A Review of Conductive Carbon Materials for 3D Printing: Materials, Technologies, Properties, and Applications

Abstract

:1. Introduction

2. Common Conductive Carbon Materials

2.1. Carbon Black

2.2. Carbon Fiber

2.3. Carbon Nanotubes

2.4. Graphene

3. 3D Printing of Conductive Carbon Materials

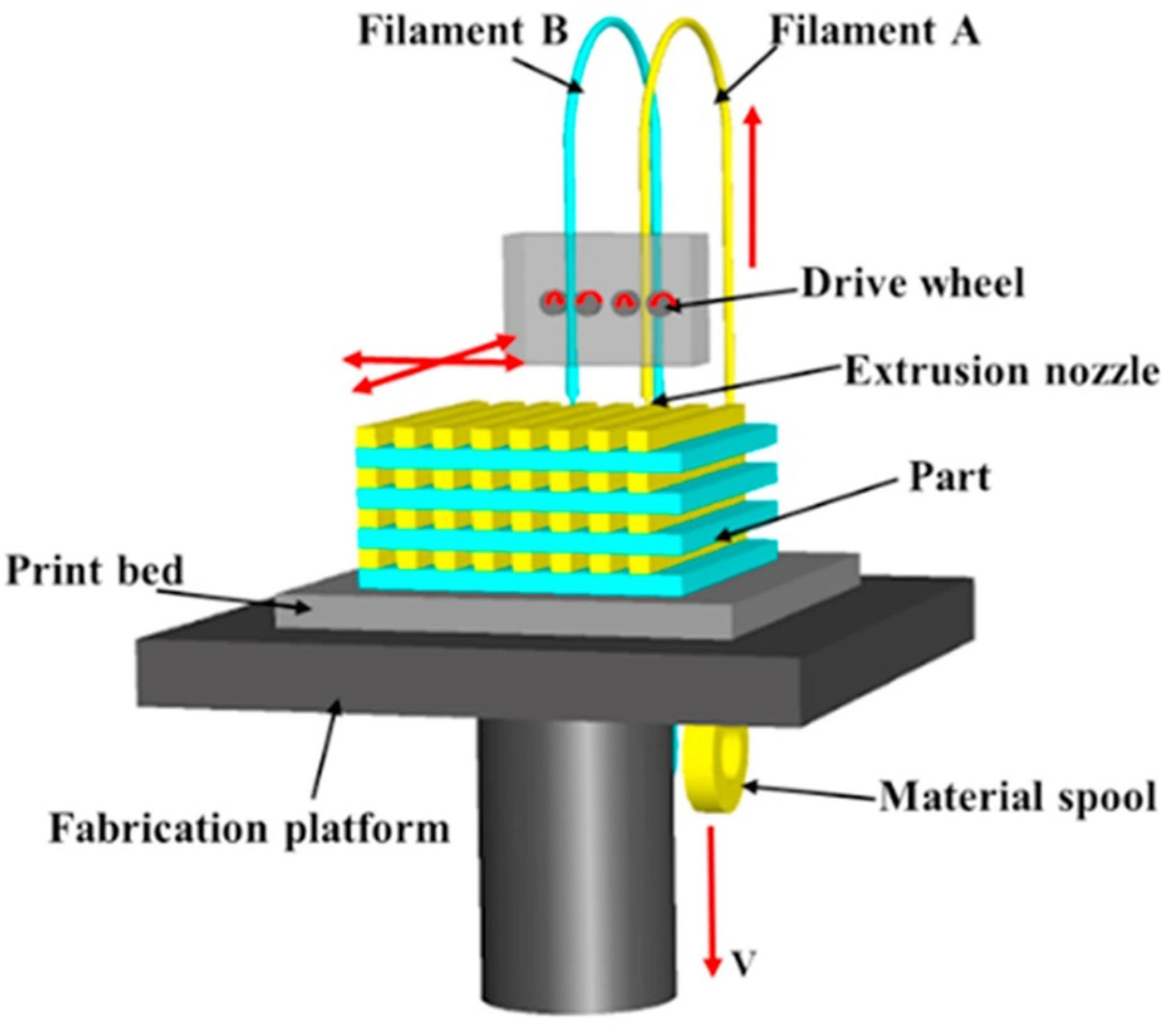

3.1. Fused Deposition Modelling

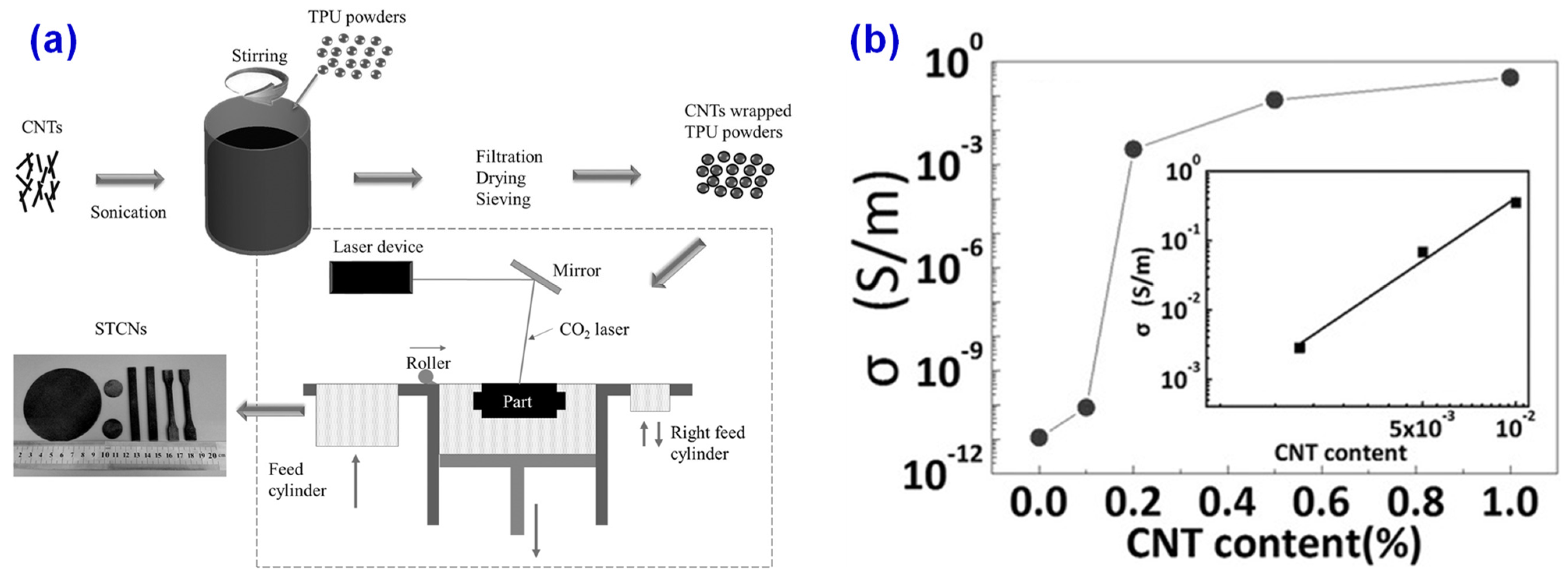

3.2. Selective Laser Sintering

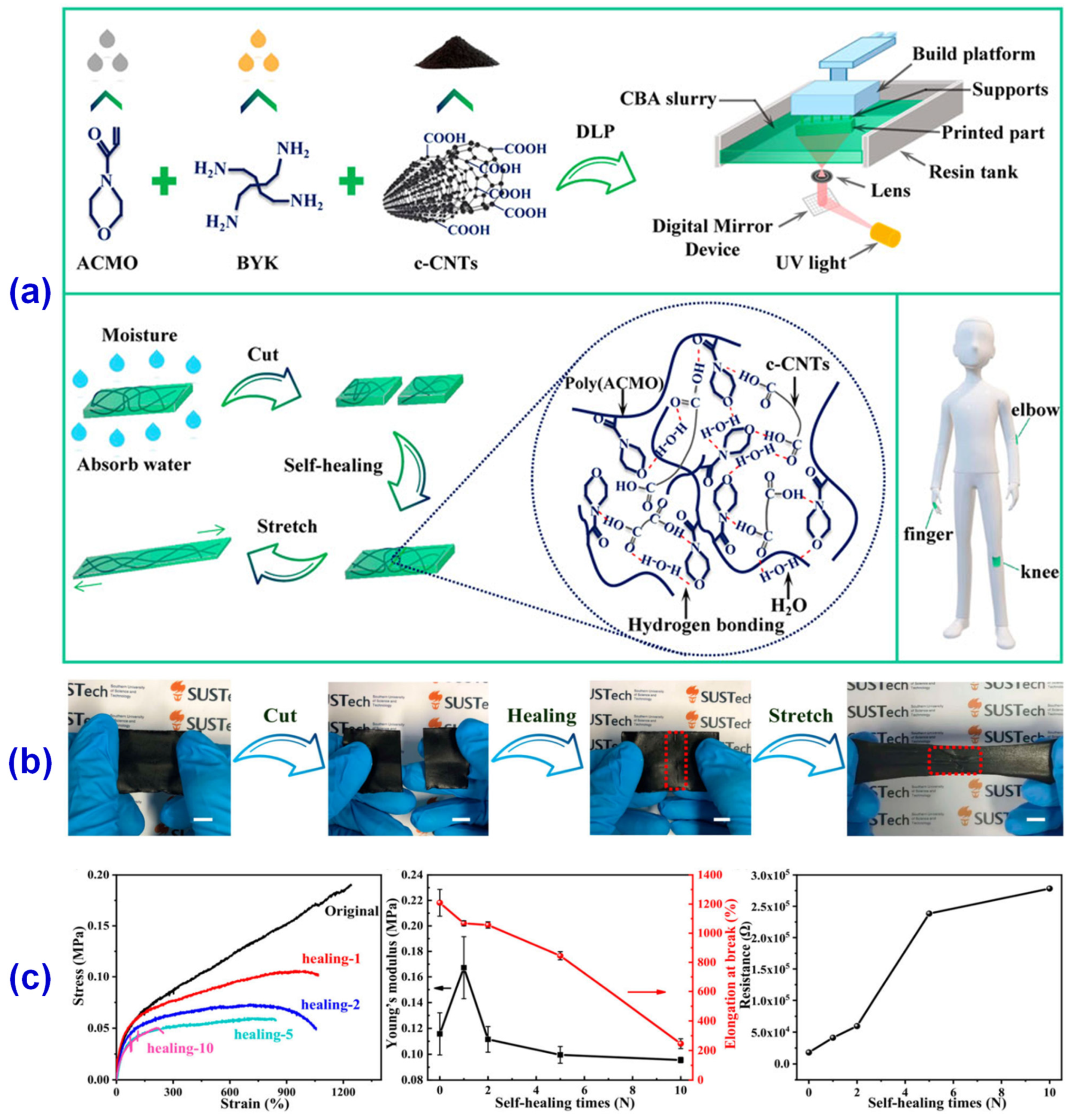

3.3. Digital Light Processing

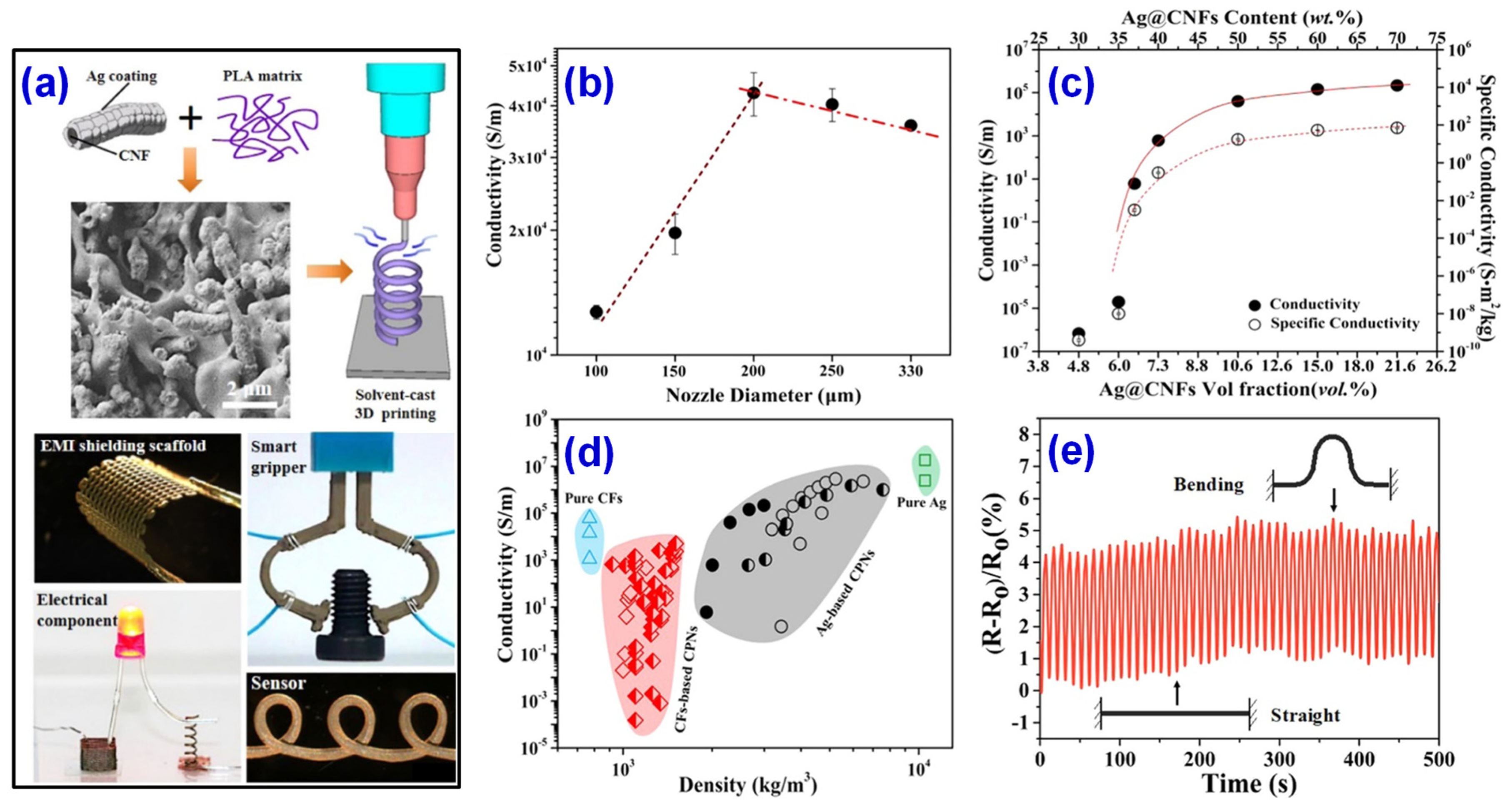

3.4. Other Printing Technologies

4. Conclusions and Outlook

- (1)

- The price of raw materials is too expensive. Taking plastics as an example, the price of traditional injection molding plastics is 2–3 dollars/kg, while the price of 3D printing plastics is 175–250 dollars/kg. The high cost of raw materials is ultimately reflected in the high price of products, which is difficult to accept in the current market.

- (2)

- There are few printable materials, which makes it difficult to meet demand. There are only 20 kinds of monomer material for 3D printing, and only 140 kinds of material can be selected after mixing, which is too limited compared with thousands of materials in various application fields.

- (3)

- The existing materials are insufficiently optimized. Additive manufacturing has higher requirements of the performance and applicability of materials, the properties of materials before and after printing remain stable, and can meet the requirements of continuous production, which requires further optimization of materials.

- (4)

