Thermal Expansion Behavior of Co-Spray Formed Al-20Si/7075 Bimetallic Gradient Alloy

Abstract

:1. Introduction

2. Experimental Details

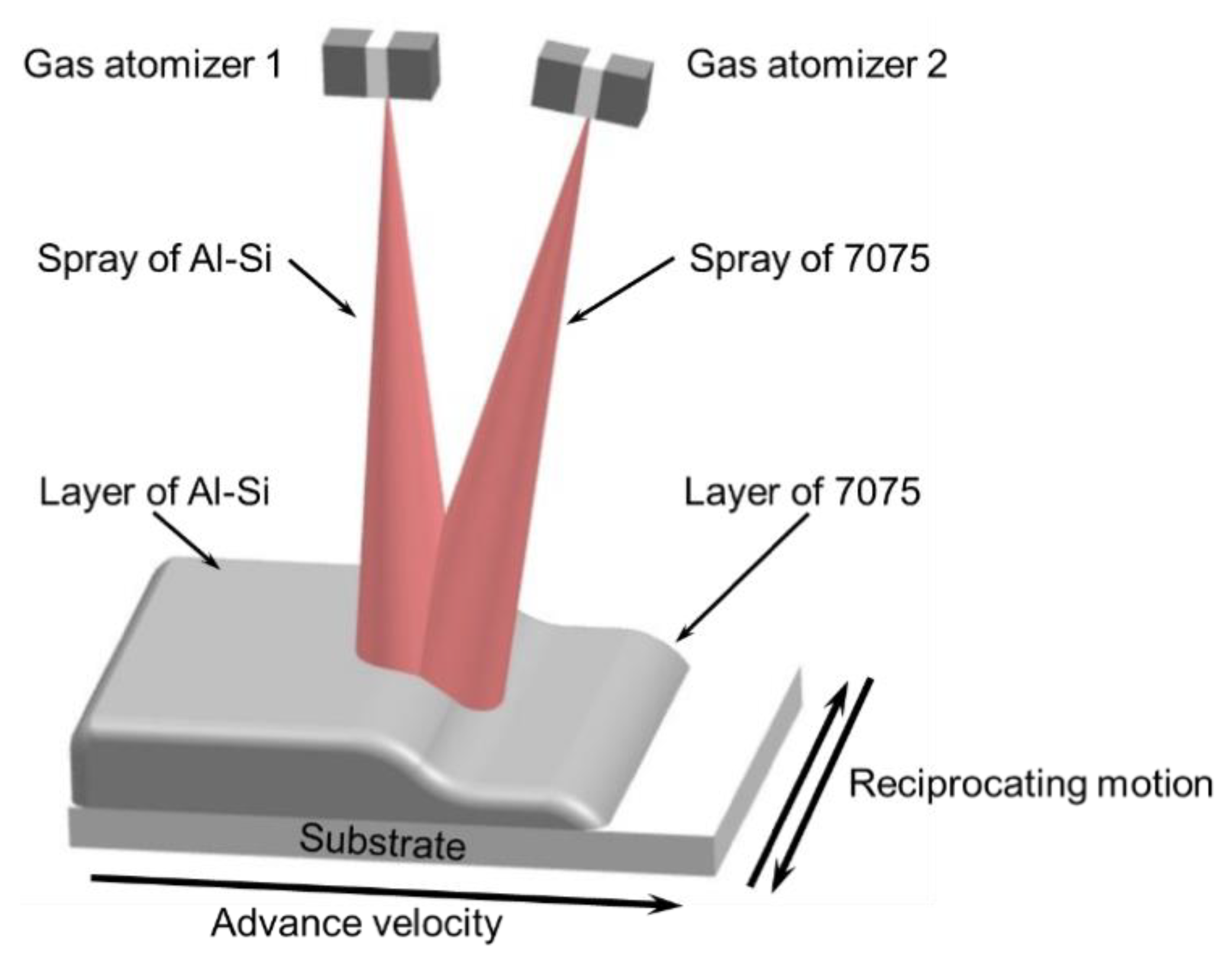

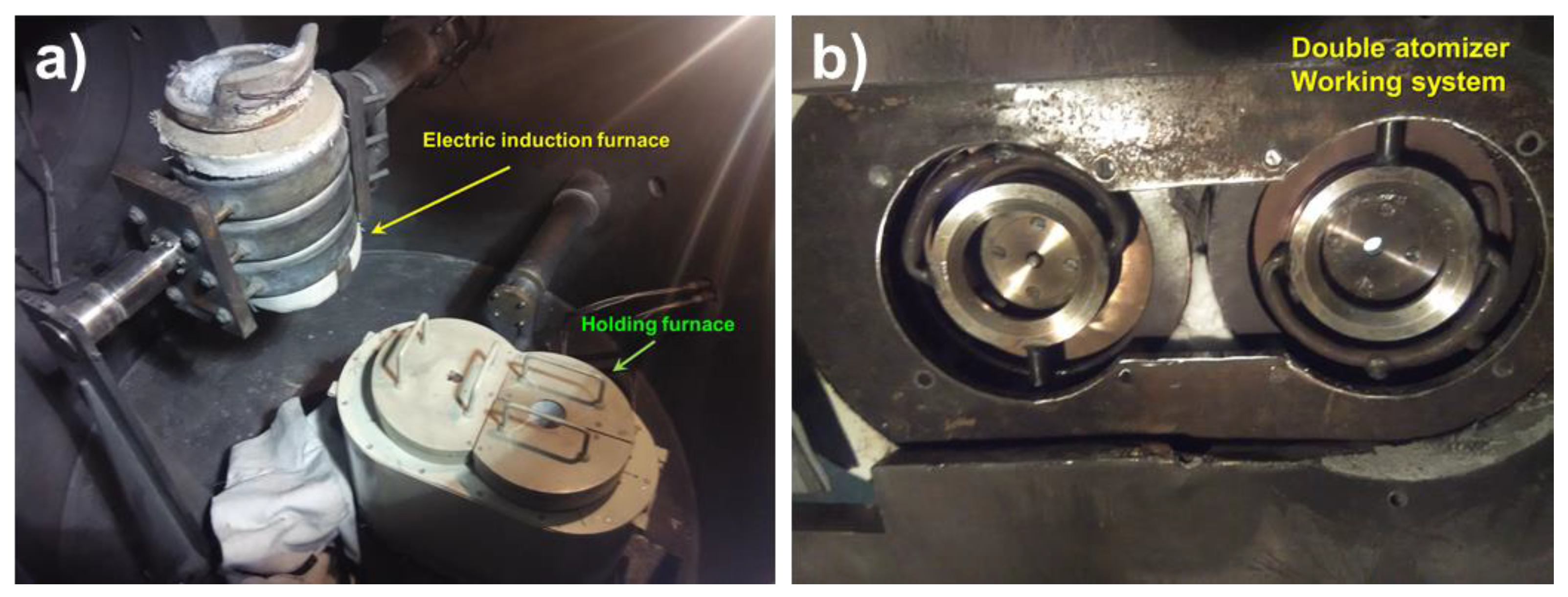

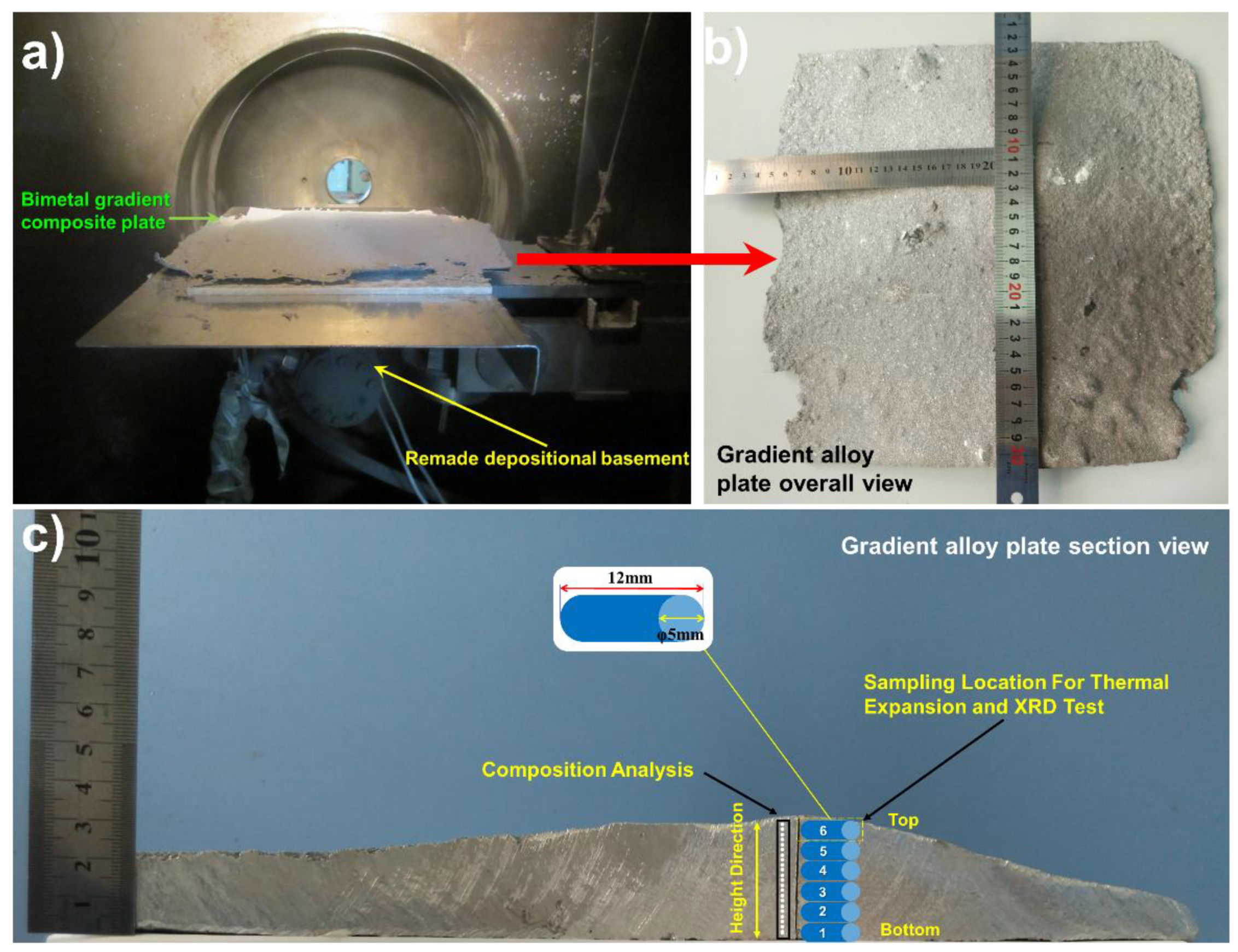

2.1. Sample Preparation

