1. Introduction

Just behind steel, aluminum and its alloys are the second most common material used in industries such as automotive, aerospace, machinery, manufacturing, transportation, and construction. Wide application of these materials is determined by their specific properties such as light weight, resistance to corrosion, and great mechanical properties including excellent strength and stiffness [

1,

2,

3]. One of the most commonly used aluminum alloys is AlSi10Mg, which belongs to the group of hypoeutectic aluminum alloys [

4]. In addition to the abovementioned properties, it is characterized by its low density, excellent castability, and high electrical conductivity [

4,

5]. Moreover, eutectic Al + Si phase, present in AlSi10Mg alloy, affects its ductility and strength but also makes this material difficult to machine. For this reason, it is mainly used in foundries. Currently, parts made of AlSi10Mg alloy are often produced in complex and irregular shapes that are difficult to obtain with the use of conventional technologies, including casting [

5,

6]. At the same time, efforts are being made to automate production processes, increase their efficiency, and reduce costs.

In order to ensure feasibility of more and more complex projects, additive manufacturing techniques (AM), also known as “3D printing”, are increasingly used. They involve the production of items based on three-dimensional Computer aided design (3D CAD) models and various methods of cumulative layer deposition. Compared to more conventional manufacturing methods, such as casting or powder sintering, AM technologies allow the production of very complex shapes with a relatively high accuracy and structure densification level [

7,

8,

9,

10]. One of the most popular AM techniques for processing metallic powder is Selective Laser Melting (SLM) [

2,

11]. In this process, a 3D model is divided into thin slices and a raw material (which is a metallic powder with a grain size of 20–60 µm [

12]), subjected to thermal energy, is melted in order to form a two-dimensional, responding layer with a thickness ranging from 10 to 80 µm [

7,

13,

14,

15]. There are many phenomena that may occur during SLM process, e.g., laser radiation, reflection and absorption, heat transfer, powder melting, phase transformation and melt flow within the molten pool (driven by surface tension gradients), evaporation, and material mass transfer. Such phenomena significantly depend on the properties of metallic powder and on the process parameters [

7].

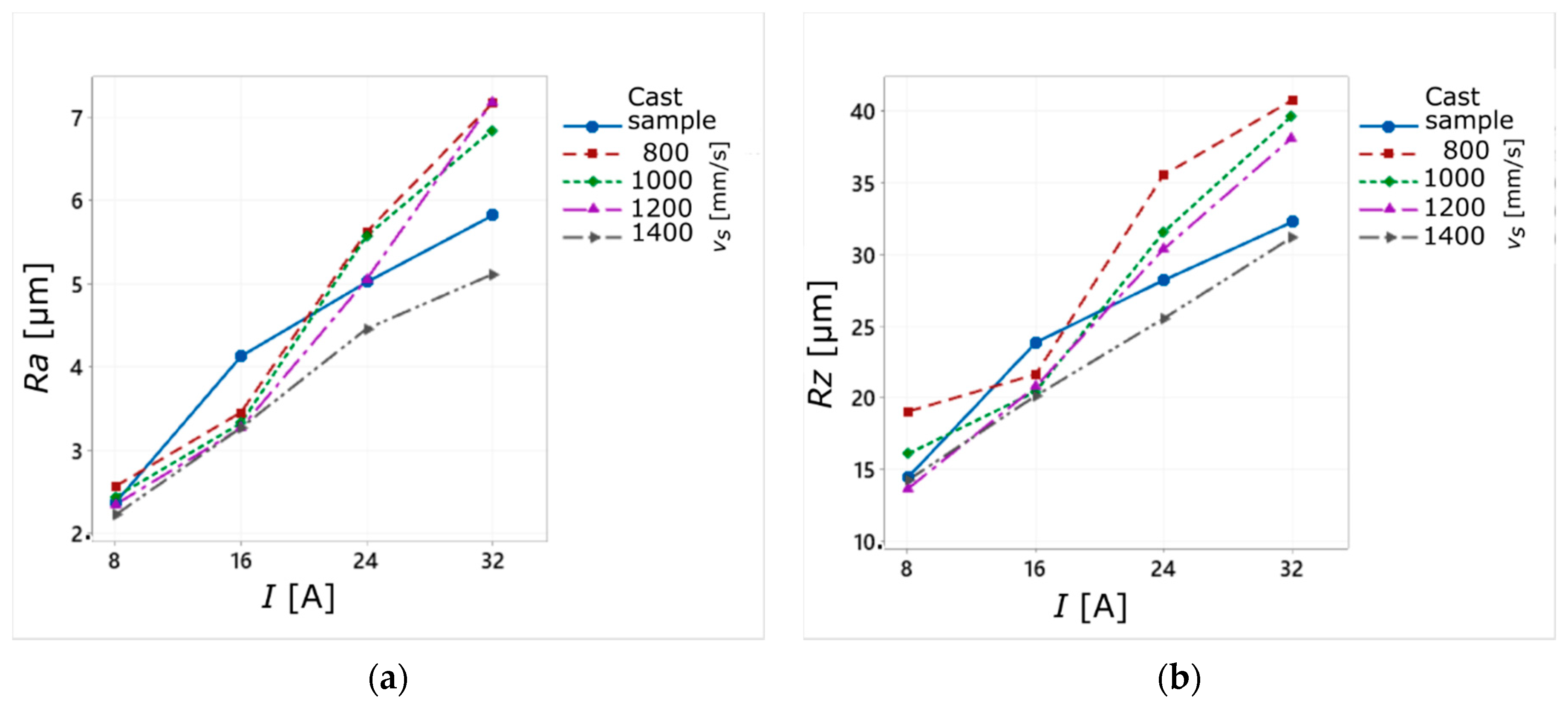

SLM technology not only enables direct fabricating of 3D parts with complex geometry, but also improves mechanical properties of objects made of AlSi10Mg alloy. On the other hand, their lower surface quality (higher values of the

Ra and

Rz parameters) and decreased dimensional-shape accuracy in comparison to machined parts are significant disadvantages [

13,

16,

17]. Consequently, additional machining operations are used to achieve the surface quality and geometric accuracy of these items equivalent to finishing and/or semi-finishing. It is worth underlining that the SLM-fabricated parts require subtractive finishing machining but without roughing, which reduces a total time duration of the manufacturing process and constitutes an advantage of this technique. Compared to other materials, the aluminum alloy powders are relatively light, with poor flowability, high reflectivity (91%), and high thermal conductivity (146 W/(m∙°K)) [

6,

18,

19]. Moreover, their ductility can be modified by proper heat treatment. As for the AlSi10Mg alloy, the presence of Si element in its composition decreases its melting point and improves weldability, fatigue performance, and resistance to corrosion. Additionally, the magnesium element (Mg) significantly enhances mechanical strength and impact performance through solution heat treatment and aging, without compromising other desirable mechanical properties [

18,

19]. On the other hand, low laser absorption and rapid heat dissipation cause some difficulties in manufacturing parts made of aluminum alloys with a use of SLM process. In addition, the Al alloys are subjected to oxidation, which contributes to the phenomenon of forming pores in the sintered material structure. The internal porosity depends also on the process parameters such as laser power, scanning speed, and hatch spacing [

19,

20]. Therefore, there is a need to conduct further research on the process of melting aluminum alloy powders.