- Lack of color options. The color options for 3D printing are very limited. In addition, the color of composite materials with conductive carbon materials is always black, which restricts the use of 3D printing technology in creative industries.

- (5)

- Deficiency of standard/certification. At present, there is no standardized database of material performance, which means it is not possible to certify the level of equipment or new materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kodama, H. Automatic method for fabricating a 3-dimensional plastic model with photo-hardening polymer. Rev. Sci. Instrum. 1981, 52, 1770–1773. [Google Scholar] [CrossRef]

- Freedman, D.H. Layer by layer. Technol. Rev. 2012, 115, 50–53. [Google Scholar]

- Gawel, T.G. Review of additive manufacturing methods. Solid State Phenom. 2020, 308, 1–20. [Google Scholar] [CrossRef]

- Pearce, J.M. Building research equipment with free, open-source hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef] [PubMed]

- Bogue, R. 3D printing: The dawn of a new era in manufacturing? Assem. Autom. 2013, 33, 307–311. [Google Scholar] [CrossRef]

- Campbell, T.A.; Ivanova, O.S. 3D printing of multifunctional nanocomposites. Nano Today 2013, 8, 119–120. [Google Scholar] [CrossRef]

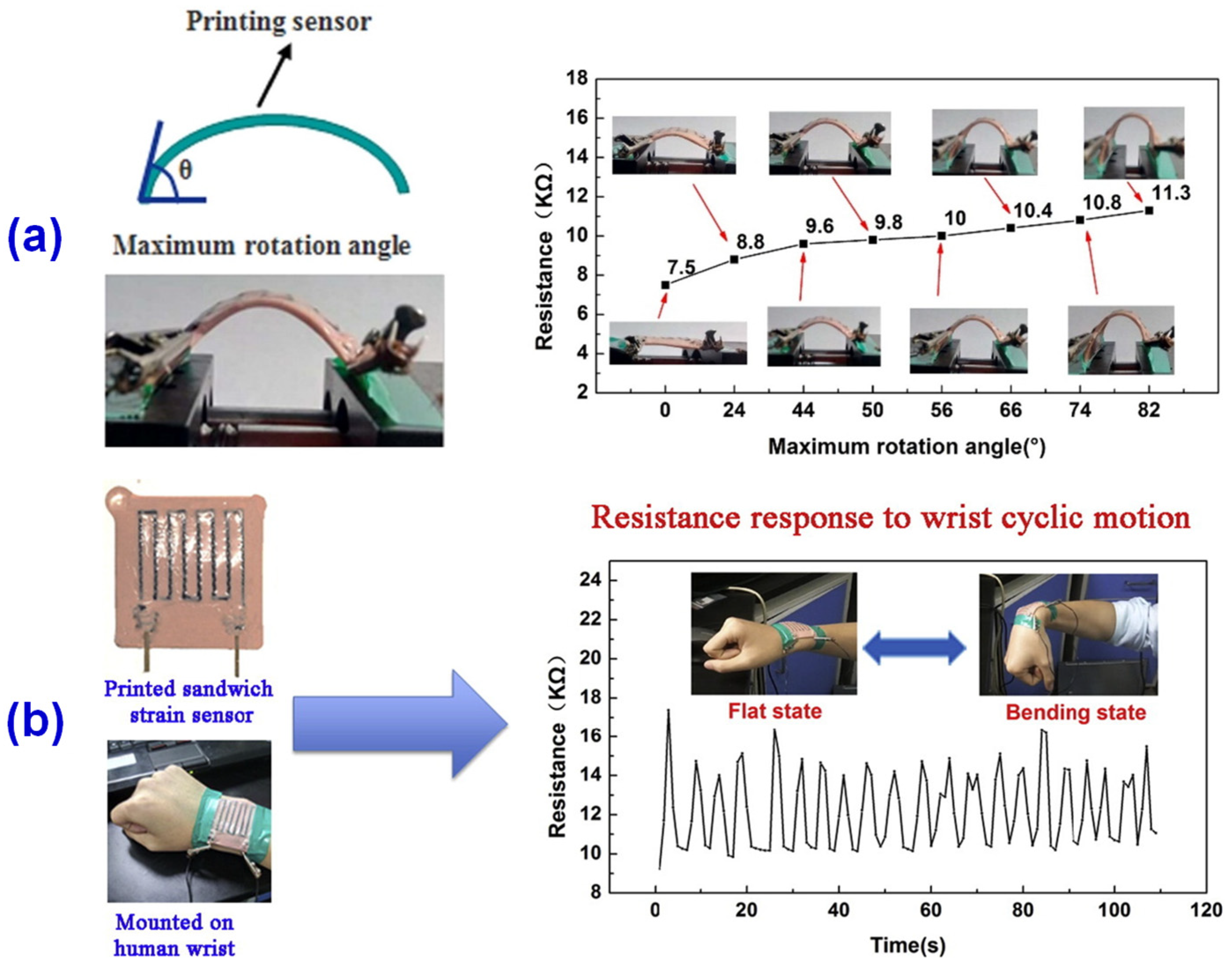

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Poetschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Mahmoodi, M.; Arjmand, M.; Sundararaj, U.; Park, S. The electrical conductivity and electromagnetic interference shielding of injection molded multi-walled carbon nanotube/polystyrene composites. Carbon 2011, 50, 1455–1464. [Google Scholar] [CrossRef]

