Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers

Abstract

:1. Introduction

2. Materials and Methods

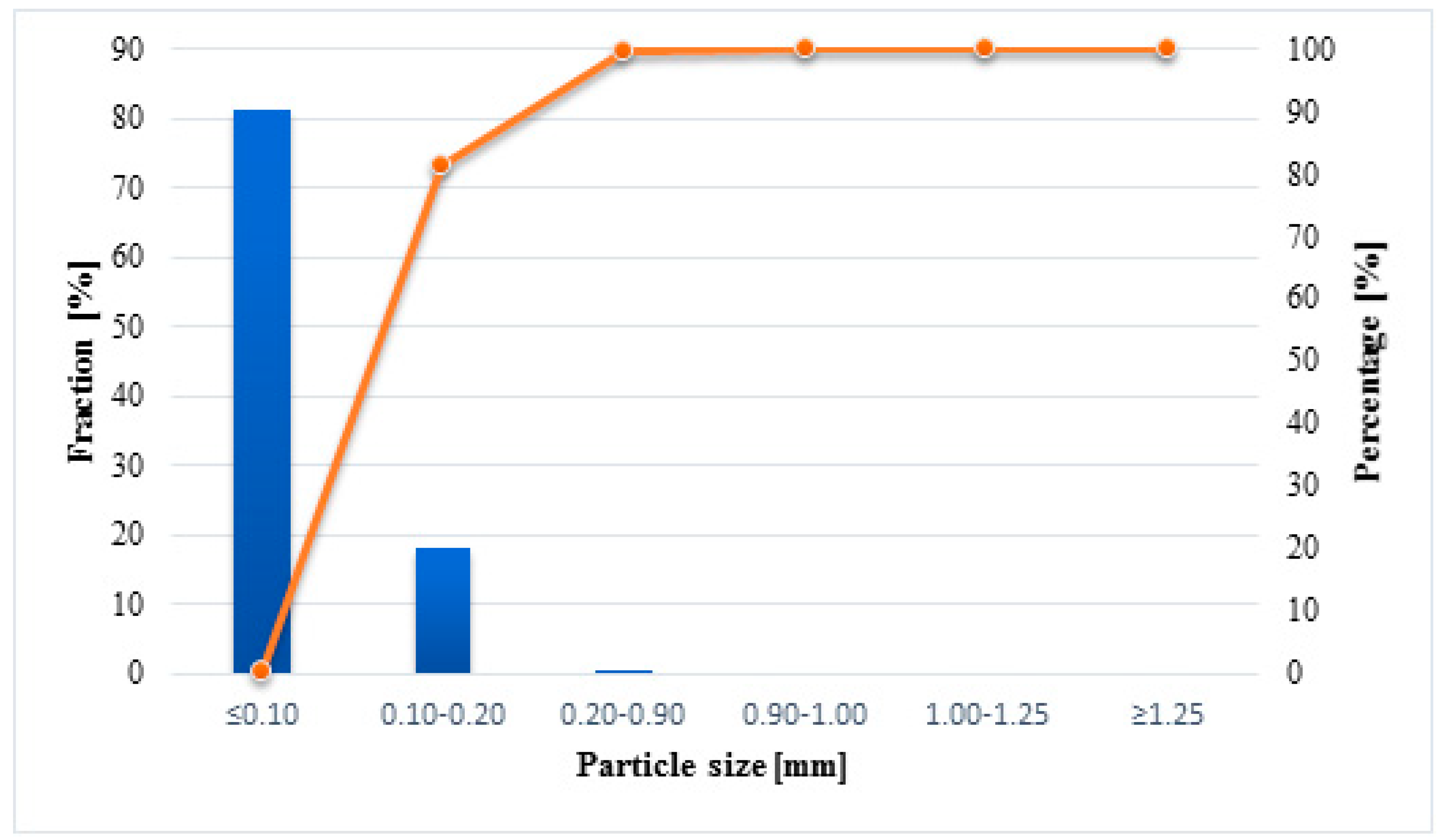

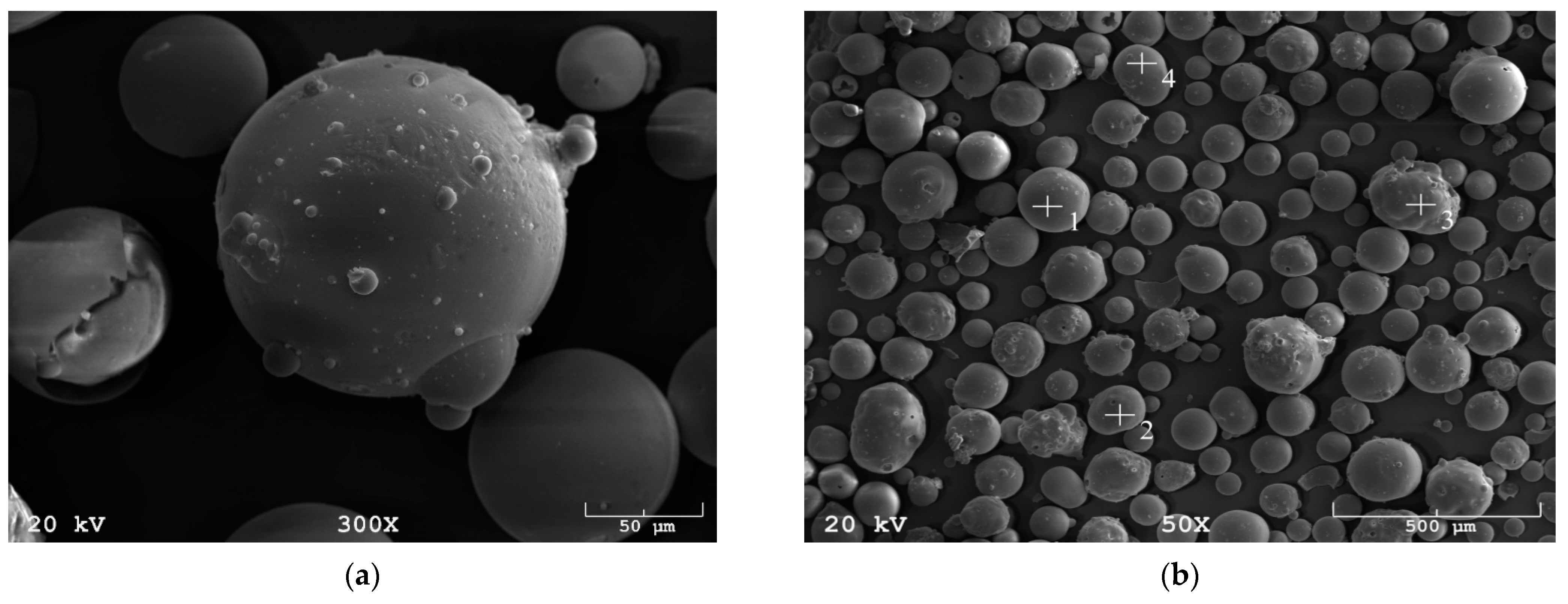

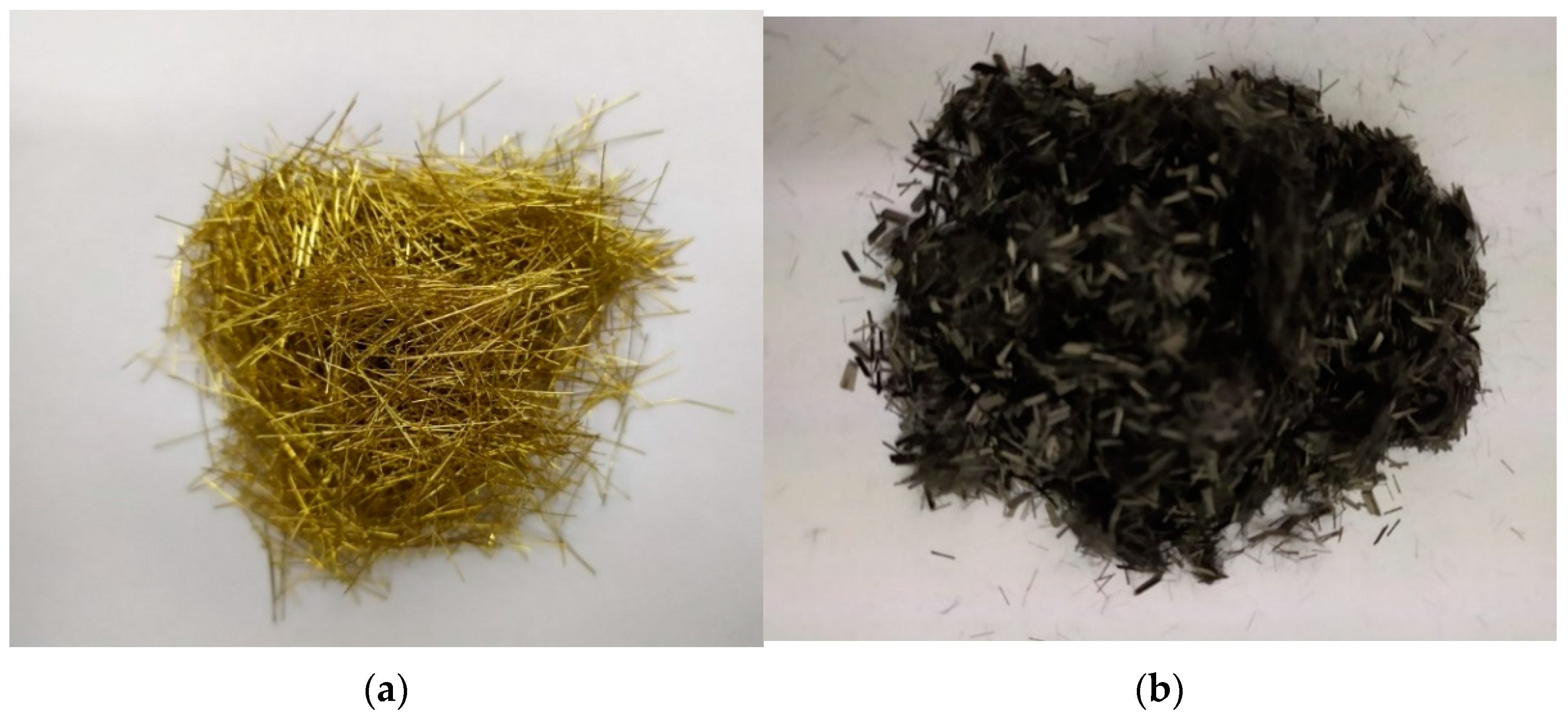

2.1. Materials

2.2. Samples Preparation

2.3. Methods

- The samples were cleaned, and loose debris was removed so that they did not come into contact with the clamping plates.

- The samples were placed in the testing machine so that they were in the center of the lower pressure plate.

- The load direction was perpendicular to the direction in which the samples were formed.

- A constant load speed of 0.5 N/mm2∙s was assumed.

- The load was increased continuously until the maximum value was reached.

- The compressive strength was determined by the machine program from Formula (2):where: —compressive strength [MPa], —maximum load [N], —the cross-sectional area of the sample [mm].