2.2. Characterization of Structure and Physical Properties

3. Results and Discussion

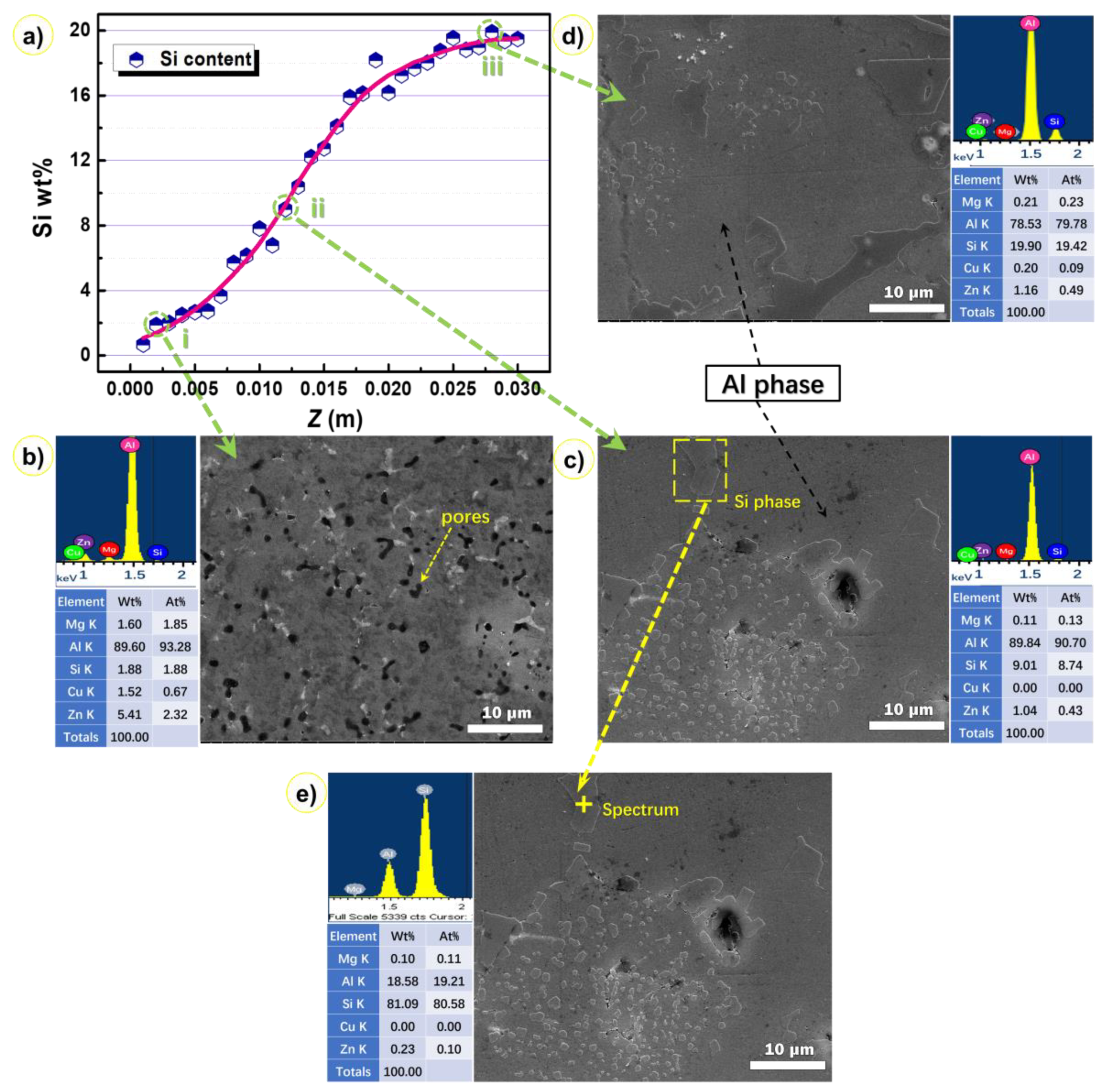

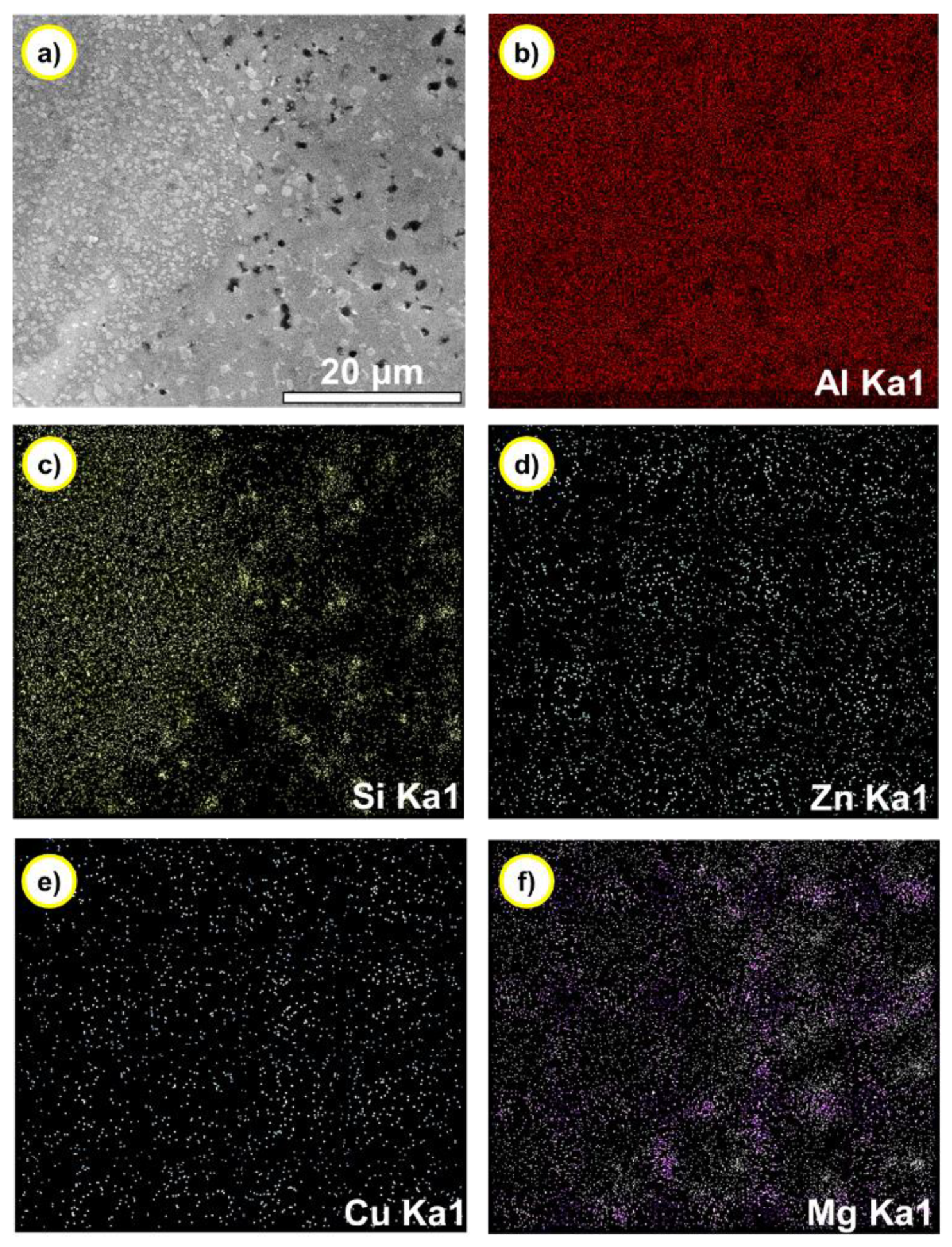

3.1. Microstructure of Bimetal Materials

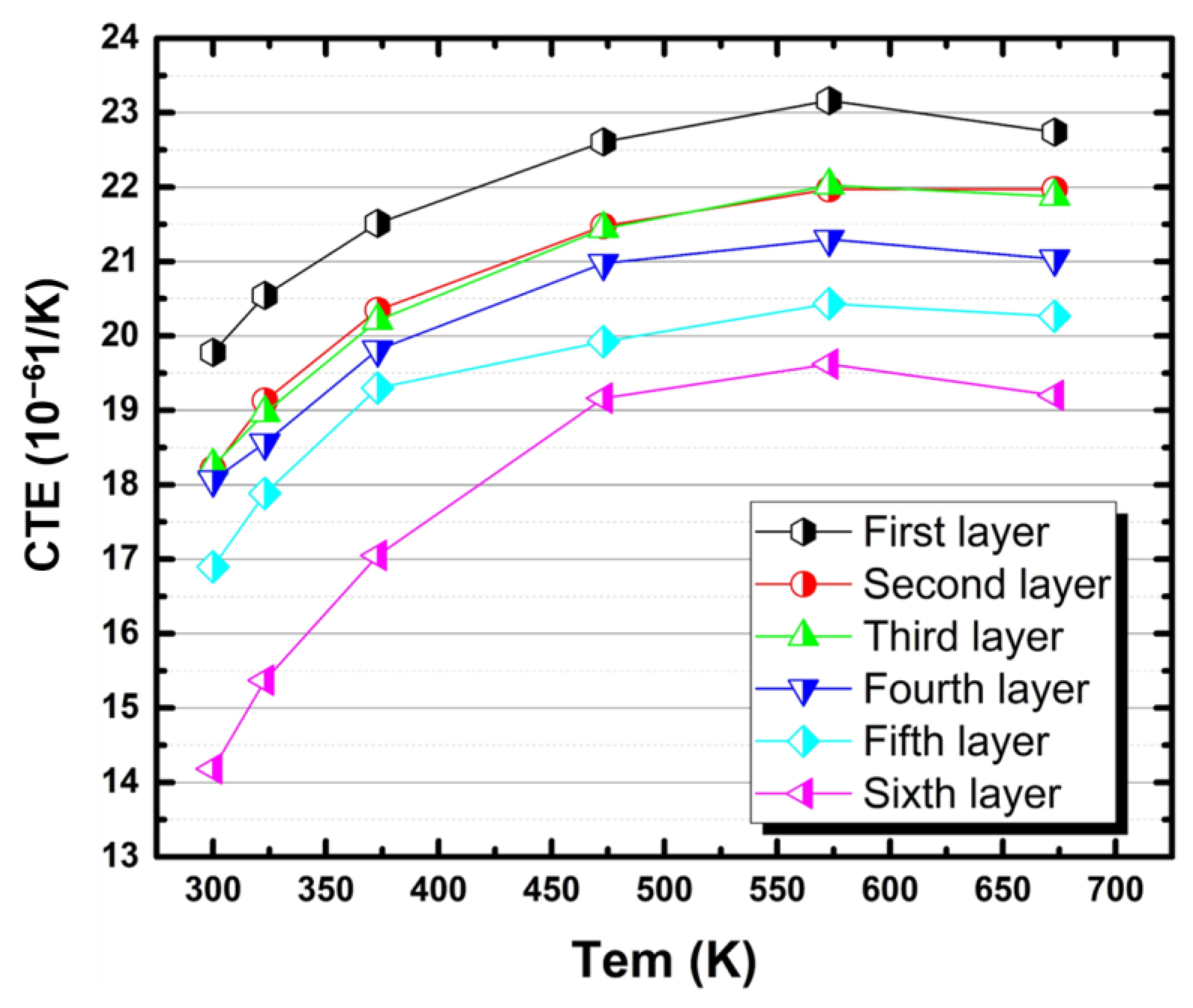

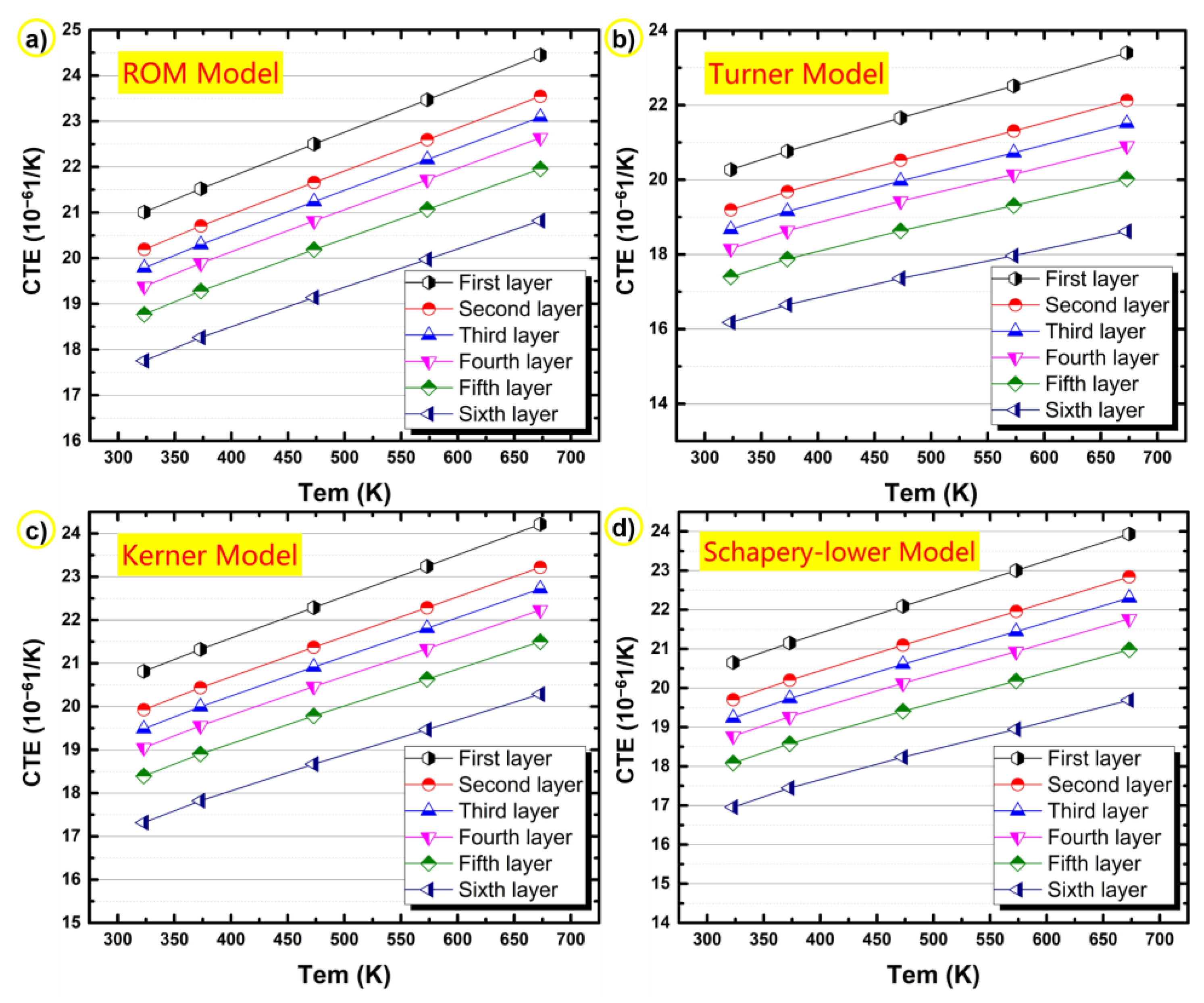

