Effects of the Water-Based Foaming Process on the Basic and Rheological Properties of Bitumen 70/100

Abstract

1. Introduction

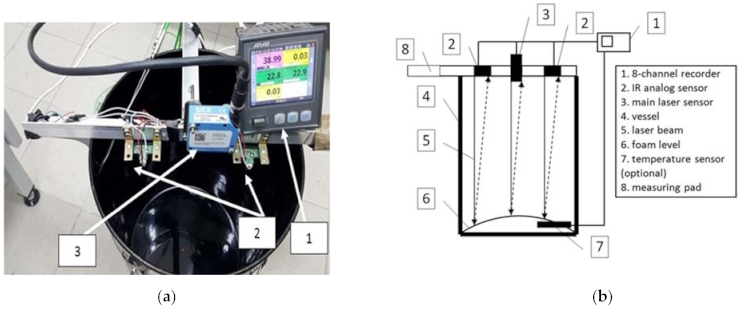

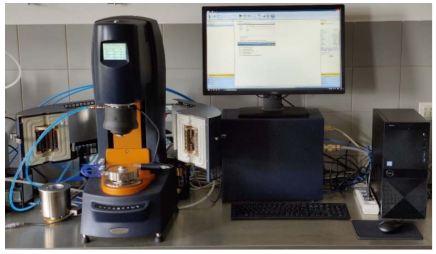

2. Materials and Research Methodology

2.1. Tested Materials

2.2. Experimental Program

- C—correction factor (ratio of measured and actual ER, ERm/ERa),

- HL—half-life (s),

- ts—discharge time (s),

- ERm—measured expansion ratio (immediately after foaming),

- ERa—actual expansion ratio.

- -

- temperature of bitumen: 155 °C,

- -

- temperature of water: 20 °C,

- -

- water flow: 100 g/s,

- -

- foaming time: 5 s,

- -

- air pressure: 500 kPa,

- -

- water pressure: 600 kPa.

- -

- rheological tests: dynamic modulus, dynamic viscosity, and phase angle at temperatures 13 °C, 25 °C, and 40 °C and loading time (0.1–10 Hz) to EN 14770 [48], and

- -

- low-temperature tests to EN 14771 [49].

- -

- The binders before BBR testing were adequately subjected to short-term ageing in the rolling thin-film oven (RTFOT, 2011, Matest, Treviolo, Italy).