- The samples were cleaned; loose debris was removed so that they would not come into contact with the rollers (the gap between rollers was 150 mm).

- The samples were placed in the testing machine so that they were properly centered and that their longitudinal axis was set at right angles to the longitudinal axis of both rollers.

- The load direction was perpendicular to the direction in which the samples were formed.

- A constant load speed of 0.05 N/mm2∙s was assumed.

- The load was increased continuously until the maximum value was reached.

- The bending strength was determined by the machine program from Formula (3):where: —bending strength [MPa], —maximum load [N], —the spacing of the support rollers [mm], —transverse dimensions of the sample [mm].

3. Results and Discussion

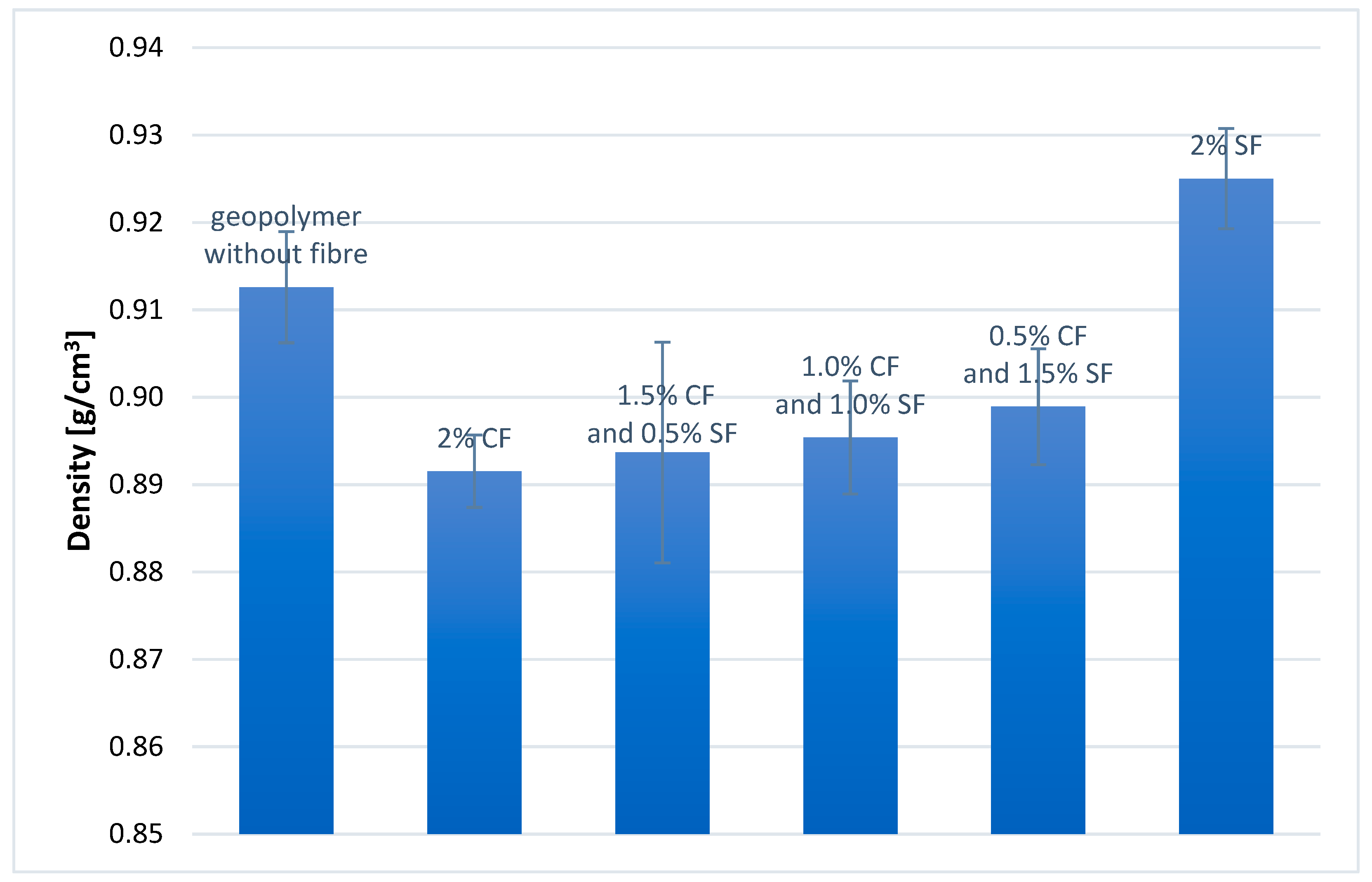

