Relationship of Different Properties from Non-Destructive Testing of Heavy Concrete from Magnetite and Serpentinite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Mix Design

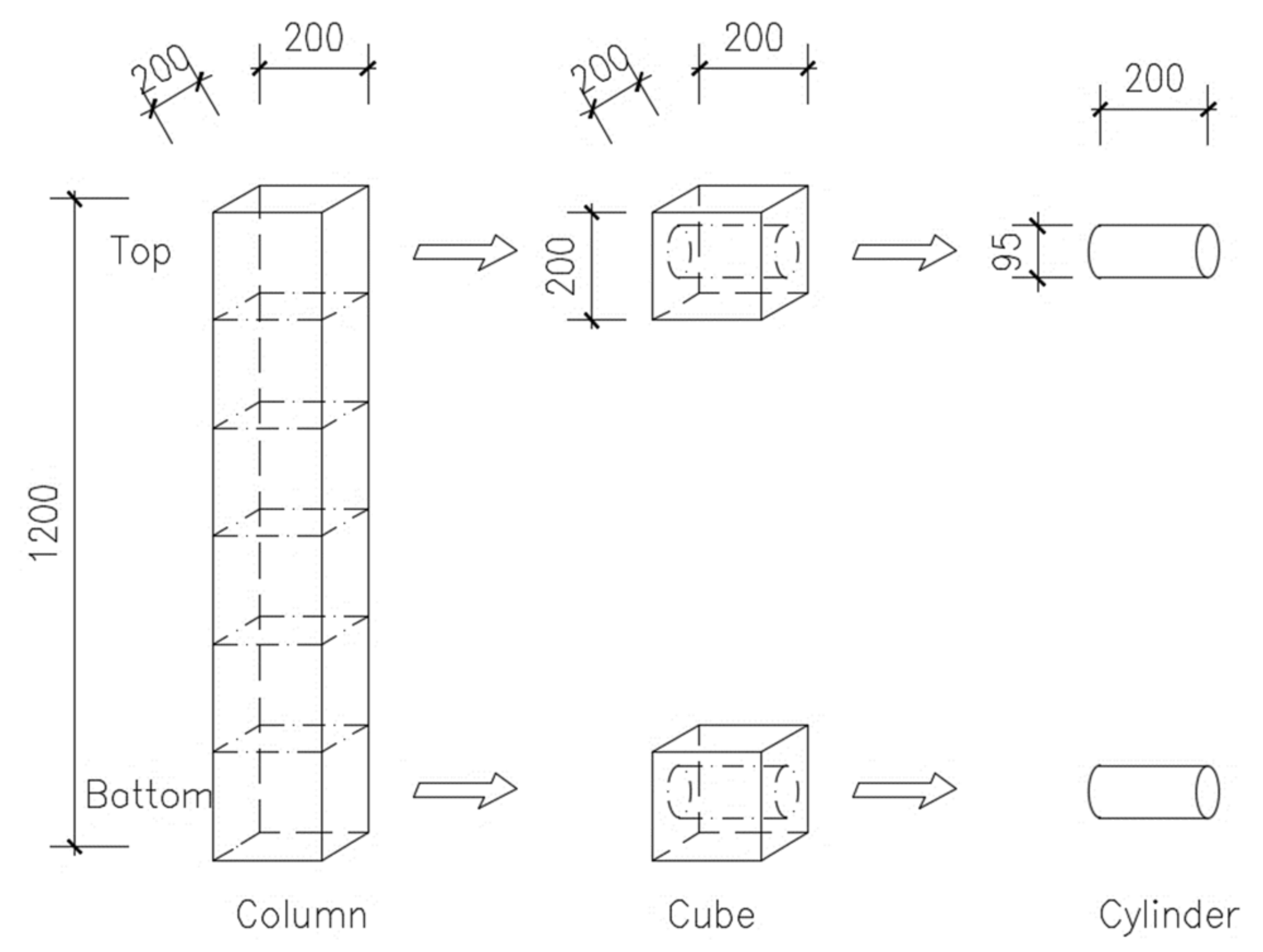

2.2. Preparation of Specimens

2.3. Testing Methods

2.3.1. Air Content and Density

2.3.2. Compressive Strength and Water Penetration

2.3.3. Dynamic Modulus of Elasticity

