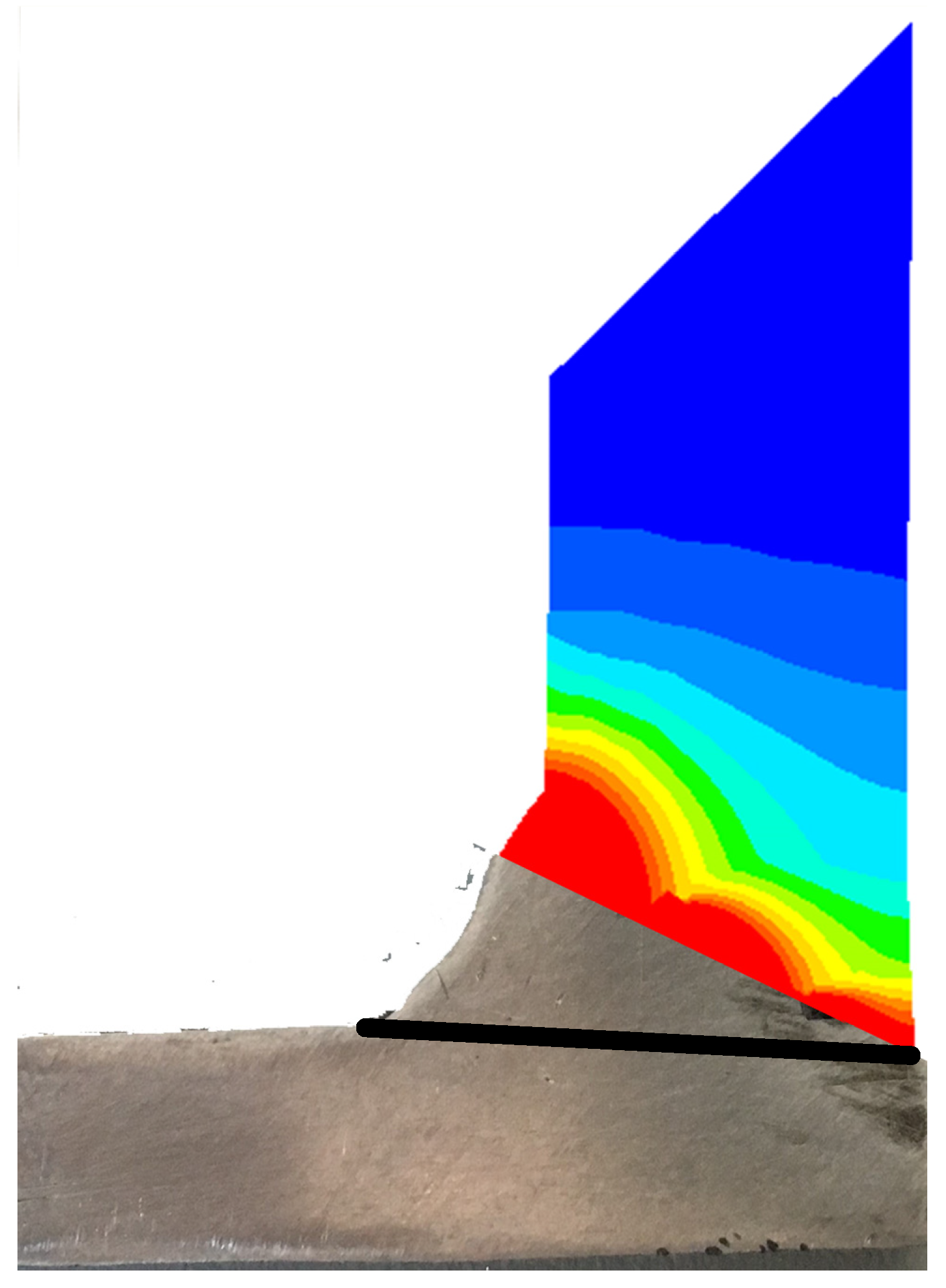

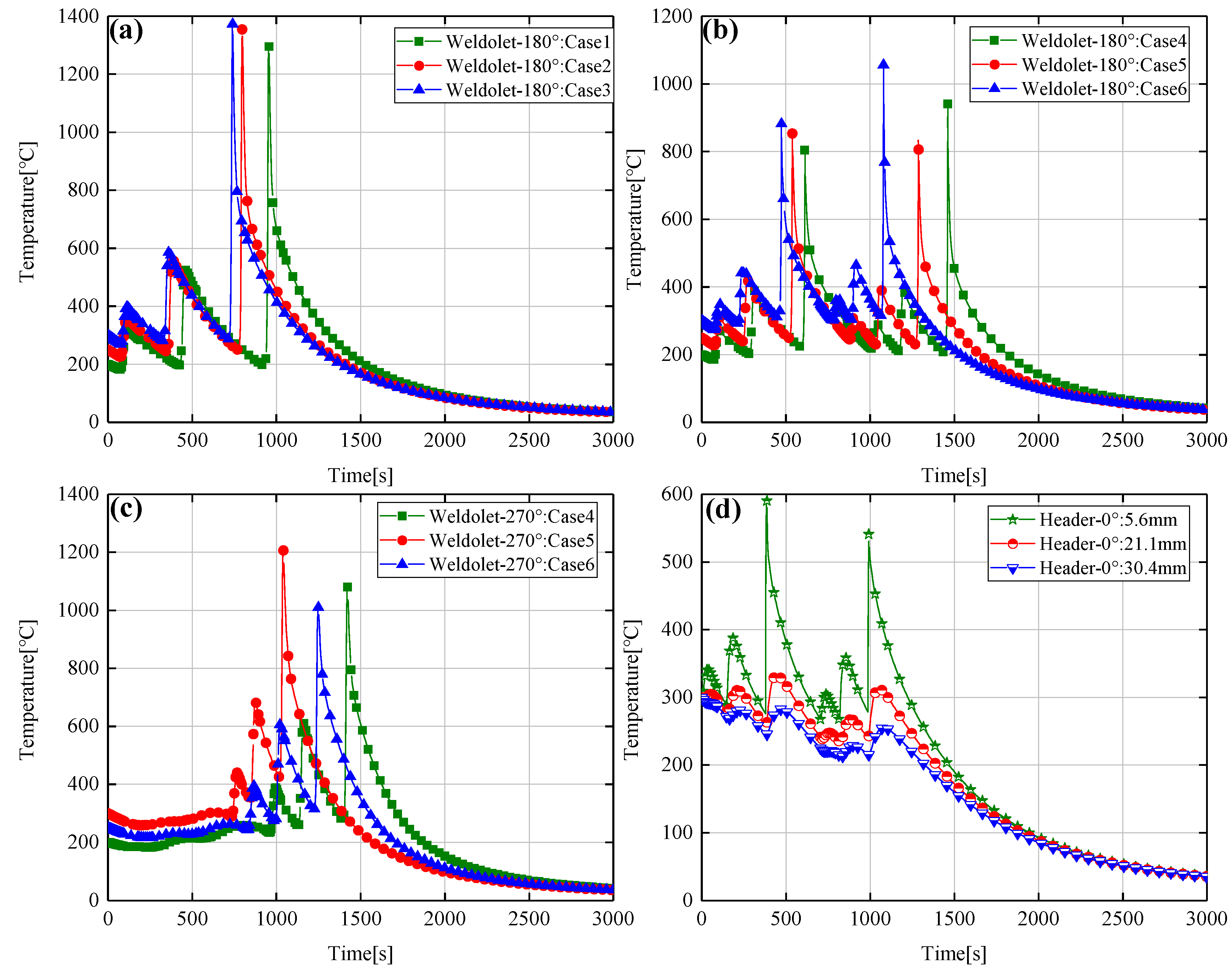

5.1. Analysis of Welding Temperature Field Results

