Estimation of Phase Ratio in Bulk, Textured TWIP/TRIP Steels from Pole Figures

Abstract

:1. Introduction

2. Materials and Methods

3. Results

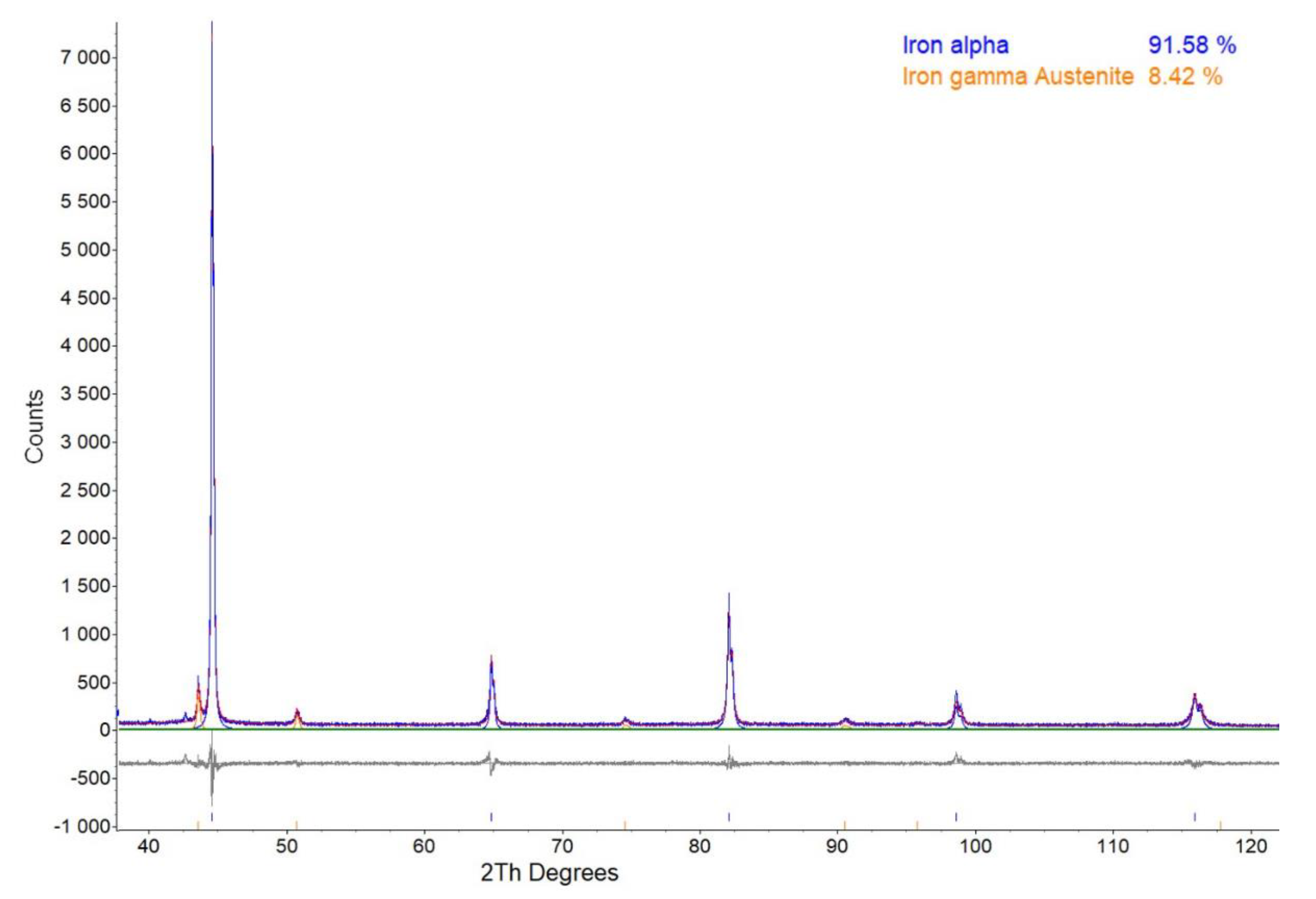