2.3.4. Electrical Resistivity and Diffusion Coefficient

3. Results

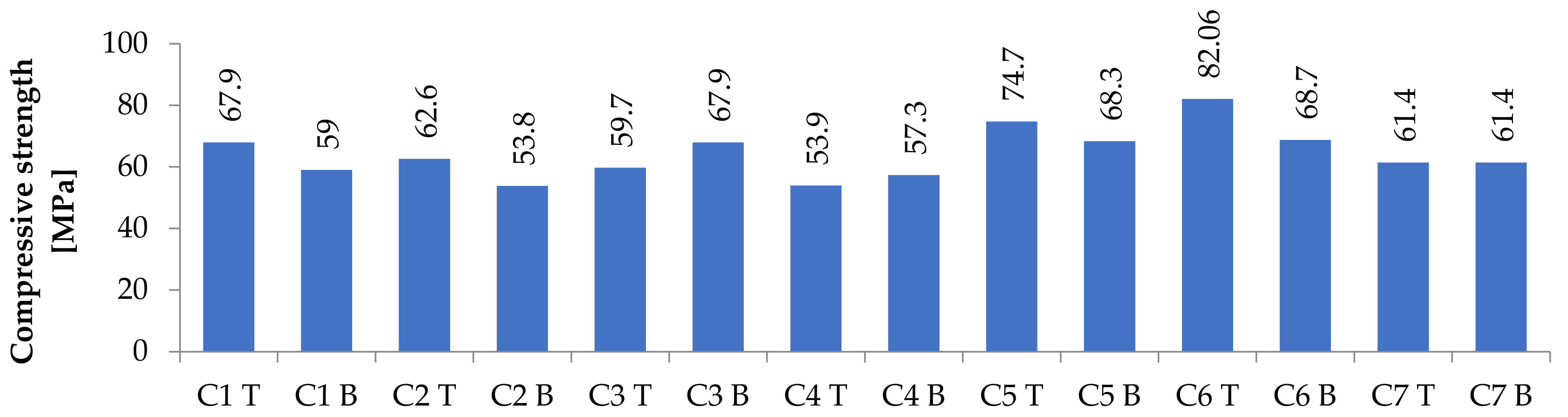

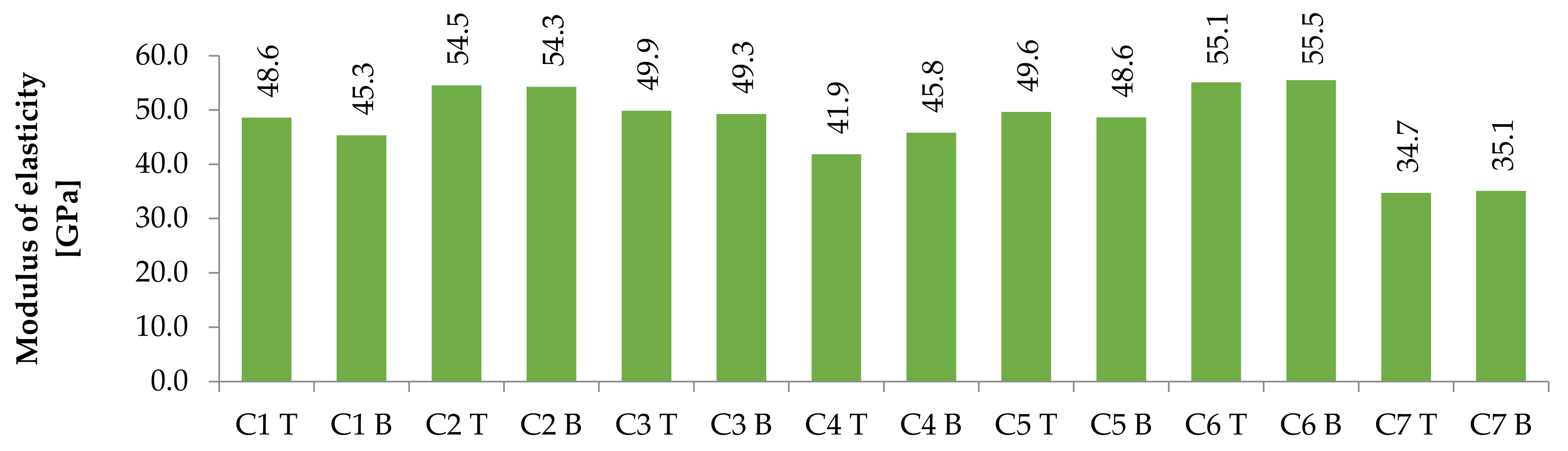

3.1. Values According to the Mixture

