Influence of the Feedstock on the Process Parameters, Product Composition and Pilot-Scale Cracking of Plastics

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Pilot Scale Cracking Set-Up Description

2.3. Cracking Product Characterization

3. Results and Discussion

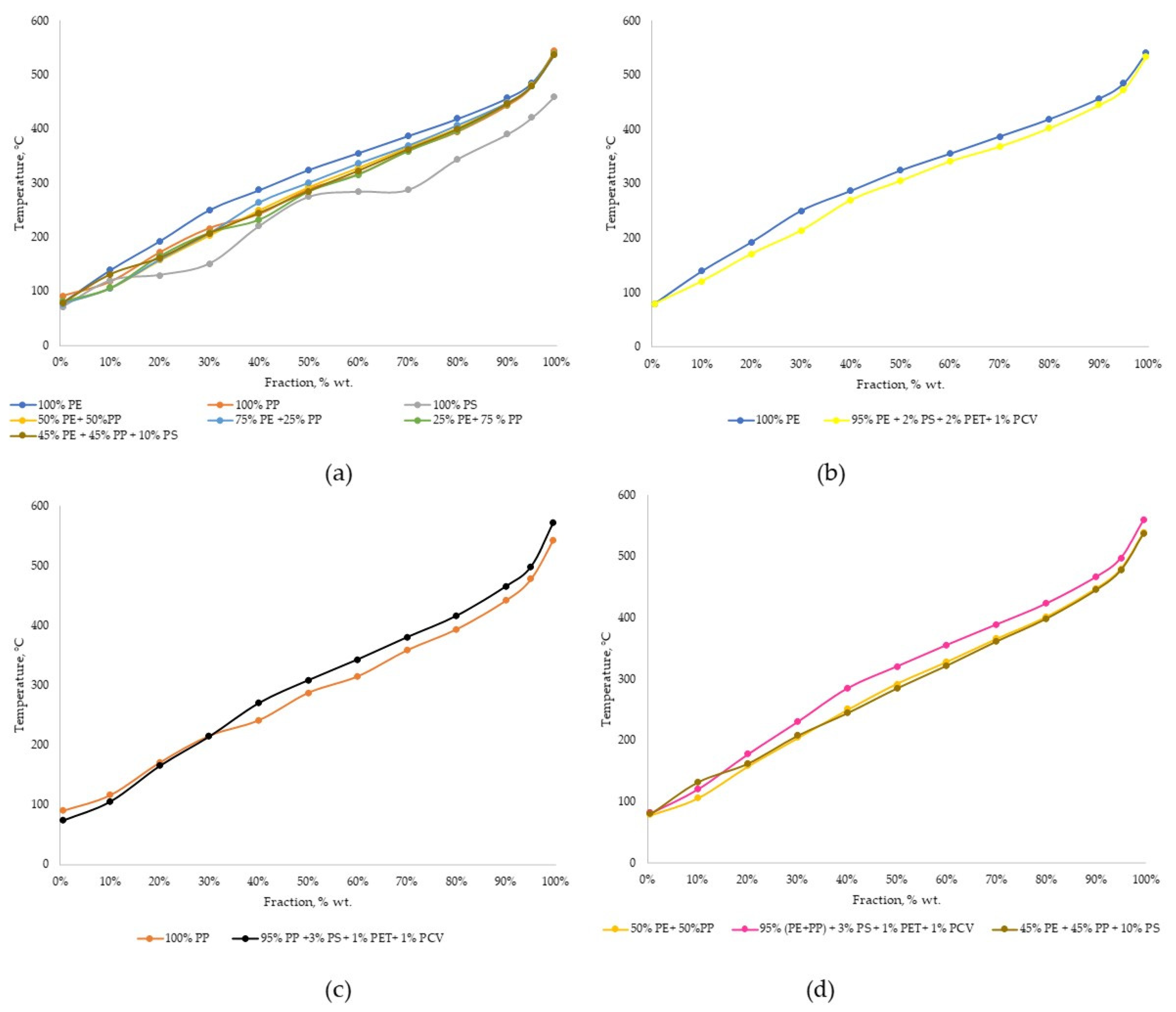

3.1. Influence of the Raw Material Composition on the Cracking Process and Yields

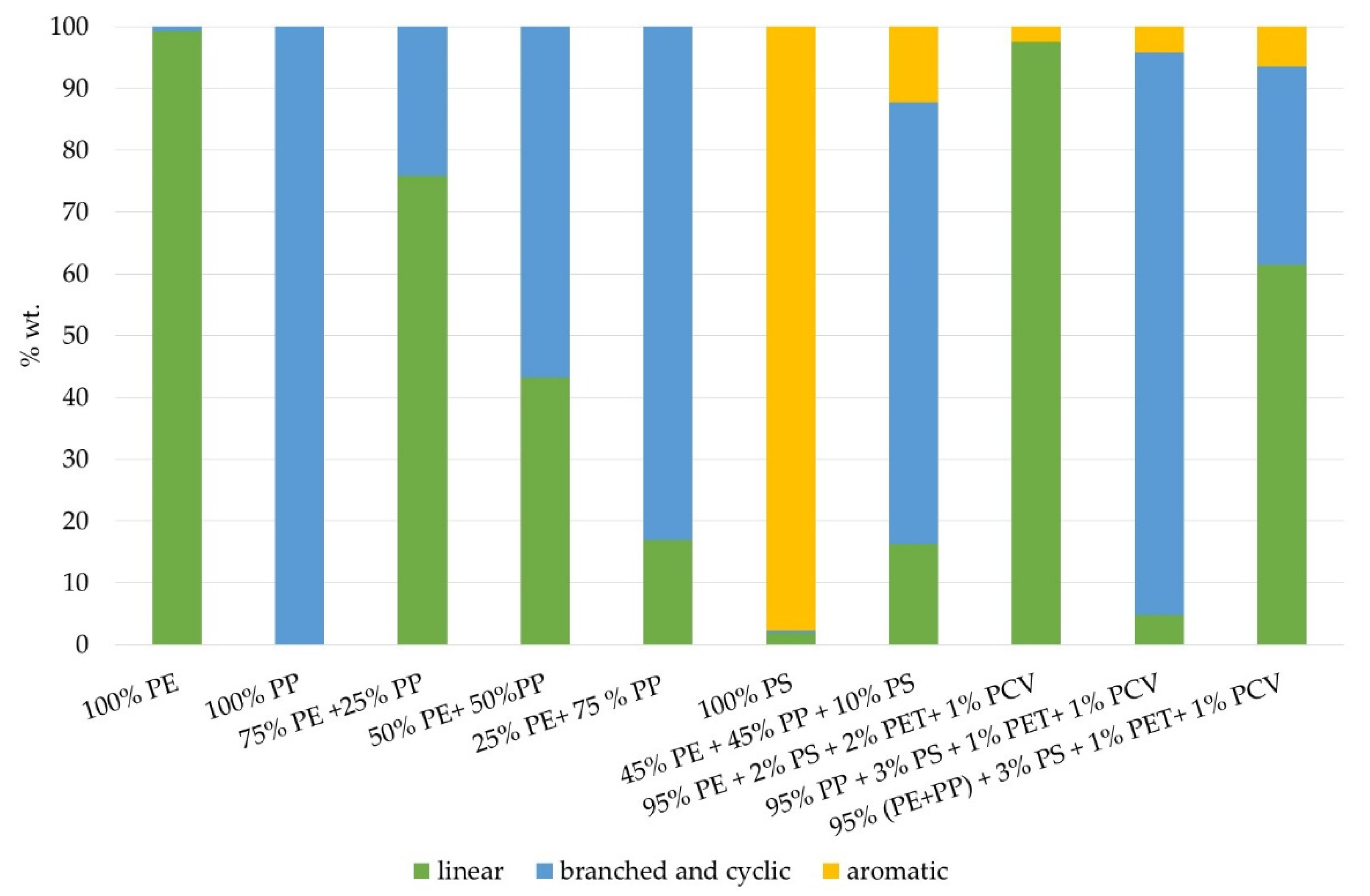

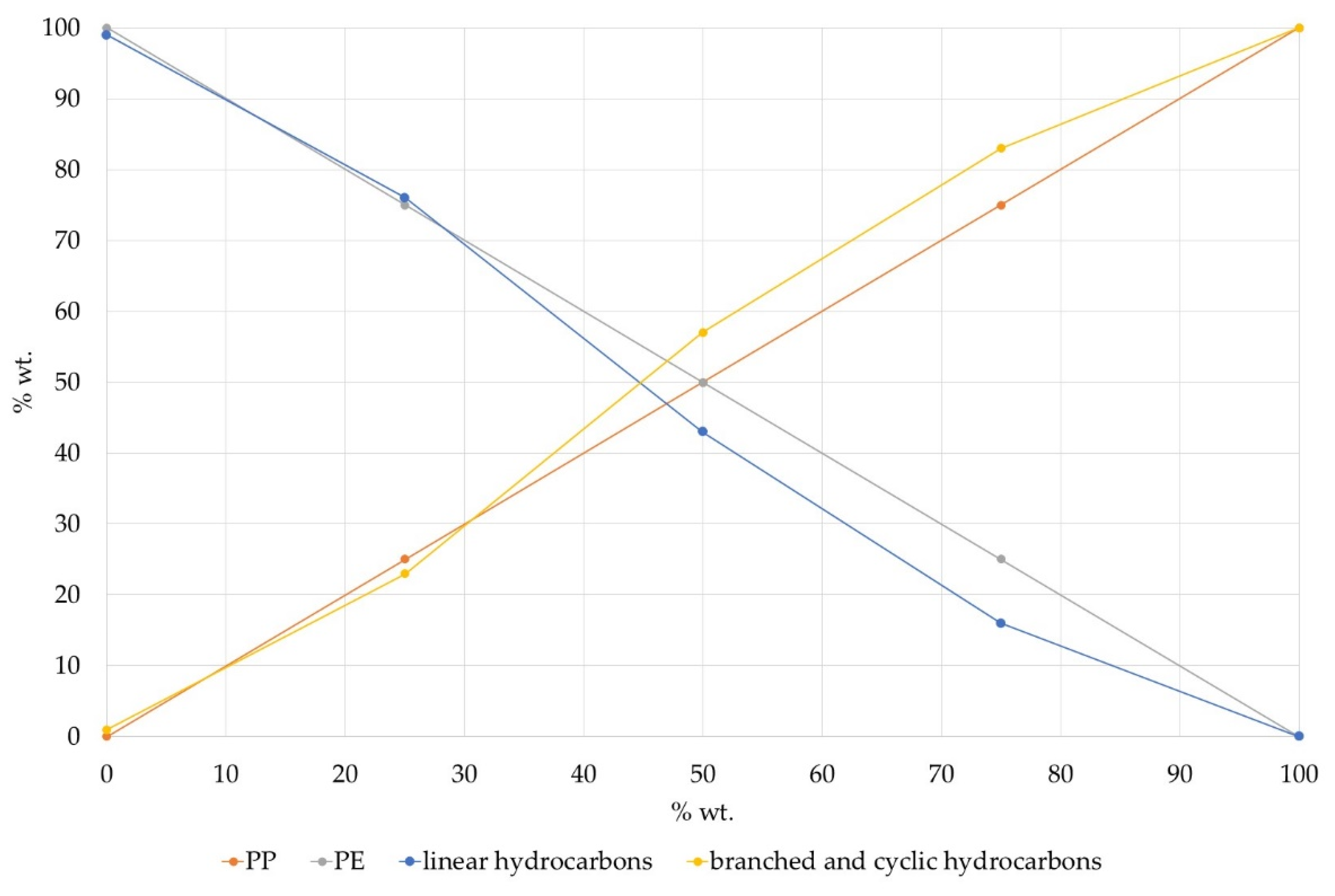

3.2. Cracking Product Characterization

4. Conclusions

- An increase of PP share caused decreases in the process temperature and losses yield, thus increasing product yield, and a shift of the boiling range towards lighter products;

