Microstructural and Mechanical Evaluation of a Cr-Mo-V Cold-Work Tool Steel Produced via Electron Beam Melting (EBM)

Abstract

1. Introduction

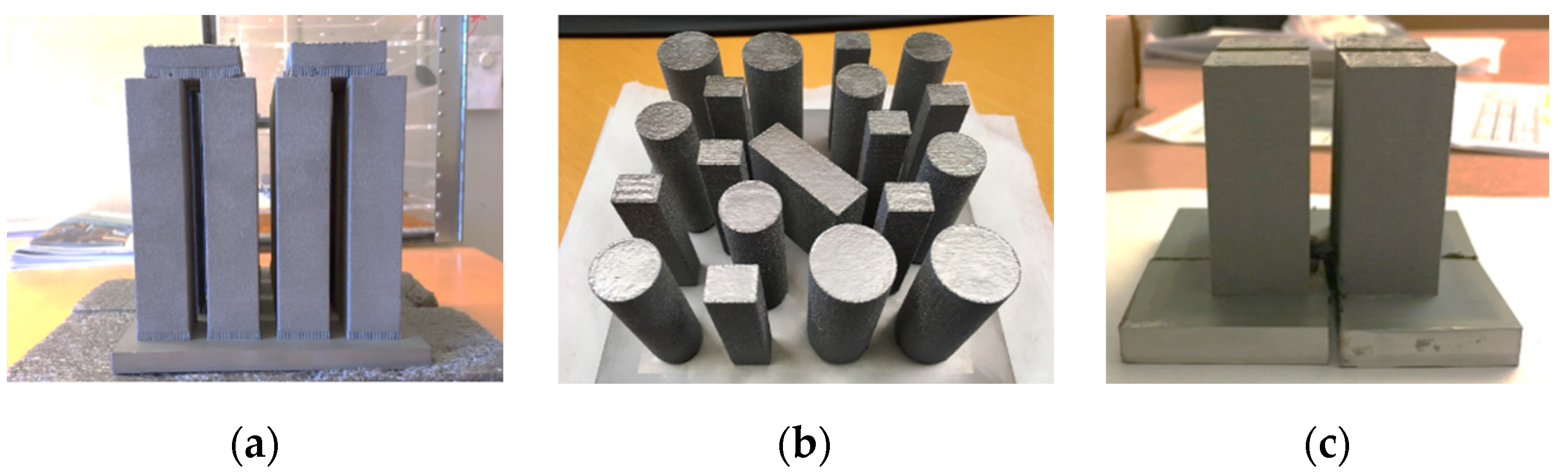

2. Materials and Methods

2.1. Powder

2.2. EBM Processing

2.3. Heat Treatment

2.4. Hot Isostatic Pressing

2.5. Microstructure and Mechanical Characterization

3. Results

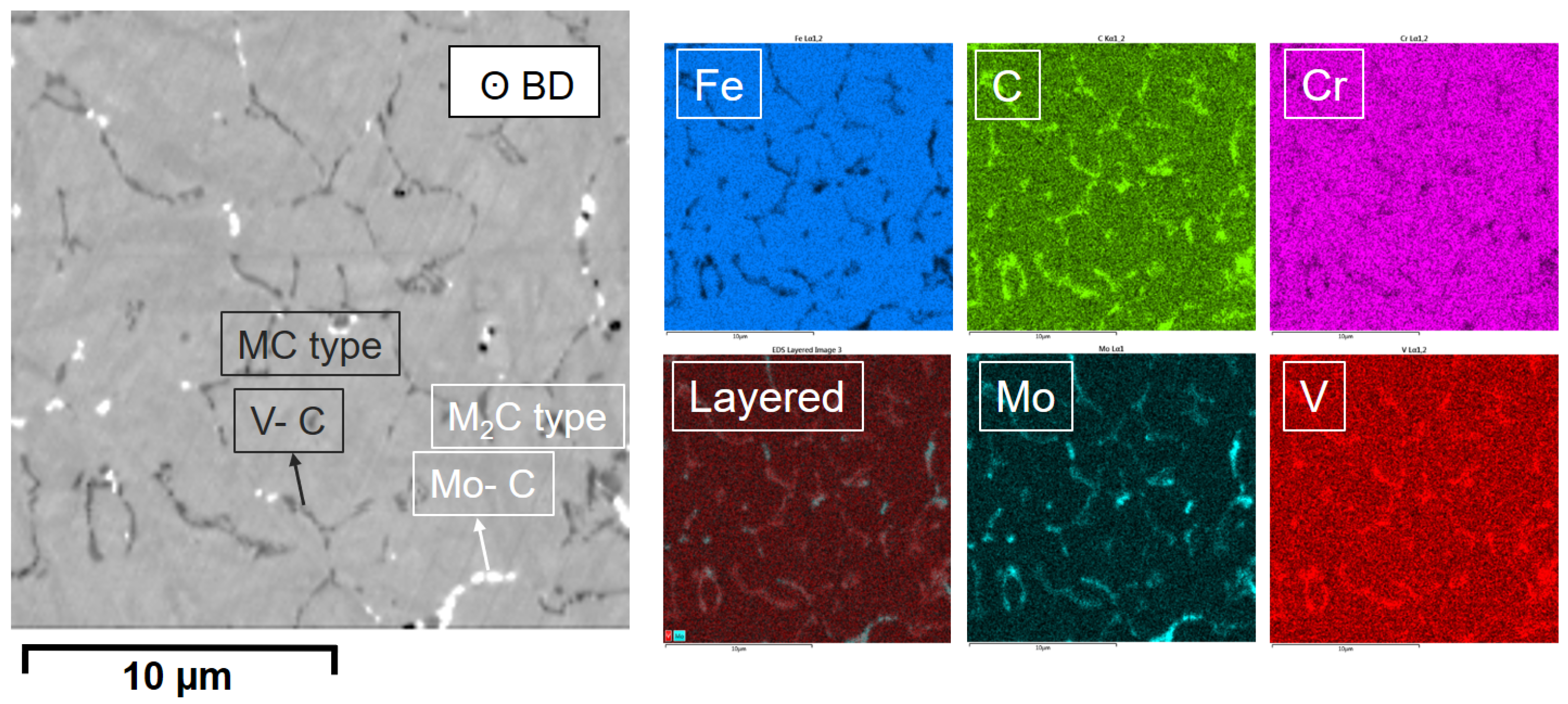

3.1. As-Built Microstructure