For further processing of the components produced with SLM, both conventional (e.g., turning, milling) and nonconventional methods (e.g., Electrical Discharge Machining (EDM) or Electrochemical Machining (ECM)) are used. Naturally, parameters of these following processes should be matched to the specific material being machined. This is due to the specific mechanical and thermophysical properties of a given material and their influence on the machining process [

16,

21]. In SLM technology, more and more frequent use is made of metallic powders of difficult-to-cut materials (such as nickel-based superalloys and titanium alloys, hardened and high-strength steels, and composite and ceramic materials). As a result, further processing of these items, performed in order to improve the surface quality to a semi-finishing or finishing class, becomes a challenge for both machining and nonconventional processes [

13,

18,

22,

23]. Different structure of the material printed with SLM technology may cause additional difficulties in the manufacturing process. When it comes to difficult-to-cut materials, nonconventional machining methods are mainly preferred. One of these such methods, ensuring high shape and dimensional accuracy (less than 5 µm) and satisfactory surface roughness (

Ra < 0.1 µm), is electrical discharge machining [

24,

25]. EDM belongs to the group of alternative technologies due to the electrothermal nature of the material removal process, in which the forces between the tool and the workpiece are negligibly small. Mechanical properties of machined material, such as hardness or ductility, do not affect this type of machining [

21,

25].

Optimization processes are used in order to select the most advantageous machining parameters for a given material. In the case of EDM, they are performed with a use of mathematical models developed on the basis of investigated effects of selected process parameters (such as current amplitude, pulse-on time, pulse-off time, duty cycle, voltage, capacitance, die-electric flushing pressure, wire feed rate, wire tension) on its performance [

26,

27,

28]. Frequently used optimization techniques include Response Surface Methodology (RSM) [

29], Artificial Neural Network (ANN) [

30], Taguchi analysis [

31], Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS), Gray Relational Analysis (GRA) [

32,

33], Taguchi Method-Based Gray Analysis [

34], and hybrid methods [

35,

36]. Simulation tools based on the finite element method can also be used for this purpose [

37]. Input parameters of EDM process may affect its various outputs such as material removal rate (MRR), tool wear rate (TWR), surface roughness (

Ra and

Rz), radial overcut (ROC), crater size, corner deviation, cutting speed, and width [

25,

27,

29,

38,

39]. Optimization of the EDM process parameters should ensure high MRR while maintaining low levels of TWR, surface roughness, white layer thickness, and surface cracks. In this kind of process, increasing the MRR is usually associated with a deterioration in surface roughness and accelerated tool wear (even up to a 100% in the case of micro-EDM) [

24,

29].

Many studies published so far concern the optimization of machining processes, including the selection of process parameters affecting its efficiency [

29]. However, few of them concern the simultaneous optimization of both processes, the SLM and the additional semi-finishing and/or finishing. An analysis of the influence of SLM laser scanning speed

v and milling parameters, feed rate (

f) and milling width (

ae) on the surface roughness (

Ra and

Rz), is presented in [

18]. RSM method is used to optimize the parameters, and the sintered material is made of AlSi10Mg aluminium powder. The best surface quality (

Ra = 0.142 ± 0.013 µm and

Rz = 1.043 ± 0.094 µm) was obtained for the lowest applied parameter values, i.e.,

v = 600 mm/s,

f = 835 mm/min, and

ae = 0.829 mm. Moreover, the article presents further optimization of the processes with regard to the required parameter values:

Ra ≤ 0.2 µm and

Rz ≤ 1.4 µm as well as

Ra ≤ 0.28 µm and

Rz ≤ 1.8 µm. Milling of the SLM-made surface also improved its roughness over 20 times. Moving on, the authors of [

13] analyzed the effect of longitudinal turning parameters such as cutting speed (

vc), feed (

f), depth of cut (

ap), and insert corner radius (

rε) on

Fc and

Ff components of the cutting force and on 2D and 3D surface roughness parameters. A workpiece made of AlSi10Mg powder using Direct Metal Laser Sintering (DMLS) was used in the research. The analysis of the obtained results proves that the values of

Ra and

Rz depend on the feed rate and corner radius. Moreover, the best result for

Ra (0.64 µm) was obtained for the cutting parameters of

f = 0.058 mm/rev,

vc = 300 m/min,

ap = 1.0 mm, and

rε = 0.4 mm, while the best result for

Rz (4.33 mm) was for

f = 0.058 mm/rev,

vc = 200 m/min,

ap = 0.5 mm, and

rε = 0.2 mm. The Authors also developed an algorithm for selecting the feed value depending on the maximum diameter of the turned shaft but, as they indicate, it needs to be verified when used for other laser-sintered material. Anyways, authors of the above papers did not analyze how the SLM process parameters influence the selection of the finishing process ones. There were also no attempts to optimize in this respect.