- The addition of 10% PS to PE/PP resulted in a higher product yield without any significant changes to the boiling temperatures distribution;

- The addition of PET resulted in the creation of insoluble solids that could clog the cooling system, but mixtures with 1% PET were able to be processed;

- The addition of 5% in total of PS, PET and PVC reduced the overall product yield and caused the creation of a product with a lower boiling temperature;

- The PE cracking product consisted of 99% linear hydrocarbons, the PP cracking product consists only of branched and cyclic compounds and PS cracking product consisted of almost 98% aromatic hydrocarbons. Aromatics were not identified in either the PE or PP cracking products;

- The method used for the post-cracking analysis of the PE/PP ratio in the raw material, based on linear/branched hydrocarbons ratio, can be used for the general estimation of the feedstock composition;

- Small additions of PS and other plastics, like PET and PVC, promoted the creation of linear components, increasing the conversion of polyethylene. The addition of about 10% polystyrene to the mixture of polyethylene and polypropylene increased the PP conversion;

- The precise identification of some of the components was challenging due to the numerous types and isomers of iso-olefins obtained during polypropylene cracking and similar fragmentation of iso-olefins and cyclo-paraffins in MS analysis.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Plastics Europe. Plastics—The Facts 2019; Plastics Europe: Brussels, Belgium, 2019. [Google Scholar]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macrom. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef]

- ISO 15270: 2008. Plastics—Guidelines for the Recovery and Recycling of Plastics Waste; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Frączak, D. Metody recyklingu odpadów polietylenu i polipropylenu. Przem. Chem. 2018, 1, 153–158. [Google Scholar] [CrossRef]

- Simon, C.M.; Kaminsky, W.; Schlesselmann, B. Pyrolysis of Polyolefins with Steam to Yield Olefins. J. Anal. Appl. Pyrolysis 1996, 38, 75–87. [Google Scholar] [CrossRef]

- Diaz-Silvarrey, L.S.; Zhang, K.; Phan, A.N. Monomer Recovery through Advanced Pyrolysis of Waste High Density Polyethylene (HDPE). Green Chem. 2018, 20, 1813–1823. [Google Scholar] [CrossRef]

- Achilias, D.S.; Kanellopoulou, I.; Megalokonomos, P.; Antonakou, E.; Lappas, A.A. Chemical Recycling of Polystyrene by Pyrolysis: Potential Use of the Liquid Product for the Reproduction of Polymer. Macromol. Mater. Eng. 2007, 292, 923–934. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.-S. Catalytic Pyrolysis of Plastic Waste: Moving Toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7, 27. [Google Scholar] [CrossRef]

- Kunwar, B.; Cheng, H.N.; Chandrashekaran, S.R.; Sharma, B.K. Plastics to Fuel: A Review. Renew. Sustain. Energy Rev. 2016, 54, 421–428. [Google Scholar] [CrossRef]

- Sharma, B.K.; Moser, B.R.; Vermillion, K.E.; Doll, K.M.; Rajagopalan, N. Production, Characterization and Fuel Properties of Alternative Diesel Fuel from Pyrolysis of Waste Plastic Grocery Bags. Fuel Process. Technol. 2014, 122, 79–90. [Google Scholar] [CrossRef]

- Rezvanipour, M.; Hesari, F.A.; Pazouki, M. Catalytic Pyrolysis of General Purpose PolyStyrene Using Red Mud as a Catalyst. Iran. J. Chem. Eng. 2014, 11, 10–20. [Google Scholar]

- Kaminsky, W.; Kim, J.-S. Pyrolysis of Mixed Plastics into Aromatics. J. Anal. Appl. Pyrolysis 1999, 51, 127–134. [Google Scholar] [CrossRef]