3.2. Heat Treatment Development

3.3. Mechanical Properties

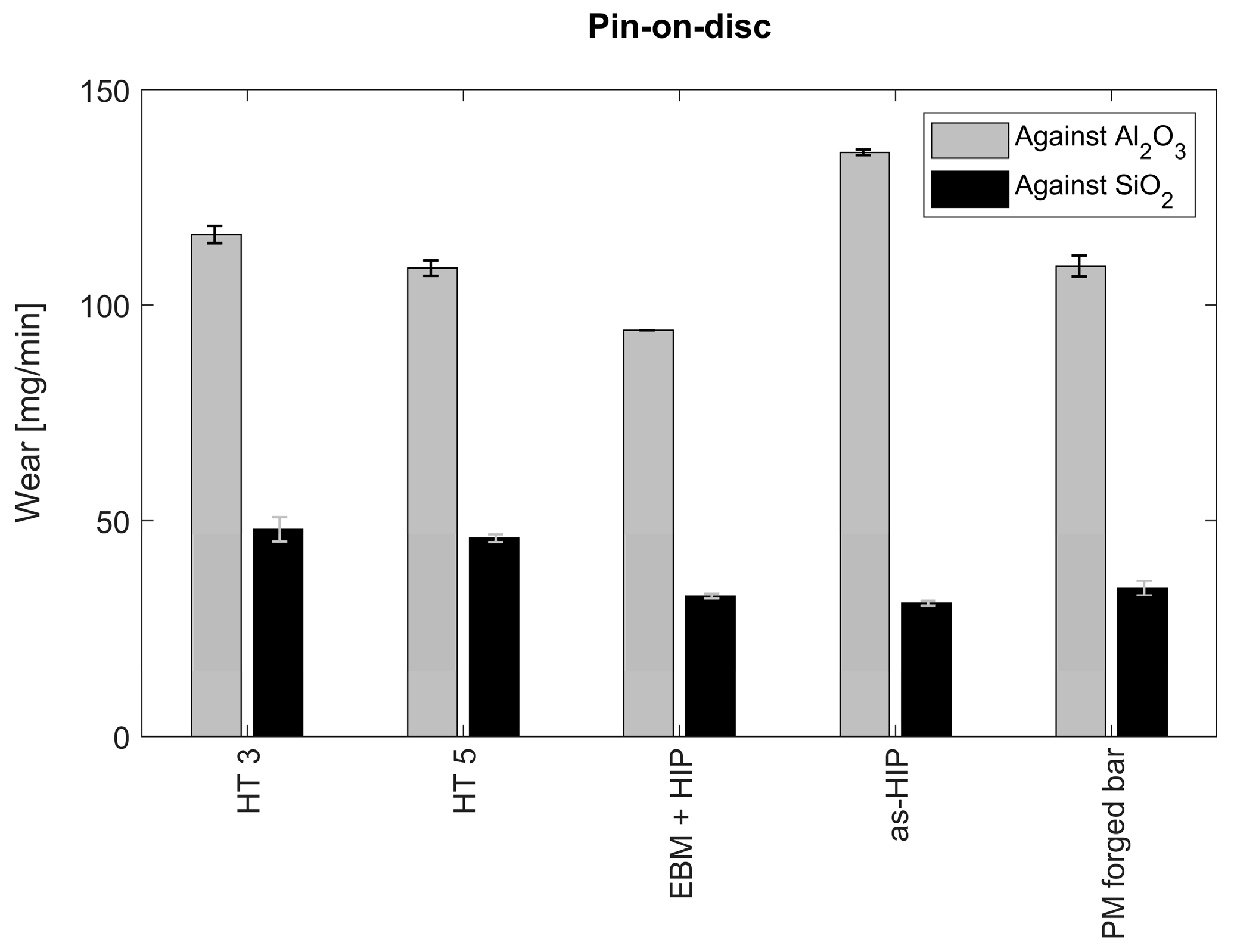

3.3.1. Abrasive Wear

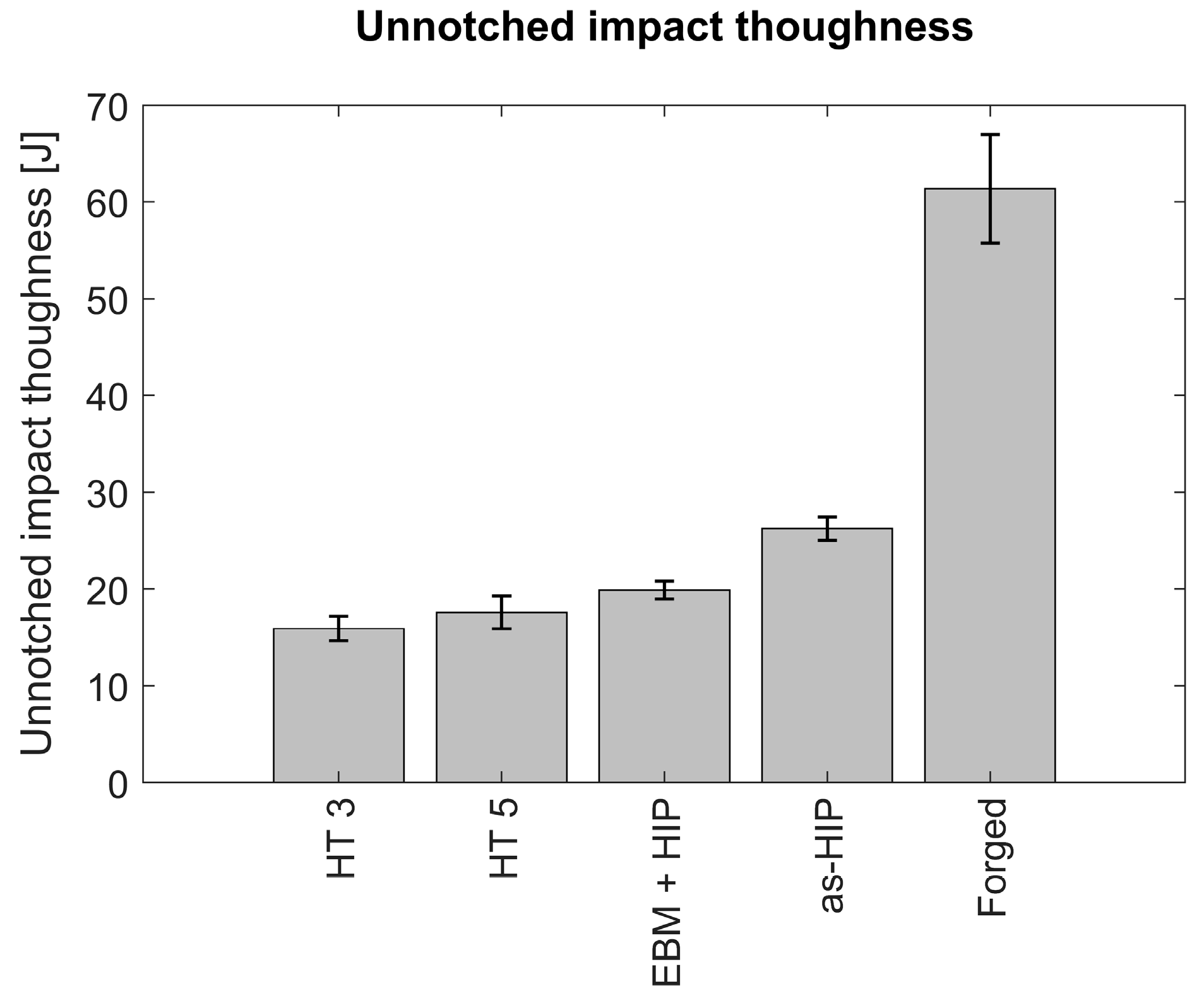

3.3.2. Ductility

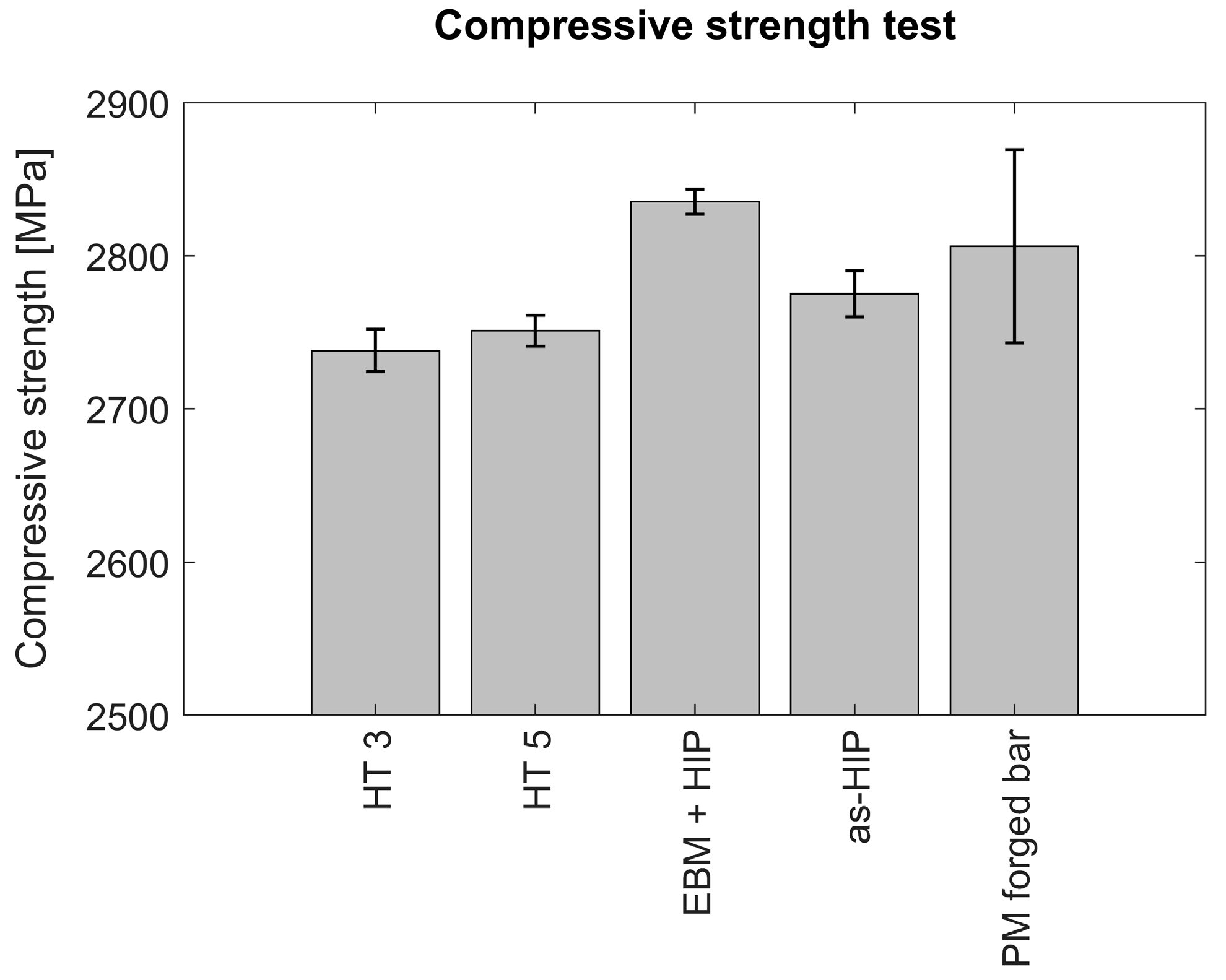

3.3.3. Compressive Strength

3.3.4. Summary of Results

4. Conclusions

- As-built specimens were manufactured with a microstructure consisting of discontinuous carbides, which is characteristic of eutectic solidification. Inter-dendritic regions showed finer carbide precipitations, predominantly M2C (Mo-rich) and MC (V-rich) types.

- Heat treatments allowed for an optimized microstructure yielding a homogeneous dispersion of discontinuous V-rich carbides and complete dissolution of Mo carbides, reaching up to HRC 65. Retained austenite was measured below 2% for all heat-treated specimens.

- The compressive strength, hardness, and wear properties of EBM-manufactured samples are superior to as-HIP manufactured products and similar to PM material. However, ductility of the as-built EBM manufactured samples exhibited low values (below 20 J), which was evaluated as a result of internal defects.

- Hot isostatic pressing (HIP) can be motivated in order to improve the mechanical properties by eliminating internal defects and by the effect of ultra-high rapid quenching with higher cooling rates. Ductility was increased to 21 J, yield strength and Young’s modulus reached up to 2843 MPa and 230 GPa after HIP, respectively.

- The EBM route provides valuable possibilities for the manufacturing of advanced components from Vanadis 4 Extra for tooling applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arcam EBM. Available online: http://www.arcam.com/ (accessed on 1 April 2021).

