Shape Prediction of the Sheet in Continuous Roll Forming Based on the Analysis of Exit Velocity

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used in Simulations and Experiments

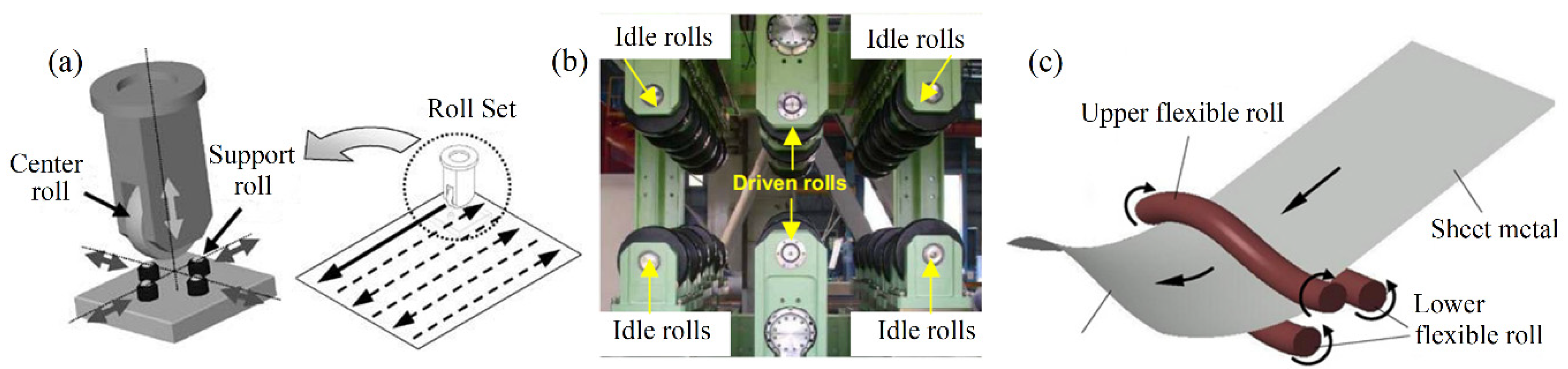

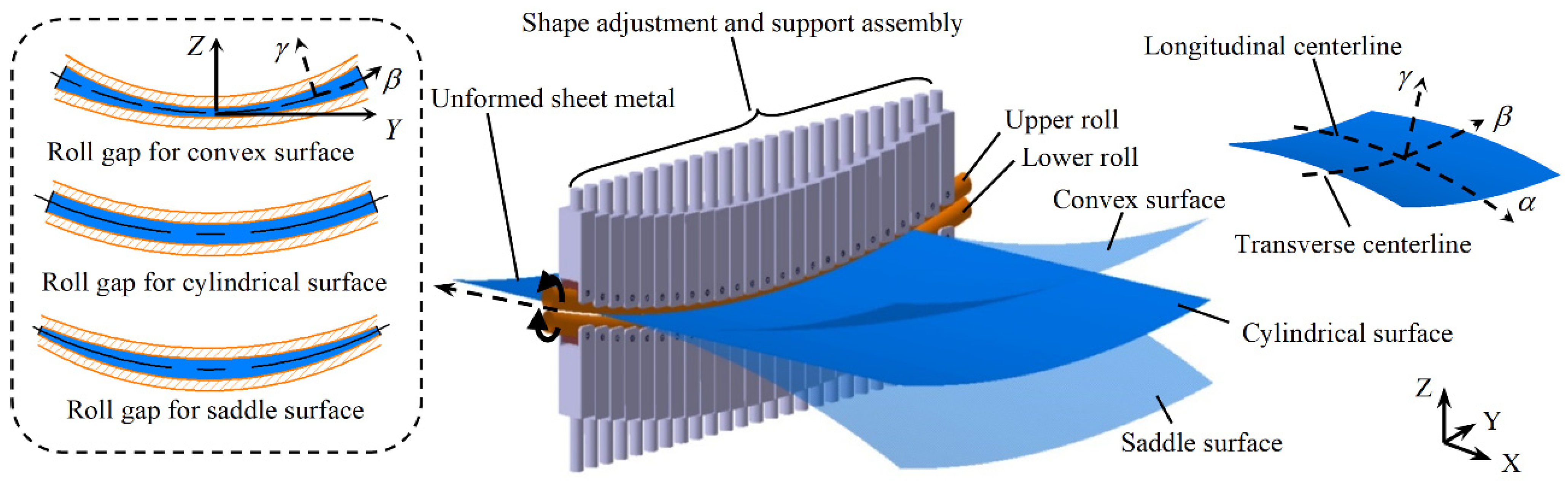

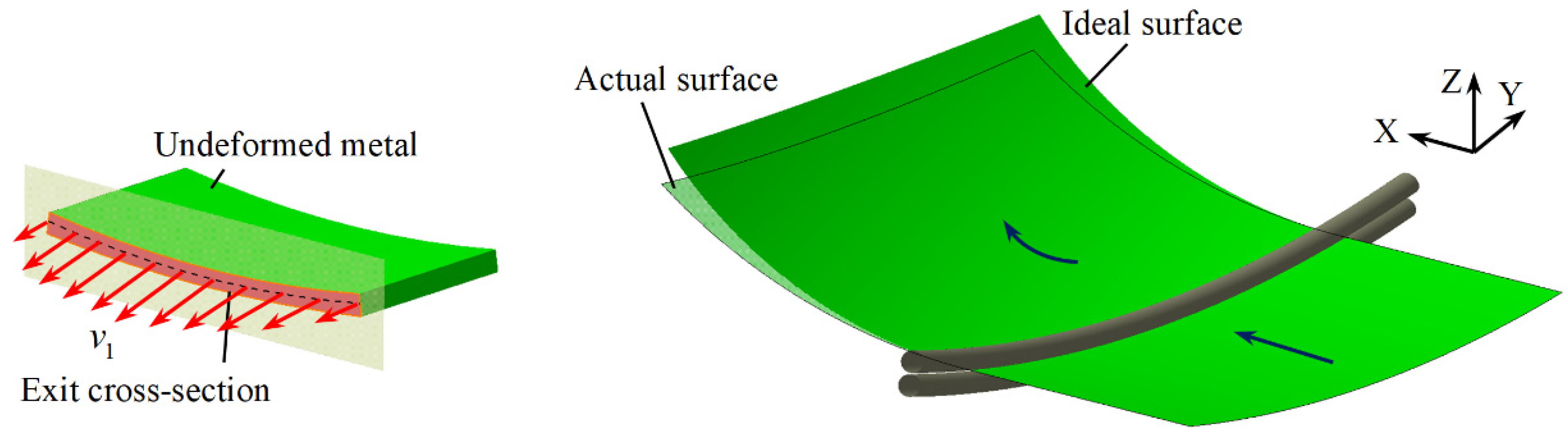

