Influence of Type of Modified Binder on Stiffness and Rutting Resistance of Low-Noise Asphalt Mixtures

Abstract

1. Introduction

2. Materials

3. Experimental Methods

3.1. Indirect Tension to Cylindrical Specimens (IT-CY)

- F—the maximum force applied to the sample (N);

- z—the amplitude of the horizontal displacement of the sample during loading (mm);

- h—sample height (mm);

- ν—Poisson’s ratio;

- ΔV—maximum vertical displacement of the sample (mm).

3.2. Rutting Resistance Test Using the British and Belgian Method

- h1—the initial rut depth (mm);

- h2—the final rut depth (mm).

4. Results and Discussion

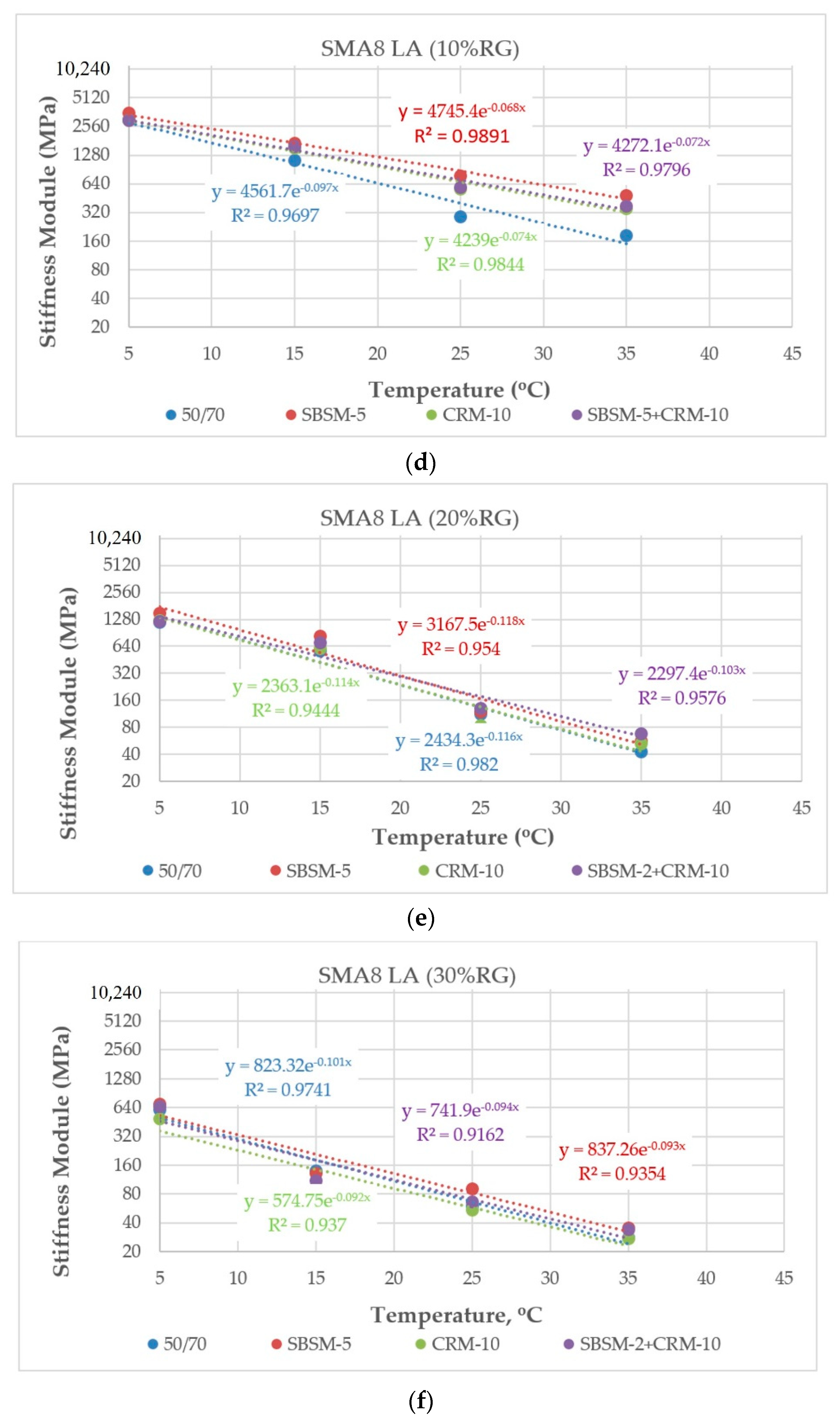

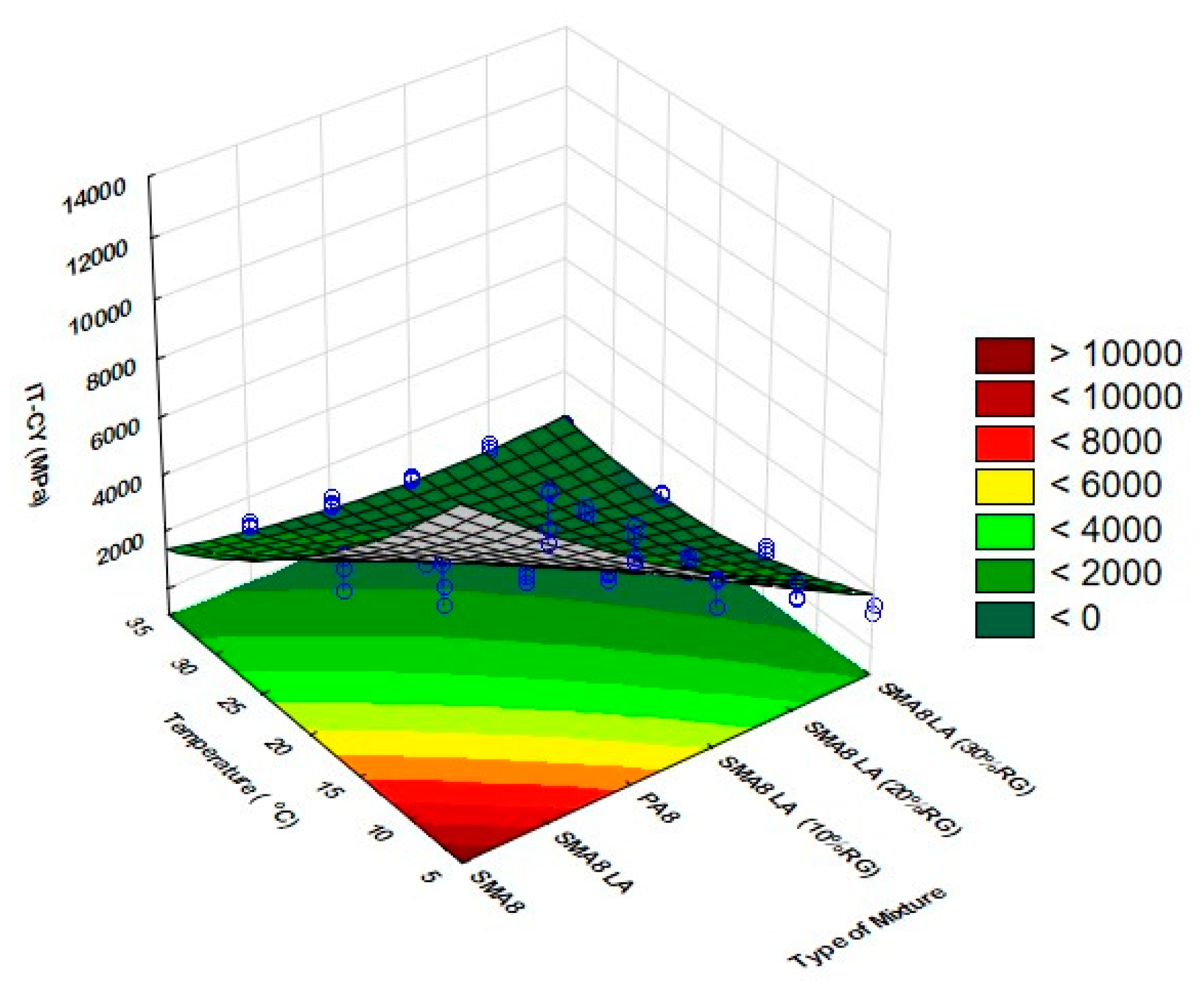

4.1. IT-CY Stiffness Modulus

- Z—analyzed parameter of the mixture (IT-CY stiffness modulus);

- —regression coefficients;

- X1—type of mixture;

- X2—type of binder;

- X3—temperature (°C).