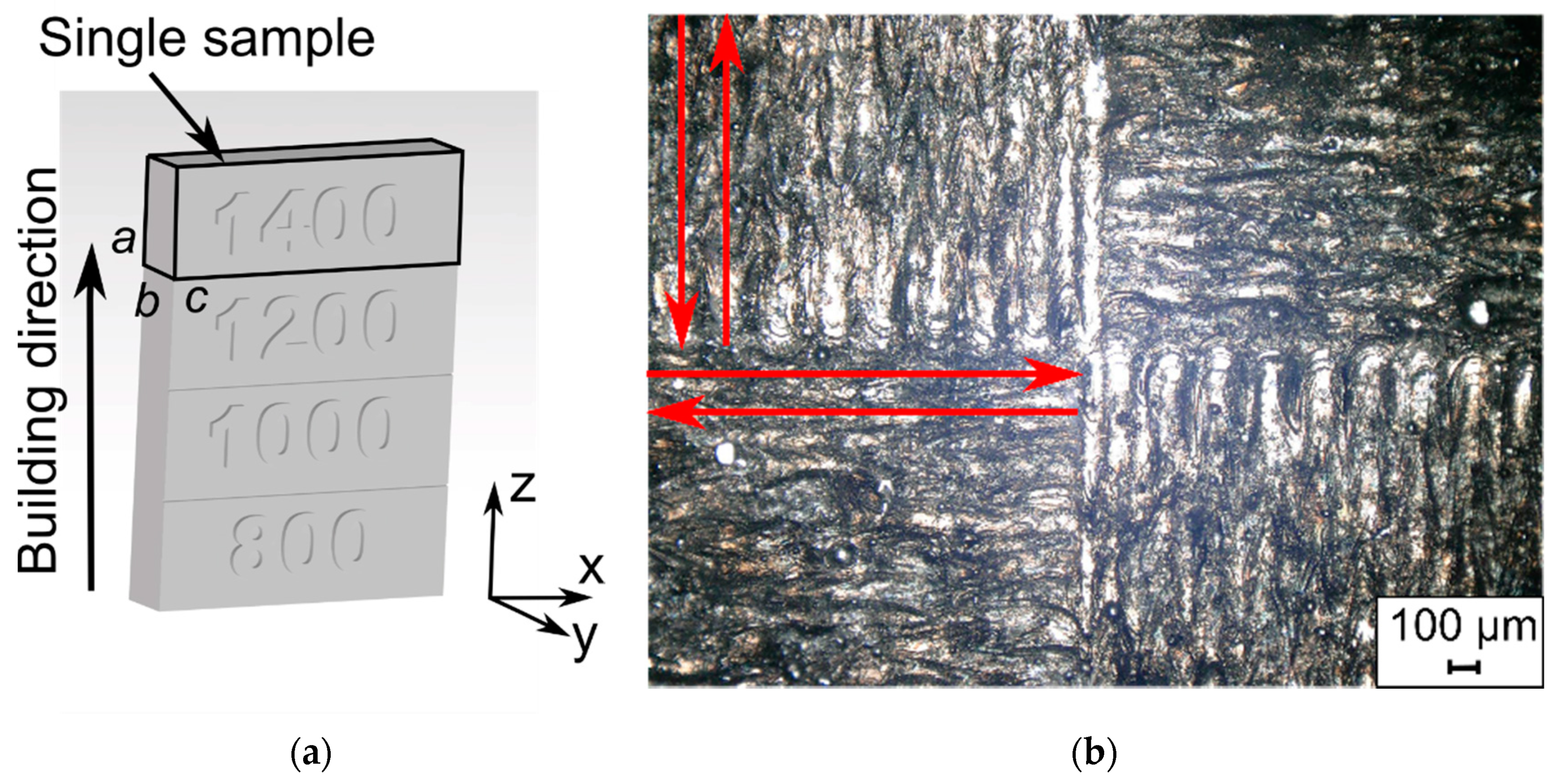

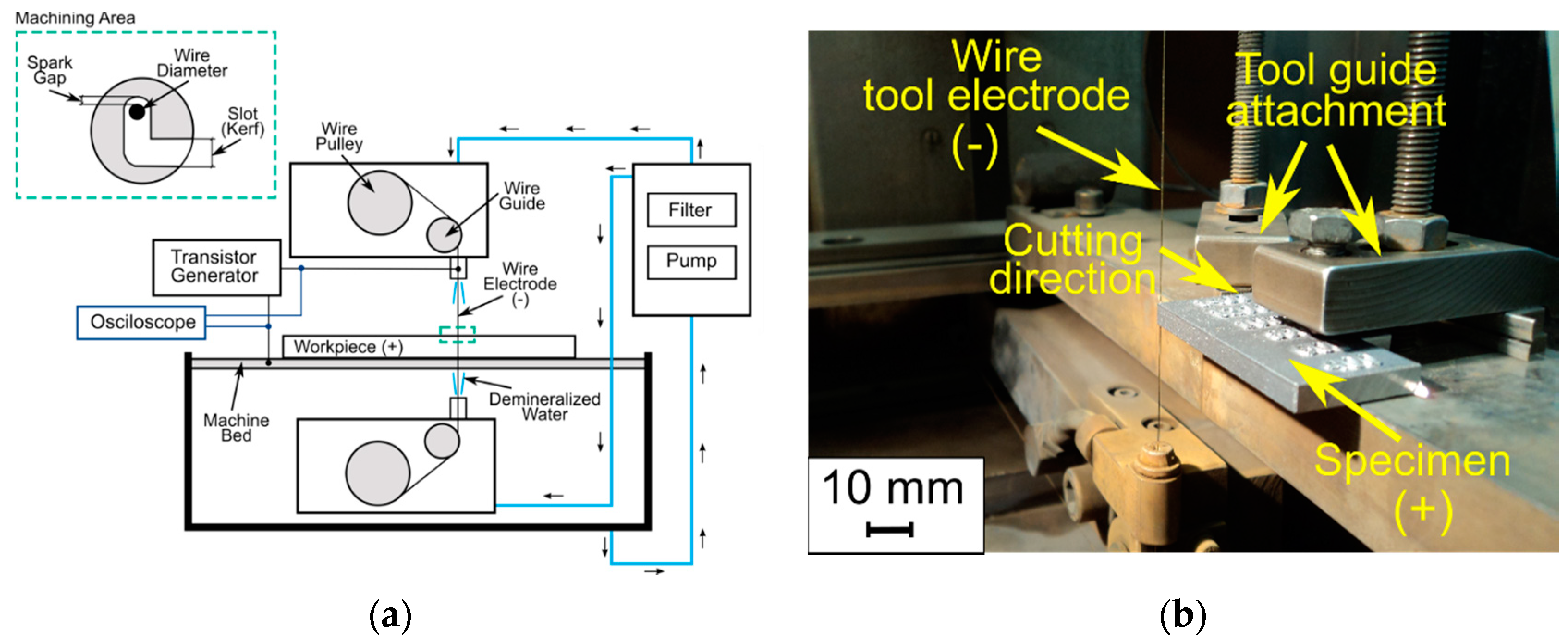

Due to the fact that AM technologies are relatively new, there are no optimized procedures for the further treatment of their products in order to improve the surface quality (obtain lower values of Ra and Rz parameters) or process efficiency. This applies to both conventional and nonconventional manufacturing technologies. Also, for the AlSi10Mg aluminum alloy processed with a use of SLM technology, there were no solutions prepared that would be used to determine the optimal machining parameters regarding surface quality and dimensional accuracy. Selecting the appropriate values of SLM printing parameters dedicated to a specific machining process can make it much easier and faster. Accordingly, the present article focused on the simultaneous study of the effect of laser scanning speed (the SLM process parameter) and the current amplitude, a parameter of Wire Electrical Discharge Machining (WEDM, a type of EDM process). In the first stage of work, samples were made of AlSi10Mg powder using SLM technology and with different values of laser scanning speed. Then they were cut with WEDM using different values of current amplitude. An analysis of the influence of WEDM current amplitude and SLM laser scanning speed on output parameters such as WEDM cutting speed and process energy as well as surface roughness (Ra and Rz) was carried out. Then, based on the obtained mathematical models, optimal parameter values were established. Additionally, in order to compare the results, WEDM cutting of a cast sample made of AlSi10Mg aluminum alloy was performed using the same current amplitude values.