3. Results

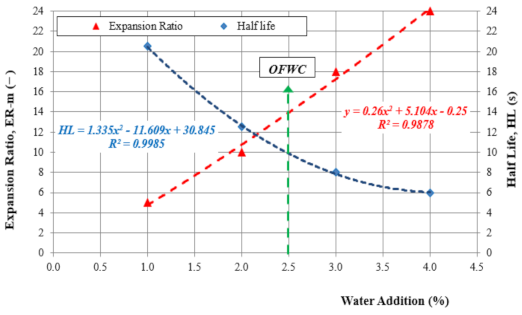

3.1. Properties of Water-Foamed Bitumen 70/100

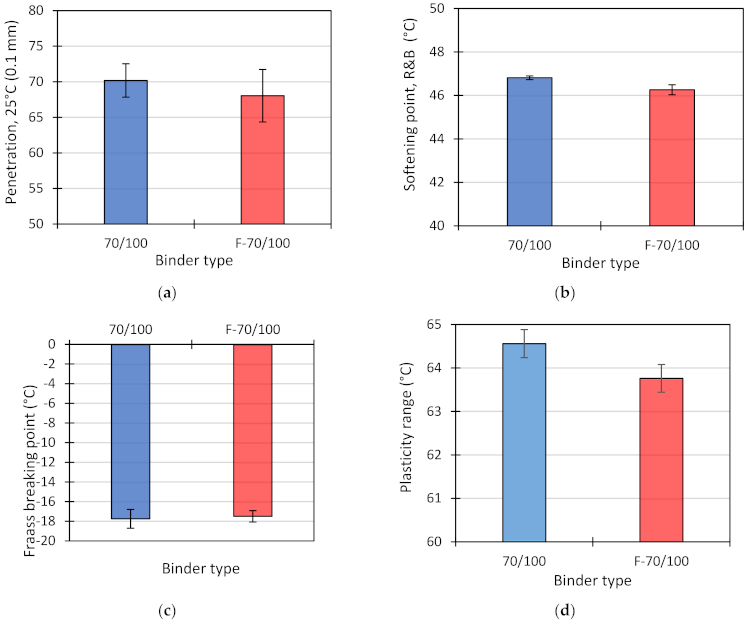

3.2. Basic Properties of Bitumen

- non-foamed binder 70/100 meets the requirements set forth in EN 12591; after foaming, the penetration value of the binder was lower (68.0 (0.1 mm); min = 70.0 (0.1 mm));

- the foaming process had a statistically significant effect only on the softening point, which dropped from 46.8 to 46.3 °C;

- foaming had non-significant impact on penetration and Fraass breaking point,

- the plasticity range of the binder after foaming decreased slightly (from 64.6 to 63.7) as a result of a decrease in the softening point and a slight increase in the Fraass breaking point.

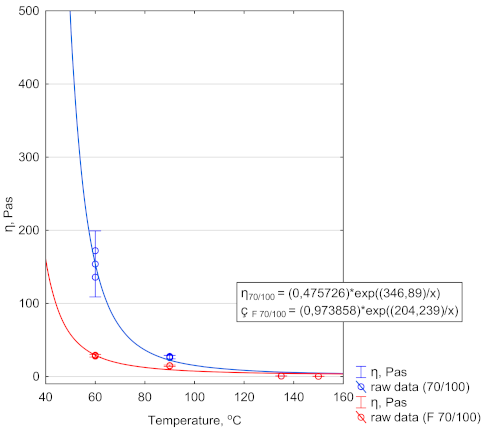

- A, B—material constants of the fluid,

- T—temperature, °C,

- η—dynamic viscosity, Pas.

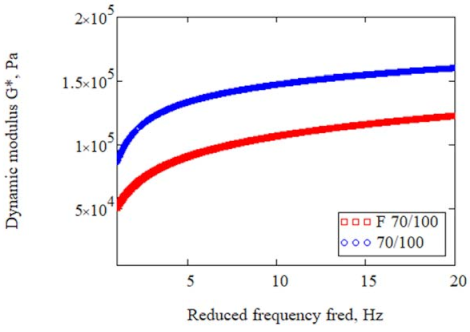

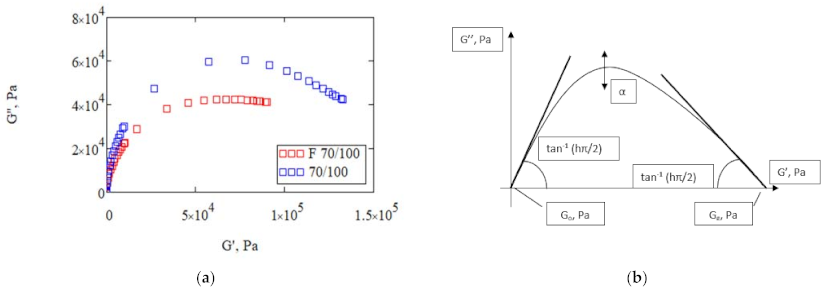

3.3. Rheological and Low-Temperature Tests

- -

- G∞ (equivalent of the static modulus/the loading time tends to infinity),

- -

- G0 (instantaneous modulus/the loading time tends to zero),

- -

- two parabolic dashpots: h and k,

- -

- a linear dashpot β (defined by zero shear viscosity η0),

- -

- t—loading time,

- -

- h—exponent changing from 0 to 1 (h = 0 elastic behaviour, h = 1 viscous behaviour).

- —dynamic modulus in the frequency domain,

- k and h—exponents 0 < k < h < 1 h changing from 0 to 1 (h = 0 elastic response, h = 1 viscous response),

- α, —constants,

- —characteristic time,

- T—test temperature,

- —initial characteristic time,

- A0, A1—parameters of the model.

