Synthesis and Characterization of Anatase TiO2 Microspheres Self-Assembled by Ultrathin Nanosheets

Abstract

1. Introduction

2. Experimental Section

2.1. Instruments and Reagents

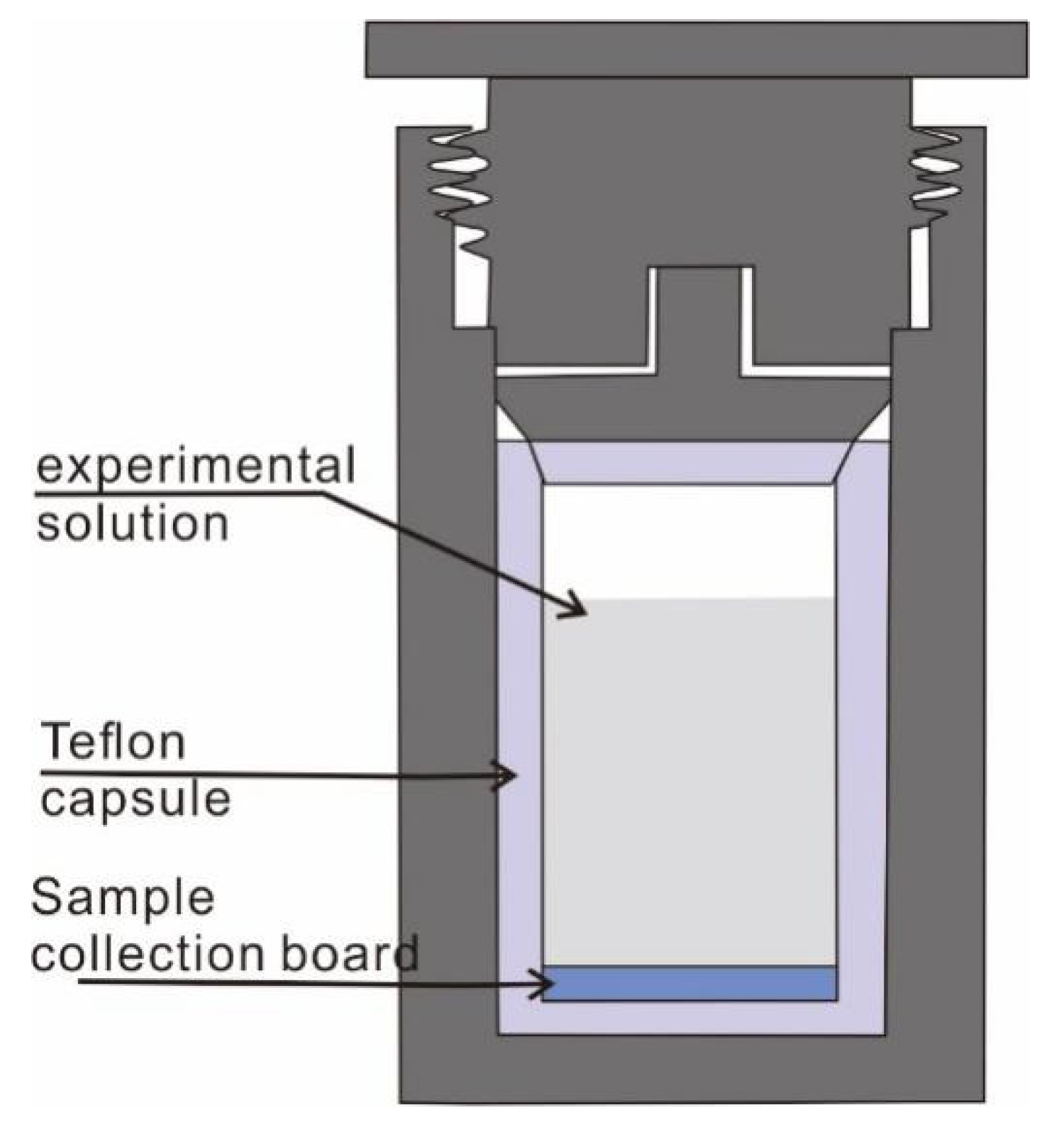

2.2. Synthesis Method

3. Experimental Results and Discussion

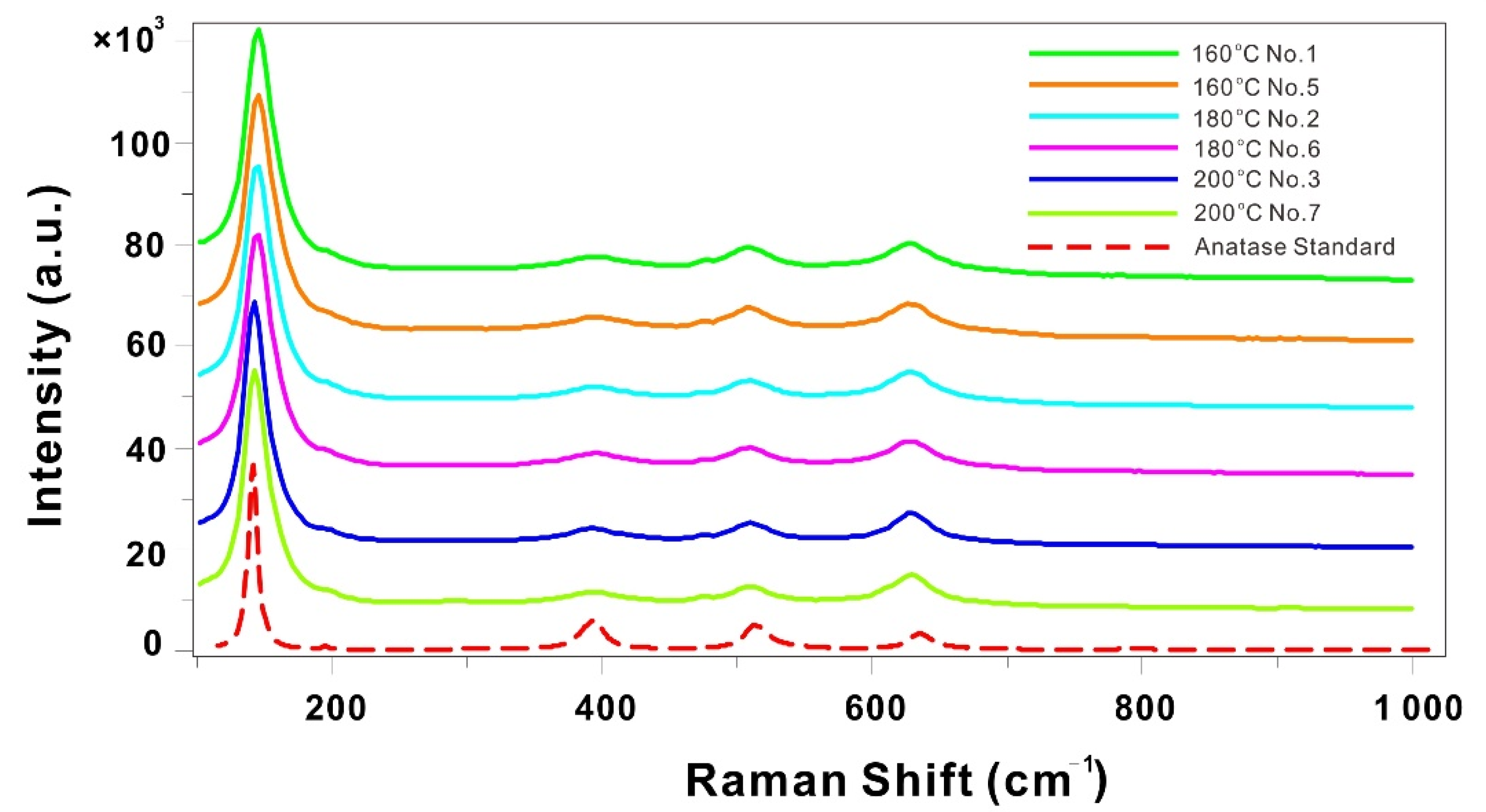