- Jung, S.-H.; Cho, M.-H.; Kang, B.-S.; Kim, J.-S. Pyrolysis of a Fraction of Waste Polypropylene and Polyethylene for the Recovery of BTX Aromatics Using a Fluidized Bed Reactor. Fuel Process. Technol. 2010, 91, 277–284. [Google Scholar] [CrossRef]

- Angyal, A.; Miskolczi, N.; Bartha, L.; Tungler, A.; Nagy, L.; Vida, L.; Nagy, G. Production of Steam Cracking Feedstocks by Mild Cracking of Plastic Wastes. Fuel Process. Technol. 2010, 91, 1717–1724. [Google Scholar] [CrossRef]

- Reade, L. Chemical Recycling. Chem. Ind. 2020, 84, 30–33. [Google Scholar] [CrossRef]

- Kumar, A. Method for Producing Waxes and Grease Base Stocks through Catalytic Depolymerisation of Waste Plastics. U.S. Patent 8664458B2, 4 March 2014. [Google Scholar]

- Predel, M.; Kaminsky, W. Pyrolysis of Mixed Polyolefins in a Fluidised-Bed Reactor and on a Pyro-GC/MS to Yield Aliphatic Waxes. Polym. Degrad. Stab. 2000, 70, 373–385. [Google Scholar] [CrossRef]

- Walendziewski, J. Hydrocarbon fractions from the thermal cracking of polyolefin wastes—Synthesis, purification and applications. Polimery 2010, 55, 782–787. [Google Scholar] [CrossRef][Green Version]

- Bylicki, A.; Kozlowski, E. Method of Obtaining High-Quality Products from Polyolefin Waste Material or Polyolefins. U.S. Patent 7714178B2, 11 May 2010. [Google Scholar]

- Czajczyńska, D.; Anguilano, L.; Ghazal, H.; Krzyżyńska, R.; Reynolds, A.J.; Spencer, N.; Jouhara, H. Potential of Pyrolysis Processes in the Waste Management Sector. Therm. Sci. Eng. Prog. 2017, 3, 171–197. [Google Scholar] [CrossRef]

- Butler, E.; Devlin, G.; McDonnell, K. Waste Polyolefins to Liquid Fuels via Pyrolysis: Review of Commercial State-of-the-Art and Recent Laboratory Research. Waste Biomass Valor. 2011, 2, 227–255. [Google Scholar] [CrossRef]

- Anuar Sharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A Review on Pyrolysis of Plastic Wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Antelava, A.; Constantinou, A.; Manos, G.; Dutta, A. A Review on Thermal and Catalytic Pyrolysis of Plastic Solid Waste (PSW). J. Environ. Manag. 2017, 197, 177–198. [Google Scholar] [CrossRef]

- Jin, Z.; Chen, D.; Yin, L.; Hu, Y.; Zhu, H.; Hong, L. Molten Waste Plastic Pyrolysis in a Vertical Falling Film Reactor and the Influence of Temperature on the Pyrolysis Products. Chin. J. Chem. Eng. 2018, 26, 400–406. [Google Scholar] [CrossRef]

- Lopez, G.; Artetxe, M.; Amutio, M.; Bilbao, J.; Olazar, M. Thermochemical Routes for the Valorization of Waste Polyolefinic Plastics to Produce Fuels and Chemicals. A Review. Renew. Sustain. Energy Rev. 2017, 73, 346–368. [Google Scholar] [CrossRef]

- Onwudili, J.A.; Insura, N.; Williams, P.T. Composition of Products from the Pyrolysis of Polyethylene and Polystyrene in a Closed Batch Reactor: Effects of Temperature and Residence Time. J. Anal. Appl. Pyrolysis 2009, 86, 293–303. [Google Scholar] [CrossRef]

- Marcilla, A.; Beltrán, M.I.; Navarro, R. Evolution of Products during the Degradation of Polyethylene in a Batch Reactor. J. Anal. Appl. Pyrolysis 2009, 86, 14–21. [Google Scholar] [CrossRef]