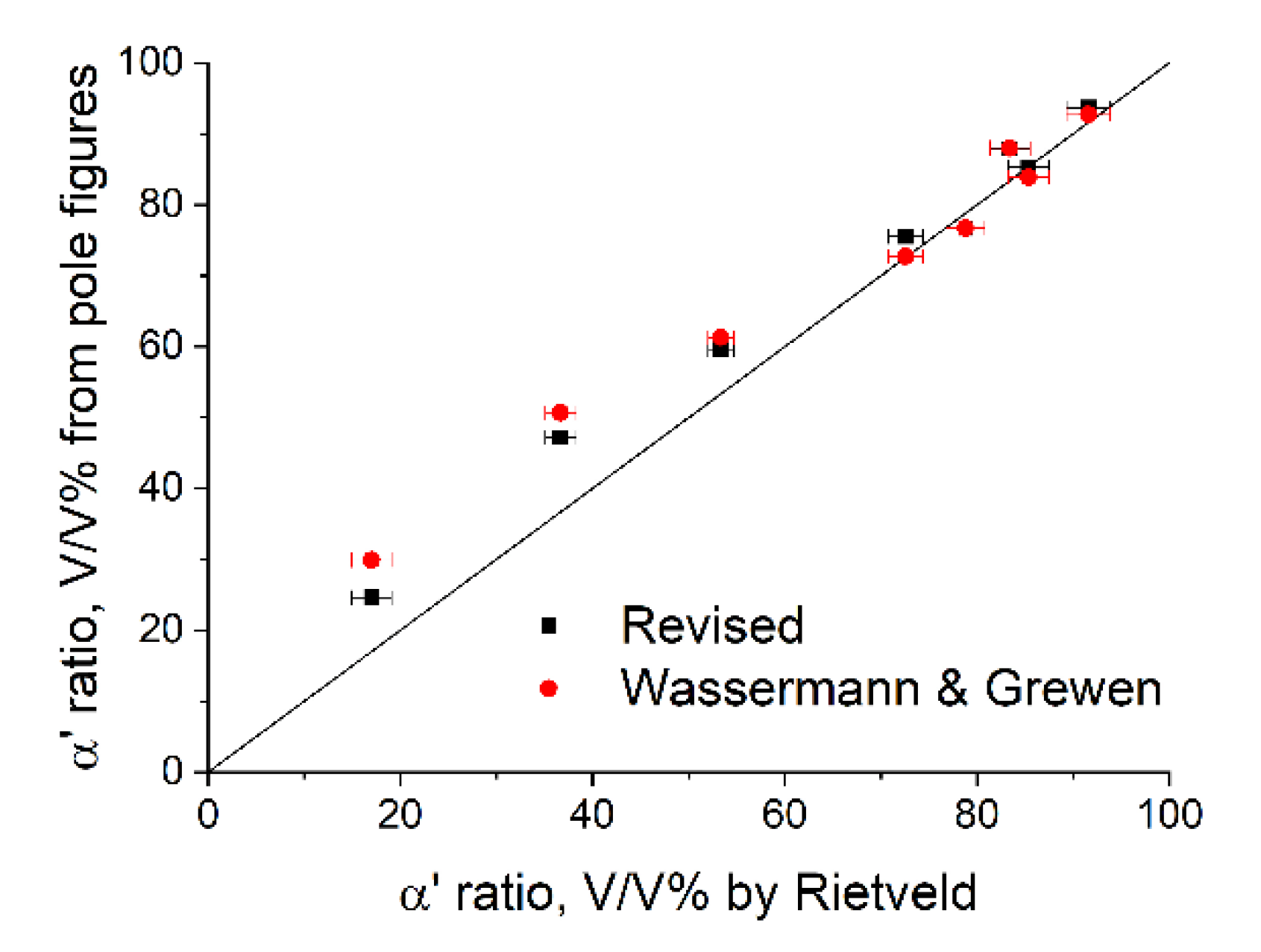

3.1. Two-Phase Powder Mixtures

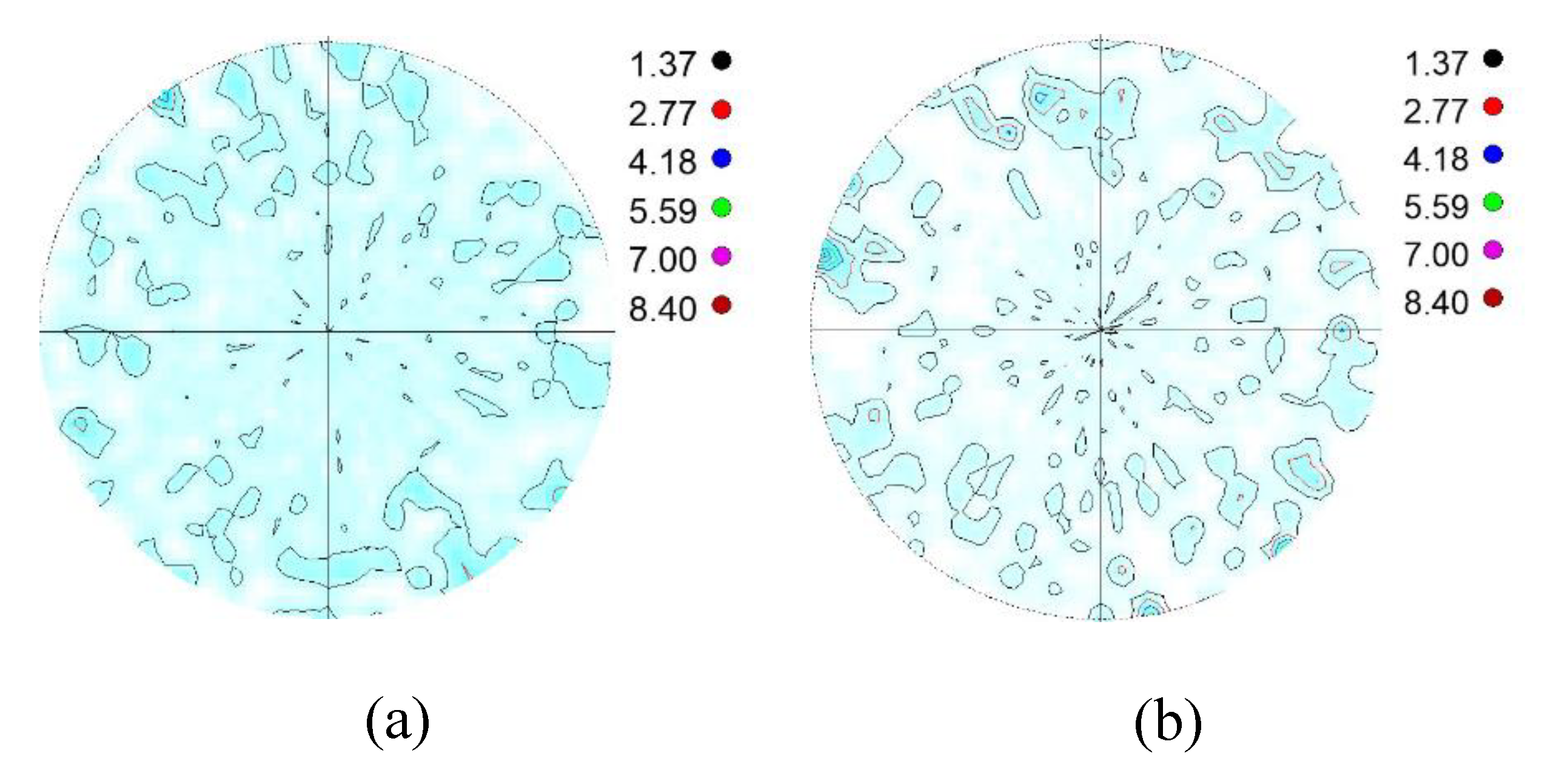