- Palenzuela, C.L.M.; Novotny, F.; Krupicka, P.; Sofer, Z.; Pumera, M. 3D-printed graphene/polylactic acid electrodes promise high sensitivity in electroanalysis. Anal. Chem. 2018, 90, 5753–5757. [Google Scholar] [CrossRef]

- Ahn, B.Y.; Duoss, E.B.; Motala, M.J.; Guo, X.; Park, S.I.; Xiong, Y.; Yoon, J.; Nuzzo, R.G.; Rogers, J.A.; Lewis, J.A. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 2009, 323, 1590–1593. [Google Scholar] [CrossRef] [Green Version]

- Rymansaib, Z.; Iravani, P.; Emslie, E.; Medvidovic-Kosanovic, M.; Sak-Bosnar, M.; Verdejo, R.; Marken, F. All-polystyrene 3D-printed electrochemical device with embedded carbon nanofiber-graphite-polystyrene composite conductor. Electroanalysis 2016, 28, 1517–1523. [Google Scholar] [CrossRef] [Green Version]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Menguc, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef] [PubMed]

- Mu, Q.Y.; Dunn, C.K.; Wang, L.; Dunn, M.L.; Qi, H.J.; Wang, T.J. Thermal cure effects on electromechanical properties of conductive wires by direct ink write for 4D printing and soft machines. Smart Mater. Struct. 2017, 26, 045008. [Google Scholar] [CrossRef]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, B.; Fu, F.; You, F.; Dong, X.; Dai, M. Resistivity and its anisotropy characterization of 3D-printed acrylonitrile butadiene styrene copolymer (ABS)/carbon black (CB) composites. Appl. Sci. 2017, 7, 20. [Google Scholar] [CrossRef] [Green Version]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.Q.; Xu, Y.; Yang, Y.; Li, L.S.; Song, C.R.; Su, X. Conductive mechanism of carbon black/polyimide composite films. J. Polym. Eng. 2018, 38, 147–156. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Electromagnetic interference shielding mechanisms of CNT/polymer composites. Carbon 2009, 47, 1738–1746. [Google Scholar] [CrossRef]

- Cao, M.S.; Wang, X.X.; Cao, W.Q.; Yuan, J. Ultrathin graphene: Electrical properties and highly efficient electromagnetic interference shielding. J. Mater. Chem. C 2015, 3, 6589–6599. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Neves, R.M.; Monticeli, F.M.; Almeida, J.H.S. Viscoelastic characteristics of carbon fiber-reinforced epoxy filament wound laminates. Compos. Commun. 2020, 21, 100418. [Google Scholar] [CrossRef]

- Khodabakhshi, S.; Fulvio, P.F.; Andreoli, E. Carbon black reborn: Structure and chemistry for renewable energy harnessing. Carbon 2020, 162, 604–649. [Google Scholar] [CrossRef] [Green Version]

- Donnet, J.B.; Bansal, R.C.; Wang, M.J. Carbon Black: Science and Technology; Dekker: New York, NY, USA, 1993. [Google Scholar]

- Cheah, K.; Forsyth, M.; Simon, G.P. Processing and morphological development of carbon black filled conducting blends using a binary host of poly(styrene co-acrylonitrile) and poly(styrene). J. Polym. Sci. Part B Polym. Phys. 2000, 38, 3106–3119. [Google Scholar] [CrossRef]

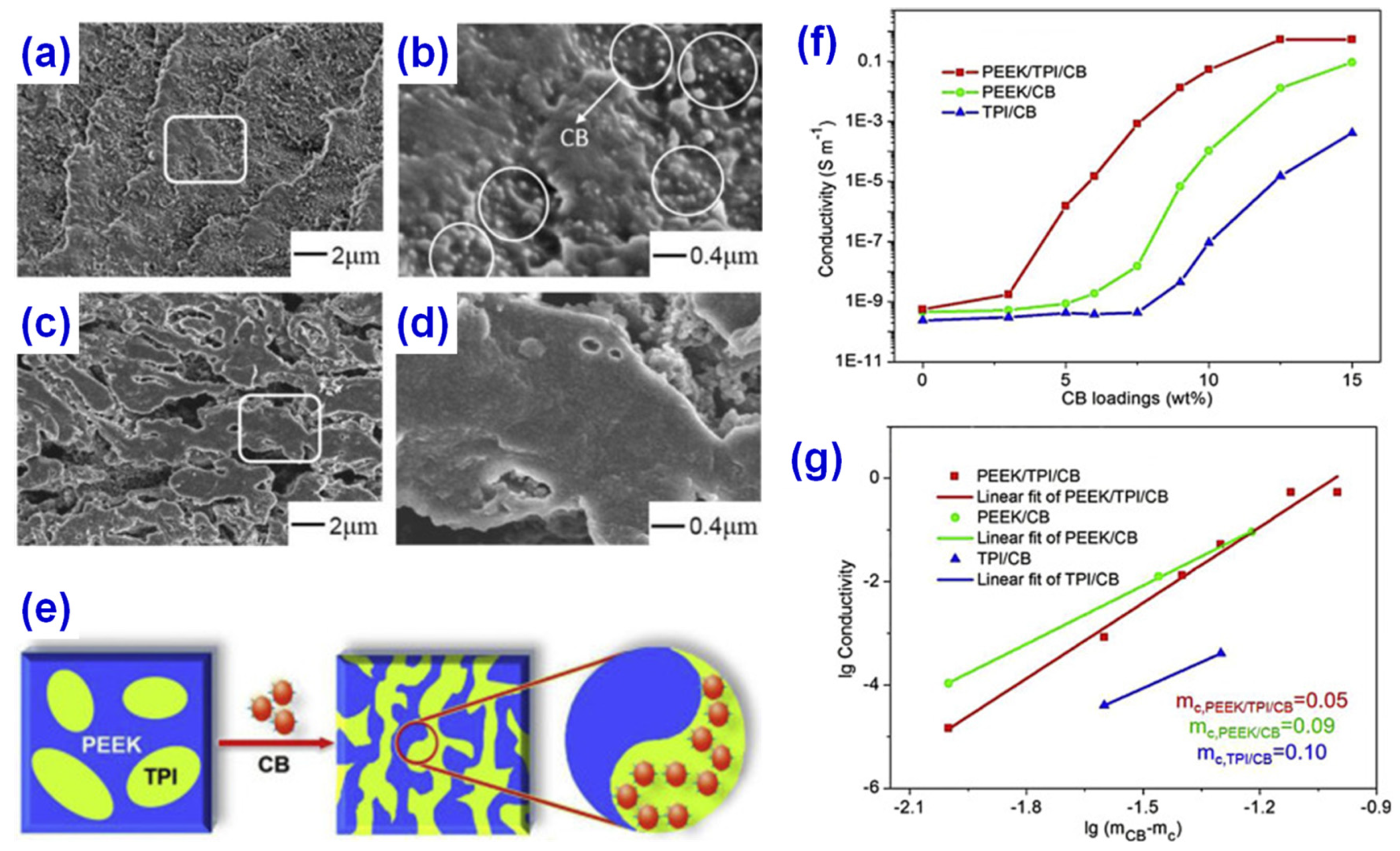

- Gao, C.; Zhang, S.L.; Lin, Y.J.; Li, F.; Guan, S.W.; Jiang, Z.H. High-performance conductive materials based on the selective location of carbon black in poly(ether ether ketone)/polyimide matrix. Compos. Part B Eng. 2015, 79, 124–131. [Google Scholar] [CrossRef]