- -

- k controlled the slope at high values of G″ in the Cole-Cole diagram,

- -

- h controlled the slope at low values of G″ in the Cole-Cole diagram,

- -

- δ controlled the slope at the low temperatures/high frequencies in the |G*| master curve and the height of the pinnacle point of the Cole-Cole diagram,

- -

- β controlled the slope at the high temperatures/low frequencies of the |G*| master curve. It is also correlated with the zero shear viscosity η0.

4. Conclusions

- Water-foaming changes basic characteristics of bitumen such as penetration at 25 °C, softening point and breaking point. In the case of the softening point, this effect is more pronounced and statistically significant.

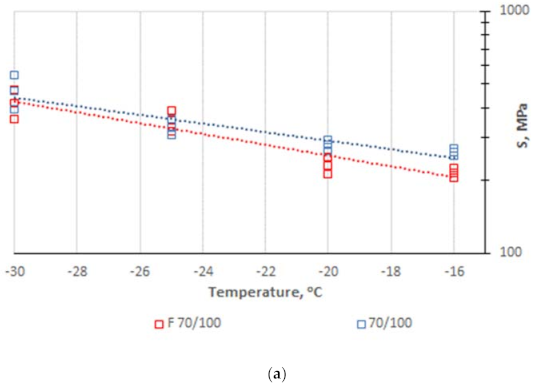

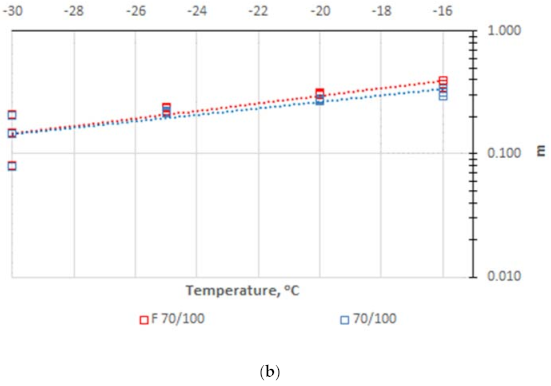

- Water-foaming reduced the critical temperature of the bitumen. The stress read at −16 °C as per EN 14023 [58] was lower for foamed bitumen F 70/100 than for the reference bitumen 70/100.

- The critical temperature was −19.8 °C in F 70/100 and −17.9 °C in 70/100. Therefore, the application of bitumen F 70/100 will ensure that a cold recycled cement-based mixture in which it is incorporated will have improved and more beneficial compliance in the range of low temperatures.

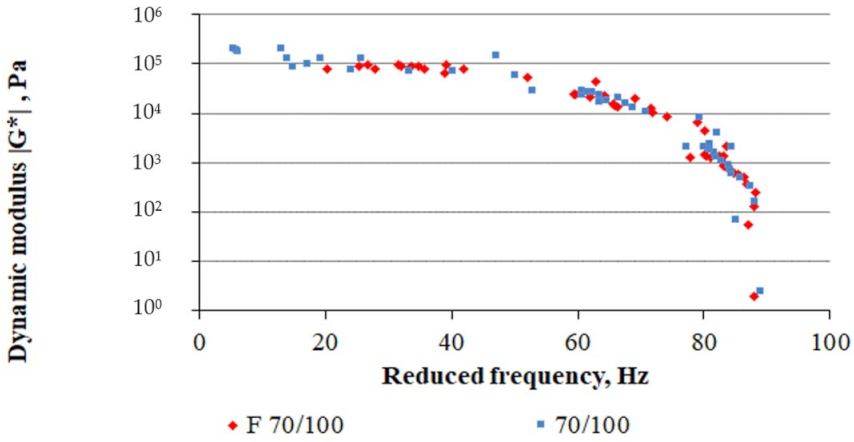

- The foaming process changed the rheological character of the bitumen under test. The reference bitumen 70/100 exhibited considerably higher stiffness at 25 °C range, as demonstrated by small values of the phase angle. Higher values of the phase angle for F 70/100 indicate that the viscous component G″ of the dynamic modulus |G*| will dominate. As a result, this bitumen will be more susceptible to creep.

