Evaluation of Mechanical and Permeability Characteristics of Microfiber-Reinforced Recycled Aggregate Concrete with Different Potential Waste Mineral Admixtures

Abstract

:1. Introduction

2. Research Significance

3. Experimental Program

3.1. Details of Materials

3.1.1. Binders

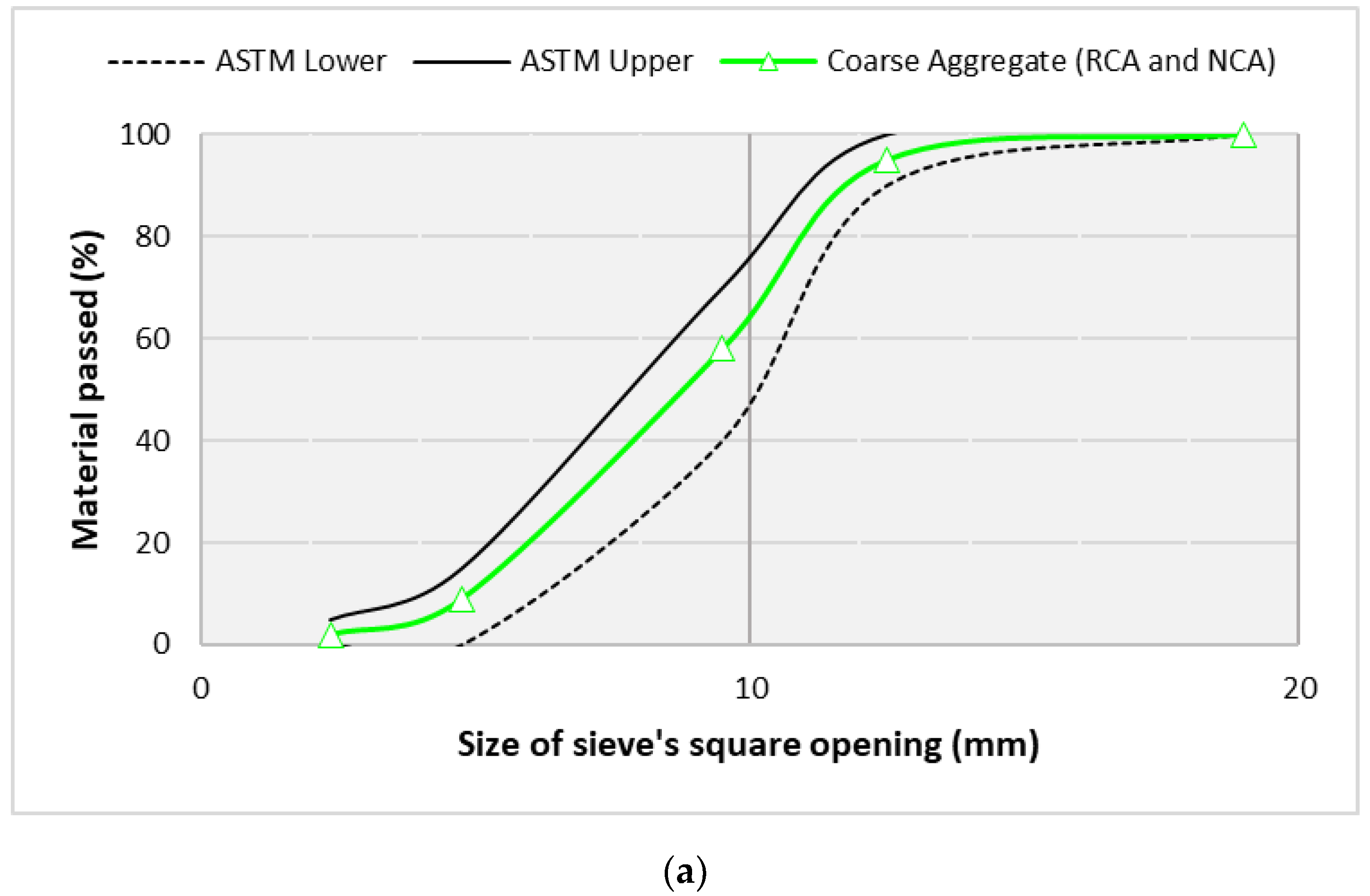

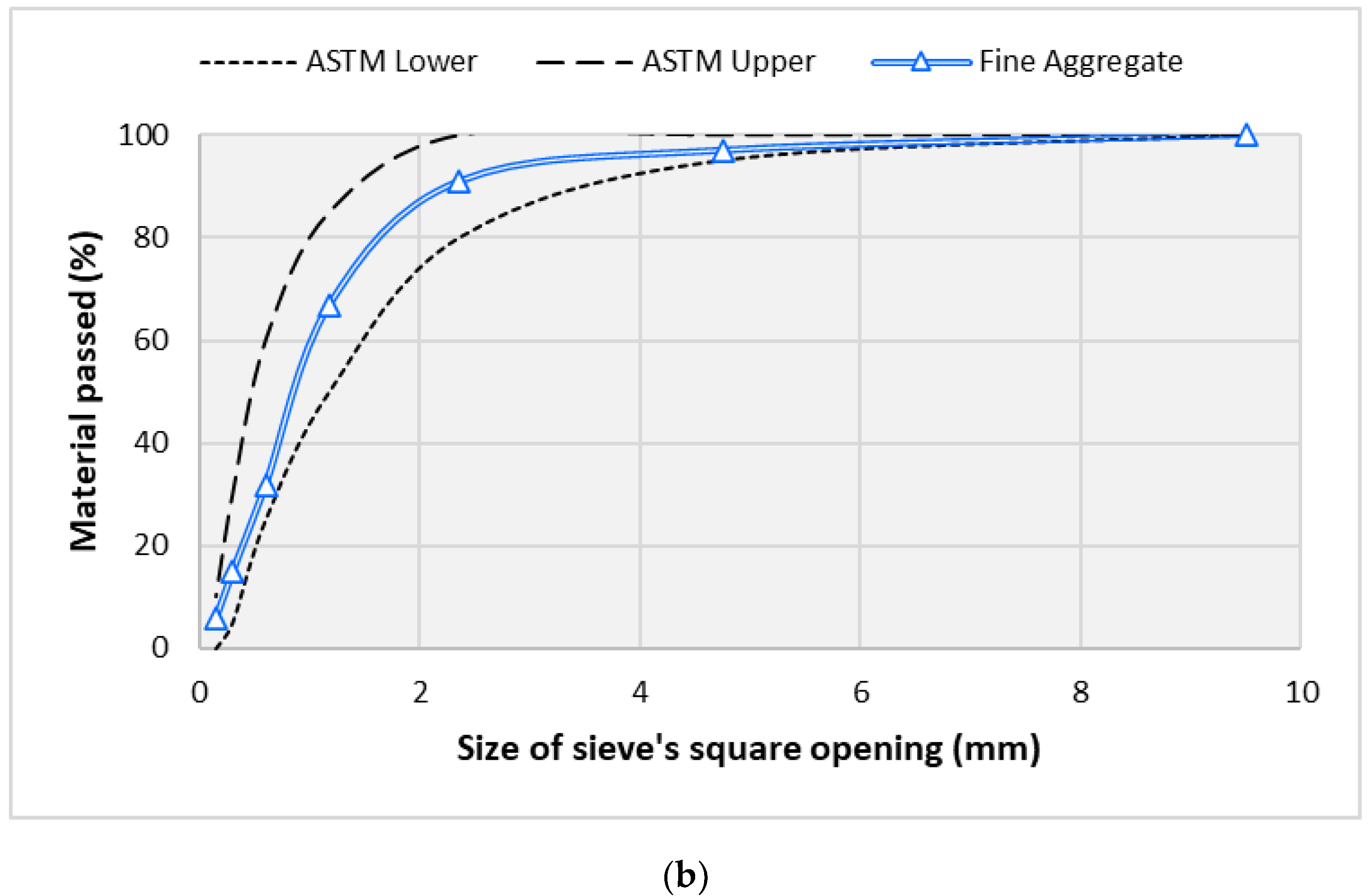

3.1.2. Aggregates

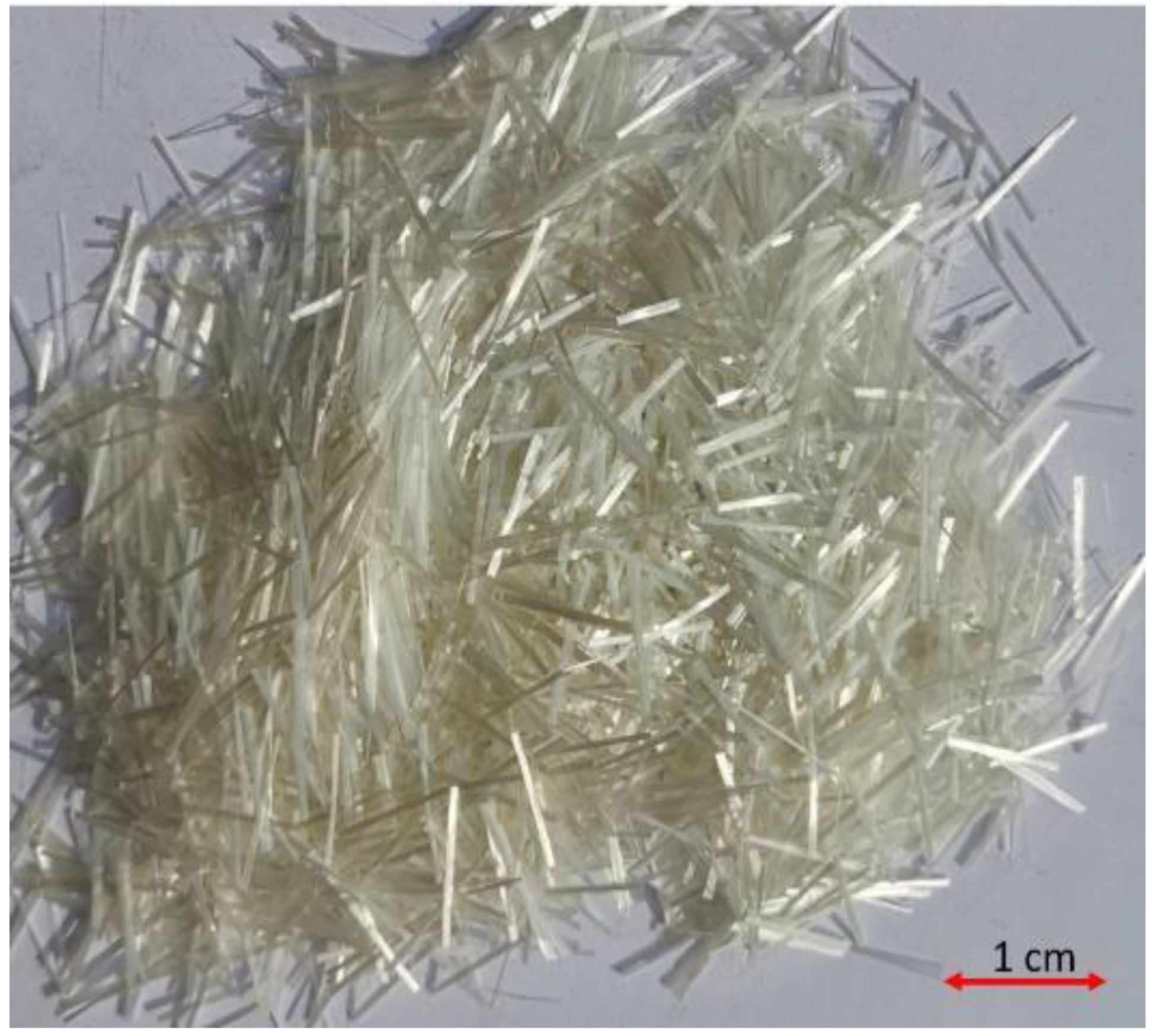

3.1.3. Glass Fibers

3.1.4. Superplasticizer and Water

3.2. Composition of All Concrete Mixtures

3.3. Preparation of Specimens for Testing

3.3.1. Compression Testing

3.3.2. Modulus of Elasticity Testing

3.3.3. Splitting Tensile Testing

3.3.4. Bending Testing

3.3.5. Water Absorption Capacity Testing

3.3.6. Chloride Penetration Testing

4. Results of Testing and Discussion

4.1. Workability

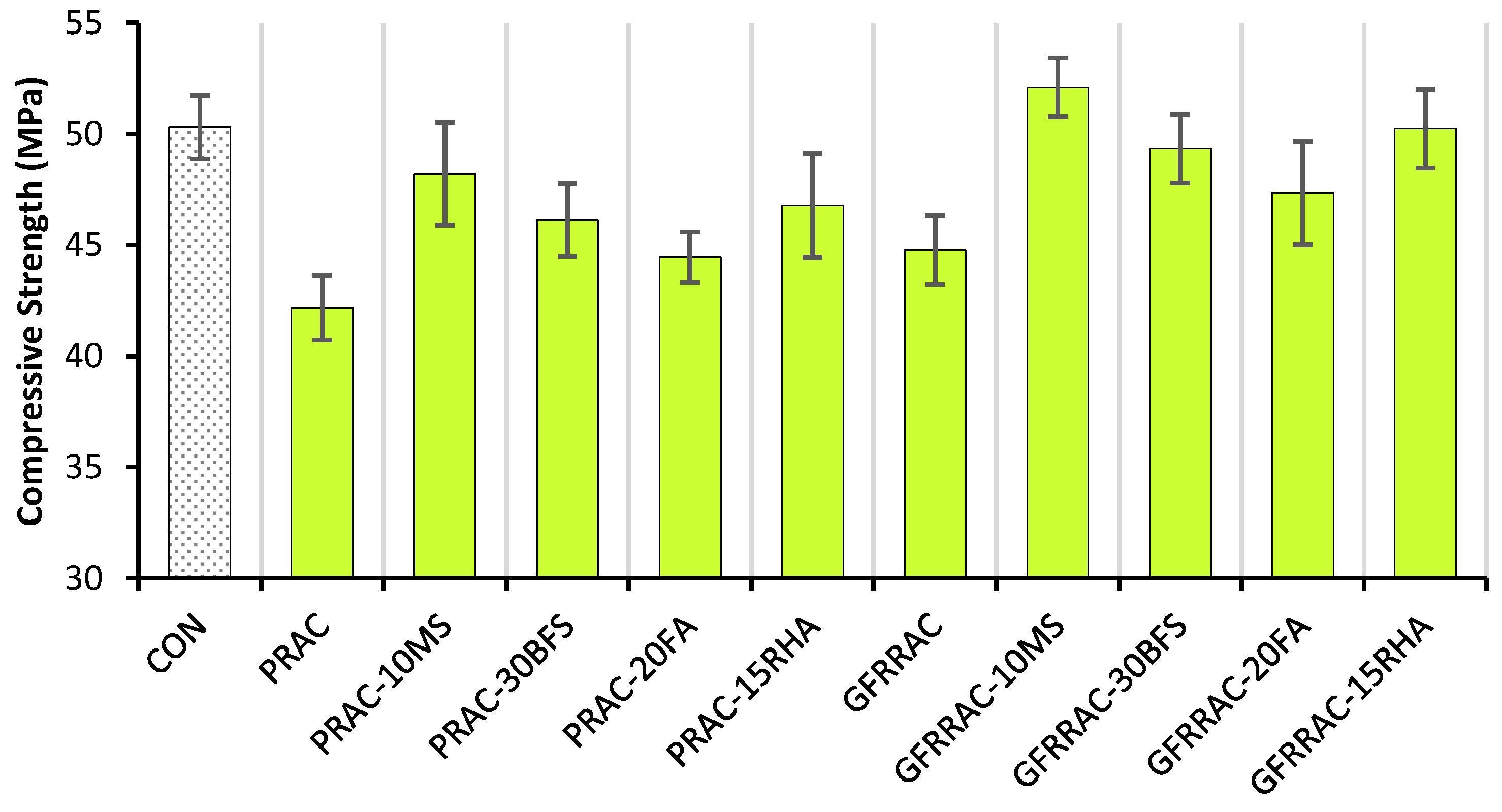

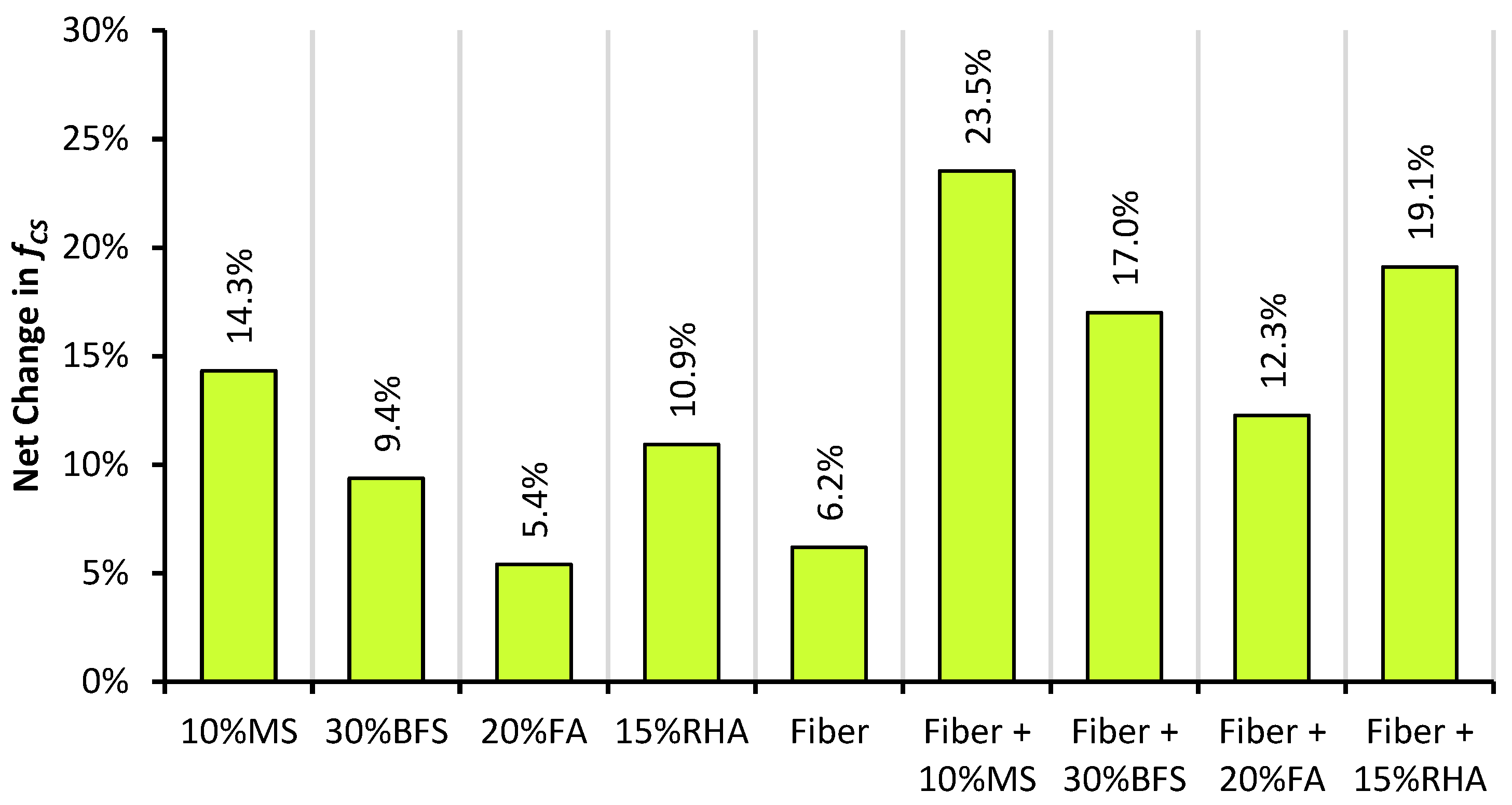

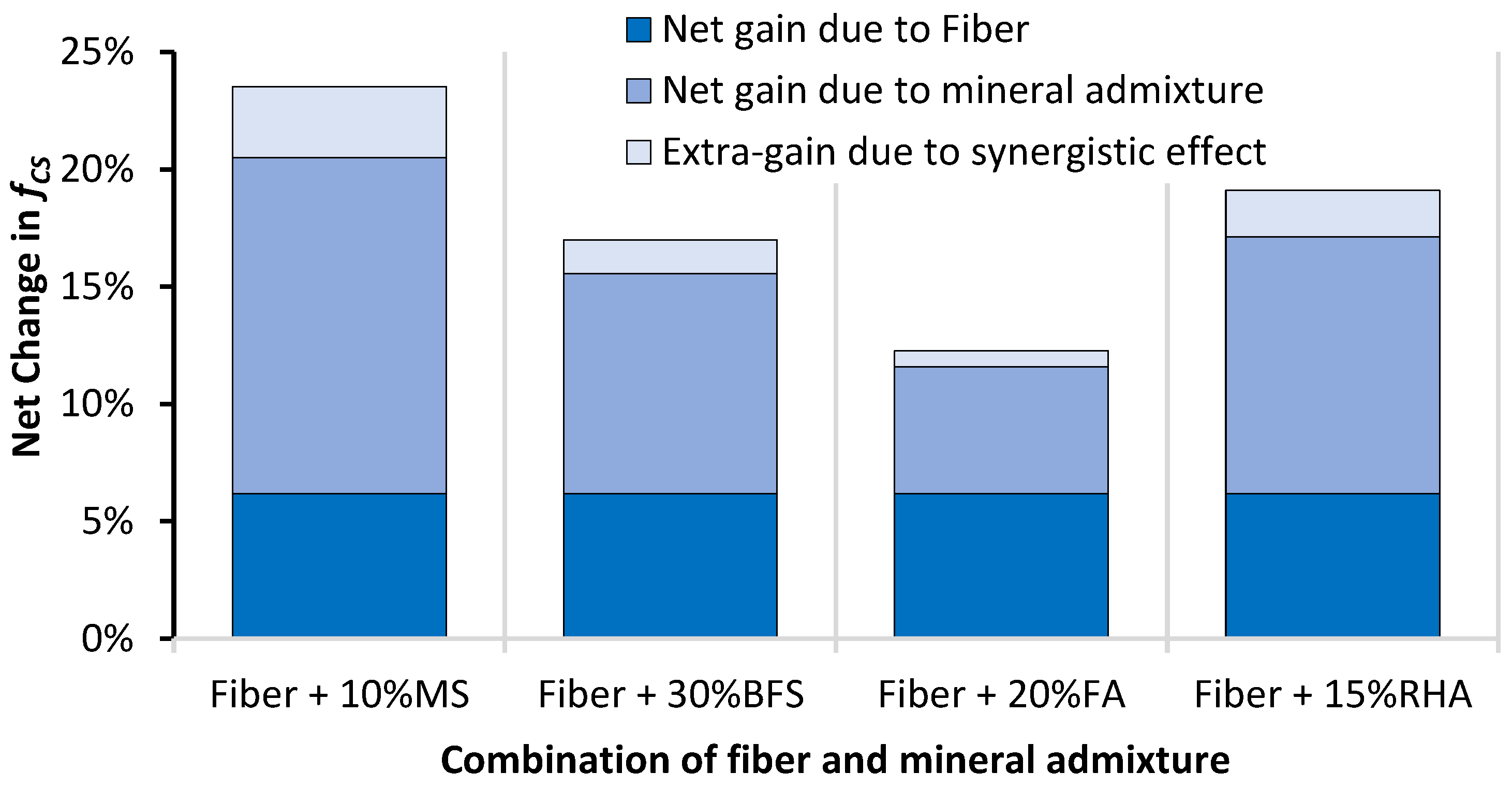

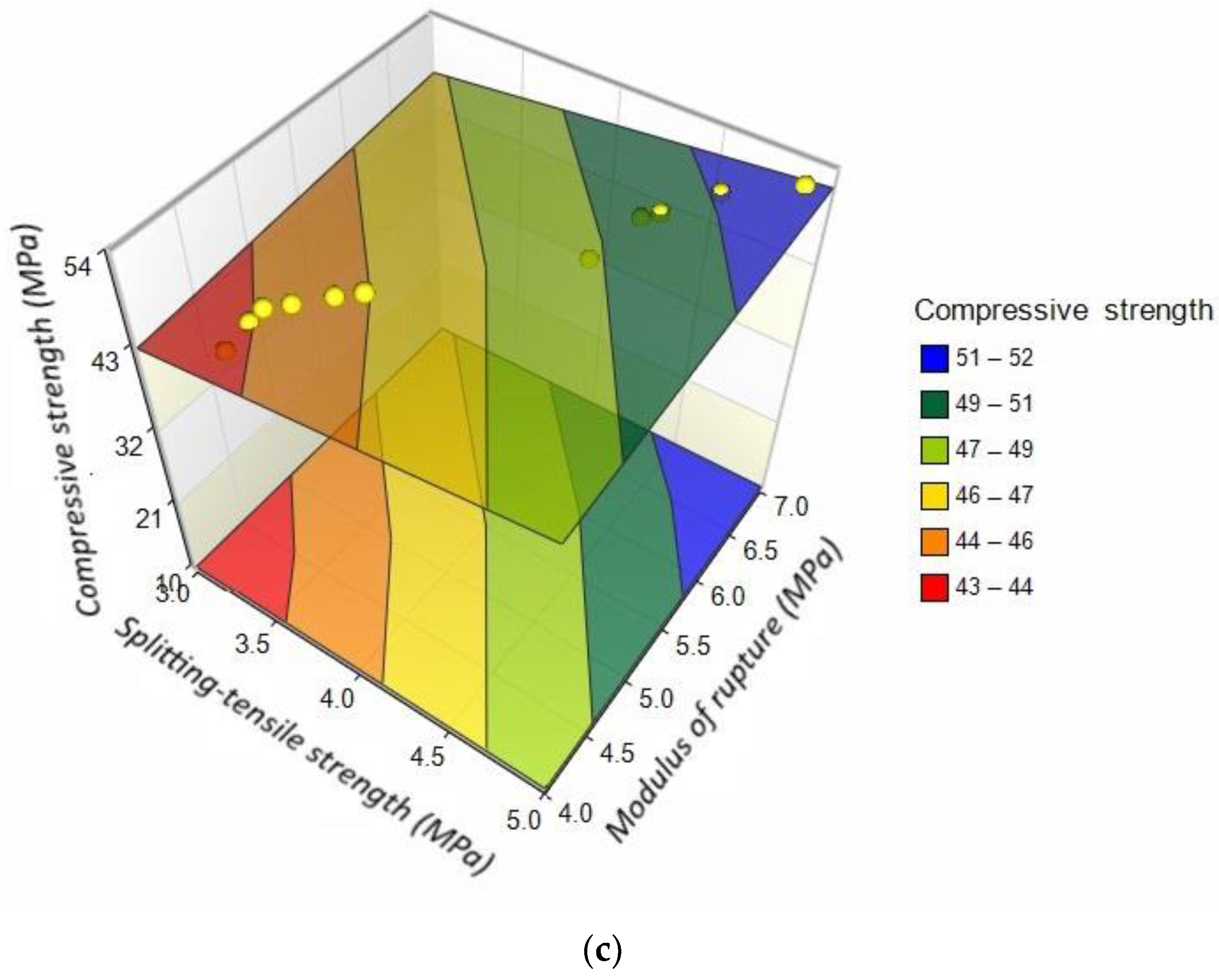

4.2. Compressive Strength

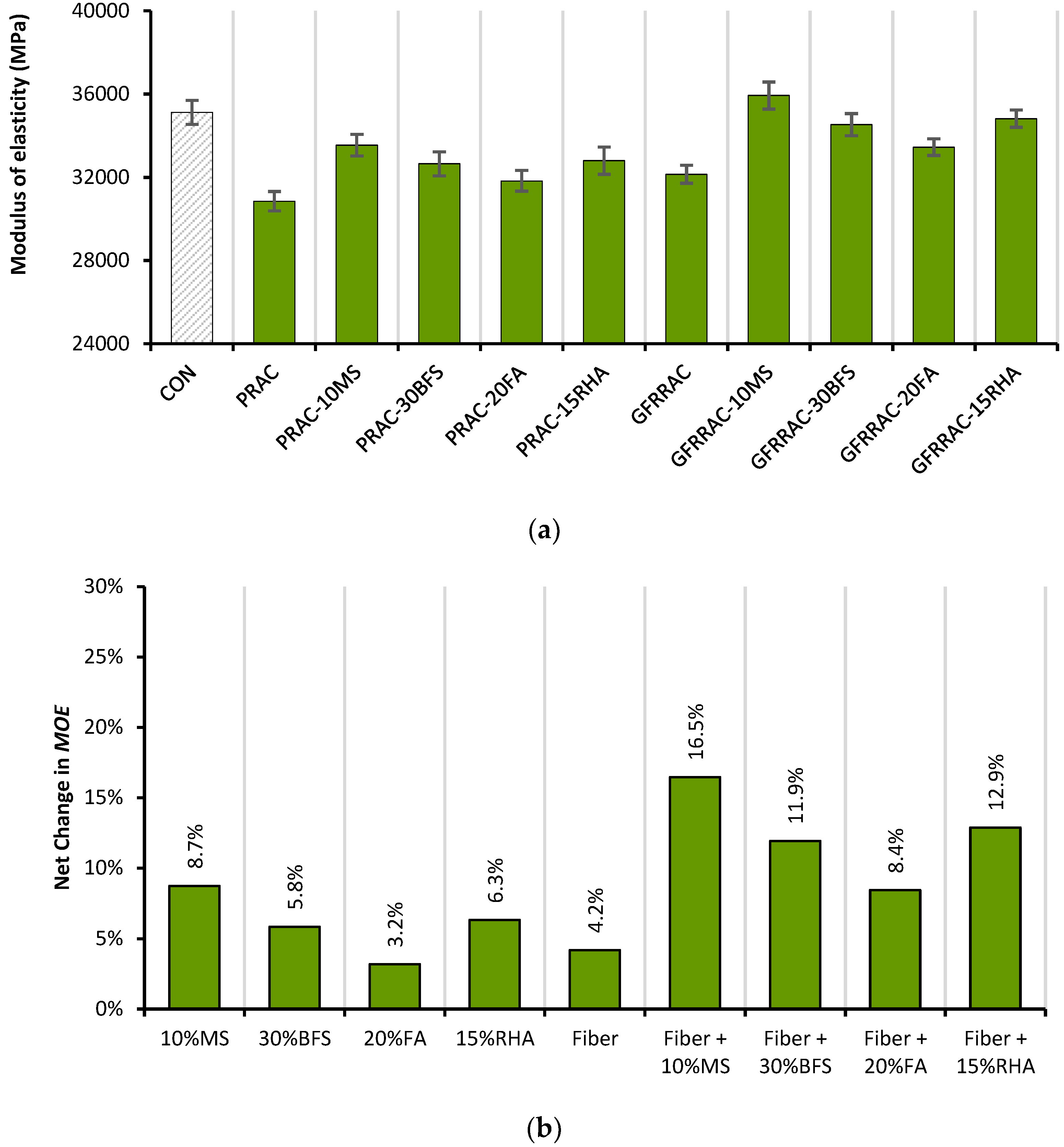

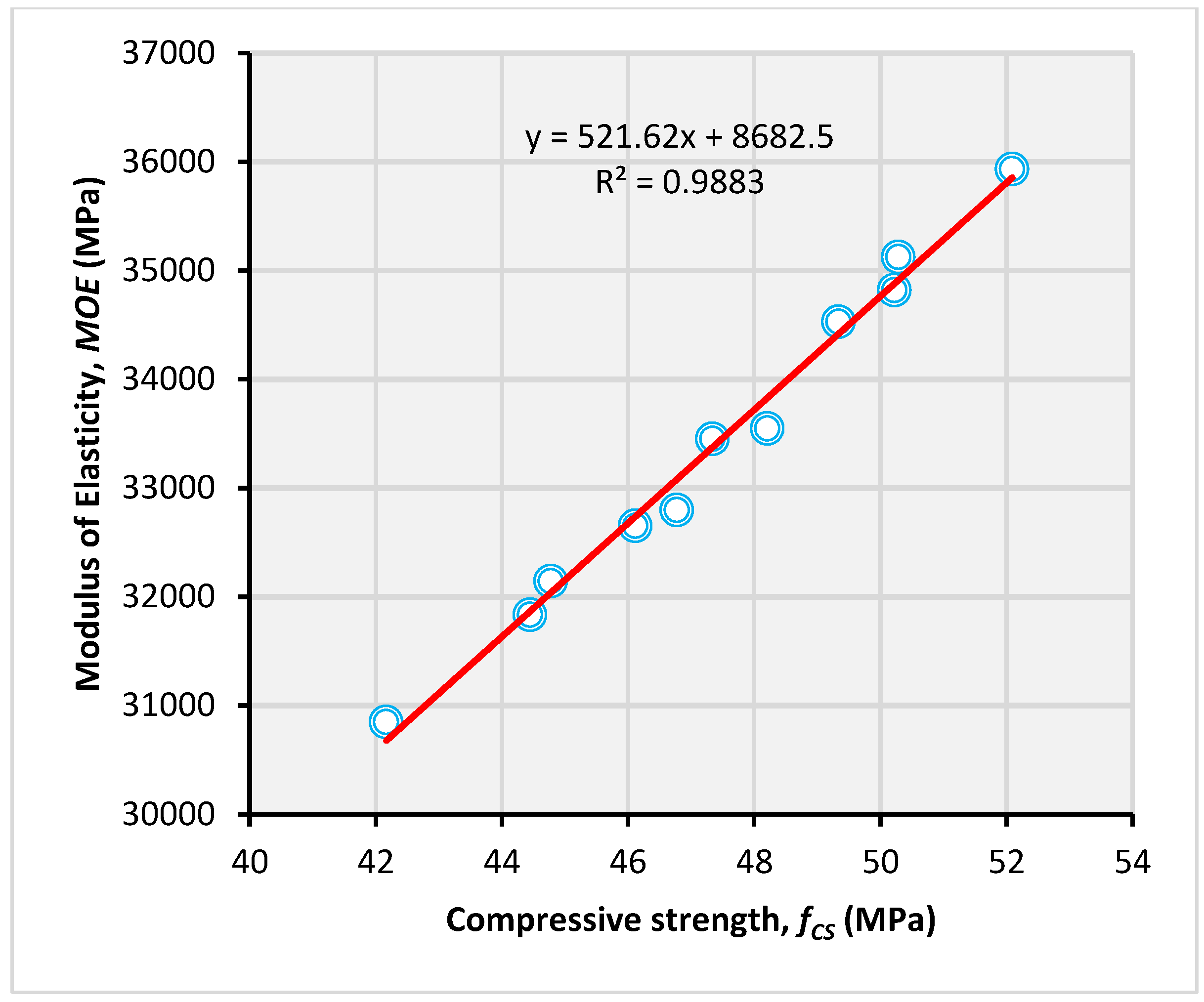

4.3. Modulus of Elasticity

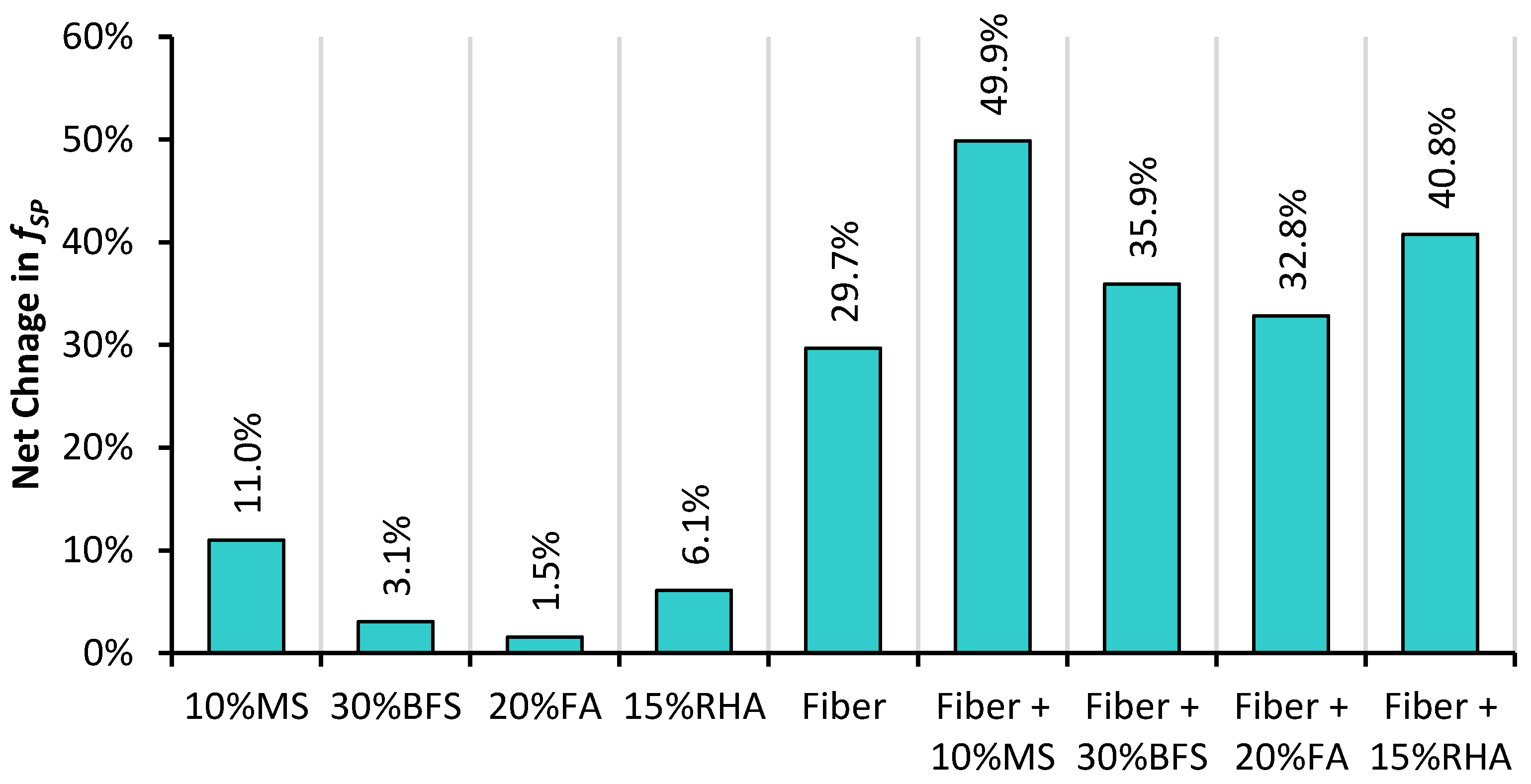

4.4. Splitting Tensile Strength

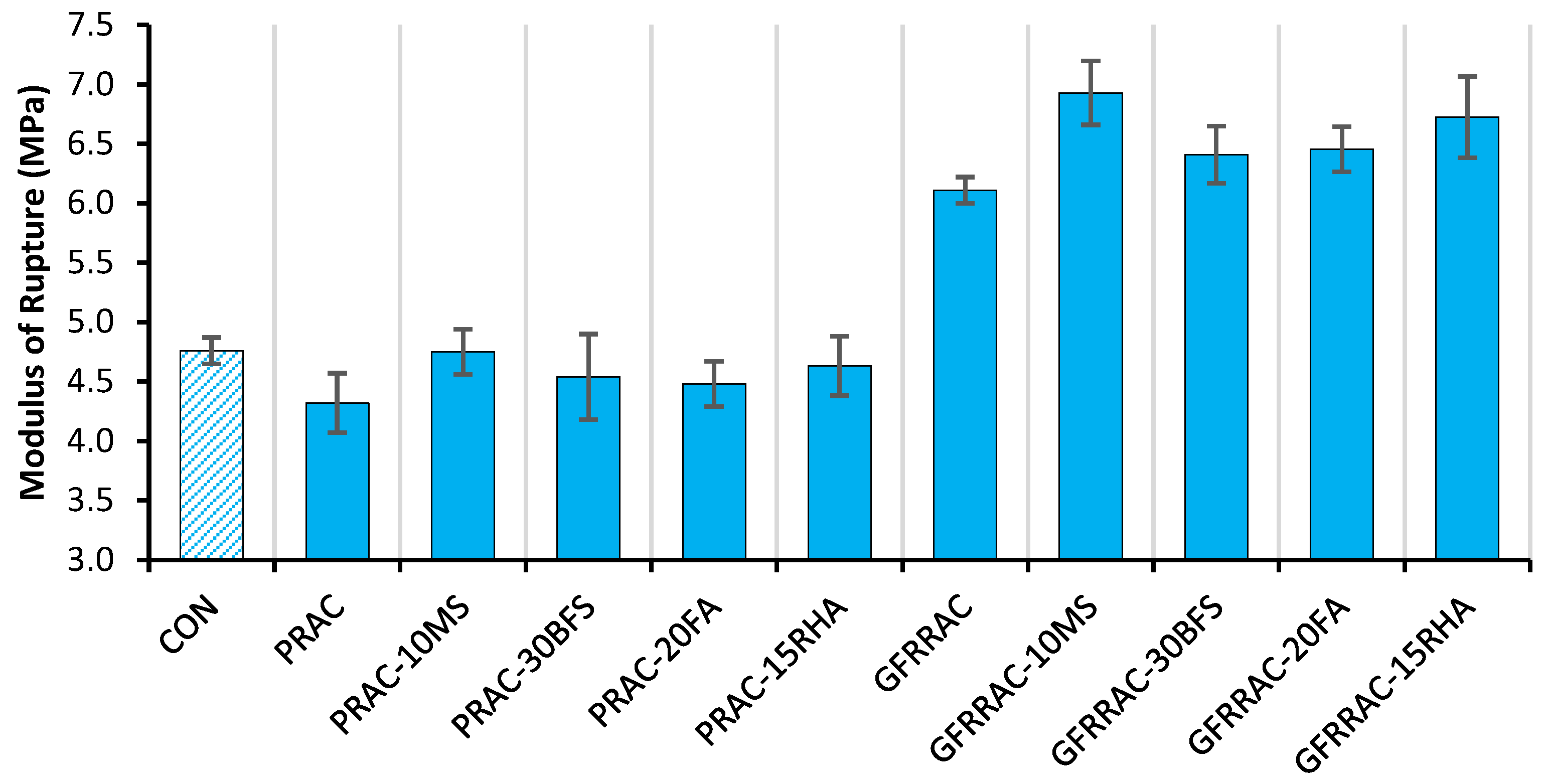

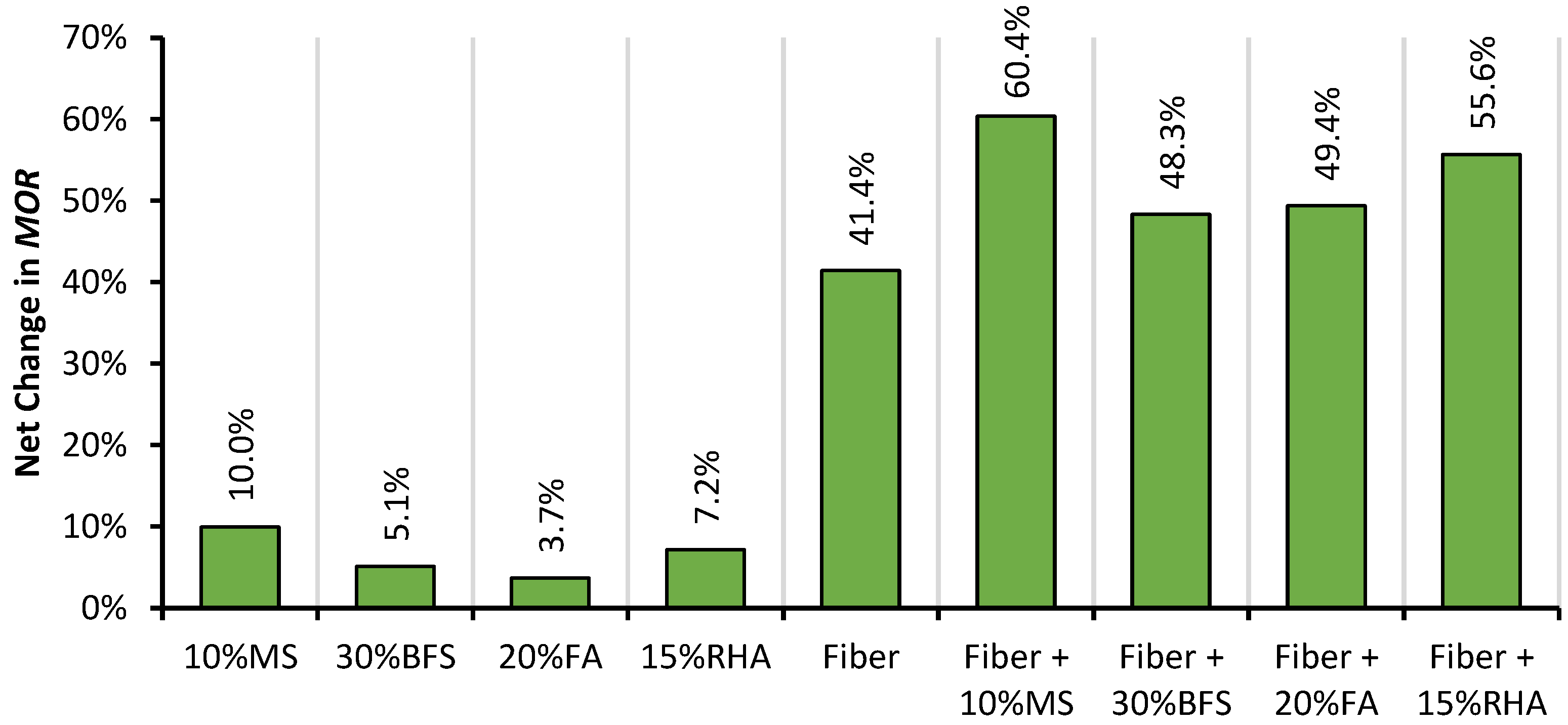

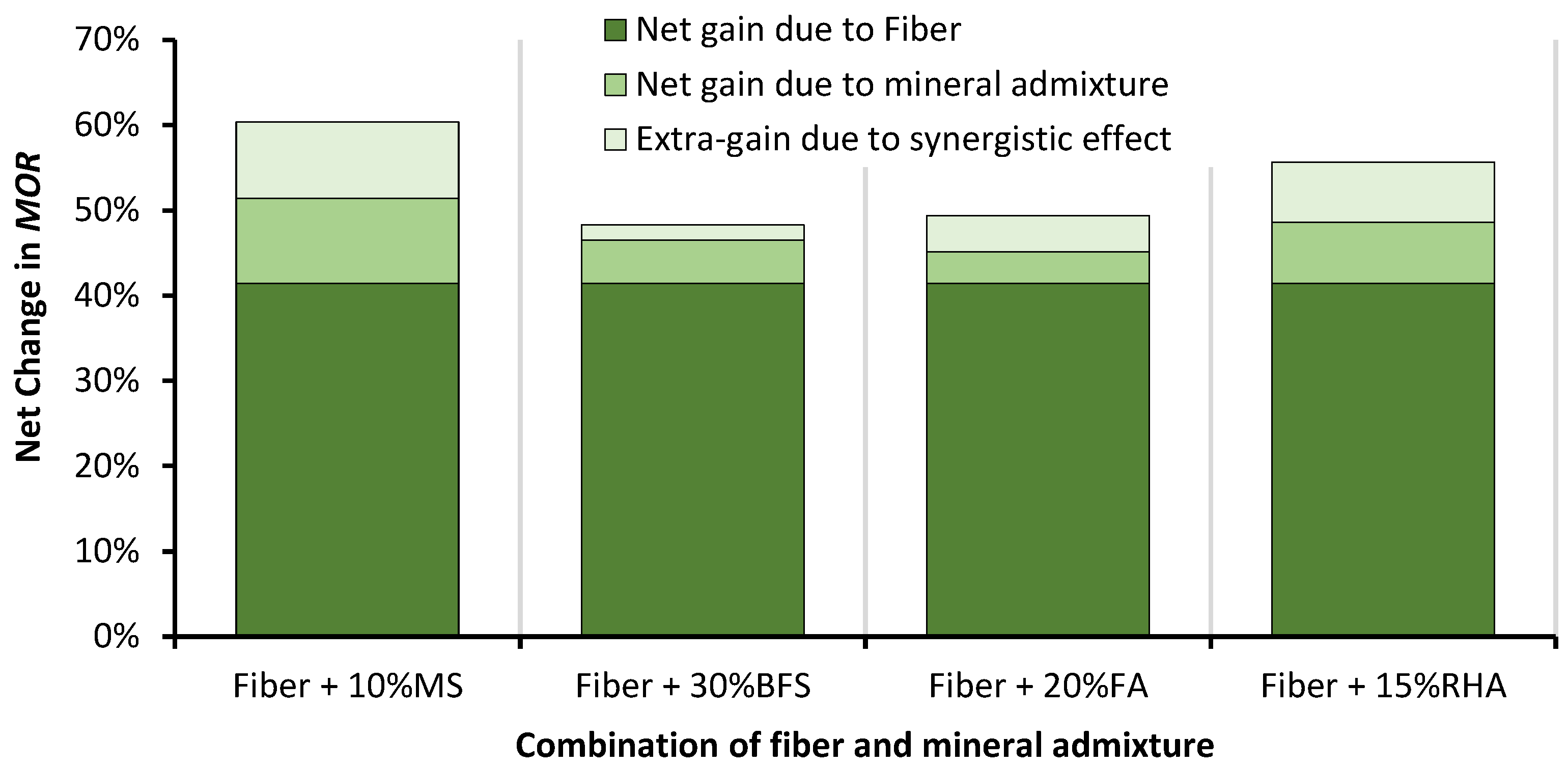

4.5. Modulus of Rupture

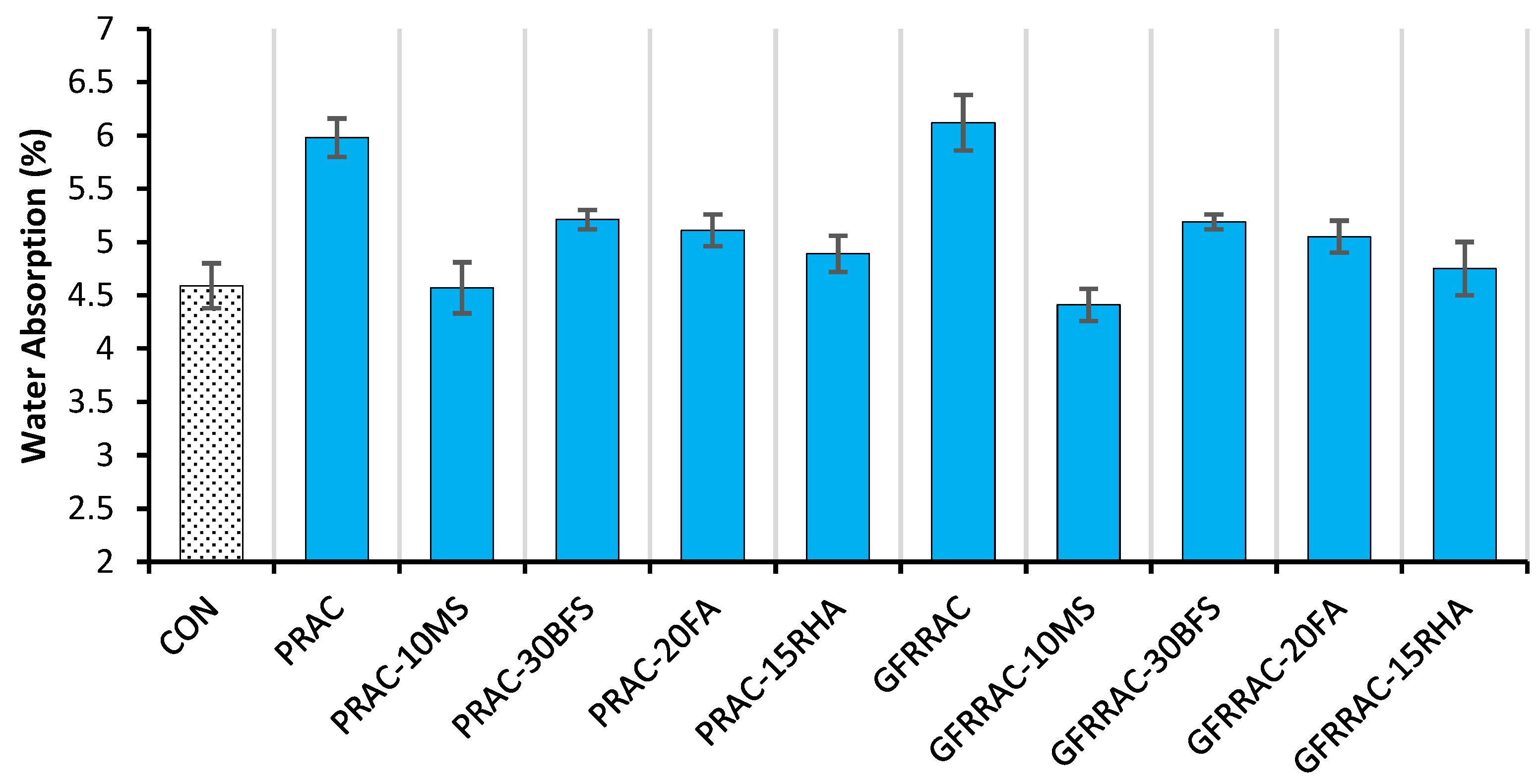

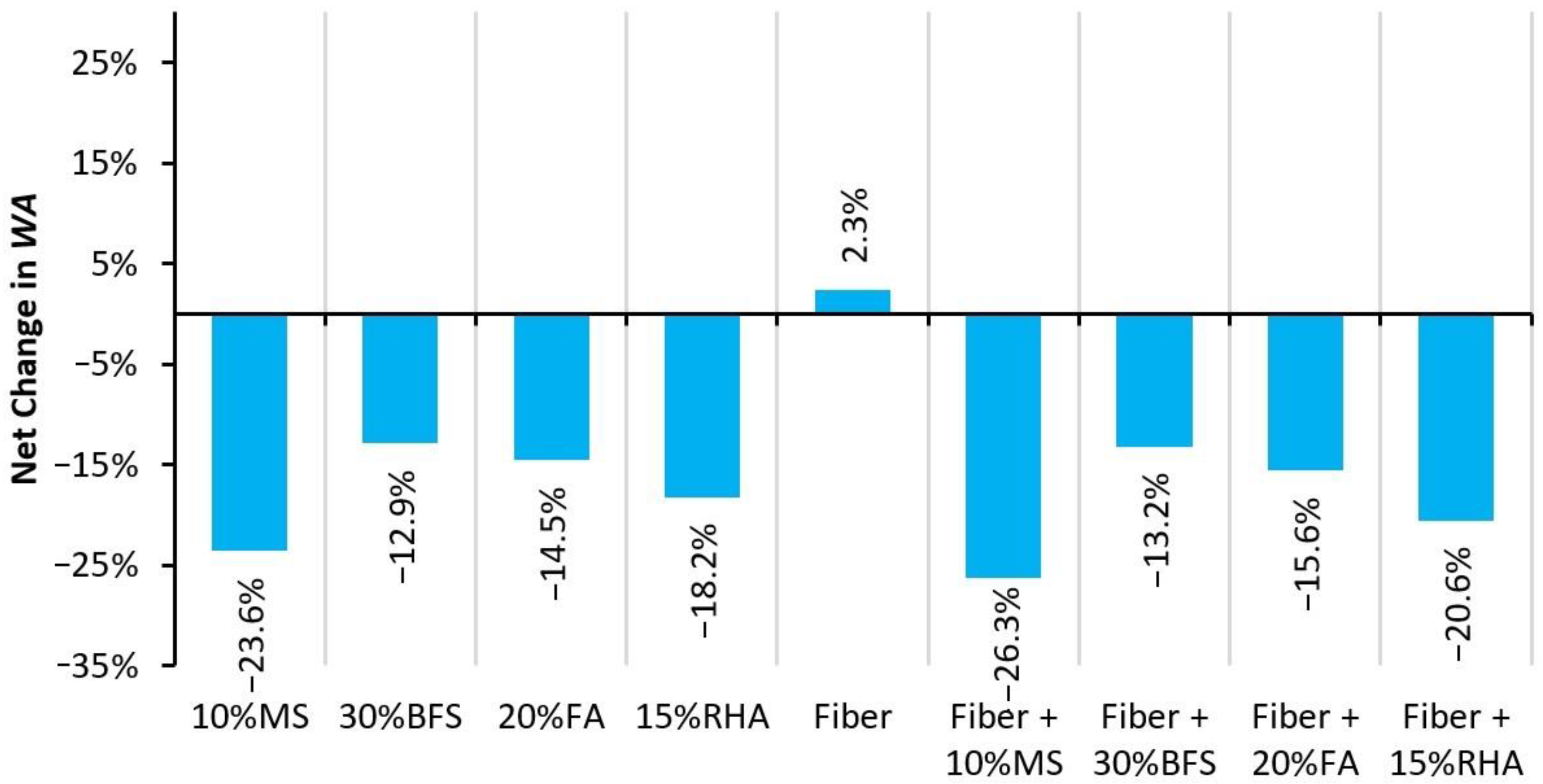