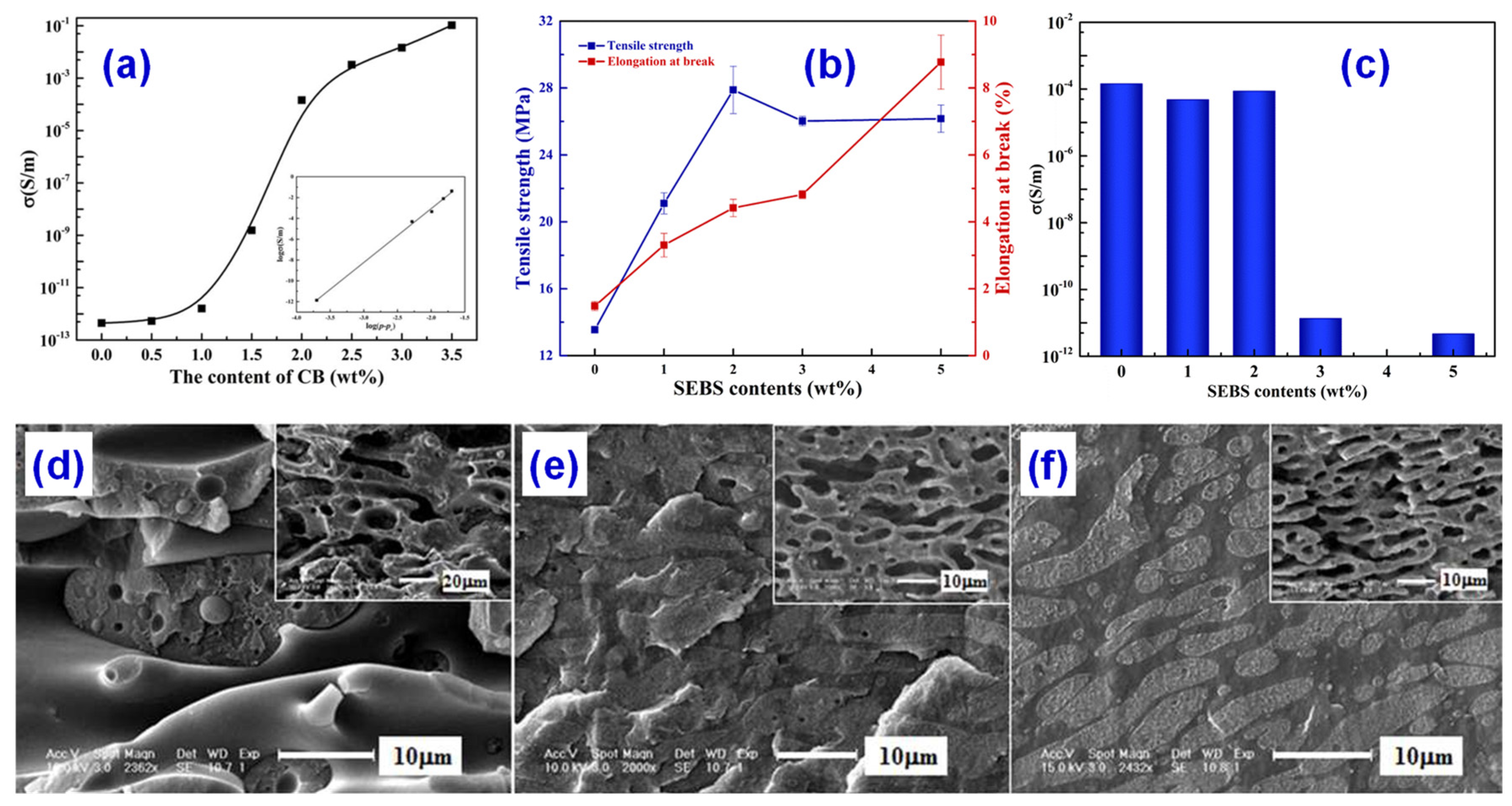

- Chen, J.W.; Cui, X.H.; Sui, K.Y.; Zhu, Y.T.; Jiang, W. Balance the electrical properties and mechanical properties of carbon black filled immiscible polymer blends with a double percolation structure. Compos. Sci. Technol. 2017, 140, 99–105. [Google Scholar] [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review. Adv. Compos. Hybrid Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Hirota, K.; Fueki, K.; Shindo, K.; Nakai, Y. Studies on the state of formic acid adsorbed on silica and alumina by a combined method of nuclear magnetic resonance and infrared absorption. Bull. Chem. Soc. Jpn. 1959, 32, 1261–1263. [Google Scholar] [CrossRef] [Green Version]

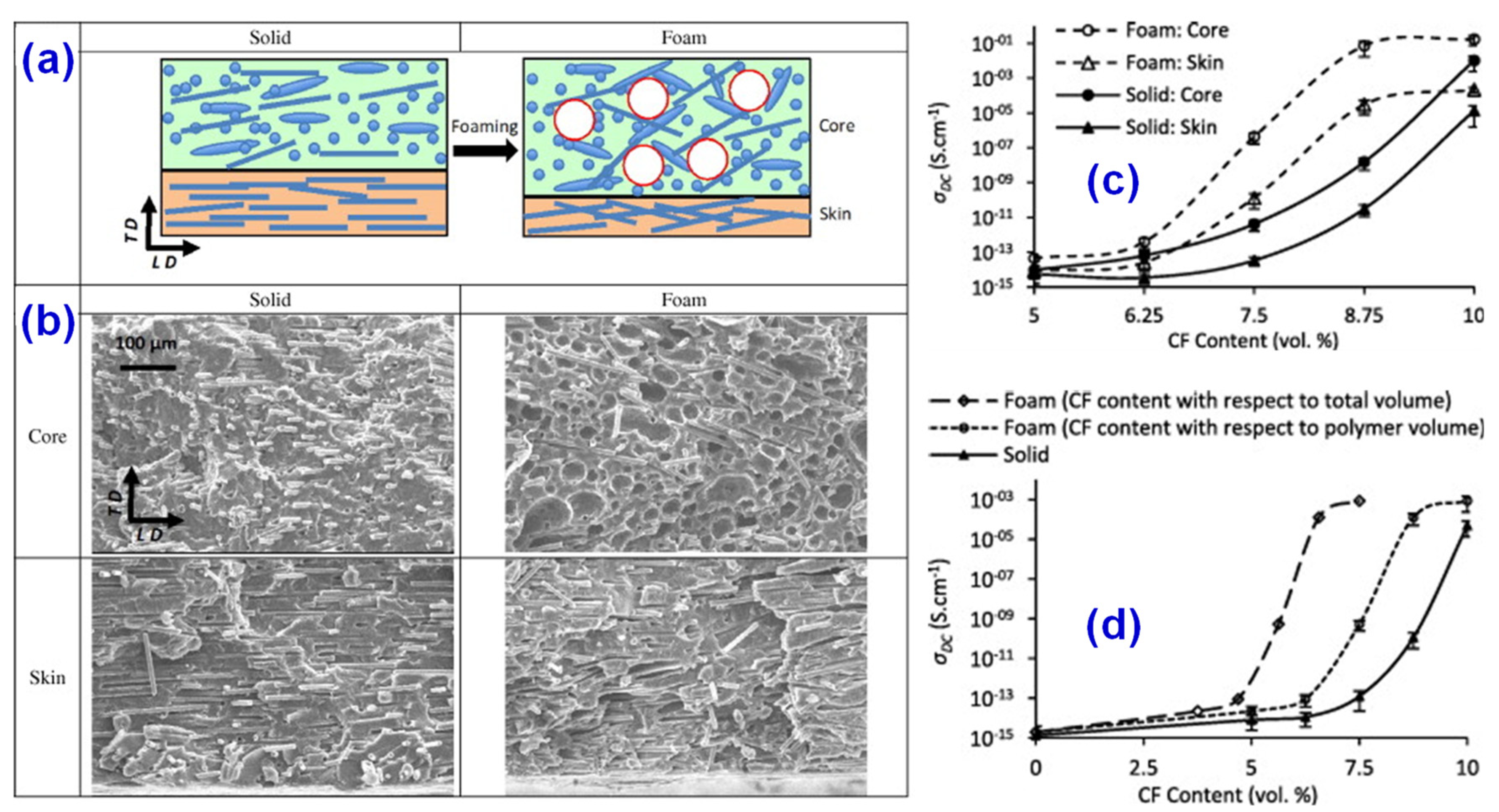

- Ameli, A.; Jung, P.U.; Park, C.B. Electrical properties and electromagnetic interference shielding effectiveness of polypropylene/carbon fiber composite foams. Carbon 2013, 60, 379–391. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Park, J.G.; Smithyman, J.; Lin, C.Y.; Cooke, A.; Kismarahardja, A.W.; Li, S.; Liang, R.; Brooks, J.S.; Zhang, C.; Wang, B. Effects of surfactants and alignment on the physical properties of single-walled carbon nanotube buckypaper. J. Appl. Phys. 2009, 106, 104310. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, S.; Park, J.G.; Liang, Z.Y.; Siegrist, T.; Liu, T.; Zhang, M.; Cheng, Q.F.; Wang, B.; Zhang, C. In situ characterization of structural changes and the fraction of aligned carbon nanotube networks produced by stretching. Carbon 2012, 50, 3859–3867. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Li, C.Y.; Chou, T.W. Nanocomposites in context. Compos. Sci. Technol. 2005, 65, 491–516. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Hou, L.Y.; Zhou, H.H. Electrochemically treated graphite/poly(3,4-ethylenedioxythiophene)-carbon nanotubes electrode: Facile preparation and remarkable enhancement in electrochemical performances. Fuller. Nanotubes Carbon Nanostruct. 2020, 28, 458–464. [Google Scholar] [CrossRef]

- Tian, F.; Zhong, S.W.; Nie, W.; Zeng, M.; Chen, B.M.; Liu, X.L. Multi-walled carbon nanotubes prepared with low-cost Fe-Al bimetallic catalysts for high-rate rechargeable Li-ion batteries. J. Solid State Electrochem. 2020, 24, 667–674. [Google Scholar] [CrossRef]

- Gan, D.F.; Dou, J.B.; Huang, Q.; Huang, H.Y.; Chen, J.Y.; Liu, M.Y.; Qi, H.X.; Yang, Z.Y.; Zhang, X.Y.; Wei, Y. Carbon nanotubes-based polymer nanocomposites: Bio-mimic preparation and methylene blue adsorption. J. Environ. Chem. Eng. 2020, 8, 103525. [Google Scholar] [CrossRef]

- Faba, L.; Garcés, D.; Díaz, E.; Ordóñez, S. Carbon materials as phase-transfer promoters for obtaining 5-hydroxymethylfurfural from cellulose in a biphasic system. ChemSusChem 2019, 12, 3769–3777. [Google Scholar] [CrossRef] [PubMed]

- Dey, B.; Ahmad, M.W.; Almezeni, A.; Sarkhel, G.; Bag, D.S.; Choudhury, A. Enhancing electrical, mechanical, and thermal properties of polybenzimidazole by 3D carbon nanotube@graphene oxide hybrid. Compos. Commun. 2020, 17, 87–96. [Google Scholar] [CrossRef]

- Shimizu, T.; Kishi, R.; Kobashi, K.; Morimoto, T.; Okazaki, T.; Yamada, T.; Hata, K. Improved thermal stability of silicone rubber nanocomposites with low filler content, achieved by well-dispersed carbon nanotubes. Compos. Commun. 2020, 22, 100482. [Google Scholar] [CrossRef]