3.1. Raman Analysis of Experimental Products

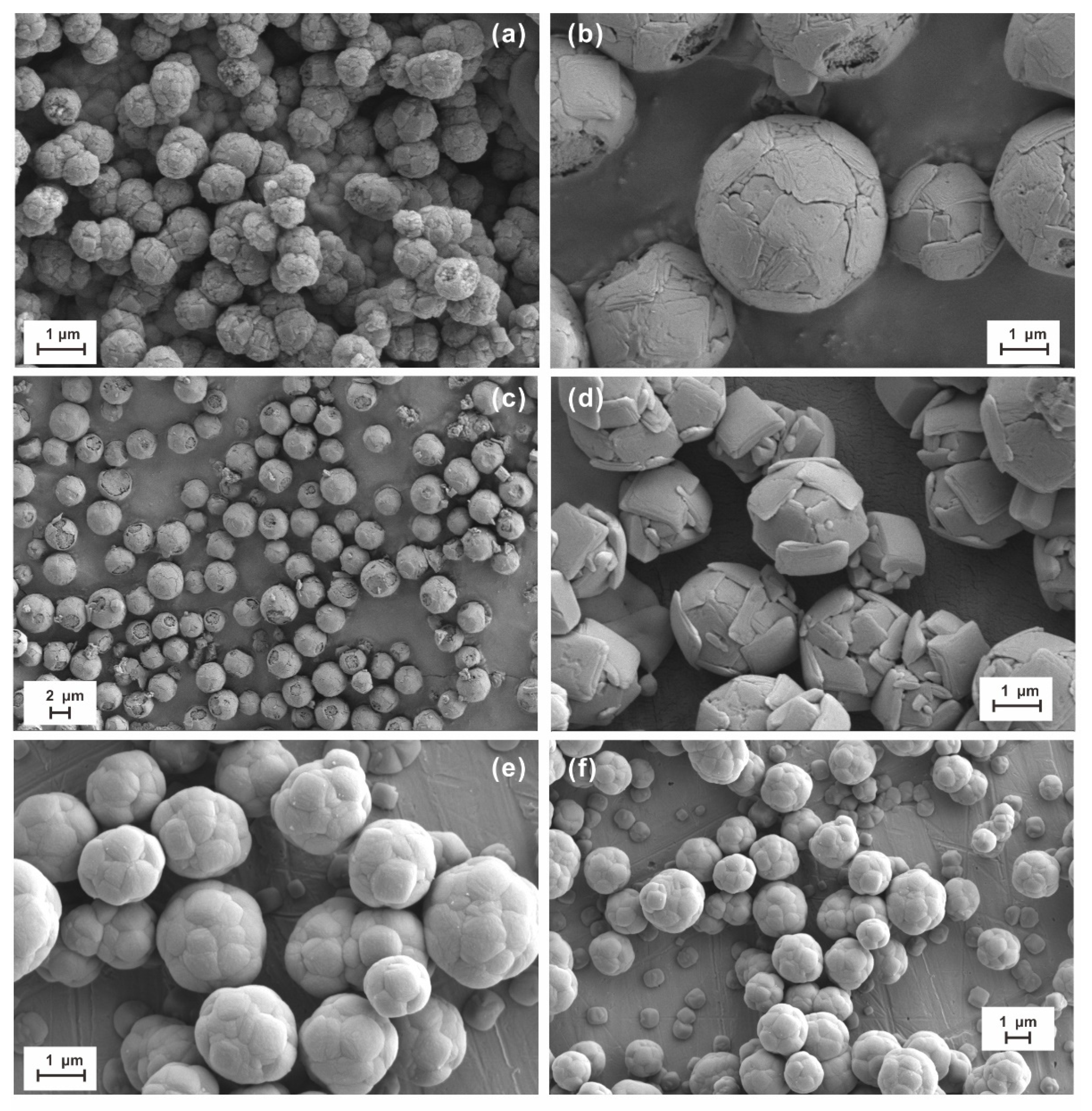

3.2. Temperature Dependence on the Microspheres’ Morphology

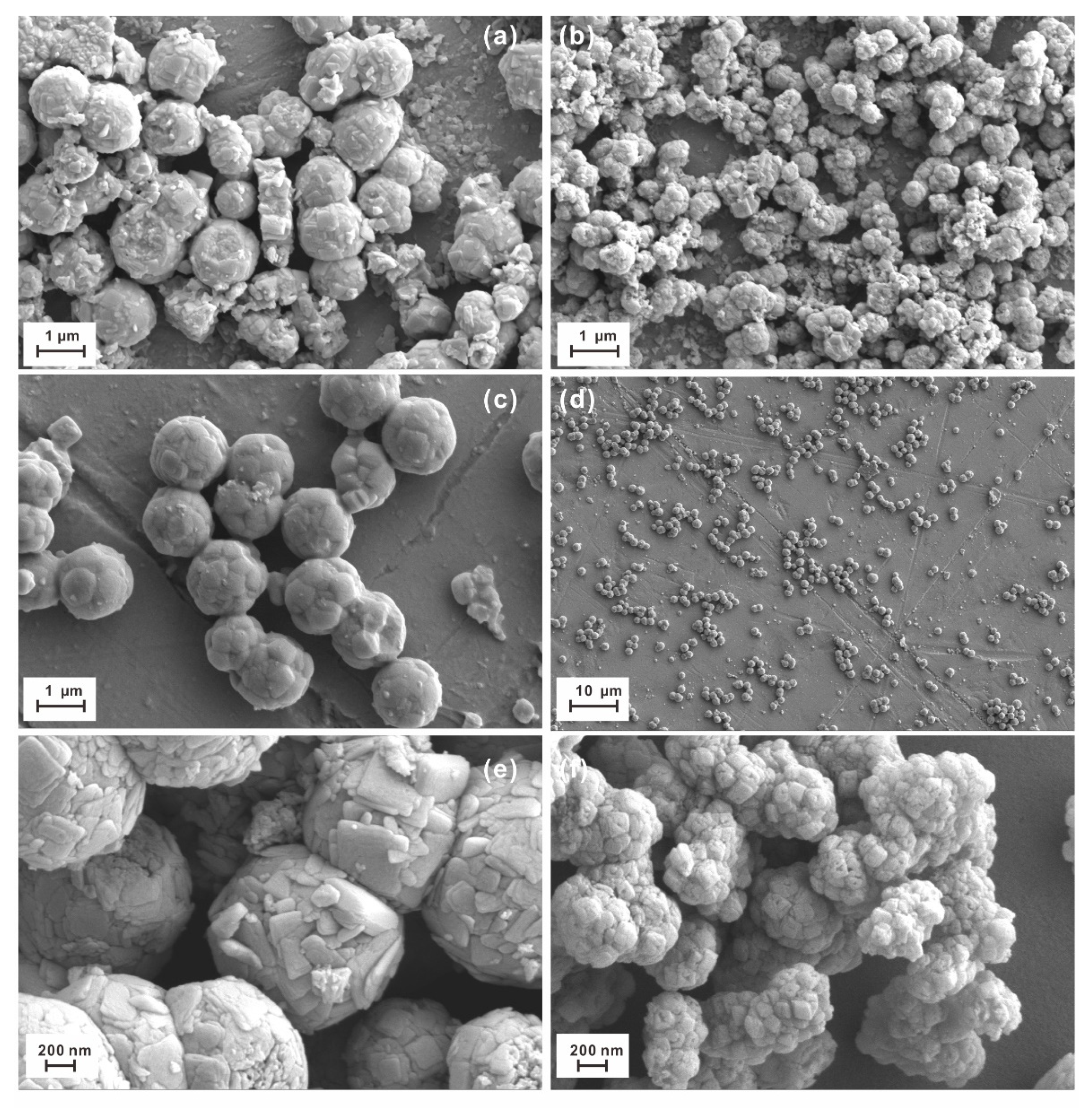

3.3. The Effect of Synthesis Time on the Microspheres’ Morphology

3.4. Comparison of the Synthesis Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, G.; Yu, J.C.; Lu, G.Q.; Cheng, H. Crystal facet engineering of semiconductor photocatalysts: Motivations, advances and unique properties. Chem. Commun. 2011, 47, 6763. [Google Scholar] [CrossRef]

- Wu, Q.P.; Li, D.Z.; Hou, Y.D.; Wu, L.; Fu, X.Z.; Wang, X.X. Study of relationship between surface transient photoconductivity and liquid-phase photocatalytic activity of titanium dioxide. Mater. Chem. Phys. 2007, 102, 53–59. [Google Scholar] [CrossRef]

- Lettieri, S.; Pavone, M.; Fioravanti, A.; Amato, L.S.; Maddalena, P. Charge carrier processes and optical properties in TiO2 and TiO2-based heterojunction photocatalysts: A review. Materials 2021, 14, 1645. [Google Scholar] [CrossRef] [PubMed]

