Development of Alternative Method for Manufacturing Structural Zirconium Elements for Nuclear Engineering

Abstract

:1. Introduction

- Briquetting by pressing and sintering zirconium powder;

- Ingot smelting;

- The production of workpieces employing hot pressure treatment methods (forging, rolling) and mechanical processing;

- Hot pressing;

- The production of finished products by cold pressure treatment methods (rolling, drawing) with intermediate thermal, mechanical, and chemical treatments.

2. Materials and Methods

3. Results and Discussion

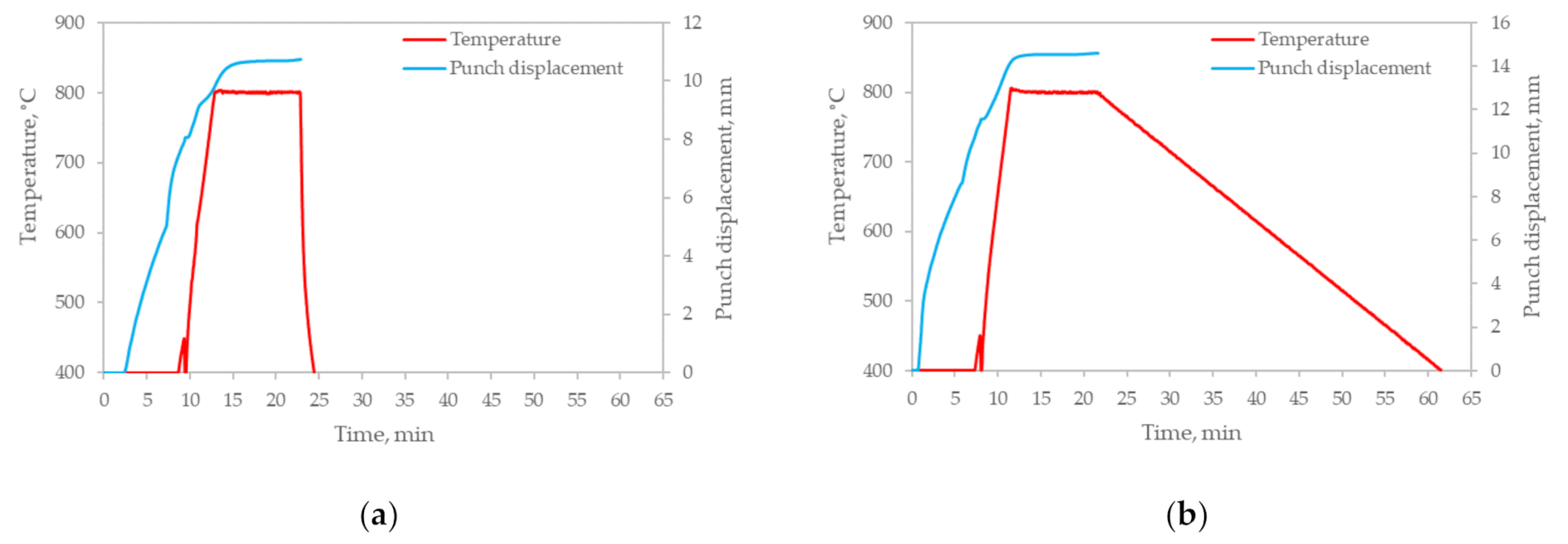

3.1. Investigation of Effect of Spark Plasma Sintering Regime on Density and Microhardness

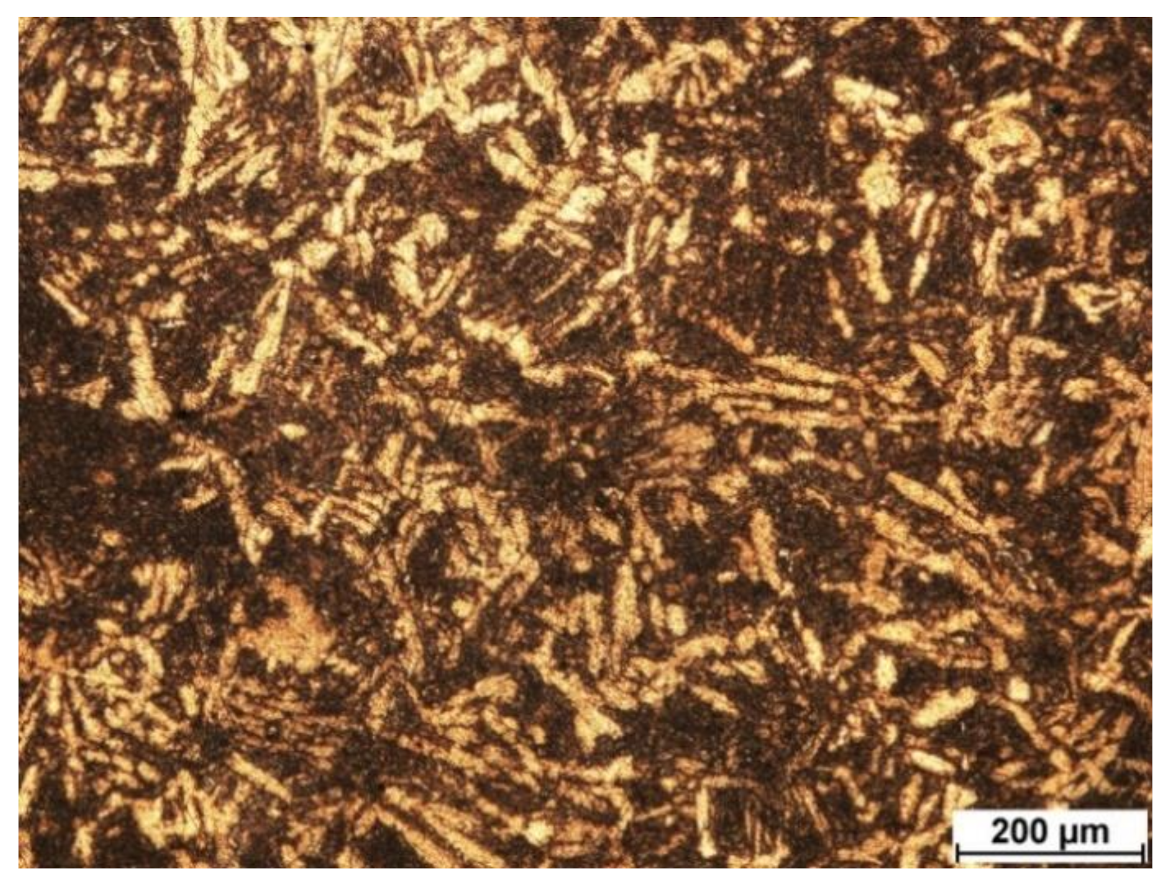

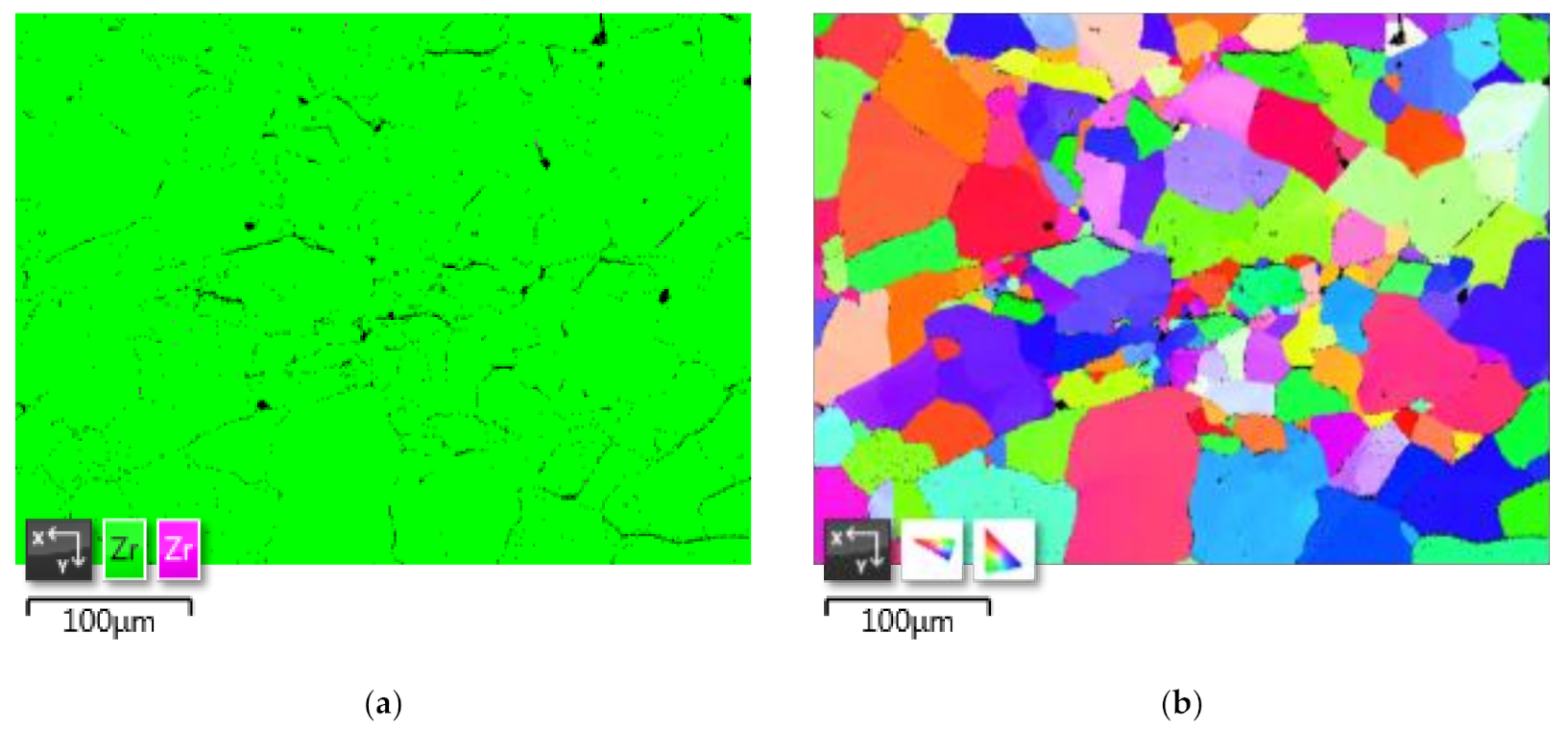

3.2. Investigation of Effect of Spark Plasma Sintering Cooling Rate and Subsequent Heat Treatment Regime on Microstructure and Microhardness