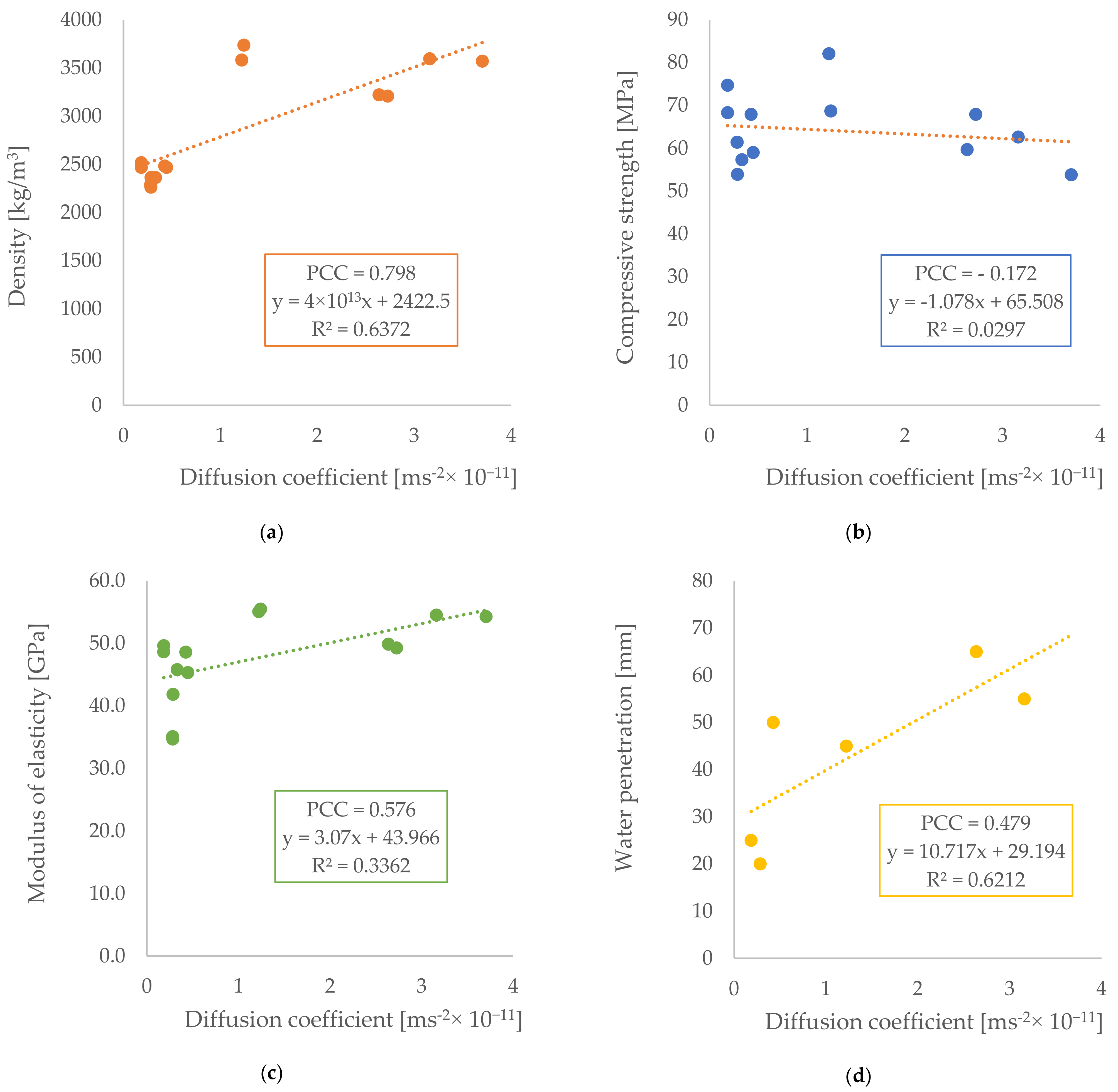

3.2. Correlation with Diffusion Coefficient

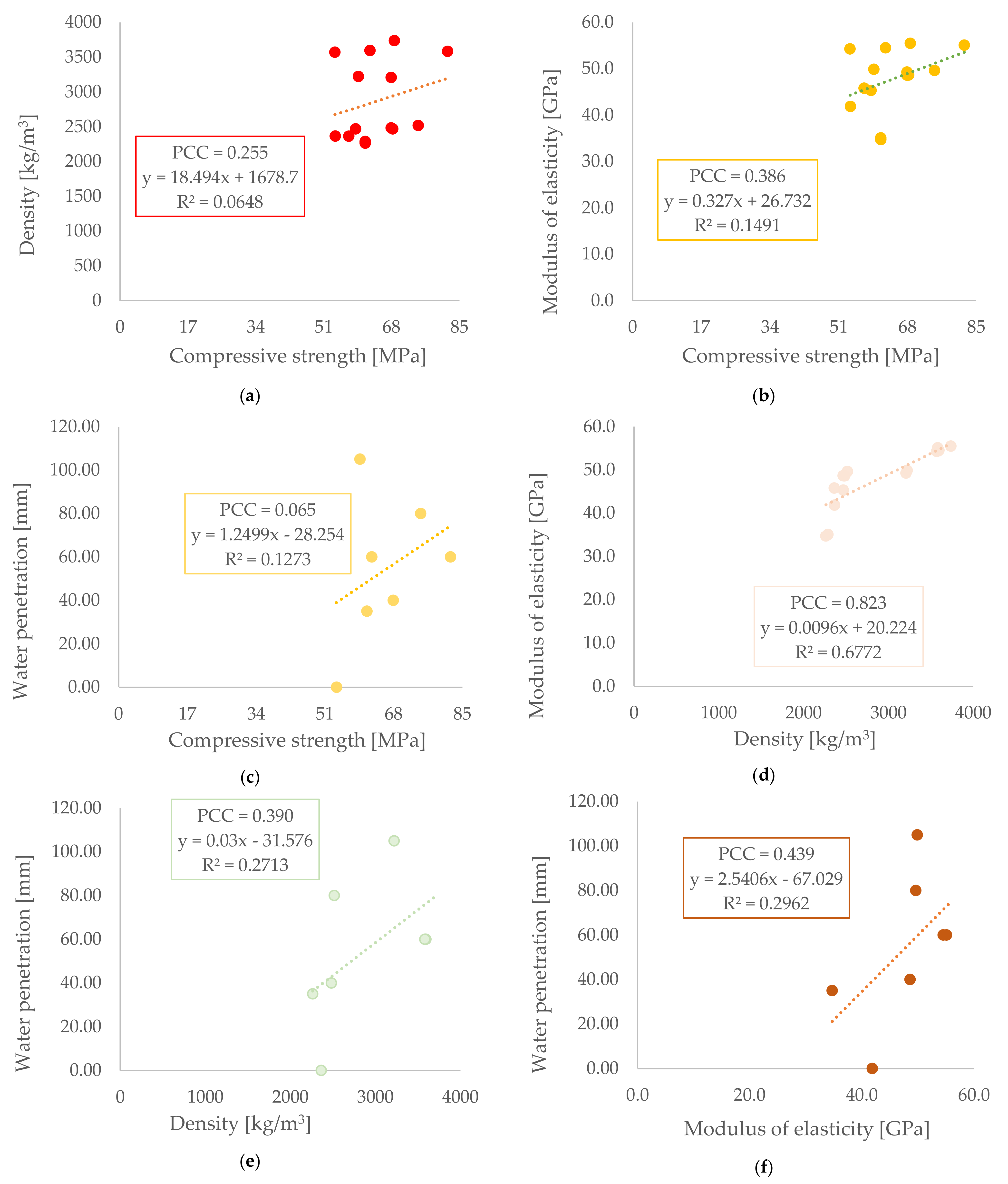

3.3. Correlation of Other Parameters

4. Discussion

5. Conclusions

- 1.