- Schloegl, R. Energy: Fuel for thought. Nat. Mater. 2008, 7, 772–774. [Google Scholar] [CrossRef]

- Gratzel, M. Photoelectrochemical cells. Nature 2001, 414, 338–344. [Google Scholar] [CrossRef]

- Mao, Q.; Liu, M.; Li, Y.; Wei, Y.; Yang, Y.; Huang, Z. Black TiOx films with photothermal-assisted photocatalytic activity prepared by reactive sputtering. Materials 2021, 14, 2508. [Google Scholar] [CrossRef]

- Chen, J.S.; Tan, Y.L.; Li, C.M.; Cheah, Y.L.; Luan, D.; Madhavi, S.; Boey, F.Y.C.; Archer, L.A.; Lou, W.L. Constructing hierarchical spheres from large ultrathin anatase TiO2 nanosheets with nearly 100% exposed (001) facets for fast reversible lithium storage. J. Am. Chem. Soc. 2010, 132, 6124–6130. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Piao, L.Y.; Lu, W.M.; Ju, S.T.; Zhao, L.; Zhou, C.L.; Li, H.L.; Wang, W.J. Flower-like TiO2 nanostructures with exposed {001} facets: Facile synthesis and enhanced photocatalysis. Nanoscale 2010, 2, 1115–1117. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.G.; Sun, C.H.; Qiao, S.Z.; Zou, J.; Liu, G.; Smith, S.C.; Cheng, H.M.; Lu, G.Q. Anatase TiO2 single crystals with a large percentage of reactive facets. Nature 2008, 453, 638–642. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.L.; Chen, B.S.; Shi, K.Y.; He, S.J.; Liu, X.D.; Du, Z.J.; Yang, K.L. Preparation and characterization of nanocrystal grain TiO2 porous microspheres. Appl. Catal. B Environ. 2003, 40, 253–258. [Google Scholar] [CrossRef]

- Naldoni, A.; Bianchi, C.L.; Pirola, C.; Suslick, K.S. Porous TiO2 microspheres with tunable properties for photocatalytic air purification. Ultrason. Sonochem. 2013, 20, 445–451. [Google Scholar] [CrossRef]

- Lee, P.F.; Zhang, X.W.; Sun, D.D.; Du, J.; Leckie, J.O. Synthesis of bimodal porous structured TiO2 microsphere with high photocatalytic activity for water treatment. Colloids Surf. A Physicochem. Eng. Asp. 2008, 324, 202–207. [Google Scholar]

- Yang, W.G.; Li, J.M.; Wang, Y.L.; Feng, Z.; Shi, W.; Wan, F.; Xu, D. A facile synthesis of anatase TiO2 nanosheets-based hierarchical spheres with over 90% {001} facets for dye-sensitized solar cells. Chem. Commun. 2011, 47, 1809–1811. [Google Scholar]

- Zhang, H.; Han, Y.; Liu, X.; Porun, Y.; Hua, S.Q. Anatase TiO2 microspheres with exposed mirror-like plane {001} facets for high performance dye-sensitized solar cells (DSSCs). Chem. Commun. 2010, 46, 8395–8397. [Google Scholar] [CrossRef]

- Ding, S.; Chen, J.S.; Wang, Z.; Cheah, Y.L.; Madhavi, S.; Hu, X.; Lou, X.W. TiO2 hollow spheres with large amount of exposed (001) facets for fast reversible lithium storage. J. Mater. Chem. 2011, 21, 1677–1680. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, X.; Sun, H.; Mashkoor, A. 3D anatase TiO2 hollow microspheres assembled with high-energy {001} facets for lithium-ion batteries. RSC Adv. 2012, 2, 7901–7905. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Ding, X.; Li, W.C. Diverse serpentinization and associated abiotic methanogenesis within multiple types of olivine-hosted fluid inclusions in orogenic peridotite from northern Tibet. Geochim. Cosmochim. Acta 2021, 296, 1–17. [Google Scholar] [CrossRef]

- He, J.J.; Ding, X.; Wang, Y.R.; Sun, W.D. The effects of temperature and concentration on hydrolysis of fluorine-rich titanium complexes in hydrothermal fluids: Constraints on titanium mobility in deep geological processes. Acta Petrol. Sin. 2015, 31, 802–815. [Google Scholar]