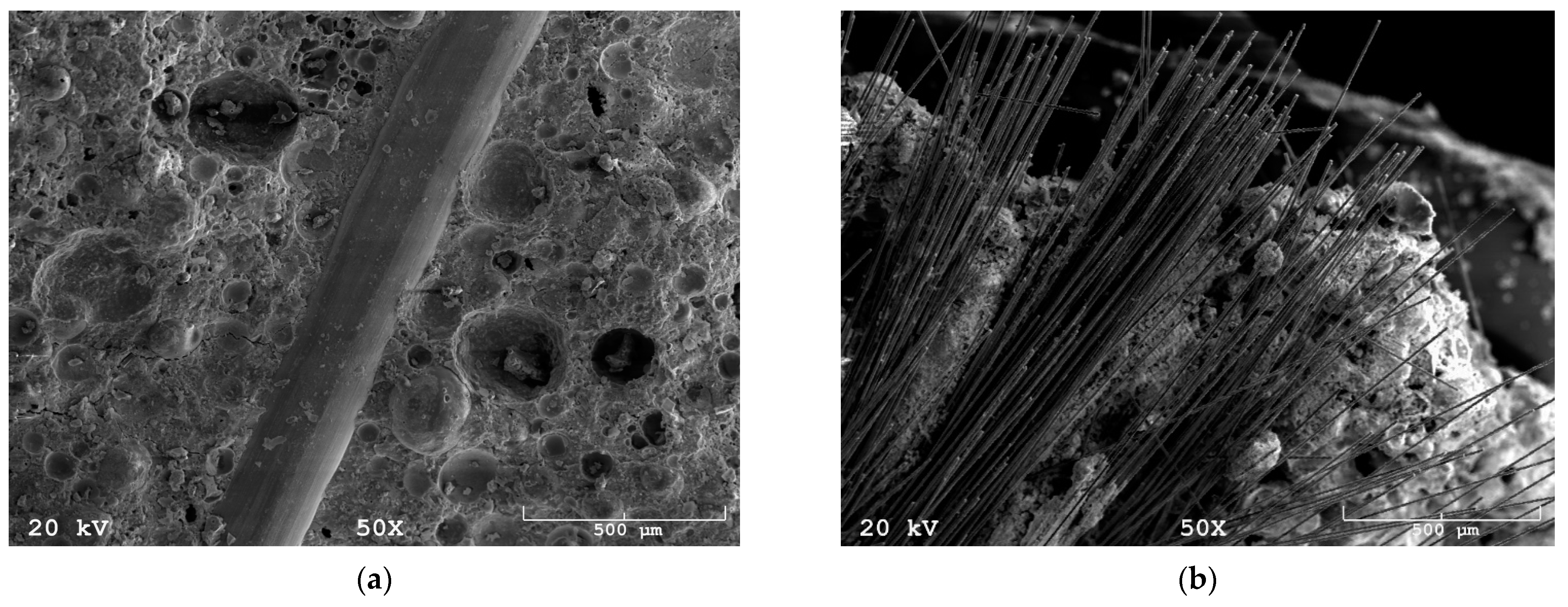

3.1. Density and Microstructure Research

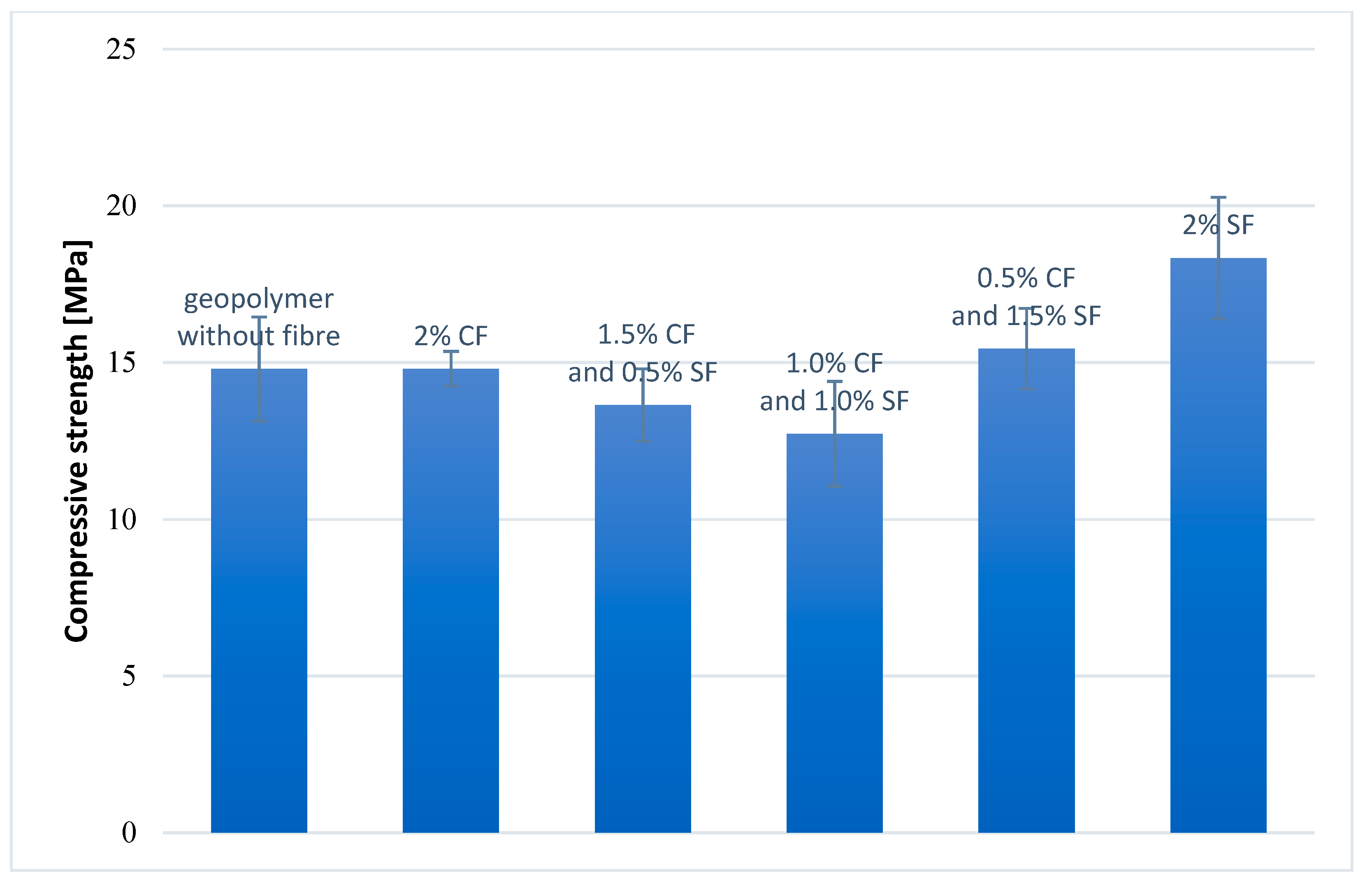

3.2. Compressive Strength

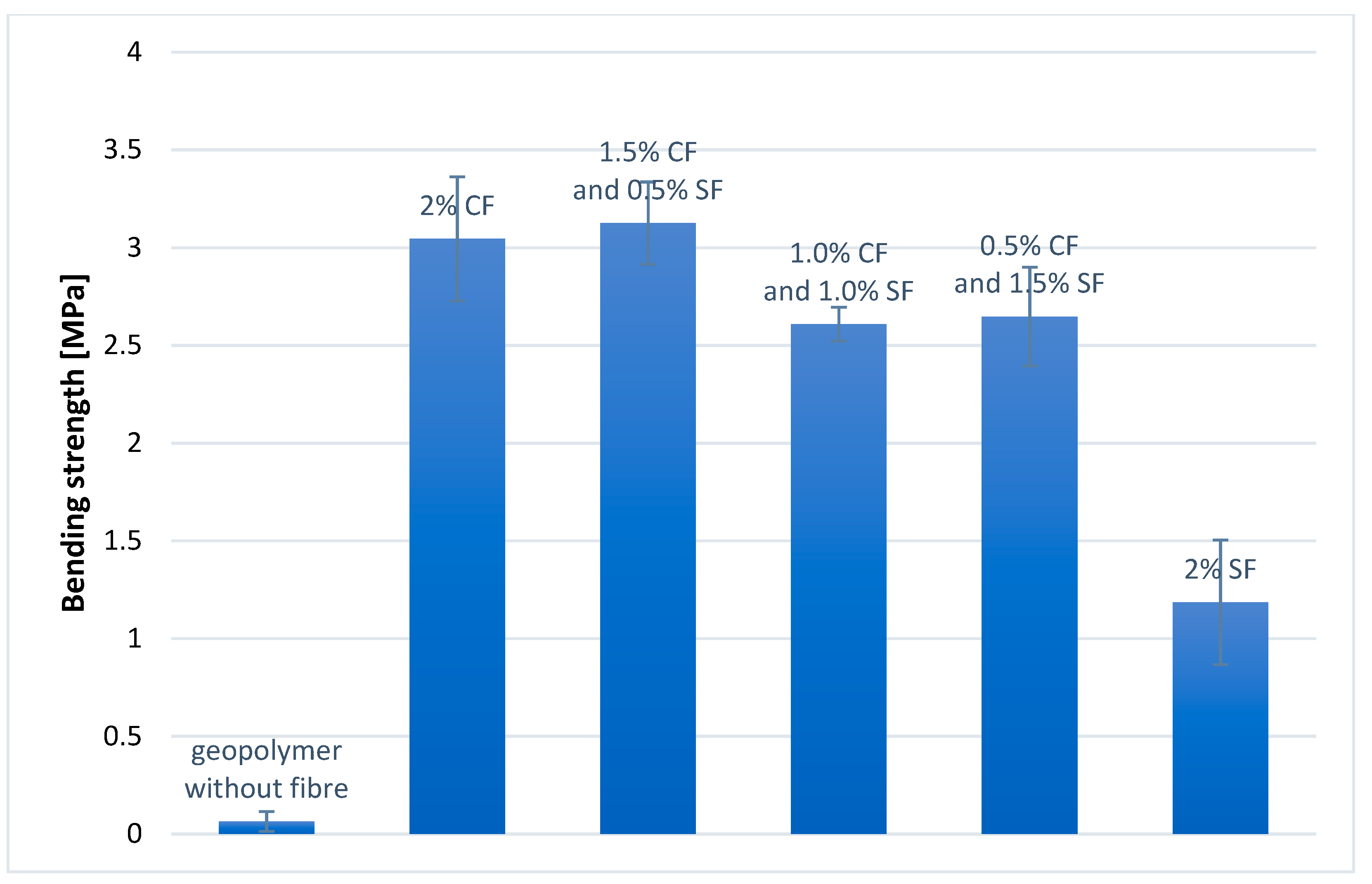

3.3. Bending Strength

3.4. Thermal Conductivity of Lightweight Matrix

4. Discussion

- In a study carried out on a geopolymer material with a matrix made of fly ash and smoke silica-reinforced with hybrid hooked steel fiber and polypropylene (PP) fiber, the same relationship was observed for the bending strength as for compressive strength. With the increasing content of steel fibers, the value of the bending strength of composites increases [48].

- In the study of a geopolymer composite with a matrix made of fly ash and slag reinforced with hybrid fibers corrugated and hooked steel fibers and PE fiber, it was observed that the strength properties of the hybrid reinforced composites were higher in the bending strength test. In the composite without the addition of fibers, the bending strength reached the lowest value of 3.89 MPa. In turn, the highest value of 11.3 MPa was achieved in a composite containing 0.8% by volume of crimped and hooked fibers and 0.4% by volume of PE [49].

- In a study conducted on a geopolymer composite with a matrix made of fly ash and sand reinforced with hybrid hooked steel and melamine fibers, the results of bending strength showed that he addition of melamine fibers as well as steel fibers increased the flexural strength in comparison to the plain matrix. The best results were obtained for the combination of both types of fibers but not exceeding the maximum value of 1% by weight [2].