- The best results in almost all tests were shown by C2 concrete, which contains about 30% magnetite 0/5 and about 70% magnetite 0/16. Conversely, in the evaluation of the diffusion coefficient, this concrete was the worst;

- 2.

- The worst results in almost all tests were shown by C7 concrete, which contains ~20% serpentinite 0/2, ~60% serpentinite 2/8, and ~20% serpentinite 8/16;

- 3.

- A correlation was observed between the diffusion coefficient and the density, between the diffusion coefficient and the water penetration, and between the density and the modulus of elasticity;

- 4.

- Evaluation of heavy concretes using electrical resistivity must be further expanded by a larger number of samples and ratios of aggregates in concrete mixtures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z. China in the transition to a low-carbon economy. Energy Policy 2010, 38, 6638–6653. [Google Scholar] [CrossRef] [Green Version]

- Sorimachi, A.; Nagamatsu, Y.; Omori, Y.; Ishikawa, T. Comparison experiments for radon and thoron measuring instruments at low-level concentrations in one room of a Japanese concrete building. Appl. Radiat. Isot. 2021, 173, 109696. [Google Scholar] [CrossRef] [PubMed]

- Aygün, B.; Şakar, E.; Agar, O.; Sayyed, M.; Karabulut, A.; Singh, V. Development of new heavy concretes containing chrome-ore for nuclear radiation shielding applications. Prog. Nucl. Energy 2021, 133, 103645. [Google Scholar] [CrossRef]

- Lukuttsova, N.P.; Golovin, S.N.; Artamonov, P.A. Heavy concrete with mineral additive tripoli. IOP Conf. Series: Mater. Sci. Eng. 2019, 687, 022033. [Google Scholar] [CrossRef]

- Sikora, P.; Elrahman, M.A.; Horszczaruk, E.; Brzozowski, P.; Stephan, D. Incorporation of magnetite powder as a cement additive for improving thermal resistance and gamma-ray shielding properties of cement-based composites. Constr. Build. Mater. 2019, 204, 113–121. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Sikora, P.; Cendrowski, K.; Mijowska, E. The effect of elevated temperature on the properties of cement mortars containing nanosilica and heavyweight aggregates. Constr. Build. Mater. 2017, 137, 420–431. [Google Scholar] [CrossRef]

- Kapтушина, Ю.; Sevriukova, G.A.; Parinov, S.V. Production Wastes of Heavy Concrete: Technological Solution of Recycling Problem. IOP Conf. Ser. Earth Environ. Sci. 2019, 272, 022151. [Google Scholar] [CrossRef]

- Yastrebinskii, R.N.; Bondarenko, G.G.; Pavlenko, V. Attenuation of photon and neutron radiation using iron–magnetite–serpentinite radiation-protective composite. Inorg. Mater. Appl. Res. 2017, 8, 275–278. [Google Scholar] [CrossRef]

- Pavlenko, V.I.; Yastrebinskii, R.N.; Voronov, D.V. Investigation of heavy radiation-shielding concrete after activation by fast neutrons and gamma radiation. J. Eng. Phys. Thermophys. 2008, 81, 686–691. [Google Scholar] [CrossRef]

- Glinicki, M.; Gołaszewski, J.; Cygan, G. Formwork Pressure of a Heavyweight Self-Compacting Concrete Mix. Materials 2021, 14, 1549. [Google Scholar] [CrossRef]