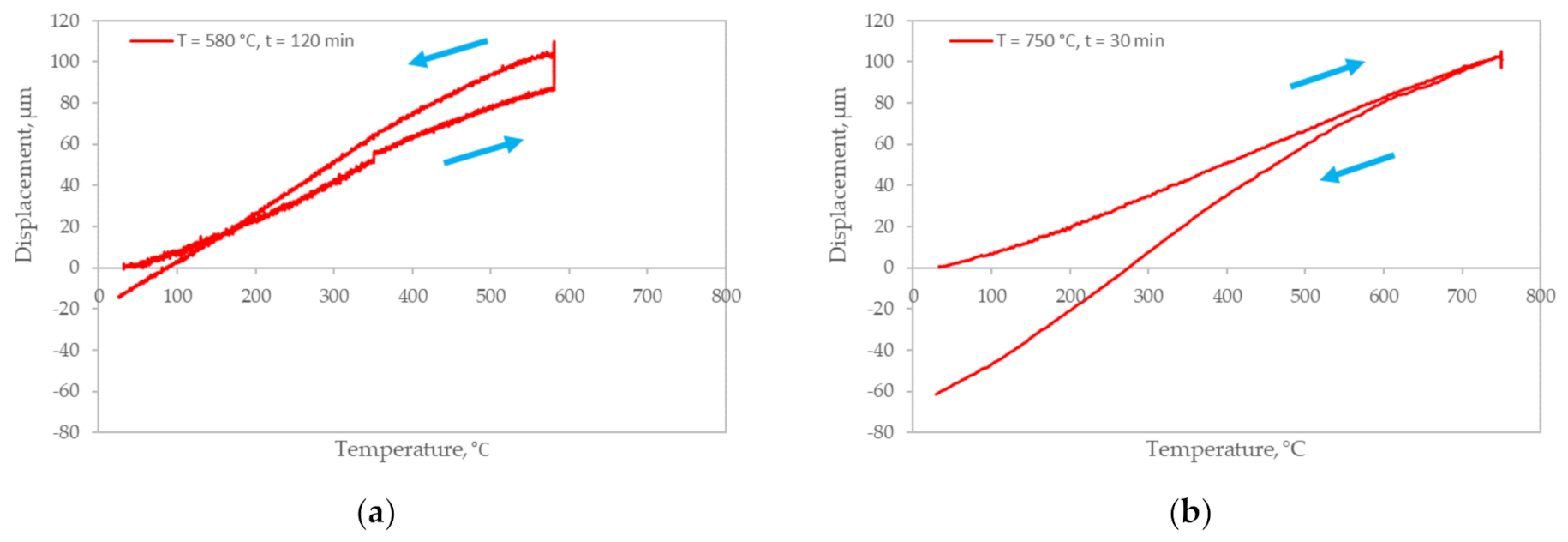

3.3. Dilatometric Tests of Spark Plasma Sintered Zirconium

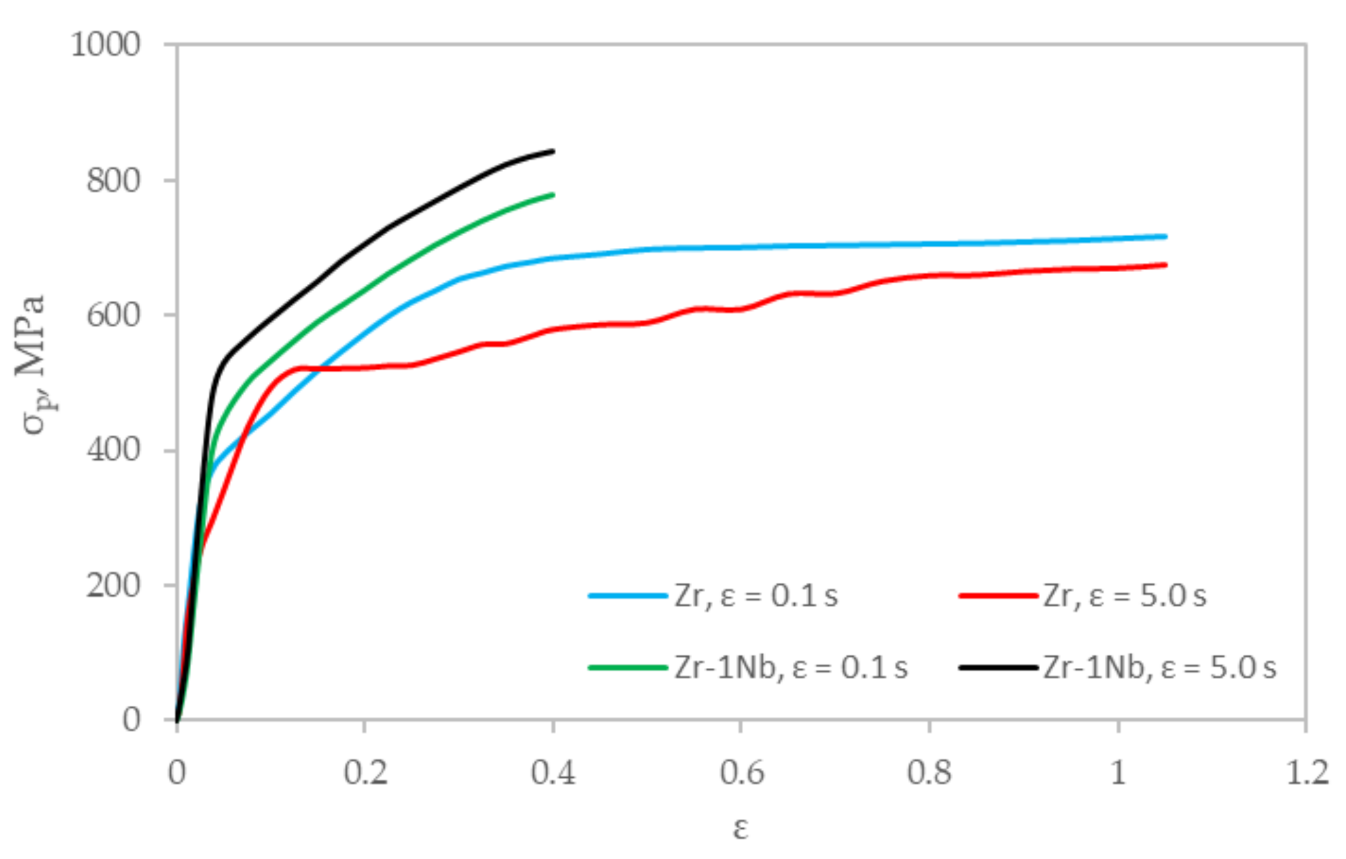

3.4. Results of Mechanical and Rheological Tests of Spark Plasma Sintered Zirconium. Comparison of Results with Traditional Manufacturing Route

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Melechow, R.; Tubielewicz, K. Materiały Stosowane w Energetyce Jądrowej [Materials Used in Nuclear Energy]; Wydawnictwo Politechniki Częstochowskiej: Częstochowa, Poland, 2002; Volume 86, p. 229. [Google Scholar]