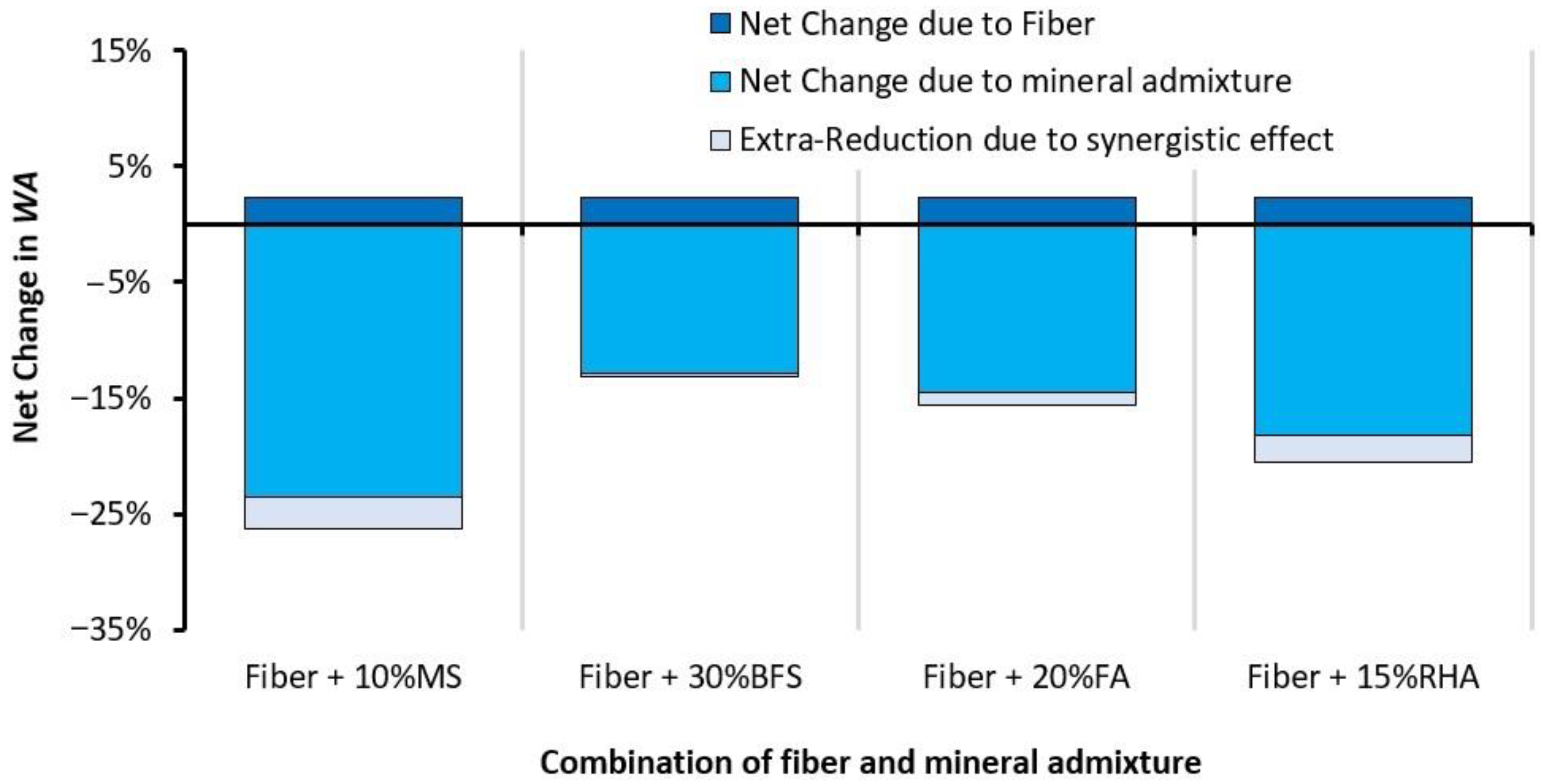

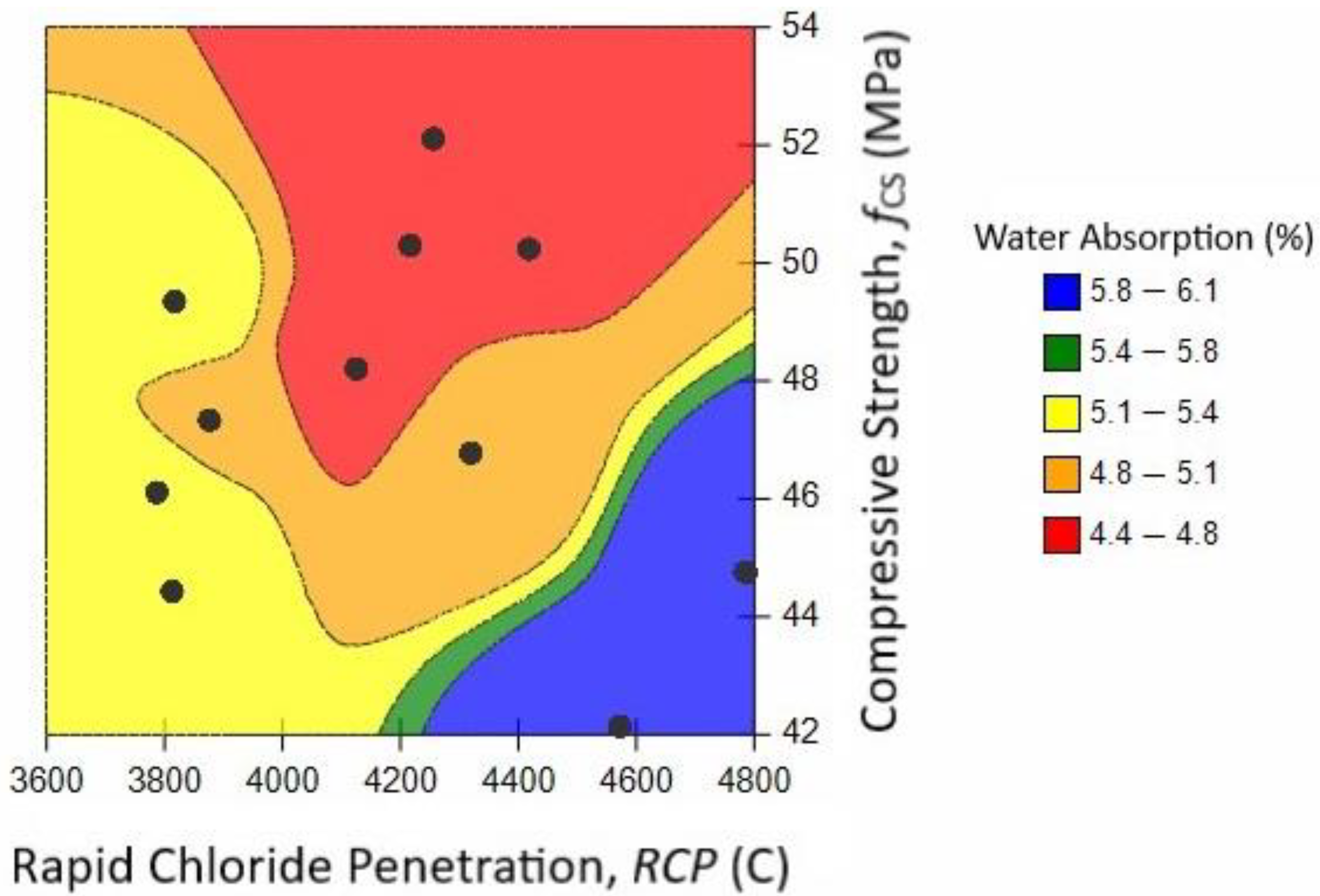

4.6. Water Absorption

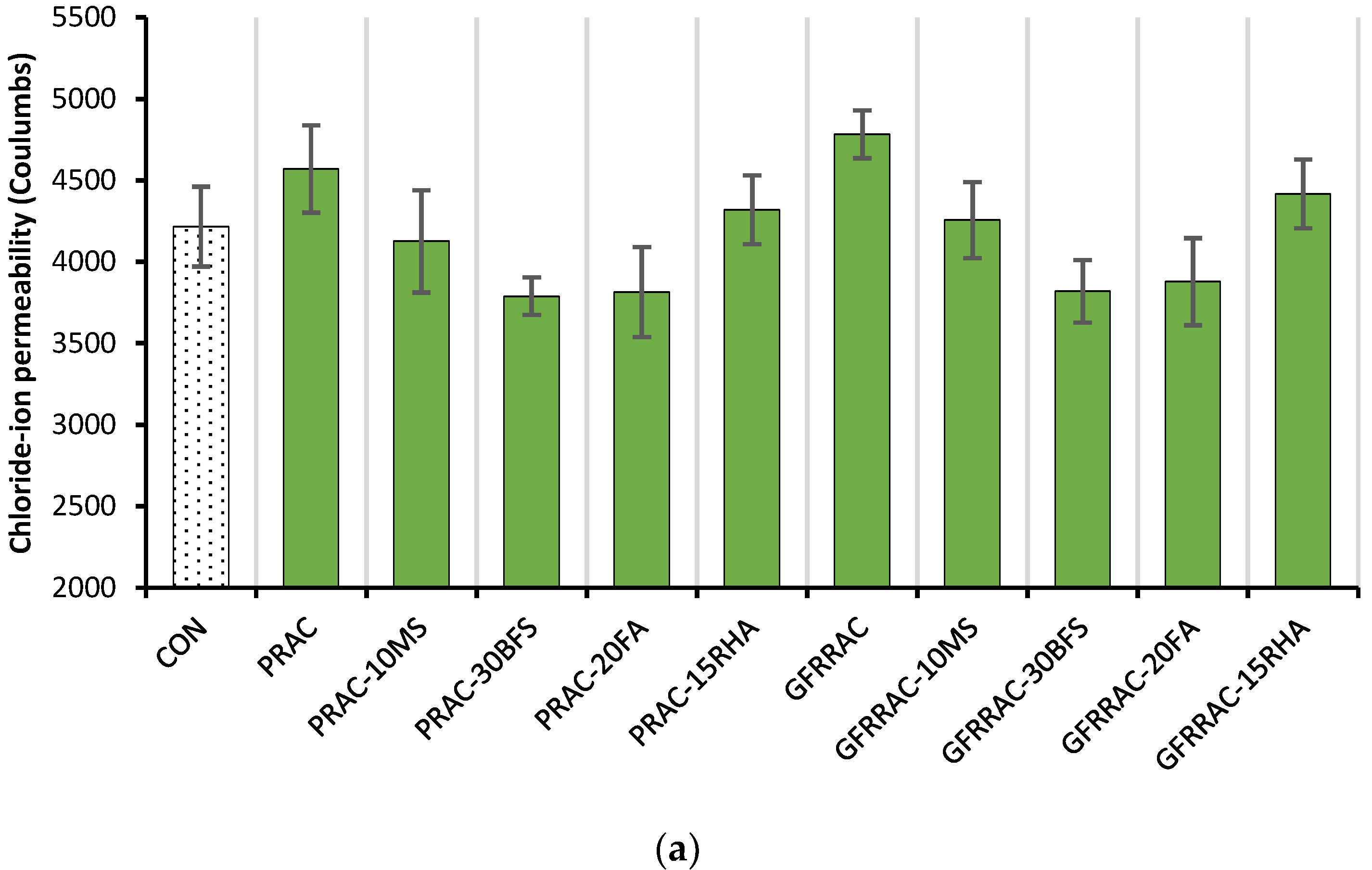

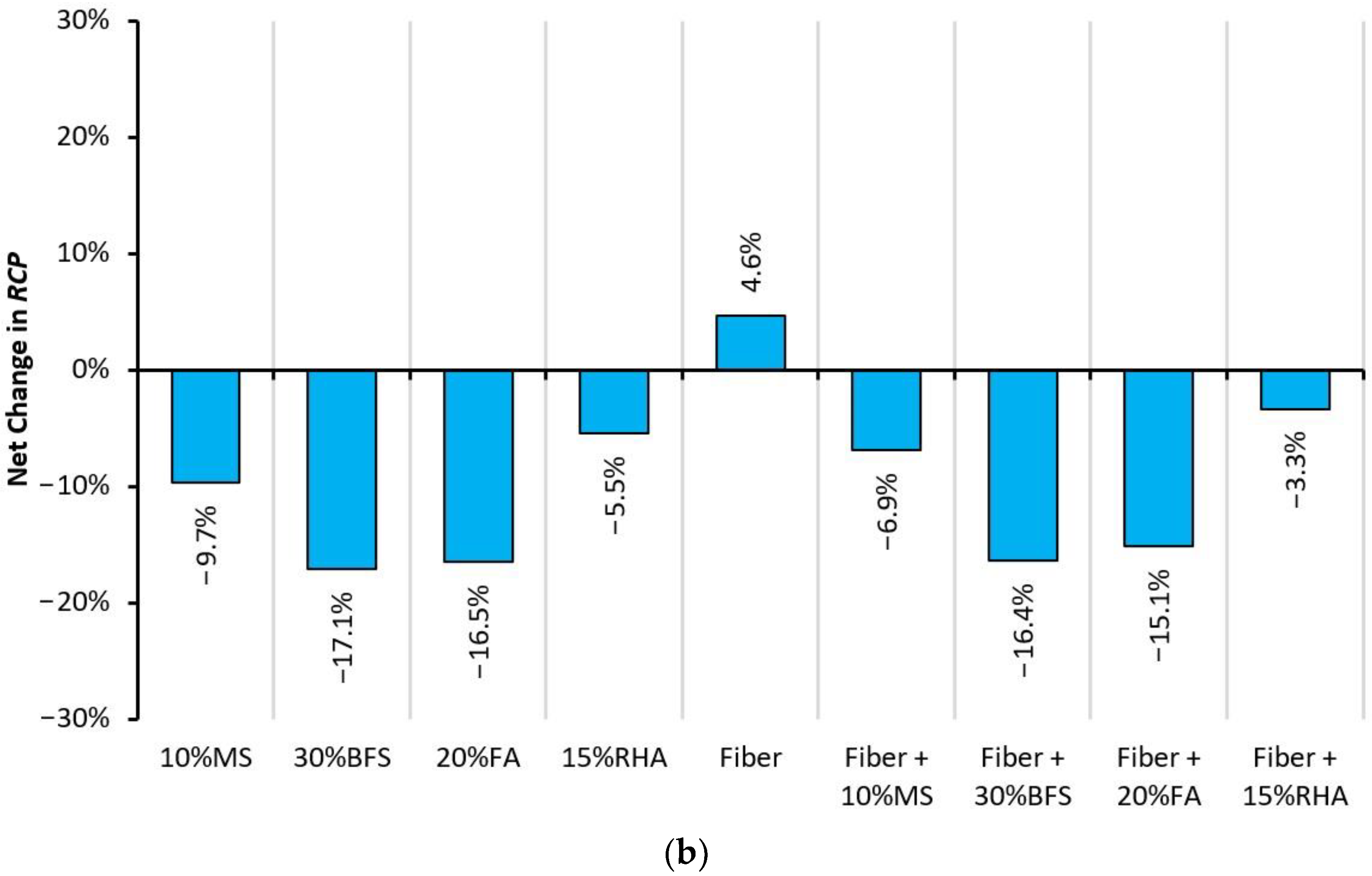

4.7. Chloride Penetration

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BFS | Blast furnace steel slag |

| CDW | Construction and demolition waste |

| FA | Fly ash |

| PRAC | Plain recycled aggregate concrete |

| RA | Recycled aggregate |

| RCA | Recycled coarse aggregate |

| RAC | Recycled aggregate concrete |

| RHA | Rice husk ash |

| FRRAC | Fiber-reinforced recycled aggregate concrete |

| GFRRAC | Glass fiber-reinforced recycled aggregate concrete |

References

- Freedonia Group. Global Construction Aggregates—Demand and Sales Forecasts, Market Share, Market Size, Market Leaders; Freedonia Group: Cleveland, OH, USA, 2016. [Google Scholar]

- Langer, W.H.; Arbogast, B.F. Environmental impacts of mining natural aggregate. In Deposit and Geoenvironmental Models for Resource Exploitation and Environmental Security; Springer: Cham, Switzerland, 2002; pp. 151–169. [Google Scholar]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Toxicity and environmental and economic performance of fly ash and recycled concrete aggregates use in concrete: A review. Heliyon 2018, 4, e00611. [Google Scholar] [CrossRef]

- Tai, J.; An, M.; Wang, X. Annual Research Report on the Development of Urban 637 Environmental and Sanitation Industry in China: 2015–2016; Shanghai Jiao Tong University Press: Shanghai, China, 2017. [Google Scholar]