- Fedorova, N.; Medyankin, M.; Fedorov, S. Strength of heavy concrete during static-dynamic deformation. IOP Conf. Series Mater. Sci. Eng. 2021, 1030, 012046. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, K.; Song, B.; Yu, W.; Li, D. Dynamic Modeling and CAE Cosimulation Method for Heavy-Duty Concrete Spreader. Adv. Civ. Eng. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Jaskulski, R.; Kubissa, W.; Reiterman, P.; Holčapek, O. Thermal properties of heavy concrete for small pre-cast shielding elements. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2020; p. 020011. [Google Scholar]

- Králik, J.; Králik, J., Jr. Seismic Analysis of the Soil-Structure Interaction Considering the Local Site Effects. Trans. VSB-Tech. Univ. Ostrav. Civ. Eng. Ser. 2020, 20, 8–16. [Google Scholar] [CrossRef]

- Luo, P.; Zhang, X.; Che, K.; Zeng, B. Numerical Analysis of Passive Heavy Concrete Wall Cool Discharge Performance. Lect. Notes Electr. Eng. 2013, 263, 323–333. [Google Scholar] [CrossRef]

- Horňáková, M.; Lehner, P. Relationship of Surface and Bulk Resistivity in the Case of Mechanically Damaged Fibre Reinforced Red Ceramic Waste Aggregate Concrete. Materials 2020, 13, 5501. [Google Scholar] [CrossRef]

- Hrabová, K.; Lehner, P.; Ghosh, P.; Konečný, P.; Teplý, B. Sustainability Levels in Comparison with Mechanical Properties and Durability of Pumice High-Performance Concrete. Appl. Sci. 2021, 11, 4964. [Google Scholar] [CrossRef]

- Alwaeli, M.; Gołaszewski, J.; Niesler, M.; Pizoń, J.; Gołaszewska, M. Recycle option for metallurgical sludge waste as a partial replacement for natural sand in mortars containing CSA cement to save the environment and natural resources. J. Hazard. Mater. 2020, 398, 123101. [Google Scholar] [CrossRef] [PubMed]

- Ouda, A. Development of high-performance heavy density concrete using different aggregates for gamma-ray shielding. Prog. Nucl. Energy 2015, 79, 48–55. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, M.; Bohner, E.; Sjöblom, V.; Al-Neshawy, F.; Ojala, T. Construction of realistic NPP containment wall mock-up for challenging NDE methods. In Proceedings of the Fib Symposium 2019: Concrete-Innovations in Materials, Design and Structures, Krakow, Poland, 27–29 May 2019; pp. 1651–1658. [Google Scholar]

- Konečný, P.; Lehner, P.; Ponikiewski, T.; Miera, P. Comparison of Chloride Diffusion Coefficient Evaluation Based on Electrochemical Methods. Procedia Eng. 2017, 190, 193–198. [Google Scholar] [CrossRef]

- Pyka, N.; Noack, K.; Rogov, A. Optimization of a partially non-magnetic primary radiation. shielding for the triple-axis spectrometer PANDA at the Munich high-flux reactor FRM-II. Appl. Phys. A 2002, 74, s277–s279. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Litorowicz, A. Crack system evaluation in concrete elements at mesoscale. Bull. Pol. Acad. Sci. Tech. Sci. 2006, 54, 371–379. [Google Scholar]

- Gökçe, H.; Öztürk, B.C.; Çam, N. Andiç-Çakır, Özge Gamma-ray attenuation coefficients and transmission thickness of high consistency heavyweight concrete containing mineral admixture. Cem. Concr. Compos. 2018, 92, 56–69. [Google Scholar] [CrossRef]

- EN197-1. Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cement; British Standards Institution: London, UK, 2011; p. 50. [Google Scholar]

- Baran, T.; Glinicki, M.A.; Jóźwiak-Niedźwiedzka, D. The properties of special cements for shielding constructions in nuclear power plants. Cem. Wapno Bet. 2016, 21/83, 207–216. [Google Scholar]

- Gołaszewski, J.; Ponikiewski, T.; Kostrzanowska-Siedlarz, A.; Miera, P. The Influence of Calcareous Fly Ash on the Effectiveness of Plasticizers and Superplasticizers. Materials 2020, 13, 2245. [Google Scholar] [CrossRef]