- Ahmad, I.; Khan, M.I.; Khan, H.; Ishaq, M.; Tariq, R.; Gul, K.; Ahmad, W. Pyrolysis Study of Polypropylene and Polyethylene Into Premium Oil Products. Int. J. Green Energy 2015, 12, 663–671. [Google Scholar] [CrossRef]

- Akubo, K.; Nahil, M.A.; Williams, P.T. Aromatic Fuel Oils Produced from the Pyrolysis-Catalysis of Polyethylene Plastic with Metal-Impregnated Zeolite Catalysts. J. Energy Inst. 2019, 92, 195–202. [Google Scholar] [CrossRef]

- Seo, Y.-H.; Lee, K.-H.; Shin, D.-H. Investigation of Catalytic Degradation of High-Density Polyethylene by Hydrocarbon Group Type Analysis. J. Anal. Appl. Pyrolysis 2003, 70, 383–398. [Google Scholar] [CrossRef]

- Anene, A.; Fredriksen, S.; Sætre, K.; Tokheim, L.-A. Experimental Study of Thermal and Catalytic Pyrolysis of Plastic Waste Components. Sustainability 2018, 10, 3979. [Google Scholar] [CrossRef]

- Ramesohl, S.; Vetter, L.; Meys, R.; Steger, S. Chemical Plastics Recycling—Potentials and Development Prospectives. A Contribution to Defossiling the Chemical and Plastics Processing Industry in NRW. A Discussion Paper by the Circular Economy Working Group; IN4climate.NRW GmbH: Gelsenkirchen, Germany, 2020. [Google Scholar]

- Solis, M.; Silveira, S. Technologies for Chemical Recycling of Household Plastics—A Technical Review and TRL Assessment. Waste Manag. 2020, 105, 128–138. [Google Scholar] [CrossRef]

- Gholizadeh, M.; Li, C.; Zhang, S.; Wang, Y.; Niu, S.; Li, Y.; Hu, X. Progress of the Development of Reactors for Pyrolysis of Municipal Waste. Sustain. Energy Fuels 2020, 4, 5885–5915. [Google Scholar] [CrossRef]

- Maafa, I.M. Pyrolysis of Polystyrene Waste: A Review. Polymers 2021, 13, 225. [Google Scholar] [CrossRef]

- Miskolczi, N.; Angyal, A.; Bartha, L.; Valkai, I. Fuels by Pyrolysis of Waste Plastics from Agricultural and Packaging Sectors in a Pilot Scale Reactor. Fuel Process. Technol. 2009, 90, 1032–1040. [Google Scholar] [CrossRef]

- Miandad, R.; Nizami, A.S.; Rehan, M.; Barakat, M.A.; Khan, M.I.; Mustafa, A.; Ismail, I.M.I.; Murphy, J.D. Influence of Temperature and Reaction Time on the Conversion of Polystyrene Waste to Pyrolysis Liquid Oil. Waste Manag. 2016, 58, 250–259. [Google Scholar] [CrossRef]

- Park, K.-B.; Jeong, Y.-S.; Guzelciftci, B.; Kim, J.-S. Characteristics of a New Type Continuous Two-Stage Pyrolysis of Waste Polyethylene. Energy 2019, 166, 343–351. [Google Scholar] [CrossRef]

- Podeszfa, A.; Karbowy, B.; Samardakiewicz, B. Apparatus and Method for Conducting Thermolysis of Plastic Waste in Continuous Manner. U.S. Patent 8674154B2, 18 March 2014. [Google Scholar]

- ASTM D2425—19. Test Method for Hydrocarbon Types in Middle Distillates by Mass Spectrometry; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Robinson, C.J. Low-Resolution Mass Spectrometric Determination of Aromatics and Saturates in Petroleum Fractions. Anal. Chem. 1971, 43, 1425–1434. [Google Scholar] [CrossRef]

- Krasodomski, W.; Krasodomski, M. GC/MS Application in the Structural Group Analysis of Basic Lubricant Oils. Part I—State of Knowledge. Nafta Gaz 2010, 66, 711–718. [Google Scholar]