- Chen, C.; Liu, J.W.; Li, X.W.; Wen, Y.F.; Li, X.J.; Shi, D.A.; Xue, Z.G.; Xie, X.L. Epoxy/ionic liquid-like mwcnts composites with improved processability and mechanical properties. Compos. Commun. 2019, 15, 46–52. [Google Scholar] [CrossRef]

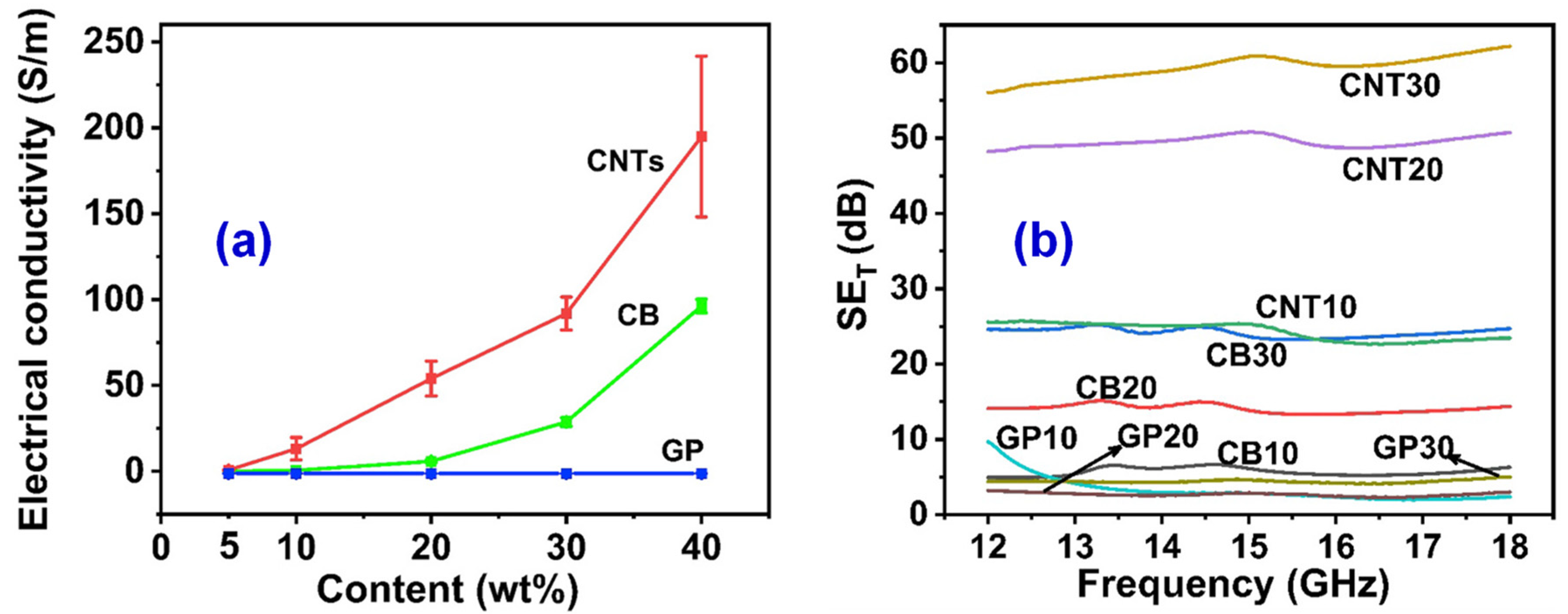

- Wang, G.X.; Yu, Q.Z.; Hu, Y.M.; Zhao, G.Y.; Chen, J.W.; Li, H.; Jiang, N.; Hu, D.W.; Xu, Y.Q.; Zhu, Y.T.; et al. Influence of the filler dimensionality on the electrical, mechanical and electromagnetic shielding properties of isoprene rubber-based flexible conductive composites. Compos. Commun. 2020, 21, 100417. [Google Scholar] [CrossRef]

- Brownson, D.A.C.; Kelly, P.J.; Banks, C.E. In situ electrochemical characterisation of graphene and various carbon-based electrode materials: An internal standard approach. RSC Adv. 2015, 5, 37281–37286. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Tan, C.; Lowe, M.A.; Abruna, H.D.; Ralph, D.C. Electrochemistry of individual monolayer graphene sheets. ACS Nano 2011, 5, 2264–2270. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, C.; Wei, X.D.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Service, R.F. Materials science carbon sheets an atom thick give rise to graphene dreams. Science 2009, 324, 875–877. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Jiang, Z.; Zhang, Y.; Morozov, S.V.; Stormer, H.L.; Zeitler, U.; Maan, J.C.; Boebinger, G.S.; Kim, P.; Geim, A.K. Room-temperature quantum hall effect in graphene. Science 2007, 315, 1379. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.H.; Li, X.F.; Liao, K.N.; Min, P.; Liu, T.; Dasari, A.; Yu, Z.Z. Thermally annealed anisotropic graphene aerogels and their electrically conductive epoxy composites with excellent electromagnetic interference shielding efficiencies. ACS Appl. Mater. Interfaces 2016, 8, 33230–33239. [Google Scholar] [CrossRef]

- Yang, J.M.; Liao, X.; Wang, G.; Chen, J.; Guo, F.M.; Tang, W.Y.; Wang, W.; Yan, Z.H.; Li, G.X. Gradient structure design of lightweight and flexible silicone rubber nanocomposite foam for efficient electromagnetic interference shielding. Chem. Eng. J. 2020, 390, 124589. [Google Scholar] [CrossRef]

- Li, J.T.; Zhang, G.C.; Ma, Z.L.; Fan, X.L.; Fan, X.; Qin, J.B.; Shi, X.T. Morphologies and electromagnetic interference shielding performances of microcellular epoxy/multi-wall carbon nanotube nanocomposite foams. Compos. Sci. Technol. 2016, 129, 70–78. [Google Scholar] [CrossRef]

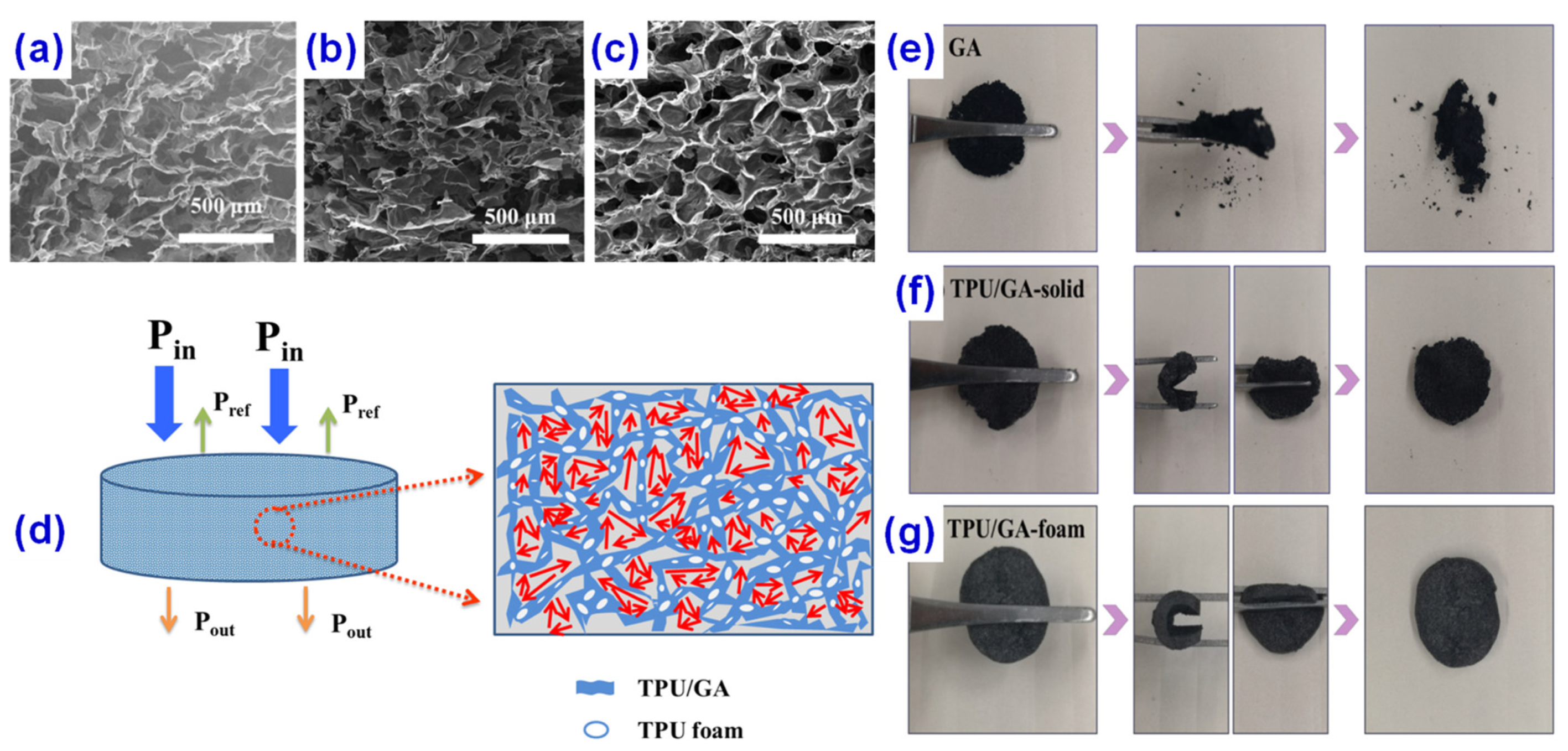

- Jiang, Q.Y.; Liao, X.; Yang, J.M.; Wang, G.; Chen, J.; Tian, C.X.; Li, G.X. A two-step process for the preparation of thermoplastic polyurethane/graphene aerogel composite foams with multi-stage networks for electromagnetic shielding. Compos. Commun. 2020, 21, 100416. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Tian, X.Y.; Liu, T.F.; Yang, C.C.; Wang, Q.R.; Li, D.C. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Ning, F.D.; Cong, W.L.; Qiu, J.J.; Wei, J.H.; Wang, S.R. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Seto, Y.; Sado, A.; Asami, K.; Hanada, A.; Umehara, M.; Akiyama, K.; Yamaguchi, S. Carlactone is an endogenous biosynthetic precursor for strigolactones. Proc. Natl. Acad. Sci. USA 2014, 111, 1640–1645. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rombouts, M.; Kruth, J.P.; Froyen, L.; Mercelis, P. Fundamentals of selective laser melting of alloyed steel powders. CIRP Ann. Manuf. Technol. 2006, 55, 187–192. [Google Scholar] [CrossRef]