- TM—type of mixture: SMA8 = 6, SMA8 LA = 7, PA8 = 8, SMA8 LA (10%RG) = 9, SMA8 LA (20%RG) = 10, SMA8 LA (30%RG) = 11;

- TB—type of binder: 50/70 = 12, SBSM-5 = 13, CRM-10 = 14, SBSM-2+CRM-10 = 15;

- Temp—test temperature.

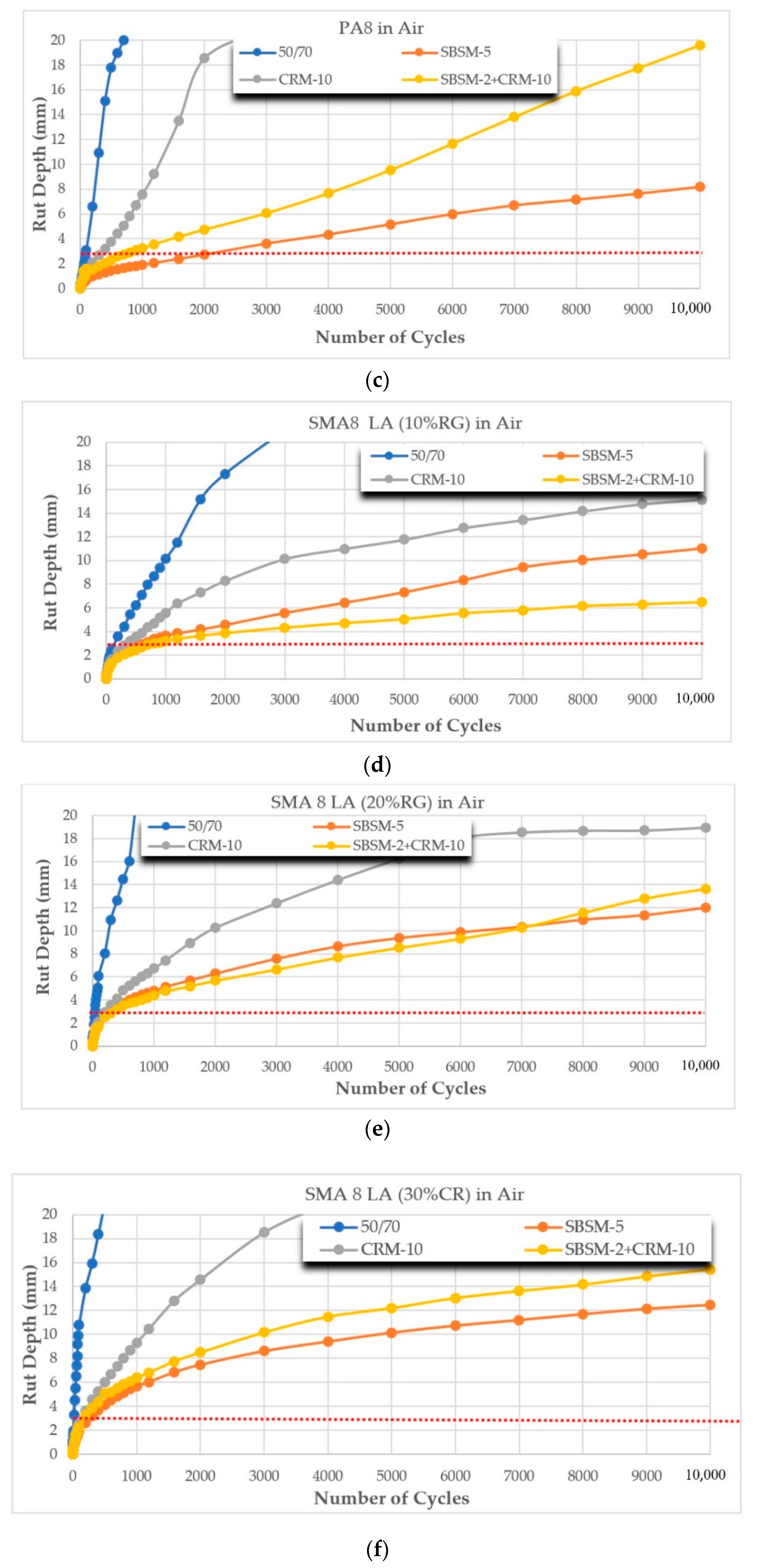

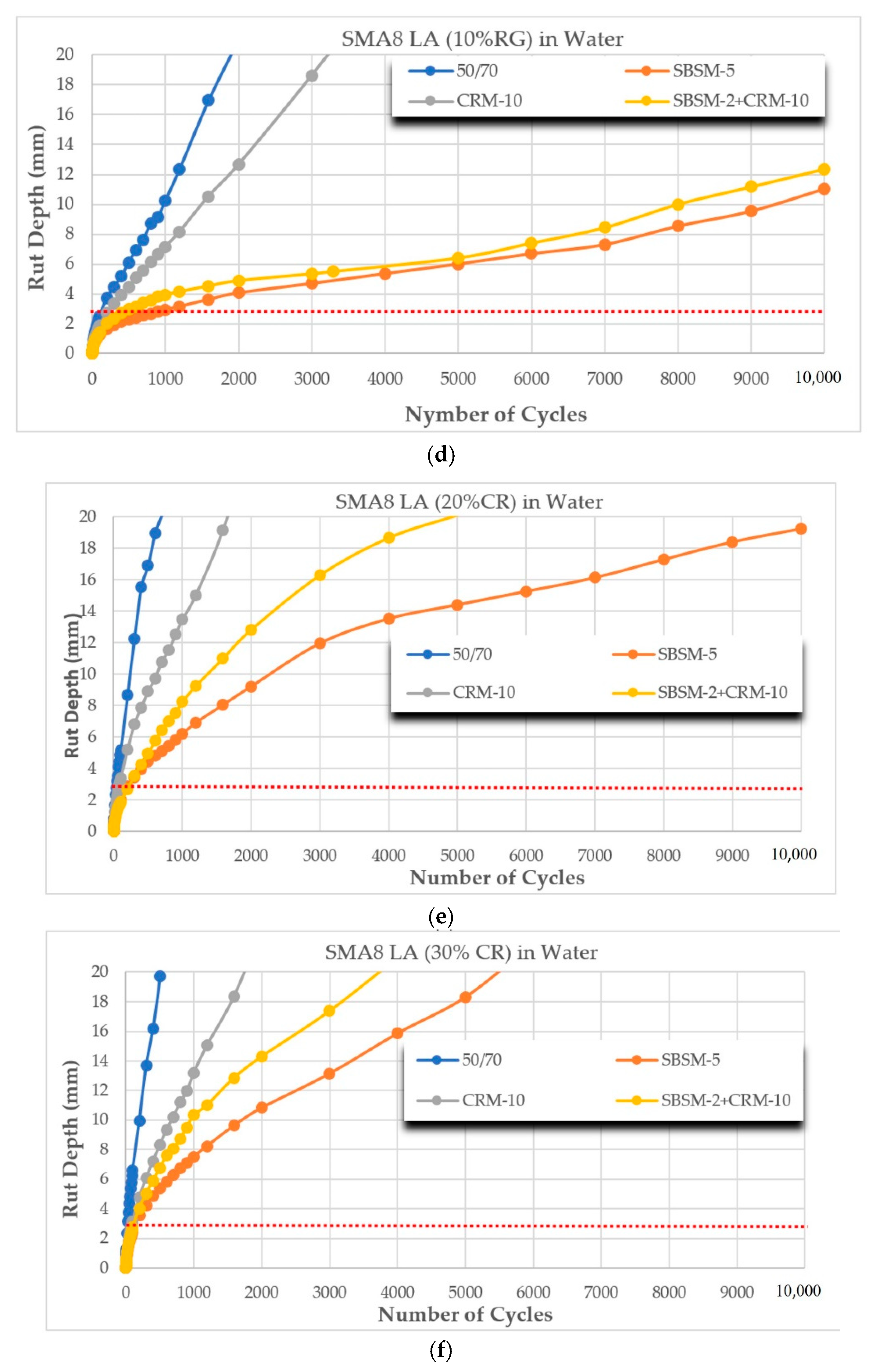

