Plasma Modification of Carbon Coating Produced by RF CVD on Oxidized NiTi Shape Memory Alloy under Glow-Discharge Conditions

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bakir, M. Haemocompatibility of titanium and its alloys. J. Biomater. Appl. 2012, 27, 3–15. [Google Scholar] [CrossRef]

- Jaganathan, S.K.; Supriyanto, E.; Murugesan, S.; Balaji, A.; Asokan, M.K. Biomaterials in cardiovascular research: Applications and clinical implications. BioMed Res. Int. 2014, 2014, 459–465. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, T.; Li, J.-A.; Chen, J.-Y.; Wang, J.; Huang, N. Surface modification of implanted cardiovascular metal stents: From antithrombosis and antirestenosis to endothelialisation. J. Biomed. Mater. Res. Part A 2014, 102, 588–609. [Google Scholar] [CrossRef]

- Yang, D.; Lü, X.; Hong, Y.; Xi, T.; Zhang, D. The molecular mechanism for effects of TiN coating on NiTi alloy on endothelial cell function. Biomaterials 2014, 35, 6195–6205. [Google Scholar] [CrossRef] [PubMed]

- Chou, S.F.; Caltrider, B.A.; Azghani, A.; Neuenschwander, P.F. Inhibition of platelet adhesion from surface modified polyurethane membranes. Biomed. J. Sci. Tech. Res. 2020, 32, 3. [Google Scholar] [CrossRef]

- Park, J.-W.; Han, S.H.; Hanawa, T. Effects of surface nanotopography and calcium chemistry of titanium bone implants on early blood platelet and macrophage cell function. BioMed Res. Int. 2018, 1362958. [Google Scholar] [CrossRef]

- Krsmanovic, M.; Biswas, D.; Ali, H.; Kumar, A.; Ghosh, R.; Dickerson, A.K. Hydrodynamics and surface properties influence biofilm proliferation. Adv. Colloid Interface Sci. 2021, 288, 102336. [Google Scholar] [CrossRef] [PubMed]

- Akhidime, I.D.; Slate, A.J.; Hulme, A.; Whitehead, K.A. The influence of surface topography and wettability on Escherichia coli removal from polymeric materials in the presence of a blood conditioning film. Int. J. Environ. Res. Public. Health 2020, 17, 7368. [Google Scholar] [CrossRef] [PubMed]

- Suarez, A.M.A.; van der Ham, I.; Brinker, M.G.L.; van Rijn, P.; Harmsen, M.C. Topography-driven alterations in endothelial cell phenotype and contact guidance. Heliyon 2020, 6, e04329. [Google Scholar] [CrossRef]

- Chai, F.; Ochsenbein, A.; Traisnel, M.; Busch, R.; Breme, J.; Hildebrand, H.F. Improving endothelial cell adhesion and proliferation on titanium by sol-gel derived oxide coating. J. Biomed. Mater. Res. Part A 2010, 92, 754–765. [Google Scholar] [CrossRef]

- Liu, X.; Chu, P.K.; Ding, C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater. Sci. Eng. R Rep. 2004, 47, 49–121. [Google Scholar] [CrossRef]