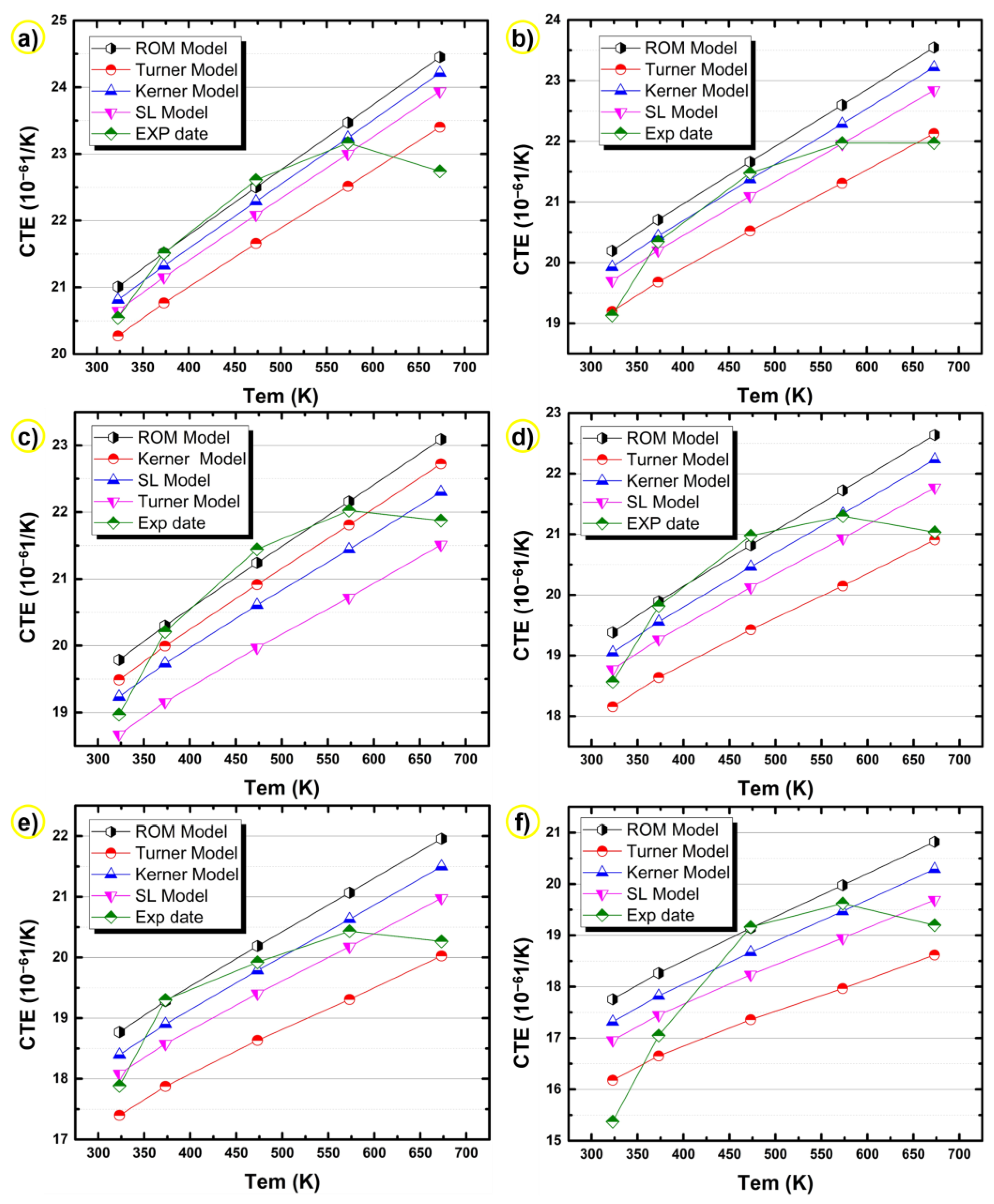

3.2. Thermal Expansion Behaviors

4. Conclusions

- The silicon content of Al-20Si/7075 bimetallic gradient alloy presents a gradient distribution in the direction of height, and correspondingly, the microstructure and CTE at different heights show the same distribution trend as that of silicon content.

- The variation trend of CTE at different heights is consistent. As the temperature increased to 673 K, CTE first increased and then began to decrease when the temperature rose to 573 K.

- The CTE of Al-20Si/7075 bimetallic gradient alloy is affected by many factors such as microstructure evolution, thermal stress, silicon precipitation, and pores. The small spherical silicon phase is beneficial to reduce CTE, while the coarse silicon phase would increase the CTE. In the process of heating, the silicon phase precipitates from the matrix, so the strength of the alloy is lower than the thermal stress, causing plastic deformation, and finally leading to the increase of CTE. CTE would decrease as the solid solubility of silicon in aluminum increases. The presence of primary pores in the alloy contributes to the increase of CTE.