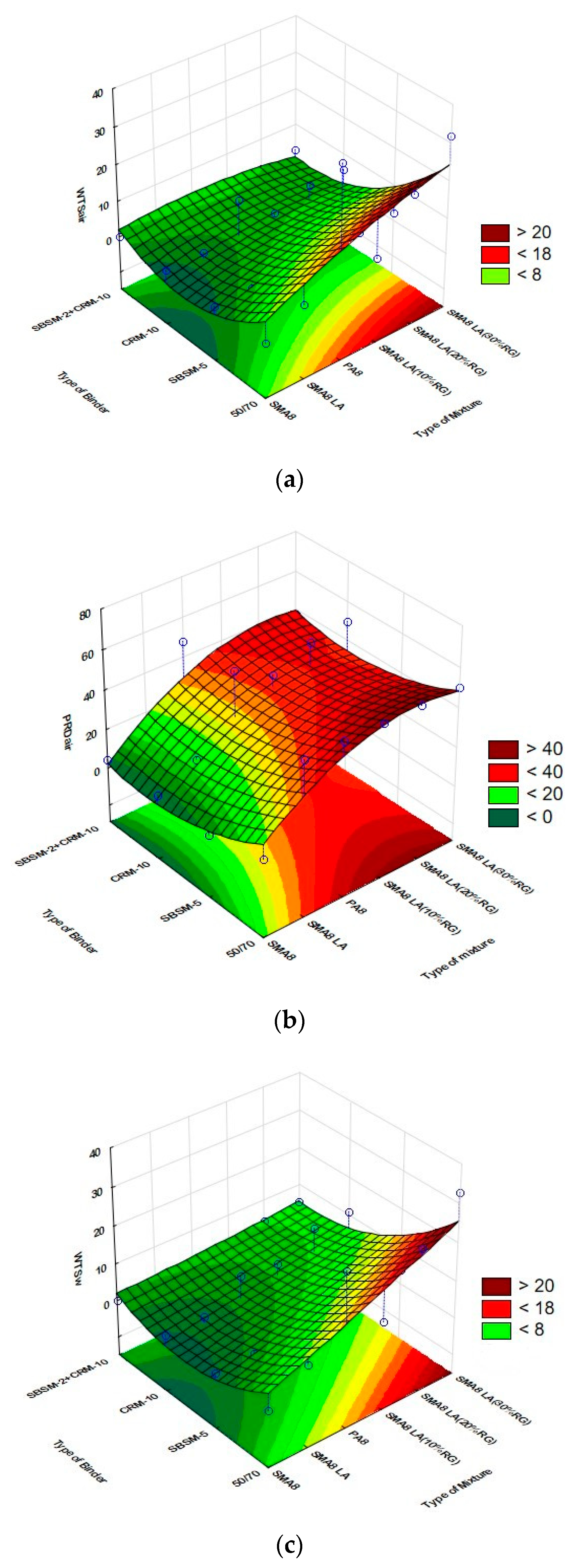

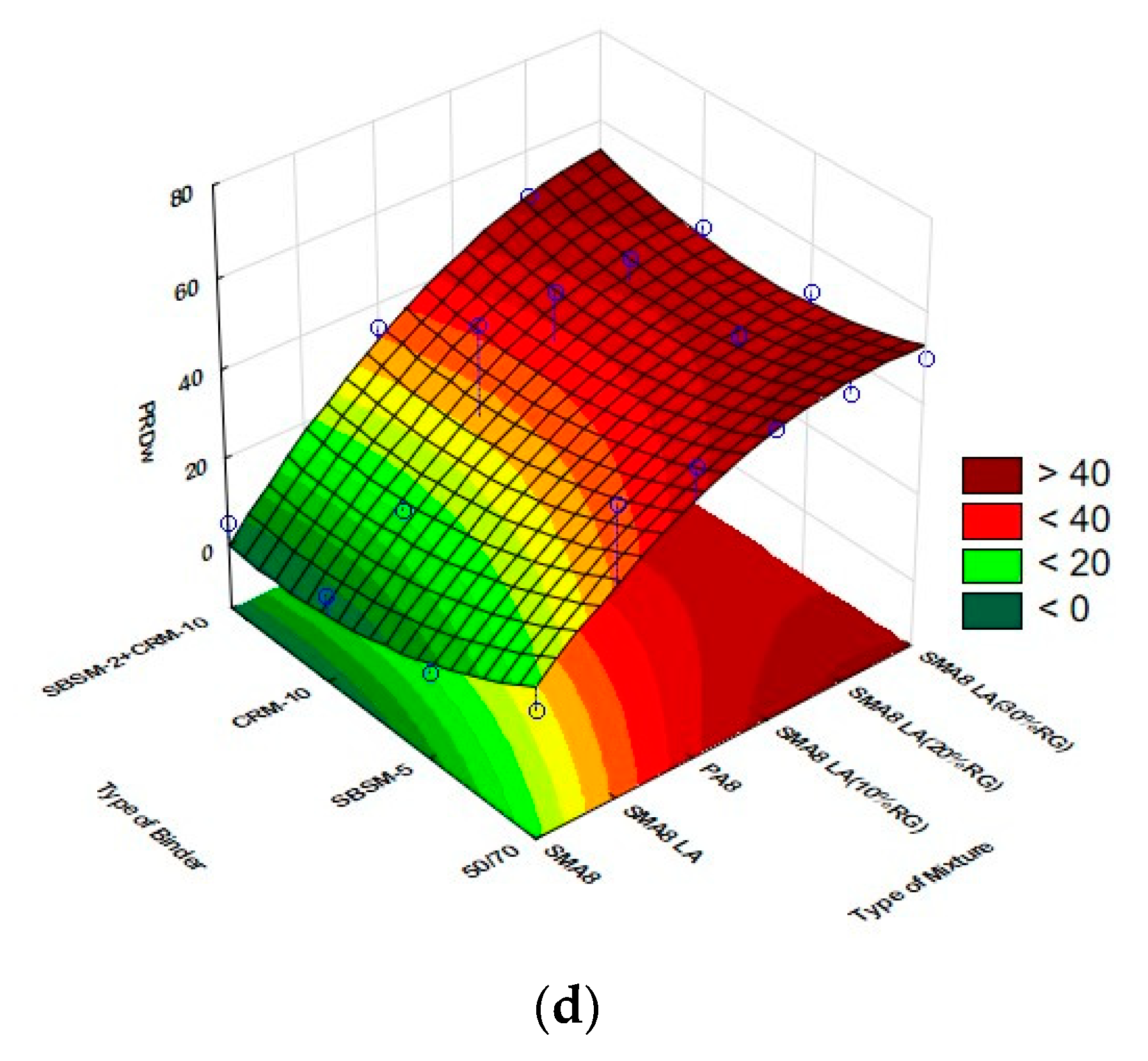

4.2. Rutting Resistance by British and Belgian Method

- TM—type of mixture: SMA8 = 6, SMA8 LA =7, PA8 = 8, SMA8 LA (10%RG) = 9, SMA8 LA (20%RG) = 10, SMA8 LA (30%RG) = 11;

- TB—type of binder: 50/70 = 12, SBSM-5 = 13, CRM-10 = 14, SBSM-2+CRM-10 = 15.

