Model-Based Feedforward Control of Part Height in Directed Energy Deposition

Abstract

1. Introduction

2. Dynamic Model on Melt-Pool Height

2.1. Single-Hatch Deposition

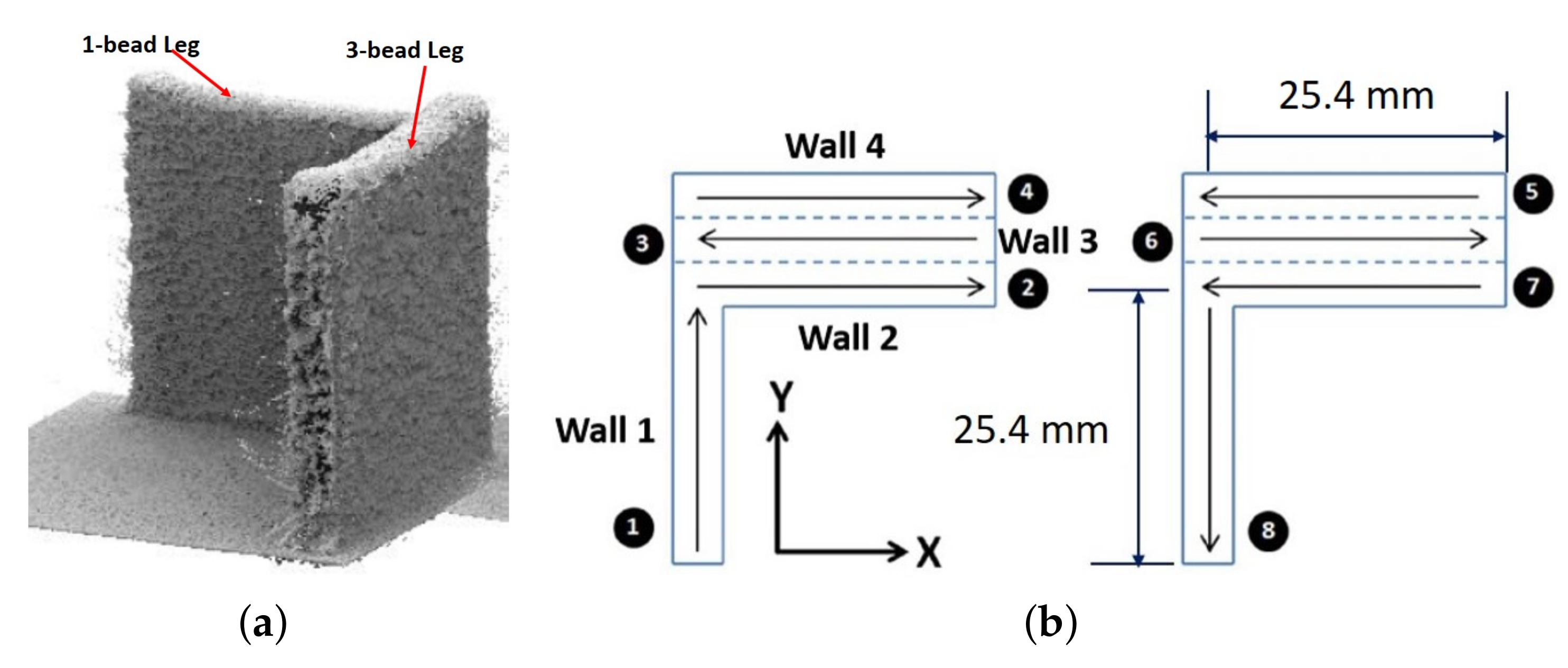

2.2. Multi-Hatch Deposition

2.3. Moving-Source Model in Space Coordinate

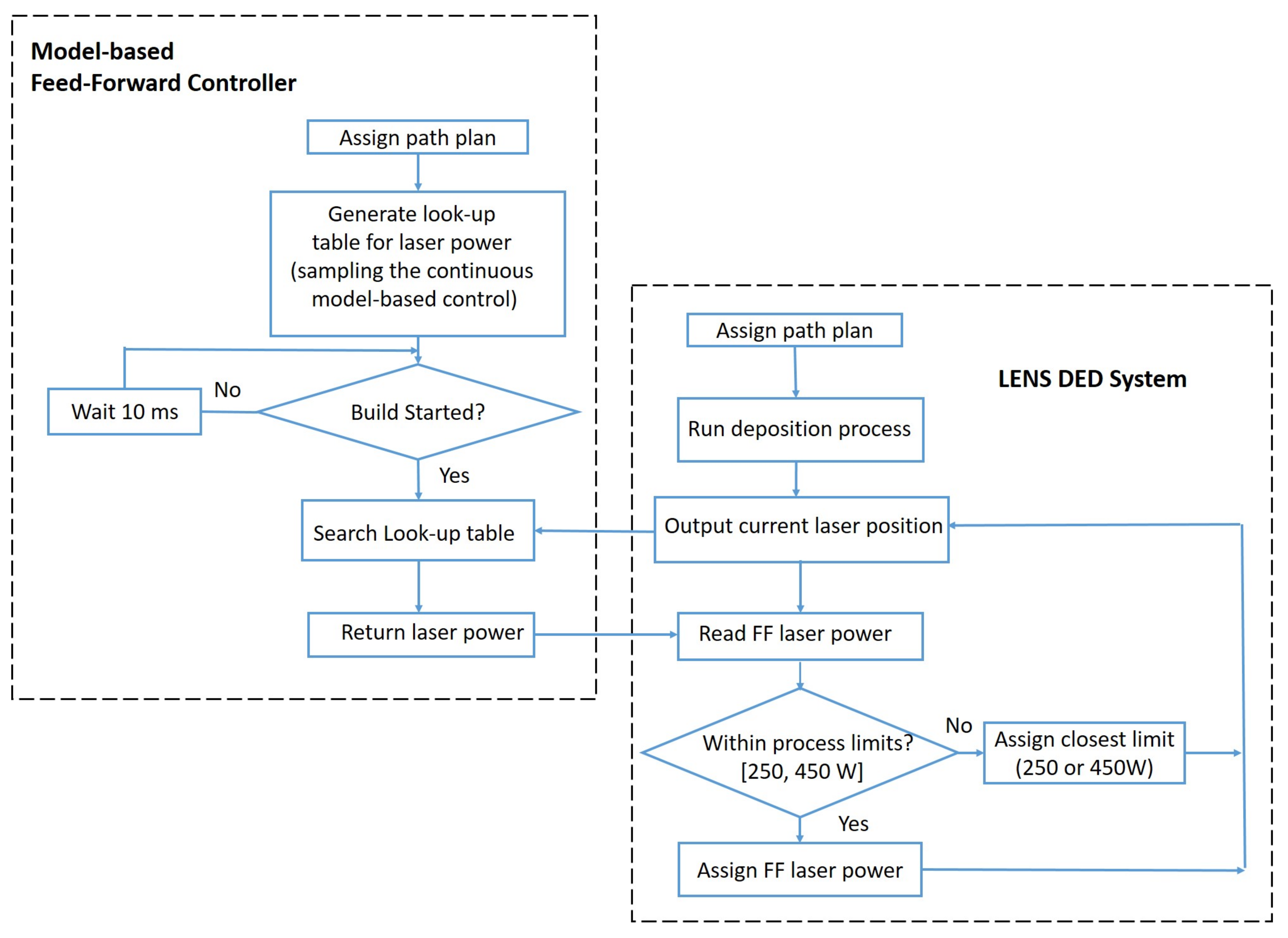

3. Control Design

3.1. Control Problem Formulation

3.2. Control Design for Laser Power in a Hatch-by-Hatch, Layer-by-Layer Manner

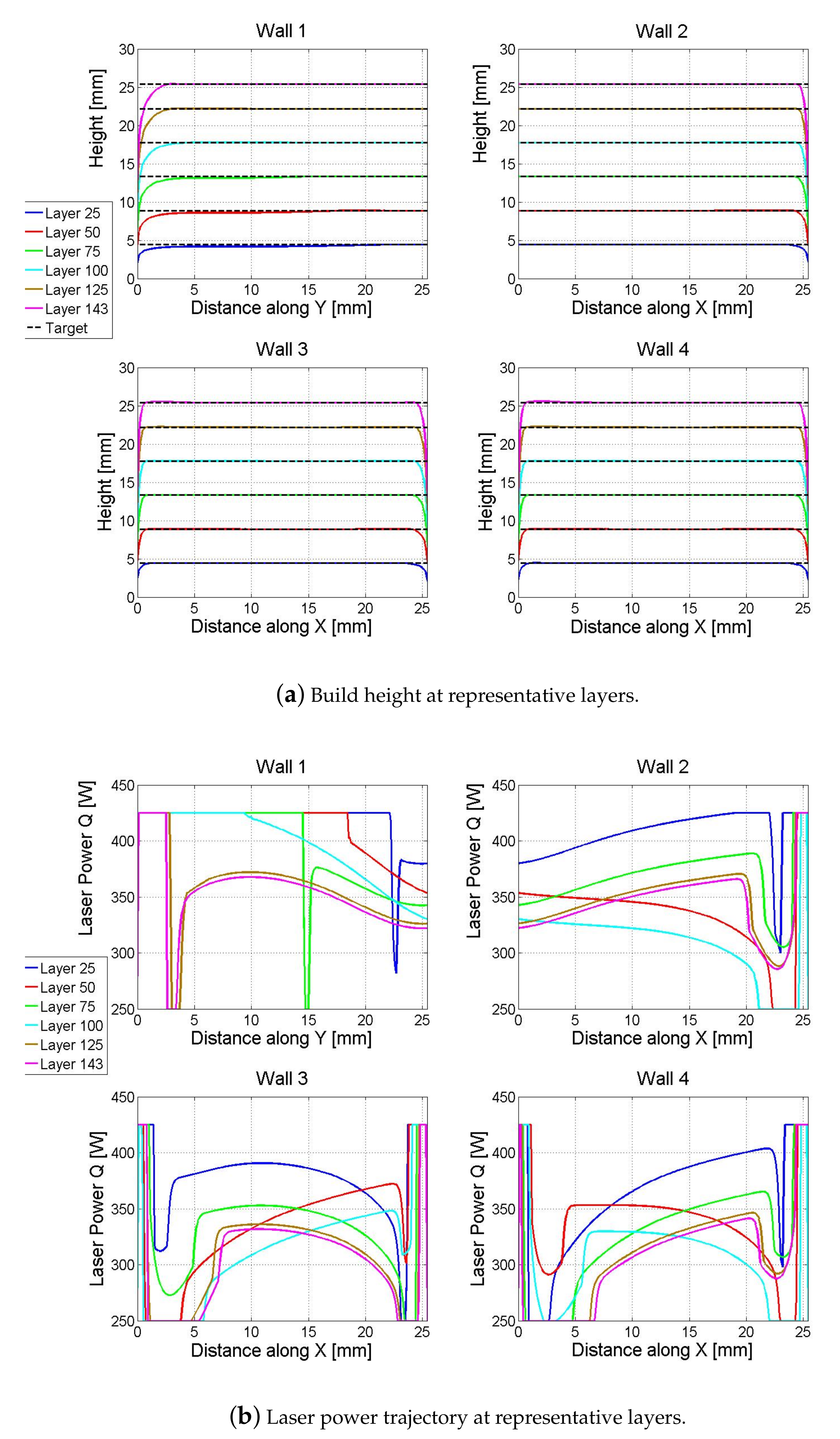

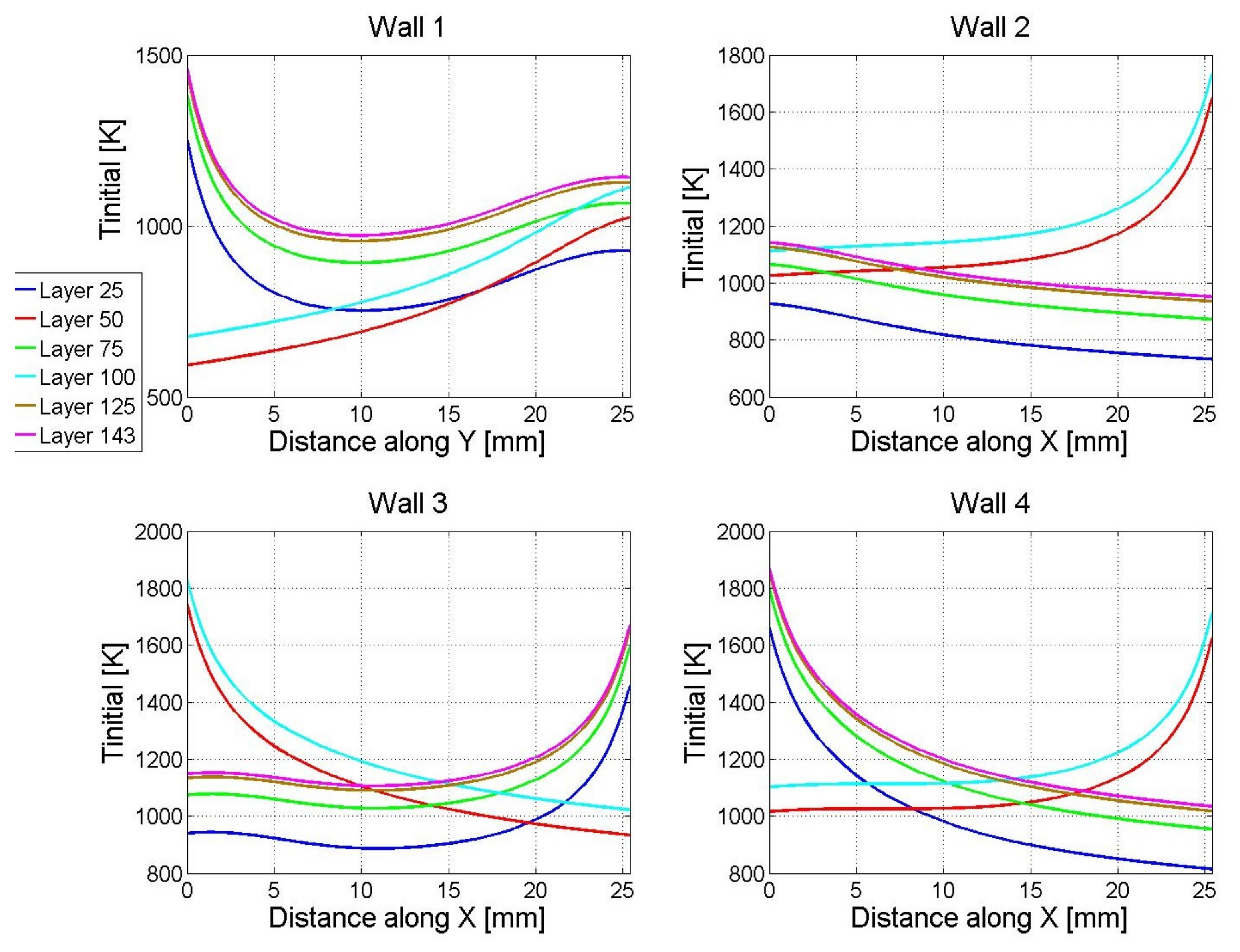

4. Simulation Results

4.1. Open-Loop Simulation for Part Height

4.2. Closed-Loop Simulation under Nonlinear Inverse-Dynamics Control

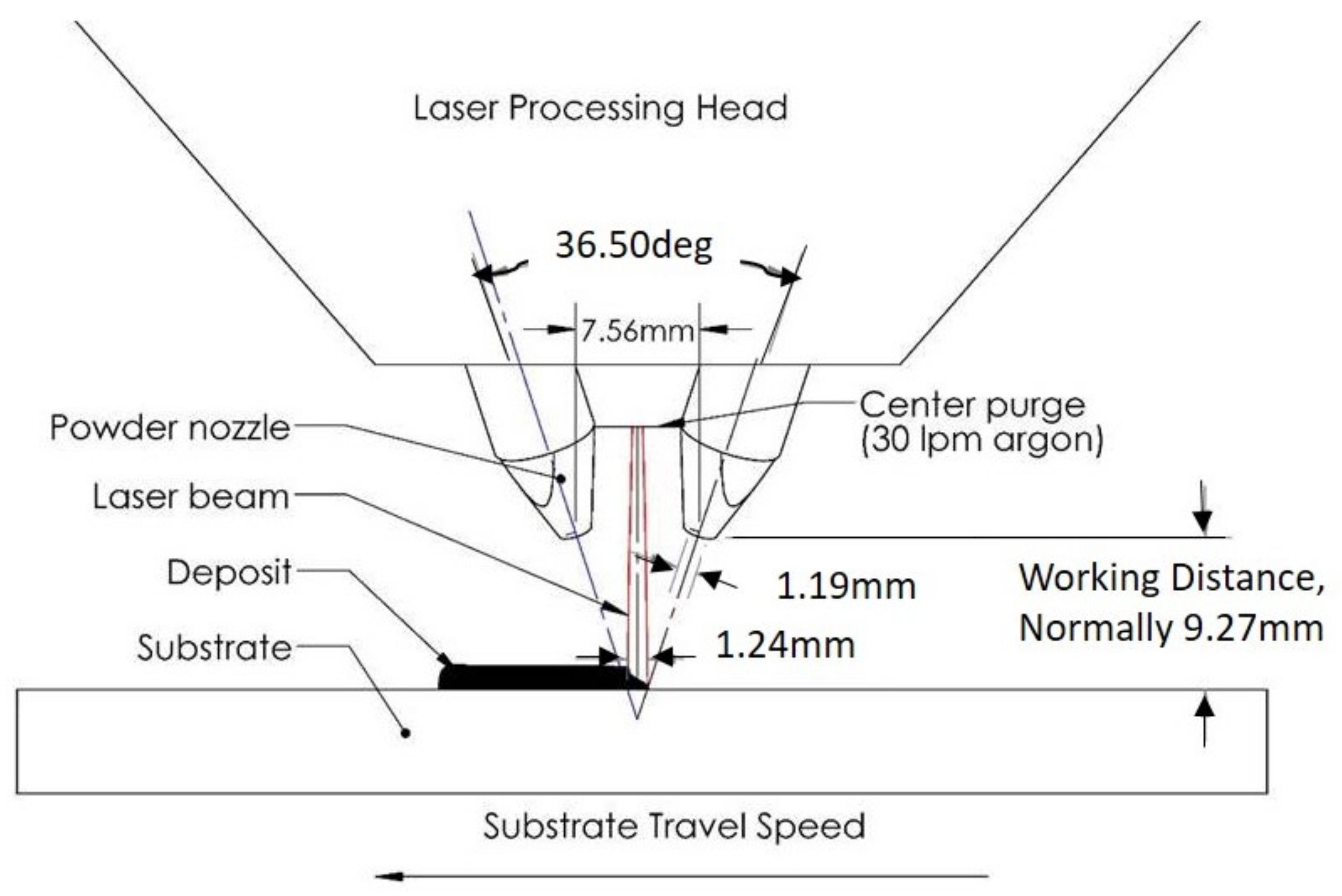

5. Experimental Methods

6. Results of Experimental Evaluation

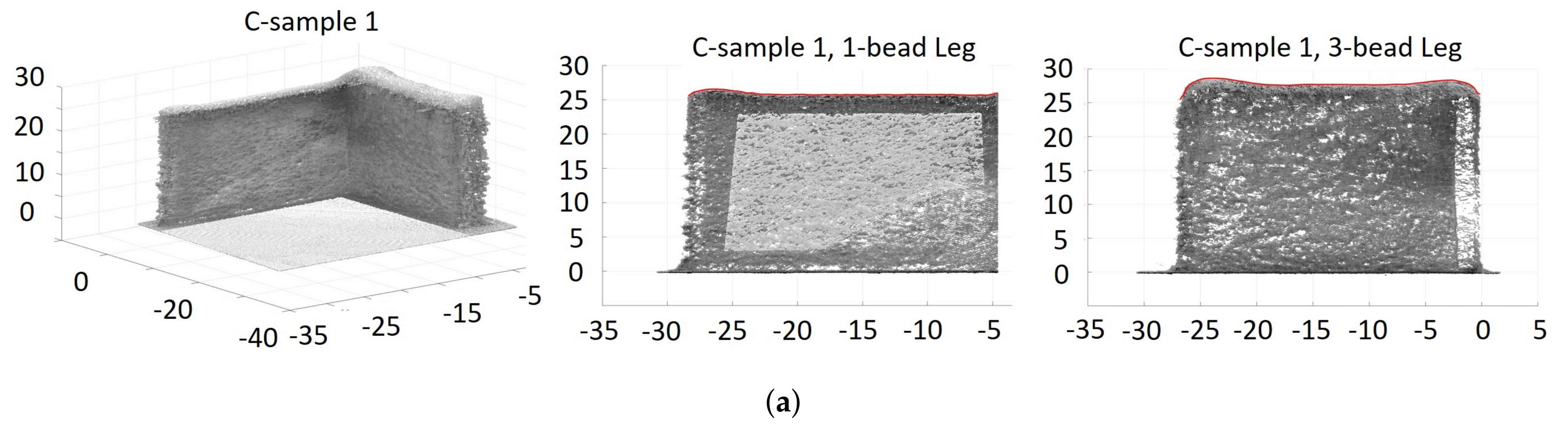

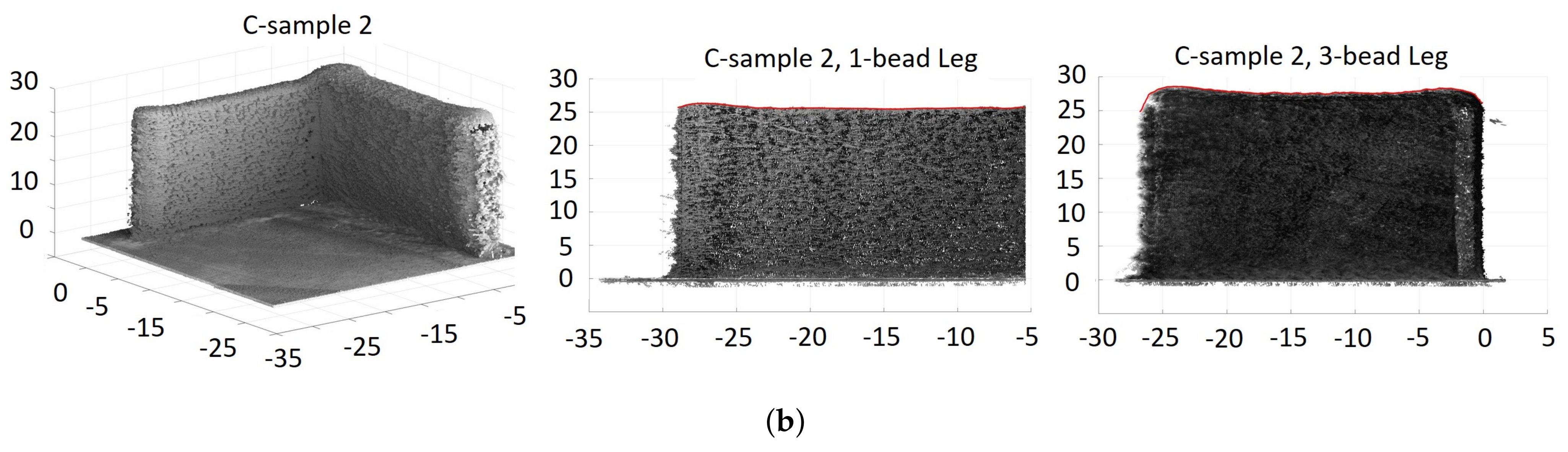

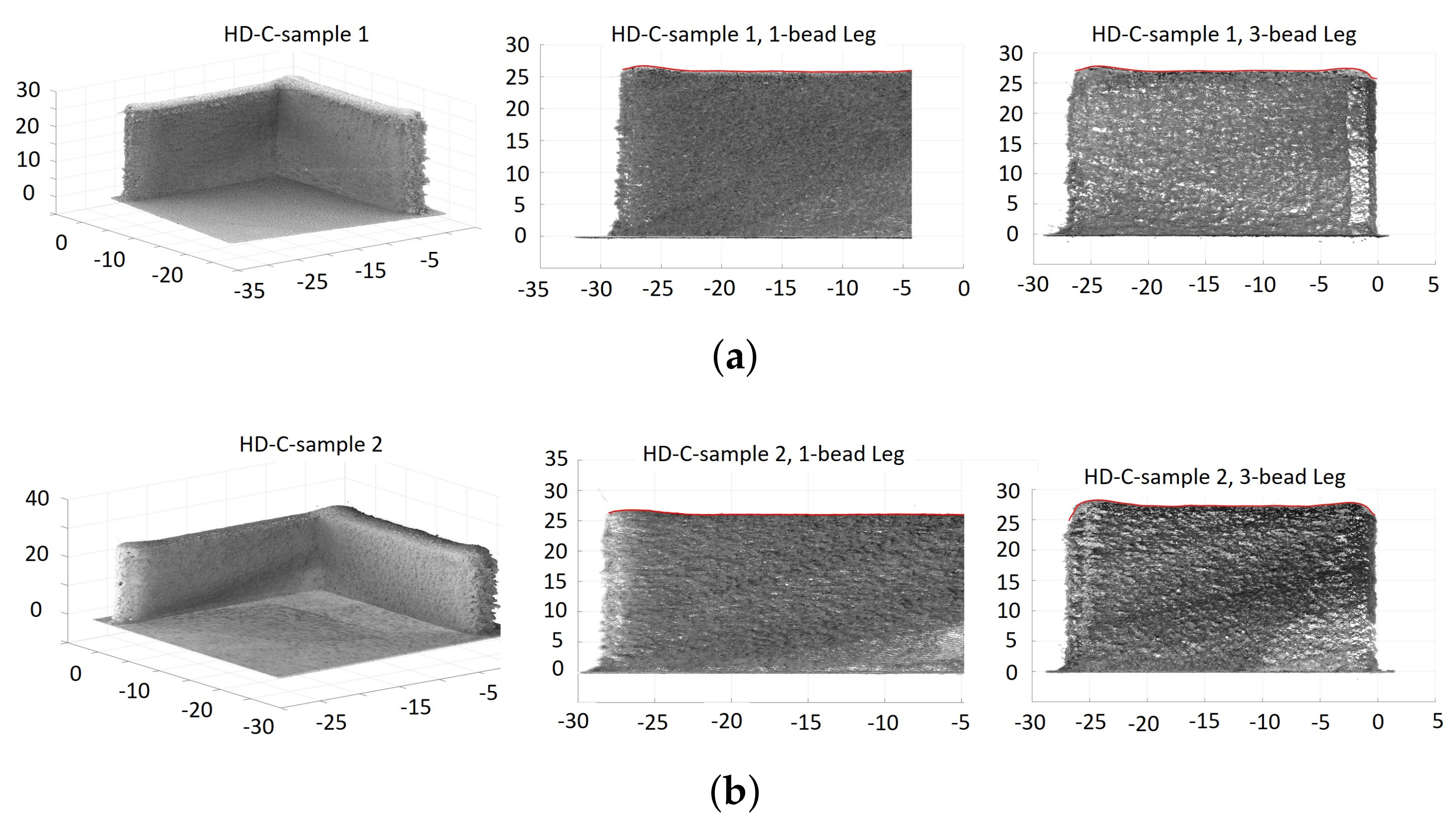

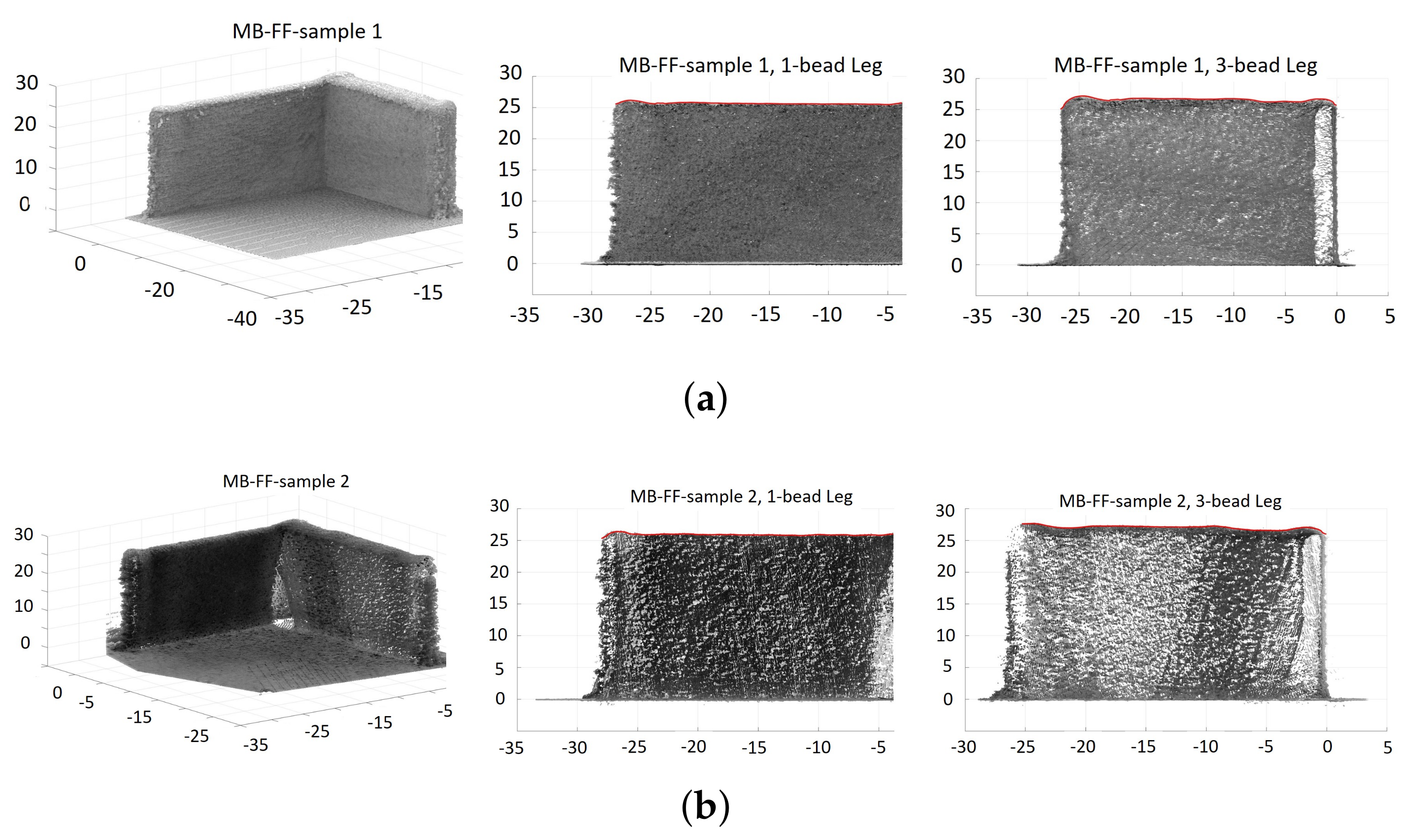

