Influence of the Structure of Lattice Beams on Their Strength Properties

Abstract

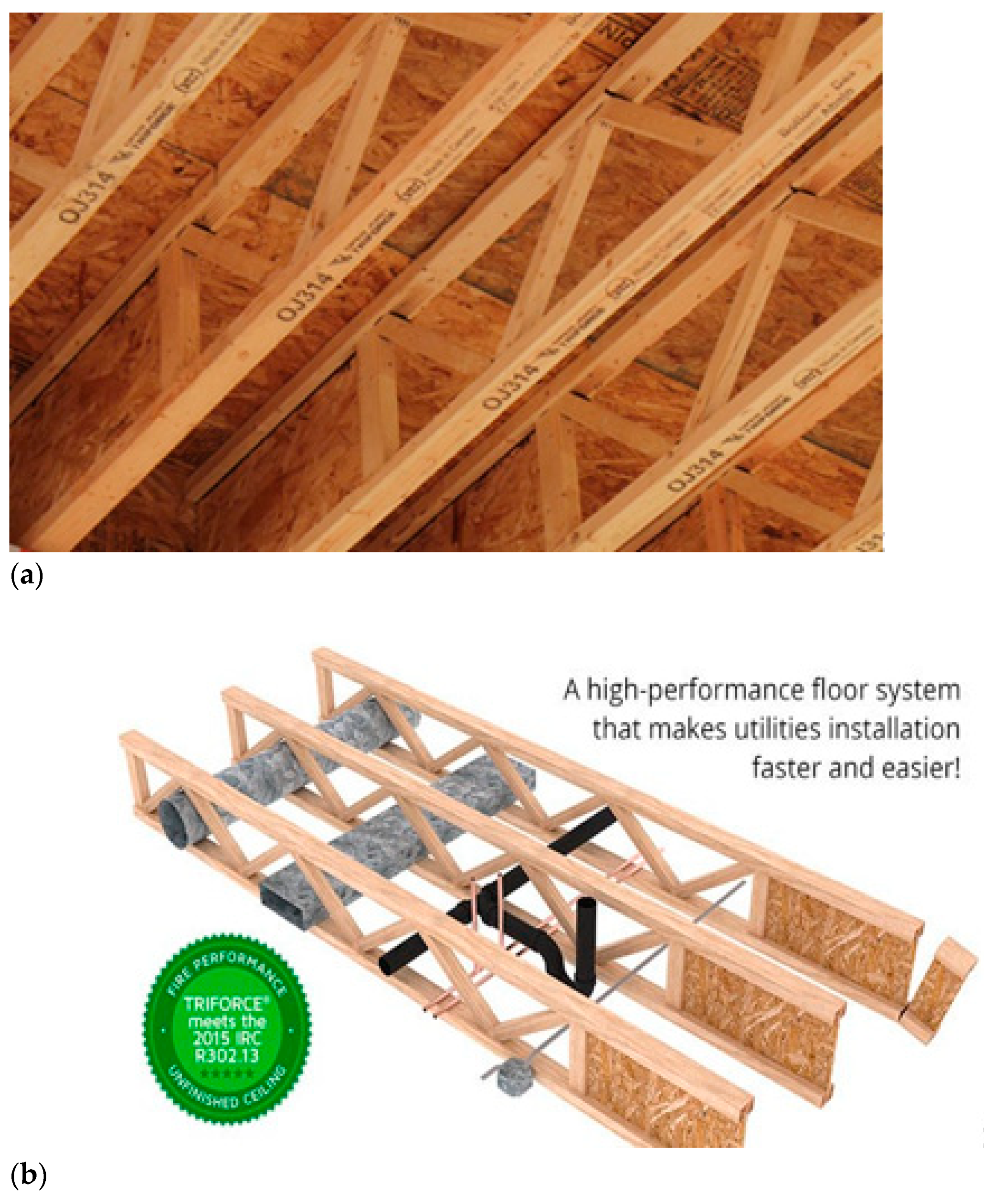

1. Introduction

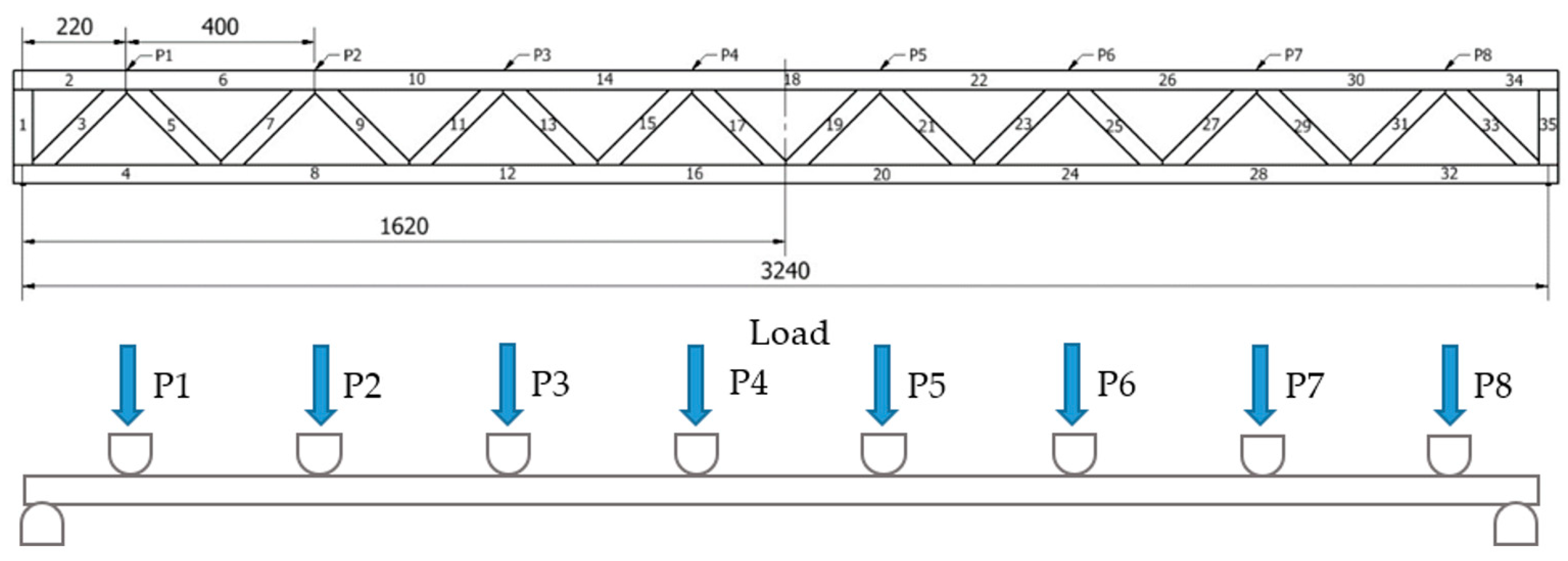

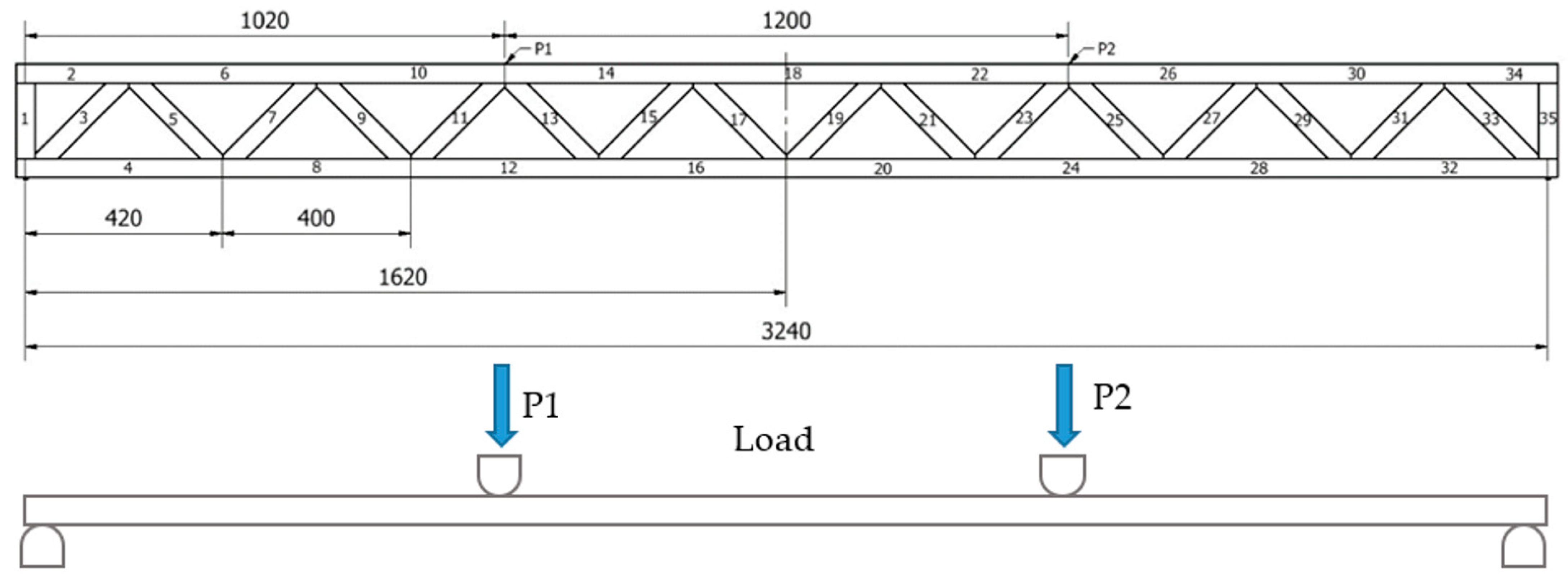

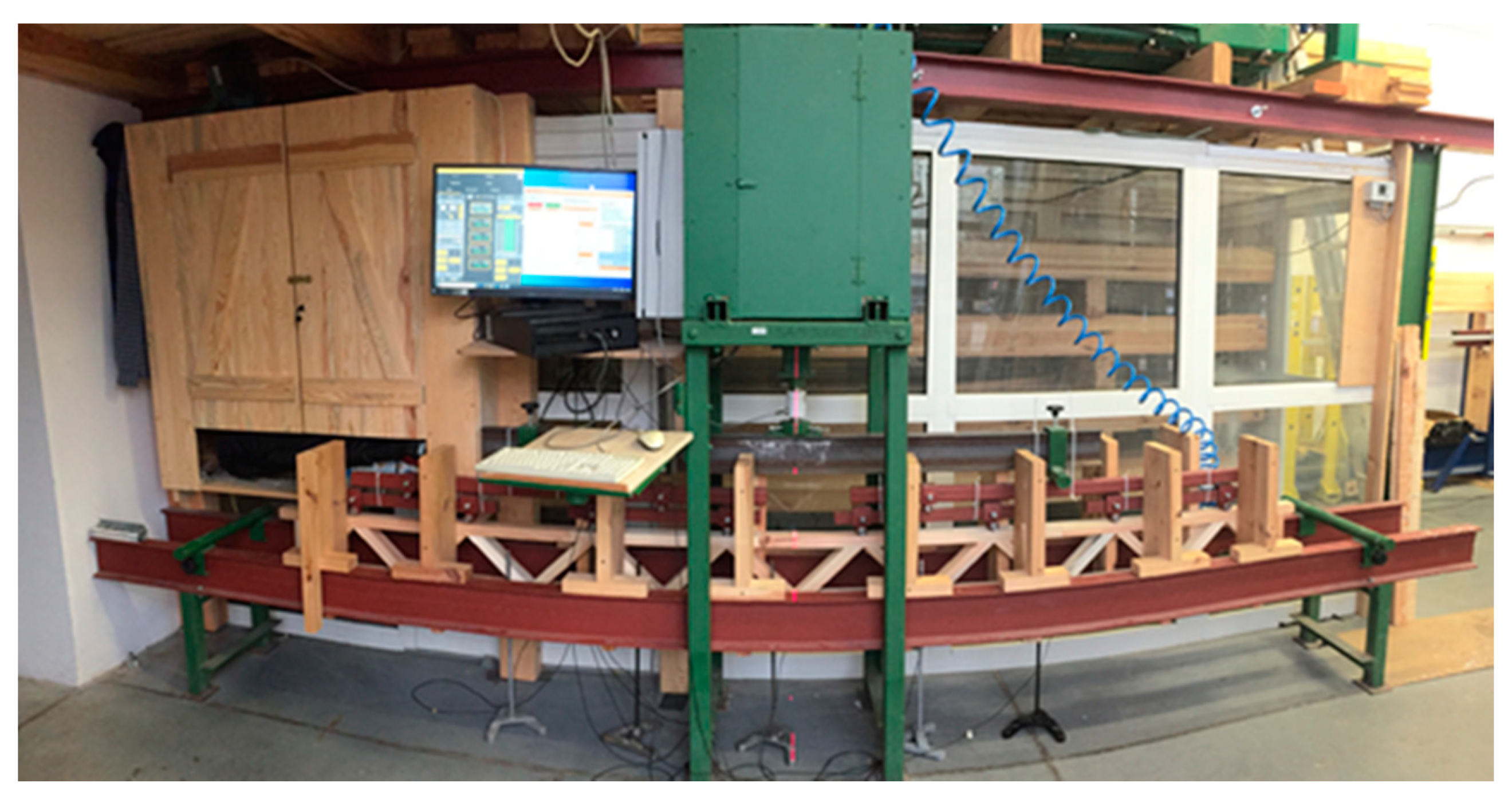

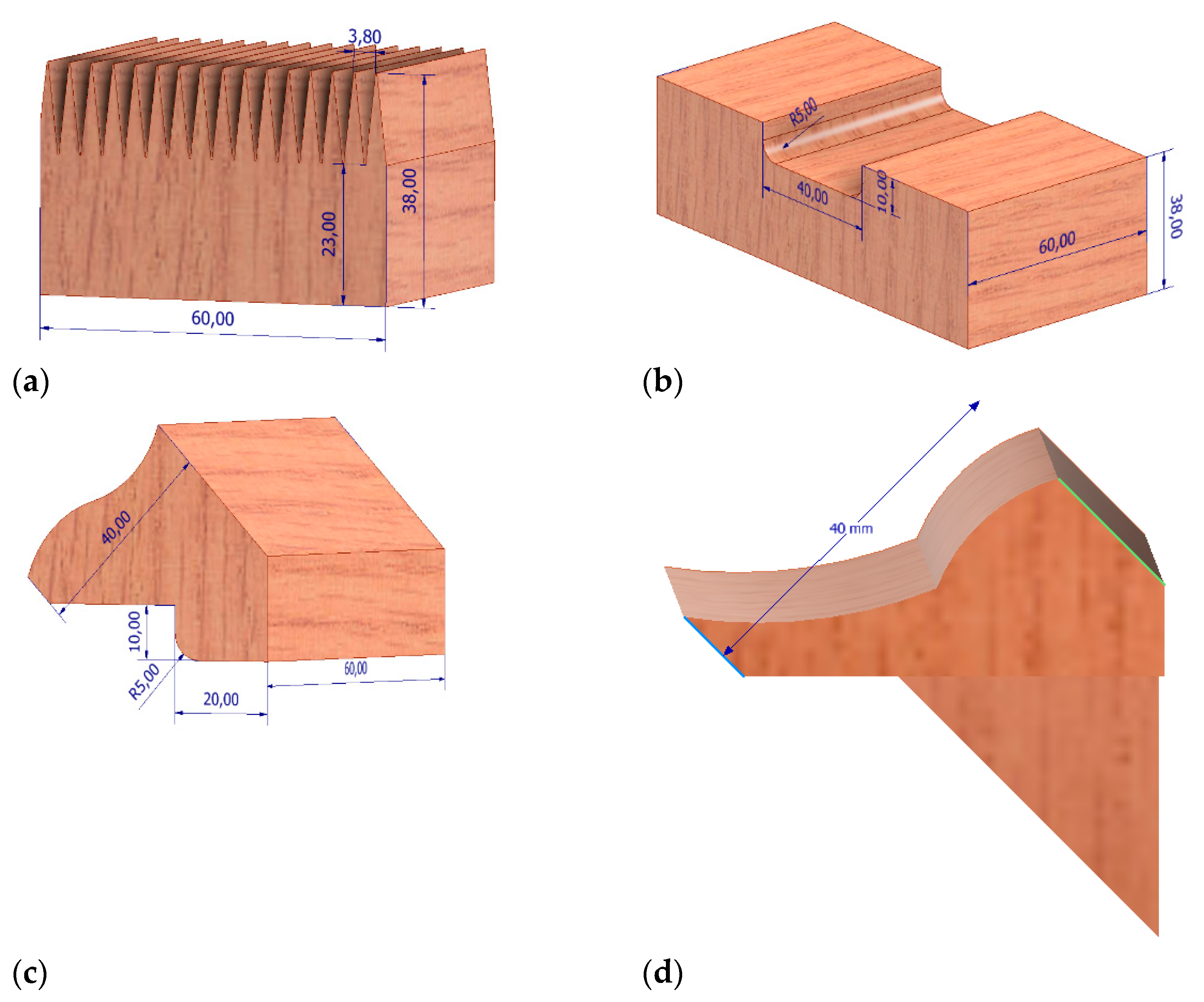

2. Materials and Methods

3. Results and Discussion

3.1. Calculation of Internal Axial Forces in Truss Members

3.2. Lattice Beam as a Solid Beam

3.3. Analysis of Laboratory Testing Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Togan, V.; Durmaz, M.; Daloglu, A. Optimization of roof trusses under snow loads given in Turkish Codes. Eng. Struct. 