Effect of Third-Stage Heat Treatments on Microstructure and Properties of Dual-Phase Titanium Alloy

Abstract

1. Introduction

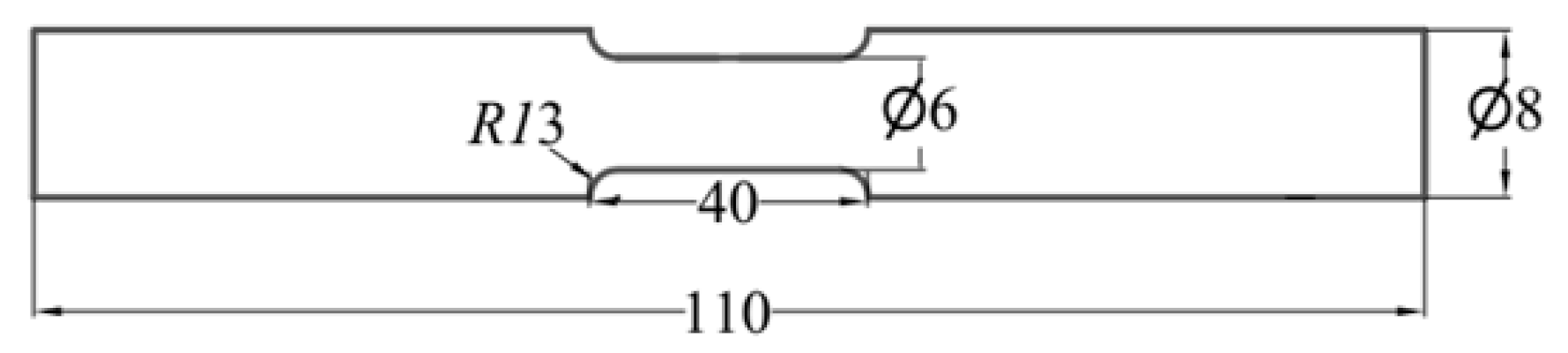

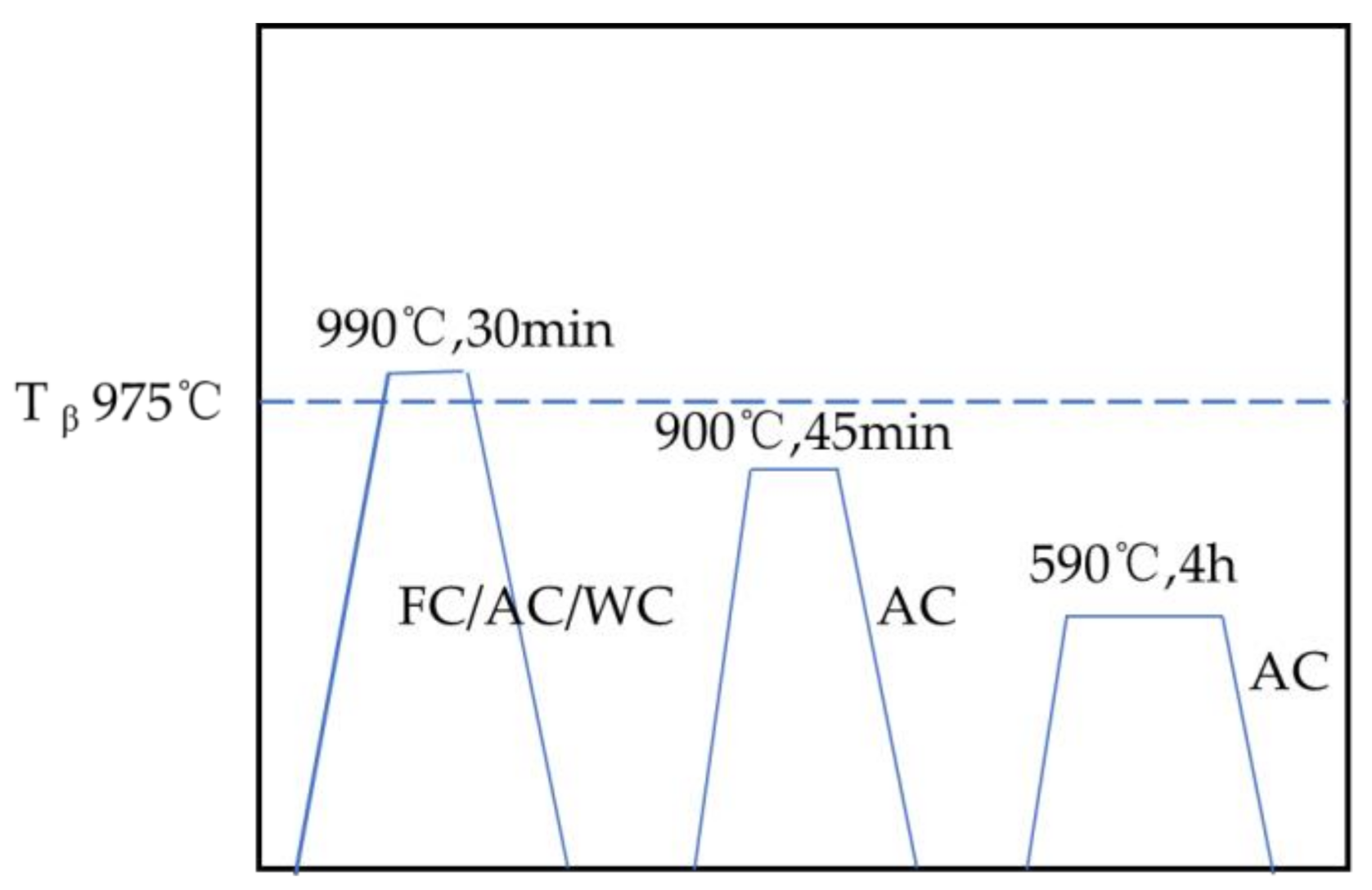

2. Materials and Methods

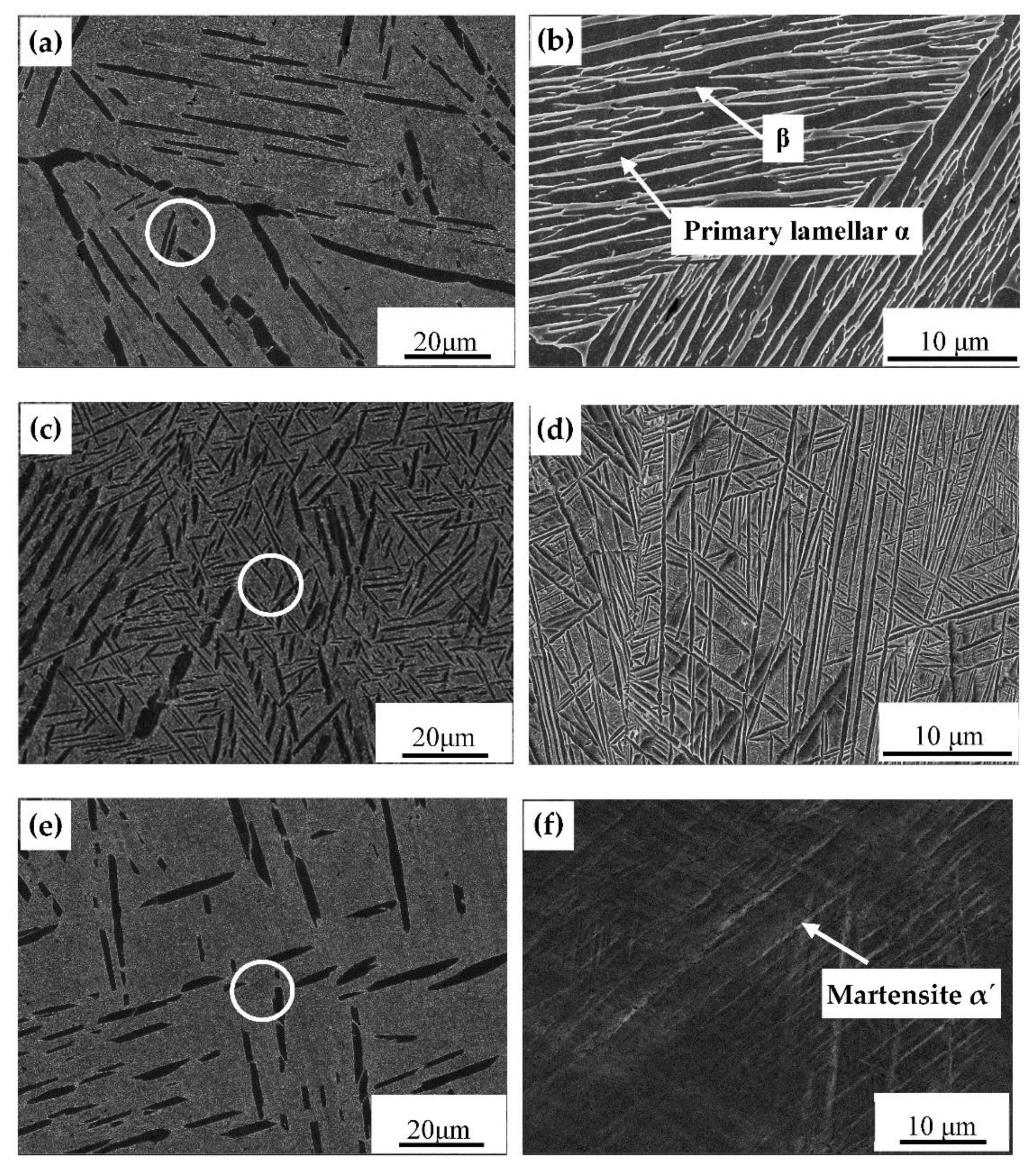

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wen, X.; Wan, M.; Huang, C.; Tan, Y.; Lei, M.; Liang, Y.; Cai, X. Effect of microstructure on tensile properties, impact toughness and fracture toughness of TC21 alloy. Mater. Des. 2019, 180, 107898. [Google Scholar] [CrossRef]