- Zajmovskij, A.S.; Nikulina, A.V.; Reshetnikov, N.G. Cirkonievye Splavy v Yadernoj Ehnergetike [Zirconium Alloys in Nuclear Power]; Energoatomizdat: Moscow, Russia, 1994. [Google Scholar]

- Azhazha, V.M.; V’yugov, P.N.; Lavrinenko, S.D. Cirkonij i Ego Splavy: Tekhnologii Proizvodstva, Oblasti Primeneniya [Zirconium and Its Alloys: Production Technologies, Applications]; NNC HFTI: Kharkiv, Ukraine, 1998. [Google Scholar]

- Dric, M.E.; Budberg, P.B.; Kuznecov, N.T. Svojstva Elementov: Sprav. izd. V 2-h kn. [Element Properties: Ref. Ed. in 2 Books]; GUP ZHurnal Cvetnye Metally: Moscow, Russia, 1997. [Google Scholar]

- Gaillac, A.; Ly, C. Optimized manufacture of nuclear fuel cladding tubes by FEA of hot extrusion and cold pilgering processes. In AIP Conference Proceedings; AIP Publishing LLC: College Park, MD, USA, 2018; Volume 1960. [Google Scholar]

- Arbuz, A.; Kawalek, A.; Ozhmegov, K.; Dyja, H.; Panin, E.; Lepsibayev, A.; Sultanbekov, S.; Shamenova, R. Using of Radial-Shear Rolling to Improve the Structure and Radiation Resistance of Zirconium-Based Alloys. Materials 2020, 13, 4306. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shabani, A. Spark Plasma Sintering: Process Fundamentals. In Spark Plasma Sintering of Materials: Advances in Processing and Applications; Cavaliere, P., Ed.; Springer: Cham, Switzerland, 2019; pp. 3–20. [Google Scholar]

- ASTM B-351. Standard Specification for Hot-Rolled and Cold-Finished Zirconium and Zirconium Alloy Bars, Rod, and Wire for Nuclear Application; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Garbiec, D.; Kawałek, A.; Ozhmegov, K.V. Sposób otrzymywania półwyrobów z cyrkonu [Method of producing semi-finished products of zirconium]; The Patent Office of the Republic of Poland: Warsaw, Poland, 2018. [Google Scholar]

- Zavodchikov, S.Y. Metallovedcheskie Voprosy Proizvodstva Izdelij iz Splavov Cirkoniya [Metallurgical Issues of the Production of Products from Zirconium Alloys]; Nauka: Novosibirsk, Russia, 2012; p. 256. [Google Scholar]

- ISO 3369:2006. Impermeable Sintered Metal Materials and Hardmetals—Determination of Density; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 6507-1:2007. Metallic Materials—Vickers Hardness Test—Part 1: Test Method; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- GOST 25.503-87. Design Calculation and Strength Testing. Methods of Mechanical Testing of Metals. Method of Compression Testing; Rosstandart: Moscow, Russia, 1999. [Google Scholar]

- Kawałek, A.; Gałkin, A.; Dyja, H.; Ozhmegov, K.; Knapiński, M.; Koczurkiewicz, B. Plastometric Modelling of the E635M Zirconium Alloy Multistage Forging Process. Solid State Phenom. 2015, 220–221, 808–812. [Google Scholar] [CrossRef]

- Kawałek, K.; Dyja, H.; Galkin, A.M.; Ozhmegov, K.V.; Knapiński, M. Physical modelling of the plastic working processes of modified Zr-Nb zirconium alloy bars and tubes. Metalurgija 2015, 54, 79–82. [Google Scholar]

- Kawałek, A.; Rapalska-Nowakowska, J.; Dyja, H.; Koczurkiewicz, B. Physical and numerical modelling of heat treatment the precipitation-hardening complex-phase steel (CP). Metalurgija Sisak Zagreb 2013, 52, 23–26. [Google Scholar]

- Poluhin, P.I.; Gun, G.Y.; Galkin, A.M. Soprotivlenie Plasticheskoj Deformacii Metallov i Splavov [Resistance to Plastic Deformation of Metals and Alloys]; Metallurgiya: Moscow, Russia, 1983; p. 352. [Google Scholar]

- Douglass, D.L. The Metallurgy of Zirconium; International Atomic Energy Agency: Vienna, Austria, 1971; p. 466. [Google Scholar]

- Neogy, S.; Srivastava, D.; Dey, G.; Chakravartty, J.K.; Banerjee, S. Annealing studies on Zr-1Nb and Zr-1Nb-1Sn-0.1Fe alloys. Trans. Indian Inst. Met. 2004, 57, 509–519. [Google Scholar]

