The Effect of Thermal Oxidation on the Photothermal Conversion Property of Tantalum Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Plasma Sputtered Tantalum Coatings

2.2. Characterization and Photothermal Test

2.3. Photothermal Ablation In Vitro

3. Results and Discussion

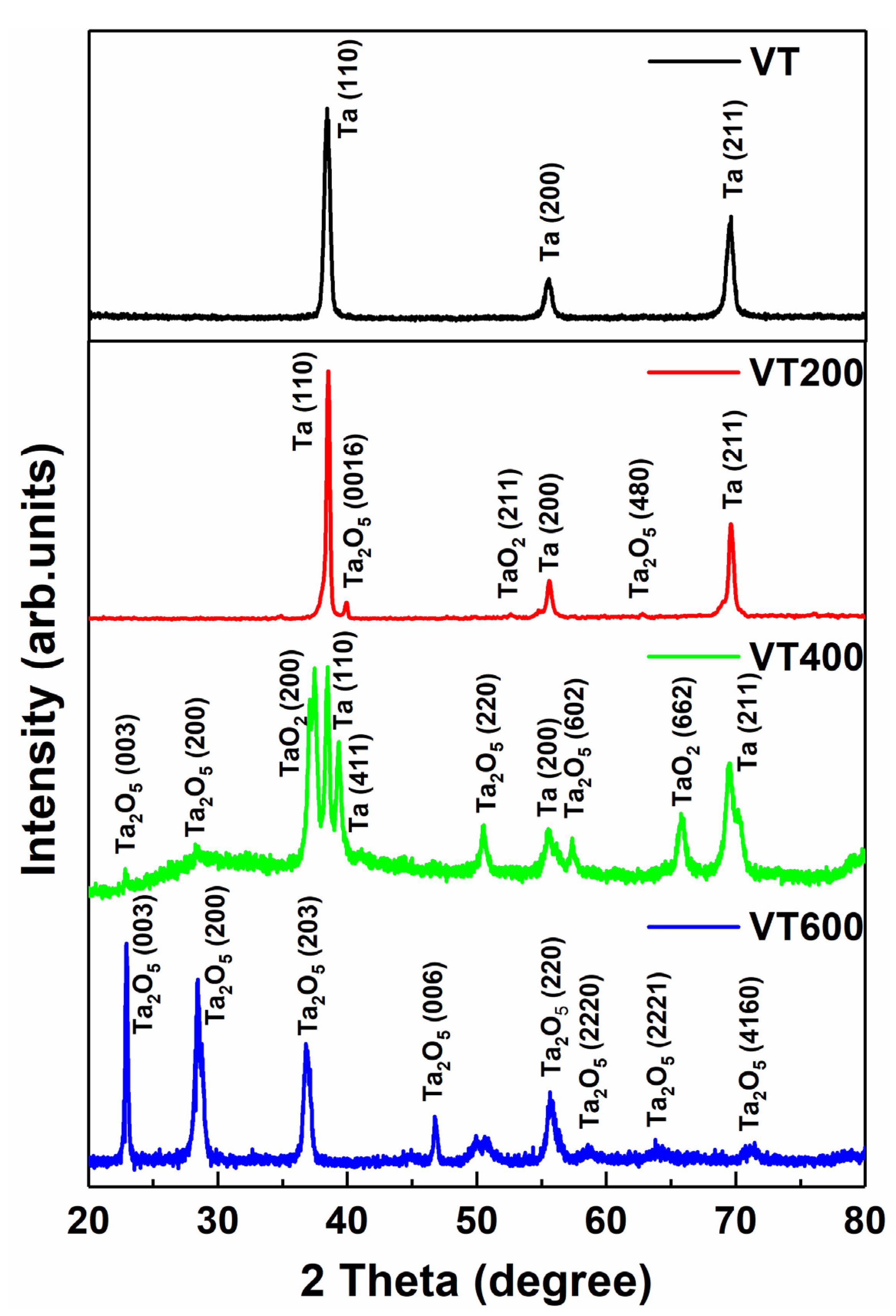

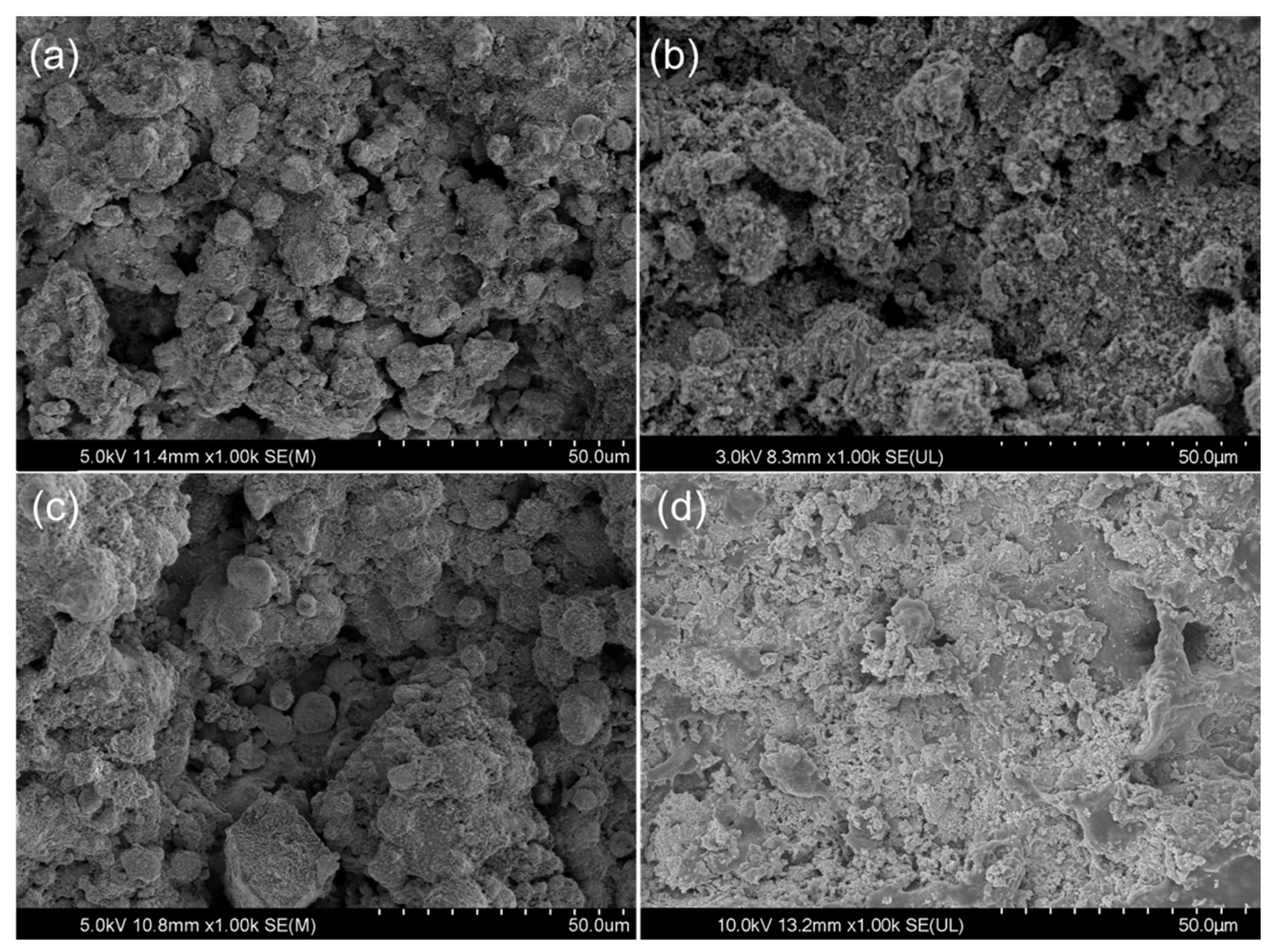

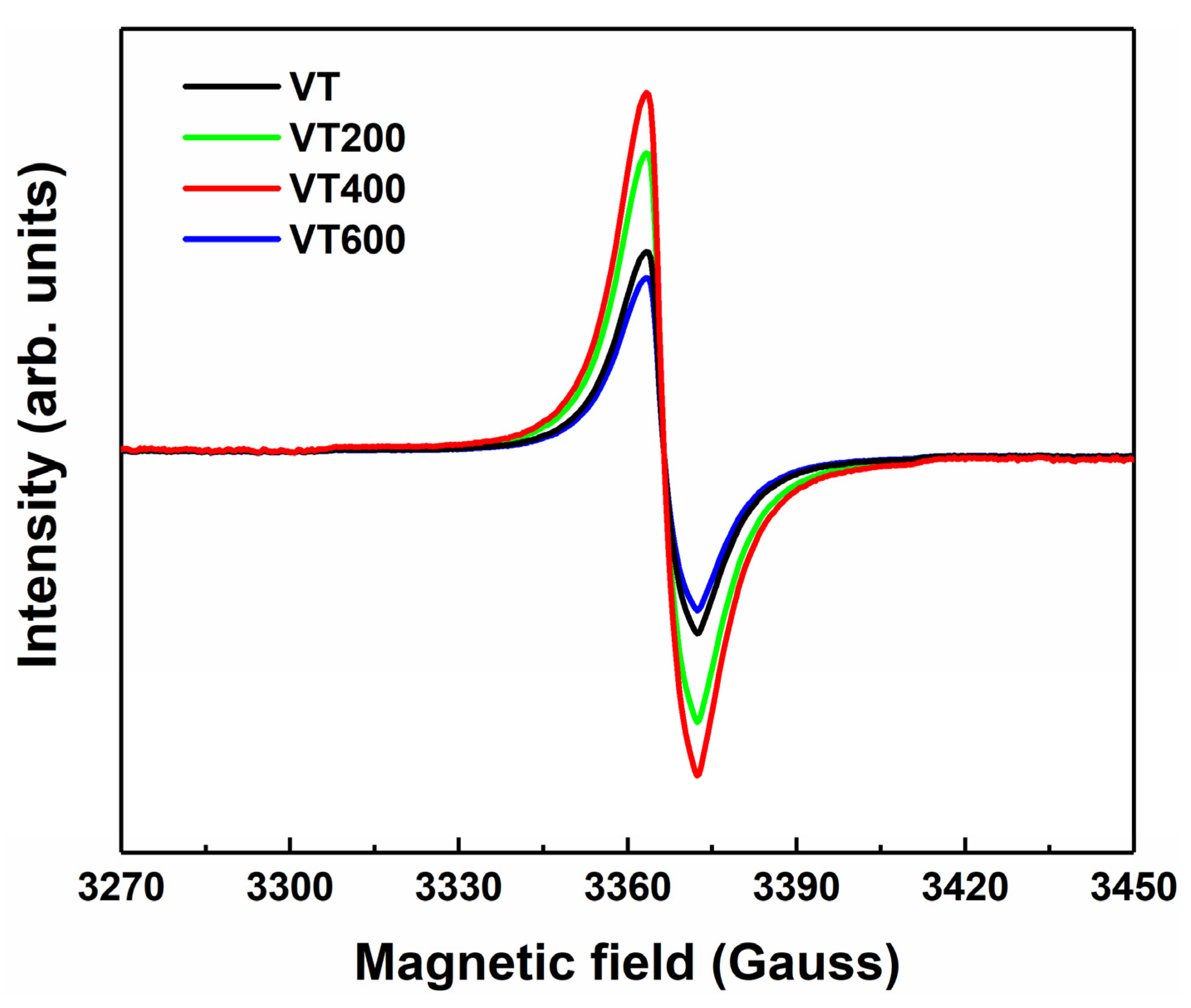