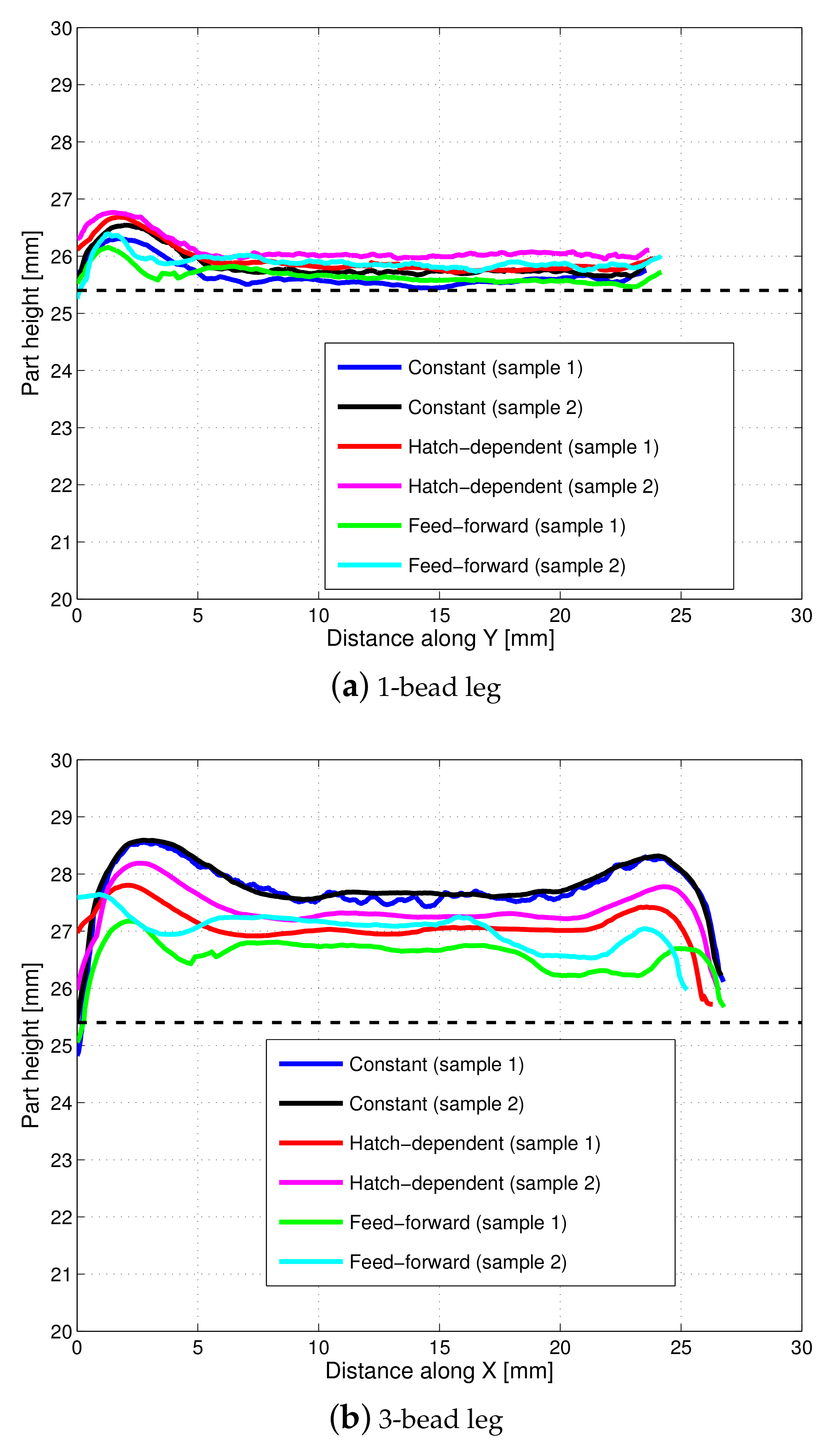

6.1. Measured Height of Experimental Samples

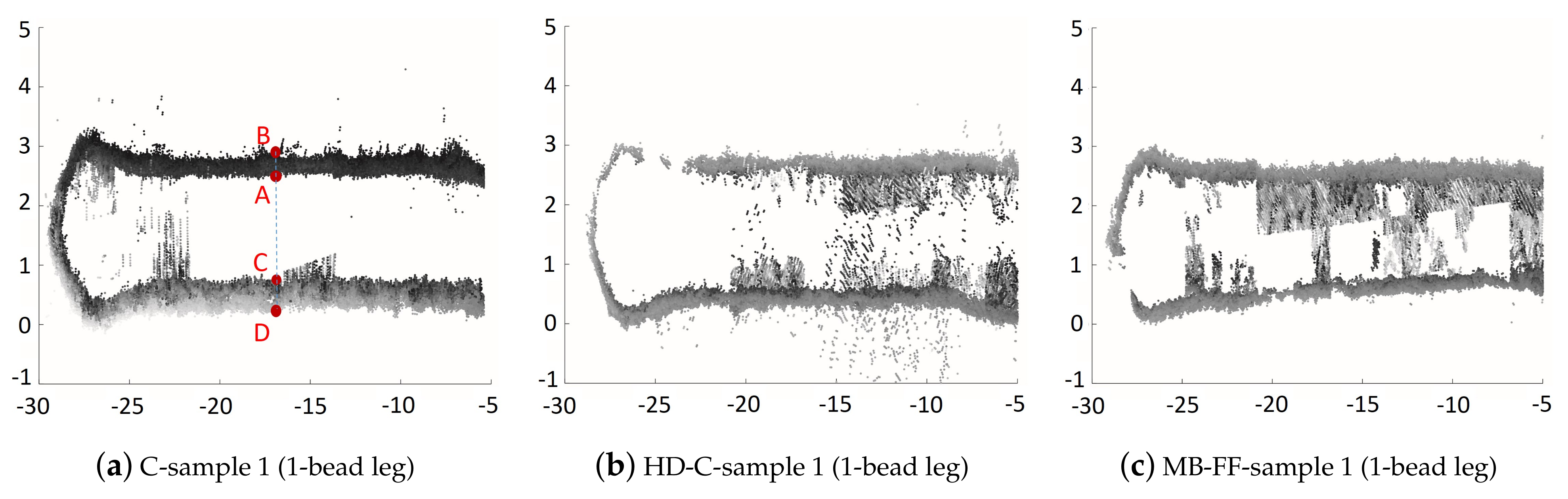

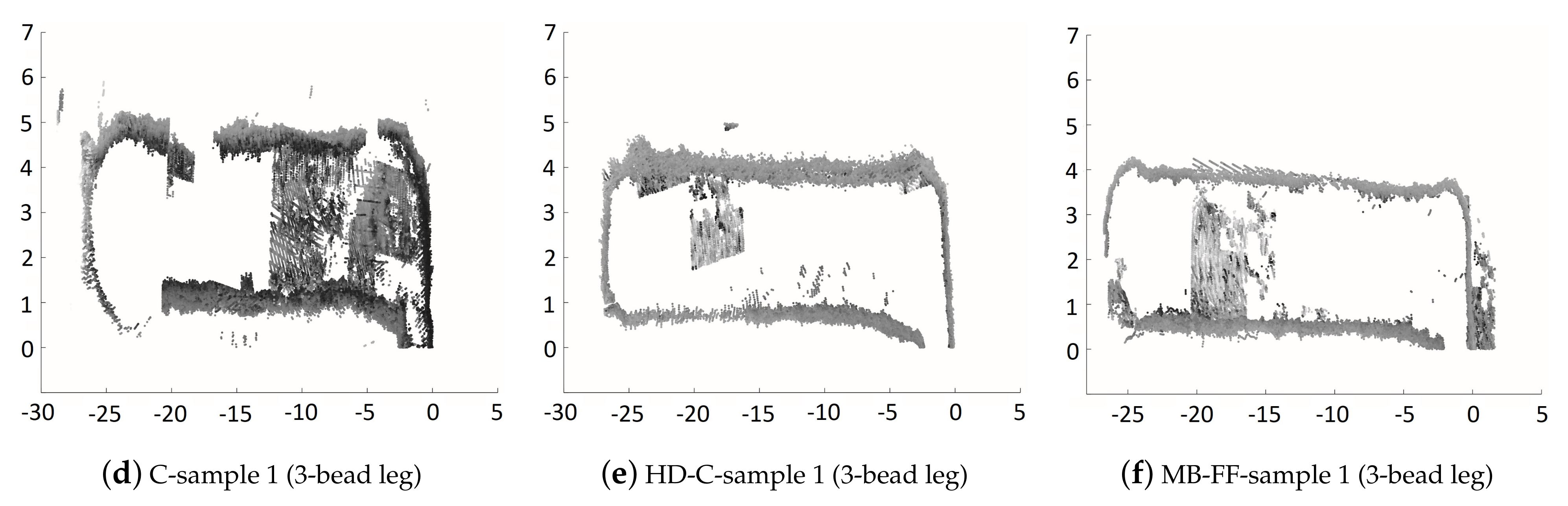

6.2. Model Validation

6.3. Evaluation of the Performance of MB-FF

7. Discussions

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahn, D.-G. Direct metal additive manufacturing processes and their sustainable applications for green technology: A review. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 381–395. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the art in directed energy deposition: From additive manufacturing to materials design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An overview of additive manufacturing of titanium components by directed energy deposition: Microstructure and mechanical properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Mazumder, J.; Dutta, D.; Kikuchi, N.; Ghosh, A. Closed loop direct metal deposition: Art to part. Opt. Lasers Eng. 2000, 34, 397–414. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A. A mechatronics approach to laser powder deposition process. Mechatronics 2006, 16, 631–641. [Google Scholar] [CrossRef]

- Hu, D.; Kovacevic, R. Sensing, modeling and control for laser-based additive manufacturing. Int. J. Mach. Tools Manuf. 2003, 43, 51–60. [Google Scholar] [CrossRef]

- Bi, G.; Schürmann, B.; Gasser, A.; Wissenbach, K.; Poprawe, R. Development and qualification of a novel laser-cladding head with integrated sensors. Int. J. Mach. Tools Manuf. 2007, 47, 555–561. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Mercelis, P.; VanVaerenbergh, J.; Craeghs, T. Feedback control of selective laser melting. In Proceedings of the 3rd International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 24–29 September 2007; pp. 521–527. [Google Scholar]

- Fathi, A.; Khajepour, A.; Toyserkani, E.; Durali, M. Clad height control in laser solid freeform fabrication using a feedforward PID controller. Int. J. Adv. Manuf. Technol. 2007, 35, 280–292. [Google Scholar] [CrossRef]

- Ding, Y.; Warton, J.; Kovacevic, R. Development of sensing and control system for robotized laser-based direct metal addition system. Addit. Manuf. 2016, 10, 24–35. [Google Scholar] [CrossRef]

- Akbari, M.; Kovacevic, R. Closed loop control of melt pool width in robotized laser powder—Directed energy deposition process. Int. J. Adv. Manuf. Technol. 2019, 104, 2887–2898. [Google Scholar] [CrossRef]

- Hua, Y.; Choi, J. Feedback control effects on dimensions and defects of H13 tool steel by direct metal deposition process. J. Laser Appl. 2005, 17, 118–126. [Google Scholar] [CrossRef]

- Fathi, A.; Khajepour, A.; Durali, M.; Toyserkani, E. Geometry Control of the Deposited Layer in a Nonplanar Laser Cladding Process Using a Variable Structure Controller. J. Manuf. Sci. Eng. 2008, 130, 031003. [Google Scholar] [CrossRef]