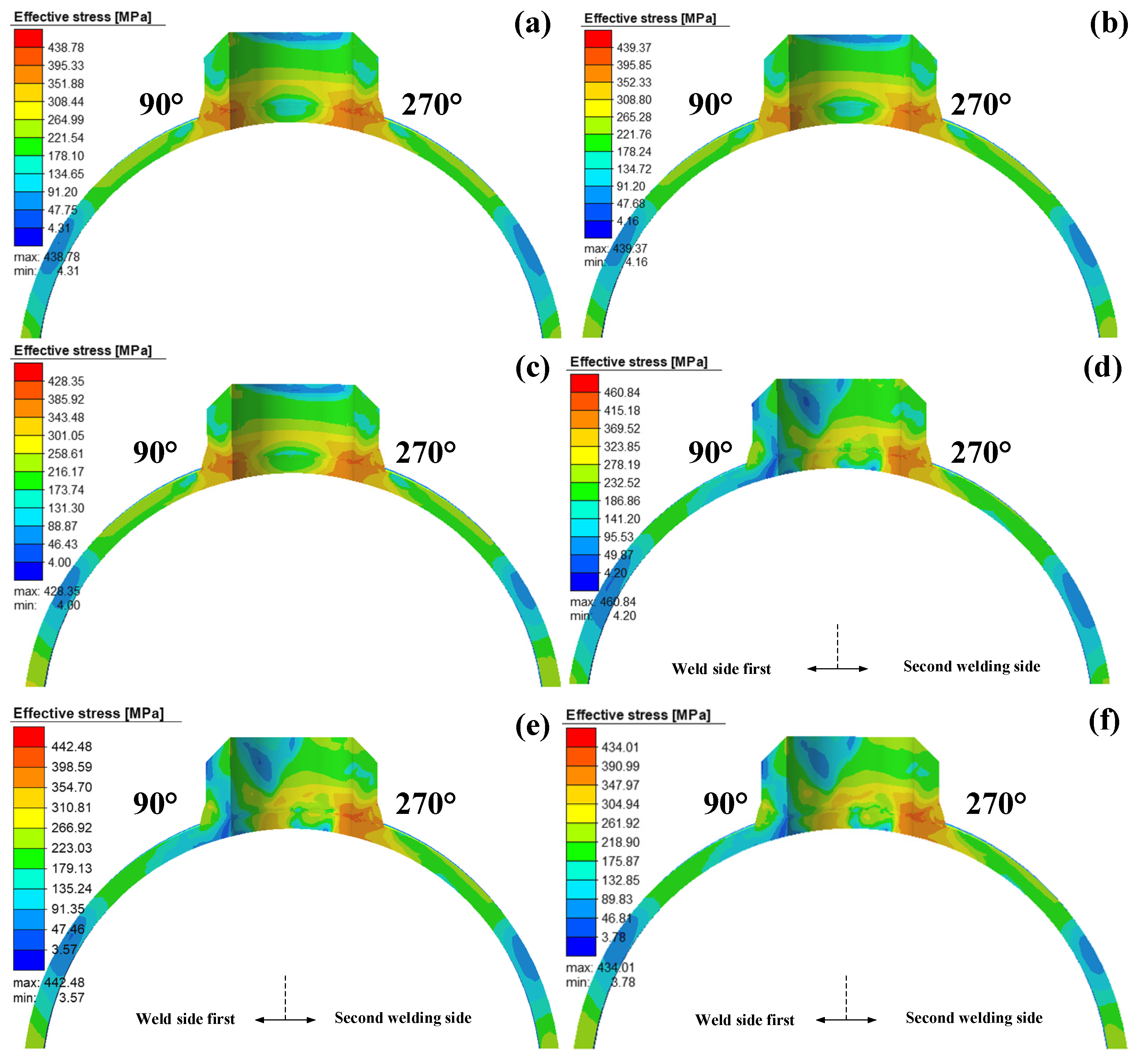

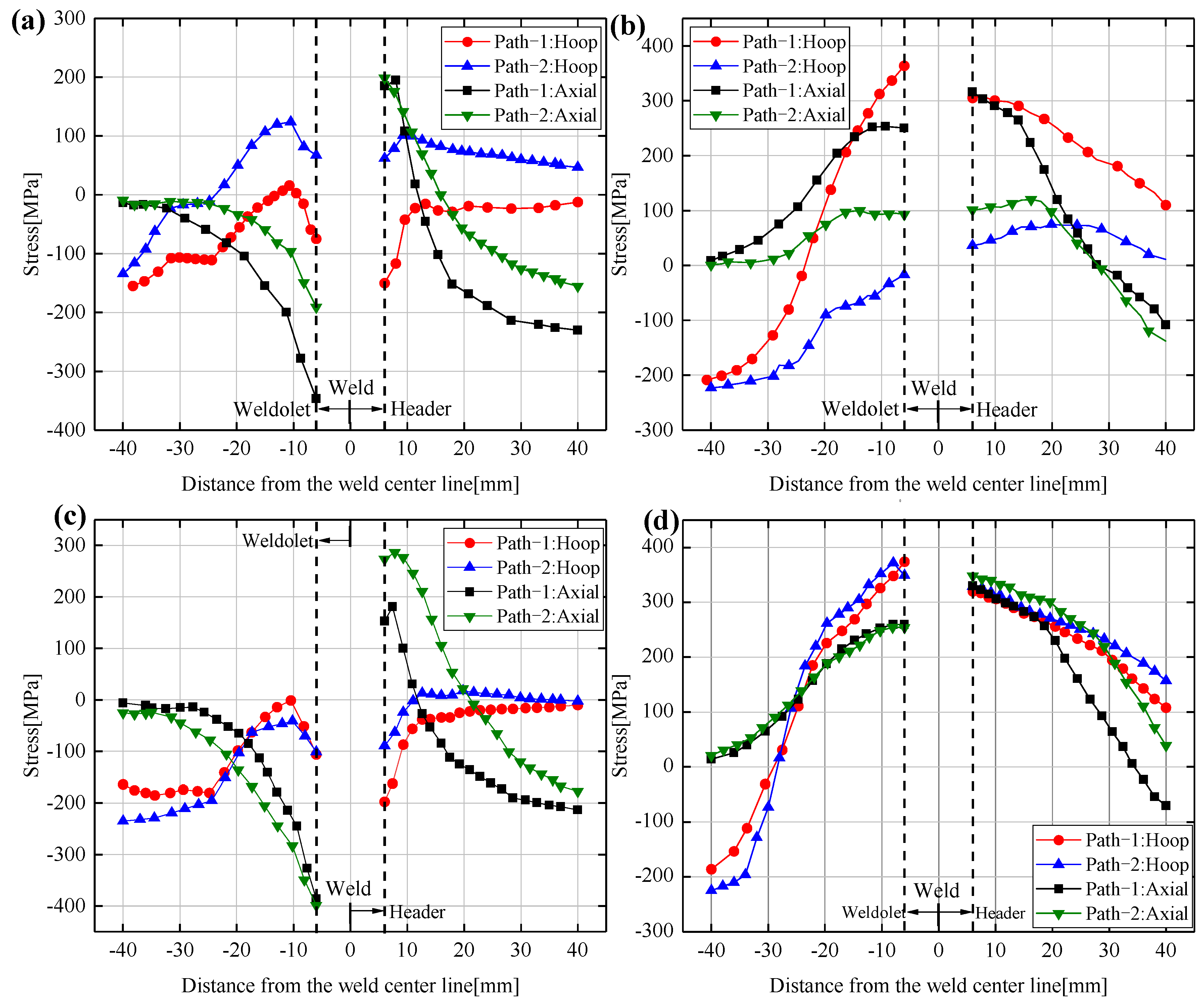

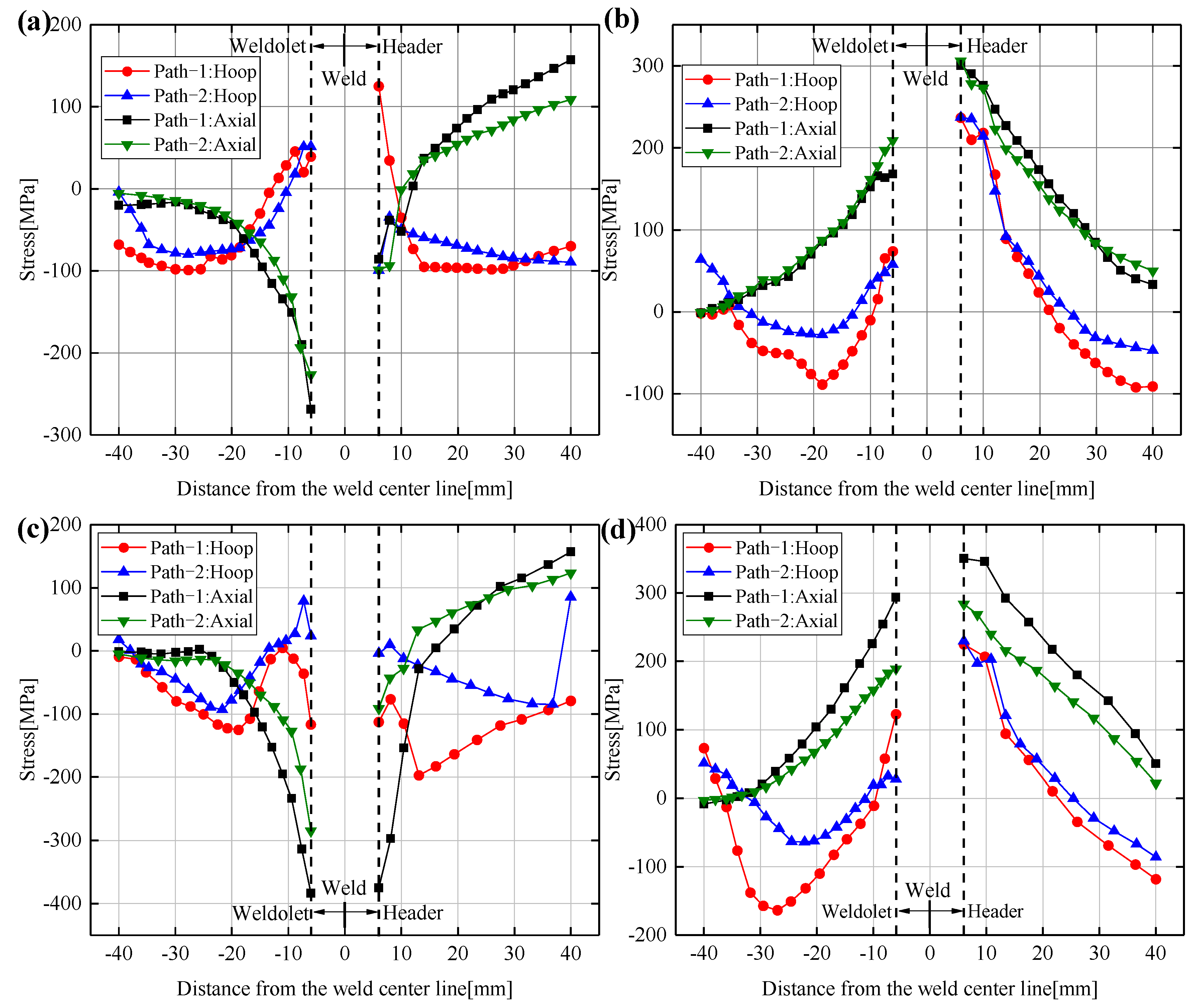

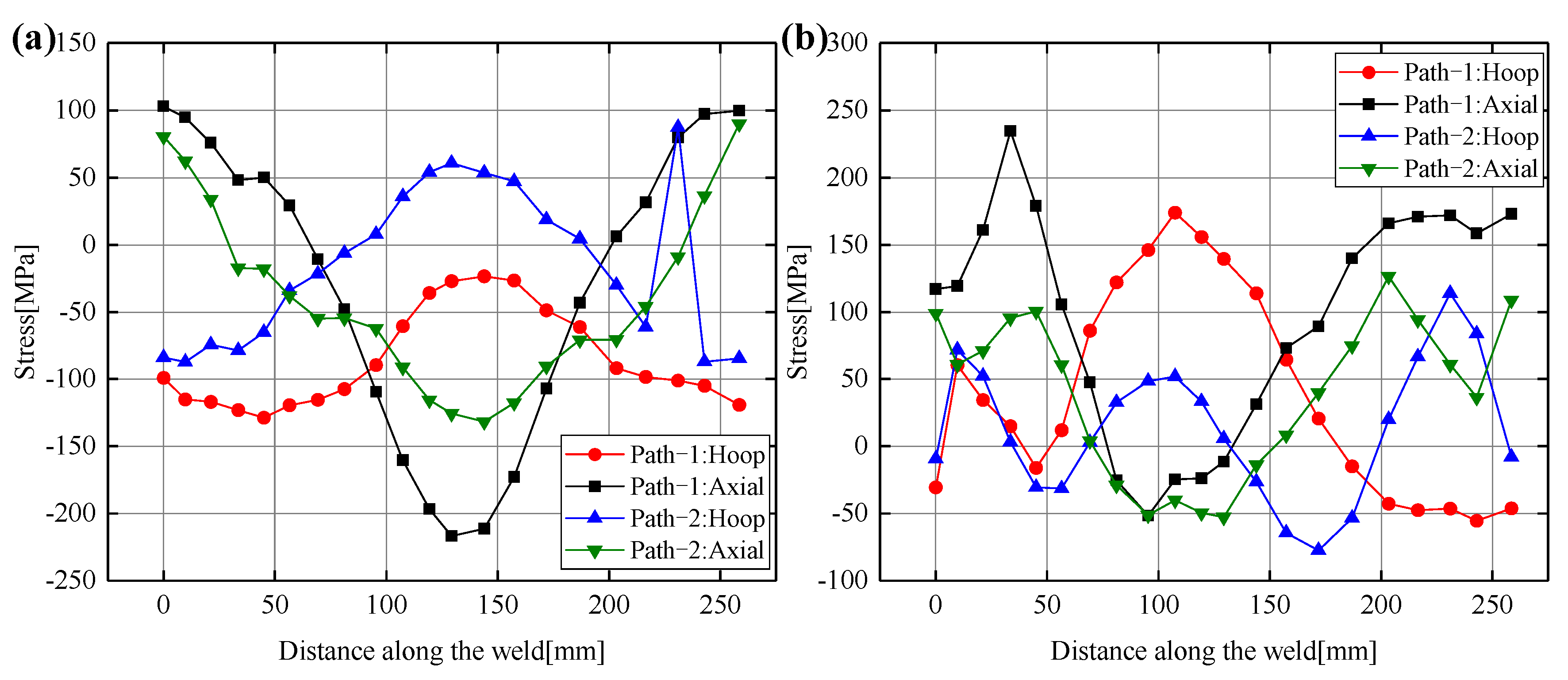

5.2. Analysis of Welding Stress Field Results

6. Conclusions

- In this paper, the heat source is fitted to the finite element model, and the size of the experimental melt pool matches that of the melt pool in the finite element simulation. The experimentally measured transient thermal cycles and residual stress distribution are in agreement with the numerical simulation results, which proves the validity of the finite element model established.