3.1. Surface Characterization

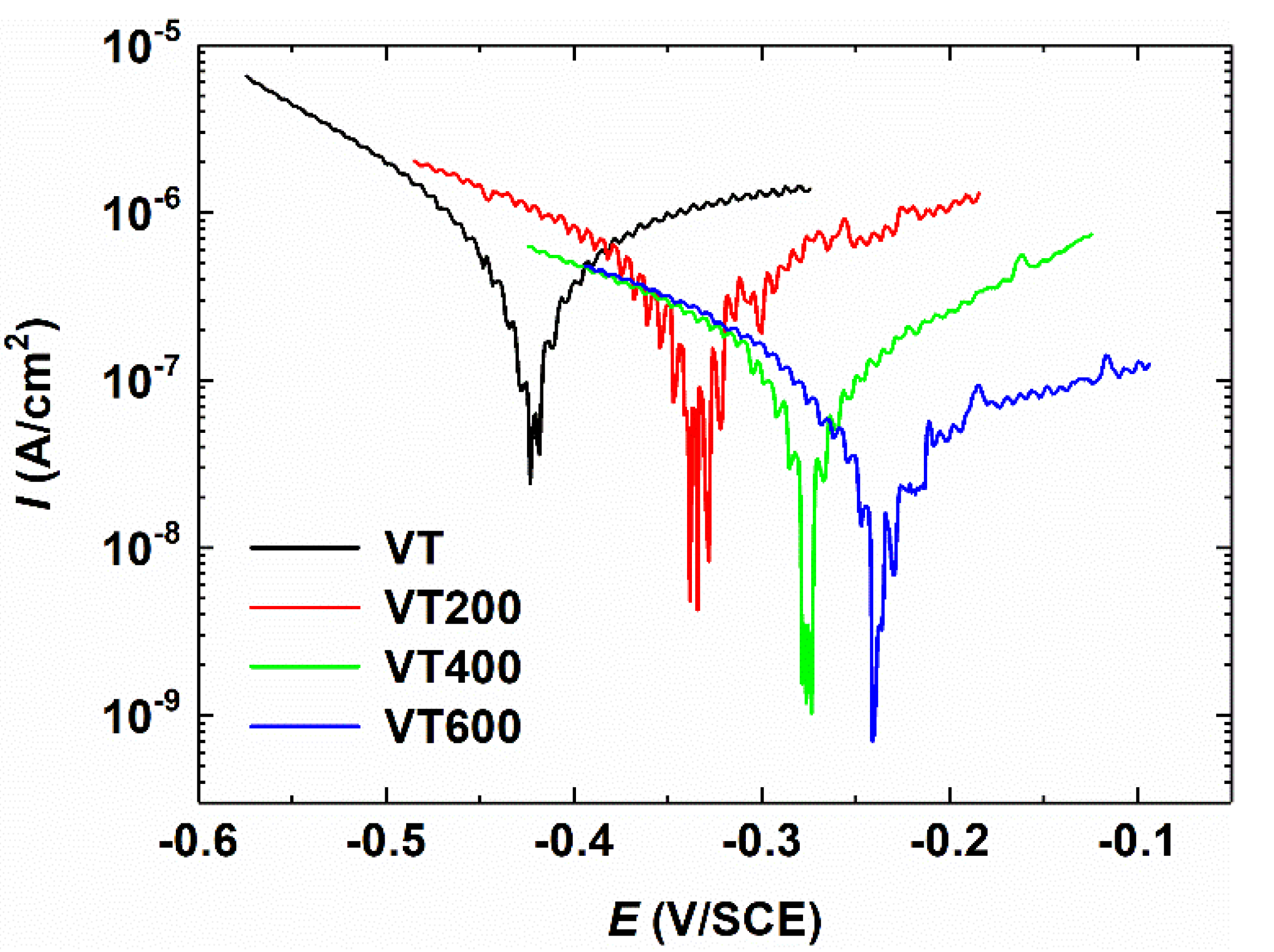

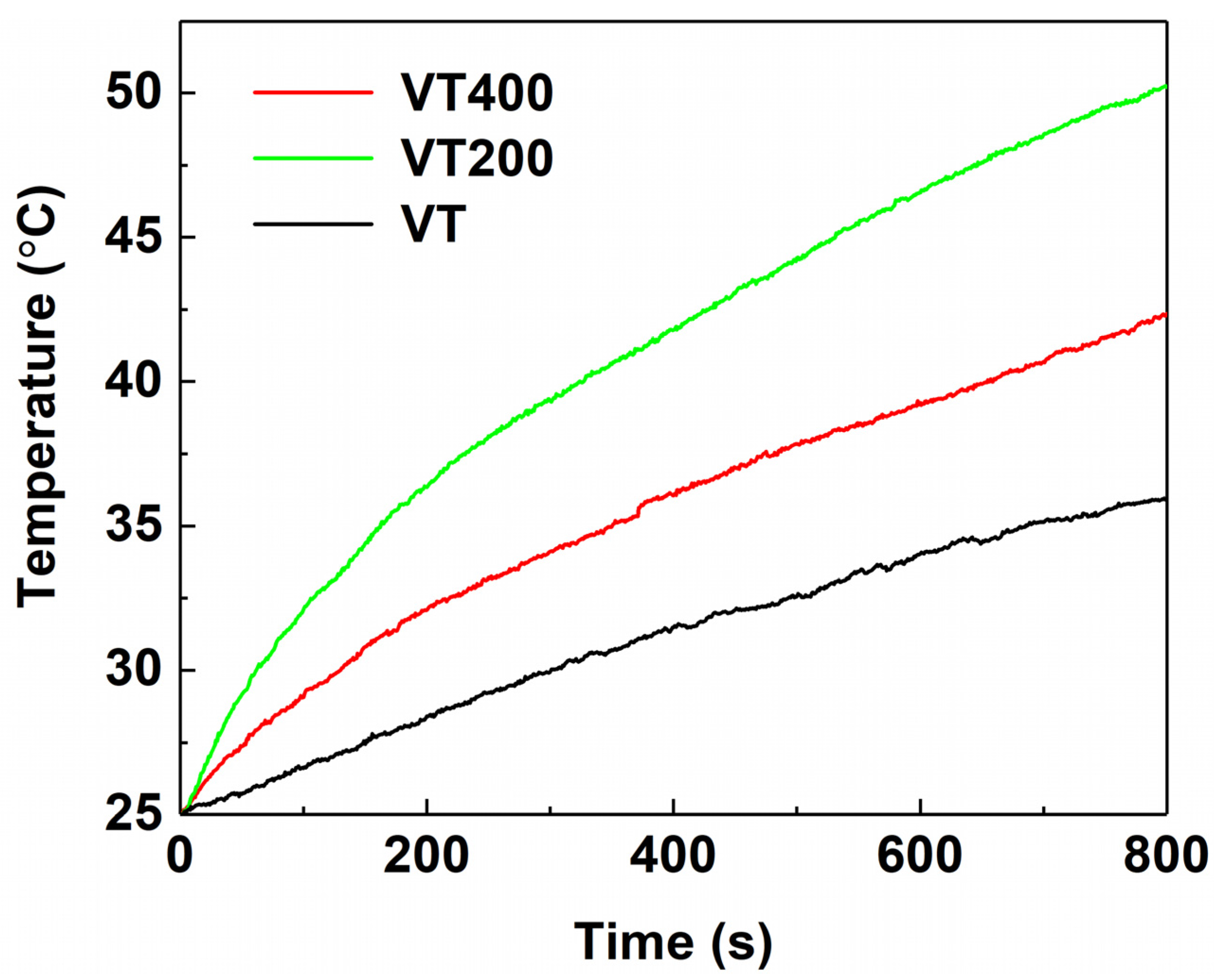

3.2. Photothermal Effect of Tantalum Coatings

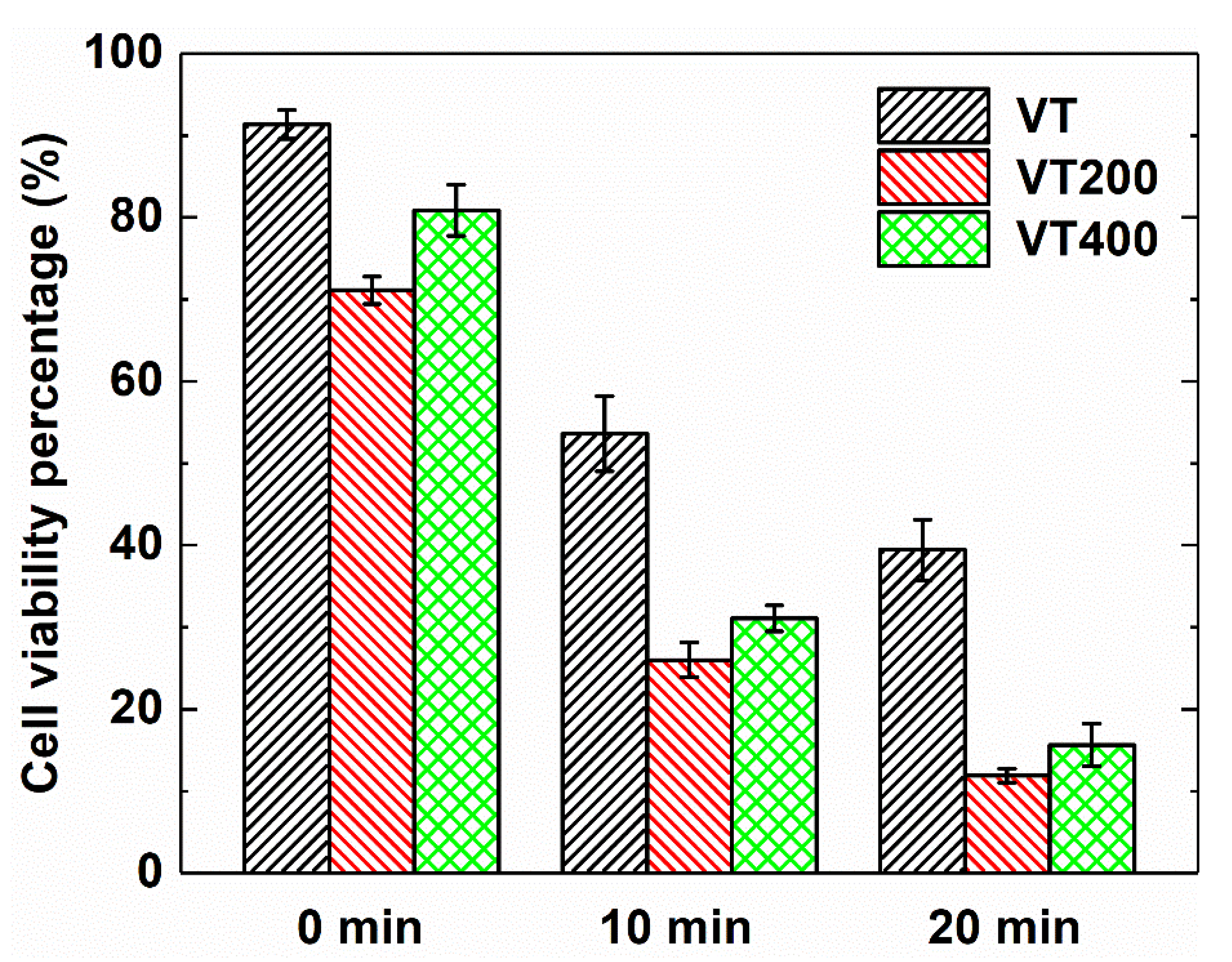

3.3. Photothermal Effect of Tantalum Coatings for Killing Bone-Tumor Cells

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, S.; Ke, J.; Yao, M.; Shao, H.; Zhou, J.; Wang, M.; Ji, X.F.; Zhong, G.Q.; Peng, F.; Ma, L.M.; et