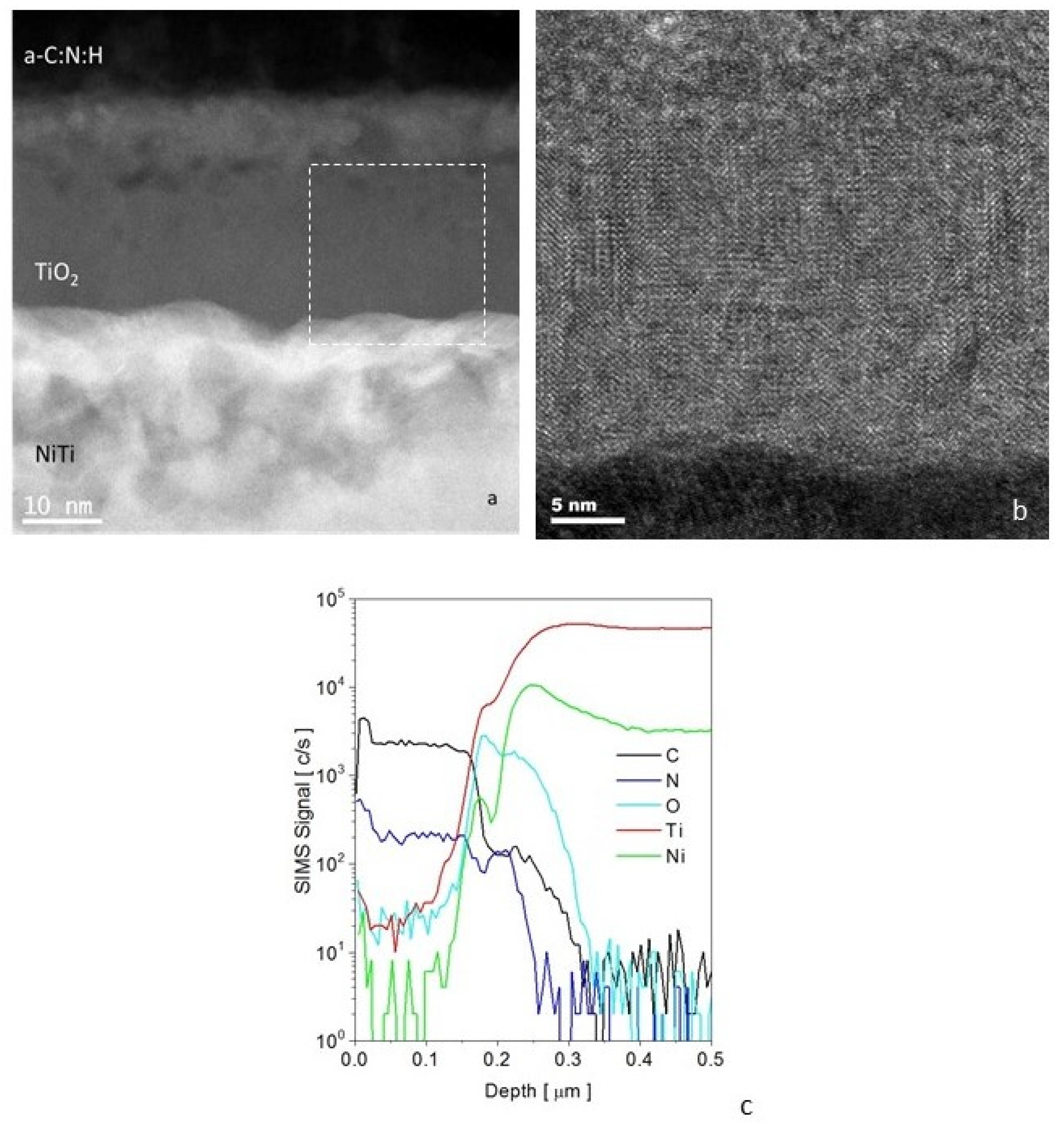

- Tarnowski, M.; Witkowska, J.; Morgiel, J.; Jakubowski, W.; Walkowiak, B.; Borowski, T.; Wierzchoń, T. Formation of nitrogen doped titanium dioxide surface layer on NiTi shape memory alloy. Materials 2021, 14, 1575. [Google Scholar] [CrossRef]

- Chrzanowski, W.; Abou, E.A.; Ae, N.; Armitage, D.A.; Knowles, A.J.C. Surface preparation of bioactive Ni-Ti alloy using alkali, thermal treatments and spark oxidation. J. Mater. Sci. Mater. Med. 2008, 19, 1553–1557. [Google Scholar] [CrossRef] [PubMed]

- Shabalovskaya, S.; Anderegg, J.; van Humbeeck, J. Critical overview of Nitinol surfaces and their modifications for medical applications. Acta Biomater. 2008, 4, 447–467. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Zheng, Y.F. Deposition of TiN coatings on shape memory NiTi alloy by plasma immersion ion implantation and deposition. Thin Solid Films 2006, 515, 1358–1363. [Google Scholar] [CrossRef]