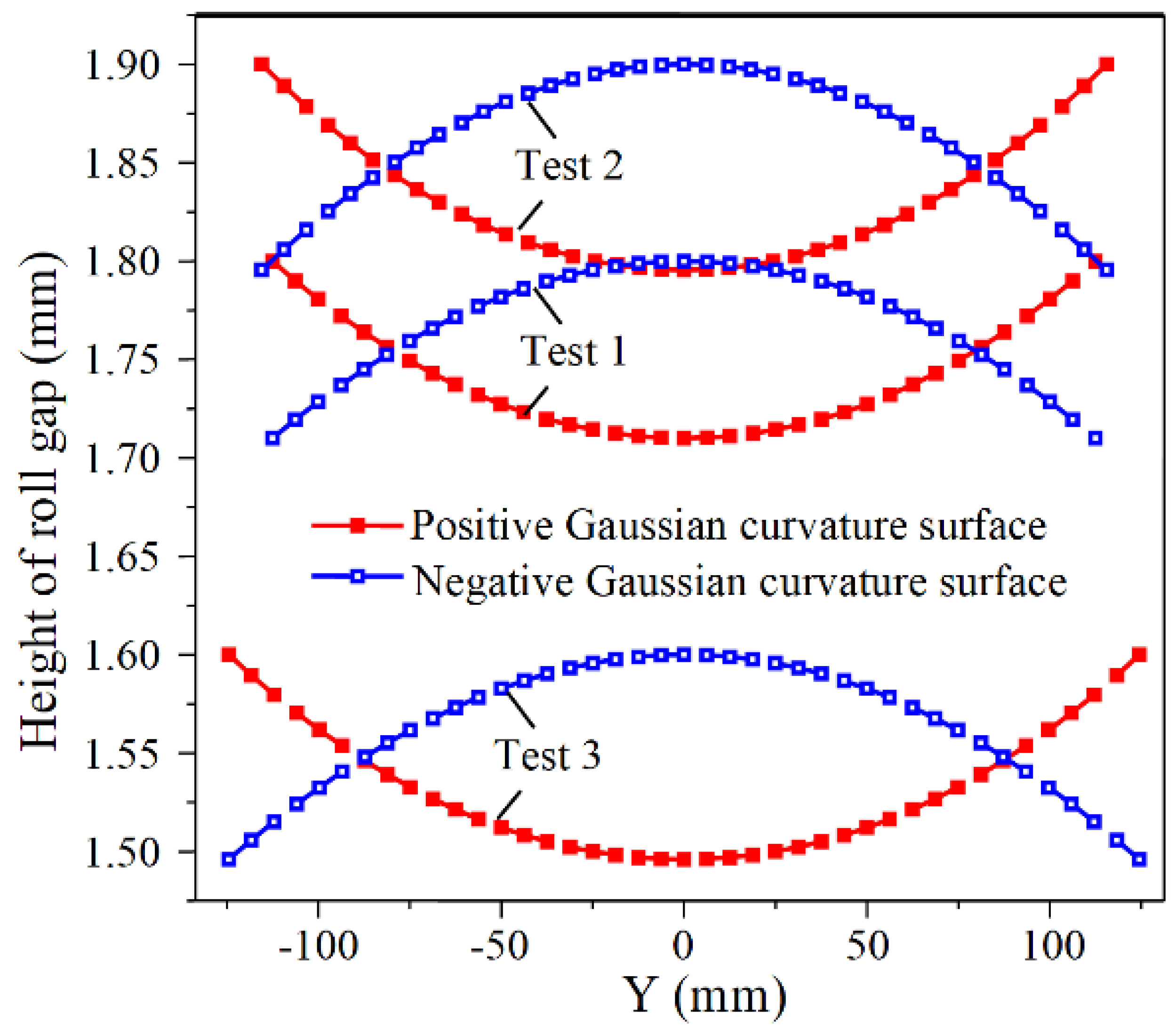

2.2. The Principle of CRF

2.3. The Basic Equation and Some Simplifications in CRF

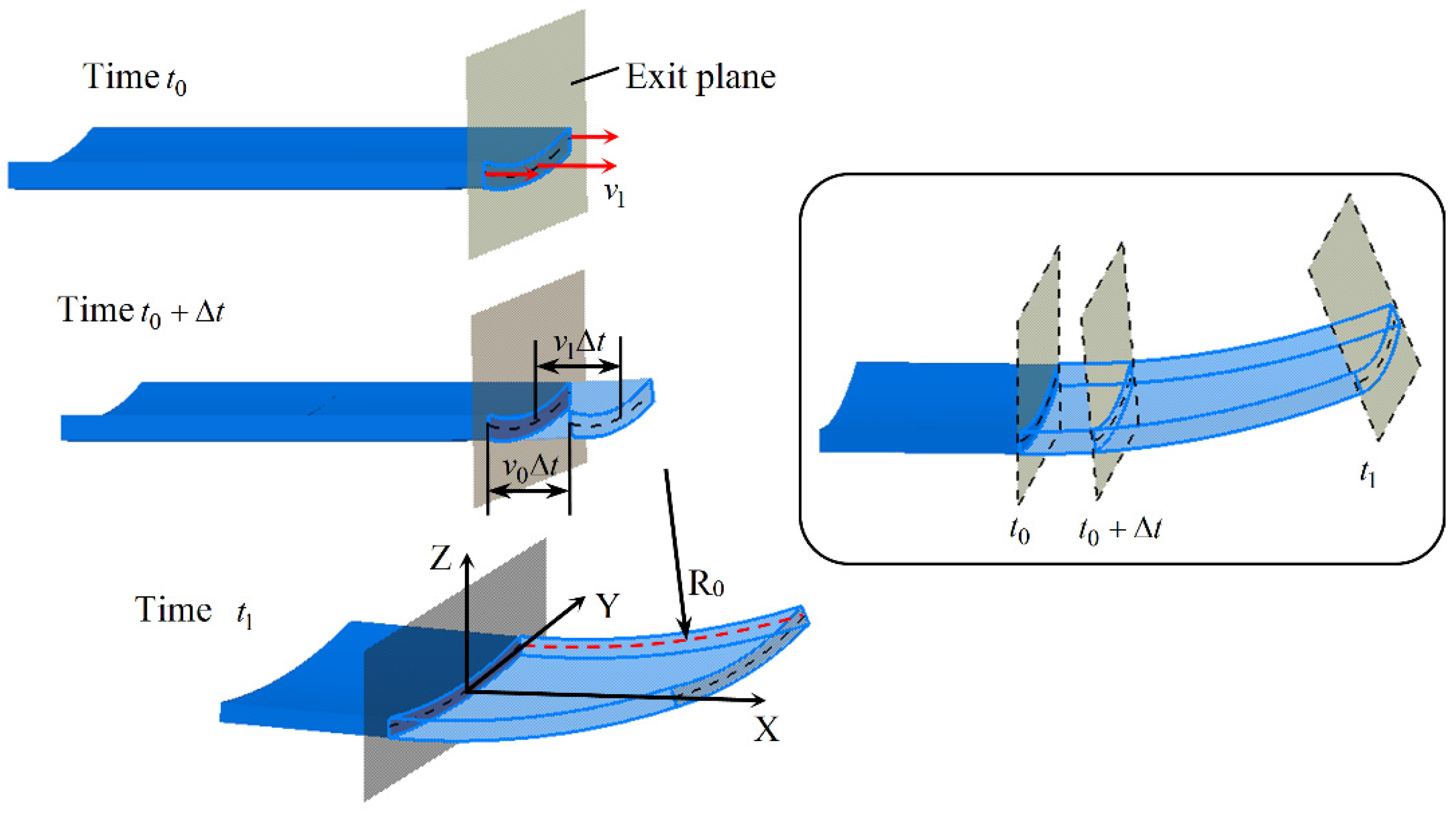

2.4. Derivation of Longitudinal Curvature Radius in Ideal Continuous Roll Forming

3. Results and Discussion