al. Improved osteointegration and angiogenesis of strontium-incorporated 3d-printed tantalum scaffold via bioinspired polydopamine coating. J. Mater. Sci. Technol. 2021, 69, 106–118. [Google Scholar] [CrossRef]

- Ding, D.; Xie, Y.; Li, K.; Huang, L.; Zheng, X. Micro/Nano structural tantalum coating for enhanced osteogenic differentiation of human bone marrow stem cells. Materials 2018, 11, 546. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rahmati, B.; Sarhan, A.A.; Zalnezhad, E.; Kamiab, Z.; Dabbagh, A.; Choudhury, D.; Abas, W.A.B.W. Development of tantalum oxide (Ta-O) thin film coating on biomedical Ti-6Al-4V alloy to enhance mechanical properties and biocompatibility. Ceram. Int. 2016, 42, 466–480. [Google Scholar] [CrossRef]

- Sowa, M.; Woszczak, M.; Kazek-Kęsik, A.; Dercz, G.; Korotin, D.M.; Zhidkov, I.S.; Kurmaev, E.Z.; Cholakh, S.O.; Basiaga, M.; Simk, W. Influence of process parameters on plasma electrolytic surface treatment of tantalum for biomedical applications. Appl. Surf. Sci. 2017, 407, 52–63. [Google Scholar] [CrossRef]

- Li, X.; Wang, F.; Liang, A. Effect of spraying process on microstructure and tribological properties of Ta2O5 In situ composite nanocrystalline Ta-based coatings. Acta Metall. Sin. 2021, 57, 237–246. [Google Scholar]

- Patel, K.D.; El-Fiqi, A.; Lee, H.Y.; Singh, R.K.; Kim, D.A.; Lee, H.H.; Kim, H.W. Chitosan-nanobioactive glass electrophoretic coatings with bone regenerative and drug delivering potential. J. Mater. Chem. 2012, 22, 24945–24956. [Google Scholar] [CrossRef]