- Witkowska, J.; Kamiński, J.; Płociński, T.; Tarnowski, M.; Wierzchoń, T. Corrosion resistance of NiTi shape memory alloy after hybrid surface treatment using low-temperature plasma. Vaccum 2017, 137, 92–96. [Google Scholar] [CrossRef]

- Michiardi, A.; Aparicio, C.; Ratner, B.D.; Planell, J.A.; Gil, J. The influence of surface energy on competitive protein adsorption on oxidized NiTi surfaces. Biomaterials 2007, 28, 586–594. [Google Scholar] [CrossRef] [PubMed]

- Spijker, H.T.; Graaff, R.; Boonstra, P.W.; Busscher, H.J.; van Oeveren, W. On the influence of flow conditions and wettability on blood material interactions. Biomaterials 2003, 24, 4717–4727. [Google Scholar] [CrossRef]

- Hang, R.; Zhang, M.; Ma, S.; Chu, P.K. Biological response of endothelial cells to diamond-like carbon-coated NiTi alloy. J. Biomed. Mater. Res. Part A 2012, 100, 496–506. [Google Scholar] [CrossRef]

- Fedel, M.; Motta, A.; Maniglio, D.; Migliaresi, C. Carbon coatings for cardiovascular applications: Physico-chemical properties and blood compatibility. J. Biomater. Appl. 2010, 25, 57–74. [Google Scholar] [CrossRef]

- Movahed, S.; Nguyen, A.K.; Goering, P.L.; Skoog, S.A.; Narayan, R.J. Argon and oxygen plasma treatment increases hydrophilicity and reduces adhesion of silicon-incorporated diamond-like coatings. Biointerphases 2020, 15, 041007. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Nakao, S.; Ikeyama, M.; Kato, T. Effect of oxygen plasma treatment on the tribological properties of Si-DLC coatings. Phys. Status Solidi 2008, 5, 956–959. [Google Scholar] [CrossRef]

- Kavaliauskas, I.; Marcinauskas, L.; Valincius, V. Infuence of the oxygen plasma treatment on carbon electrode and capacity of supercapacitors. Acta Phys. Pol. A 2014, 125, 1316–1318. [Google Scholar] [CrossRef]

- Mayama, T.; Hiratsuka, M.; Nakamori, H.; Homma, A.; Hirakuri, K.; Ohgoe, Y. Effect of oxygen plasma treatment on film structure for different types of DLC film. Trans. Mater. Res. Soc. Jpn. 2018, 43, 275–278. [Google Scholar] [CrossRef][Green Version]

- De Camargo, J.G.; de Menezes, A.J.; da Cruz, N.C.; Rangel, E.C.; Delgado-Silva, A.O. Morphological and chemical effects of plasma treatment with oxygen (O2) and sulfur hexafluoride (SF6) on cellulose surface. Mat. Res. 2017, 20, 842–850. [Google Scholar] [CrossRef]

- Mozetic, M. Plasma-stimulated super-hydrophilic surface finish of polymers. Polymers 2020, 12, 2498. [Google Scholar] [CrossRef] [PubMed]

- Learn, G.D.; Lai, E.J.; von Recum, H.A. Nonthermal plasma treatment improves uniformity and adherence of cyclodextrin-based coatings on hydrophobic polymer substrates. Coatings 2020, 10, 1056. [Google Scholar] [CrossRef]