- Ponnamma, D.; Yin, Y.; Salim, N.; Parameswaranpillai, J.; Thomas, S.; Hameed, N. Recent progress and multifunctional applications of 3D printed graphene nanocomposites. Compos. Part B Eng. 2021, 204, 108493. [Google Scholar] [CrossRef]

- Xu, W.P.; Miao, L.T.; Liu, L.G. Review on Structure Optimization in 3D Printing. J. Comput. Aided Des. Comput. Graph. 2017, 29, 1155–1168. [Google Scholar]

- Dou, H.; Cheng, Y.Y.; Ye, W.G.; Zhang, D.H.; Li, J.J.; Miao, Z.J.; Rudykh, S. Effect of process parameters on tensile mechanical properties of 3D printing continuous carbon fiber-reinforced PLA composites. Materials 2020, 13, 3850. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.L.; Liu, T.X. 3D printing of polycaprolactone-based composites with diversely tunable mechanical gradients via multi-material fused deposition modeling. Compos. Commun. 2021, 23, 100600. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, W.; Liu, T.X. Fused deposition modeling 3D printing of polyamide-based composites and its applications. Compos. Commun. 2020, 21, 100413. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Hajnys, J.; Kozior, T.; Gogolewski, D.; Zmarzly, P. Quality of surface texture and mechanical properties of PLA and PA-based material reinforced with carbon fibers manufactured by FDM and CFF 3D printing technologies. Polymers 2021, 13, 1671. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.L. Controllable interfacial adhesion behaviors of polymer-on-polymer surfaces during fused deposition modeling 3D printing process. Chem. Phys. Lett. 2020, 739, 136959. [Google Scholar] [CrossRef]

- Peng, X.S.; Zhang, M.M.; Guo, Z.C.; Sang, L.; Hou, W.B. Investigation of processing parameters on tensile performance for FDM-printed carbon fiber reinforced polyamide 6 composites. Compos. Commun. 2020, 22, 100478. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Fostert, C.W.; Down, M.P.; Zhang, Y.; Ji, X.B.; Rowley-Neale, S.J.; Smith, G.C.; Kelly, P.J.; Banks, C.E. 3D printed graphene based energy storage devices. Sci. Rep. 2017, 7, 42233. [Google Scholar] [CrossRef]

- Bárnik, F.; Vaško, M.; Handrik, M.; Dorčiak, F.; Majko, J. Comparing mechanical properties of composites structures on Onyx base with different density and shape of fill. Transp. Res. Procedia 2019, 40, 616–622. [Google Scholar] [CrossRef]

- Strozzi, M.; Giacomobono, R.; Rubini, R.; Cocconcelli, M. Preliminary orthotropic elastic model for the study of natural frequencies and mode shapes of a 3D printed Onyx thin circular cylindrical shell. Int. J. Mech. Control 2020, 21, 51–62. [Google Scholar]

- Ghebretinsae, F.; Mikkelsen, O.; Akessa, A.D. Strength analysis of 3D printed carbon fibre reinforced thermoplastic using experimental and numerical methods. IOP Conf. Ser. Mater. Sci. Eng. 2019, 700, 012024. [Google Scholar] [CrossRef]

- Huang, P.; Xia, Z.D.; Cui, S. 3D printing of carbon fiber-filled conductive silicon rubber. Mater. Des. 2018, 142, 11–21. [Google Scholar] [CrossRef]

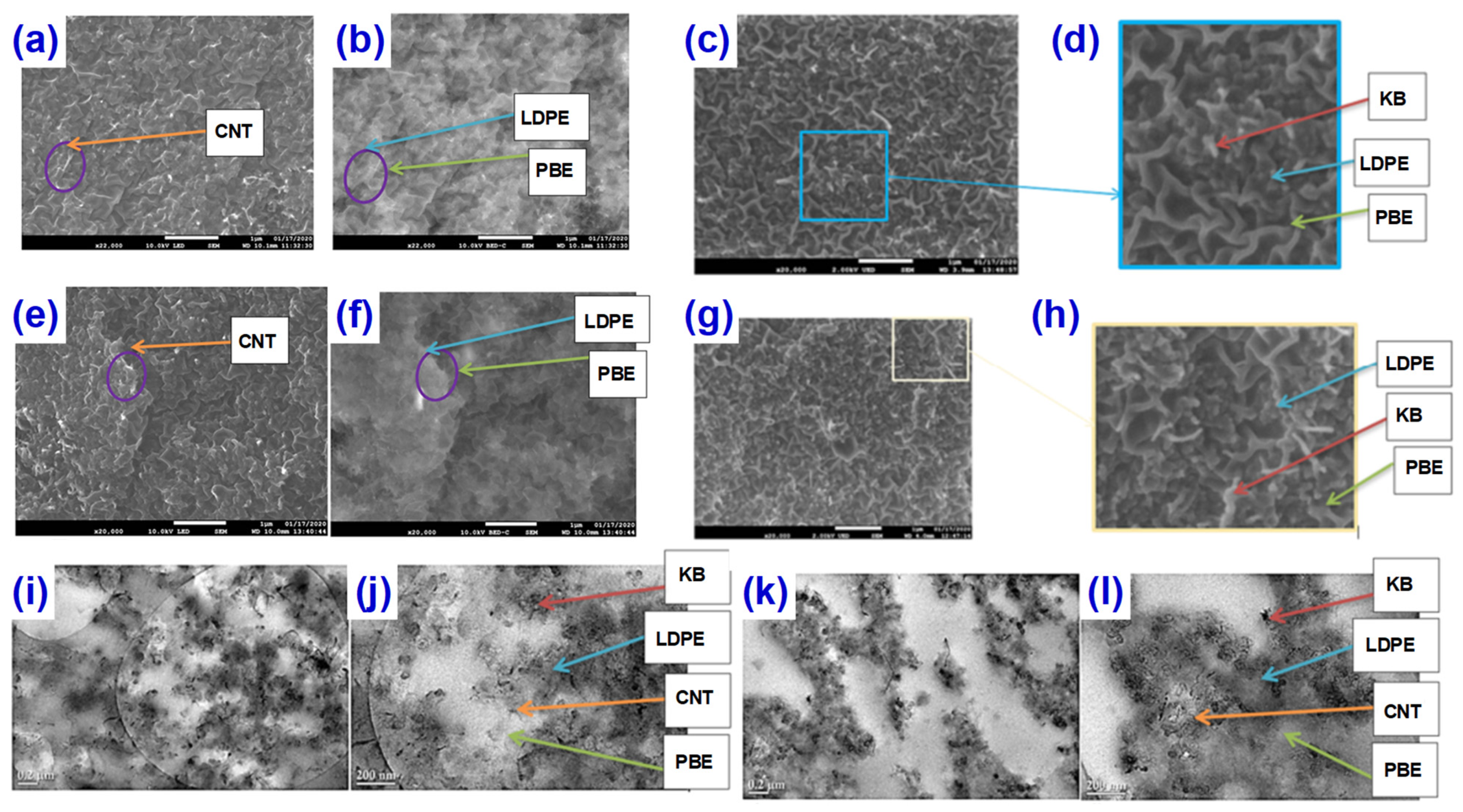

- Daver, F.; Baez, E.; Shanks, R.A.; Brandt, M. Conductive polyolefin-rubber nanocomposites with carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2016, 80, 13–20. [Google Scholar] [CrossRef]

- Lukić, M.; Clarke, J.; Tuck, C.; Whittow, W.; Wells, G. Printability of elastomer latex for additive manufacturing or 3D printing. J. Appl. Polym. Sci. 2016, 133, 42931. [Google Scholar] [CrossRef] [Green Version]

- Spahiu, T.; Fafenrot, S.; Grimmelsmann, N.; Piperi, E.; Shehi, E.; Ehrmann, A. Varying fabric drape by 3D-imprinted patterns for garment design. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 172023. [Google Scholar] [CrossRef]

- Shin, D.G.; Kim, T.H.; Kim, D.E. Review of 4D printing materials and their properties. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 349–357. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Cayla, A.; Campagne, C.; Nierstrasz, V. Morphological and electrical characterization of conductive polylactic acid based nanocomposite before and after FDM 3D printing. J. Appl. Polym. Sci. 2019, 136, 47040. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Ransley, M.; Smitham, P.; Miodownik, M. Active chainmail fabrics for soft robotic applications. Smart Mater. Struct. 2017, 26, 08LT02. [Google Scholar] [CrossRef]

- Pei, E.J.; Shen, J.S.; Watling, J. Direct 3D printing of polymers onto textiles: Experimental studies and applications. Rapid Prototyp. J. 2015, 21, 556–571. [Google Scholar] [CrossRef] [Green Version]

- Mpofu, N.S.; Mwasiagi, J.I.; Nkiwane, L.C.; Njuguna, D. Use of regression to study the effect of fabric parameters on the adhesion of 3D printed PLA polymer onto woven fabrics. Fash. Text. 2019, 6, 24. [Google Scholar] [CrossRef]

- Grimmelsmann, N.; Kreuziger, M.; Korger, M.; Meissner, H.; Ehrmann, A. Adhesion of 3D printed material on textile substrates. Rapid Prototyp. J. 2018, 24, 166–170. [Google Scholar] [CrossRef]

- Eutionnat-Diffo, P.A.; Chen, Y.; Guan, J.P.; Cayla, A.; Campagne, C.; Zeng, X.Y.; Nierstrasz, V. Stress, strain and deformation of poly-lactic acid filament deposited onto polyethylene terephthalate woven fabric through 3D printing process. Sci. Rep. 2019, 9, 14333. [Google Scholar] [CrossRef]