- The plot of the master curve at 40 °C indicates that, compared with the foamed bitumen, the reference bitumen attains higher values of the dynamic modulus |G*|, hence the higher stiffness over the entire frequency range. The shape of the bitumen 70/100 curve suggests that this bitumen type attains elastic state much faster than F 70/100.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jenkins, K.J. Mix Design Considerations for Cold and Half-Warm Bituminous Mixes with Emphasis on Foamed Bitumen. Ph.D. Thesis, Department of Civil Engineering, Faculty of Engineering, University of Stellenbosch, Stellebosch, South Africa, 2000. [Google Scholar]

- Muthen, K.M. Foamed asphalt mixes. mix design procedure. In Contract Report CR 98/077; SABITA Ltd&CSIR Transportek: Pretoria, South Africa, 2009. [Google Scholar]

- Iwański, M.; Chomicz-Kowalska, A. Evaluation of the effect of using foamed bitumen and bitumen emulsion in cold recycling technology. In Proceedings of the 3rd International Conference on Transportation Infrastructure (ICTI), Sustainability, Eco-Efficiency and Conservation in Transportation Infrastructure Asset Management, Pisa, Italy, 22–25 April 2014; Taylor and Francis: Abington, UK, 2014; Volume 8, pp. 69–76. [Google Scholar]

- Saleh, M. Characterization of Foam Bitumen Quality and the Mechanical Properties of Foam Stabilized Mixes; University of Canterbury Research Repository: Christchurch, New Zealand, 2006. [Google Scholar]

- Wirtgen. Wirtgen Cold Recycling Technology, 1st ed.; Wirtgen GmbH: Windhagen, Germany, 2012. [Google Scholar]

- Mallick, R.B.; Hendrix, G. Use of foamed asphalt in recycling incinerator ash for construction of stabilized base course. Resour. Conserv. Recycl. 2004, 42, 239–248. [Google Scholar] [CrossRef]

- Iwański, M.; Cholewińska, M. Application of the foamed bitumen and bitumen emulsion to the road base mixes in the deep cold recycling technology. Balt. J. Road Bridge Eng. 2014, 11, 291–301. [Google Scholar] [CrossRef]

- Yan, J.; Ni, F.; Yang, M.; Li, J. An experimental study on fatigue properties of emulsion and foam cold recycled mixes. Constr. Build. Mater. 2010, 24, 2151–2156. [Google Scholar] [CrossRef]

- Iwański, M.; Chomicz-Kowalska, A.; Maciejewski, K. Application of synthetic wax for improvement of foamed bitumen parameters. Constr. Build. Mater. 2015, 83, 62–69. [Google Scholar] [CrossRef]

- Iwański, M.M.; Chomicz-Kowalska, A.; Maciejewski, K. Impact of additives on the foamability of a road paving bitumen. IOP Conf. Ser. Mater. Sci. Eng. 2019, 603, 1–10. [Google Scholar] [CrossRef]

- Buczyński, P.; Iwański, M. Inactive Mineral filler as a stiffness modulus regulator in foamed bitumen-modified recycled base layers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 1–9. [Google Scholar] [CrossRef]

- Mazurek, G.; Iwański, M. Multidimensional analysis of the effects of waste materials on physical and mechanical properties of recycled mixtures with foamed bitumen. Appl. Sci. 2018, 8, 282. [Google Scholar] [CrossRef]

- Stefańczyk, B.; Mieczkowski, P. Mieszanki Mineralno-Asfaltowe: Wykonawstwo i Badania. (Bituminous Mixtures: Performance and Research); WKiŁ: Warszawa, Poland, 2008; p. 322. (In Polish) [Google Scholar]

- Piłat, J.; Radziszewski, P. Nawierzchnie Asfaltowe: Podręcznik Akademicki. (Asphalt Pavements; Academic Handbook); WKiŁ: Warszawa, Poland, 2010. (In Polish) [Google Scholar]

- Pszczola, M.; Jaczewski, M.; Rys, D.; Jaskula, P.; Szydlowski, C. Evaluation of asphalt mixture low-temperature performance in bending beam creep test. Materials 2018, 11, 100. [Google Scholar] [CrossRef]