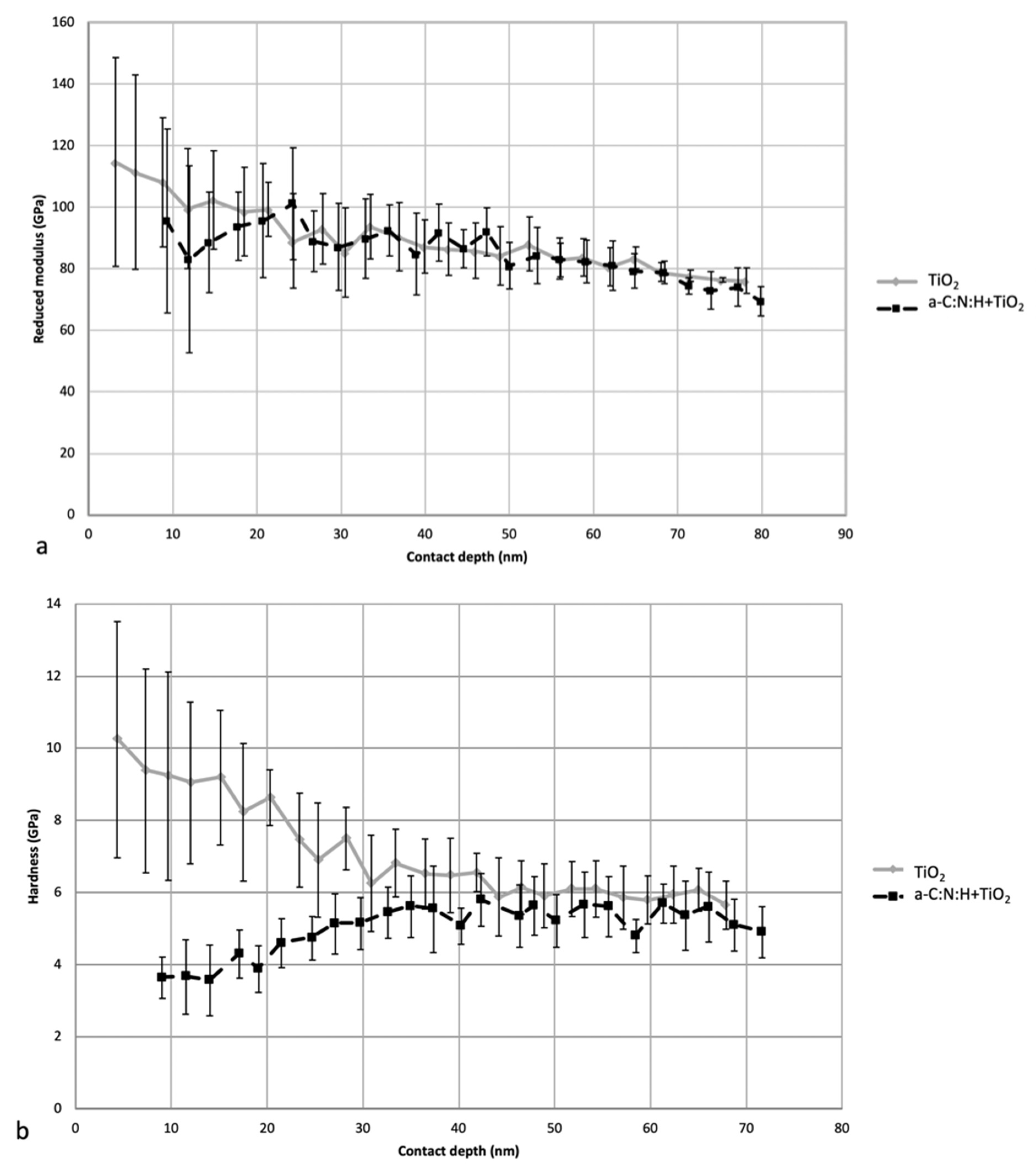

- Chlanda, A.; Witkowska, J.; Morgiel, J.; Nowińska, K.; Choińska, E.; Swieszkowski, W.; Wierzchoń, T. Multi-scale characterization and biological evaluation of composite surface layers produced under glow discharge conditions on NiTi shape memory alloy for potential cardiological application. Micron 2018, 114, 14–22. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Witkowska, J.; Sowińska, A.; Czarnowska, E.; Płociński, T.; Borowski, T.; Wierzchoń, T. NiTi shape-memory alloy oxidized in low-temperature plasma with carbon coating: Characteristic and a potential for cardiovascular applications. Appl. Surf. Sci. 2017, 421, 89–96. [Google Scholar] [CrossRef]

- Zhi, C.Y.; Bai, X.D.; Wang, E.G. Enhanced field emission from carbon nanotubes by hydrogen plasma treatment. Appl. Phys. Lett. 2002, 81, 1690–1962. [Google Scholar] [CrossRef]