- Gołaszewski, J. Influence of Viscosity Enhancing Agent on Rheology and Compressive Strength of Superplasticized Mortars. J. Civ. Eng. Manag. 2009, 15, 181–188. [Google Scholar] [CrossRef] [Green Version]

- Kubissa, W.; Glinicki, M.A. Influence of internal relative humidity and mix design of radiation shielding concrete on air permeability index. Constr. Build. Mater. 2017, 147, 352–361. [Google Scholar] [CrossRef]

- British Standards Institution. EN 12350-7. In Testing Fresh Concrete. Air Content. Pressure Methods; British Standards Institution: London, UK, 2019; p. 28. [Google Scholar]

- British Standards Institution. EN 12350-6. In Testing Fresh Concrete. Density; British Standards Institution: London, UK, 2019; p. 14. [Google Scholar]

- British Standards Institution. EN 12390-3. In Testing Hardened Concrete Part. 3: Compressive Strength of Test. Specimens; British Standards Institution: London, UK, 2002. [Google Scholar]

- British Standards Institution. EN 12390-8. In Testing Hardened Concrete Part. 8: Depth of Penetration of Water under Pressure; British Standards Institution: London, UK, 2009. [Google Scholar]

- British Standards Institution. EN 12504-4. In Determination of Ultrasonic Pulse Velocity; British Standards Institution: London, UK, 2004; Volume 3, p. 18. [Google Scholar]

- American Association of State Highway and Transportation Officials. AASHTO T358. In AASHTO T358-Standard Method of Test. for Surface Resistivity Indication of Concrete’s Ability to Resist. Chloride Ion. Penetration; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- Lu, X.Y. Application of the Nernst-Einstein equation to concrete. Cem. Concr. Res. 1997, 27, 293–302. [Google Scholar] [CrossRef]

- Zhang, Z.; Thiery, M.; Baroghel-Bouny, V. Investigation of moisture transport properties of cementitious materials. Cem. Concr. Res. 2016, 89, 257–268. [Google Scholar] [CrossRef] [Green Version]

- Nikbin, I.; Mehdipour, S.; Dezhampanah, S.; Mohammadi, R.; Mohebbi, R.; Moghadam, H.; Sadrmomtazi, A. Effect of high temperature on mechanical and gamma ray shielding properties of concrete containing nano-TiO2. Radiat. Phys. Chem. 2020, 174, 108967. [Google Scholar] [CrossRef]

- Shams, T.; Eftekhar, M.; Shirani, A. Investigation of gamma radiation attenuation in heavy concrete shields containing hematite and barite aggregates in multi-layered and mixed forms. Constr. Build. Mater. 2018, 182, 35–42. [Google Scholar] [CrossRef]

- Malaikah, A. A Proposed Relationship for the Modulus of Elasticity of High Strength Concrete Using Local Materials in Riyadh. J. King Saud Univ. Eng. Sci. 2005, 17, 131–141. [Google Scholar] [CrossRef]

- de Grazia, M.T.; Deda, H.; Sanchez, L.F. The influence of the binder type & aggregate nature on the electrical resistivity of conventional concrete. J. Build. Eng. 2021, 43, 102540. [Google Scholar] [CrossRef]

- Saini, A.; Prabhune, A.; Mishra, A.; Dey, R. Density, ultrasonic velocity, viscosity, refractive index and surface tension of aqueous choline chloride with electrolyte solutions. J. Mol. Liq. 2021, 323, 114593. [Google Scholar] [CrossRef]