- Eutionnat-Diffo, P.A.; Chen, Y.; Guan, J.P.; Cayla, A.; Campagne, C.; Zeng, X.Y.; Nierstrasz, V. Optimization of adhesion of poly lactic acid 3D printed onto polyethylene terephthalate woven fabrics through modelling using textile properties. Rapid Prototyp. J. 2020, 26, 390–401. [Google Scholar] [CrossRef]

- Eutionnat-Diffo, P.A.; Cayla, A.; Chen, Y.; Guan, J.P.; Nierstrasz, V.; Campagne, C. Development of flexible and conductive immiscible thermoplastic/elastomer monofilament for smart textiles applications using 3D printing. Polymers 2020, 12, 2300. [Google Scholar] [CrossRef]

- Evans, R.S.; Bourell, D.L.; Beaman, J.J.; Campbell, M.I. Rapid manufacturing of silicon carbide composites. Rapid Prototyp. J. 2005, 11, 37–40. [Google Scholar] [CrossRef] [Green Version]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2011, 57, 229–267. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Bose, S.; Bhattacharyya, A.R.; Kulkarni, A.R.; Poetschke, P. Electrical, rheological and morphological studies in co-continuous blends of polyamide 6 and acrylonitrile-butadiene-styrene with multiwall carbon nanotubes prepared by melt blending. Compos. Sci. Technol. 2009, 69, 365–372. [Google Scholar] [CrossRef]

- Araby, S.; Meng, Q.S.; Zhang, L.Q.; Kang, H.L.; Majewski, P.; Tang, Y.H.; Ma, J. Electrically and thermally conductive elastomer/graphene nanocomposites by solution mixing. Polymer 2014, 55, 201–210. [Google Scholar] [CrossRef]

- Zhan, Y.H.; Lavorgna, M.; Buonocore, G.; Xia, H.S. Enhancing electrical conductivity of rubber composites by constructing interconnected network of self-assembled graphene with latex mixing. J. Mater. Chem. 2012, 22, 10464–10468. [Google Scholar] [CrossRef]

- Lao, S.C.; Koo, J.H.; Moon, T.J.; Londa, M.; Ibeh, C.C.; Wissler, G.E.; Pilato, L.A. Flame-retardant polyamide 11 nanocomposites: Further thermal and flammability studies. J. Fire Sci. 2011, 29, 479–498. [Google Scholar] [CrossRef]

- Jacobs, C.J.; Tate, J.S.; Olson, B.; Theodoropoulou, N.; Koo, J.H. Thermal characterization of polyamide 11/nanographene platelet nanocomposites. J. Nanosci. Nanotechnol. 2012, 12, 1799–1805. [Google Scholar] [CrossRef]

- Athreya, S.R.; Kalaitzidou, K.; Das, S. Processing and characterization of a carbon black-filled electrically conductive nylon-12 nanocomposite produced by selective laser sintering. Mater. Sci. Eng. A 2010, 527, 2637–2642. [Google Scholar] [CrossRef]

- Li, Z.C.; Wang, Z.H.; Gan, X.P.; Fu, D.H.; Fei, G.X.; Xia, H.S. Selective laser sintering 3D printing: A way to construct 3D electrically conductive segregated network in polymer matrix. Macromol. Mater. Eng. 2017, 302, 1700211. [Google Scholar] [CrossRef]

- Florence, J.M.; Yoder, L.A. Display system architectures for digital micromirror device (DMD(TM)) based projectors. Proc. Soc. Photo-Opt. Instrum. Eng. (SPIE) 1996, 2650, 193–208. [Google Scholar]

- Quan, H.Y.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X.Q. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mulhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, S.Q.; Wang, Z.; Lin, J.B.; Miao, J.T.; Zheng, L.H.; Yang, Z.; Weng, Z.X.; Wu, L.X. Tailored and highly stretchable sensor prepared by crosslinking an enhanced 3D printed UV-curable sacrificial mold. Adv. Funct. Mater. 2020, 31, 2008729. [Google Scholar] [CrossRef]

- Li, S.Y.; Yuan, S.Q.; Zhu, J.H.; Wang, C.; Li, J.; Zhang, W.H. Additive manufacturing-driven design optimization: Building direction and structural topology. Addit. Manuf. 2020, 36, 101406. [Google Scholar]

- Sun, J.X.; Binner, J.; Bai, J.M. 3D printing of zirconia via digital light processing: Optimization of slurry and debinding process. J. Eur. Ceram. Soc. 2020, 40, 5837–5844. [Google Scholar] [CrossRef]

- Tan, L.J.Y.; Zhu, W.; Zhou, K. Recent progress on polymer materials for additive manufacturing. Adv. Funct. Mater. 2020, 30, 2003062. [Google Scholar] [CrossRef]

- Mu, Q.Y.; Wang, L.; Dunn, C.K.; Kuang, X.; Duan, F.; Zhang, Z.; Qi, H.J.; Wang, T.J. Digital light processing 3D printing of conductive complex structures. Addit. Manuf. 2017, 18, 74–83. [Google Scholar] [CrossRef]

- Wang, R.J.; Tan, Z.Q.; Zhong, W.B.; Liu, K.; Li, M.F.; Chen, Y.L.; Wang, W.W.; Wang, D. Polypyrrole (PPy) attached on porous conductive sponge derived from carbonized graphene oxide coated polyurethane (PU) and its application in pressure sensor. Compos. Commun. 2020, 22, 100426. [Google Scholar] [CrossRef]

- Liang, G.J.; Hu, H.B.; Liao, L.; He, Y.B.; Ye, C.H. Highly flexible and bright electroluminescent devices based on Ag nanowire electrodes and top-emission structure. Adv. Electron. Mater. 2017, 3, 1600535. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.Y.; Lin, Y.J.; Enriquez, E.; Peng, X.F.; Turng, L.S. Highly stretchable and biocompatible strain sensors based on mussel-inspired super-adhesive self-healing hydrogels for human motion monitoring. ACS Appl. Mater. Interfaces 2018, 10, 20897–20909. [Google Scholar] [CrossRef]

- Guo, B.B.; Ji, X.Z.; Chen, X.T.; Li, G.; Lu, Y.G.; Bai, J.M. A highly stretchable and intrinsically self-healing strain sensor produced by 3D printing. Virtual Phys. Prototyp. 2020, 15, 520–531. [Google Scholar] [CrossRef]

- Yuan, H.; Xing, K.; Hsu, H.Y. Trinity of three-dimensional (3D) scaffold, vibration, and 3D printing on cell culture application: A systematic review and indicating future direction. Bioengineering 2018, 5, 57. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kloft, H.; Krauss, H.W.; Hack, N.; Herrmann, E.; Neudecker, S.; Varady, P.A.; Lowke, D. Influence of process parameters on the interlayer bond strength of concrete elements additive manufactured by shotcrete 3D printing (SC3DP). Cem. Concr. Res. 2020, 134, 106078. [Google Scholar] [CrossRef]

- Chizari, K.; Arjmand, M.; Liu, Z.; Sundararaj, U.; Therriault, D. Three-dimensional printing of highly conductive polymer nanocomposites for EMI shielding applications. Mater. Today Commun. 2017, 11, 112–118. [Google Scholar] [CrossRef]

- Gong, Y.; Wang, F.; Al-Furjan, M.S.H.; Shan, L.J.; He, J.Y.; Bian, X.J.; Bi, Z.K.; Liu, H.A.; Li, W.X.; Shao, H.F.; et al. Experimental investigation and optimal 3D bioprinting parameters of SA-Gel porous cartilage scaffold. Appl. Sci. 2020, 10, 768. [Google Scholar] [CrossRef] [Green Version]

- Cuellar, J.S.; Plettenburg, D.; Zadpoor, A.A.; Breedveld, P.; Smit, G. Design of a 3D-printed hand prosthesis featuring articulated bio-inspired fingers. Proc. Inst. Mech. Eng. Part H 2021, 235, 336–345. [Google Scholar] [CrossRef] [PubMed]

- Jakus, A.E.; Shah, R.N. Multi and mixed 3D-printing of graphene-hydroxyapatite hybrid materials for complex tissue engineering. J. Biomed. Mater. Res. Part A 2017, 105, 274–283. [Google Scholar] [CrossRef]

- Marsalek, P.; Sotola, M.; Rybansky, D.; Repa, V.; Halama, R.; Fusek, M.; Prokop, J. Modeling and testing of flexible structures with selected planar patterns used in biomedical applications. Materials 2020, 14, 140. [Google Scholar] [CrossRef]

- Abdollahi, S.; Markvicka, E.J.; Majidi, C.; Feinberg, A.W. 3D printing silicone elastomer for patient-specific wearable pulse oximeter. Adv. Healthc. Mater. 2020, 9, 1901735. [Google Scholar] [CrossRef]

- Wei, H.Q.; Cauchy, X.; Navas, I.O.; Abderrafai, Y.; Chizari, K.; Sundararaj, U.; Liu, Y.J.; Leng, J.; Therriault, D. Direct 3D printing of hybrid nanofiber-based nanocomposites for highly conductive and shape memory applications. ACS Appl. Mater. Interfaces 2019, 11, 24523–24532. [Google Scholar] [CrossRef]

- Lawrentschuk, N.; Bolton, D.M. Experience and attitudes of final-year medical students to digital rectal examination. Med. J. Aust. 2004, 181, 323–325. [Google Scholar] [CrossRef]

- Wang, H.B.; Li, N.; Wang, W.; Shi, J.; Xu, Z.W.; Liu, L.S.; Hu, Y.L.; Jing, M.L.; Liu, L.Y.; Zhang, X.X. Bead nano-necklace spheres on 3D carbon nanotube scaffolds for high-performance electromagnetic-interference shielding. Chem. Eng. J. 2019, 360, 1241–1246. [Google Scholar] [CrossRef]