- Lim, Y.-S.; Kim, H.-G.; Jeong, Y.-H. Recrystallization Behavior of Zr-xNb Alloys. Mater. Trans. 2008, 49, 1702–1705. [Google Scholar] [CrossRef] [Green Version]

- Abe, H.; Furugen, M. Method of Evaluating Workability in Cold Pilgering of Zirconium Alloy Tube. Mater. Trans. 2010, 51, 1200–1205. [Google Scholar] [CrossRef] [Green Version]

- Zaefferer, S.; Wright, S.I.; Raabe, D. Three-Dimensional Orientation Microscopy in a Focused Ion Beam–Scanning Electron Microscope: A New Dimension of Microstructure Characterization. Metall. Mater. Trans. A 2008, 39, 374–389. [Google Scholar] [CrossRef] [Green Version]

- Jaworska, L.; Skrzekut, T.; Stępień, M.; Pałka, P.; Boczkal, G.; Zwoliński, A.; Noga, P.; Podsiadło, M.; Wnuk, R.; Ostachowski, P. The Pressure Compaction of Zr-Nb Powder Mixtures and Selected Properties of Sintered and KOBO-Extruded Zr-xNb Materials. Materials 2021, 14, 3172. [Google Scholar] [CrossRef]

- Dyja, H.; Gałkin, A.; Knapiński, M. Reologia Metali Odkształcanych Plastycznie [Rheology of Plastically Deformed Metals]; Wydawnictwo Politechniki Częstochowskiej: Częstochowa, Poland, 2010; Volume 190, p. 371. [Google Scholar]

| Zr wt % | B wt % | Al ppm | Fe ppm | Si ppm | Mn ppm | Ni ppm | Ti ppm | Cr ppm | Hf ppm | O ppm | C ppm | N ppm | F ppm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 99.80 | 0.43 | 30 | 163 | <30 | 3 | 19 | <30 | 18 | 361 | 730 | 36 | 29 | 180 |

| SPS Temperature | T = 800 °C | |||

|---|---|---|---|---|

| SPS cooling | Rapid | Rapid | Rapid | Slow |

| 400 °C/min | 400 °C/min | 400 °C/min | 10 °C/min | |

| Heat treatment temperature and time (residual pressure in vacuum no more than 1 × 10−4 torr) | – | – | ||

| Heat treatment heating & cooling | 100 °C 10 °C until 300 °C then free cooling | 100 °C 10 °C until 300 °C then free cooling | – | – |

| Sintering Temperature, °C | Cooling Rate, °C/min | Bulk Density, g/cm3 | Microhardness, HV0.05 |

|---|---|---|---|

| 700 | 400 | 6.38 | 135 ± 12 |

| 10 | 6.39 | 139 ± 9 | |

| 750 | 400 | 6.38 | 136 ± 15 |

| 10 | 6.39 | 134 ± 14 | |

| 800 | 400 | 6.40 | 151 ± 18 |

| 10 | 6.44 | 151 ± 14 | |

| 1400 | 400 | 6.48 | 150 ± 20 |

| Sample | Yield Strength, MPa | Ultimate Tensile Strength, MPa |

|---|---|---|

| Zr (grade R60001) | >140 | >290 |

| Zr (SPS) | 220 | 380 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozhmegov, K.; Kawalek, A.; Garbiec, D.; Dyja, H.; Arbuz, A. Development of Alternative Method for Manufacturing Structural Zirconium Elements for Nuclear Engineering. Materials 2021, 14, 5006. https://doi.org/10.3390/ma14175006

Ozhmegov K, Kawalek A, Garbiec D, Dyja H, Arbuz A. Development of Alternative Method for Manufacturing Structural Zirconium Elements for Nuclear Engineering. Materials. 2021; 14(17):5006. https://doi.org/10.3390/ma14175006

Chicago/Turabian StyleOzhmegov, Kirill, Anna Kawalek, Dariusz Garbiec, Henryk Dyja, and Alexandr Arbuz. 2021. "Development of Alternative Method for Manufacturing Structural Zirconium Elements for Nuclear Engineering" Materials 14, no. 17: 5006. https://doi.org/10.3390/ma14175006

APA StyleOzhmegov, K., Kawalek, A., Garbiec, D., Dyja, H., & Arbuz, A. (2021). Development of Alternative Method for Manufacturing Structural Zirconium Elements for Nuclear Engineering. Materials, 14(17), 5006. https://doi.org/10.3390/ma14175006