5. Conclusions

- The type of modifier used has a significant effect on the stiffness of asphalt mixtures and their temperature sensitivity confirmed by the change in the value of the stiffness modulus as a function of temperature. The highest increase was obtained at the temperature of 35 °C for SMA8 LA mixtures with 10% rubber granulate: by 163% for the binder modified with SBS copolymer, by 92% for the binder modified with crumb rubber and by 104% for the modification with 2% SBS + 10% crumb rubber, compared to mixtures with bitumen 50/70.

- Replacing coarse aggregate in the mixture with rubber granulate in an amount exceeding 20% (by volume) causes a significant decrease in the stiffness modulus. The greatest changes were observed in the case of SMA8 LA (30% rubber granulate) with a binder modified with 10% crumb rubber. The decrease in IT-CY stiffness modulus in this case was 95% compared to the reference mixture with bitumen 50/70.

- In SMA mixtures, their rutting resistance was found to be lower in Belgian test (in water) compared to the British test (in air). The SMA8 LA (10% rubber granulate) mixture showed an increase in the WTSw rut depth by 334% in relation to the results measured in the air. Percentage of rut depth PRDw of SMA8 LA (30% rubber granulate) mixture increased by 65% compared to PRDair.

- The opposite effect was achieved for porous asphalt. Water present in the open pores of PA mixtures during the test is likely to act as a “shock absorber”, partially taking the load while improving the rutting resistance of these mixtures. The WTSw index decreased by 34% compared to WTSair for samples with binder containing 10% crumb rubber. Percentage of rut depth decreased by 27% when binder was modified with a combined SBS copolymer and crumb rubber was applied.

- The addition of rubber granulate directly affects the WTS and PRD parameters. The higher the replacement ratio of mineral aggregate with rubber granulate, the more the rutting parameters deteriorate. For example, for SMA8 LA mixture with a 5% copolymer modified binder, WTSair is 0.05 and PRDair is 3.93. If the addition of rubber granulate in SMA LA is 30%, the rutting indexes are: WTSair = 2.11 and PRDair = 30.31.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, M.; Huang, X.; Xue, G. Effects of double layer porous asphalt pavement of urban streets on noise reduction. Int. J. Sustain. Built Environ. 2016, 5, 183–196. [Google Scholar] [CrossRef]

- Gardziejczyk, W. The effect of time on acoustic durability of low noise pavements—The case studies in Poland. Transp. Res. Part Transp. Environ. 2016, 44, 93–104. [Google Scholar] [CrossRef]

- Jaskula, P.; Rys, D.; Szydlowski, C.; Stienss, M.; Mejlun, L.; Jaczewski, M.; Ronowski, G. Optimisation and field assessment of poroelastic wearing course bond quality. Road Mater. Pavement Des. 2021, 1–20. [Google Scholar] [CrossRef]

- Gawdzik, B.; Matynia, T.; Błażejowski, K. The use of de-vulcanized recycled rubber in the modification of road bitumen. Materials 2020, 13, 4864. [Google Scholar] [CrossRef]

- Brovelli, C.; Crispino, M.; Pais, J.; Pereira, P. Using polymers to improve the rutting resistance of asphalt concrete. Constr. Build. Mater. 2015, 77, 117–123. [Google Scholar] [CrossRef]

- Wu, S.; He, R.; Chen, H.; Li, W.; Li, G. Rheological properties of SBS/CRP composite modified asphalt under different aging treatments. Materials 2020, 13, 4921. [Google Scholar] [CrossRef] [PubMed]

- Gardziejczyk, W.; Plewa, A.; Pakholak, R. Effect of addition of rubber granulate and type of modified binder on the viscoelastic properties of stone mastic asphalt reducing tire/road noise (SMA LA). Materials 2020, 13, 3446. [Google Scholar] [CrossRef] [PubMed]

- Pakholak, R.; Plewa, A.; Hatalski, R. Evaluation of selected technical properties of bitumen binders modified with SBS copolymer and crumb rubber. Struct. Environ. 2020, 12. [Google Scholar] [CrossRef]

- Li, J.; Guo, W.; Meng, A.; Han, M.; Tan, Y. Investigation on the micro deformation mechanism of asphalt mixtures under high temperatures based on a self-developed laboratory test. Materials 2020, 13, 1791. [Google Scholar] [CrossRef]

- Iwański, M.; Mazurek, G. Hydrated lime effect on rutting resistance of SMA pavements. Roads Bridg. Drogi. Mosty. 2013, 12, 361–383. [Google Scholar] [CrossRef]

- Van Thanh, D.; Feng, C.P. Study on marshall and rutting test of SMA at abnormally high temperature. Constr. Build. Mater. 2013, 47, 1337–1341. [Google Scholar] [CrossRef]

- Zhang, Y. Mechanical evaluation of aggregate gradation to characterize load carrying capacity and rutting resistance of asphalt mixtures. Constr. Build. Mater. 2019, 205, 499–510. [Google Scholar] [CrossRef]

- Zou, G.; Xu, J.; Wu, C. Evaluation of factors that affect rutting resistance of asphalt mixes by orthogonal experiment design. Int. J. Pavement Res. Technol. 2017, 10, 282–288. [Google Scholar] [CrossRef]

- Mendez Larrain, M.M.; Tarefder, R.A. Weibull model for rutting prediction of warm-mix asphalt agents: Using hamburg wheel-tracking device results. Transp. Res. Rec. J. Transp. Res. Board 2016, 2575, 206–212. [Google Scholar] [CrossRef]

- Coleri, E.; Harvey, J.T.; Yang, K.; Boone, J.M. Investigation of asphalt concrete rutting mechanisms by X-ray computed tomography imaging and micromechanical finite element modeling. Mater. Struct. 2013, 46, 1027–1043. [Google Scholar] [CrossRef]

- Jeong, K.-D.; Hwang, S.-D.; Lee, S.-J.; Kim, K.W. Investigation of rutting potential of open graded friction course (OGFC) mixes using asphalt pavement analyzer. KSCE J. Civ. Eng. 2011, 15, 1259. [Google Scholar] [CrossRef]

- Laukkanen, O.-V.; Soenen, H.; Pellinen, T.; Heyrman, S.; Lemoine, G. Creep-recovery behavior of bituminous binders and its relation to asphalt mixture rutting. Mater. Struct. 2015, 48, 4039–4053. [Google Scholar] [CrossRef]

- Cao, W.; Liu, S.; Li, Y.; Xue, Z. Rutting-resistance performance of SBS and anti-rutting additive composite-modified asphalt-concrete mixtures. J. Test. Eval. 2016, 44, 921–929. [Google Scholar] [CrossRef]

- Polaczyk, P.; Ma, Y.; Xiao, R.; Hu, W.; Jiang, X.; Huang, B. Characterization of aggregate interlocking in hot mix asphalt by mechanistic performance tests. Road Mater. Pavement Des. 2021, 1–16. [Google Scholar] [CrossRef]

- Chomicz-Kowalska, A.; Gardziejczyk, W.; Iwański, M.M. Analysis of IT-CY stiffness modulus of foamed bitumen asphalt concrete compacted at 95 °C. Procedia. Eng. 2017, 172, 550–559. [Google Scholar] [CrossRef]

- Du, Y.; Chen, J.; Han, Z.; Liu, W. A review on solutions for improving rutting resistance of asphalt pavement and test methods. Constr. Build. Mater. 2018, 168, 893–905. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Santos, S.; dos Bueno, M.; Kuentzel, S.; Hugener, M.; Partl, M.N. Influence of short and long term aging on chemical, microstructural and macro-mechanical properties of recycled asphalt mixtures. Constr. Build. Mater. 2014, 51, 414–423. [Google Scholar] [CrossRef]

- European Standard: 12697-26:2018 Bituminous Mixtures—Test Methods—Part 26: Stiffness. Available online: https://www.sis.se/api/document/preview/80004874/ (accessed on 17 April 2021).