- Leng, Z.; Gamez, A.; Al-Qadi, I.L. Mechanical property characterization of warm-mix asphalt prepared with chemical additives. J. Mater. Civ. Eng. 2014, 26, 304–311. [Google Scholar] [CrossRef]

- Cheraghian, G.; Cannone Falchetto, A.; You, Z.; Chen, S.; Kim, Y.S.; Westerhoff, J.; Moon, K.H.; Wistuba, M.P. Warm mix asphalt technology: An up to date review. J. Clean. Prod. 2020, 268, 122128. [Google Scholar] [CrossRef]

- Jenkins, K.J.; de Groot, J.L.A.; Van de Ven, M.F.C.; Molenaar, A. Half-warm foamed bitumen treatment, a new process. In Proceedings of the 7th Conference on Asphalt Pavements for Southern Africa, Victoria Falls, Zimbabwe, 29 August–2 September 1999. [Google Scholar]

- Van De Ven, M.F.C.; Jenkins, K.J.; Voskuilen, J.L.M.; Van De Beemt, R. Development of (half-) warm foamed bitumen mixes: State of the art. Int. J. Pavement Eng. 2007, 8, 163–175. [Google Scholar] [CrossRef]

- Chomicz-Kowalska, A.; Gardziejczyk, W.; Iwański, M.M. Analysis of IT-CY stiffness modulus of foamed bitumen asphalt concrete compacted at 95 degrees C. Procedia Eng. 2017, 172, 550–559. [Google Scholar] [CrossRef]

- Mrugała, J.; Iwański, M.M. Resistance to permanent deformation of asphalt concrete with F-T wax modified foamed bitumen. Procedia Eng. 2015, 108, 459–466. [Google Scholar] [CrossRef]

- Król, J.; Kowalski, K.; Radziszewski, P. Rheological behavior of n-alkane modified bitumen in aspect of Warm Mix Asphalt technology. Constr. Build. Mater. 2015, 93, 703–710. [Google Scholar] [CrossRef]

- Yu, X.; Leng, Z.; Wang, Y.; Lin, S. Characterization of the effect of foaming water content on the performance of foamed crumb rubber modified asphalt. Constr. Build. Mater. 2014, 67, 279–284. [Google Scholar] [CrossRef]

- Vaiana, R.; Iuele, T.; Gallelli, V.; Tighe, S.L. Warm mix asphalt by water-containing methodology: A laboratory study on workability properties versus micro-foaming time. Can. J. Civ. Eng. 2014, 41, 183–190. [Google Scholar] [CrossRef]

- Iwański, M.M. Synergistic Effect of F–T synthetic wax and surface-active agent content on the properties and foaming characteristics of bitumen. Materials 2021, 14, 300. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Y.; Luo, T. Impacts of water content on rheological properties and performance-related behaviours of foamed war-mix asphalt. Constr. Build. Mater. 2013, 48, 203–209. [Google Scholar] [CrossRef]

- Iwański, M.M.; Chomicz-Kowalska, A.; Maciejewski, K. Resistance to moisture-induced damage of half-warm-mix asphalt concrete with foamed bitumen. Materials 2020, 13, 654. [Google Scholar] [CrossRef]

- Hailesilassie, B.W.; Hugener, M.; Partl, M.N. Influence of foaming water content on foam asphalt mixtures. Constr. Build. Mater. 2015, 85, 65–77. [Google Scholar] [CrossRef]

- Cholewińska, M.; Iwański, M.; Mazurek, G. The impact of aging on the bitumen stiffness modulus using the CAM Model. Balt. J. Road Bridge Eng. 2018, 13, 34–39. [Google Scholar] [CrossRef]

- Iwański, M.; Mazurek, G.; Buczyński, P.; Zapała-Sławeta, J. Multi-dimensional analysis of the foaming process impact on 50/70 bitumen ageing. Constr. Build. Mater. 2020, 266, 1–15. [Google Scholar] [CrossRef]