- Lei, L.; Zhao, Q.; Zhao, Y.; Huang, S.; Wu, C.; Jia, W.; Zeng, W. Study on the intrinsic factors determining impact toughness of TC21 alloy. Mater. Charact. 2021, 177, 111164. [Google Scholar] [CrossRef]

- Li, W.; Li, M.; Sun, R.; Xing, X.; Wang, P.; Sakai, T. Faceted crack induced failure behavior and micro-crack growth based strength evaluation of titanium alloys under very high cycle fatigue. Int. J. Fatigue 2020, 131, 105369. [Google Scholar] [CrossRef]

- Yumak, N.; Aslantaş, K. A review on heat treatment efficiency in metastable β titanium alloys: The role of treatment process and parameters. J. Mater. Res. Technol. 2020, 9, 15360–15380. [Google Scholar] [CrossRef]

- Huang, S.; Zhao, Q.; Wu, C.; Lin, C.; Zhao, Y.; Jia, W.; Mao, C. Effects of β-stabilizer elements on microstructure formation and mechanical properties of titanium alloys. J. Alloy. Compd. 2021, 160085. [Google Scholar] [CrossRef]

- Wang, Y.; Xiu, S.; Zhang, S.; Jiang, C. Effect of grinding parameters on microstructure evolution of TC21 titanium alloy with bimodal starting microstructure. J. Alloy. Compd. 2020, 831, 154882. [Google Scholar] [CrossRef]