2006, 28, 1019–1027. [Google Scholar]

- Rinaldin, G.; Amadio, C.; Fragiacomo, M. A component approach for the hysteretic behaviour of connections in cross-laminate wooden structures. J. Inter. Ass. Earthq. Eng. 2013, 1, 1–21. [Google Scholar] [CrossRef]

- American Wood Council. A Builders Guide to Trusses. Connection Solution for Wood Frame Structures; Alpine Systems Corporation: Leesburg, VA, USA, 2014; Available online: https://www.awc.org/pdf/education/des/AWC-DES310-Connections-1hr-141128.pdf (accessed on 2 July 2021).

- Macchioni, N.; Mannucci, M. The assessment of Italian trusses: Survey methodology and typical pathologies. Int. J. Archit. Herit. 2018, 12, 533–535. [Google Scholar] [CrossRef]

- Woods, B.; Hill, I.; Friswell, M.I. Ultra-efficient wound composite truss structures. Compos. Part A 2016, 90, 111–124. [Google Scholar] [CrossRef]

- Lengvarský, P.; Bocko, J. The Static Analysis of the Truss. Am. J. Mech. Eng. 2016, 4, 440–444. [Google Scholar]

- Frans, R.; Arfiadi, Y. Sizing, shape and topology optimizations of roof trusses using hybrid genetic algorithms. Procedia Eng. 2014, 95, 185–195. [Google Scholar] [CrossRef][Green Version]