- Dong, F.; Yu, X.; Liang, X.; Ding, G.; Wei, J. Influence of foaming water and aging process on the properties of foamed asphalt. Constr. Build. Mater. 2017, 153, 866–874. [Google Scholar] [CrossRef]

- Chomicz-Kowalska, A.; Gardziejczyk, W.; Iwański, M.M. Moisture resistance and compactibility of asphalt concrete produced in half-warm mix asphalt technology with foamed bitumen. Constr. Build. Mater. 2016, 15, 108–118. [Google Scholar] [CrossRef]

- Zhang, H.L.; Yu, J.Y.; Feng, Z.G.; Xue, L.H.; Wu, S.P. Effect of Aging on the Morphology of Bitumen by Atomic Force Microscopy: Effect of aging on morphology of bitumen. J. Microsc. 2012, 246, 11–19. [Google Scholar] [CrossRef]

- Yu, X.; Burnham, N.A.; Tao, M. Surface microstructure of bitumen characterized by atomic force microscopy. Adv. Interface Sci. 2015, 218, 17–33. [Google Scholar] [CrossRef]

- Dong, F.; Yu, X.; Wang, T.; Yin, L.; Li, N.; Si, J.; Li, J. Influence of base asphalt aging levels on the foaming characteristics and rheological properties of foamed asphalt. construction and building materials. Constr. Build. Mater. 2018, 177, 43–50. [Google Scholar] [CrossRef]

- Iwański, M.M. Effect of Hydrated Lime on Indirect Tensile Stiffness Modulus of Asphalt Concrete Produced in Half-Warm Mix Technology. Materials 2020, 13, 4731. [Google Scholar] [CrossRef] [PubMed]

- General Directorate for National Roads and Motorways. WT-2. Technical Guidelines 2: Asphalt Pavements for National Roads. Part I: Asphaltmixes; General Directorate for National Roads and Motorways: Warsaw, Poland, 2014; p. 48. [Google Scholar]

- Judycki, J.; Jaskuła, P.; Pszczoła, M.; Alenowicz, J.; Dołżycki, B.; Jaczewski, M.; Ryś, D.; Stienss, M. Katalog Typowych Konstrukcji Nawierzchni Podatnych i Półsztywnych (Catalogue of Typical Flexible and Semi-Rigid Pavement Constructions); GDDKiA: Warsaw, Poland, 2014; p. 112. (In Polish) [Google Scholar]

- Comite Europeen de Normalisation. EN 1426:2015-08. Bitumen and Bituminous Binders—Determination of Needle Penetration; Comite Europeen de Normalisation: Brussels, Belgium, 2015. [Google Scholar]

- Comite Europeen de Normalisation. EN 1427:2015-08. Bitumen and Bituminous Binders—Determination of Softening Point—Ring and Ball Method; Comite Europeen de Normalisation: Brussels, Belgium, 2015. [Google Scholar]

- Comite Europeen de Normalisation. EN 12593:2015-08. Bitumen and Bituminous Binders—Determination of the Fraass Breaking Point; Comite Europeen de Normalisation: Brussels, Belgium, 2015. [Google Scholar]

- Comite Europeen de Normalisation. EN 13302-2018. Bitumen and Bituminous Binders-Determination of Dynamic Viscosity of Bituminous Binder Using a Rotating Spindle Apparatus Viscosity of Bituminous Binder Using a Rotating Spindle Apparatus; Comite Europeen de Normalisation: Brussels, Belgium, 2018. [Google Scholar]

- Comite Europeen de Normalisation. EN 12594:2014-12. Bitumen and Bituminous Binders—Preparation of Test Samples; Comite Europeen de Normalisation: Brussels, Belgium, 2014. [Google Scholar]

- Iwański, M.; Mazurek, G.; Buczyński, P. Bitumen foaming optimisation process on the basis of rheological properties. Materials 2018, 11, 1854. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Arguelles, G.; Giustozzi, F.; Crispino, M.; Flintsch, G.W. Investigating physical and rheological properties of foamed bitumen. Constr. Build. Mater. 2014, 72, 423–433. [Google Scholar] [CrossRef]