- Maity, S.; Chatterjee, A. Conductive polymer-based electro-conductive textile composites for electromagnetic interference shielding: A review. J. Ind. Text. 2018, 47, 2228–2252. [Google Scholar] [CrossRef]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.M. Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.F.; Dong, H.L.; Hu, W.P. Charge Transport in Organic and Polymeric Semiconductors for Flexible and Stretchable Devices. Adv. Mater. 2016, 28, 4513–4523. [Google Scholar] [CrossRef]

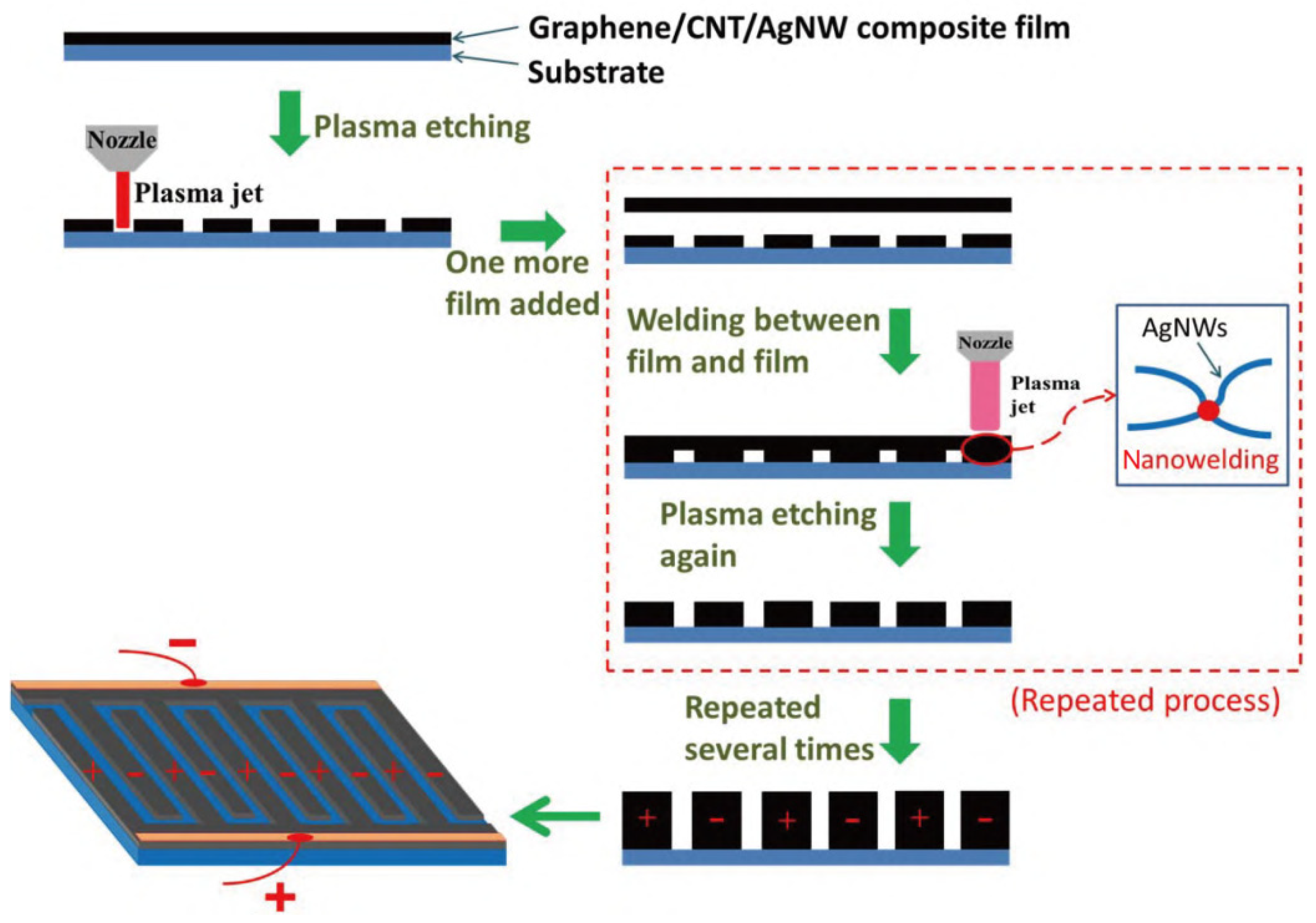

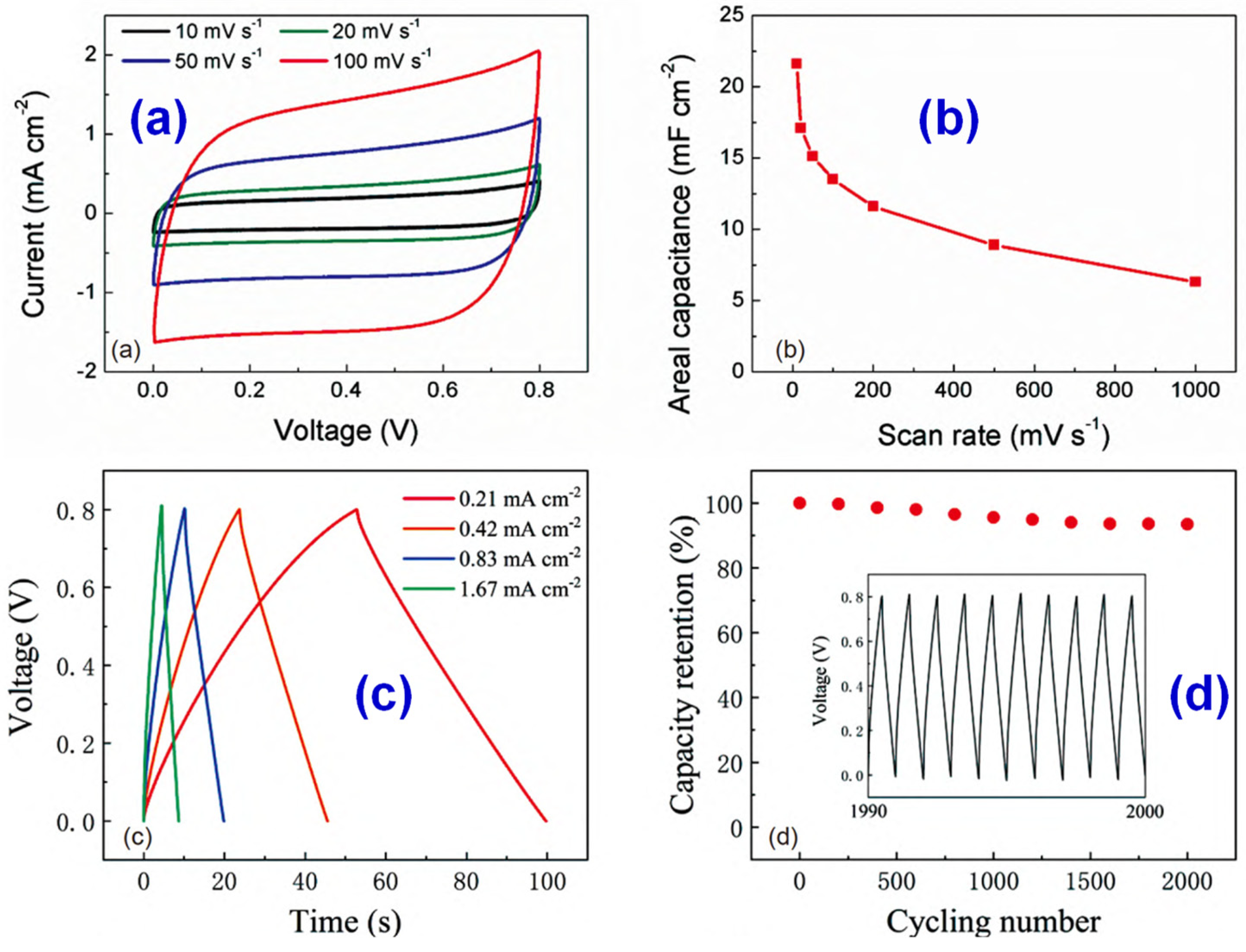

- Liu, L.; Lu, J.Y.; Long, X.L.; Zhou, R.; Liu, Y.Q.; Wu, Y.T.; Yan, K.W. 3D printing of high-performance micro-supercapacitors with patterned exfoliated graphene/carbon nanotube/silver nanowire electrodes. Sci. China Technol. Sci. 2021, 64, 1065–1073. [Google Scholar] [CrossRef]

- Zhang, C.Z.; Mahmood, N.; Yin, H.; Liu, F.; Hou, Y.L. Synthesis of phosphorus-doped graphene and its multifunctional applications for oxygen reduction reaction and lithium ion batteries. Adv. Mater. 2013, 25, 4932–4937. [Google Scholar] [CrossRef]

- Wen, Y.Y.; Wang, B.; Huang, C.C.; Wang, L.Z.; Hulicova-Jurcakova, D. Synthesis of phosphorus-doped graphene and its wide potential window in aqueous supercapacitors. Chem. Eur. J. 2015, 21, 80–85. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Huang, X.; Chen, J.; Wu, K.; Wang, J.; Zhang, X. A Review of Conductive Carbon Materials for 3D Printing: Materials, Technologies, Properties, and Applications. Materials 2021, 14, 3911. https://doi.org/10.3390/ma14143911

Zheng Y, Huang X, Chen J, Wu K, Wang J, Zhang X. A Review of Conductive Carbon Materials for 3D Printing: Materials, Technologies, Properties, and Applications. Materials. 2021; 14(14):3911. https://doi.org/10.3390/ma14143911

Chicago/Turabian StyleZheng, Yanling, Xu Huang, Jialiang Chen, Kechen Wu, Jianlei Wang, and Xu Zhang. 2021. "A Review of Conductive Carbon Materials for 3D Printing: Materials, Technologies, Properties, and Applications" Materials 14, no. 14: 3911. https://doi.org/10.3390/ma14143911

APA StyleZheng, Y., Huang, X., Chen, J., Wu, K., Wang, J., & Zhang, X. (2021). A Review of Conductive Carbon Materials for 3D Printing: Materials, Technologies, Properties, and Applications. Materials, 14(14), 3911. https://doi.org/10.3390/ma14143911