- Pacheco, J.; de Brito, J.; Ferreira, J.; Soares, D. Dynamic characterization of full-scale structures made with recycled coarse aggregates. J. Clean. Prod. 2017, 142, 4195–4205. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Wang, J.; Basheer, P.A.M.; Nanukuttan, S.V.; Long, A.E.; Bai, Y. Influence of service loading and the resulting micro-cracks on chloride resistance of concrete. Constr. Build. Mater. 2016, 108, 56–66. [Google Scholar] [CrossRef] [Green Version]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J. Combined Economic and Mechanical Performance Optimization of Recycled Aggregate Concrete with High Volume of Fly Ash. Appl. Sci. 2018, 8, 1189. [Google Scholar] [CrossRef] [Green Version]

- Ali, B.; Qureshi, L.A. Durability of recycled aggregate concrete modified with sugarcane molasses. Constr. Build. Mater. 2019, 229, 116913. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A. Influence of glass fibers on mechanical and durability performance of concrete with recycled aggregates. Constr. Build. Mater. 2019, 228, 116783. [Google Scholar] [CrossRef]

- Masood, B.; Elahi, A.; Barbhuiya, S.; Ali, B. Mechanical and durability performance of recycled aggregate concrete incorporating low calcium bentonite. Constr. Build. Mater. 2019, 237, 117760. [Google Scholar] [CrossRef]