- Saleh, M.F. Effect of rheology on the bitumen foamability and mechanical properties of foam bitumen stabilised mixes. Int. J. Pavement Eng. 2007, 8, 99–110. [Google Scholar] [CrossRef]

- Newcomb, D.E.; Arambul, E.; Yin, F.; Zhang, J.; Bhasin, A.; Li, W.; Arega, Z. Properties of Foamed Asphalt for Warm Mix Asphalt Applications; Transportation Research Board: Washington, DC, USA, 2015. [Google Scholar]

- Comite Europeen de Normalisation. EN 14770, Bitumen and Bituminous Binders—Determination of Complex Shear Modulus and Phase Angle. Dynamic Shear Rheometer (DSR); Comite Europeen de Normalisation: Brussels, Belgium, 2012. [Google Scholar]

- Comite Europeen de Normalisation. EN 14771, Bitumen and Bituminous Binders—Determination of The Flexural Creep Stiffnes—Bending Beam Rheometer (BBR); Comite Europeen de Normalisation: Brussels, Belgium, 2012. [Google Scholar]

- Petersen, J.C.; Strategic Highway Research Program (U.S.). Binder Characterization and Evaluation; National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Olard, F.; Di Benedetto, H. General “2S2P1D” model and relation between the linear viscoelastic behaviours of bituminous binders and mixes. Road Mater. Pavement Des. 2003, 4, 185–224. [Google Scholar]

- Iwański, M.; Mazurek, G. Applying of 2S2P1D model for assessing viscoelastic properties of bituminous binder extracted from SMA mixture with hydrated lime addition. Cem. Lime Concr. 2018, 23, 124–136. [Google Scholar]

- Pilat, J.; Król, J.; Błażejowski, K.; Kowalski, K.; Sarnowski, M. Badania Sztywności Pełzania Asfaltów w Reometrze Zginanej Belki (BBR)”. (Research on the Creep Stiffness of Bitumen in the Beam Bending Rheometer (BBR)), Drogownictwo (Road Construction); Stowarzyszenie Inżynierów i Techników Komunikacji Rzeczpospolitej Polskiej: Warsaw, Poland, 2010; pp. 75–80. [Google Scholar]

- Piasta, Z.; Lenarcik, A. Methods of statistical multi-criteria optimization. In Optimization Methods for Material Design of Cement-based Composites; CRC Press: Boca Raton, FL, USA, 1998; pp. 45–59. [Google Scholar]

- Koronacki, J.; Mielniczuk, J. Statystyka dla Studentów Kierunków Technicznych i Przyrodniczych. (Statistics for Technical and Natural Sciences Students); Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 2004. (In Polish) [Google Scholar]

- Iwański, M.; Mazurek, G. The effect of hydrated lime on the rheological properties of extracted bitumen from stone mastic asphalt. Cem. Lime Concr. 2014, 2014, 378–383. [Google Scholar]

- Yusoff, N.I. Modelling the Linear Viscoelastic Rheological Properties of Bituminous Binders; University of Nottingham: Nottingham, UK, 2012. [Google Scholar]

- Comite Europeen de Normalisation. EN 14023:2011, Bitumen qnd Bituminous Binders. Specification Framework for Polymer Modified Bitumens; Comite Europeen de Normalisation: Brussels, Belgium, 2011. [Google Scholar]

- Schramm, G. Reologia: Podstawy i Zastosowania, (Rheology: Fundamentals and applications); Ośrodek Wydawnictw Naukowych PAN: Poznan, Poland, 1998. [Google Scholar]

- Benker, H. Practical Use of Mathcad®: Solving Mathematical Problems with a Computer Algebra System; Springer: London, UK, 1999. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Yusoff, N.I.; Mounier, D.; Marc-Stéphane, G.; Rosli Hainin, M.; Airey, G.D.; Di Benedetto, H. Modelling the rheological properties of bituminous binders using the 2S2P1D Model. Constr. Build. Mater. 2013, 38, 395–406. [Google Scholar] [CrossRef]