- Walubita, L.F.; Fuentes, L.; Prakoso, A.; Rico Pianeta, L.M.; Komba, J.J.; Naik, B. Correlating the HWTT laboratory test data to field rutting performance of in-service highway sections. Constr. Build. Mater. 2020, 236, 117552. [Google Scholar] [CrossRef]

- Özen, H. Rutting evaluation of hydrated lime and SBS modified asphalt mixtures for laboratory and field compacted samples. Constr. Build. Mater. 2011, 25, 756–765. [Google Scholar] [CrossRef]

- Chaturabong, P.; Bahia, H.U. Mechanisms of asphalt mixture rutting in the dry hamburg wheel tracking test and the potential to be alternative test in measuring rutting resistance. Constr. Build. Mater. 2017, 146, 175–182. [Google Scholar] [CrossRef]

- Wang, W.-H.; Huang, C.-W. Establishing indicators and an analytic method for moisture susceptibility and rutting resistance evaluation using a hamburg wheel tracking test. Materials 2020, 13, 3269. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Ni, F.; Gao, L.; Yuan, Q.; Xiao, Y. Evaluating the rutting resistance of asphalt mixtures using an advanced repeated load permanent deformation test under field conditions. Constr. Build. Mater. 2014, 61, 241–251. [Google Scholar] [CrossRef]

- Wang, X.; Gu, X.; Ni, F.; Deng, H.; Dong, Q. Rutting resistance of porous asphalt mixture under coupled conditions of high temperature and rainfall. Constr. Build. Mater. 2018, 174, 293–301. [Google Scholar] [CrossRef]

- Gu, X.; Dong, Q.; Yuan, Q. Development of an innovative uniaxial compression test to evaluate permanent deformation of asphalt mixtures. J. Mater. Civ. Eng. 2015, 27, 04014104. [Google Scholar] [CrossRef]

- Kakade, V.B.; Reddy, M.A.; Reddy, K.S. Rutting performance of hydrated lime modified bituminous mixes. Constr. Build. Mater. 2018, 186, 1–10. [Google Scholar] [CrossRef]

- Das, A.K. Investigation of rutting, fracture and thermal cracking behavior of asphalt mastic containing basalt and hydrated lime fillers. Constr. Build. Mater. 2017, 141, 442–452. [Google Scholar] [CrossRef]

- Hajikarimi, P.; Rahi, M.; Moghadas Nejad, F. Comparing different rutting specification parameters using high temperature characteristics of rubber-modified asphalt binders. Road Mater. Pavement Des. 2015, 16, 751–766. [Google Scholar] [CrossRef]

- Lv, Q. Investigation of the rutting performance of various modified asphalt mixtures using the hamburg wheel-tracking device test and multiple stress creep recovery test. Constr. Build. Mater. 2019, 206, 62–70. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N.; Putman, B.J. Evaluation of rutting resistance in warm-mix asphalts containing moist aggregate. Transp. Res. Rec. J. Transp. Res. Board. 2010, 2180, 75–84. [Google Scholar] [CrossRef]

- European Standard: EN 12607-1:2014 Bitumen and Bituminous Binders—Determination of the Resistance to Hardening under Influence of Heat and Air—Part 1: RTFOT Method. Available online: https://www.sis.se/api/document/preview/104363/ (accessed on 9 April 2021).

- European Standard: EN 12697-30:2019 Bituminous Mixtures—Test Methods—Part 30: Specimen Preparation by Impact Compactor. Available online: https://www.sis.se/api/document/preview/80009154. (accessed on 29 April 2021).

- European Standard: EN 12697-33:2019 Bituminous Mixtures—Test Method—Part 33: Specimen Prepared by Roller Compactor. Available online: https://www.sis.se/api/document/preview/80010375/ (accessed on 17 April 2021).

- European Standard EN 12697-22:2020. Bituminous Mixtures—Test Methods—Part 22: Wheel Tracking. Available online: https://www.sis.se/api/document/preview/80020492/ (accessed on 19 April 2021).

- Kök, B.V.; Çolak, H. Laboratory comparison of the crumb-rubber and SBS modified bitumen and hot mix asphalt. Constr. Build. Mater. 2011, 25, 3204–3212. [Google Scholar] [CrossRef]

- Moreno, F.; Sol, M.; Martín, J.; Pérez, M.; Rubio, M.C. The effect of crumb rubber modifier on the resistance of asphalt mixes to plastic deformation. Mater. Des. 2013, 47, 274–280. [Google Scholar] [CrossRef]

- Poland Technical Requirements: TR-2 2014. Asphalt Pavements on National Roads—Asphalt Mixtures—Part 2. Available online: https://www.gddkia.gov.pl/frontend/web/userfiles/articles/d/dokumenty-techniczne_8162/domenty%20tecniczne/WT2%20cz1.pdf (accessed on 17 April 2021).

- Veeraragavan, A. Dynamic mechanical characterization of asphalt concrete mixes with modified asphalt binders. Mater. Sci. Eng. A. 2011, 528, 6445–6454. [Google Scholar] [CrossRef]

- Gibreil, H.A.; Feng, C.P. Effects of high-density polyethylene and crumb rubber powder as modifiers on properties of hot mix asphalt. Constr. Build. Mater. 2017, 142, 101–108. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Yi-qiu, T. Effect of styrene-butadiene-styrene on the properties of asphalt and stone-matrix-asphalt mixture. J. Mater. Civ. Eng. 2011, 23, 504–510. [Google Scholar] [CrossRef]

| Indexes | Units of Measurement | Type of Binder | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 50/70 | SBSM-5 | CRM-10 | SBSM-2+CRM-10 | ||||||

| (a) | (b) | (a) | (b) | (a) | (b) | (a) | (b) | ||

| Penetration | 0.1 mm | ||||||||

| 5 °C | 11.4 | 8.4 | 8.7 | 6.1 | 8.7 | 6.8 | 7.7 | 5.6 | |

| 15 °C | 32.8 | 20.3 | 20.6 | 16.2 | 19.5 | 14.1 | 16.2 | 13.1 | |

| 25 °C | 58.3 | 44.3 | 40.2 | 30.1 | 40.0 | 27.8 | 30.6 | 24.8 | |

| Softening Point | °C | 50.8 | 56.3 | 78.6 | 77.8 | 60.6 | 68.2 | 70.7 | 77.8 |

| Fraass Breaking Point | °C | −14.7 | −12.9 | −19.3 | −17.3 | −16.1 | −15.5 | −17.9 | −16.5 |