- Wang, Y.; Kou, H.; Chang, H.; Zhu, Z.; Zhang, F.; Li, J.; Zhou, L. Influence of solution temperature on phase transformation of TC21 alloy. Mater. Sci. Eng. A 2009, 508, 76–82. [Google Scholar] [CrossRef]

- Filip, R.; Kubiak, K.; Ziaja, W.; Sieniawski, J. The effect of microstructure on the mechanical properties of two-phase titanium alloys. J. Mater. Process. Technol. 2003, 133, 84–89. [Google Scholar] [CrossRef]

- Wanying, L.; Yuanhua, L.; Yuhai, C.; Taihe, S.; Singh, A. Effect of Different Heat Treatments on Microstructure and Mechanical Properties of Ti6Al4V Titanium Alloy. Rare Met. Mater. Eng. 2017, 46, 634–639. [Google Scholar] [CrossRef]

- Wang, K.; Wu, M.; Yan, Z.; Li, D.; Xin, R.; Liu, Q. Microstructure evolution and static recrystallization during hot rolling and annealing of an equiaxed-structure TC21 titanium alloy. J. Alloy. Compd. 2018, 752, 14–22. [Google Scholar] [CrossRef]

- Zhimin, H.; Yongqing, Z.; Weidong, Z.; Xiaonan, M.; Wenguang, L.; Pengsheng, Z. Effect of Heat Treatment on the Microstructure Development of TC21 Alloy. Rare Met. Mater. Eng. 2017, 46, 2087–2091. [Google Scholar] [CrossRef][Green Version]

- Li, D.; Wang, K.; Yan, Z.; Cao, Y.; Misra, R.D.K.; Xin, R.; Liu, Q. Evolution of microstructure and tensile properties during the three-stage heat treatment of TA19 titanium alloy. Mater. Sci. Eng. A 2018, 716, 157–164. [Google Scholar] [CrossRef]

- Chi, G.; Liu, H.; Yi, D. Drastic improvement in elongation and impact toughness of Ti–Al–V–Mo–Zr alloy tube via three-step heat treatment. Mater. Lett. 2021, 284, 128925. [Google Scholar] [CrossRef]

- Shi, Z.-F.; Guo, H.-Z.; Han, J.-Y.; Yao, Z.-K. Microstructure and mechanical properties of TC21 titanium alloy after heat treatment. Trans. Nonferrous Met. Soc. China 2013, 23, 2882–2889. [Google Scholar] [CrossRef]

- Long, W.; Zhang, S.; Liang, Y.-L.; Ou, M.-G. Influence of multi-stage heat treatment on the microstructure and mechanical properties of TC21 titanium alloy. Int. J. Miner. Metall. Mater. 2021, 28, 296–304. [Google Scholar] [CrossRef]

- Shi, Z.-F.; Guo, H.-Z.; Zhang, J.-W.; Yin, J.-N. Microstructure−fracture toughness relationships and toughening mechanism of TC21 titanium alloy with lamellar microstructure. Trans. Nonferrous Met. Soc. China 2018, 28, 2440–2448. [Google Scholar] [CrossRef]

- Lutjering, G. Influence of Processing on Microstructure and Mechanical Properties of (α+β) Titanium Alloys. Mater. Sci. Eng. A 1998, 243. [Google Scholar] [CrossRef]

- Li, C.-L.; Hong, J.-K.; Narayana, P.L.; Choi, S.-W.; Lee, S.W.; Park, C.H.; Yeom, J.-T.; Mei, Q. Realizing superior ductility of selective laser melted Ti-6Al-4V through a multi-step heat treatment. Mater. Sci. Eng. A 2021, 799, 140367. [Google Scholar] [CrossRef]

- Sieniawski, J.; Ziaja, W.; Kubiak, K.; Motyka, M. Microstructure and Mechanical Properties of High Strength Two-Phase Titanium Alloys. In Titanium Alloys—Advances in Properties Control; Intech: London, UK, 2013; pp. 69–80. [Google Scholar] [CrossRef]