- He, J.J.; Ding, X.; Wang, Y.R.; Sun, W.D. The effects of precipitation-aging-re-dissolution and pressure on hydrolysis of fluorine-rich titanium complexes in hydrothermal fluids and its geological implications. Acta Petrol. Sin. 2015, 31, 1870–1878. [Google Scholar]

- Baea, J.C.F.; Mesmer, R.E. The thermodynamics of cation hydrolysis. Am. J. Sci. 1981, 281, 935–962. [Google Scholar]

- Ding, X.; Harlov, D.E.; Chen, B.; Sun, W.D. Fluids, metals, and mineral/ore deposits. Geofluids 2018. [Google Scholar] [CrossRef]

- Ding, X.; He, J.J.; Liu, Z.Y. Experimental studies on crystal growth of anatase under hydrothermal conditions. Earth Sci. 2018, 43, 1763–1772. [Google Scholar]

- Hanaor, D.A.H.; Sorrell, C.C. Review of the anatase to rutile phase transformation. J. Mater. Sci. 2011, 46, 855–874. [Google Scholar] [CrossRef]

- Standard Raman Spectrum of Anatase. Available online: https://rruff.info/anatase/display=default/R070582 (accessed on 1 April 2021).

- Liu, S.H.; Sun, X.D.; Li, J.G.; Li, X.D.; Xiu, Z.M.; Yang, H.; Xue, X.X. Fluorine-and iron-modified hierarchical anatase microsphere photocatalyst for water cleaning: Facile wet chemical synthesis and wavelength-sensitive photocatalytic reactivity. Langmuir 2010, 26, 4546–4553. [Google Scholar] [CrossRef] [PubMed]

| Experiment Number | Concentration of the Solution | Collection Board | Temperature | Synthesis Time | Particle Size |

|---|---|---|---|---|---|

| 1 | 0.04 mol/L K2TiF6 dilute solution | PTFE sheet | 160 °C | 3 h | 1–3 μm |

| 2 | 0.04 mol/L K2TiF6 dilute solution | PTFE sheet | 180 °C | 2 h | 1–2 μm |

| 3 | 0.02 mol/L K2TiF6 dilute solution | PTFE sheet | 200 °C | 2 h | 1–2 μm |

| 4 | 0.04 mol/L K2TiF6 dilute solution | Gold flake | 200 °C | 5 h | 1–2 μm |

| 5 | 0.04 mol/L K2TiF6 dilute solution | Copper flake | 160 °C | 2 h | 0.5–1.5 μm |

| 6 | 0.02 mol/L K2TiF6 dilute solution | Copper flake | 180 °C | 5 h | 0.5–1 μm |

| 7 | 0.04 mol/L K2TiF6 dilute solution | Copper flake | 200 °C | 5 h | 1–2 μm |

| 8 | 0.04 mol/L K2TiF6 dilute solution | Glass sheet | 200 °C | 2 h | 0.8–1 μm |

| 9 | 0.04 mol/L K2TiF6 dilute solution | Glass sheet | 160 °C | 3 h | 0.5–1 μm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di, J.; Yan, H.; Liu, Z.; Ding, X. Synthesis and Characterization of Anatase TiO2 Microspheres Self-Assembled by Ultrathin Nanosheets. Materials 2021, 14, 2870. https://doi.org/10.3390/ma14112870

Di J, Yan H, Liu Z, Ding X. Synthesis and Characterization of Anatase TiO2 Microspheres Self-Assembled by Ultrathin Nanosheets. Materials. 2021; 14(11):2870. https://doi.org/10.3390/ma14112870

Chicago/Turabian StyleDi, Jian, Haibo Yan, Zhuoyu Liu, and Xing Ding. 2021. "Synthesis and Characterization of Anatase TiO2 Microspheres Self-Assembled by Ultrathin Nanosheets" Materials 14, no. 11: 2870. https://doi.org/10.3390/ma14112870

APA StyleDi, J., Yan, H., Liu, Z., & Ding, X. (2021). Synthesis and Characterization of Anatase TiO2 Microspheres Self-Assembled by Ultrathin Nanosheets. Materials, 14(11), 2870. https://doi.org/10.3390/ma14112870