| Dynamic Viscosity | Pa s | ||||||||

| 90 °C | 11.3 | 19.3 | 224.4 | 258.7 | 83.6 | 265.4 | 292.2 | 574.1 | |

| 110 °C | 2.2 | 3.6 | 25.1 | 27.7 | 13.4 | 39.3 | 43.7 | 74.9 | |

| 135 °C | 0.5 | 0.7 | 2.5 | 3.6 | 2.1 | 4.8 | 5.4 | 8.8 | |

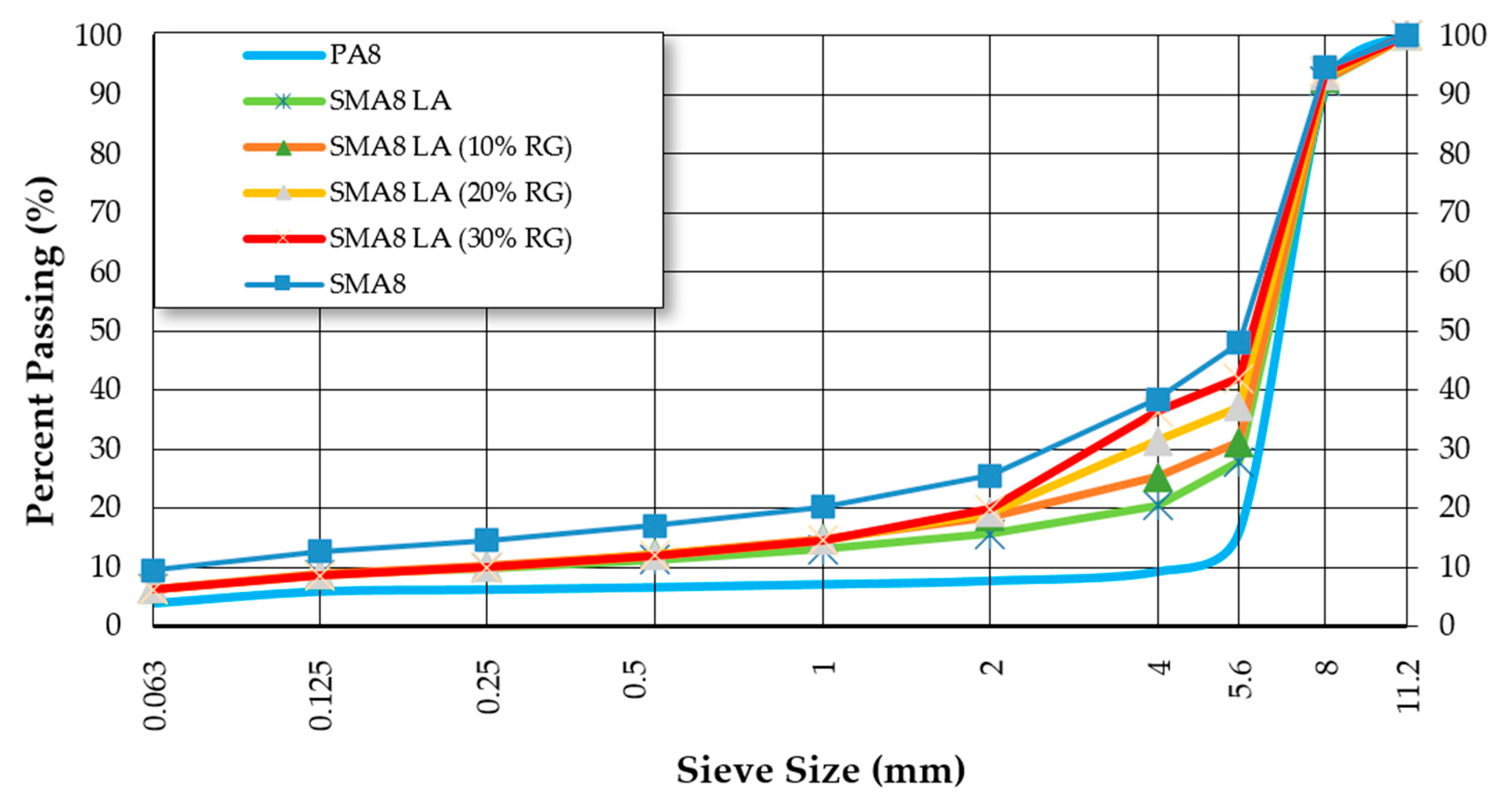

| Properties | Type of Mixture | |||||

|---|---|---|---|---|---|---|

| PA8 | SMA8 | SMA8 LA | SMA8 LA (10% RG) | SMA8 LA (20% RG) | SMA8 LA (30% RG) | |

| Air void content (%) | 23.8 | 2.89 | 10.56 | 11.64 | 11.99 | 15.0 |

| Binder content (%) | 6.3 | 6.8 | 6.8 | 8.0 | 10.0 | 12.0 |

| Bulk density (Mg/m3) | 1.954 | 2.378 | 2.261 | 2.045 | 1.819 | 1.651 |

| Type of Mixture | Type of Binder | Value of Statistical Parameters of Stiffness Modules | |||