- Song, L.; Mazumder, J. Feedback control of melt pool temperature during laser cladding process. IEEE Trans. Control Syst. Technol. 2011, 19, 1349–1356. [Google Scholar] [CrossRef]

- Song, L.; Bagavath-Singh, V.; Dutta, B.; Mazumder, J. Control of melt pool temperature and deposition height during direct metal deposition process. Int. J. Adv. Manuf. Technol. 2012, 58, 247–256. [Google Scholar] [CrossRef]

- Wang, Q.; Li, J.; Gouge, M.; Nassar, A.R.; Michaleris, P.; Reutzel, E.W. Physics-based multivariable modeling and feedback linearization control of melt-pool geometry and temperature in Directed Energy Deposition. J. Manuf. Sci. Eng. 2017, 139, 021013. [Google Scholar] [CrossRef]

- Tang, L.; Landers, R.G. Layer-to-layer height control for laser metal deposition process (iterative learning control). J. Manuf. Sci. Eng. 2011, 133, 021009. [Google Scholar] [CrossRef]

- Sammons, P.M.; Bristow, D.A.; Landers, R. Height dependent laser metal deposition process modeling. J. Manuf. Sci. Eng. 2013, 135, 054501. [Google Scholar] [CrossRef]

- Tang, L.; Landers, R. Melt pool temperature control for laser metal deposition processes-part ii: Layer-to-layer temperature control. J. Manuf. Sci. Eng. 2010, 132, 011011. [Google Scholar] [CrossRef]

- Heralić, A.; Christiansson, A.-K.; Lennartson, B. Height control of laser metal-wire deposition based on iterative learning control and 3D scanning. Opt. Lasers Eng. 2012, 50, 1230–1241. [Google Scholar] [CrossRef]

- Lhachemi, H.; Malik, A.; Shorten, R. Augmented reality, cyber-physical systems, and feedback control for additive manufacturing: A review. IEEE Access 2019, 7, 50119–50135. [Google Scholar] [CrossRef]

- Tang, Z.-J.; Liu, W.-W.; Wang, Y.-W.; Saleheen, K.M.; Liu, Z.-C.; Peng, S.-T.; Zhang, Z.; Zhang, H.-C. A review on in situ monitoring technology for directed energy deposition of metals. Int. J. Adv. Manuf. Technol. 2020, 1–27. [Google Scholar] [CrossRef]

- Haley, J.; Schoenung, J.M.; Lavernia, E.J. Observations of particle-melt pool impact events in directed energy deposition. Addit. Manuf. 2018, 22, 368–374. [Google Scholar] [CrossRef]

- Kledwig, C.; Perfahl, H.; Reisacher, M.; Brueckner, F.; Bliedtner, J.; Leyens, C. Analysis of melt pool characteristics and process parameters using a coaxial monitoring system during directed energy deposition in additive manufacturing. Materials 2019, 12, 308. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Prabhu, V. Simulation modeling for optimal control of additive manufacturing processes. Addit. Manuf. 2016, 12, 197–203. [Google Scholar] [CrossRef]

- Yeung, H.; Lane, B.; Fox, J. Part geometry and conduction-based laser power control for powder bed fusion additive manufacturing. Addit. Manuf. 2019, 30, 100844. [Google Scholar] [CrossRef]

- Wang, Q.; Michaleris, P.; Nassar, A.R.; Irwin, J.E.; Ren, Y.; Stutzman, C.B. Model-based feedforward control of laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 31, 100985. [Google Scholar] [CrossRef]