- Kim, Y.R. Modeling of Asphalt Concrete; ASCE Press: Reston, VA, USA; McGraw-Hill: New York, NY, USA, 2009. [Google Scholar]

- Read, J.; Whiteoak, D.; Hunter, R.N. The Shell Bitumen Handbook, 5th ed.; Thomas Telford: London, UK, 2003. [Google Scholar]

| Property | Test Method | Unit of Measure | Result |

|---|---|---|---|

| Penetration at 25 °C | EN 1426 [39] | 0.1 mm | 70 |

| Softening point TR&B | EN 1427 [40] | °C | 47 |

| Fraass breaking point | EN 12593 [41] | °C | −18 |

| Dynamic viscosity at: | EN 13302:2011 [42] | Pa∙s | |

| 60 °C | 154 | ||

| 90 °C | 27 | ||

| 135 °C | 0.9 |

| Binder Type | Pen (0.1 mm) | TR&B (°C) | TFraass (°C) | |||

|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | |

| 70/100 | 70.2 | 2.346 | 46.8 | 0.085 | −17.8 | 0.957 |

| F 70/100 | 68.0 | 3.690 | 46.3 | 0.230 | −17.5 | 0.577 |

| variable: Pen | Repeatability Error | p (α = 0.05) |

| Binder | 9.600 | 0.105 |

| variable: TR&B | Repeatability | p (α = 0.05) |

| Binder | 0.030 | <0.001 |

| variable: TFraass | Repeatability | p (α = 0.05) |

| Binder | 0.625 | 0.670 |

| Bitumen | S(60) = 300 (MPa) T(S) 60 (°C) | m(60) = 0.3 T(m) 60 (°C) | S(T)−16 (MPa) |

|---|---|---|---|

| 70/100 | −19.2 | −17.9 | 262 |

| F 70/100 | −21.3 | −19.8 | 215 |

| Bitumen | 2S2P1D Model Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| δ | k | h | β/η0 | Go/G∞ | τ | A0/A1 | R2 | RMSE | |

| (-) | (-) | (-) | (-)/Pas | (Pa) | (s) | (-) | (-) | (%) | |

| F 70/100 | 1.7 | 0.13 | 0.26 | 172.3/1 × 107 | 3.5210−5/8.93 × 105 | 0.065 | −0.201/2.5 × 10−3 | 0.97 | 9.2 |

| 70/100 | 2.01 | 0.28 | 0.56 | 12.6/2.97 × 107 | 0.027/2.37 × 106 | 0.1 | −0.22/0.158 | 0.99 | 14.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iwański, M.; Chomicz-Kowalska, A.; Mazurek, G.; Buczyński, P.; Cholewińska, M.; Iwański, M.M.; Maciejewski, K.; Ramiączek, P. Effects of the Water-Based Foaming Process on the Basic and Rheological Properties of Bitumen 70/100. Materials 2021, 14, 2803. https://doi.org/10.3390/ma14112803

Iwański M, Chomicz-Kowalska A, Mazurek G, Buczyński P, Cholewińska M, Iwański MM, Maciejewski K, Ramiączek P. Effects of the Water-Based Foaming Process on the Basic and Rheological Properties of Bitumen 70/100. Materials. 2021; 14(11):2803. https://doi.org/10.3390/ma14112803

Chicago/Turabian StyleIwański, Marek, Anna Chomicz-Kowalska, Grzegorz Mazurek, Przemysław Buczyński, Małgorzata Cholewińska, Mateusz M. Iwański, Krzysztof Maciejewski, and Piotr Ramiączek. 2021. "Effects of the Water-Based Foaming Process on the Basic and Rheological Properties of Bitumen 70/100" Materials 14, no. 11: 2803. https://doi.org/10.3390/ma14112803

APA StyleIwański, M., Chomicz-Kowalska, A., Mazurek, G., Buczyński, P., Cholewińska, M., Iwański, M. M., Maciejewski, K., & Ramiączek, P. (2021). Effects of the Water-Based Foaming Process on the Basic and Rheological Properties of Bitumen 70/100. Materials, 14(11), 2803. https://doi.org/10.3390/ma14112803