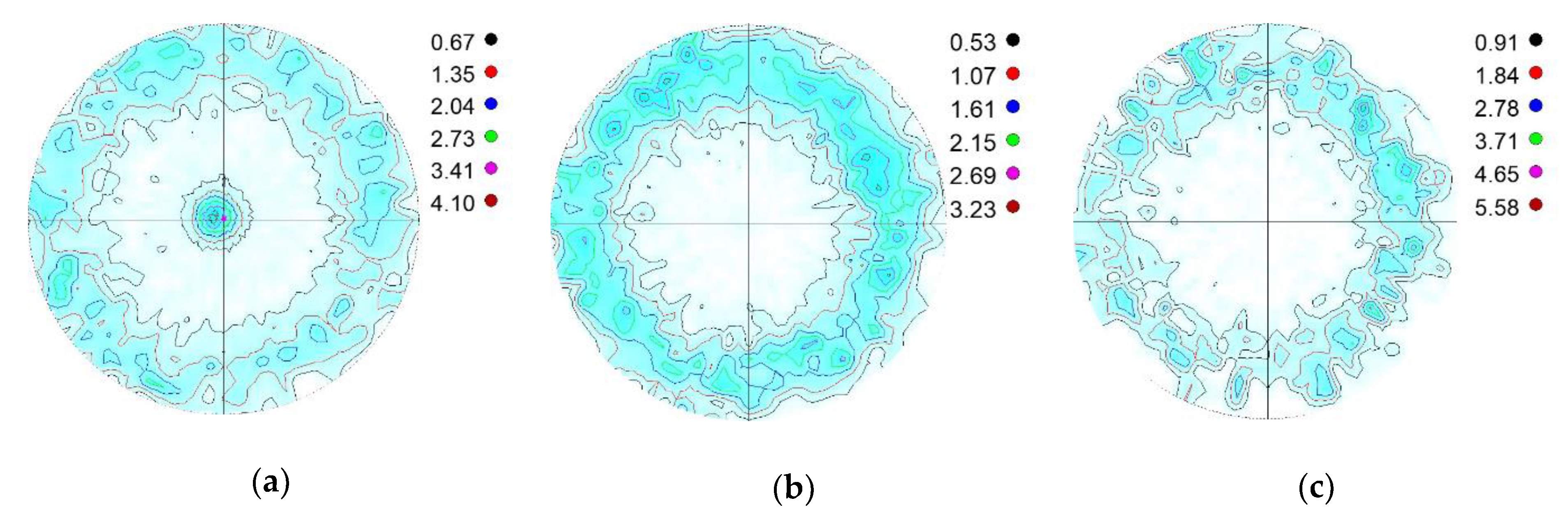

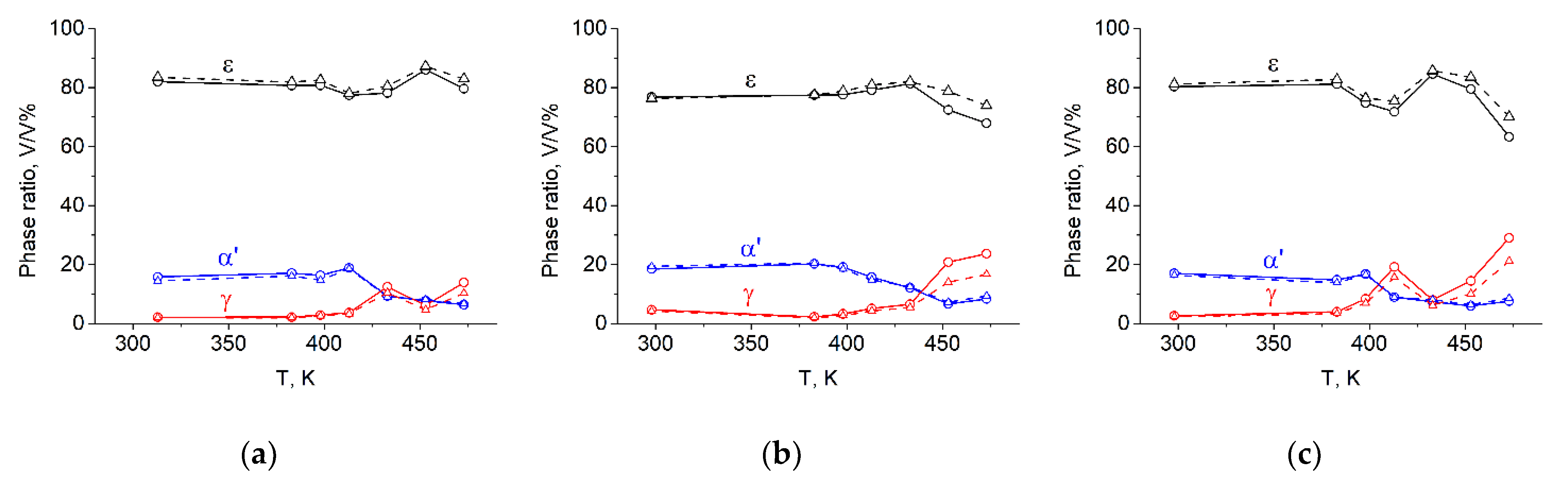

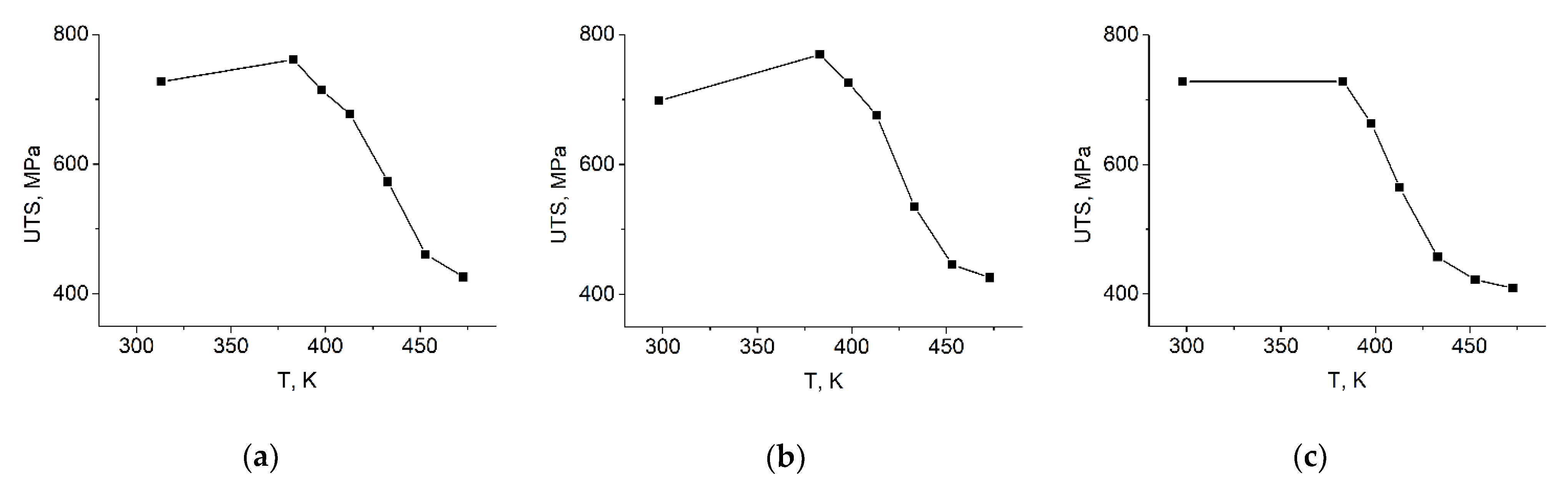

3.2. Bulk Tensile Tested TWIP/TRIP Steels

4. Discussion

5. Conclusions

- (1)