|---|---|---|---|---|---|

| Temperature | Mean | Standard Deviation | Coefficient of Variation (%) | ||

| SMA8 | 50/70 | 5 | 8447 | 467.3 | 5.5 |

| 15 | 3679 | 249.0 | 6.7 | ||

| 25 | 1431 | 97.7 | 6.8 | ||

| 35 | 624 | 11.6 | 1.8 | ||

| SBSM-5 | 5 | 8945 | 356.5 | 3.9 | |

| 15 | 4311 | 300.5 | 6.9 | ||

| 25 | 2216 | 139.5 | 6.2 | ||

| 35 | 1065 | 134.6 | 12.64 | ||

| CRM-10 | 5 | 10,183 | 720.7 | 7.0 | |

| 15 | 5314 | 214.4 | 4.0 | ||

| 25 | 2602 | 58.3 | 2.2 | ||

| 35 | 976 | 51.1 | 5.2 | ||

| SBSM-2+CRM-10 | 5 | 10,156 | 707.7 | 6.9 | |

| 15 | 5096 | 133.5 | 2.6 | ||

| 25 | 2693 | 122.9 | 4.5 | ||

| 35 | 1174 | 152.8 | 13.0 | ||

| SMA8 LA | 50/70 | 5 | 7894 | 205.3 | 2.6 |

| 15 | 3207 | 224.1 | 6.9 | ||

| 25 | 1181 | 147.9 | 12.5 | ||

| 35 | 505 | 24.5 | 4.8 | ||

| SBSM-5 | 5 | 6808 | 377.3 | 5.5 | |

| 15 | 3464 | 237.1 | 6.8 | ||

| 25 | 1420 | 90.1 | 6.3 | ||

| 35 | 710 | 21.6 | 3.0 | ||

| CRM-10 | 5 | 6633 | 424.1 | 6.3 | |

| 15 | 3557 | 146.2 | 4.1 | ||

| 25 | 1490 | 33.7 | 2.2 | ||

| 35 | 633 | 20.3 | 3.2 | ||

| SBSM-2+CRM-10 | 5 | 7526 | 345.9 | 4.5 | |

| 15 | 4082 | 317.4 | 7.7 | ||

| 25 | 1754 | 121.1 | 6.9 | ||

| 35 | 910 | 19.2 | 2.1 | ||

| PA8 | 50/70 | 5 | 4840 | 322.1 | 6.6 |

| 15 | 2303 | 120.1 | 5.2 | ||

| 25 | 770 | 34.7 | 4.5 | ||

| 35 | 313 | 12.5 | 4.0 | ||

| SBSM-5 | 5 | 4860 | 355.5 | 7.3 | |

| 15 | 2575 | 163.5 | 6.3 | ||

| 25 | 1092 | 44.0 | 4.0 | ||

| 35 | 419 | 18.5 | 4.4 | ||

| CRM-10 | 5 | 4794 | 173.9 | 3.6 | |

| 15 | 2350 | 83.8 | 3.5 | ||

| 25 | 1176 | 146.9 | 12.4 | ||

| 35 | 307 | 18.0 | 5.8 | ||

| SBSM-2+CRM-10 | 5 | 3901 | 287.1 | 7.3 | |

| 15 | 2067 | 166.1 | 8.1 | ||

| 25 | 1018 | 55.9 | 5.4 | ||

| 35 | 427 | 19.0 | 4.4 | ||

| SMA8 LA (10% RG) | 50/70 | 5 | 2996 | 150.2 | 5.0 |

| 15 | 1126 | 91.1 | 8.0 | ||

| 25 | 291 | 58.5 | 20.1 | ||

| 35 | 184 | 22.0 | 12.0 | ||

| SBSM-5 | 5 | 3537 | 153.2 | 4.3 | |

| 15 | 1712 | 56.4 | 3.2 | ||

| 25 | 769 | 51.7 | 6.7 | ||

| 35 | 483 | 27.6 | 5.6 | ||

| CRM-10 | 5 | 2962 | 161.0 | 5.4 | |

| 15 | 1508 | 94.2 | 6.2 | ||

| 25 | 566 | 70.2 | 12.4 | ||

| 35 | 353 | 26.0 | 7.3 | ||

| SBSM-2+CRM-10 | 5 | 2983 | 195.6 | 6.5 | |

| 15 | 1588 | 41.4 | 2.6 | ||

| 25 | 581 | 47.4 | 8.1 | ||

| 35 | 376 | 25.6 | 6.8 | ||

| SMA8 LA (20% RG) | 50/70 | 5 | 1196 | 71.6 | 5.9 |

| 15 | 563 | 65.1 | 11.5 | ||

| 25 | 112 | 113.0 | 4.8 | ||

| 35 | 43 | 7.4 | 17.6 | ||

| SBSM-5 | 5 | 1484 | 132.7 | 5.4 | |

| 15 | 830 | 56.1 | 6.7 | ||

| 25 | 119 | 7.7 | 6.4 | ||

| 35 | 56 | 11.5 | 20.6 | ||

| CRM-10 | 5 | 1235 | 79.8 | 6.4 | |

| 15 | 602 | 31.3 | 5.2 | ||

| 25 | 85 | 10.0 | 11.8 | ||

| 35 | 52 | 6.3 | 12.1 | ||

| SBSM-2+CRM-10 | 5 | 1202 | 42.0 | 3.4 | |

| 15 | 699 | 36.9 | 5.2 | ||

| 25 | 132 | 21.9 | 16.6 | ||

| 35 | 69 | 12.1 | 17.7 | ||

| SMA8 LA (30% RG) | 50/70 | 5 | 609 | 97.0 | 15.9 |

| 15 | 140 | 15.8 | 11.2 | ||

| 25 | 60 | 12.1 | 20.2 | ||

| 35 | 28 | 5.3 | 19.1 | ||

| SBSM-5 | 5 | 691 | 85.1 | 12.3 | |

| 15 | 132 | 21.6 | 16.4 | ||

| 25 | 90 | 3.3 | 3.7 | ||

| 35 | 35 | 5.2 | 14.9 | ||

| CRM-10 | 5 | 485 | 58.4 | 12.0 | |

| 15 | 96 | 13.9 | 14.4 | ||

| 25 | 54 | 4.3 | 7.9 | ||

| 35 | 27 | 2.9 | 10.8 | ||

| SBSM-2+CRM-10 | 5 | 655 | 53.4 | 8.1 | |

| 15 | 111 | 16.9 | 15.3 | ||

| 25 | 66 | 6.2 | 9.4 | ||

| 35 | 34 | 7.0 | 20.8 | ||

| Type of Mixture | Type of Binder | Stiffness Modules Change (MPa) |

|---|---|---|

| SMA8 LA | 50/70 | 505 (0%)—reference |

| SBSM-5 | 710 (+41%) | |

| CRM-10 | 633 (+25%) | |

| SBSM-2+CRM-10 | 910 (+80%) | |

| SMA8 LA (10%RG) | 50/70 | 184 (−64%) |

| SBSM-5 | 483 (−4%) | |

| CRM-10 | 353 (−30%) | |

| SBSM-2+CRM-10 | 376 (−26%) | |

| SMA8 LA (20%RG) | 50/70 | 43 (−91%) |

| SBSM-5 | 56 (−89%) | |

| CRM-10 | 52 (−90%) | |

| SBSM-2+CRM-10 | 69 (−86%) | |

| SMA8 LA (30%RG) | 50/70 | 28 (−94%) |

| SBSM-5 | 35 (−93%) | |

| CRM-10 | 27 (−95%) | |

| SBSM-2+CRM-10 | 34 (−93%) |

| Effect | Variable: ITCY (MPa); R2 = 0.9692; = 0.96598; Error MS = 195,455 | |||

|---|---|---|---|---|

| SS | MS | F | P | |

| (1) Type of Mixture (L) | 196,457,349 | 196,457,349 | 1005.128 | 0.000000 |

| Type of Mixture (Q) | 4,757,592 | 4,757,592 | 24.341 | 0.000004 |

| (2) Type of Binder (L) | 874,866 | 874,866 | 4.476 | 0.037265 |

| Type of Binder (Q) | 168,650 | 168,650 | 0.863 | 0.355539 |

| (3) Temperature (L) | 206,716,650 | 206,716,650 | 1057.618 | 0.000000 |

| Temperature (Q) | 18,324,926 | 18,324,926 | 93.755 | 0.000000 |

| 1L*2L | 1,654,081 | 1,654,081 | 8.463 | 0.004613 |

| 1L*3L | 100,039,110 | 100,039,110 | 511.827 | 0.000000 |

| 2L*3L | 13,525 | 13,525 | 0.069 | 0.793137 |

| Error | 16,809,128 | 195,455 | ||

| Total SS | 545,815,879 | |||

| Effect | Variable: ITCY (MPa); R2 = 0.9692; = 0.96598; Error MS = 195,455 | |||||

|---|---|---|---|---|---|---|

| Regression Coefficients | Std. Error | t | p-Value | −95% Conf. Lmt | +95% Conf. Lmt | |

| Intercept | 4006.42 | 14,340.78 | 0.2794 | 0.780630 | −24,502.1 | 32,514.95 |

| (1) Type of Mixture (L) | −2221.01 | 518.19 | −4.2861 | 0.000047 | −3251.1 | −1190.89 |

| Type of Mixture (Q) | 89.25 | 18.09 | 4.9337 | 0.000004 | 53.3 | 125.21 |

| (2) Type of Binder (L) | 2117.72 | 1594.14 | 1.3284 | 0.187547 | −1051.3 | 5286.76 |

| Type of Binder (Q) | −41.91 | 45.12 | −0.9289 | 0.355539 | −131.6 | 47.79 |

| (3) Temperature (L) | −777.06 | 68.82 | −11.2914 | 0.000000 | −913.9 | −640.25 |