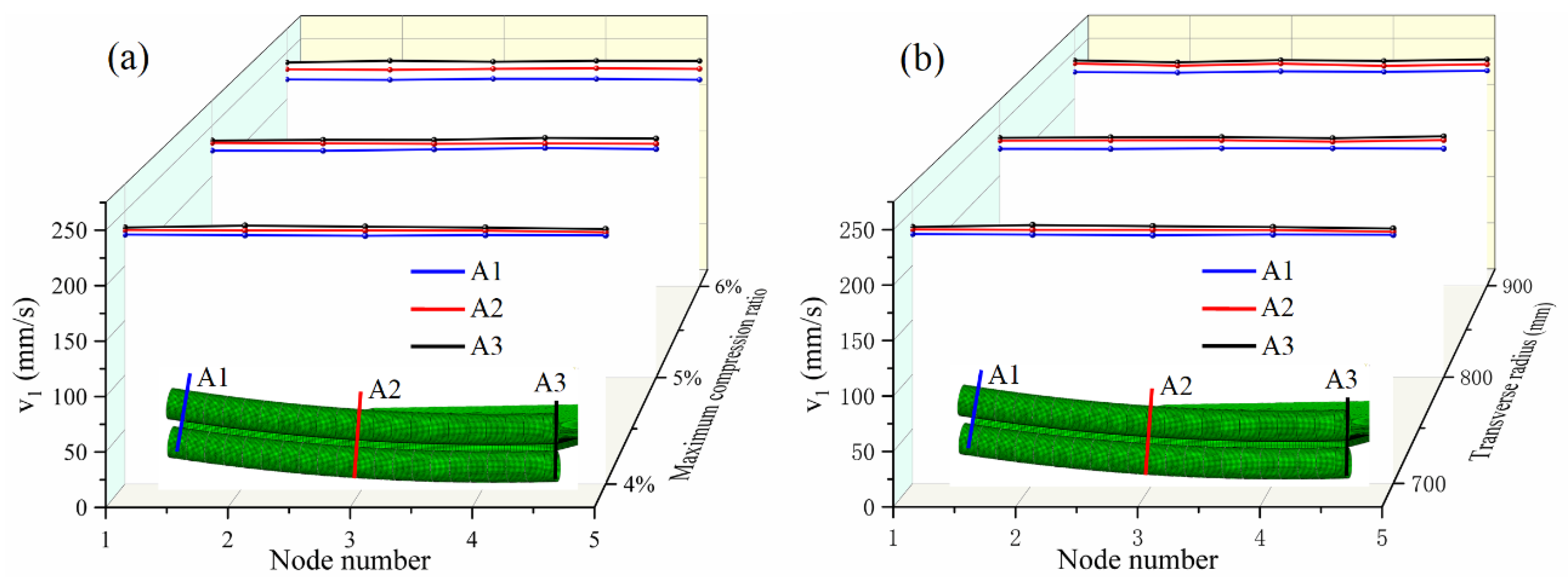

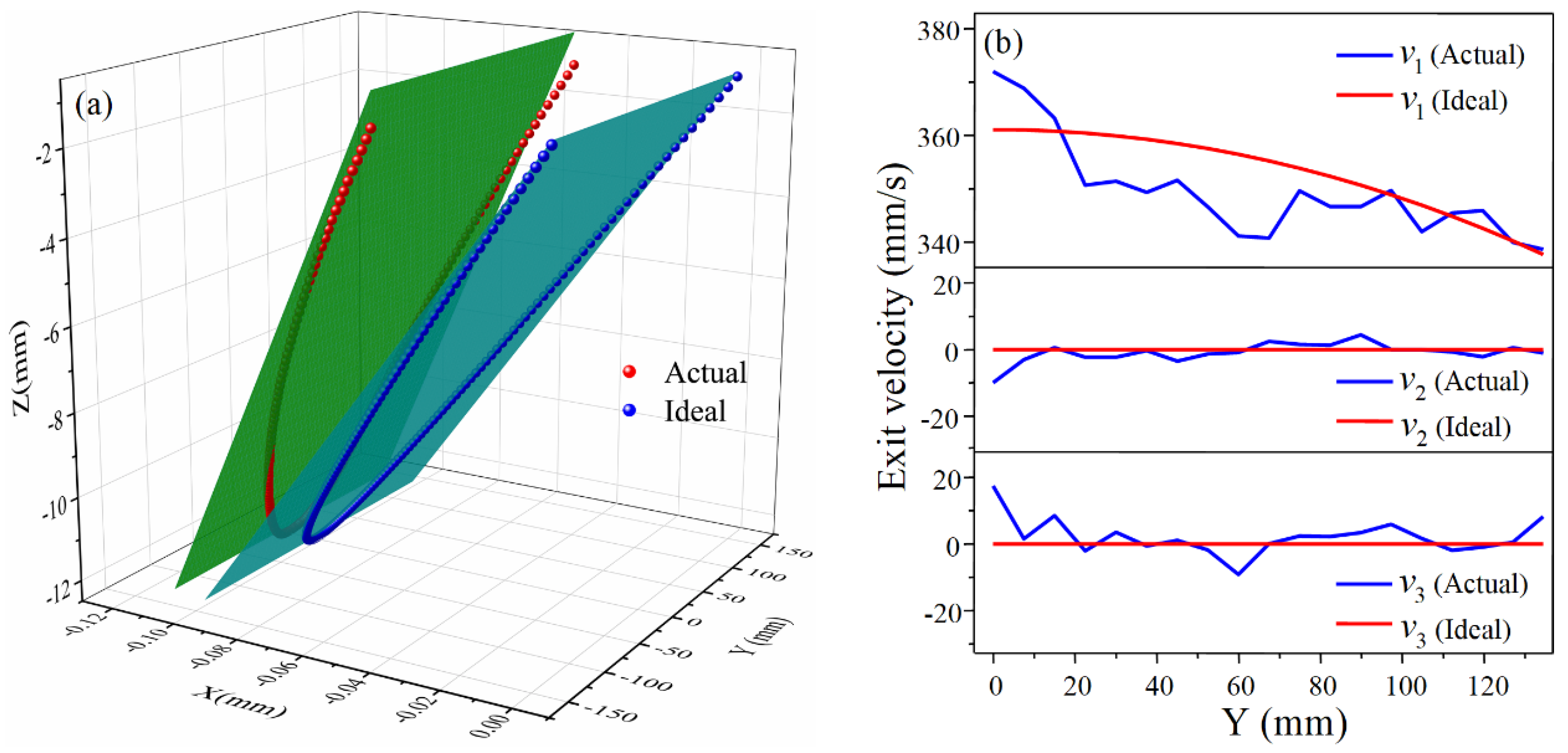

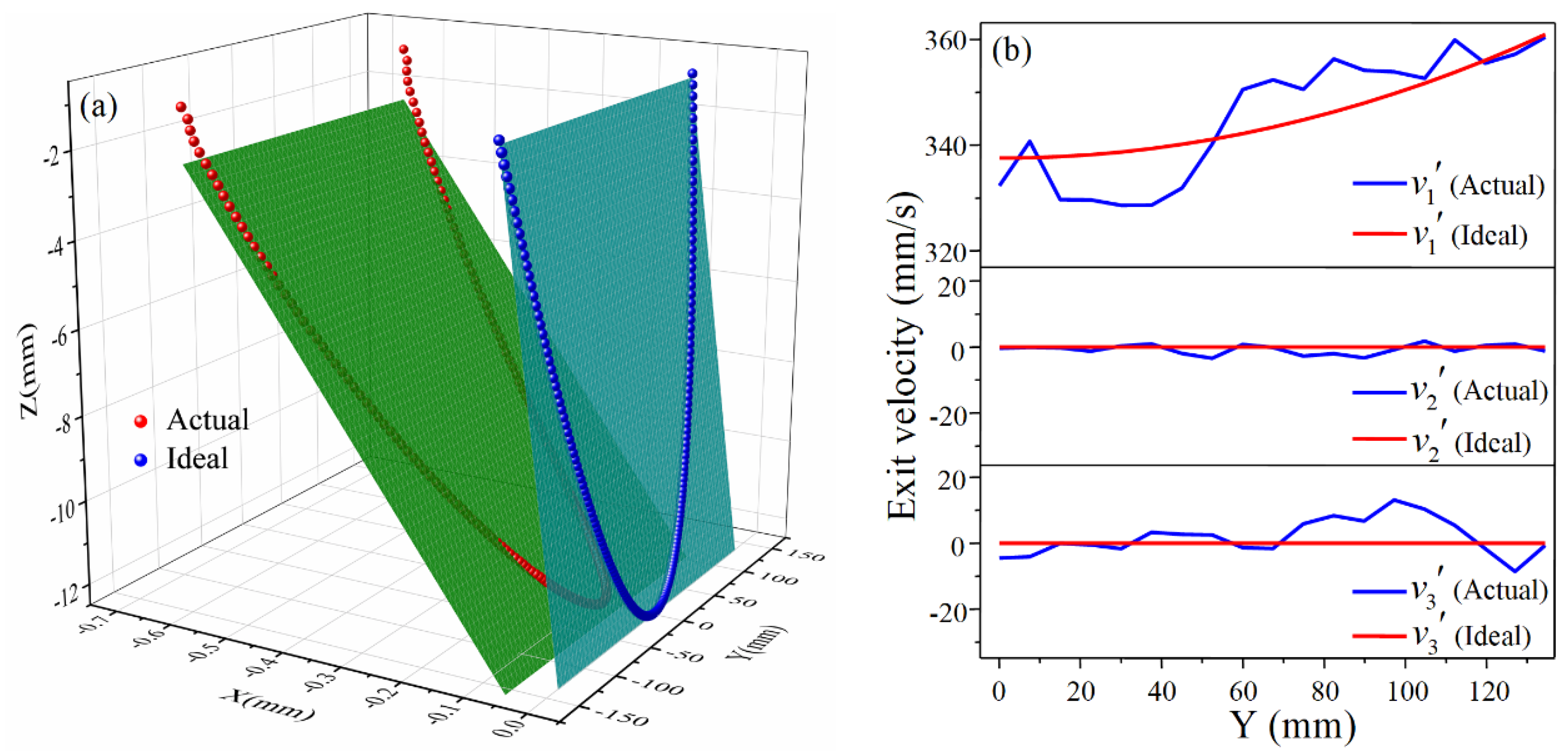

3.1. Generation and Analysis of Forming Errors

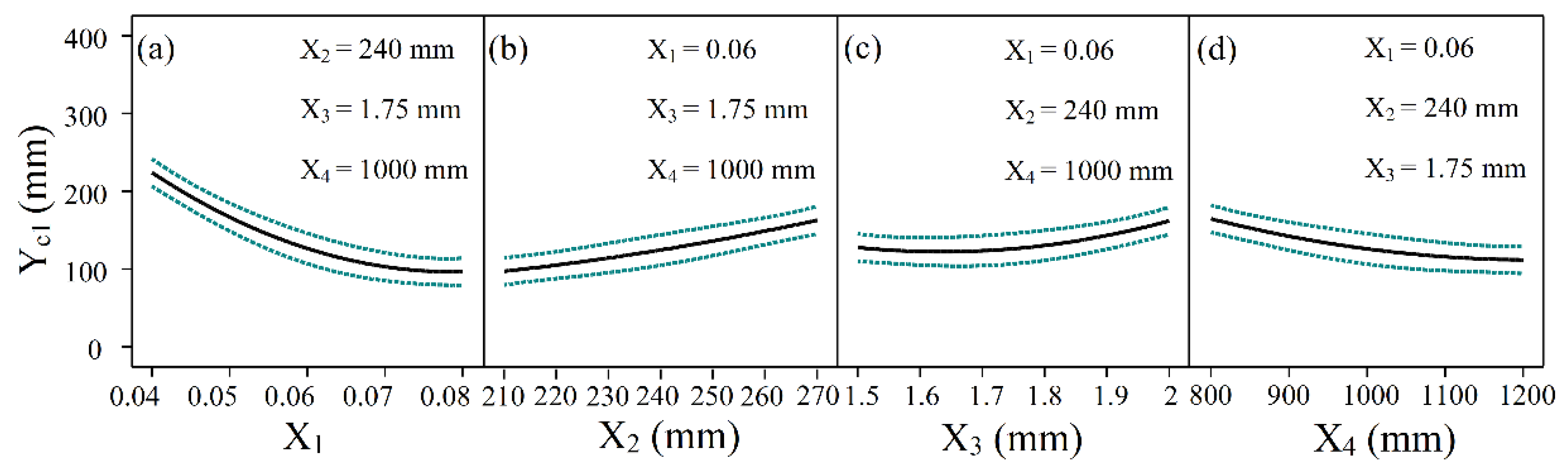

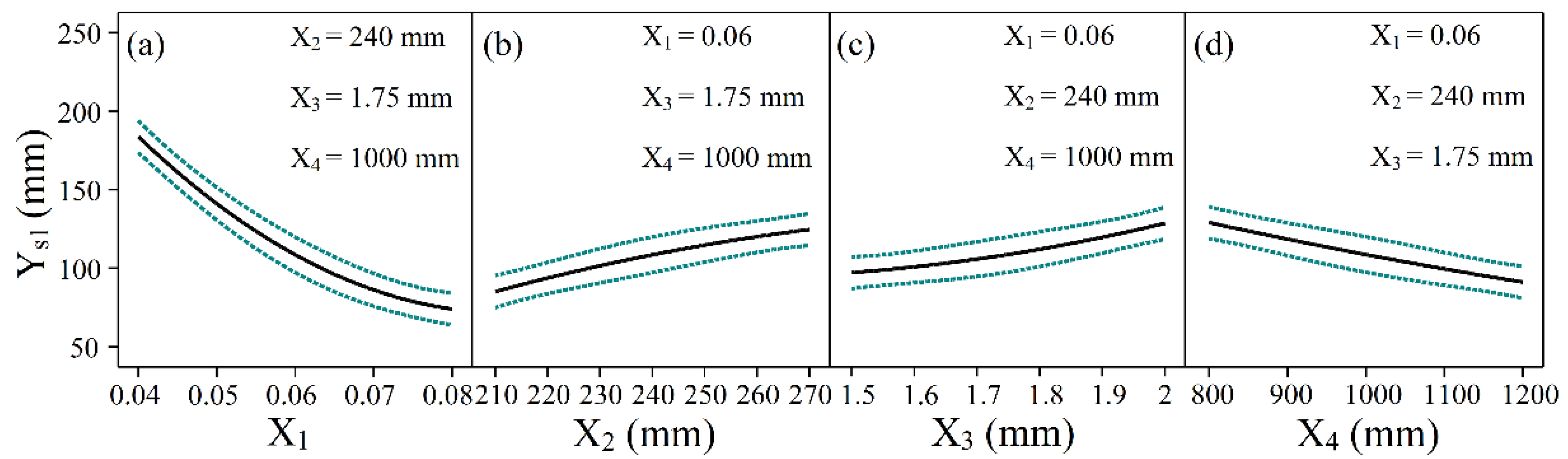

3.2. Influence of Various Factors on Longitudinal Radius Studied by Response Surface Methodology