- Hendriks, C.F.; Janssen, G.M.T. Use of recycled materials in constructions. Mater. Struct. 2003, 36, 604–608. [Google Scholar] [CrossRef]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Nawaz, M.A.; Qureshi, L.A.; Ali, B.; Raza, A. Mechanical, durability and economic performance of concrete incorporating fly ash and recycled aggregates. SN Appl. Sci. 2020, 2, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of fly ash as cement replacement on the properties of recycled aggregate concrete. J. Mater. Civ. Eng. 2007, 19, 709–717. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Barbudo, A.; de Brito, J.; Evangelista, L.; Bravo, M.; Agrela, F. Influence of water-reducing admixtures on the mechanical performance of recycled concrete. J. Clean. Prod. 2013, 59, 93–98. [Google Scholar] [CrossRef]

- Huoth, P.; Suntharavadivel, T.G.; Duan, K. Effect of Silica Fume on Recycled Aggregate Concrete; Southern Cross University: Lismore, Australia, 2014. [Google Scholar]

- Dilbas, H.; Şimşek, M.; Çakır, Ö. An investigation on mechanical and physical properties of recycled aggregate concrete (RAC) with and without silica fume. Constr. Build. Mater. 2014, 61, 50–59. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Z.; Lu, Z.; Sun, M. Coupling effects of silica fume and steel-fiber on the compressive behaviour of recycled aggregate concrete after exposure to elevated temperature. Constr. Build. Mater. 2018, 184, 752–764. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water absorption and electrical resistivity of concrete with recycled concrete aggregates and fly ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Nawaz, M.A.; Aslam, H.M.U. Combined Influence of Fly Ash and Recycled Coarse Aggregates on Strength and Economic Performance of Concrete. Civ. Eng. J. 2019, 5, 832–844. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Baig, H.S.; Malik, S.; Din, M.; Aslam, H.M.U. Effect of Molasses and Water–Cement Ratio on Properties of Recycled Aggregate Concrete. Arab. J. Sci. Eng. 2019, 45, 3455–3467. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Optimizing recycled concrete containing high volume of fly ash in terms of the embodied energy and chloride ion resistance. J. Clean. Prod. 2018, 194, 735–750. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Raza, A.; Nawaz, M.A.; Rehman, S.U.; Rashid, M.U. Influence of Glass Fibers on Mechanical Properties of Concrete with Recycled Coarse Aggregates. Civ. Eng. J. 2019, 5, 1007–1019. [Google Scholar] [CrossRef] [Green Version]

- Ahmadi, M.; Farzin, S.; Hassani, A.; Motamedi, M. Mechanical properties of the concrete containing recycled fibers and aggregates. Constr. Build. Mater. 2017, 144, 392–398. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I. Effect of macro-synthetic fibers on the fracture energy and mechanical behavior of recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 857–868. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Axial stress-strain behavior of macro-synthetic fiber reinforced recycled aggregate concrete. Cem. Concr. Compos. 2019, 97, 341–356. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Influence of different treatment methods on the mechanical behavior of recycled aggregate concrete: A comparative study. Cem. Concr. Compos. 2019, 104, 103398. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of recycled aggregate treatment techniques on the durability of concrete: A comparative evaluation. Constr. Build. Mater. 2020, 264, 120284. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of different aggregate treatment techniques on the freeze-thaw and sulfate resistance of recycled aggregate concrete. Cold Reg. Sci. Technol. 2020, 178, 103126. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Anike, E.E.; Saidani, M.; Olubanwo, A.O.; Tyrer, M. Extended application of the Equivalent Mortar Volume mix design method for recycled aggregate concrete. In Proceedings of the 5th World Congress on Civil, Structural, and Environmental Engineering (CSEE’20), Lisbon, Portugal, 18–20 October 2020. [Google Scholar]

- Anike, E.E.; Saidani, M.; Olubanwo, A.O.; Tyrer, M.; Ganjian, E. Effect of mix design methods on the mechanical properties of steel fibre-reinforced concrete prepared with recycled aggregates from precast waste. Structures 2020, 27, 664–672. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Sun, X.; Jin, W. Improving performance of recycled aggregate concrete with superfine pozzolanic powders. J. Cent. South Univ. 2013, 20, 3715–3722. [Google Scholar] [CrossRef]