4. Conclusions

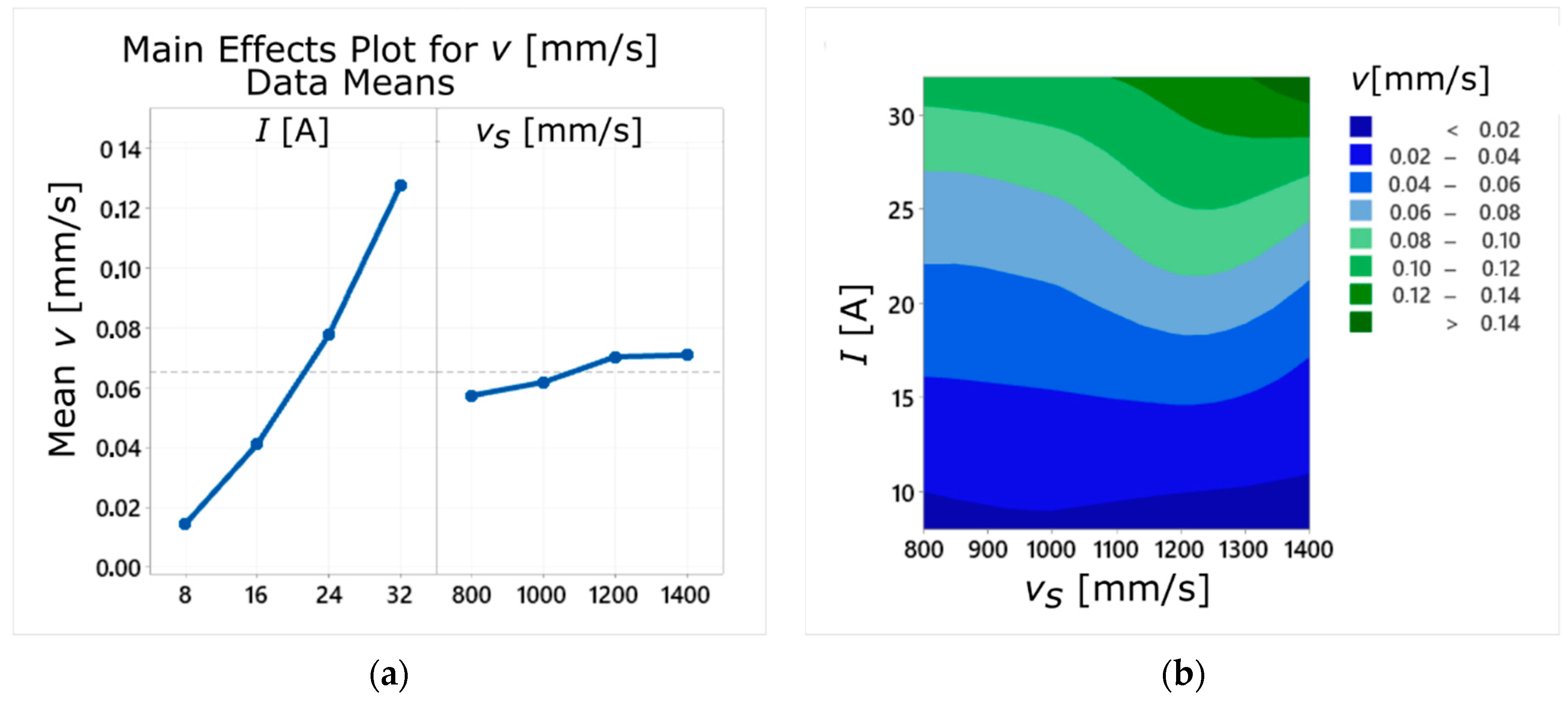

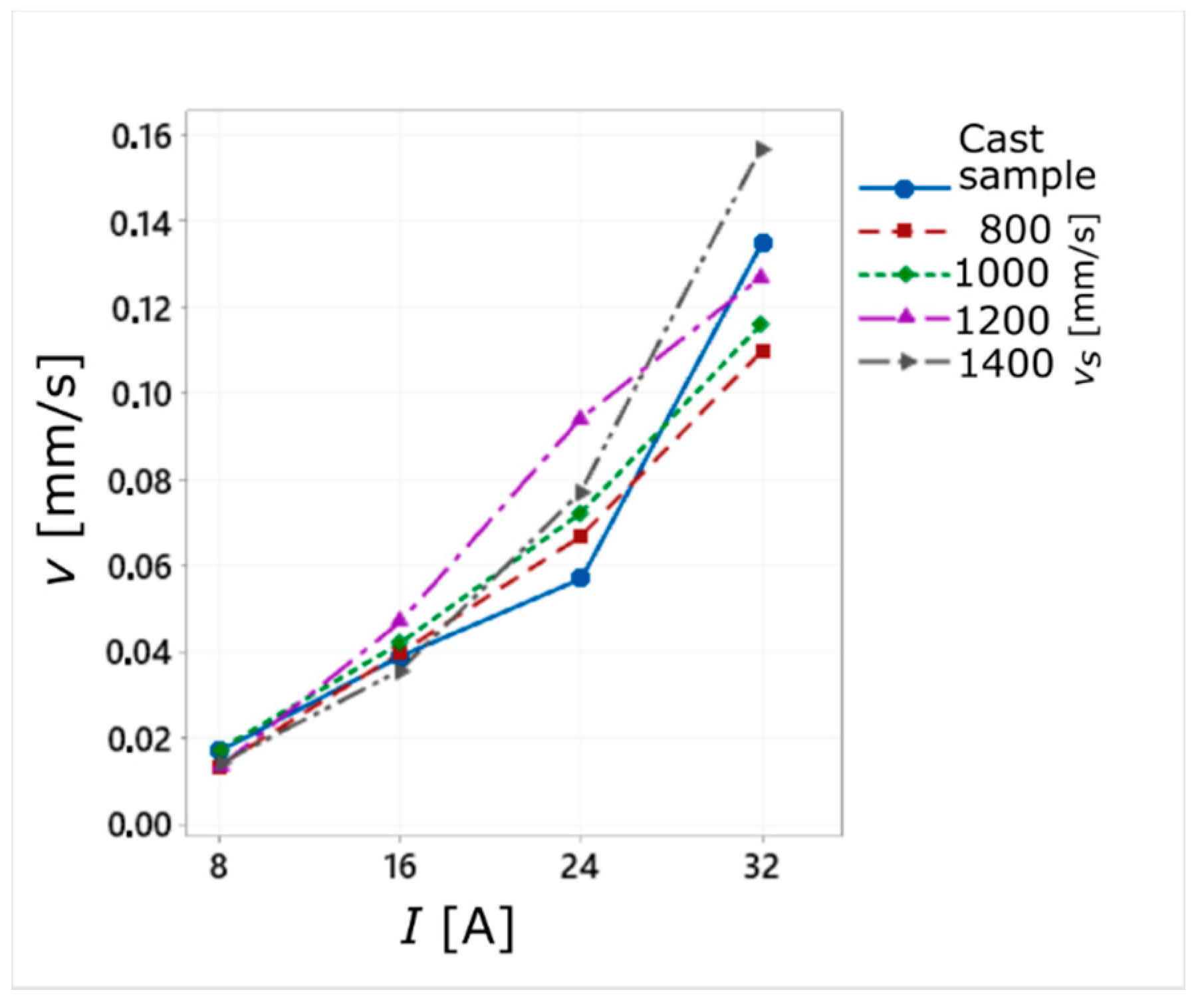

As a result of the conducted research, it is possible to demonstrate the influence of the tested parameters of the SLM and WEDM processes (laser scanning speed and current amplitude, respectively) on the machined surface roughness and the resulting characteristics of the WEDM process. The following conclusions were obtained on the basis of results analysis:

- (1)

For the current amplitude of I = 32 A, an increase in the laser scanning speed vs positively affected the cutting speed v. Changing the vs parameter value from 800 to 1400 mm/s resulted in an increase in the cutting speed by approx. 45%, and the value obtained in this case was the highest in the entire research (v = 0.16 mm/s).

- (2)