4. Correction and Verification of the Formulas for Longitudinal Curvature Radius

4.1. Correction of the Formulas

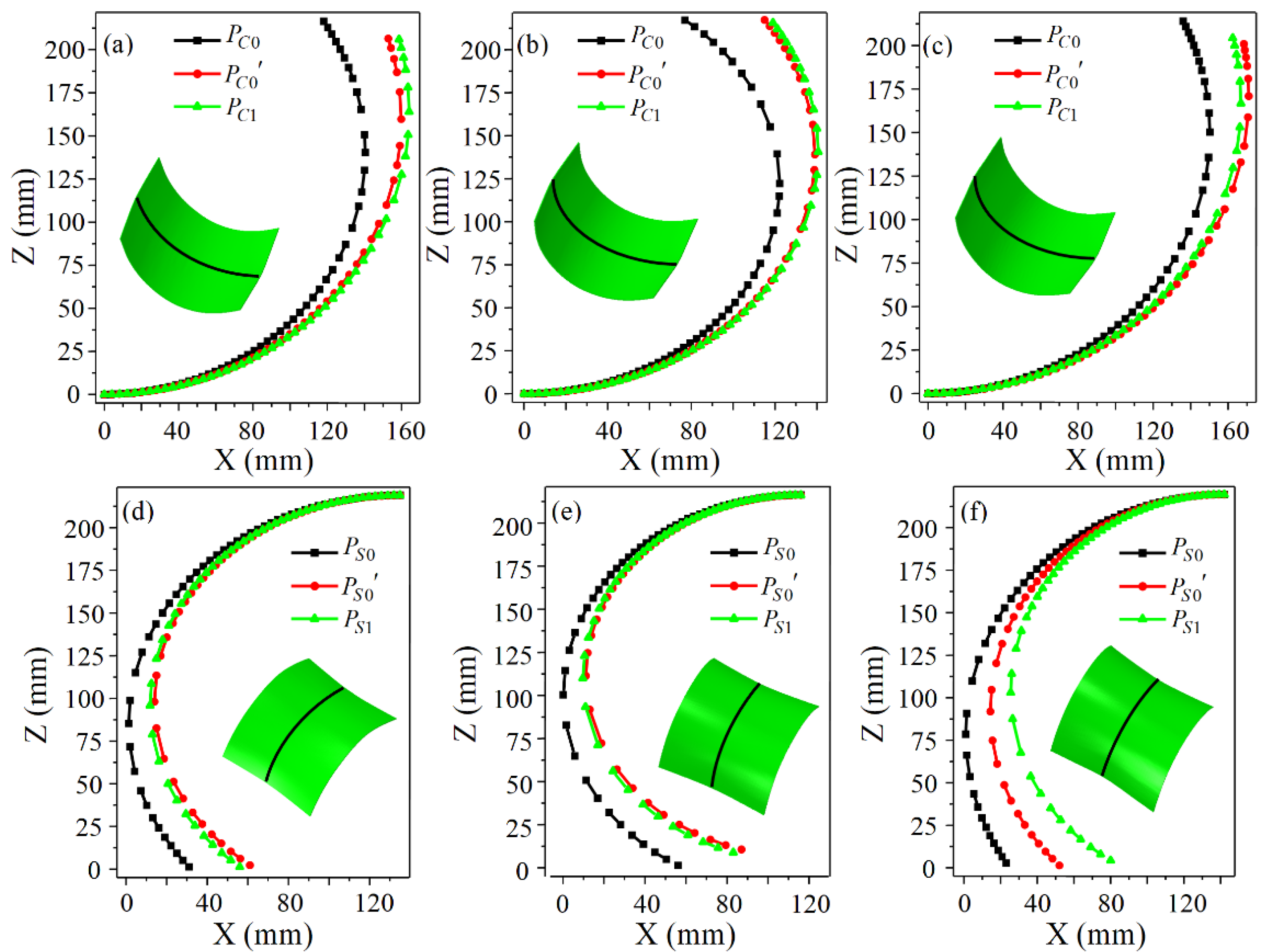

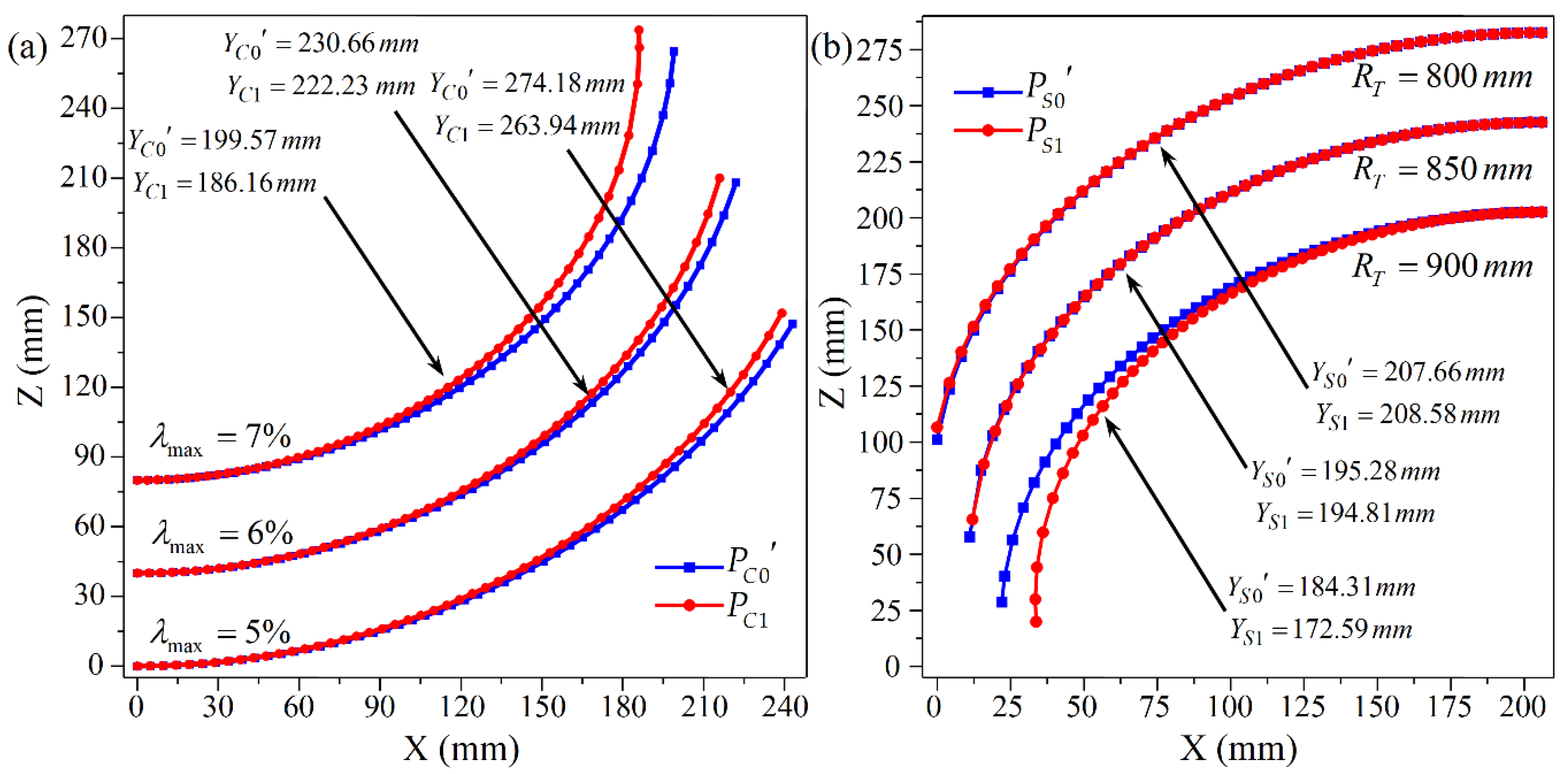

4.2. Verification of the Revised Formulas by Numerical Simulations