- Nicolescu, T.O. Interpretation of Mass Spectra; IntechOpen: London, UK, 2017; ISBN 978-953-51-3224-0. [Google Scholar]

- ASTM D7500—15. Test Method for Determination of Boiling Range Distribution of Distillates and Lubricating Base Oilsin Boiling Range from 100C to 735C by Gas Chromatography; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM D1159—07. Test Method for Bromine Numbers of Petroleum Distillates and Commercial Aliphatic Olefins by Electrometric Titration; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Gao, F. Pyrolysis of Waste Plastics into Fuels. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2010. [Google Scholar]

- Dubdub, I.; Al-Yaari, M. Pyrolysis of Mixed Plastic Waste: I. Kinetic Study. Materials 2020, 13, 4912. [Google Scholar] [CrossRef]

- Panda, A.K.; Singh, R.K.; Mishra, D.K. Thermolysis of Waste Plastics to Liquid Fuel A Suitable Method for Plastic Waste Management and Manufacture of Value Added Products—A World Prospective. Renew. Sustain. Energy Rev. 2010, 14, 233–248. [Google Scholar] [CrossRef]

- Osman, A.I.; Farrell, C.; Al-Muhtaseb, A.H.; Al-Fatesh, A.S.; Harrison, J.; Rooney, D.W. Pyrolysis Kinetic Modelling of Abundant Plastic Waste (PET) and in-Situ Emission Monitoring. Environ. Sci. Eur. 2020, 32, 112. [Google Scholar] [CrossRef]

- Dhahak, A.; Hild, G.; Rouaud, M.; Mauviel, G.; Burkle-Vitzthum, V. Slow Pyrolysis of Polyethylene Terephthalate: Online Monitoring of Gas Production and Quantitative Analysis of Waxy Products. J. Anal. Appl. Pyrolysis 2019, 142, 104664. [Google Scholar] [CrossRef]

- Brems, A.; Baeyens, J.; Vandecasteele, C.; Dewil, R. Polymeric Cracking of Waste Polyethylene Terephthalate to Chemicals and Energy. J. Air Waste Manag. Assoc. 2011, 61, 721–731. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.K.; Ruj, B. Time and Temperature Depended Fuel Gas Generation from Pyrolysis of Real World Municipal Plastic Waste. Fuel 2016, 174, 164–171. [Google Scholar] [CrossRef]

| Sample No. | Mass Fraction, % wt. | ||||

|---|---|---|---|---|---|

| PE | PP | PS | PET | PVC | |

| 1 | 100 | 0 | 0 | 0 | 0 |

| 2 | 0 | 100 | 0 | 0 | 0 |

| 3 | 75 | 25 | 0 | 0 | 0 |

| 4 | 50 | 50 | 0 | 0 | 0 |

| 5 | 25 | 75 | 0 | 0 | 0 |

| 6 | 0 | 0 | 100 | 0 | 0 |

| 7 | 45 | 45 | 10 | 0 | 0 |

| 8 | 95 | 0 | 2 | 2 | 1 |

| 9 | 0 | 95 | 3 | 1 | 1 |

| 10 | 47.5 | 47.5 | 3 | 1 | 1 |

| Sample | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Process temperature, °C | 403 | 379 | 397 | 387 | 384 | 330 | 387 | 400 | 384 | 386 |

| Product yield, % wt. | 78.1 | 90.6 | 78.8 | 82.5 | 91.3 | 73.8 | 83.8 | 48.1 | 85.0 | 79.4 |

| Loss (residue + gas), % wt. | 21.9 | 9.4 | 21.2 | 17.5 | 8.7 | 26.2 | 16.2 | 51.9 | 15.0 | 20.6 |

| Fraction, % wt. | Temperature, °C | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| IBP (0.5) | 80.3 | 91.8 | 77.9 | 78.3 | 82.2 | 71.8 | 79.7 | 79.8 | 75.5 | 81.7 |

| 10 | 140.0 | 117.8 | 106.1 | 106.1 | 107.1 | 120.0 | 131.9 | 121.4 | 107.1 | 120.8 |