- Wang, F.; Li, C.; Zhang, S.; Liu, H. Tantalum coated on titanium dioxide nanotubes by plasma spraying enhances cytocompatibility for dental implants. Surf. Coat. Tech. 2020, 382, 125161. [Google Scholar] [CrossRef]

- Frandsen, C.J.; Brammer, K.S.; Noh, K.; Johnston, G.; Jin, S. Tantalum coating on TiO2 nanotubes induces superior rate of matrix mineralization and osteofunctionality in human osteoblasts. Mater. Sci. Eng. C Mater. 2014, 37, 332–341. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pishbin, F.; Mourino, V.; Gilchrist, J.B.; McComb, D.W.; Kreppel, S.; Salih, V.; Ryan, M.P.; Boccaccini, A.R. Single-step electrochemical deposition of antimicrobial orthopaedic coatings based on a bioactive glass/chitosan/nano-silver composite system. Acta Biomater. 2013, 9, 7469–7479. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, J.; Li, K.; Zhao, J.; Ma, H.; Wu, C.; Zhang, C.; Xie, Y.; Yang, F.; Zheng, X. A hydrogenated black TiO2 coating with excellent effects for photothermal therapy of bone tumor and bone regeneration. Mater. Sci. Eng. C Mater. 2019, 102, 458–470. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, X.; Yin, C. A study on improving the efficacy of nanoparticle-based photothermal therapy: From nanoscale to micron scale to millimeter scale. Materials 2021, 14, 2407. [Google Scholar] [CrossRef]

- Chen, X.; Liu, L.; Peter, Y.Y.; Mao, S.S. Increasing solar absorption for photocatalysis with black hydrogenated titanium dioxide nanocrystals. Science 2011, 331, 746–750. [Google Scholar] [CrossRef]

- Ren, W.; Yan, Y.; Zeng, L.; Shi, Z.; Gong, A.; Schaaf, P.; Wang, D.; Zhao, J.S.; Zou, B.B.; Yu, H.S.; et al. A near infrared light triggered hydrogenated black TiO2 for cancer photothermal therapy. Adv. Healthc. Mater. 2015, 4, 1526–1536. [Google Scholar] [CrossRef]

- DDing, D.; Xie, Y.; Li, K.; Huang, L.; Zheng, X. Black plasma-sprayed Ta2O5 coatings with photothermal effect for bone tumor therapy. Ceram. Int. 2018, 44, 12002–12006. [Google Scholar] [CrossRef]

- Dong, L.; Chu, H.; Wang, X.; Li, Y.; Zhao, S.; Li, D. Enhanced broadband nonlinear optical response of TiO2/CuO nanosheets via oxygen vacancy engineering. Nanophotonics 2021, 10, 1541–1551. [Google Scholar] [CrossRef]

- Chandrasekharan, R.; Park, I.; Masel, R.I.; Shannon, M.A. Thermal oxidation of tantalum films at various oxidation states from 300 to 700 °C. J. Appl. Phys. 2005, 98, 114908. [Google Scholar] [CrossRef]

- Alves, C.A.; Cavaleiro, A.; Carvalho, S. Bioactivity response of Ta1-xOx coatings deposited by reactive DC magnetron sputtering. Mater. Sci. Eng. C Mater. 2016, 58, 110–118. [Google Scholar] [CrossRef] [Green Version]

- Zhu, M.; Zhang, Z.; Miao, W. Intense photoluminescence from amorphous tantalum oxide films. Appl. Phys. Lett. 2006, 89, 021915. [Google Scholar] [CrossRef]

- Inoue, N.; Ninomiya, T.; Kashiwabara, S.; Fujimoto, R. Ta2O5 thin-films deposited by off-axis and on-axis pulsed laser deposition techniques. Appl. Phys. A Mater. 1999, 69, S609–S612. [Google Scholar] [CrossRef]

- VOrlov, V.M.; Prokhorova, T.Y.; Belyaevskii, A.T. Effect of Ta2O5 precursor morphology on characteristics of magnesiothermic tantalum powders. Inorg. Mater. 2021, 57, 255–261. [Google Scholar] [CrossRef]