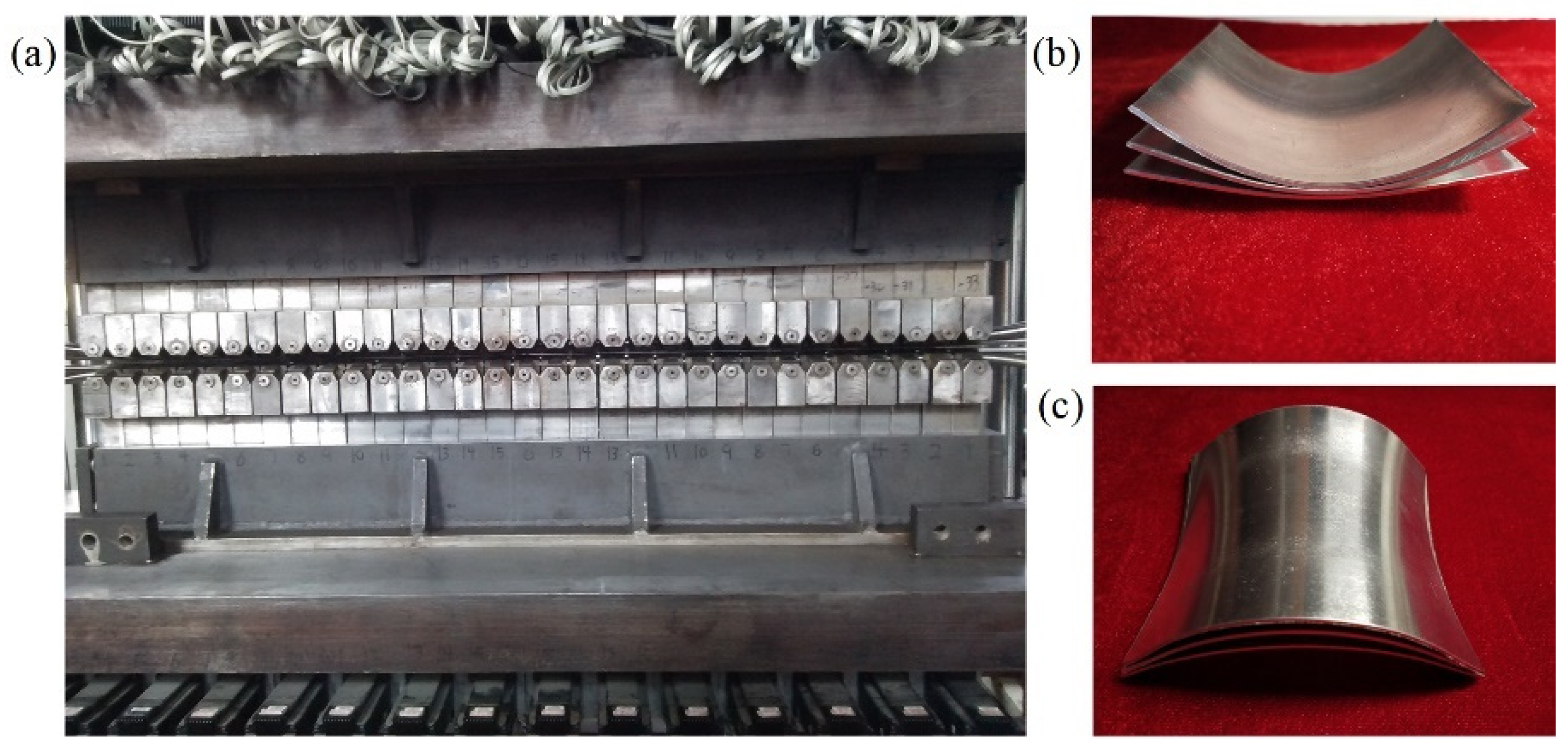

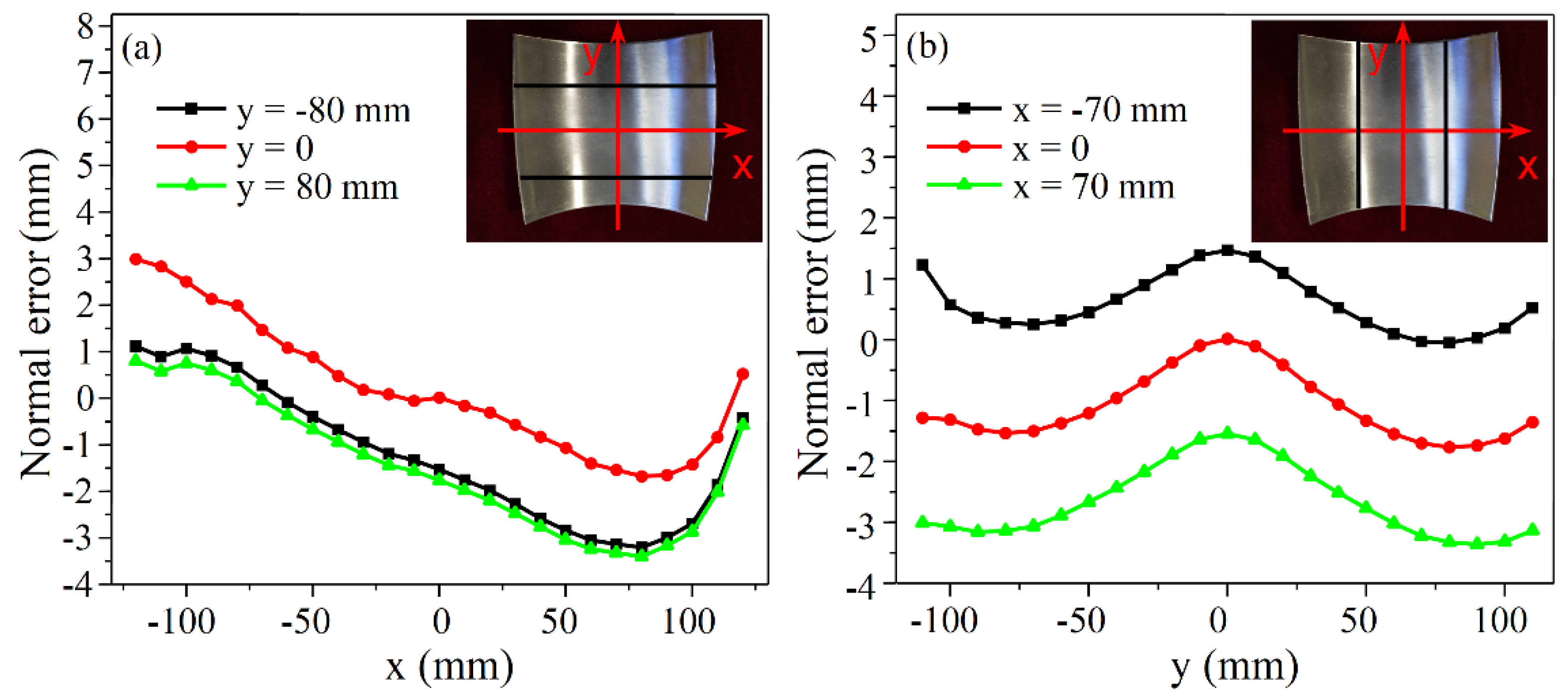

4.3. Verification of the Revised Formulas by Forming Experiment

4.4. Extension of the Revised Formulas for Different Materials

5. Conclusions

- The critical aspect of CRF is that the rolls are curved and the roll gap is not constant in the transverse direction. The fundamental reason for the longitudinal bending of sheet metal is that the uneven roll gap causes the velocity difference of the exit cross-section at different positions in the transverse direction, which makes the exit cross-section rotate.