- The welding sequence is a key factor affecting the residual stress distribution in welding. The peak residual stress for the continuous welding path-1 is 428.35 MPa and the peak residual stress for the two-stage welding path-2 is 434.01 MPa, which are very close values. The two-stage welding path-2 does not have a high-stress area on the first welding side, so it is more suitable for welding saddle-shaped welding joints.

- The interlayer temperature of the weld is the main factor affecting the maximum value and distribution area of welding residual stress. In the two-stage welding path-2, when the interlayer temperature increases from 200 to 300 °C, the peak value of the residual stress gradually decreases from 460.84 to 434.01 MPa, and the distribution area of the high-stress area inside the weld is also reduced.

- Saddle welded joints have special welding characteristics. Although adjusting the welding sequence can change the distribution of residual stresses, high-stress areas always appear at the saddle shoulder (at the 0° and 180° sections) or at the saddle web (at the 90° and 270° sections).

- The temperature and residual stress distribution on the header and the weldolet are asymmetrical, and the range of the high temperature area on the weldolet is larger than that on the header. The axial residual stresses on the outer surface are inversely distributed on the weldolet and the header, while the distribution trend on the inner surface is symmetrical to some extent. The hoop residual stresses on the inner and outer surfaces are distributed asymmetrically on the weldolet and the header, but the distribution trends are similar.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thong-On, A.; Boonruang, C. Design of boiler welding for improvement of lifetime and cost control. Materials 2016, 9, 891. [Google Scholar] [CrossRef] [Green Version]

- Vetri Selvan, R.; Sathiya, P.; Devakumaran, K.; Ravichandran, G. The effect of ligament size on the thermal fatigue life of 9cr 1mo steel boiler header under cold, warm and hot starts. Eng. Fail. Anal. 2019, 97, 727–739. [Google Scholar] [CrossRef]

- Sunil, P.U.; Barve, J.; Nataraj, P.S.V. Mathematical modeling, simulation and validation of a boiler drum: Some investigations. Energy 2017, 126, 312–325. [Google Scholar] [CrossRef]

- Li, D. Mechanical stress analysis of a 600mw supercritical boiler superheater outlet header. Engineering 2013, 5, 66–68. [Google Scholar] [CrossRef]

- Pandya, D.; Badgujar, A.; Ghetiya, N. A novel perception toward welding of stainless steel by activated tig welding: A review. Mater. Manuf. Process. 2020, 36, 877–903. [Google Scholar] [CrossRef]

- Fuštar, B.; Lukačević, I.; Dujmović, D. Review of fatigue assessment methods for welded steel structures. Adv. Civ. Eng. 2018, 2018, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Rong, Y.; Xu, J.; Huang, Y.; Zhang, G. Review on finite element analysis of welding deformation and residual stress. Sci. Technol. Weld. Join. 2017, 23, 198–208. [Google Scholar] [CrossRef]

- Goncharov, N.G.; Kolesnikov, O.I.; Yushin, A.A. Weldolets welding technology features. Nauka Tekhnol. Truboprovodn. Transp. Nefti Nefteprod. 2018, 8, 232–239. [Google Scholar] [CrossRef]

- Vremenko, A.V.; Goncharov, N.G.; Ponomarev, P.A.; Kolesnikov, O.I. The choice of the weldolet parameters based on computer modeling. Nauka Tekhnol. Truboprovodn. Transp. Nefti Nefteprod. 2019, 9, 151–155. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, J.-S.; Kang, S.-U.; Hirohata, M.; Chang, K.-H. Fatigue life analysis of steel tube member with t-shaped welded joint by fem. Int. J. Steel Struct. 2017, 17, 833–841. [Google Scholar] [CrossRef]

- Moussavi Torshizi, S.E.; Jahangiri, A. Analysis of fatigue–creep crack growth in the superheater header of a power plant boilers and estimation of its remaining lifetime. Eng. Fail. Anal. 2018, 18, 189–198. [Google Scholar] [CrossRef]

- Xia, J.; Jin, H. Numerical study of welding simulation and residual stress on butt welding of dissimilar thickness of austenitic stainless steel. Int. J. Adv. Manuf. Technol. 2016, 91, 227–235. [Google Scholar] [CrossRef]