- Anastasiou, E.; Filikas, K.G.; Stefanidou, M. Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr. Build. Mater. 2014, 50, 154–161. [Google Scholar] [CrossRef]

- Madandoust, R.; Ranjbar, M.M.; Moghadam, H.A.; Mousavi, S.Y. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Kazemi, M.J.; Mosavi, H.; Mohseni, E. Acid resistance and durability properties of steel fiber-reinforced concrete incorporating rice husk ash and recycled aggregate. Constr. Build. Mater. 2019, 202, 266–275. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Buranasing, R.; Jaturapitakkul, C.; Chindaprasirt, P. Influence of rice husk–bark ash on mechanical properties of concrete containing high amount of recycled aggregates. Constr. Build. Mater. 2008, 22, 1812–1819. [Google Scholar] [CrossRef]

- Passuello, A.; Moriconi, G.; Shah, S.P. Cracking behavior of concrete with shrinkage reducing admixtures and PVA fibers. Cem. Concr. Compos. 2009, 31, 699–704. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. Fibre reinforced concrete with a combination of polyolefin and steel-hooked fibres. Compos. Struct. 2017, 171, 317–325. [Google Scholar] [CrossRef]

- Biolzi, L.; Cattaneo, S. Response of steel fiber reinforced high strength concrete beams: Experiments and code predictions. Cem. Concr. Compos. 2017, 77, 1–13. [Google Scholar] [CrossRef]