- Tiwaria, S.; Bijwe, J. Surface Treatment of Carbon Fibers—A Review. Proc. Technol. 2014, 14, 505–512. [Google Scholar] [CrossRef]

- Chen, C.; Liang, B.; Ogino, A.; Wang, X.; Nagatsu, M. Oxygen functionalization of multiwall carbon nanotubes by microwave-excited surface-wave plasmatreatment. J. Phys. Chem. C 2009, 113, 7659–7665. [Google Scholar] [CrossRef]

- Li, C.; Dong, H.; Zhang, W.-W. Low-temperature plasma treatment of carbon fibre/epoxy resin composite. Surf. Eng. 2018, 34, 870–876. [Google Scholar] [CrossRef]

- Duch, J.; Kubisiak, P.; Adolfsson, K.H.; Hakkarainen, M.; Golda-Cepa, M.; Kotarba, A. Work function modifications of graphite surface via oxygen plasma treatment. Appl. Surf. Sci. 2017, 419, 439–446. [Google Scholar] [CrossRef]

- Popov, C.; Kulisch, W.; Bliznakov, S.; Ceccone, G.; Gilliland, D.; Sirghi, L.; Rossi, F. Surface modification of nanocrystalline diamond/amorphous carbon composite films. Diam. Relat. Mater. 2008, 17, 1229–1234. [Google Scholar] [CrossRef]

- Gołda, M.; Brzychczy-Włoch, M.; Faryna, M.; Engvall, K.; Kotarba, A. Oxygen plasma functionalization of parylene C coating for implants surface: Nanotopography and active sites for drug anchoring. Mater. Sci. Eng. C 2013, 33, 4221–4227. [Google Scholar] [CrossRef]

- Felten, A.; Bittencourt, C.; Pireaux, J.J.; van Lier, G.; Charlier, J.C. Radio-frequencyplasma functionalization of carbon nanotubes surface O2, NH3, and CF4 treatments. J. Appl. Phys. 2005, 98, 74308. [Google Scholar] [CrossRef]

- Boudou, J.P.; Paredes, J.I.; Cuesta, A.; Martinez-Alonso, A.; Tascon, J.M.D. Oxygen plasma modification of pitch-based isotropic carbon fibres. Carbon 2003, 41, 41–56. [Google Scholar] [CrossRef]

- Lelątko, J.; Freitag, M.; Rak, J.; Wierzchoń, T.; Goryczka, T. Structure of nitride and nitride/oxide layers formed on NiTi alloy. Solid State Phenom. 2012, 186, 259–262. [Google Scholar] [CrossRef]