- Simpson, R.; White, R.G.; Watts, J.F.; Baker, M.A. XPS investigation of monatomic and cluster argon ion sputtering of tantalum pentoxide. Appl. Surf. Sci. 2017, 405, 79–87. [Google Scholar] [CrossRef]

- Xu, J.; ke Bao, X.; Fu, T.; Lyu, Y.; Munroe, P.; Xie, Z.H. In vitro biocompatibility of a nanocrystalline beta-Ta2O5 coating for orthopaedic implants. Ceram. Int. 2018, 44, 4660–4675. [Google Scholar] [CrossRef]

- Lahoz, R.; Espinós, J.P.; Yubero, F.; González-Elipe, A.R.; de la Fuente, G.F. In situ XPS studies of laser-induced surface nitridation and oxidation of tantalum. J. Mater. Res. 2015, 30, 2967–2976. [Google Scholar] [CrossRef]

- Cheng, Y.; Cai, W.; Li, H.T.; Zheng, Y.F.; Zhao, L.C. Surface characteristics and corrosion resistance properties of TiNi shape memory alloy coated with Ta. Surf. Coat. Technol. 2004, 186, 346–352. [Google Scholar] [CrossRef]

- Li, H.; Muraki, Y.; Karahashi, K.; Hamaguchi, S. Suboxide/subnitride formation on Ta masks during magnetic material etching by reactive plasmas. J. Vac. Sci. Technol. A 2015, 33, 040602. [Google Scholar] [CrossRef]

- Houssa, M.; Tuominen, M.; Naili, M.; Afanas’ev, V.; Stesmans, A.; Haukka, S.; Heyns, M.M. Trap-assisted tunneling in high permittivity gate dielectric stacks. J. Appl. Phys. 2000, 87, 8615–8620. [Google Scholar] [CrossRef]

- Egorov, K.V.; Kuzmichev, D.S.; Chizhov, P.S.; Lebedinskii, Y.Y.; Hwang, C.S.; Markeev, A.M. In Situ Control of Oxygen Vacancies in TaOx Thin Films via Plasma-Enhanced Atomic Layer Deposition for Resistive Switching Memory Applications. ACS Appl. Mater. Int. 2017, 9, 13286–13292. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Lu, W.D.; Kioupakis, E. Electronic and optical properties of oxygen vacancies in amorphous Ta2O5 from first principles. Nanoscale 2017, 9, 1120–1127. [Google Scholar] [CrossRef] [PubMed]

- Maeda, K.; Terashima, H.; Kase, K.; Domen, K. Nanoparticulate precursor route to fine particles of TaON and ZrO2–TaON solid solution and their photocatalytic activity for hydrogen evolution under visible light. Appl. Catal. A 2009, 357, 206–212. [Google Scholar] [CrossRef]

- Ziolek, M.; Sobczak, I.; Decyk, P.; Sobańska, K.; Pietrzyk, P.; Sojka, Z. Search for reactive intermediates in catalytic oxidation with hydrogen peroxide over amorphous niobium (V) and tantalum (V) oxides. Appl. Catal. B 2015, 164, 288–296. [Google Scholar] [CrossRef]

- Sowa, M.; Simka, W. Electrochemical impedance and polarization corrosion studies of tantalum surface modified by DC plasma electrolytic oxidation. Materials 2018, 11, 545. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, D.; Zeng, Q.; He, F.; Chen, Z. The Effect of Thermal Oxidation on the Photothermal Conversion Property of Tantalum Coatings. Materials 2021, 14, 4031. https://doi.org/10.3390/ma14144031

Ding D, Zeng Q, He F, Chen Z. The Effect of Thermal Oxidation on the Photothermal Conversion Property of Tantalum Coatings. Materials. 2021; 14(14):4031. https://doi.org/10.3390/ma14144031

Chicago/Turabian StyleDing, Ding, Qingping Zeng, Feng He, and Zhuojun Chen. 2021. "The Effect of Thermal Oxidation on the Photothermal Conversion Property of Tantalum Coatings" Materials 14, no. 14: 4031. https://doi.org/10.3390/ma14144031

APA StyleDing, D., Zeng, Q., He, F., & Chen, Z. (2021). The Effect of Thermal Oxidation on the Photothermal Conversion Property of Tantalum Coatings. Materials, 14(14), 4031. https://doi.org/10.3390/ma14144031