5. Conclusions

- All the obtained composites have densities in the range of approx. 0.89–0.93 g/cm3. Therefore, they can be classified as lightweight aggregate concretes.

- The best compressive strength is obtained for a steel fiber (2.0% by weight).

- In all cases, the addition of reinforcing fibers to lightweight geopolymer composites significantly improves the bending strength value and may change the fractured nature of the brittle material to a more ductile one. The best bending strength is obtained for the hybrid reinforced composite: 1.5 wt.% CFs and 0.5 wt.% SFs.

- Analysis of the microstructure of the steel and carbon fiber-reinforced composite shows good coherence of the fibers with the matrix.

- The geopolymer composite is characterized by low thermal conductivity (0.22 W/m K) at low density, giving values comparable to aerated concrete blocks. Geopolymer matrix is made of fly ash and microspheres and is therefore characterized by better thermal insulation properties (0.18 W/m K).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roviello, G.; Ricciotti, L.; Ferone, C.; Colangelo, F.; Cioffi, R.; Tarallo, O. Synthesis and Characterization of Novel Epoxy Geopolymer Hybrid Composites. Materials 2013, 6, 3943–3962. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bazan, P.; Kozub, B.; Łach, M.; Korniejenko, K. Evaluation of Hybrid Melamine and Steel Fiber Reinforced Geopolymers Composites. Materials 2020, 13, 5548. [Google Scholar] [CrossRef] [PubMed]

- Korniejenko, K.; Łach, M.; Mikuła, J. The Influence of Short Coir, Glass and Carbon Fibers on the Properties of Composites with Geopolymer Matrix. Materials 2021, 14, 4599. [Google Scholar] [CrossRef] [PubMed]

- Mierzwiński, D.; Łach, M.; Hebda, M.; Walter, J.; Szechyńska-Hebda, M.; Mikuła, J. Thermal phenomena of alkali-activated metakaolin studied with a negative temperature coefficient system. J. Therm. Anal. Calorim. 2019, 138, 4167–4175. [Google Scholar] [CrossRef] [Green Version]

- Katarzyna, B.; Le, C.H.; Louda, P.; Michał, S.; Bakalova, T.; Tadeusz, P.; Prałat, K. The Fabrication of Geopolymer Foam Composites Incorporating Coke Dust Waste. Processes 2020, 8, 1052. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Megat Johari, M.A.; Demirboğa, R. Impact of fiber reinforcements on properties of geopolymer composites: A review. J. Build. Eng. 2021, 44, 102628. [Google Scholar] [CrossRef]

- Korniejenko, K.; Lin, W.-T.; Šimonová, H. Mechanical Properties of Short Polymer Fiber-Reinforced Geopolymer Composites. J. Compos. Sci. 2020, 4, 128. [Google Scholar] [CrossRef]

- Łach, M.; Hebdowska-Krupa, M.; Mierzwiński, D.; Korniejenko, K. Mechanical properties of geopolymers reinforced with carbon and aramid long fibers. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kazimierz Dolny, Poland, 21–23 November 2019; Volume 706, p. 01016. [Google Scholar]

- Adesina, A. Performance of fibre reinforced alkali-activated composites—A review. Materialia 2020, 12, 100782. [Google Scholar] [CrossRef]

- Gailitis, R.; Sprince, A.; Kozlovskis, T.; Radina, L.; Pakrastins, L.; Vatin, N. Long-Term Properties of Different Fiber Reinforcement Effect on Fly Ash-Based Geopolymer Composite. Crystals 2021, 11, 760. [Google Scholar] [CrossRef]

- Samal, S.; Blanco, I. An Application Review of Fiber-Reinforced Geopolymer Composite. Fibers 2021, 9, 23. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cement Concrete Comp. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mat. Techn. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Aswathi, R.; Shahla, C.P. Mechanical Properties of Hybrid Fiber Reinforced Geopolymer Concrete. Int. Res. J. Eng. Technol. 2019, 6, 170–173. [Google Scholar]

- Sakulich, A.R. Reinforced geopolymer composites for enhanced material greenness and durability. Sustain. Cities Soc. 2011, 1, 195–210. [Google Scholar] [CrossRef]

- Al-Mashhadani, M.M.; Canpolat, O.; Aygörmez, Y.; Uysal, M.; Erdem, S. Mechanical and microstructural characterization of fiber reinforced fly ash based geopolymer composites. Constr. Build. Mater. 2018, 167, 505–513. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Ghazali, N.B.; Yusoff, S.; Bashar, I.I. Influence of steel fibers on the mechanical properties and impact resistance of lightweight geopolymer concrete. Constr. Build. Mater. 2017, 152, 964–977. [Google Scholar] [CrossRef]

- Łach, M. Geopolymer Foams—Will They Ever Become a Viable Alternative to Popular Insulation Materials?—A Critical Opinion. Materials 2021, 14, 3568. [Google Scholar] [CrossRef] [PubMed]

- Azimi, E.A.; Al Bakri Abdullah, M.M.; Ming, L.Y.; Yong, H.C.; Hussin, K.; Aziz, I.H. Processing and properties of geopolymers as thermal insulating materials: A review. Rev. Adv. Mater. Sci. 2015, 44, 273–285. [Google Scholar]

- Khater, H.M. Development and characterization of sustainable lightweight geopolymer composites. Ceramica 2019, 65, 153–161. [Google Scholar] [CrossRef]