| Chemical Composition and Properties | CEM I 42.5N | CEM III/A 42.5N |

|---|---|---|

| SiO2 (%) | 21.48 | 31.38 |

| Al2O3 (%) | 4.80 | 5.98 |

| Fe2O3 (%) | 2.62 | 2.09 |

| CaO (%) | 65.60 | 52.51 |

| MgO (%) | 0.87 | 3.73 |

| SO3 (%) | 2.84 | 1.45 |

| K2O (%) | 0.47 | 0.56 |

| Na2O (%) | 0.12 | 0.34 |

| Cl (%) | 0.008 | 0.058 |

| Loss on ignition (%) | 1.12 | 0.12 |

| Flow (cm) | 18.1 | 15.4 |

| Water demand (%) | 28.0 | 34.0 |

| Blaine (cm2/g) | 3800 | 4700 |

| Density (g/cm3) | 3.15 | 2.99 |

| 28-day bending strength (MPa) | 8.1 | 9.5 |

| 28-day compressive strength (MPa) | 52.6 | 58.2 |

| Type of Aggregate * | Density (kg/m3) | Water Absorption (%) |

|---|---|---|

| Crushed basalt 2/16 | 3000 | 0.80 |

| Crushed serpentine 0/2 | 2600 | 2.14 |

| Crushed serpentine 2/8 | 2600 | 2.41 |

| Crushed serpentine 8/16 | 2600 | 1.47 |

| Crushed magnetite 0/5 | 4800 | 0.40 |

| Crushed magnetite 0/16 | 4800 | 0.40 |

| Composition and Properties | C1 | C2 | C3 | C4 | C5 | C6 | C7 |

|---|---|---|---|---|---|---|---|

| Cement CEM I (kg/m3) | 350 | 350 | 350 | 350 | - | - | - |

| Cement CEM III (kg/m3) | - | - | - | - | 350 | 350 | 350 |

| Water (kg/m3) | 168 | 168 | 168 | 168 | 168 | 168 | 211 |

| w/c | 0.48 | 0.48 | 0.48 | 0.48 | 0.48 | 0.48 | 0.60 |

| w/ceff | - | - | - | - | - | - | 0.48 |

| Quartz sand 0/2 (kg/m3) | 687 | 371 | 371 | 371 | 687 | 371 | 371 |

| Crushed basalt 2/16 (kg/m3) | 1001 | - | - | - | 1001 | - | - |

| Crushed magnetite 0/5 (kg/m3) | 300 | 839 | 772 | 895 | 300 | 839 | - |

| Crushed magnetite 0/16 (kg/m3) | - | 1846 | 1018 | - | - | 1846 | - |

| Crushed serpentine 0/2 (kg/m3) | - | - | - | - | - | - | 273 |

| Crushed serpentine 2/8 (kg/m3) | - | - | 485 | 485 | - | - | 909 |

| Crushed serpentine 8/16 (kg/m3) | - | - | 371 | 485 | - | - | 273 |

| HRWR CEM I (%m.c.) | 0.36 | 0.3 | 2 | 1.6 | - | - | - |

| HRWR CEM III/A (%m.c.) | - | - | - | - | 0.2 | 0.2 | 1.4 |

| VMA (%m.c.) | 0.15 | - | - | - | - | - | - |

| Expected density (kg/m3) | 2506 | 3574 | 3537 | 2756 | 2506 | 3574 | 2389 |

| Composition and Properties | C1 | C2 | C3 | C4 | C5 | C6 | C7 |

|---|---|---|---|---|---|---|---|

| Water penetration (mm) | 40 | 60 | 105 | n/a * | 80 | 60 | 35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lehner, P.; Gołaszewski, J. Relationship of Different Properties from Non-Destructive Testing of Heavy Concrete from Magnetite and Serpentinite. Materials 2021, 14, 4288. https://doi.org/10.3390/ma14154288

Lehner P, Gołaszewski J. Relationship of Different Properties from Non-Destructive Testing of Heavy Concrete from Magnetite and Serpentinite. Materials. 2021; 14(15):4288. https://doi.org/10.3390/ma14154288

Chicago/Turabian StyleLehner, Petr, and Jacek Gołaszewski. 2021. "Relationship of Different Properties from Non-Destructive Testing of Heavy Concrete from Magnetite and Serpentinite" Materials 14, no. 15: 4288. https://doi.org/10.3390/ma14154288

APA StyleLehner, P., & Gołaszewski, J. (2021). Relationship of Different Properties from Non-Destructive Testing of Heavy Concrete from Magnetite and Serpentinite. Materials, 14(15), 4288. https://doi.org/10.3390/ma14154288