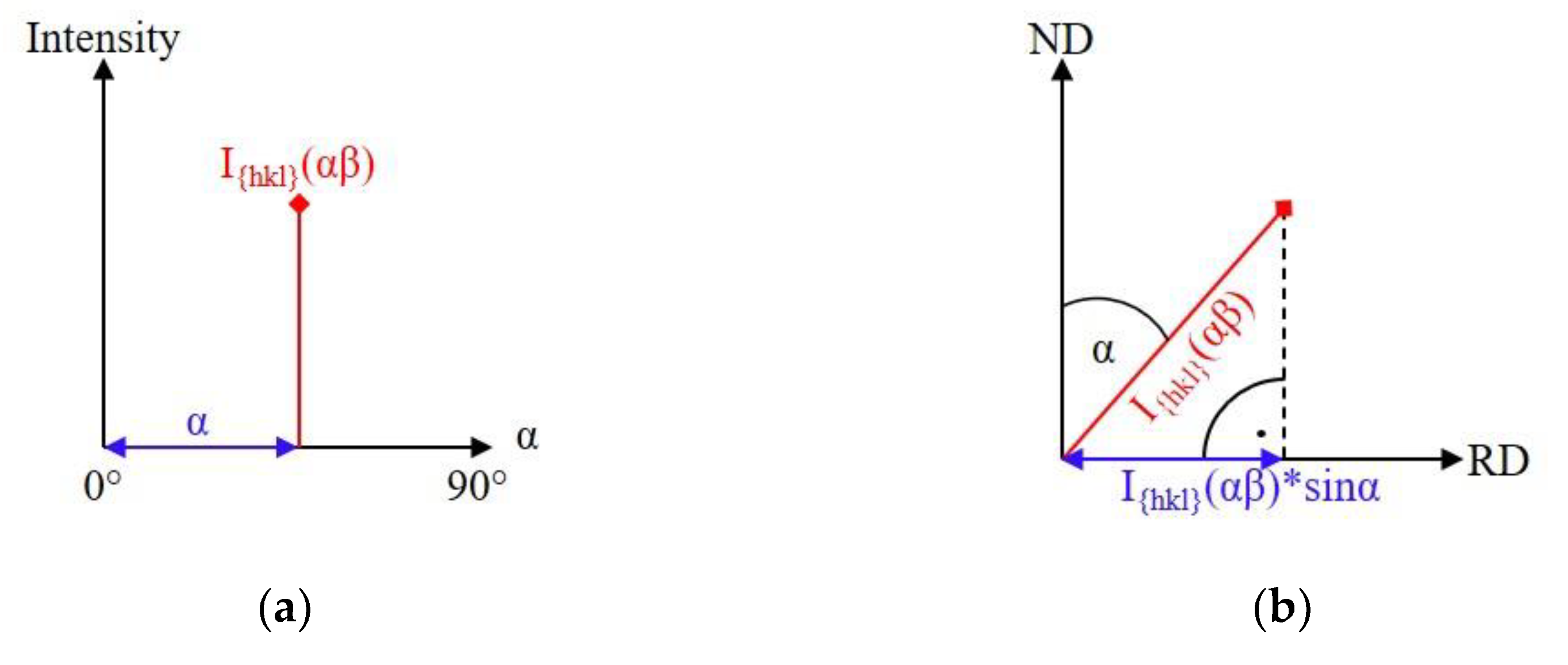

- The phase ratio determination method proposed by Wassermann and Grewen can be simplified by determining the intensities of the pole figures instead of calculating the texture-free (random) intensities, and by omitting the “sinα” multiplier term, which has no reasonable role in the calculation.

- (2)

- The revised method can be realized on non-transmittable, bulk steel samples through X-ray diffraction pole figure measurements performed in the reflection mode up to 75° tilting.

- (3)

- In the case of texture-free powder samples, the results of the revised method were in good agreement with the results of the Rietveld refinement method.

- (4)

- In the case of steels showing both TWIP and TRIP behaviour, it was found that at lower tensile test temperatures, the relative amount of α′ martensite is larger than at higher test temperatures, while the amount of austenite varies inversely. The UTS values correlate well with the relative amount of α′ martensite, which is linked to the strengthening effect of α′ martensite.