- Šešok, D.; Belevičius, R. Use of genetic algorithms in topology optimization of truss structure. Mechanika 2007, 2, 34–39. [Google Scholar]

- Deb, K.; Gulati, S. Design of truss-structures for minimum weight using genetic algorithms. Finite Elem. Anal. Des. 2001, 37, 447–465. [Google Scholar] [CrossRef]

- Rajan, S.D. Sizing, shape and topology optimization of trusses using genetic algorithm. J. Struct. Eng. 1995, 121, 1480–1487. [Google Scholar] [CrossRef]

- Delyová, I.; Frankovský, P.; Bocko, J.; Trebuňa, P.; Živčák, J.; Schürger, B.; Janigová, S. Sizing and Topology Optimization of Trusses Using Genetic Algorithm. Materials 2021, 14, 715. [Google Scholar] [CrossRef]

- Tiachacht, S.; Bouazzouni, A.; Khatir, S.; Wahab, M.A.; Behtani, A.; Capozucca, R. Damage assessment in structures using combination of a modified Cornwell indicator and genetic algorithm. Eng. Struct. 2018, 177, 421–430. [Google Scholar] [CrossRef]

- Sivakumar, P.; Natarajan, K.; Rajaraman, A.; Samuel Knight, G.M. Artificial intelligence techniques for optimisation of steel lattice towers. In Proceedings of the Structural Engineering Convention, Honolulu, HI, USA, 24–27 January 2001; pp. 435–445. [Google Scholar]