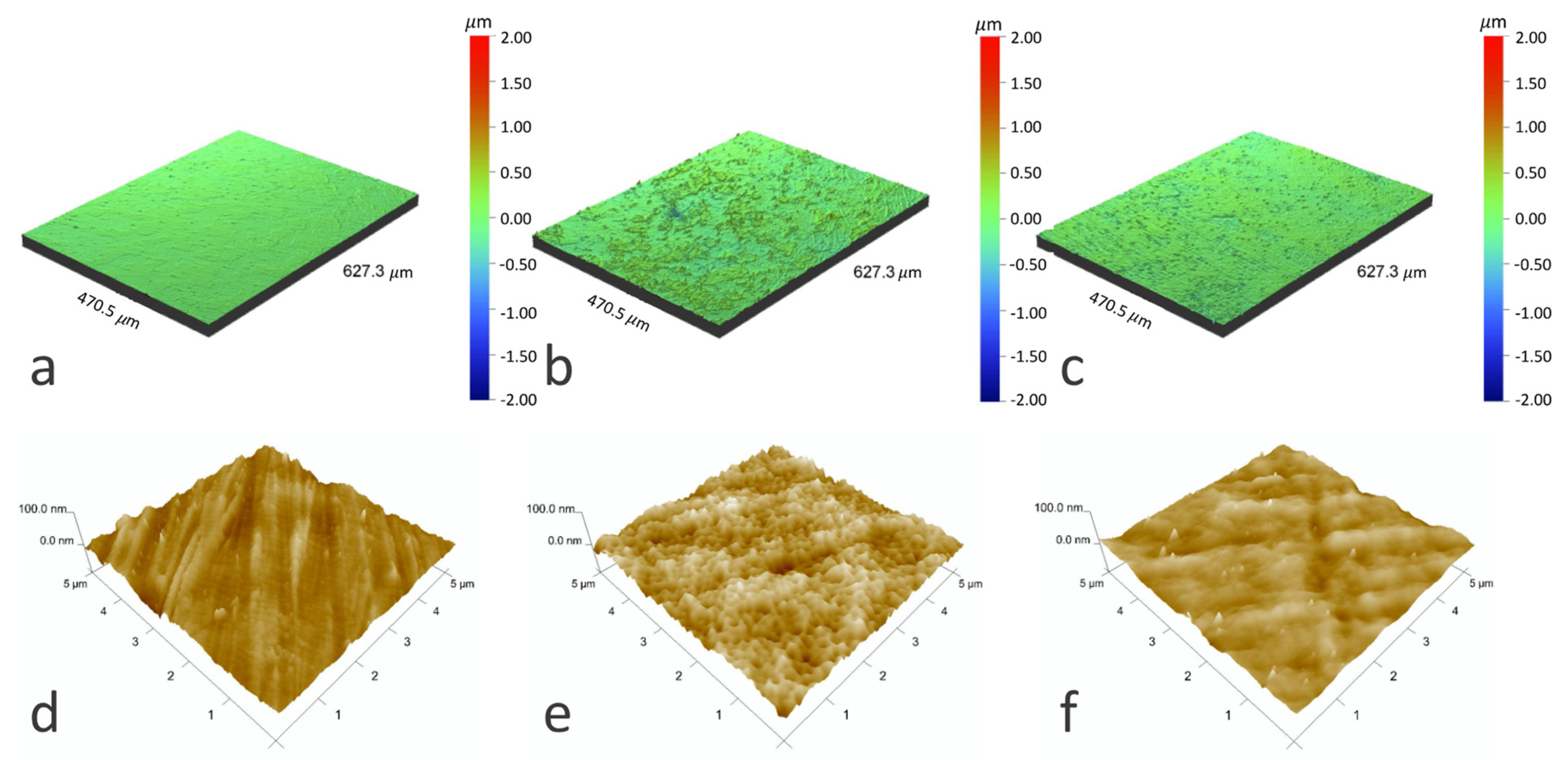

| Method | Sample | Ra [nm] | Rq [nm] | Rt [nm] |

|---|---|---|---|---|

| Optical profilometer | NiTi | 22 ± 3 | 30 ± 2 | 1321 ± 226 |

| a-C:N:H+TiO2 | 63 ± 16 | 87 ± 24 | 2243 ± 504 | |

| (a-C:N:H+TiO2)O | 52 ± 18 | 70 ± 2 | 1157 ± 7 | |

| AFM | NiTi | 10 ± 2 | 15 ± 3 | 188 ± 34 |

| a-C:N:H+TiO2 | 11 ± 2 | 14 ± 3 | 196 ± 93 | |

| (a-C:N:H+TiO2)O | 14 ± 7 | 21 ± 12 | 214 ± 137 |

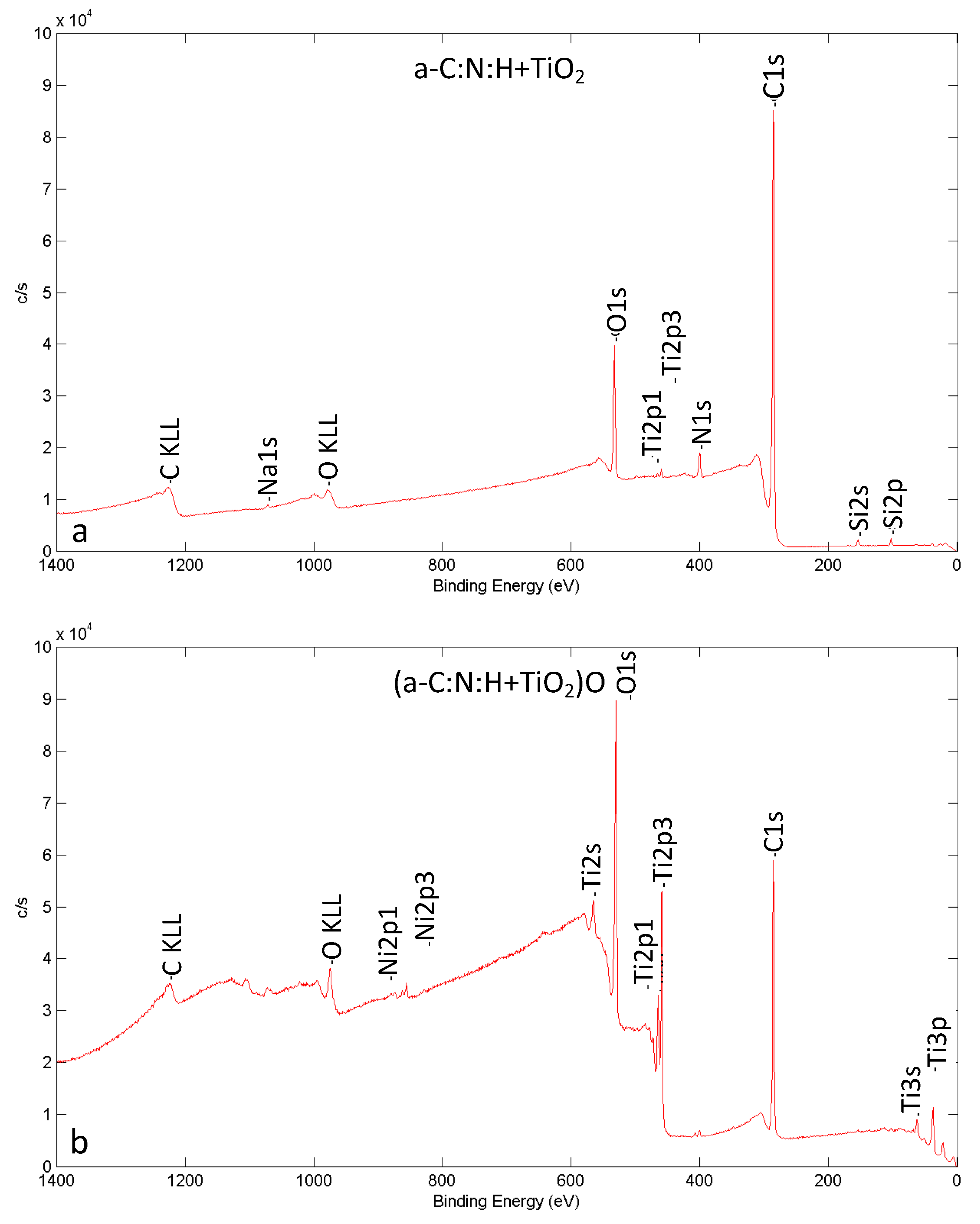

| Elemental Composition of the Surface (XPS) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| % at. | C | O | N | Ti | Ni | Si | rest | O/C | N/C |

| a-C:N:H+TiO2 | 83.3 | 11.3 | 3 | 0.2 | 0.1 | 1.3 | 0.8 | 0.14 | 0.04 |

| (a-C:N:H+TiO2)O | 51.6 | 34 | 1 | 11 | 0.7 | 0.5 | 1.2 | 0.66 | 0.02 |

| a-C:N:H+TiO2 | (a-C:N:H+TiO2)O | ||||||||

| Line | Bonding energy (eV) | FWHM (eV) | Chemical state/bonds | Atomic % | Bonding energy (eV) | FWHM (eV) | Chemical state/bonds | Atomic % | |

| C1s | 285.3 | 1.5 | C-C | 71.7 | 285.4 | 1.2 | C-C | 46.4 | |

| C1s | 286.9 | 1.6 | C-N | 8.3 | 286.5 | 1.3 | C-N | 3.6 | |

| C1s | 288.8 | 2 | C-O | 3.3 | 288.8 | 1.7 | C-O | 1.6 | |

| N1s | 399 | 1.6 | pyridinic-N. N-C | 0.9 | 399 | 1.3 | pyridinic-N. N-C | 0.1 | |