- Cormier, D.; Harrysson, O.; West, H. Characterization of H13 steel produced via electron beam melting. Rapid Prototyp. J. 2004, 10, 35–41. [Google Scholar] [CrossRef]

- Rännar, L.-E.; Glad, A.; Gustafson, C.-G. Efficient cooling with tool inserts manufactured by electron beam melting. Rapid Prototyp. J. 2007, 13, 128–135. [Google Scholar] [CrossRef]

- Sigl, M. Ein Beitrag zur Entwicklung des Elektronenstrahlsinterns. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2008. [Google Scholar]

- Junker, D.; Hentschel, O.; Schmidt, M.; Merklein, M. Tailor-Made Forging Tools by Laser Metal Deposition. Key Eng. Mater. 2015, 651–653, 707. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Hentschel, O.; Scheitler, C.; Fedorov, A.; Junker, D.; Gorunov, A.; Haimerl, A.; Merklein, M.; Schmidt, M. Experimental investigations of processing the high carbon cold-work tool steel 1.2358 by laser metal deposition for the additive manufacturing of cold forging tools. J. Laser Appl. 2017, 29, 022307. [Google Scholar] [CrossRef]

- Sander, J.; Hufenbacha, J.; Giebeler, L.; Bleckmann, M.; Eckert, J.; Kühn, U. Microstructure, mechanical behavior, and wear properties of FeCrMoVC steel prepared by selective laser melting and casting. Scripta Mater. 2017, 126, 41–44. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, C.; Qin, L.; Yan, K.; Cheng, G.; Jing, H.; Zou, T. Laser additive manufacturing of M2 high-speed steel. Mater. Sci. Technol. 2018, 34, 69–78. [Google Scholar] [CrossRef]

- Valloton, J.; Herlach, D.M.; Henein, H.; Sediako, D. Microstructural Quantification of Rapidly Solidified Undercooled D2 Tool Steel. Metall. Mater. Trans. A 2017, 48, 4735–4743. [Google Scholar] [CrossRef]

- Casati, R.; Coduri, M.; Lecis, N.; Andrianopoli, C.; Vedani, M. Microstructure and mechanical behavior of hot-work tool steels processed by Selective Laser Melting. Mater. Charact. 2018, 137, 50–57. [Google Scholar] [CrossRef]

- Ramsperger, M.; Singer, R.; Körner, C. Microstructure of the Nickel-Base Superalloy CMSX-4 Fabricated by Selective Electron Beam Melting. Metall. Mater. Trans. A 2016, 47, 1469. [Google Scholar] [CrossRef]

- Ramsperger, M.; Roncery, L.; Lopez-Galilea, I.; Singer, R.; Theisen, W.; Körner, C. Solution Heat Treatment of the Single Crystal Nickel-Base Superalloy CMSX-4 Fabricated by Selective Electron Beam Melting. Adv. Eng. Mater. 2015, 17, 1486–1493. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Pan, X.M.; Gaytan, S.M.; Castro, J.A.; Terrazas, C.A.; Medina, F.; Wicker, R.B.; Abbott, D.H. Microstructures of Rene 142 nickel-based superalloy fabricated by electron beam melting. Acta Mater. 2013, 61, 4289–4296. [Google Scholar] [CrossRef]

- VBN Components. Available online: https://vbncomponents.se/ (accessed on 1 April 2021).

- Beste, U. 3D Printing for Demanding Applications. 2017. Available online: http://www.iucsyd.se/media/1812/ulrik-beste-vbn.pdf (accessed on 1 April 2021).