- (5)

- It was concluded that in cases when every pole is within the realized tilting range, the revised method can be applied in the reflection mode of XRD pole-figure measurements to estimate the phase ratios of bulk specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhadeshia, H.K.D.H.; Honeycombe, R.W.K. Steels Microstructure and Properties, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2006; pp. 223–229. [Google Scholar]

- Vercammen, S.; Blanpain, B.; De Cooman, B.C.; Wollants, P. Cold rolling behaviour of an austenitic Fe–30Mn–3Al–3Si TWIP-steel: The importance of deformation twinning. Acta Mater. 2004, 52, 2005–2012. [Google Scholar] [CrossRef]

- Gey, N.; Petit, B.; Humbert, M. Electron backscattered diffraction study of ε/α′ martensitic variants induced by plastic deformation in 304 stainless steel. Met. Mat. Trans. A 2005, 36, 3291–3299. [Google Scholar] [CrossRef]

- Bracke, L.; Verbeken, K.; Kestens, L.; Penning, J. Microstructure and texture evolution during cold rolling and annealing of a high Mn TWIP steel. Acta Mater. 2009, 57, 1512–1524. [Google Scholar] [CrossRef]

- Lü, Y.; Hutchinson, B.; Molodov, D.A.; Gottstein, G. Effect of deformation and annealing on the formation and reversion of ε-martensite in an Fe–Mn–C alloy. Acta Mater. 2010, 58, 3079–3090. [Google Scholar] [CrossRef]

- Lü, Y.; Molodov, D.A.; Gottstein, G. Correlation between microstructure and texture development in a cold-rolled TWIP steel. ISIJ Int. 2011, 51, 812–817. [Google Scholar] [CrossRef] [Green Version]

- Lu, F.; Yang, P.; Meng, L.; Cui, F.; Ding, H. Influences of thermal martensites and grain orientations on strain-induced martensites in high manganese TRIP/TWIP steels. J. Mat. Sci. Technol. 2011, 27, 257–265. [Google Scholar] [CrossRef]

- Fang, X.; Yang, P.; Lu, F.; Meng, L. Dependence of deformation twinning on grain orientation and texture evolution of high manganese TWIP steels at different deformation temperatures. J. Iron Steel Res. Int. 2011, 18, 46–52. [Google Scholar] [CrossRef]

- Saleh, A.A.; Pereloma, E.V.; Gazder, A.A. Texture evolution of cold rolled and annealed Fe–24Mn–3Al–2Si–1Ni–0.06 C TWIP steel. Mat. Sci. Eng. A 2011, 528, 4537–4549. [Google Scholar] [CrossRef]

- Haase, C.; Chowdhury, S.G.; Baralles-Mora, L.A.; Molodov, D.A.; Gottstein, G. On the relation of microstructure and texture evolution in an austenitic Fe-28Mn-0.28 C TWIP steel during cold rolling. Met. Mat. Tran. A 2013, 44, 911–922. [Google Scholar] [CrossRef]

- Matsumoto, A.; Chen, M.; Shibata, A.; Miyazawa, T.; Sato, M.; Tsuji, N. Relationship between local stress field in austenite and variant selection in deformation-induced martensitic transformation in Fe-24Ni-0.3 C alloy. Mat. Today Proc. 2015, 2, S945–S948. [Google Scholar] [CrossRef]

- Escobar, D.P.; Ferreira De Dafé, S.S.; Santos, D.B. Martensite reversion and texture formation in 17Mn-0.06C TRIP/TWIP steel after hot cold rolling and annealing. J. Mat. Res. Technol. 2015, 4, 162–170. [Google Scholar] [CrossRef] [Green Version]

- Benke, M.; Hlavacs, A.; Nagy, E.; Karacs, G.; Mertinger, V. The Effect of Variant Selection on Texture of TWIP/TRIP Steels During Uniaxial Tensile Loading. Met. Mat. Trans. A 2020, 51, 1519–1527. [Google Scholar] [CrossRef] [Green Version]

- Young, R.A. The Rietveld Method, 1st ed.; Oxford University Press: Oxford, UK, 1993; pp. 1–39. [Google Scholar]

- Rietveld, H.M. The rietveld method. Phys. Scripta 2014, 89, 098002. [Google Scholar] [CrossRef]

- Klug, H.P.; Alexander, L.E. X-ray Diffraction Procedures, 1st ed.; Wiley: New York, NY, USA, 1974. [Google Scholar]

- Arnell, R.D. Determination of Retained Austenite in Steel by X-ray Diffraction. J. Iron Steel Inst. 1968, 206, 1035. [Google Scholar] [CrossRef]

- Durnin, J.; Ridal, K.A. Quantitative determination of retained austenite in steel by X-ray diffraction. J. Iron Steel Inst. 1968, 206, 669. [Google Scholar]