- The calculation formulas for the longitudinal curvature radius are deduced, and it is found that the longitudinal radius of the positive Gaussian curvature surface is larger than the calculated value, and the longitudinal radius of the negative Gaussian curvature surface is smaller than the calculated value. It is analyzed that the error is caused by the longitudinal exit velocity not following the ideal linear distribution with respect to the Z-coordinate. The correction coefficients of the formulas based on Box–Behnken design are given as 1.138 and 0.905 for positive and negative Gaussian curvature surfaces, respectively.

- The effects of maximum compression ratio, sheet width, sheet thickness, and transverse curvature radius on the longitudinal curvature radius are analyzed by adopting the response surface methodology. The results reveal that the sheet width and sheet thickness have positive effects, while the maximum compression ratio and transverse curvature radius have negative effects.

- The validity of the corrected formulas is verified by numerical simulations and forming experiments. The numerical simulations show that the simulated profiles of the longitudinal centerlines fit well with the corrected calculated profiles. The experimental results indicate that the forming errors of the parts are very small. Compared with the predicted surfaces, the absolute values of the normal errors of the transverse profiles (x = 0 and x = ±70 mm) are within 3.5 mm for the positive Gaussian curvature surface and within 2 mm for the negative Gaussian curvature surface.

- Numerical simulations are conducted to demonstrate that the predicted formulas for the longitudinal curvature radius are equally applicable to the 08 Al sheet, so it is considered that the formulas derived in this paper can be applied to the shape prediction of the sheet in continuous roll forming with different materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xing, J.; Cheng, Y.Y.; Li, M.Z. Research on swinging unit multi-point die with discrete elastic cushion in flexible stretch forming process. Int. J. Adv. Manuf. Technol. 2017, 91, 237–245. [Google Scholar] [CrossRef]

- Beglarzadeh, B.; Davoodi, B. Numerical simulation and experimental examination of forming defects in multi-point deep drawing process. Mechanika 2016, 22, 182–189. [Google Scholar] [CrossRef][Green Version]

- Alavizadeh, S.M.; Karami, J.S. Experimental and numerical investigation on metal tubes forming with a novel reconfigurable hydroforming die based on multi-point forming. Prod. Eng.-Res. Dev. 2019, 13, 489–500. [Google Scholar] [CrossRef]

- Gong, X.P.; Li, M.Z.; Lu, Q.P.; Peng, Z.Q. Research on continuous multi-point forming method for rotary surface. J. Mater. Process. Technol. 2012, 212, 227–236. [Google Scholar] [CrossRef]

- Yamashita, I.; Yamakawa, T. Apparatus for Forming Plate with a Double-Curved Surface. U.S. Patent 4,770,017, 13 September 1988. [Google Scholar]

- Yoon, S.J.; Yang, D.Y. Development of a highly flexible incremental roll forming process for the manufacture of a doubly curved sheet metal. CIRP Ann-Manuf. Technol. 2003, 52, 201–204. [Google Scholar] [CrossRef]

- Yoon, S.J.; Yang, D.Y. An incremental roll forming process for manufacturing doubly curved sheets from general quadrilateral sheet blanks with enhanced process features. CIRP Ann-Manuf. Technol. 2005, 54, 221–224. [Google Scholar] [CrossRef]

- Shim, D.S.; Yang, D.Y.; Kim, K.H.; Chung, S.W.; Han, M.S. Investigation into forming sequences for the incremental forming of doubly curved plates using the line array roll set (LARS) process. Int. J. Mach. Tools Manuf. 2010, 50, 214–218. [Google Scholar] [CrossRef]

- Shim, D.S.; Yang, D.Y.; Kim, K.H.; Han, M.S.; Chung, S.W. Numerical and experimental investigation into cold incremental rolling of doubly curved plates for process design of a new LARS (line array roll set) rolling process. CIRP Ann-Manuf. Technol. 2009, 58, 239–242. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Lan, Y.W.; Li, M.Z.; Hu, Z.Q.; Wang, M. Continuous sheet metal forming for doubly curved surface parts. Int. J. Precis. Eng. Manuf. 2012, 13, 1997–2003. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Li, M.Z.; Lan, Y.W. Three-dimensional sheet metal continuous forming process based on flexible roll bending: Principle and experiments. J. Mater. Process. Technol. 2012, 212, 120–127. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Li, M.Z. Mechanical mechanism of continuous roll forming for three-dimensional surface parts and the calculation of bending deformation. J. Mech. Eng. 2013, 49, 35–41. [Google Scholar] [CrossRef]

- Li, M.Z.; Cai, Z.Y.; Li, R.J.; Lan, Y.W.; Qiu, N.J. Continuous forming method for three-dimensional surface parts based on the rolling process using bended roll. J. Mech. Eng. 2012, 48, 44–49. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Guan, D.B.; Wang, M.; Li, M.Z. A novel continuous roll forming process of sheet metal based on bended rolls. Int. J. Adv. Manuf. Technol. 2014, 73, 1807–1814. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Li, L.L.; Wang, M.; Li, M.Z. Process design and longitudinal deformation prediction in continuous sheet metal roll forming for three- dimensional surface. Int. J. Precis. Eng. Manuf. 2014, 15, 1889–1895. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Li, M.Z. Principle and theoretical analysis of continuous roll forming for three-dimensional surface parts. Sci. China-Technol. Sci. 2013, 56, 351–358. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Wang, M.; Li, M.Z. Study on the continuous roll forming process of swept surface sheet metal part. J. Mater. Process. Technol. 2014, 214, 1820–1827. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.Z.; Liu, K. Study on the utilization rate of processed spherical surface part in flexible rolling. Int. J. Adv. Manuf. Technol. 2019, 100, 3207–3218. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.Z.; Liu, K.; Li, Z. Effect of differential speed rotation technology on the forming uniformity in flexible rolling process. Materials 2018, 11, 1906. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Liu, Z.N.; Lu, G.L.; Cai, Z.Y. Analysis of continuous roll forming for manufacturing 3D surface part with lateral bending deformation. Int. J. Adv. Manuf. Technol. 2017, 93, 2251–2261. [Google Scholar] [CrossRef]

- Yoon, J.S.; Kim, J.; Kang, B.S. Deformation analysis and shape prediction for sheet forming using flexibly reconfigurable roll forming. J. Mater. Process. Technol. 2016, 233, 192–205. [Google Scholar] [CrossRef]