| 20 | 193.5 | 172.3 | 159.5 | 157.7 | 166.0 | 130.3 | 162.4 | 171.9 | 166.7 | 177.7 |

| 30 | 251.1 | 217.0 | 207.9 | 203.9 | 208.9 | 151.4 | 208.0 | 214.8 | 215.8 | 230.6 |

| 40 | 287.6 | 243.0 | 264.8 | 250.2 | 232.9 | 221.0 | 244.8 | 270.7 | 271.7 | 285.6 |

| 50 | 325.1 | 288.9 | 301.2 | 293.1 | 284.7 | 275.1 | 285.6 | 305.9 | 309.9 | 321.5 |

| 60 | 356.0 | 316.5 | 336.8 | 328.9 | 316.2 | 284.4 | 322.7 | 341.8 | 344.7 | 356.6 |

| 70 | 387.7 | 360.3 | 369.8 | 366.6 | 359.3 | 287.7 | 362.4 | 369.1 | 381.9 | 390.1 |

| 80 | 419.5 | 395.3 | 407.7 | 402.5 | 396.5 | 344.6 | 399.6 | 402.8 | 417.9 | 424.2 |

| 90 | 457.3 | 443.5 | 449.1 | 449.0 | 446.2 | 390.6 | 446.6 | 445.4 | 467.2 | 467.7 |

| 95 | 485.9 | 479.2 | 480.2 | 481.1 | 480.1 | 421.4 | 479.3 | 474.1 | 500.0 | 498.7 |

| FBP (99.5) | 541.1 | 544.2 | 537.5 | 539.2 | 539.7 | 460.0 | 537.7 | 534.2 | 573.2 | 559.5 |

| Sample: | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Bromine numer, gBr2/100 g | 34.20 | 72.80 | 53.27 | 58.22 | 65.82 | 4.25 | 57.22 | 41.62 | 73.0 | 60.18 |

| N-paraffins | 70.39 | 0.00 | 52.19 | 28.95 | 9.72 | 1.83 | 9.06 | 71.15 | 4.59 | 40.76 |

| N-olefins | 28.81 | 0.00 | 23.73 | 14.27 | 7.21 | 0.00 | 7.26 | 26.41 | 0.17 | 20.73 |

| Iso-paraffins | 0.00 | 6.83 | 5.96 | 7.91 | 7.29 | 0.00 | 3.27 | 0.00 | 3.77 | 2.77 |

| Iso-olefins/cyclo-paraffins | 0.80 | 93.17 | 18.12 | 48.87 | 75.27 | 0.42 | 68.08 | 0.00 | 87.06 | 39.28 |

| Cyclo-olefins | 0.00 | 0.00 | 0.00 | 0.00 | 0.51 | 0.00 | 0.13 | 0.00 | 0.17 | 0.00 |

| Aromatics | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 97.75 | 12.20 | 2.44 | 4.24 | 6.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frączak, D.; Fabiś, G.; Orlińska, B. Influence of the Feedstock on the Process Parameters, Product Composition and Pilot-Scale Cracking of Plastics. Materials 2021, 14, 3094. https://doi.org/10.3390/ma14113094

Frączak D, Fabiś G, Orlińska B. Influence of the Feedstock on the Process Parameters, Product Composition and Pilot-Scale Cracking of Plastics. Materials. 2021; 14(11):3094. https://doi.org/10.3390/ma14113094

Chicago/Turabian StyleFrączak, Daria, Grażyna Fabiś, and Beata Orlińska. 2021. "Influence of the Feedstock on the Process Parameters, Product Composition and Pilot-Scale Cracking of Plastics" Materials 14, no. 11: 3094. https://doi.org/10.3390/ma14113094

APA StyleFrączak, D., Fabiś, G., & Orlińska, B. (2021). Influence of the Feedstock on the Process Parameters, Product Composition and Pilot-Scale Cracking of Plastics. Materials, 14(11), 3094. https://doi.org/10.3390/ma14113094