- Dickson, M.J. The significance of texture parameters in phase analysis by X-ray diffraction. J. Appl. Crystallogr. 1969, 2, 176–180. [Google Scholar] [CrossRef]

- Bunge, H.J.; Dahms, M.; Brokmeier, H.G. The determination of integrated intensities from polycrystalline samples with preferred orientation. Cryst. Rev. 1989, 2, 67–86. [Google Scholar] [CrossRef]

- Wassermann, G.; Grewen, J. Texturen Metallischer Werkstoffe, 2nd ed.; Springer: Berlin, Germany, 1962. [Google Scholar]

- Brokmeier, H.G. Quantitative Phase Analysis in Textures Materials. Mat. Sci. For. 1991, 79–82, 67–72. [Google Scholar]

- He, S.; Tomota, Y.; Gong, W.; Harjo, S.; Zhao, G. Unusual Tempering Behavior of Fe–Cr–C Martensite. ISIJ Int. 2015, 55, 686–690. [Google Scholar] [CrossRef] [Green Version]

- Benke, M. Prediction of Earing of Aluminium Sheets from {111} Pole Figures. Cryst. Rep. 2020, 65, 980–984. [Google Scholar] [CrossRef]

- Kravitz, A.D. Introduction to Diffraction in Materials Science and Engineering, 1st ed.; Wiley and Sons: New York, NY, USA, 2001; pp. 240–245. [Google Scholar]

| Steel Type | Composition, wt% | ||||

|---|---|---|---|---|---|

| C | Mn | Cr | Si | S | |

| Steel 0.07 | 0.03 | 18.00 | 0.07 | 0.03 | 0.03 |

| Steel 2.26 | 0.03 | 17.70 | 2.26 | 0.10 | 0.03 |

| Steel 6.12 | 0.08 | 17.70 | 6.12 | 0.06 | 0.03 |

| α′ Content, V/V% | |||||

|---|---|---|---|---|---|

| Rietveld | Waasermann & Grewen | Revised | |||

| Measured | Error | Calculated | Δ | Calculated | Δ |

| 17.0 | 4.15 | 29.9 | 12.9 | 24.6 | 7.6 |

| 36.7 | 3.17 | 50.7 | 14.0 | 47.2 | 10.5 |

| 53.4 | 2.67 | 61.3 | 7.9 | 59.6 | 6.2 |

| 72.6 | 3.63 | 72.7 | 0.1 | 75.5 | 2.98 |

| 78.8 | 3.94 | 76.7 | 2.1 | 76.7 | 2.1 |

| 83.4 | 4.17 | 88.0 | 4.6 | 87.9 | 4.5 |

| 85.4 | 4.27 | 83.9 | 1.5 | 85.3 | 0.1 |

| 91.6 | 4.58 | 92.7 | 1.1 | 93.7 | 2.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benke, M.; Hlavacs, A.; Kristaly, F.; Sepsi, M.; Mertinger, V. Estimation of Phase Ratio in Bulk, Textured TWIP/TRIP Steels from Pole Figures. Materials 2021, 14, 4132. https://doi.org/10.3390/ma14154132

Benke M, Hlavacs A, Kristaly F, Sepsi M, Mertinger V. Estimation of Phase Ratio in Bulk, Textured TWIP/TRIP Steels from Pole Figures. Materials. 2021; 14(15):4132. https://doi.org/10.3390/ma14154132

Chicago/Turabian StyleBenke, Marton, Adrienn Hlavacs, Ferenc Kristaly, Mate Sepsi, and Valeria Mertinger. 2021. "Estimation of Phase Ratio in Bulk, Textured TWIP/TRIP Steels from Pole Figures" Materials 14, no. 15: 4132. https://doi.org/10.3390/ma14154132

APA StyleBenke, M., Hlavacs, A., Kristaly, F., Sepsi, M., & Mertinger, V. (2021). Estimation of Phase Ratio in Bulk, Textured TWIP/TRIP Steels from Pole Figures. Materials, 14(15), 4132. https://doi.org/10.3390/ma14154132