- Abbas, W.; Khalil, W.; Nasser, I. Production of lightweight Geopolymer concrete using artificil local lightweight aggregate. In Proceedings of the The 3rd International Conference on Buildings, Construction and Environmental Engineering (BCEE3-2017), Sharm el-Shiekh, Egypt, 23–25 October 2017; Volume 162, p. 02024. [Google Scholar] [CrossRef] [Green Version]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A. Formation mechanism and applications of cenospheres: A review. J. Mater. Sci. 2020, 55, 4539–4557. [Google Scholar] [CrossRef]

- Haustein, E.; Kuryłowicz-Cudowska, A. The Effect of Fly Ash Microspheres on the Pore Structure of Concrete. Minerals 2020, 10, 58. [Google Scholar] [CrossRef] [Green Version]

- Walbrück, K.; Maeting, F.; Witzleben, S.; Stephan, D. Natural Fiber-Stabilized Geopolymer Foams—A Review. Materials 2020, 13, 3198. [Google Scholar] [CrossRef]

- Nyale, S.M.; Babajide, O.O.; Birch, G.D.; Böke, N.; Petrik, L.F. Synthesis and Characterization of Coal Fly Ash-based Foamed Geopolymer. Procedia Environ. Sci. 2013, 18, 722–730. [Google Scholar] [CrossRef] [Green Version]

- Yan, S.; Zhang, F.; Feng, X.; Kong, J.; Wang, B.; Yang, J. Effect of high temperature on the mechanical properties of hierarchical porous cenosphere/geopolymer composite foams. Int. J. Appl. Ceram. Technol. 2021, 18, 817–829. [Google Scholar] [CrossRef]

- Gencel, O.; Gholampour, A.; Tokay, H.; Ozbakkaloglu, T. Replacement of Natural Sand with Expanded Vermiculite in Fly Ash-Based Geopolymer Mortars. Appl. Sci. 2021, 11, 1917. [Google Scholar] [CrossRef]

- Colangelo, F.; Roviello, G.; Ricciotti, L.; Ferrándiz-Mas, V.; Messina, F.; Ferone, C.; Tarallo, O.; Cioffi, R.; Cheeseman, C.R. Mechanical and thermal properties of lightweight geopolymer composites. Cem. Concr. Compos. 2018, 86, 266–272. [Google Scholar] [CrossRef]

- Kristály, F.; Szabó, R.; Mádai, F.; Debreczeni, Á.; Mucsi, G. Lightweight composite from fly ash geopolymer and glass foam. J. Sustain. Cem. -Based Mater. 2021, 10, 1–22. [Google Scholar] [CrossRef]

- Pichór, W.; Kamiński, A.; Szołdra, P.; Frąc, M. Lightweight Cement Mortars with Granulated Foam Glass and Waste Perlite Addition. Adv. Civ. Eng. 2019, 2019, 1705490. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Mucsi, G.; Szabó, R.; Nagy, S.; Bohács, K.; Gombkötő, I.; Debreczeni, Á. Development of polystyrene-geopolymer composite for thermal insulating material and its properties with special regards to flame resistance. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Busan, Korea, 25–27 August 2017; Volume 251, p. 012079. [Google Scholar] [CrossRef] [Green Version]

- Caiza, M.; Gonzalez, C.; los Toulkeridis, T.; Bonifaz, H. Physical properties of pumice and its behavior as a coarse aggregate in concrete. Malays. Constr. Res. J. 2019, 25, 85–95. [Google Scholar]

- Allahverdi, A.; Mehrpour, K.; Kani, E.N. Investigating the possibility of utilizing pumice-type natural pozzolan in production of geopolymer cement. Ceram. Silik. 2008, 52, 16–23. [Google Scholar]

- Top, S.; Vapur, H.; Altiner, M.; Kaya, D.; Ekicibil, A. Properties of fly ash-based lightweight geopolymer concrete prepared using pumice and expanded perlite as aggregates. J. Mol. Struct. 2020, 15, 1202. [Google Scholar] [CrossRef]

- Tsaousi, G.M.; Douni, I.; Panias, D. Characterization of the properties of perlite geopolymer pastes. Mater. De Construcción 2016, 66, 324. [Google Scholar] [CrossRef] [Green Version]

- Ma, C.K.; Awang, A.Z.; Omar, W. Structural and material performance of geopolymer concrete: A review. Constr. Build. Mater. 2018, 186, 90–102. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Rickard, W.D.A.; Gluth, G.J.G.; Pistol, K. In-situ thermo-mechanical testing of fly ash geopolymer concretes made with quartz and expanded clay aggregates. Cem. Concr. Res. 2016, 80, 33–43. [Google Scholar] [CrossRef]

- Hassan, A.; Mourad, A.H.I.; Rashid, Y.; Ismail, N.; Laghari, M.S. Thermal and structural performance of geopolymer concrete containing phase change material encapsulated in expanded clay. Energy Build. 2019, 191, 72–81. [Google Scholar] [CrossRef]

- Kozub, B.; Bazan, P.; Mierzwiński, D.; Korniejenko, K. Fly-Ash-Based Geopolymers Reinforced by Melamine Fibers. Materials 2021, 14, 400. [Google Scholar] [CrossRef] [PubMed]

- Nath, S.K.; Maitra, S.; Mukherjee, S.; Kumar, S. Microstructural and morphological evolution of fly ash based geopolymers. Constr. Build. Mater. 2016, 111, 758–765. [Google Scholar] [CrossRef]

- Lin, K.-L.; Lo, K.-W.; Cheng, T.-W.; Lin, W.-T.; Lin, Y.-W. Influence of SiC Sludge on the Microstructure of Geopolymers. Materials 2020, 13, 2203. [Google Scholar] [CrossRef]

- Nath, S.K.; Kumar, S. Role of particle fineness on engineering properties and microstructure of fly ash derived geopolymer. Constr. Build. Mater. 2020, 233, 117294. [Google Scholar] [CrossRef]