- Elshaer, R.N.; Ibrahim, K.M. Effect of cold deformation and heat treatment on microstructure and mechanical properties of TC21 Ti alloy. Trans. Nonferrous Met. Soc. China 2020, 30, 1290–1299. [Google Scholar] [CrossRef]

- Fei, Y.; Zhou, L.; Qu, H.; Zhao, Y.; Huang, C. The phase and microstructure of TC21 alloy. Mater. Sci. Eng. A 2008, 494, 166–172. [Google Scholar] [CrossRef]

- Shi, X.; Zeng, W.; Zhao, Q. The effects of lamellar features on the fracture toughness of Ti-17 titanium alloy. Mater. Sci. Eng. A 2015, 636, 543–550. [Google Scholar] [CrossRef]

- Nag, S.; Banerjee, R.; Srinivasan, R.; Hwang, J.Y.; Harper, M.; Fraser, H.L. ω-Assisted nucleation and growth of α precipitates in the Ti–5Al–5Mo–5V–3Cr–0.5Fe β titanium alloy. Acta Mater. 2009, 57, 2136–2147. [Google Scholar] [CrossRef]

- Shi, Z.-F.; Guo, H.-Z.; Liu, R.; Wang, X.-C.; Yao, Z.-K. Microstructure and mechanical properties of TC21 titanium alloy by near-isothermal forging. Trans. Nonferrous Met. Soc. China 2015, 25, 72–79. [Google Scholar] [CrossRef]

- Fan, J.K.; Li, J.S.; Kou, H.C.; Hua, K.; Tang, B. The interrelationship of fracture toughness and microstructure in a new near β titanium alloy Ti–7Mo–3Nb–3Cr–3Al. Mater. Charact. 2014, 96, 93–99. [Google Scholar] [CrossRef]

- Wang, T.; Guo, H.; Wang, Y.; Peng, X.; Zhao, Y.; Yao, Z. The effect of microstructure on tensile properties, deformation mechanisms and fracture models of TG6 high temperature titanium alloy. Mater. Sci. Eng. A 2011, 528, 2370–2379. [Google Scholar] [CrossRef]

- Wen, X.; Wan, M.; Huang, C.; Lei, M. Strength and fracture toughness of TC21 alloy with multi-level lamellar microstructure. Mater. Sci. Eng. A 2019, 740–741, 121–129. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Tarzimoghadam, Z.; Sandlöbes, S.; Pradeep, K.G.; Raabe, D. Microstructure design and mechanical properties in a near-α Ti–4Mo alloy. Acta Mater. 2015, 97, 291–304. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, L.F.; Tang, H.P.; Liu, C.T.; Liu, B.; Huang, B.Y. Design of powder metallurgy titanium alloys and composites. Mater. Sci. Eng. A 2006, 418, 25–35. [Google Scholar] [CrossRef]

- Zang, M.C.; Niu, H.Z.; Zhang, H.R.; Tan, H.; Zhang, D.L. Cryogenic tensile properties and deformation behavior of a superhigh strength metastable beta titanium alloy Ti–15Mo–2Al. Mater. Sci. Eng. A 2021, 817, 141344. [Google Scholar] [CrossRef]