- Jarfors, A.E.; Matsushita, T.; Bogdanoff, T.; Börrison, M.; Beste, U. Effect of Use in High Pressure Die Casting on Vibenite®60 Tool insert Made by Additive Manufacturing. In Proceedings of the 3rd Fraunhofer Direct Digital Manufacturing Conference, Berlin, Germany, 16–17 March 2016; pp. 405–410. [Google Scholar]

- Botero, C.A.; Ramsperger, M.; Selte, A.; Åsvik, K.; Koptyug, A.; Skoglund, P.; Roos, S.; Rännar, L.-E.; Bäckström, M. Additive Manufacturing of a Cold-Work Tool Steel using Electron Beam Melting. Steel Res. Int. 2019, 1900448, 1–6. [Google Scholar] [CrossRef]

- Uddeholm Vanadis®4 Extra SuperClean. Edition 10, Revised November 2016. Available online: https://www.uddeholm.com/files/PB_Uddeholm_vanadis_4_extra_english.pdf (accessed on 1 April 2021).

- Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus; ASTM G99-17; ASTM International: West Conshohocken, PA, USA, 2017.

- Metallic Materials—Charpy Pendulum Impact Test—Part 1: Test Method; ISO148-1; ISO: Geneva, Switzerland, 2016.

- Jin, J.; Gao, R.; Peng, H.; Guo, H.; Gong, S.; Chen, B. Rapid Solidification Microstructure and Carbide Precipitation Behavior in Electron Beam Melted High-Speed Steel. Metall. Mater. Trans. A 2020, 51, 2411–2429. [Google Scholar] [CrossRef]

- Charleux, M.; Poole, W.J.; Militzer, M.; Deschamps, A. Precipitation behavior and its effect on strengthening of an HSLA-Nb/Ti steel. Metall. Mater. Trans. A 2001, 32, 1635–1647. [Google Scholar] [CrossRef]

- Soto, R.; Saikaly, W.; Bano, X.; Issartel, C.; Rigaut, G.; Charai, A. Statistical and theoretical analysis of precipitates in dual-phase steels microalloyed with titanium and their effect on mechanical properties. Acta Mater. 1999, 47, 3475–3481. [Google Scholar] [CrossRef]

- Toji, Y.; Matsuda, H.; Herbig, M.; Choi, P.; Raabe, D. Atomic-scale analysis of carbon partitioning between martensite and austenite by atom probe tomography and correlative transmission electron microscopy. Acta Mater. 2014, 65, 215–228. [Google Scholar] [CrossRef]

- Speich, G.R.; Schwoeble, A.J.; Leslie, W.C. Elastic constants of binary iron-base alloys. Metall. Trans. 1972, 3, 2031–2037. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Forouzan, F.; Vuorinen, E.; Mücklich, F. Post weld-treatment of laser welded AHSS by application of quenching and partitioning technique. Mater. Sci. Eng. A 2017, 698, 174–182. [Google Scholar] [CrossRef]

- Clarke, A.J.; Speer, J.G.; Miller, M.K.; Hackenberg, R.E.; Edmonds, D.V.; Matlock, D.K.; Rizzo, F.C.; Clarke, K.D.; De Moor, E. Carbon partitioning to austenite from martensite or bainite during the quench and partition (Q&P) process: A critical assessment. Acta Mater. 2008, 56, 16–22. [Google Scholar]

- Junker, D.; Hentschel, O.; Schmidt, M.; Merklein, M. Investigation of Heat Treatment Strategies for Additively-Manufactured Tools of X37CrMoV5-1. Metals 2018, 8, 854. [Google Scholar] [CrossRef]

- Michaud, P.; Delagnes, D.; Lamesle, P.; Mathon, M.H.; Levaillant, C. The effect of the addition of alloying elements on carbide precipitation and mechanical properties in 5% chromium martensitic steels. Acta Mater. 2007, 55, 4877–4889. [Google Scholar] [CrossRef]