| Temperature (Q) | 4.37 | 0.45 | 9.6827 | 0.000000 | 3.5 | 5.27 |

| 1L*2L | −68.75 | 23.63 | −2.9091 | 0.004613 | −115.7 | −21.77 |

| 1L*3L | 53.46 | 2.36 | 22.6236 | 0.000000 | 48.8 | 58.16 |

| 2L*3L | 0.95 | 3.61 | 0.2631 | 0.793137 | −6.2 | 8.13 |

| Type of Mixture | Type of Binder | |||

|---|---|---|---|---|

| 50/70 | SBSM-5 | CRM-10 | SBSM-2+CRM-10 | |

| WTS/PRD in air | ||||

| SMA8 | 0.20/11.02 | 0.03/3.47 | 0.06/4.49 | 0.01/4.37 |

| SMA8 LA | 5.48/50.00 | 0.05/3.93 | 0.29/13.57 | 0.06/5.63 |

| PA8 | 37.79/50.00 | 0.61/19.55 | 10.23/50.00 | 1.89/47.87 |

| SMA8 LA (10%RG) | 8.17/50.00 | 0.55/24.37 | 2.24/39.28 | 0.31/16.49 |

| SMA8 LA (20%RG) | 20.78/50.00 | 1.32/29.99 | 5.38/47.04 | 1.27/34.93 |

| SMA8 LA (30%RG) | 31.88/50.00 | 2.11/30.31 | 5.39/50.00 | 2.65/37.52 |

| WTS/PRD in water | ||||

| SMA8 | 0.23/13.94 | 0.04/4.46 | 0.08/5.22 | 0.06/5.12 |

| SMA8 LA | 6.97/50.00 | 0.06/4.45 | 0.40/16.25 | 0.08/7.53 |

| PA8 | 26.36/50.00 | 0.50/17.26 | 6.74/50.00 | 1.66/34.74 |

| SMA8 LA (10%RG) | 8.37/50.00 | 1.08/28.81 | 5.43/50.00 | 1.35/32.99 |

| SMA8 LA (20%RG) | 23.05/50.00 | 1.85/47.86 | 10.76/50.00 | 4.00/50.00 |

| SMA8 LA (30%RG) | 32.82/50.00 | 3.91/50.00 | 10.94/50.00 | 5.02/50.00 |

| Effect | Variable: WTSair; R2 = 0.54327; = 0.4164; Error MS = 59.81792 | |||

| SS | MS | F | P | |

| (1) Type of Mixture (L) | 202.295 | 202.2951 | 3.38185 | 0.082475 |

| Type of Mixture (Q) | 14.643 | 14.6431 | 0.24480 | 0.626749 |

| (2) Type of Binder (L) | 631.904 | 631.9037 | 10.56379 | 0.004443 |

| Type of Binder (Q) | 281.791 | 281.7909 | 4.71081 | 0.043597 |

| 1L*2L | 150.114 | 150.1137 | 2.50951 | 0.130572 |

| Error | 1076.723 | 59.8179 | ||

| Total SS | 2357.469 | |||

| Effect | Variable: PRDair; R2 = 0.61231; = 0.50462; Error MS = 168.3381 | |||

| SS | MS | F | P | |

| (1) Type of Mixture (L) | 3234.400 | 3234.400 | 19.21371 | 0.000358 |

| Type of Mixture (Q) | 655.989 | 655.989 | 3.89685 | 0.063926 |

| (2) Type of Binder (L) | 520.331 | 520.331 | 3.09098 | 0.095719 |

| Type of Binder (Q) | 351.261 | 351.261 | 2.08664 | 0.165775 |

| 1L*2L | 23.677 | 23.677 | 0.14065 | 0.712014 |

| Error | 3030.086 | 168.338 | ||

| Total SS | 7815.744 | |||

| Effect | Variable: WTSw; R2 = 0.63418; = 0.53256; Error MS = 37.379 | |||

| SS | MS | F | P | |

| (1) Type of Mixture (L) | 410.188 | 410.1882 | 10.97376 | 0.003872 |

| Type of Mixture (Q) | 0.450 | 0.4504 | 0.01205 | 0.913810 |

| (2) Type of Binder (L) | 440.681 | 440.6810 | 11.78953 | 0.002963 |

| Type of Binder (Q) | 193.663 | 193.6630 | 5.18106 | 0.035285 |

| 1L*2L | 121.387 | 121.3871 | 3.24747 | 0.088306 |

| Error | 672.822 | 37.3790 | ||

| Total SS | 1839.192 | |||

| Effect | Variable: PRDw; R2 = 0.76691 = 0.70217; Error MS = 108.761 | |||

| SS | MS | F | P | |

| (1) Type of Mixture (L) | 5359.360 | 5359.360 | 49.27651 | 0.000001 |

| Type of Mixture (Q) | 447.183 | 447.183 | 4.11161 | 0.057657 |

| (2) Type of Binder (L) | 276.121 | 276.121 | 2.53878 | 0.128489 |

| Type of Binder (Q) | 204.261 | 204.261 | 1.87807 | 0.187404 |

| 1L*2L | 154.382 | 154.382 | 1.41946 | 0.248965 |

| Error | 1957.697 | 108.761 | ||

| Total SS | 8399.004 | |||

| Effect | Variable: WTSair; R2 = 0.54327; = 0.4164; Pure Error MS = 59.81792 | |||||

| Regression Coefficients | Std. Error | T | p-value | −95% Conf. Lmt | +95% Conf. Lmt | |

| Intercept | 900.203 | 499.5835 | 1.80191 | 0.088333 | −149.383 | 1949.789 |

| (1) Type of Mixture (L) | 29.945 | 18.0549 | 1.65854 | 0.114531 | −7.987 | 67.877 |

| Type of Mixture (Q) | −0.313 | 0.6329 | −0.49477 | 0.626749 | −1.643 | 1.017 |

| (2) Type of Binder (L) | −113.386 | 55.7189 | −2.03496 | 0.056855 | −230.447 | 3.675 |

| Type of Binder (Q) | 3.427 | 1.5787 | 2.17044 | 0.043597 | 0.110 | 6.743 |

| 1L*2L | −1.310 | 0.8268 | −1.58414 | 0.130572 | −3.047 | 0.427 |

| Effect | Variable: PRDair; R2 = 0.61231; = 0.50462; Pure Error MS = 168.3381 | |||||

| Regression Coefficients | Std. Error | t | p-value | −95% Conf. Lmt | +95% Conf. Lmt | |

| Intercept | 1144.160 | 838.0765 | 1.36522 | 0.189005 | −616.573 | 2904.893 |

| (1) Type of Mixture (L) | 33.324 | 30.2881 | 1.10025 | 0.285722 | −30.309 | 96.957 |

| Type of Mixture (Q) | −2.096 | 1.0617 | −1.97404 | 0.063926 | −4.327 | 0.135 |

| (2) Type of Binder (L) | −142.485 | 93.4712 | −1.52438 | 0.144792 | −338.861 | 53.890 |

| Type of Binder (Q) | 3.826 | 2.6484 | 1.44452 | 0.165775 | −1.738 | 9.390 |

| 1L*2L | 0.520 | 1.3870 | 0.37504 | 0.712014 | −2.394 | 3.434 |

| Effect | Variable: PRDair; R2 = 0.61231; = 0.50462; Pure Error MS = 168.3381 | |||||

| Regression Coefficients | Std. Error | t | p-value | −95% Conf. Lmt | +95% Conf. Lmt | |

| Intercept | 747.8221 | 394.9175 | 1.89362 | 0.074464 | −81.869 | 1577.513 |

| (1) Type of Mixture (L) | 22.0991 | 14.2723 | 1.54839 | 0.138930 | −7.886 | 52.084 |

| Type of Mixture (Q) | 0.0549 | 0.5003 | 0.10976 | 0.913810 | −0.996 | 1.106 |

| (2) Type of Binder (L) | −93.2439 | 44.0454 | −2.11699 | 0.048448 | −85.780 | −0.708 |

| Type of Binder (Q) | 2.8406 | 1.2480 | 2.27619 | 0.035285 | 0.219 | 5.463 |

| 1L*2L | −1.1778 | 0.6536 | −1.80207 | 0.088306 | −2.551 | 0.195 |

| Effect | Variable: PRDair; R2 = 0.61231; = 0.50462; Pure Error MS = 168.3381 | |||||

| Regression Coefficients | Std. Error | t | p-value | −95% Conf. Lmt | +95% Conf. Lmt | |

| Intercept | 980.219 | 673.6416 | 1.45511 | 0.162859 | −435.049 | 2395.488 |

| (1) Type of Mixture (L) | 14.923 | 24.3454 | 0.61296 | 0.547568 | −36.225 | 66.071 |

| Type of Mixture (Q) | −1.730 | 0.8534 | −2.02771 | 0.057657 | −3.523 | 0.062 |

| (2) Type of Binder (L) | −16.431 | 75.1317 | −1.54969 | 0.138618 | −274.277 | 41.415 |

| Type of Binder (Q) | 2.917 | 2.1288 | 1.37043 | 0.187404 | −1.555 | 7.390 |

| 1L*2L | 1.328 | 1.1149 | 1.19141 | 0.248965 | −1.014 | 3.671 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pakholak, R.; Plewa, A.; Gardziejczyk, W. Influence of Type of Modified Binder on Stiffness and Rutting Resistance of Low-Noise Asphalt Mixtures. Materials 2021, 14, 2884. https://doi.org/10.3390/ma14112884

Pakholak R, Plewa A, Gardziejczyk W. Influence of Type of Modified Binder on Stiffness and Rutting Resistance of Low-Noise Asphalt Mixtures. Materials. 2021; 14(11):2884. https://doi.org/10.3390/ma14112884

Chicago/Turabian StylePakholak, Raman, Andrzej Plewa, and Wladyslaw Gardziejczyk. 2021. "Influence of Type of Modified Binder on Stiffness and Rutting Resistance of Low-Noise Asphalt Mixtures" Materials 14, no. 11: 2884. https://doi.org/10.3390/ma14112884

APA StylePakholak, R., Plewa, A., & Gardziejczyk, W. (2021). Influence of Type of Modified Binder on Stiffness and Rutting Resistance of Low-Noise Asphalt Mixtures. Materials, 14(11), 2884. https://doi.org/10.3390/ma14112884