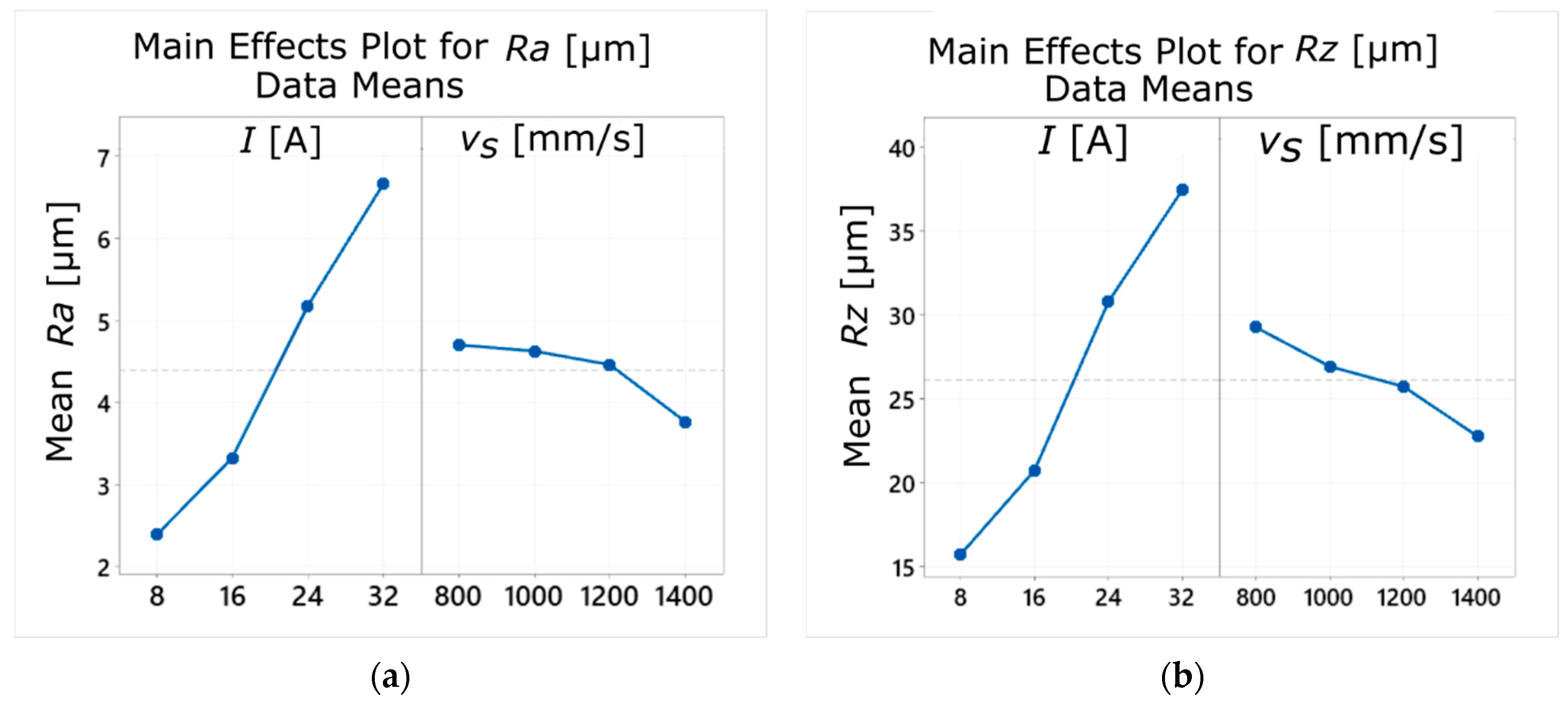

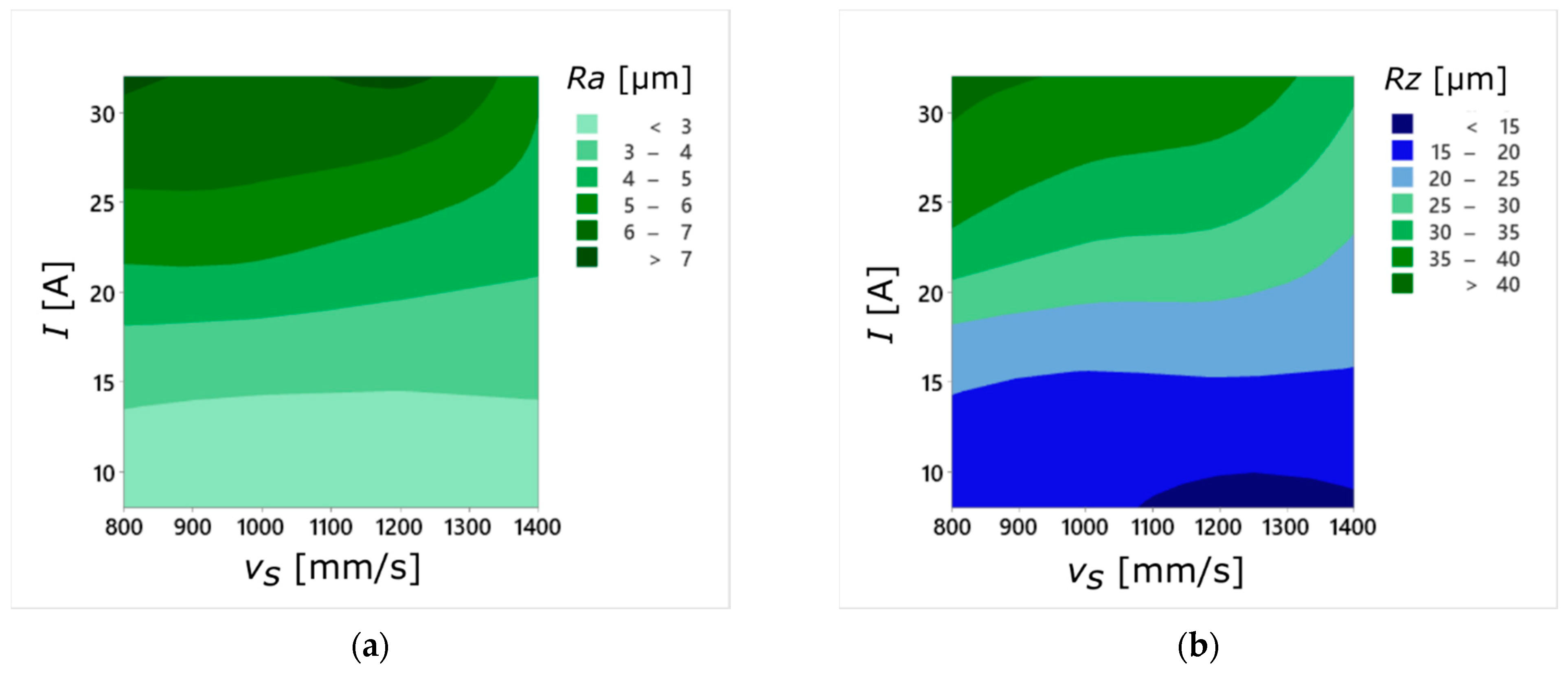

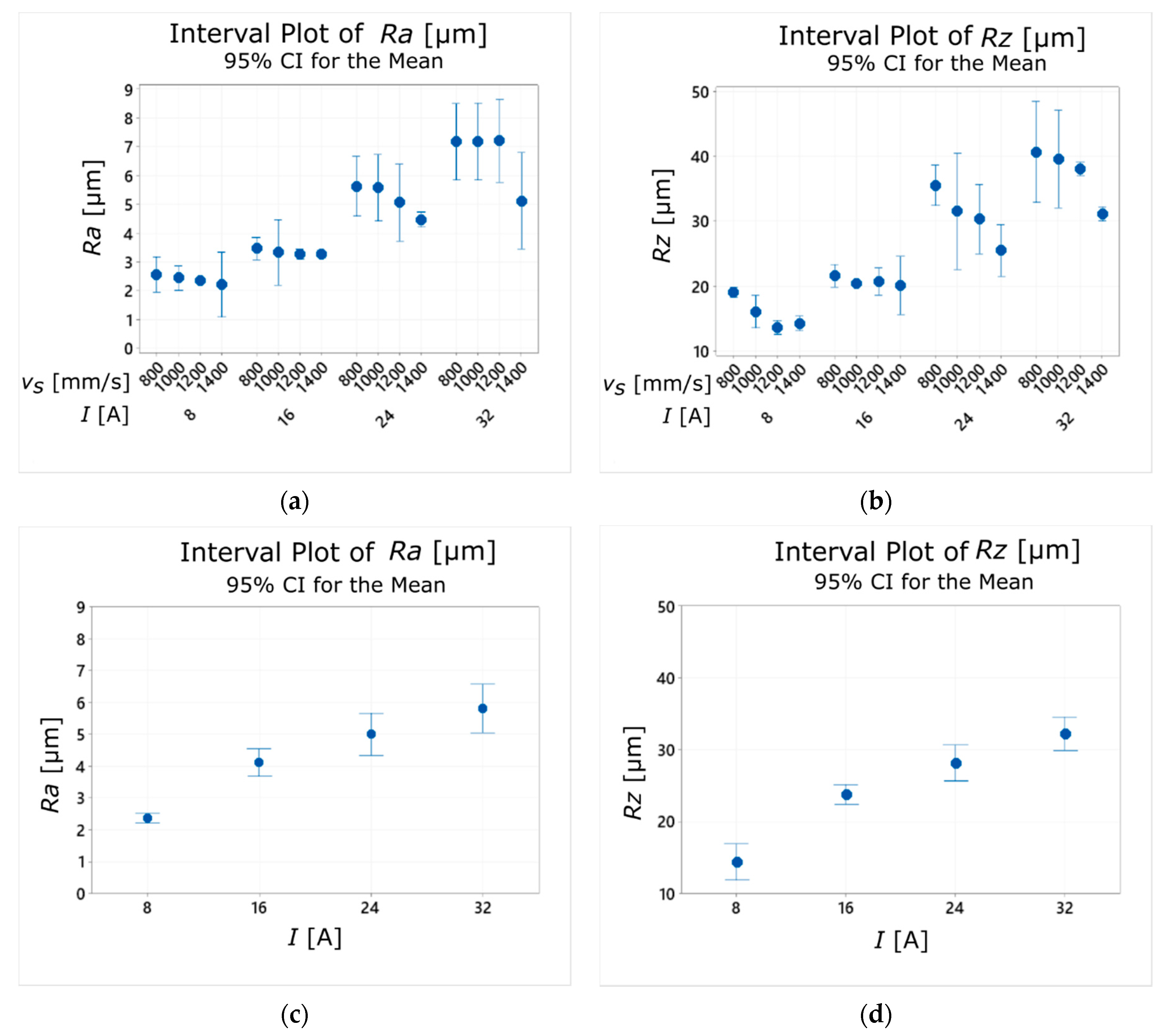

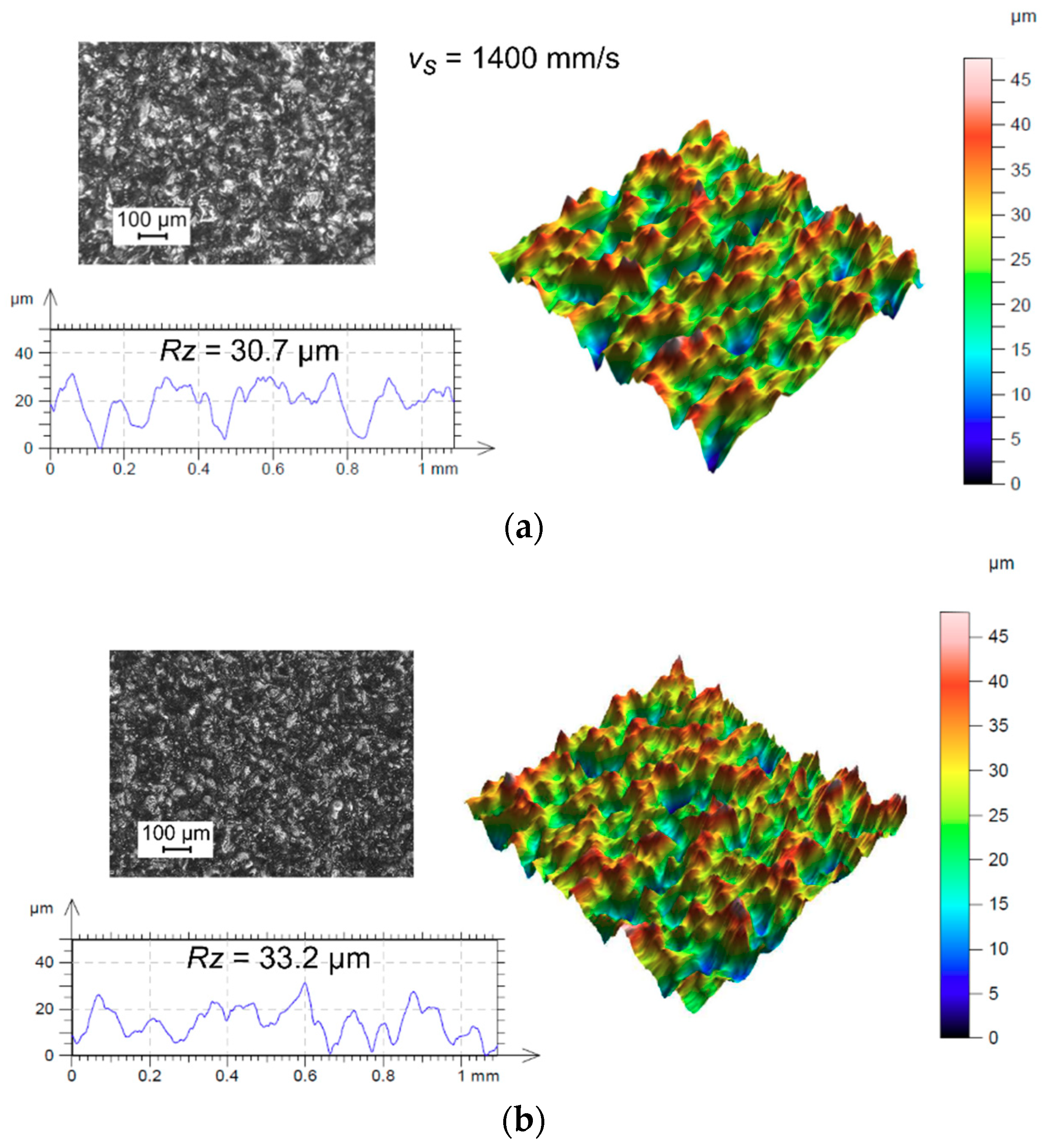

For the sintered samples, regardless of the applied current amplitude, an increase in the vs parameter value resulted in an improvement in the surface roughness parameters (decrease in Ra and Rz parameters values). Moreover, values of these parameters for the sample sintered with vs = 1400 mm/s were, on average, 10% lower than for the cast sample.

- (3)

The conducted research showed that during processing of a workpiece made of AlSi10Mg alloy in the SLM technology with sufficiently high laser scanning speed it was possible, in contrast to the cast sample, to increase the WEDM cutting speed and simultaneously to obtain reduced roughness of the machined surface.