- Compared with the actual CTE showing a tendency of first increasing and then decreasing, the curves of four conventional theoretical models for composite materials (i.e., ROM model, Turner model, Kernel model, and Schapery lower model) show a linear relationship, which is different from the actual test results. The reason for this discrepancy is that the theoretical model only considers the strengthening effect of particles on composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lou, S.M.; Qu, C.D.; Guo, G.X.; Ran, L.W.; Wang, Q.B. Effect of Fabrication Parameters on the Performance of 0.5 wt.% Graphene Nanoplates-Reinforced Aluminum Composites. Materials 2020, 13, 3483. [Google Scholar] [CrossRef]

- Qiao, K.; Zhu, A.; Wang, B.; Di, C.; Yu, J.; Zhu, B. Characteristics of Heat Resistant Aluminum Alloy Composite Core Conductor Used in overhead Power Transmission Lines. Materials 2020, 13, 1592. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carroll, B.E.; Otis, R.A.; Borgonia, J.P.; Suh, J.O.; Dillon, R.P.; Shapiro, A.A.; Hofmann, D.C.; Liu, Z.K.; Beese, A.M. Functionally graded material of 304L stainless steel and inconel 625 fabricated by directed energy deposition: Characterization and thermodynamic modeling. Acta Mater. 2016, 108, 46–54. [Google Scholar] [CrossRef] [Green Version]

- Muller, P.; Mognol, P.; Hascoet, J.Y. Modeling and control of a direct laser powder deposition process for Functionally Graded Materials (FGM) parts manufacturing. J. Mater. Process. Technol. 2013, 213, 685–692. [Google Scholar] [CrossRef]

- Lian, G.F.; Yao, M.P.; Zhang, Y.; Huang, X. Analysis and Respond Surface Methodology Modeling on Property and Performance of Two-Dimensional Gradient Material Laser Cladding on Die-cutting Tool. Materials 2018, 11, 2052. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shanmugavel, P.G.B.B.; Chandrasekaran, M.; Mani, P.S.; Srinivasan, S.P. An overview of fracture analysis in Functionally Graded Materials. Eur. J. Sci. Res. 2012, 68, 412–439. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.S. Fracture Mechanics for Delamination Problems in Composite Materials. J. Compos. Mater. 2016, 17, 210–223. [Google Scholar] [CrossRef]

- Li, W.; Karnati, S.; Kriewall, C.; Liou, F.; Newkirk, J.; Taminger, K.M.B.; Seufzer, W.J. Fabrication and characterization of a functionally graded material from Ti-6Al-4V to SS316 by laser metal deposition. Addit Manuf. 2017, 14, 95–104. [Google Scholar] [CrossRef]

- Cui, C.; Schulz, A.; Uhlenwinkel, V. Materials characterization and mechanical properties of graded tool steels processed by a new co-spray forming technique. Materialwiss. Werkstofftech. 2014, 9999, 652–665. [Google Scholar] [CrossRef]

- Lee, S.W.; Yeh, J.W.; Liao, Y.S. Premium 7075 Aluminium Alloys Produced by Reciprocating Extrusion. Adv. Eng. Mater. 2004, 6, 936–943. [Google Scholar] [CrossRef]

- Liu, D.; Atkinson, H.V.; Kapranos, P.; Jirattiticharoean, W.; Jones, H. Microstructural evolution and tensile mechanical properties of thixoformed high performance aluminium alloys. Mater. Sci. Eng. A 2003, 361, 213–224. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, A.; Xie, J.; Liu, P. Hot Deformation Behavior and Strain-Compensated Constitutive Equation of Nano-Sized SiC Particle-Reinforced Al-Si Matrix Composites. Materials 2020, 13, 1812. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alshmri, F.; Atkinson, H.V.; Hainsworth, S.V.; Haidon, C.; Lawes, S.D.A. Dry sliding wear of aluminium-high silicon hypereutectic alloys. Wear 2014, 313, 106–116. [Google Scholar] [CrossRef]

- Raghukiran, N.; Kumar, R. Processing and dry sliding wear performance of spray deposited hyper-eutectic aluminum–silicon alloys. J. Mater. Process. Technol. 2013, 213, 401–410. [Google Scholar] [CrossRef]

- Yu, L.; Cao, F.Y.; Hou, L.G.; Jia, Y.D.; Shen, H.X.; Li, H.C.; Ning, Z.L.; Xing, D.W.; Sun, J.F. The study of preparation process of spray formed 7075/Al–Si bimetallic gradient composite plate. J. Mater. Res. 2017, 32, 3109–3116. [Google Scholar] [CrossRef]

- Turner, P. Thermal expansion stresses in reinforceed plastics. J. Res. NBS 1946, 37, 239–250. [Google Scholar] [CrossRef]

- Kerner, E.H. The Elastic and Thermo-elastic Properties of Composite Media. Proc. Phys. Soc. Lond. Sect. B 1956, 69, 808–813. [Google Scholar] [CrossRef]

- Jia, Y.D.; Ma, P.; Prashanth, K.G.; Wang, G.; Yi, J.; Scudino, S.; Cao, F.Y.; Sun, J.F.; Eckert, J. Microstructure and thermal expansion behavior of Al-50Si synthesized by selective laser melting. J. Alloys Compd. 2017, 699, 548–553. [Google Scholar] [CrossRef]

- Schapery, R.A. Thermal Expansion Coefficients of Composite Materials Based on Energy Principles. J. Compos. Mater. 1968, 2, 380–404. [Google Scholar] [CrossRef]

- Wei, Z.J.; Ma, P.; Wang, H.W.; Zou, C.M.; Scudino, S.; Song, K.; Prashanth, K.G.; Jiang, W.; Eckert, J. The thermal expansion behaviour of SiCp/Al–20Si composites solidified under high pressures. Mater. Des. 2015, 65, 387–394. [Google Scholar] [CrossRef]