- Lee, J.-H. Influence of concrete strength combined with fiber content in the residual flexural strengths of fiber reinforced concrete. Compos. Struct. 2017, 168, 216–225. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Simões, T.; Costa, H.; Dias-da-Costa, D.; Júlio, E. Influence of type and dosage of micro-fibres on the physical properties of fibre reinforced mortar matrixes. Constr. Build. Mater. 2018, 187, 1277–1285. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Kurda, R. Environmental and economic benefits of steel, glass, and polypropylene fiber reinforced cement composite application in jointed plain concrete pavement. Compos. Commun. 2020, 22, 100437. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Influence of silica fume content on microstructure development and bond to steel fiber in ultra-high strength cement-based materials (UHSC). Cem. Concr. Compos. 2016, 71, 97–109. [Google Scholar] [CrossRef] [Green Version]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete. Compos. Struct. 2017, 181, 273–284. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Shah, S.H.A.; Rehman, S.U.; Hussain, I.; Iqbal, M. A step towards durable, ductile and sustainable concrete: Simultaneous incorporation of recycled aggregates, glass fiber and fly ash. Constr. Build. Mater. 2020, 251, 118980. [Google Scholar] [CrossRef]

- Ali, B.; Ahmed, H.; Ali Qureshi, L.; Kurda, R.; Hafez, H.; Mohammed, H.; Raza, A. Enhancing the Hardened Properties of Recycled Concrete (RC) through Synergistic Incorporation of Fiber Reinforcement and Silica Fume. Materials 2020, 13, 4112. [Google Scholar] [CrossRef]

- Ahmed, M.L.; Javed, M.A.; Qureshi, A.S. Benefits of Incorporating Induction Furnace Slag in Concrete as Replacement of Cement: A Case Study of Pakistan. Mehran Univ. Res. J. Eng. Technol. 2018, 37, 701–714. [Google Scholar] [CrossRef]

- Rehman, S.U.; Yaqub, M.; Noman, M.; Ali, B.; Ayaz Khan, M.N.; Fahad, M.; Muneeb Abid, M.; Gul, A. The Influence of Thermo-Mechanical Activation of Bentonite on the Mechanical and Durability Performance of Concrete. Appl. Sci. 2019, 9, 5549. [Google Scholar] [CrossRef] [Green Version]

- Qureshi, L.A.; Ali, B.; Ali, A. Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete. Constr. Build. Mater. 2020, 263, 120636. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI-211.1-91 Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. In ACI Manual of Concrete Practice 2000, Part 1: Materials and General Properties of Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2000. [Google Scholar]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Nedunuri, S.S.S.A.; Sertse, S.G.; Muhammad, S. Microstructural study of Portland cement partially replaced with fly ash, ground granulated blast furnace slag and silica fume as determined by pozzolanic activity. Constr. Build. Mater. 2020, 238, 117561. [Google Scholar] [CrossRef]

- Ozturk, M.; Karaaslan, M.; Akgol, O.; Sevim, U.K. Mechanical and electromagnetic performance of cement based composites containing different replacement levels of ground granulated blast furnace slag, fly ash, silica fume and rice husk ash. Cem. Concr. Res. 2020, 136, 106177. [Google Scholar] [CrossRef]

- ASTM-C39. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM-C496. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM-C1609. Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM-C948. Standard Test Method for Dry and Wet Bulk Density, Water Absorption, and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

- Boukendakdji, O.; Kenai, S.; Kadri, E.H.; Rouis, F. Effect of slag on the rheology of fresh self-compacted concrete. Constr. Build. Mater. 2009, 23, 2593–2598. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Khan, S.U. Flexural behavior of glass fiber-reinforced recycled aggregate concrete and its impact on the cost and carbon footprint of concrete pavement. Constr. Build. Mater. 2020, 262, 120820. [Google Scholar] [CrossRef]

- Hefni, Y.; El Zaher, Y.A.; Wahab, M.A. Influence of activation of fly ash on the mechanical properties of concrete. Constr. Build. Mater. 2018, 172, 728–734. [Google Scholar] [CrossRef]

- Ali, B.; Raza, S.S.; Hussain, I.; Iqbal, M. Influence of different fibers on mechanical and durability performance of concrete with silica fume. Struct. Concr. 2020, 22, 318–333. [Google Scholar] [CrossRef]

- Xie, J.; Li, J.; Lu, Z.; Li, Z.; Fang, C.; Huang, L.; Li, L. Combination effects of rubber and silica fume on the fracture behaviour of steel-fibre recycled aggregate concrete. Constr. Build. Mater. 2019, 203, 164–173. [Google Scholar] [CrossRef]

- Chung, D.D. Dispersion of short fibers in cement. J. Mater. Civ. Eng. 2005, 17, 379–383. [Google Scholar] [CrossRef]

- Toutanji, H.A. Properties of polypropylene fiber reinforced silica fume expansive-cement concrete. Constr. Build. Mater. 1999, 13, 171–177. [Google Scholar] [CrossRef]

- Tassew, S.T.; Lubell, A.S. Mechanical properties of glass fiber reinforced ceramic concrete. Constr. Build. Mater. 2014, 51, 215–224. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical properties of steel fiber-reinforced concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- Ali, B.; Kurda, R.; Herki, B.; Alyousef, R.; Mustafa, R.; Mohammed, A.; Raza, A.; Ahmed, H.; Fayyaz Ul-Haq, M. Effect of Varying Steel Fiber Content on Strength and Permeability Characteristics of High Strength Concrete with Micro Silica. Materials 2020, 13, 5739. [Google Scholar] [CrossRef]

- Köksal, F.; Altun, F.; Yiğit, İ.; Şahin, Y. Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater. 2008, 22, 1874–1880. [Google Scholar] [CrossRef]

- Abbass, W.; Khan, M.I.; Mourad, S. Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete. Constr. Build. Mater. 2018, 168, 556–569. [Google Scholar] [CrossRef]

- Hussain, I.; Ali, B.; Akhtar, T.; Jameel, M.S.; Raza, S.S. Comparison of mechanical properties of concrete and design thickness of pavement with different types of fiber-reinforcements (steel, glass, and polypropylene). Case Stud. Constr. Mater. 2020, 13, e00429. [Google Scholar] [CrossRef]

- Mengxiao, S.; Qiang, W.; Zhikai, Z. Comparison of the properties between high-volume fly ash concrete and high-volume steel slag concrete under temperature matching curing condition. Constr. Build. Mater. 2015, 98, 649–655. [Google Scholar] [CrossRef]

- Raza, S.S.; Qureshi, L.A.; Ali, B.; Raza, A.; Khan, M.M. Effect of different fibers (steel fibers, glass fibers and carbon fibers) on mechanical properties of reactive powder concrete (RPC). Struct. Concr. 2020, 22, 334–346. [Google Scholar] [CrossRef]

- Uysal, M.; Yilmaz, K. Effect of mineral admixtures on properties of self-compacting concrete. Cem. Concr. Compos. 2011, 33, 771–776. [Google Scholar] [CrossRef]

| Property | Cement | MS | FA | BFS | RHA |

|---|---|---|---|---|---|

| CaO (%) | 64.3 | 0.35 | 4.2 | 43.4 | 1.8 |

| SiO2 (%) | 20.4 | 98.3 | 57.1 | 36.2 | 90.5 |

| Al2O3 (%) | 7.1 | - | 29.7 | 14.6 | 0.33 |

| MgO (%) | 2.8 | - | - | - | 0.62 |

| Fe2O3 (%) | 3.4 | - | 11.9 | 1 | 0.41 |

| SO3 (%) | 1.3 | - | 0.24 | - | |

| Loss of ignition (800 °C) | 1.1 | 0.8 | 4.61 | 3.22 | 5.41 |

| Specific-surface area (m2/kg) | 365 | 27,500 | 305 | 341 | 368 |

| Sp.gravity | 3.13 | 2.22 | 2.44 | 2.94 | 2.14 |

| Aggregate Type | Source | Water Absorption (%) | Bulk Density (kg/m3) | Specific Gravity |

|---|---|---|---|---|

| Fine aggregate | Lawrancepur siliceous sand | 0.78 | 1625 | 2.68 |

| NCA | Crushed limestone | 0.67 | 1547 | 2.67 |

| RCA | Normal strength concrete samples | 5.34 | 1375 | 2.37 |

| Mix Nomenclature | Fiber | Mineral Admixture | RCA | Superplasticizer |

|---|---|---|---|---|

| CON | x | x | x | x |

| PRAC | x | x | ✓ | x |

| PRAC-10MS | x | 10% MS | ✓ | ✓ |

| PRAC-30BFS | x | 30% BFS | ✓ | x |

| PRAC-20FA | x | 20% FA | ✓ | x |

| PRAC-15RHA | x | 15% RHA | ✓ | x |

| GFRRAC | 1% Microglass fiber | No | ✓ | ✓ |

| GFRRAC-10MS | 1% Microglass fiber | 10% MS | ✓ | ✓ |

| GFRRAC-30BFS | 1% Microglass fiber | 30% BFS | ✓ | ✓ |

| GFRRAC-20FA | 1% Microglass fiber | 20% FA | ✓ | ✓ |

| GFRRAC-15RHA | 1% Microglass fiber | 15% RHA | ✓ | ✓ |

| Mix Nomenclature | Type I Cement (kg/m3) | MS (kg/m3) | BFS (kg/m3) | FA (kg/m3) | RHA (kg/m3) | NCA (kg/m3) | RCA (kg/m3) | Fine Aggregate (kg/m3) | Water (kg/m3) | Fiber (kg/m3) | Superplasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CON | 565 | x | x | x | x | 820 | x | 664 | 215 | 0 | 0 |

| PRAC | 565 | x | x | x | x | x | 720 | 664 | 215 | 0 | 0 |

| PRAC-10MS | 509 | 42 | x | x | x | x | 720 | 664 | 215 | 0 | 2.65 |

| PRAC-30BFS | 396 | x | 159 | x | x | x | 720 | 664 | 215 | 0 | 0 |

| PRAC-20FA | 452 | x | x | 88 | x | x | 720 | 664 | 215 | 0 | 0 |

| PRAC-15RHA | 480 | x | x | x | 58 | x | 720 | 664 | 215 | 0 | 0 |

| GFRRAC | 565 | x | x | x | x | x | 707 | 651 | 215 | 26 | 3.89 |

| GFRRAC-10MS | 509 | 42 | x | x | x | x | 707 | 651 | 215 | 26 | 5.52 |

| GFRRAC-30BFS | 396 | x | 159 | x | x | x | 707 | 651 | 215 | 26 | 3.17 |

| GFRRAC-20FA | 452 | x | x | 88 | x | x | 707 | 651 | 215 | 26 | 3.46 |

| GFRRAC-15RHA | 480 | x | x | x | 58 | x | 707 | 651 | 215 | 26 | 3.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alyousef, R.; Ali, B.; Mohammed, A.; Kurda, R.; Alabduljabbar, H.; Riaz, S. Evaluation of Mechanical and Permeability Characteristics of Microfiber-Reinforced Recycled Aggregate Concrete with Different Potential Waste Mineral Admixtures. Materials 2021, 14, 5933. https://doi.org/10.3390/ma14205933

Alyousef R, Ali B, Mohammed A, Kurda R, Alabduljabbar H, Riaz S. Evaluation of Mechanical and Permeability Characteristics of Microfiber-Reinforced Recycled Aggregate Concrete with Different Potential Waste Mineral Admixtures. Materials. 2021; 14(20):5933. https://doi.org/10.3390/ma14205933

Chicago/Turabian StyleAlyousef, Rayed, Babar Ali, Ahmed Mohammed, Rawaz Kurda, Hisham Alabduljabbar, and Sobia Riaz. 2021. "Evaluation of Mechanical and Permeability Characteristics of Microfiber-Reinforced Recycled Aggregate Concrete with Different Potential Waste Mineral Admixtures" Materials 14, no. 20: 5933. https://doi.org/10.3390/ma14205933

APA StyleAlyousef, R., Ali, B., Mohammed, A., Kurda, R., Alabduljabbar, H., & Riaz, S. (2021). Evaluation of Mechanical and Permeability Characteristics of Microfiber-Reinforced Recycled Aggregate Concrete with Different Potential Waste Mineral Admixtures. Materials, 14(20), 5933. https://doi.org/10.3390/ma14205933