- Gero, M.B.P.; García, A.B.; del Coz Díaz, J.J. Design optimization of 3D steel structures: Genetic algorithms vs. classical techniques. J. Constr. Steel Res. 2006, 62, 1303–1309. [Google Scholar] [CrossRef]

- Neeraja, D.; Kamireddy, T.; Kumar, P.S.; Reddy, V.S. Weight optimization of plane truss using genetic algorithm. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 32015. [Google Scholar] [CrossRef]

- Olhoff, N.; Bendsøe, M.P.; Rasmussen, J. On CAD-integrated structural topology and design optimization. Comput. Methods Appl. Mech. Eng. 1991, 89, 259–279. [Google Scholar] [CrossRef]

- Kim, N.H.; Sankar, B.V.; Kumar, A.V. Introduction to Finite Element Analysis and Design; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Rajeev, S.; Krishnamoorthy, C.S. Genetic Algorithms-Based Methodologies for Design Optimization of Trusses. J. Struct. Eng. 1997, 123, 350–358. [Google Scholar] [CrossRef]

- Nan, B.; Bai, Y.; Wu, Y. Multi-Objective Optimization of Spatially Truss Structures Based on Node Movement. Appl. Sci. 2020, 10, 1964. [Google Scholar] [CrossRef]

- Bocko, J.; Delyová, I.; Frankovský, P.; Neumann, V. Lifetime Assessment of the Technological Equipment for a Robotic Workplace. Int. J. Appl. Mech. 2020, 12, 2050097. [Google Scholar] [CrossRef]

- Massafra, A.; Prati, D.; Predari, G.; Gulli, R. Wooden Truss Analysis, Preservation Strategies, and Digital Documentation through Parametric 3D Modeling and HBIM Workflow. Sustainability 2020, 12, 4975. [Google Scholar] [CrossRef]

- Ruggieri, N. In Situ Observations on the Crack Morphology in the Ancient Timber Beams. Sustainability 2021, 13, 439. [Google Scholar] [CrossRef]

- Shanuka, F.; Hansen, E.; Kozak, R.; Sinha, A. Organizational cultural compatibility of engineered wood products manufacturers and building specifiers in the Pacific Northwest. Archit. Eng. Desig. Manag. 2018, 14, 398–434. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Lifecycle primary energy analysis of low-energy timber building systems for multi-storey residential buildings. Energ. Build. 2014, 81, 84–97. [Google Scholar] [CrossRef]

- Kromoser, B.; Ritt, M.; Spitzer, A.; Stangl, R.; Idam, F. Design Concept for a Greened Timber Truss Bridge in City Area. Sustainability 2020, 12, 3218. [Google Scholar] [CrossRef]

- Svajlenka, J.; Kozlovská, M.; Spisáková, M. The benefits of modern method of construction based on wood in the context of sustainability. Int. J. Environ. Sci. Technol. 2017, 14, 1591–1602. [Google Scholar] [CrossRef]

- Jin, M.; Hu, Y.; Wang, B. Compressive and bending behaviours of wood-based two-dimensional lattice truss core sandwich structures. Compos. Struct. 2015, 124, 3. [Google Scholar] [CrossRef]

- Houlihan, W.; Georges, L.; Dokka, T.H.; Haase, M.; Time, B.; Lien, A.; Mellegard, S.; Maltha, M. A net zero emission concept analysis of a single-family house. Energy Build. 2014, 74, 101–110. [Google Scholar] [CrossRef]

- Rivera-Tenorio, M.; Moya, R.; Navarro-Mora, A. Wooden trusses using metal plate connections and fabricated with Gmelina arborea, Tectona grandis and Cupressus lusitanica timber from forest plantations. J. Ind. Acad. Wood Sci. 2020, 17, 183–194. [Google Scholar] [CrossRef]

- Guo, W.; Song, S.; Jiang, Z.; Wang, G.; Sun, Z.; Wang, X.; Yang, F.; Chen, H.; Shi, S.Q.; Fei, B. Effect of metal-plate connector on tension properties of metal-plate connected dahurian larch lumber joints. J. Mater. Sci. Res. 2014, 3, 40–47. [Google Scholar] [CrossRef]