- Mondière, A.; Déneux, V.; Binot, N.; Delagnes, D. Controlling the MC and M2C carbide precipitation in Ferrium® M54® steel to achieve optimum ultimate tensile strength/fracture toughness balance. Mater. Charact. 2018, 140, 103–112. [Google Scholar] [CrossRef]

| Build Job | Hardness (HRC) | % Retained Austenite |

|---|---|---|

| 1 | 55–56 | 17 ± 4 |

| 2 | 56–58 | 16 ± 4 |

| 3 | 56–58 | 17 ± 3 |

| HT | Austenitization | Quenching | Tempering | Hardness | RA | |||

|---|---|---|---|---|---|---|---|---|

| T (°C) | t (min) | Conditions | t (s) | T (°C) | t (h) | HRC | % | |

| 1 | 1020 | 30 | Vacuum | 300 | 540 | 4 × 1 | 60–61 | <2 |

| 2 | 1100 | 30 | Vacuum | 300 | 525 | 4 × 1 | 60–61 | <2 |

| 3 | 1100 | 30 | Vacuum | 300 | 540 | 4 × 1 | 63–64 | <2 |

| 4 | 1160 | 10 | Vacuum + DC | 3600 | 525 | 3 × 1 | 61–62 | <2 |

| 5 | 1160 | 10 | Vacuum + DC | 300 | 525 | 3 × 1 | 63–65 | <2 |

| 6 | 1160 | 10 | Vacuum + DC | 10,800 | 525 | 3 × 1 | 61–62 | <2 |

| 7 | 1200 | 10 | Vacuum + DC | 300 | 525 | 3 × 1 | 62–64 | <2 |

| 7/1 | 1020 | 30 | Vacuum | 300 | 525 | 3 × 1 | 60–62 | <2 |

| Property | As-HIP (PM) | Forged HIP, Forged and Heat Treated Conventional PM Route | EBM + HT (Not Forged) | EBM + HIP + HT (Not Forged) |

|---|---|---|---|---|

| Hardness, HRc | 61–63 | 62–64 | 62–64 | 64–65 |

| Retained Austenite, % | <2 | <2 | <2 | <2 |

| Unnotched Impact Toughness, J | ≈25 | ≈60 | Up to ≈17 | Up to ≈21 |

| Yield strength (MPa) (Compression) | 2760–2790 (at 63 HRc) | 2743–2869 (at 64 HRc) | 2724–2761 (at 64 HRc) | 2827–2843 (at 64 HRc) |

| Young Modulus (GPa) (Compression) | - | ≈230 (at 60 HRc) | ≈225 (at 63 HRc) | ≈230 (at 64 HRc) |

| Pin on Disc (mg/mm) | ≈135 | ≈110 | ≈110 | ≈90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botero, C.A.; Şelte, A.; Ramsperger, M.; Maistro, G.; Koptyug, A.; Bäckström, M.; Sjöström, W.; Rännar, L.-E. Microstructural and Mechanical Evaluation of a Cr-Mo-V Cold-Work Tool Steel Produced via Electron Beam Melting (EBM). Materials 2021, 14, 2963. https://doi.org/10.3390/ma14112963

Botero CA, Şelte A, Ramsperger M, Maistro G, Koptyug A, Bäckström M, Sjöström W, Rännar L-E. Microstructural and Mechanical Evaluation of a Cr-Mo-V Cold-Work Tool Steel Produced via Electron Beam Melting (EBM). Materials. 2021; 14(11):2963. https://doi.org/10.3390/ma14112963

Chicago/Turabian StyleBotero, Carlos Alberto, Aydın Şelte, Markus Ramsperger, Giulio Maistro, Andrey Koptyug, Mikael Bäckström, William Sjöström, and Lars-Erik Rännar. 2021. "Microstructural and Mechanical Evaluation of a Cr-Mo-V Cold-Work Tool Steel Produced via Electron Beam Melting (EBM)" Materials 14, no. 11: 2963. https://doi.org/10.3390/ma14112963

APA StyleBotero, C. A., Şelte, A., Ramsperger, M., Maistro, G., Koptyug, A., Bäckström, M., Sjöström, W., & Rännar, L.-E. (2021). Microstructural and Mechanical Evaluation of a Cr-Mo-V Cold-Work Tool Steel Produced via Electron Beam Melting (EBM). Materials, 14(11), 2963. https://doi.org/10.3390/ma14112963