- Gao, Q.; Zhan, X.; Shen, H.; Ling, W.; Bu, H. Effect of welding sequence on stress and deformation field of invar alloy multi-layer and multi-pass welding: A simulation study. Mod. Phys. Lett. B 2020, 34, 2050129. [Google Scholar] [CrossRef]

- Yang, X.; Yan, G.; Xiu, Y.; Yang, Z.; Wang, G.; Liu, W.; Li, S.; Jiang, W. Welding temperature distribution and residual stresses in thick welded plates of sa738gr.B through experimental measurements and finite element analysis. Materials 2019, 12, 2346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zubairuddin, M.; Albert, S.K.; Vasudevan, M.; Mahadevan, S.; Chaudhari, V.; Suri, V.K. Numerical simulation of multi-pass gta welding of grade 91 steel. J. Manuf. Process. 2017, 27, 87–97. [Google Scholar] [CrossRef]

- Ravisankar, A.; Velaga, S.K.; Rajput, G.; Venugopal, S. Influence of welding speed and power on residual stress during gas tungsten arc welding (gtaw) of thin sections with constant heat input: A study using numerical simulation and experimental validation. J. Manuf. Process. 2014, 16, 200–211. [Google Scholar] [CrossRef]

- Velaga, S.K.; Rajput, G.; Murugan, S.; Ravisankar, A.; Venugopal, S. Comparison of weld characteristics between longitudinal seam and circumferential butt weld joints of cylindrical components. J. Manuf. Process. 2015, 18, 1–11. [Google Scholar] [CrossRef]

- Zhao, W.; Jiang, W.; Zhang, H.; Han, B.; Jin, H.; Gao, Q. 3D finite element analysis and optimization of welding residual stress in the girth joints of x80 steel pipeline. J. Manuf. Process. 2021, 66, 166–178. [Google Scholar] [CrossRef]

- Sepe, R.; Giannella, V.; Greco, A.; De Luca, A. Fem simulation and experimental tests on the smaw welding of a dissimilar t-joint. Metals 2021, 11, 1016. [Google Scholar] [CrossRef]

- Zhan, X.; Wu, Y.; Kang, Y.; Liu, X.; Chen, X. Simulated and experimental studies of laser-mig hybrid welding for plate-pipe dissimilar steel. Int. J. Adv. Manuf. Technol. 2018, 101, 1611–1622. [Google Scholar] [CrossRef]

- Chen, H.-C.; Ng, F.L.; Du, Z. Hybrid laser-tig welding of dissimilar ferrous steels: 10 mm thick low carbon steel to 304 austenitic stainless steel. J. Manuf. Process. 2019, 47, 324–336. [Google Scholar] [CrossRef]

- Zhu, M.; Zheng, Q.; Wu, W.; Qian, W.; Zhang, Y.; Wang, B. Influence of welding sequence on residual stress evolution in incoloy825/x52 bimetallic clad plate butt-welded joints. Sci. Technol. Weld. Join. 2021, 26, 356–362. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, G.; Pu, X.; Deng, D. Influence of welding sequence on residual stress distribution and deformation in q345 steel h-section butt-welded joint. J. Mater. Res. Technol. 2021, 13, 144–153. [Google Scholar] [CrossRef]

- Ahmad, A.S.; Wu, Y.; Gong, H.; Liu, L. Numerical simulation of thermal and residual stress field induced by three-pass tig welding of al 2219 considering the effect of interpass cooling. Int. J. Precis. Eng. 2020, 21, 1501–1518. [Google Scholar] [CrossRef]

- Velaga, S.K.; Kumar, S.A.; Ravisankar, A.; Venugopal, S. Weld characteristics of non-axisymmetrical butt welded branch pipe t-joints using finite element simulation and experimental validation. Int. J. Press. Vessel. Pip. 2017, 150, 72–88. [Google Scholar] [CrossRef]

- Carrizalez-Vazquez, M.A.; Pérez-Medina, G.Y. Effect of laser welding sequences on residual stresses and distortion of dp600 steel joints. MRS Adv. 2019, 4, 3441–3451. [Google Scholar] [CrossRef]

- Wang, X.; Gong, J.; Zhao, Y.; Wang, Y.; Ge, Z. Numerical simulation to study the effect of arc travelling speed and welding sequences on residual stresses in welded sections of new ferritic p92 pipes. High Temp. Mater. Process. 2016, 35, 121–128. [Google Scholar] [CrossRef]