- Ghiabakloo, H.; Kim, J.; Kang, B.S. An efficient finite element approach for shape prediction in flexibly-reconfigurable roll forming process. Int. J. Mech. Sci. 2018, 142, 339–358. [Google Scholar] [CrossRef]

- Ghiabakloo, H.; Kim, J.; Kang, B.S. Specialized finite elements for numerical simulation of the flexibly-reconfigurable roll forming process. Int. J. Mech. Sci. 2019, 151, 133–153. [Google Scholar] [CrossRef]

- Ghiabakloo, H.; Park, J.W.; Kil, M.G.; Lee, K.; Kang, B.S. Design of the flexibly-reconfigurable roll forming process by a progressively-improving goal seeking approach. Int. J. Mech. Sci. 2019, 157–158, 136–149. [Google Scholar] [CrossRef]

- Park, J.W.; Kang, B.S. Comparison between regression and artificial neural network for prediction model of flexibly reconfigurable roll forming process. Int. J. Adv. Manuf. Technol. 2019, 101, 3081–3091. [Google Scholar] [CrossRef]

- Park, J.W.; Yoon, J.; Lee, K.; Kim, J.; Kang, B.S. Rapid prediction of longitudinal curvature obtained by flexibly reconfigurable roll forming using response surface methodology. Int. J. Adv. Manuf. Technol. 2017, 91, 3371–3384. [Google Scholar] [CrossRef]

- Kang, Y.L.; Sun, J.L. Rolling Engineering, 2nd ed.; Tan, X.Y., Ed.; Metallurgical Industry Press: Beijing, China, 2014. [Google Scholar]

| Chemical Element | Al | Cu | Mg | Mn | Cr | Fe | Si | Ti | Zn |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 90.7–94.7 | 3.8–4.9 | 1.2–1.8 | 0.3–0.9 | 0.1 | 0.5 | 0.5 | 0.15 | 0.25 |

| Code | Level | |||

|---|---|---|---|---|

| X1 | X2 (mm) | X3 (mm) | X4 (mm) | |

| −1 | 0.04 | 210 | 1.5 | 800 |

| 0 | 0.06 | 240 | 1.75 | 1000 |

| 1 | 0.08 | 270 | 2 | 1200 |

| Run | X1 | X2 | X3 | X4 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | −1 | −1 | 159.90 | 169.55 | 9.65 | 150.85 | 114.85 | 36.00 |

| 2 | 0 | −1 | 1 | 0 | 97.66 | 144.94 | 47.28 | 92.13 | 95.44 | 3.31 |

| 3 | 1 | 0 | −1 | 0 | 97.55 | 101.67 | 4.12 | 90.33 | 65.32 | 25.01 |

| 4 | 0 | −1 | 0 | 1 | 81.31 | 97.81 | 16.50 | 76.71 | 77.53 | 0.82 |

| 5 | −1 | 1 | 0 | 0 | 238.01 | 250.80 | 12.79 | 228.86 | 208.33 | 20.53 |

| 6 | 0 | 0 | −1 | 1 | 106.27 | 110.36 | 4.09 | 100.25 | 81.88 | 18.37 |

| 7 | 1 | 0 | 1 | 0 | 97.55 | 120.13 | 22.58 | 90.33 | 88.80 | 1.53 |

| 8 | −1 | −1 | 0 | 0 | 143.72 | 187.63 | 43.91 | 138.19 | 142.53 | 4.34 |

| 9 | 0 | 1 | −1 | 0 | 161.73 | 164.11 | 2.38 | 152.57 | 114.51 | 38.06 |

| 10 | −1 | 0 | 0 | −1 | 235.33 | 256.88 | 21.55 | 226.28 | 206.11 | 20.17 |

| 11 | −1 | 0 | 0 | 1 | 156.39 | 195.09 | 38.70 | 150.38 | 153.36 | 2.98 |

| 12 | 0 | 0 | 1 | 1 | 106.27 | 141.88 | 35.61 | 100.25 | 104.32 | 4.07 |

| 13 | 0 | 0 | 0 | 0 | 127.66 | 126.46 | 1.20 | 120.44 | 108.63 | 11.81 |

| 14 | 0 | 0 | 0 | 0 | 127.66 | 126.46 | 1.20 | 120.44 | 108.63 | 11.81 |

| 15 | 0 | −1 | −1 | 0 | 97.66 | 99.29 | 1.63 | 92.13 | 80.27 | 11.86 |

| 16 | 0 | −1 | 0 | −1 | 122.26 | 121.85 | 0.41 | 115.34 | 106.25 | 9.09 |

| 17 | 0 | 1 | 0 | −1 | 202.69 | 225.29 | 22.60 | 191.21 | 152.87 | 38.34 |

| 18 | 0 | 1 | 0 | 1 | 134.58 | 164.39 | 29.81 | 126.97 | 107.11 | 19.86 |

| 19 | 0 | 0 | 0 | 0 | 127.66 | 126.46 | 1.20 | 120.44 | 108.63 | 11.81 |

| 20 | 1 | 1 | 0 | 0 | 123.58 | 139.56 | 15.98 | 114.43 | 83.12 | 31.31 |

| 21 | −1 | 0 | −1 | 0 | 187.88 | 225.79 | 37.91 | 180.65 | 161.37 | 19.28 |

| 22 | −1 | 0 | 1 | 0 | 187.88 | 300.29 | 112.41 | 180.65 | 234.78 | 54.13 |

| 23 | 0 | 0 | 1 | −1 | 159.90 | 195.65 | 35.75 | 150.85 | 149.58 | 1.27 |

| 24 | 0 | 1 | 1 | 0 | 161.73 | 172.24 | 10.51 | 152.57 | 134.33 | 18.24 |

| 25 | 1 | −1 | 0 | 0 | 74.63 | 73.13 | 1.50 | 69.10 | 60.91 | 8.19 |

| 26 | 1 | 0 | 0 | −1 | 122.19 | 136.85 | 14.66 | 113.14 | 86.04 | 27.10 |

| 27 | 1 | 0 | 0 | 1 | 81.20 | 80.35 | 0.85 | 75.19 | 64.12 | 11.07 |

| Test Number | X1 | X2 (mm) | X3 (mm) | X4 (mm) |

|---|---|---|---|---|

| 1 | 0.05 | 225 | 1.8 | 950 |

| 2 | 0.055 | 231 | 1.9 | 1050 |

| 3 | 0.065 | 249 | 1.6 | 850 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.-X.; Chen, Q.-M.; Sun, L.-R.; Cai, Z.-Y. Shape Prediction of the Sheet in Continuous Roll Forming Based on the Analysis of Exit Velocity. Materials 2021, 14, 5178. https://doi.org/10.3390/ma14185178

Gao J-X, Chen Q-M, Sun L-R, Cai Z-Y. Shape Prediction of the Sheet in Continuous Roll Forming Based on the Analysis of Exit Velocity. Materials. 2021; 14(18):5178. https://doi.org/10.3390/ma14185178

Chicago/Turabian StyleGao, Jia-Xin, Qing-Min Chen, Li-Rong Sun, and Zhong-Yi Cai. 2021. "Shape Prediction of the Sheet in Continuous Roll Forming Based on the Analysis of Exit Velocity" Materials 14, no. 18: 5178. https://doi.org/10.3390/ma14185178

APA StyleGao, J.-X., Chen, Q.-M., Sun, L.-R., & Cai, Z.-Y. (2021). Shape Prediction of the Sheet in Continuous Roll Forming Based on the Analysis of Exit Velocity. Materials, 14(18), 5178. https://doi.org/10.3390/ma14185178