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z.U. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef] [PubMed]

- Figiela, B.; Šimonová, H.; Korniejenko, K. State-of-the-Art, Challenges and Emerging trends: Geopolymer Composite Reinforced by Dispersed Steel Fibers. Rev. Adv. Mater. Sci. 2021, 60. in press. [Google Scholar]

- Sukontasukkul, P.; Pongsopha, P.; Chindaprasirt, P.; Songpiriyakij, S. Flexural performance and toughness of hybrid steel and polypropylene fibre reinforced geopolymer. Constr. Build. Mater. 2018, 161, 37–44. [Google Scholar] [CrossRef]

- Khan, M.Z.N.; Hao, Y.; Hao, H.; Shaikh, F.U.A. Mechanical properties of ambient cured high strength hybrid steel and synthetic fibers reinforced geopolymer composites. Cem. Concr. Compos. 2018, 85, 133–152. [Google Scholar] [CrossRef]

- Jia, D.; He, P.; Wang, M.; Yan, S. Geopolymer and Geopolymer Matrix Composites, 1st ed.; Springer Series in Materials Science: Singapore, 2020; Volume 311. [Google Scholar] [CrossRef]

- Stowarzyszenie Przemysłu Wapienniczego, Budowa Domu—Wybór Rodzaju Ścian. Available online: https://www.dom.pl/budowa-domu-wybor-rodzaju-scian.html (accessed on 20 August 2021).

- Wiprächtiger, M.; Haupt, M.; Heeren, N.; Waser, E.; Hellweg, S. A framework for sustainable and circular system design: Development and application on thermal insulation materials. Resour. Conserv. Recycl. 2020, 154, 104631. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

| Chemical Formula | % | Chemical Formula | Concentration % |

|---|---|---|---|

| SiO2 | 52.076 | BaO | 0.060 |

| Al2O3 | 28.697 | SrO | 0.053 |

| Fe2O3 | 5.767 | Cl | 0.048 |

| CaO | 3.467 | ZrO2 | 0.028 |

| K2O | 2.424 | ZnO | 0.024 |

| Na2O | 2.384 | CuO | 0.023 |

| MgO | 1.997 | Cr2O3 | 0.020 |

| SO3 | 1.220 | Co3O4 | 0.018 |

| TiO2 | 1.107 | PbO | 0.017 |

| P2O5 | 0.475 | NiO | 0.017 |

| MnO | 0.060 | Rb2O | 0.016 |

| No. | FA [g] | MS [g] | Alkali Solution [mL] | SFs [g] | CFs [g] |

|---|---|---|---|---|---|

| 1 | 980 | 980 | 900 | 0 | 0 |

| 2 | 980 | 980 | 900 | 0 | 40 |

| 3 | 980 | 980 | 900 | 10 | 30 |

| 4 | 980 | 980 | 900 | 20 | 20 |

| 5 | 980 | 980 | 900 | 30 | 10 |

| 6 | 980 | 980 | 900 | 40 | 0 |

| Sample | Dimensions [mm] | Weight [kg] |

|---|---|---|

| Geopolymer (50 wt.% FA + 50 wt.% sand) | 137.6 × 138.2 × 26.2 | 0.428 |

| Geopolymer (50 wt.% FA + 50 wt.% MS) | 137.3 × 138.4 × 25.5 | 0.648 |

| Sample | ρ [kg/m3] | λ [W/m·K] | Rs [MPa] |

|---|---|---|---|

| Geopolymer (50 wt.% FA + 50 wt.% sand) | 1339 | 0.22 | 42.0 |

| Geopolymer (50 wt.% FA + 50 wt.% MS) | 859 | 0.18 | 14.8 |

| Sample | ρ [kg/m3] | λ [W/m·K] | Rs [MPa] |

|---|---|---|---|

| Silicate brick | 900–2200 | 1.10 | 7.5–15.0 |

| Ceramic brick | 1800 | 0.77 | 5.0–35.0 and more |

| Aerated concrete block | 300–1000 | 0.20 | 2.0–7.5 |

| Reinforced concrete | 2400 | 1.80 | 20–150 and more |

| Mineral wool | 10–200 | 0.055 | |

| Styrofoam | 10–50 | 0.040 | |

| Wood | 550 | 0.20 | |

| Lime plaster | 1700 | 0.80 | 0.3–4.0 |

| Cement-lime plaster | 1850 | 0.90 | 1–20 |

| Cement plaster | 2000 | 1.20 | 1–30 |

| Plasterboard | 1000 | 0.9 | |

| Geopolymer (50 wt.% FA + 50 wt.% sand) | 1339 | 0.22 | 42.0 |

| Geopolymer (50 wt.% FA + 50 wt.% MS) | 859 | 0.18 | 14.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baziak, A.; Pławecka, K.; Hager, I.; Castel, A.; Korniejenko, K. Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers. Materials 2021, 14, 5741. https://doi.org/10.3390/ma14195741

Baziak A, Pławecka K, Hager I, Castel A, Korniejenko K. Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers. Materials. 2021; 14(19):5741. https://doi.org/10.3390/ma14195741

Chicago/Turabian StyleBaziak, Agnieszka, Kinga Pławecka, Izabela Hager, Arnaud Castel, and Kinga Korniejenko. 2021. "Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers" Materials 14, no. 19: 5741. https://doi.org/10.3390/ma14195741

APA StyleBaziak, A., Pławecka, K., Hager, I., Castel, A., & Korniejenko, K. (2021). Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers. Materials, 14(19), 5741. https://doi.org/10.3390/ma14195741