- Yi, J.; Zhang, J.-M.; Cao, S.-F.; Guo, P.-C. Effect of welding sequence on residual stress and deformation of 6061-t6 aluminium alloy automobile component. Trans. Nonferr. Met. Soc. China 2019, 29, 287–295. [Google Scholar] [CrossRef]

- Hemmatzadeh, M.; Moshayedi, H.; Sattari-Far, I. Influence of heat input and radius to pipe thickness ratio on the residual stresses in circumferential arc welded pipes of api x46 steels. Int. J. Press. Vessel. Pip. 2017, 150, 62–71. [Google Scholar] [CrossRef]

- Jiang, W.C.; Wang, B.Y.; Gong, J.M.; Tu, S.T. Finite element analysis of the effect of welding heat input and layer number on residual stress in repair welds for a stainless steel clad plate. Mater. Des. 2011, 32, 2851–2857. [Google Scholar] [CrossRef]

- Schroepfer, D.; Kannengiesser, T. Correlating welding reaction stresses and weld process conditions for high-strength steel s960ql. Weld. World 2014, 58, 423–432. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, Y.; Hu, Z.; Zhao, J. Optimized welding process of residual stress control of p91 steel considering martensitic transformation. Int. J. Press. Vessel. Pip. 2021, 194, 104517. [Google Scholar] [CrossRef]

- Sultan, A.R.; Ravibharath, R.; Narayanasamy, R. Study of dissimilar header welding between 2.25cr–1mo steel and 9cr–1mo steel with 9018 b9 electrode under various conditions of post weld heat treatment. Trans. Indian Inst. Met. 2017, 70, 2079–2092. [Google Scholar] [CrossRef]

- Ragab, R.; Parker, J.; Li, M.; Liu, T.; Sun, W. Modelling of a grade 91 power plant pressurised header weldment under ultra super-critical creep conditions. Int. J. Press. Vessel. Pip. 2021, 192, 104389. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Deng, D. Influence of deposition sequence on welding residual stress and deformation in an austenitic stainless steel j-groove welded joint. Mater. Des. 2013, 49, 1022–1033. [Google Scholar] [CrossRef]

| Welding Pass | Welding Method | Current/A | Voltage/V | Welding Speed/mm·s−1 |

|---|---|---|---|---|

| 1 | TIG | 93 | 18 | 1.6 |

| 2 | SMAW | 165 | 25 | 2 |

| 3 | SMAW | 220 | 30 | 2 |

| Welding Layer | Front Axle Length /mm | Rear Axle Length /mm | Width /mm | Depth /mm |

|---|---|---|---|---|

| 1 | 1.2 | 4.4 | 2.0 | 6.2 |

| 2 | 2.4 | 13.2 | 6.0 | 9.8 |

| 3 | 5.0 | 24.0 | 13.0 | 10.0 |

| Case | Welding Sequence | Preheating Temperature/°C | Interlayer Temperature /°C |

|---|---|---|---|

| Case1 | Path-1 | 200 | 200 |

| Case2 | Path-1 | 250 | 250 |

| Case3 | Path-1 | 300 | 300 |

| Case4 | Path-2 | 200 | 200 |

| Case5 | Path-2 | 250 | 250 |

| Case6 | Path-2 | 300 | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mai, C.; Hu, X.; Zhang, L.; Song, B.; Zheng, X. Influence of Interlayer Temperature and Welding Sequence on the Temperature Distribution and Welding Residual Stress of the Saddle-Shaped Joint of Weldolet-Header Butt Welding. Materials 2021, 14, 5980. https://doi.org/10.3390/ma14205980

Mai C, Hu X, Zhang L, Song B, Zheng X. Influence of Interlayer Temperature and Welding Sequence on the Temperature Distribution and Welding Residual Stress of the Saddle-Shaped Joint of Weldolet-Header Butt Welding. Materials. 2021; 14(20):5980. https://doi.org/10.3390/ma14205980

Chicago/Turabian StyleMai, Chunliang, Xue Hu, Lixin Zhang, Bao Song, and Xiongfei Zheng. 2021. "Influence of Interlayer Temperature and Welding Sequence on the Temperature Distribution and Welding Residual Stress of the Saddle-Shaped Joint of Weldolet-Header Butt Welding" Materials 14, no. 20: 5980. https://doi.org/10.3390/ma14205980

APA StyleMai, C., Hu, X., Zhang, L., Song, B., & Zheng, X. (2021). Influence of Interlayer Temperature and Welding Sequence on the Temperature Distribution and Welding Residual Stress of the Saddle-Shaped Joint of Weldolet-Header Butt Welding. Materials, 14(20), 5980. https://doi.org/10.3390/ma14205980