| N1s | 400.3 | 1.9 | pyrrolic-N. N-C | 1.9 | 400.3 | 1.9 | pyrrolic-N. N-C | 0.3 | |

| N1s | 402.7 | 2.1 | pyridine-N-oxide. N-C | 0.2 | 402.3 | 1.9 | pyridine-N-oxide. | 0.1 | |

| N-C | |||||||||

| N1s | - | - | - | - | 406.9 | 1.3 | nitrates. -NO3 | 0.4 | |

| O1s | - | - | - | - | 530 | 1.2 | TiO2 | 23.1 | |

| O1s | 531.8 | 1.6 | O-C | 1.9 | 531.1 | 1.6 | O-C | 5.1 | |

| O1s | 532.9 | 1.8 | SiO2. O-Si | 2.6 | 533 | 1.8 | SiO2. O-Si | 1.1 | |

| O1s | 532.9 | 1.8 | OH. O-H | 4.5 | 533 | 1.8 | OH. O-H | 3.5 | |

| O1s | 534.2 | 1.6 | O-H-O | 2.3 | 533 | 1.8 | nitrates | 1.2 | |

| Ti 2p | - | - | - | - | 458.8 | 1.2 | TiO2 | 11.2 | |

| Ti 2p | - | - | - | - | 464.4 | 2.1 | TiO2 | 1.8 | |

| Si2p | 103 | 1.5 | SiO2. Si-O | 1.3 | 103 | 1.5 | SiO2. Si-O | 0.5 | |

| NiTi | TiO2 | a-C:N:H+TiO2 | (a-C:N:H+TiO2)O | ||

|---|---|---|---|---|---|

| Contact angles (°) | |||||

| water | mean | 83.09 | 106.61 | 84.22 | 101.79 |

| sd | 4.26 | 0.90 | 1.78 | 1.30 | |

| diiodomethane | mean | 83.09 | 106.61 | 84.22 | 101.79 |

| sd | 4.26 | 0.90 | 1.78 | 1.30 | |

| Surface Free Energy | |||||

| γ | [mN/m] | 36.37 | 25.78 | 38.4 | 34.17 |

| γd | [mN/m] | 33.69 | 25.78 | 36.58 | 34.17 |

| γp | [mN/m] | 2.67 | 0.00 | 1.82 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Witkowska, J.; Tarnowski, M.; Choińska, E.; Kulpa, M.; Szade, J.; Raugh, G.; Święszkowski, W.; Wierzchoń, T. Plasma Modification of Carbon Coating Produced by RF CVD on Oxidized NiTi Shape Memory Alloy under Glow-Discharge Conditions. Materials 2021, 14, 4842. https://doi.org/10.3390/ma14174842

Witkowska J, Tarnowski M, Choińska E, Kulpa M, Szade J, Raugh G, Święszkowski W, Wierzchoń T. Plasma Modification of Carbon Coating Produced by RF CVD on Oxidized NiTi Shape Memory Alloy under Glow-Discharge Conditions. Materials. 2021; 14(17):4842. https://doi.org/10.3390/ma14174842

Chicago/Turabian StyleWitkowska, Justyna, Michał Tarnowski, Emilia Choińska, Marek Kulpa, Jacek Szade, Gerhard Raugh, Wojciech Święszkowski, and Tadeusz Wierzchoń. 2021. "Plasma Modification of Carbon Coating Produced by RF CVD on Oxidized NiTi Shape Memory Alloy under Glow-Discharge Conditions" Materials 14, no. 17: 4842. https://doi.org/10.3390/ma14174842

APA StyleWitkowska, J., Tarnowski, M., Choińska, E., Kulpa, M., Szade, J., Raugh, G., Święszkowski, W., & Wierzchoń, T. (2021). Plasma Modification of Carbon Coating Produced by RF CVD on Oxidized NiTi Shape Memory Alloy under Glow-Discharge Conditions. Materials, 14(17), 4842. https://doi.org/10.3390/ma14174842