- Rammer, R.D. Wood: Mechanical fasteners. In Encyclopedia of Materials: Science and Technology; Saleem, H., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; p. 3. [Google Scholar]

- Rivera-Tenorio, M.; Camacho-Cornejo, D.; Moya, R. Perception of Costa Rican market about the use of prefabricated trusses with wood from forest plantations and joined with metal plates. Rev. For. Mesoam. Kuru-RFMK 2019, 16, 35–46. [Google Scholar] [CrossRef]

- Rivera-Tenorio, M.; Moya, R. Stress, displacement joints of gmelina arborea and tectona grandis wood with metal plates, screws and nails for use in timber truss connections. CERNE 2019, 25, 172–183. [Google Scholar] [CrossRef]

- Gravit, M.; Serdjuks, D.; Bardin, A.; Prusakov, V.; Buka-Vaivade, K. Fire Design Methods for Structures with Timber Framework. Mag. Civ. Eng. 2019, 85, 92–106. [Google Scholar]

- Qin, R.; Zhou, A.; Chow, C.L.; Lau, D. Structural performance and charring of loaded wood under fire. Eng. Struct. 2021, 228, 111491. [Google Scholar] [CrossRef]

- Malanga, R. Fire endurance of lightweight wood trusses in building construction. Fire Technol. 1995, 31, 44–61. [Google Scholar] [CrossRef]

- Sultan, M.A. Fire Resistance of Wood Truss Floor Assemblies. Fire Technol. 2012, 51, 1371–1399. [Google Scholar] [CrossRef]

- TRIFORCE®. The Open Joist TRIFORCE® Adapts to All Types of Projects. Available online: https://www.openjoisttriforce.com/wp-content/uploads/2017/01/How_are_the_joints_made_on_OpenJoist_TRIFORCE (accessed on 2 July 2021).

- Antov, P.; Jivkov, V.; Savov, V.; Simeonova, R.; Yavorov, N. Structural Application of Eco-Friendly Composites from Recycled Wood Fibres Bonded with Magnesium Lignosulfonate. Appl. Sci. 2020, 10, 7526. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Trichkov, N.; Krišťák, Ľ.; Réh, R.; Papadopoulos, A.N.; Taghiyari, H.R.; Pizzi, A.; Kunecová, D.; Pachikova, M. Properties of High-Density Fiberboard Bonded with Urea–Formaldehyde Resin and Ammonium Lignosulfonate as a Bio-Based Additive. Polymers 2021, 13, 2775. [Google Scholar] [CrossRef] [PubMed]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and PMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef]

- EN 338. Structural Timber. Strength classes; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- Bogudzki, W. Budownictwo Stalowe. Część 2; Wydawnictwo Arkady: Warszawa, Poland, 1977. [Google Scholar]

- EN 1995-1-1. Eurocode 5. Design of timber Structures. Part 1-1. General—Common Rules and Rules for Buildings; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- Sagara, A.; Johannes, A.T.; Husain, A.S. Experimental study on strength and stiffness connection of wooden truss structure. MATEC Web Conf. 2017, 101, 0101. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.C. Preparation and Bending Properties of Lattice Sandwich Structure for Wooden Truss. 3rd Annual International Conference on Advanced Material Engineering (AME). AER-Adv. Eng. Res. 2017, 110, 343–349. [Google Scholar]

| No. Member | Force (kN) | Type of Member | No. Member | Force (kN) | Type of Member |

|---|---|---|---|---|---|

| 1 | 0.00 | s | 10 | −33.6 | tc |

| 2 | 0.00 | pg | 11 | −7.92 | dm |

| 3 | −15.84 | k | 12 | 39.2 | bc |

| 4 | 11.20 | pd | 13 | 3.96 | dm |

| 5 | 11.88 | s | 14 | −42.00 | tc |

| 6 | −19.60 | pg | 15 | −3.96 | dm |

| 7 | −11.88 | k | 16 | 44.80 | bc |

| 8 | 28.00 | pd | 17 | 0.00 | dm |

| 9 | 7.92 | s | 18 | −44.8 | tc |

| No. Member | Force (kN) | Type of Member | fc/t * (N/mm2) | Min. Class of Timber | fc/t by Standard ** (N/mm2) |