- Druzgalski, C.; Ashby, A.; Guss, G.; King, W.; Roehling, T.; Matthews, M. Process optimization of complex geometries using feed forward control for laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 34, 101169. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Stavropoulos, P.; Stavridis, J. Adaptive control of thermal processes: Laser welding and additive manufacturing paradigms. Procedia CIRP 2018, 67, 233–237. [Google Scholar] [CrossRef]

- Li, J.; Wang, Q.; Michaleris, P.; Reutzel, E.W.; Nassar, A.R. An extended lumped-parameter model of melt–pool geometry to predict part height for directed energy deposition. J. Manuf. Sci. Eng. 2017, 139, 091016. [Google Scholar] [CrossRef]

- Kriczky, D.A.; Irwin, J.; Reutzel, E.W.; Michaleris, P.; Nassar, A.R.; Craig, J. 3D spatial reconstruction of thermal characteristics in directed energy deposition through optical thermal imaging. J. Mater. Process. Technol. 2015, 221, 172–186. [Google Scholar] [CrossRef]

- Loughnane, G.T.; Kuntz, S.L.; Klingbeil, N.; Sosa, J.M.; Irwin, J.; Nassar, A.R.; Reutzel, E.W. Application of a microstructural characterization uncertainty quantification framework to widmanstätten alpha-Laths in additive manufactured Ti-6Al-4v. In Proceedings of the 25th International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014; pp. 647–663. [Google Scholar]

- Wang, Q.; Li, J.; Nassar, A.R.; Reutzel, E.W.; Mitchell, W. Build height control in directed energy deposition using a model-based feed-forward controller. In Proceedings of the ASME Dynamic Systems and Control Conference, Atlanta, GA, USA, 30 September–3 October 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018. [Google Scholar]

- Rosenthal, D. The theory of moving sources of heat and its application to metal treatments. Trans. ASME 1946, 68, 849–866. [Google Scholar]

- Nenadl, O.; Kuipers, W.; Koelewijn, N.; Ocelík, V.; DeHosson, J.T.M. A versatile model for the prediction of complex geometry in 3D direct laser deposition. Surf. Coat. Technol. 2016, 307, 292–300. [Google Scholar] [CrossRef]

- FARO. Laser Trackers: Defining Accuracy; FARO: Lake Mary, FL, USA, 2017. [Google Scholar]

- Nassar, A.R.; Reutzel, E.W. Additive manufacturing of ti-6al-4v using a pulsed aser beam. Metall. Mater. Trans. A 2015, 46, 2781–2789. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Density (kg/m) | 4430 | |

| Melting temperature (K) | 1923 | |

| Ambient temperature (K) | 292 | |

| Molten material specific heat (J/kg K) | 700 | |

| Thermal conductivity constant (W/m K) | k | 6.7 |

| Thermal diffusivity (m/s) | a | |

| Laser transmission efficiency | 0.4 | |

| Laser scan speed (mm/s) | v | 10.58 |

| Powder flow rate (kg/s) | f | |

| Hatch spacing (mm) | 0.8128 | |

| Inter-hatch dwell (s) | 0.097 | |

| Inter-layer dwell (s) | 0.5 | |

| Length of each hatch (mm) | L | 25.4 |

| Melt-pool height-to-width ratio | 0.13 | |

| Critical laser power (W) | 111.72 | |

| Coefficient | 0.3026 | |

| Target build height (mm) | 25.4 | |

| Number of layers | N | 143 |

| Proportional control gain | 5000 |

| Laser-Power Applied | Height of 1-Bead Leg | Height of 3-Bead Leg |

|---|---|---|

| (1-Bead-Leg/3-Bead-Leg) | (mm) | (mm) |

| 350 W/350 W | 22.2 ± 1.3 | 24.4 ± 1.3 |

| 450 W/450 W | 28.3 ± 2.0 | 32.7 ± 1.7 |

| 450 W/350 W | 26.9 ± 1.4 | 24.9 ± 1.4 |

| Laser-Power Strategy | C | HD-C | MB-FF | ||||

|---|---|---|---|---|---|---|---|

| Sample No. | s1 | s2 | s1 | s2 | s1 | s2 | |

| 1-bead leg | height (mm) | 25.72 | 25.86 | 25.96 | 26.13 | 25.68 | 25.90 |

| (±0.26) | (±0.26) | (±0.27) | (±0.23) | (±0.15) | (±0.13) | ||

| e(%) | 1.26 | 1.83 | 2.19 | 2.86 | 1.08 | 1.95 | |

| RMSE (mm) | 0.4109 | 0.5308 | 0.6126 | 0.7606 | 0.3115 | 0.5130 | |

| 3-bead leg | height (mm) | 27.76 | 27.79 | 27.07 | 27.35 | 26.57 | 26.99 |

| (±0.55) | (±0.47) | (±0.37) | (±0.40) | (±0.33) | (±0.31) | ||

| e(%) | 9.27 | 9.42 | 6.57 | 7.67 | 4.59 | 6.25 | |

| RMSE (mm) | 2.4184 | 2.4388 | 1.7081 | 1.9871 | 1.2129 | 1.6185 | |

| Laser Power | Sample No. | Range of Width of 1-Bead Leg | Range of Width of 3-Bead Leg |

|---|---|---|---|

| 450 W/450 W | C sample 1 | (1.71, 2.68) (mm) | (2.94, 4.09) (mm) |

| 450 W/350 W | HD-C sample 1 | (1.73, 2.62) (mm) | (2.65, 3.60) (mm) |

| MB-FF | MB-FF sample 1 | (1.53, 2.18) (mm) | (2.96, 3.57) (mm) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Li, J.; Nassar, A.R.; Reutzel, E.W.; Mitchell, W.F. Model-Based Feedforward Control of Part Height in Directed Energy Deposition. Materials 2021, 14, 337. https://doi.org/10.3390/ma14020337

Wang Q, Li J, Nassar AR, Reutzel EW, Mitchell WF. Model-Based Feedforward Control of Part Height in Directed Energy Deposition. Materials. 2021; 14(2):337. https://doi.org/10.3390/ma14020337

Chicago/Turabian StyleWang, Qian, Jianyi Li, Abdalla R. Nassar, Edward W. Reutzel, and Wesley F. Mitchell. 2021. "Model-Based Feedforward Control of Part Height in Directed Energy Deposition" Materials 14, no. 2: 337. https://doi.org/10.3390/ma14020337

APA StyleWang, Q., Li, J., Nassar, A. R., Reutzel, E. W., & Mitchell, W. F. (2021). Model-Based Feedforward Control of Part Height in Directed Energy Deposition. Materials, 14(2), 337. https://doi.org/10.3390/ma14020337