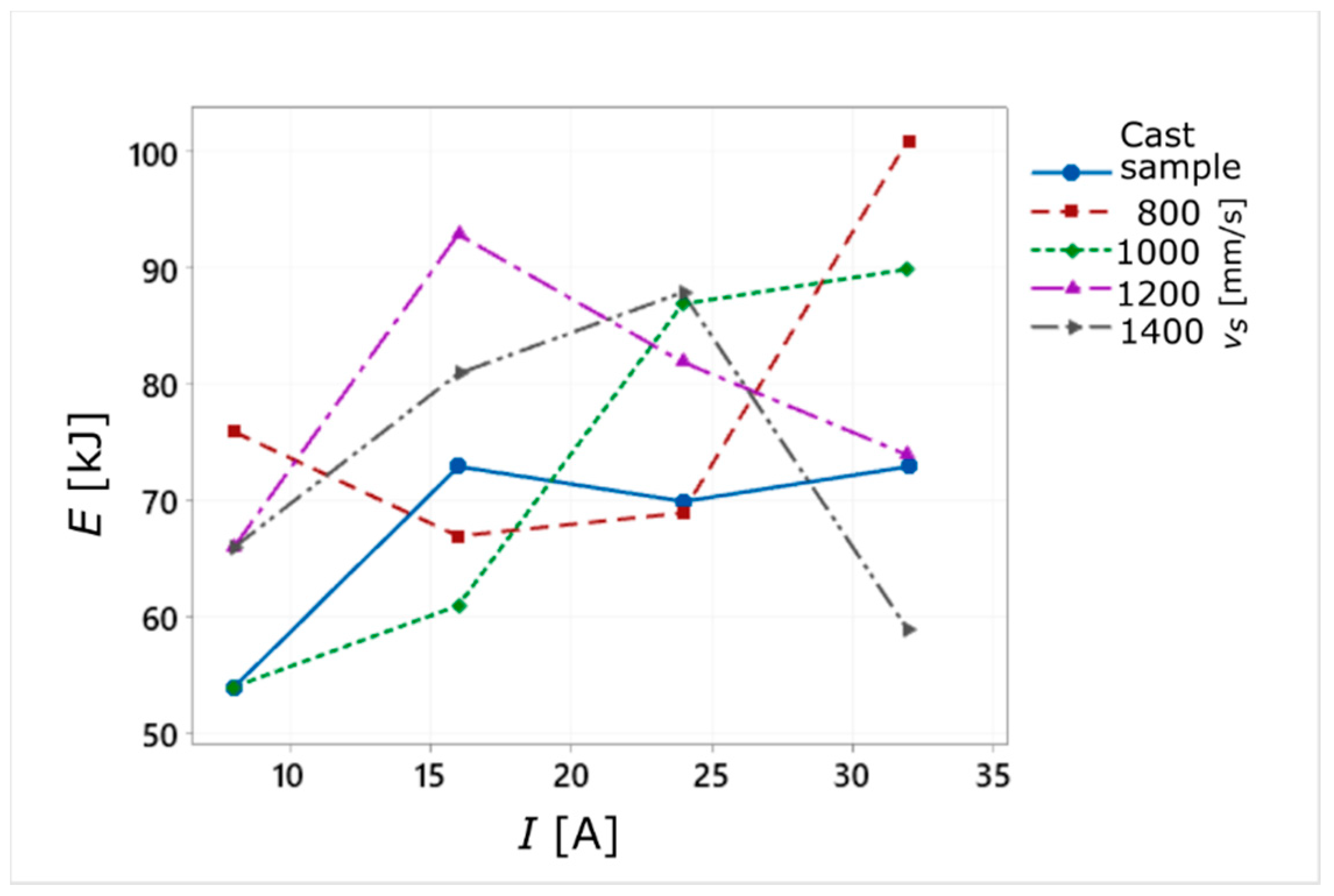

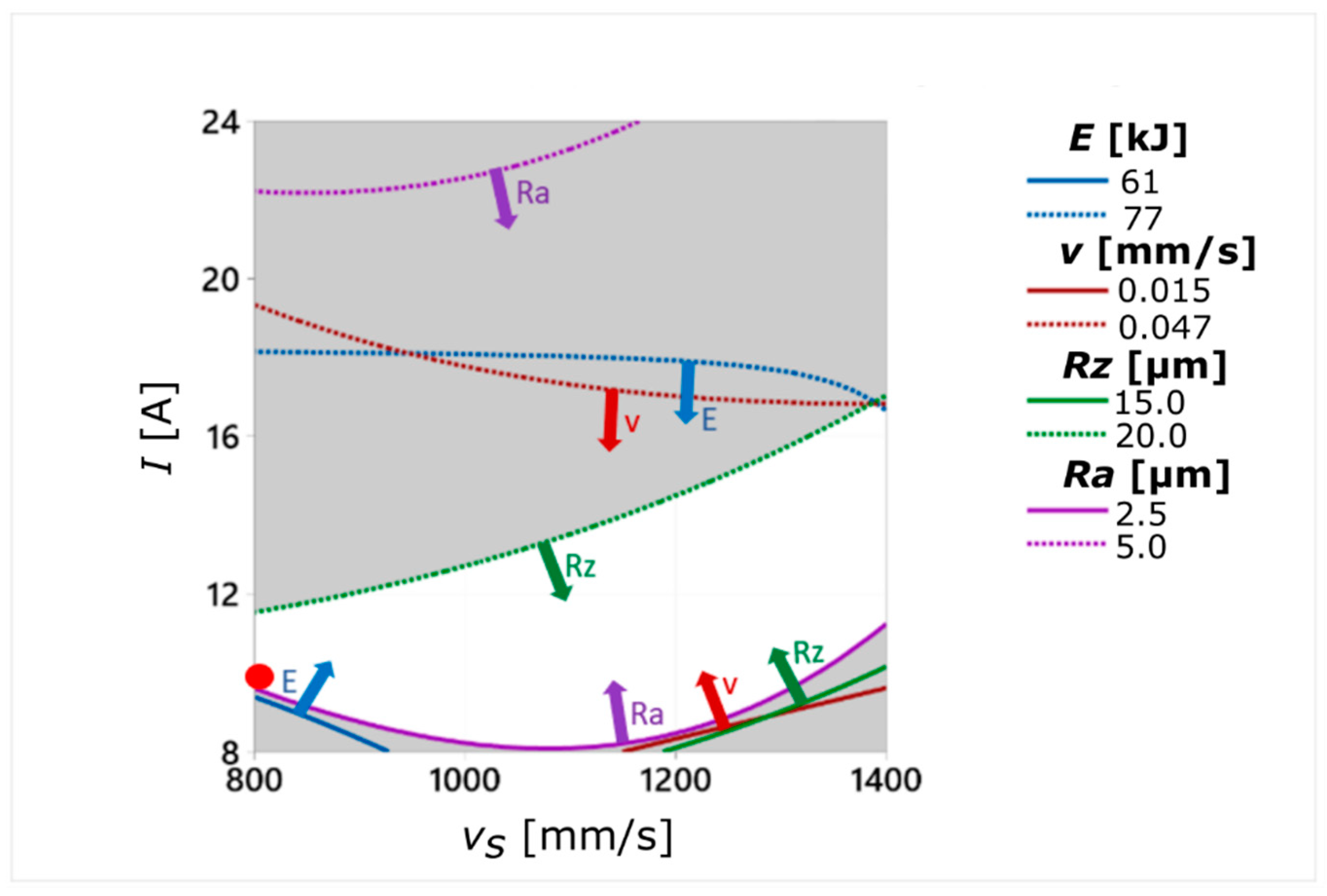

In designing the machining process the goal is often to reduce the surface roughness of the manufactured items (although there are exceptions) and to minimize the amount of energy needed to complete the task. On the other hand, its speed, due to the desired high production efficiency, should be as high as possible. Such differentiated criteria imply the need to optimize the process. In the conducted case study, the ranges of process parameters I and vs needed to produce a sample, the quality of which would correspond to the finishing (Ra = 2.5–5.0 µm; Rz = 15–20 µm), were determined. Then, the multi-criteria optimization process was applied, as a result of which the most favorable parameters of the analyzed processes were selected (I = 9 A, vs = 800 mm/s). For such values of input parameters, the amount of total energy needed to carry out the cutting process was 60 kJ, which was about 60% of the maximum value obtained during the experiment. Due to the relatively low value of the process energy, it was possible to reduce machining costs and to extend the tool electrode life. In this case, the EDM cutting speed reached the value of 0.02 mm/s, which was 1.5 times higher than the lowest value obtained during the experiment.

Further research should focus on determining the impact of other input parameters of the WEDM process (operating voltage, pulse duration and pause time, material of the working electrode) and their interaction with the SLM laser scanning speed on the tested outputs. This would allow for a wider and more accurate study of the machinability of the AlSi10Mg-sintered material regarding WEDM process.