|---|---|---|---|---|---|

| 16 | 44.80 | pd | 19.65 | C35 | 21 |

| 18 | −44.80 | pg | 19.65 | C22 | 20 |

| 3 | −15.84 | s | 6.95 | C14 | 16 |

| 5 | 11.88 | s | 5.21 | C14 | 8 |

| No. Member | Force (kN) | Type of Member | No. Member | Force (kN) | Type of Member |

|---|---|---|---|---|---|

| 1 | 0.00 | s | 10 | −44.45 | pg |

| 2 | 0.00 | pg | 11 | −15.72 | k |

| 3 | 11.12 | k | 12 | 55.57 | pg |

| 4 | −15.72 | pd | 13 | 0.00 | k |

| 5 | 15.72 | k | 14 | −55.57 | pg |

| 6 | −22.23 | pg | 15 | 0.00 | k |

| 7 | −15.72 | k | 16 | 55.57 | pg |

| 8 | 33.35 | pg | 17 | 0.00 | k |

| 9 | 15.72 | k | 18 | −55.57 | pg |

| Type of Truss | Height (mm) | Jsec. (cm4) | Wz (cm3) | Umax (mm) * |

|---|---|---|---|---|

| UPP | 240 | 4651.2 | 387.64 | 10.8 |

| Witkowski | 240 | 5017.6 | 418.13 | 10.8 |

| Joint Type | Mg max (kN·m) | fm (N/mm2) |

|---|---|---|

| UPP1 | 7.67 (0.82) * | 19.79 |

| UPP2 | 12.48 (1.39) | 32.18 |

| UPP3 | 8.32 (0.33) | 21.42 |

| Steel truss plates | 14.06 (1.34) | 33.62 |

| Connection Type | Sensor Number | Mg003 * (kN·m) | Mg max (kN·m) | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |||

| Deflection Value (mm) | |||||||

| Tenons UPP1 | −8.02 | −10.14 | −10.68 | −10.42 | −8.45 | 5.11 (0.30) ** | 7.67 |

| Finger joints UPP2 | −4.85 | −8.42 | −10.73 | −9.04 | −8.86 | 4.16 (0.26) | 12.48 |

| Tenons UPP3 | −7.69 | −9.57 | −10.76 | −9.76 | −7.80 | 5.65 (0.32) | 8.32 |

| Barbed plates | −6.46 | −9.19 | −11.00 | −9.38 | −6.97 | 5.18 (0.16) | 14.06 |

| Typ | Mg003 * (kN·m) | Mgmax (kN·m) | F (kN) | fm (N/mm2) | MC ** (%) |

|---|---|---|---|---|---|

| UPP3 | 3.77 (0.14) | 9.53 (0.65) | 2.91 | 24.58 | 6.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirski, R.; Matwiej, Ł.; Dziurka, D.; Chuda-Kowalska, M.; Marecki, M.; Pałubicki, B.; Rogoziński, T. Influence of the Structure of Lattice Beams on Their Strength Properties. Materials 2021, 14, 5765. https://doi.org/10.3390/ma14195765

Mirski R, Matwiej Ł, Dziurka D, Chuda-Kowalska M, Marecki M, Pałubicki B, Rogoziński T. Influence of the Structure of Lattice Beams on Their Strength Properties. Materials. 2021; 14(19):5765. https://doi.org/10.3390/ma14195765

Chicago/Turabian StyleMirski, Radosław, Łukasz Matwiej, Dorota Dziurka, Monika Chuda-Kowalska, Maciej Marecki, Bartosz Pałubicki, and Tomasz Rogoziński. 2021. "Influence of the Structure of Lattice Beams on Their Strength Properties" Materials 14, no. 19: 5765. https://doi.org/10.3390/ma14195765

APA StyleMirski, R., Matwiej, Ł., Dziurka, D., Chuda-Kowalska, M., Marecki, M., Pałubicki, B., & Rogoziński, T. (2021). Influence of the Structure of Lattice Beams on Their Strength Properties. Materials, 14(19), 5765. https://doi.org/10.3390/ma14195765