- Raghukiran, N.; Kumar, R. Effect of scandium addition on the microstructure, mechanical and wear properties of the spray formed hypereutectic aluminum–silicon alloys. Mater. Sci. Eng. A 2015, 641, 138–147. [Google Scholar] [CrossRef]

- Chang, J.; Moon, I.; Choi, C. Refinement of cast microstructure of hypereutectic Al-Si alloys through the addition of rare earth metals. J. Mater. Sci. 1998, 33, 5015–5023. [Google Scholar] [CrossRef]

- Cao, F.Y.; Jia, Y.D.; Prashanth, K.G.; Ma, P.; Liu, J.; Scudino, S.; Huang, F.; Eckert, J.; Sun, J.F. Evolution of microstructure and mechanical properties of as-cast Al-50Si alloy due to heat treatment and P modifier content. Mater. Des. 2015, 74, 150–156. [Google Scholar] [CrossRef]

- Huber, T.; Degischer, H.P.; Lefranc, G.; Schmitt, T. Thermal expansion studies on aluminium-matrix composites with different reinforcement architecture of SiC particles. Compos. Sci. Technol. 2006, 66, 2206–2217. [Google Scholar] [CrossRef]

- Lasagni, F.; Mingler, B.; Dumont, M.; Degischer, H.P. Precipitation kinetics of Si in aluminium alloys. Mater. Sci. Eng. A 2008, 480, 383–391. [Google Scholar] [CrossRef]

- Jia, Y.D.; Cao, F.Y.; Scudino, S.; Ma, P.; Li, H.C.; Yu, L.; Eckert, J.; Sun, J.F. Microstructure and thermal expansion behavior of spray-deposited Al–50Si. Mater. Des. 2014, 57, 585–591. [Google Scholar] [CrossRef]

- Elomari, S.; Skibo, M.D.; Sundarrajan, A.; Richards, H. Thermal expansion behavior of particulate metal-matrix composites. Compos. Sci. Technol. 1998, 58, 369–376. [Google Scholar] [CrossRef]

- Elomari, S.; Boukhili, R.; Marchi, C.S.; Mortensen, A.; Lloyd, D.J. Thermal expansion responses of pressure infiltrated SiC/Al metal-matrix composites. J. Mater. Sci. 1997, 32, 2131–2140. [Google Scholar] [CrossRef]

- Chawla, N.; Deng, X.; Schnell, D.R.M. Thermal expansion anisotropy in extruded SiC particle reinforced 2080 aluminum alloy matrix composites. Mater. Sci. Eng. A 2006, 426, 314–322. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 1963, 11, 127–140. [Google Scholar] [CrossRef]

- Wang, F.; Xiong, B.; Zhang, Y.; Zhu, B.; Liu, H.; Wei, Y. Microstructure, thermo-physical and mechanical properties of spray-deposited Si–30Al alloy for electronic packaging application. Mater. Charact 2008, 59, 1455–1457. [Google Scholar] [CrossRef]

- Hogg, S.C.; Lambourne, A.; Ogilvy, A.; Grant, P.S. Microstructural characterisation of spray formed Si–30Al for thermal management applications. Scr. Mater. 2006, 55, 111–114. [Google Scholar] [CrossRef]

- Grant, P.S. Solidification in Spray Forming. Metall. Mater. Trans. A 2007, 38, 1520–1529. [Google Scholar] [CrossRef]

- Zhu, X.W.; Wang, R.C.; Peng, C.Q.; Liu, W.S.; Peng, J. Microstructure and thermal expansion behavior of spray-formed Al–27Si alloy used for electronic packaging. J. Mater. Sci. Mater. Electron. 2014, 25, 4889–4895. [Google Scholar] [CrossRef]

| Element | Zn | Mg | Cu | Fe | Si | Mn | Al |

|---|---|---|---|---|---|---|---|

| Content | 5.63 | 2.21 | 1.41 | 0.26 | 0.1 | 0.05 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, L.; Jiang, S.; Cao, F.; Shen, H.; Zhang, L.; Gu, X.; Song, H.; Sun, J. Thermal Expansion Behavior of Co-Spray Formed Al-20Si/7075 Bimetallic Gradient Alloy. Materials 2021, 14, 4100. https://doi.org/10.3390/ma14154100

Yu L, Jiang S, Cao F, Shen H, Zhang L, Gu X, Song H, Sun J. Thermal Expansion Behavior of Co-Spray Formed Al-20Si/7075 Bimetallic Gradient Alloy. Materials. 2021; 14(15):4100. https://doi.org/10.3390/ma14154100

Chicago/Turabian StyleYu, Lei, Sida Jiang, Fuyang Cao, Hongxian Shen, Lunyong Zhang, Xu Gu, Heqian Song, and Jianfei Sun. 2021. "Thermal Expansion Behavior of Co-Spray Formed Al-20Si/7075 Bimetallic Gradient Alloy" Materials 14, no. 15: 4100. https://doi.org/10.3390/ma14154100

APA StyleYu, L., Jiang, S., Cao, F., Shen, H., Zhang, L., Gu, X., Song, H., & Sun, J. (2021). Thermal Expansion Behavior of Co-Spray Formed Al-20Si/7075 Bimetallic Gradient Alloy. Materials, 14(15), 4100. https://doi.org/10.3390/ma14154100