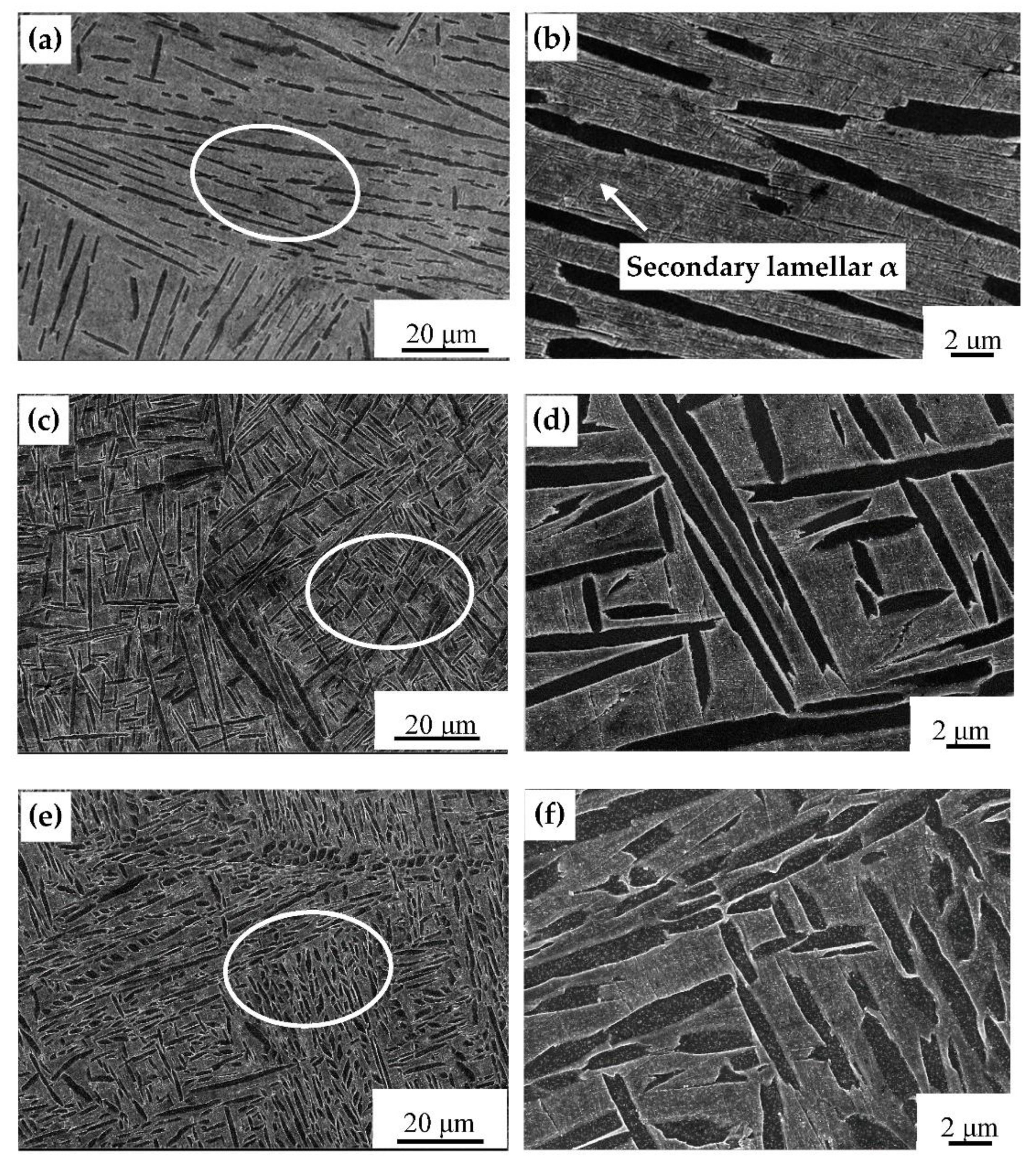

| Heat Treatments | First Solution Stage | Second Solution Stage | Third Solution Stage | |||

|---|---|---|---|---|---|---|

| Cooling Way | Thickness/μm | Volume Percentage/% | Thickness/μm | Volume Percentage/% | Thickness/μm | Volume Percentage/% |

| FC | 0.64 | 60.1 | 0.92 | 19.8 | 1.01 | 11.0 |

| AC | 0.26 | 24.9 | 0.78 | 29.4 | 0.89 | 25.7 |

| WQ | 0.11 | 7.6 | 0.73 | 23.1 | 1.19 | 12.4 |

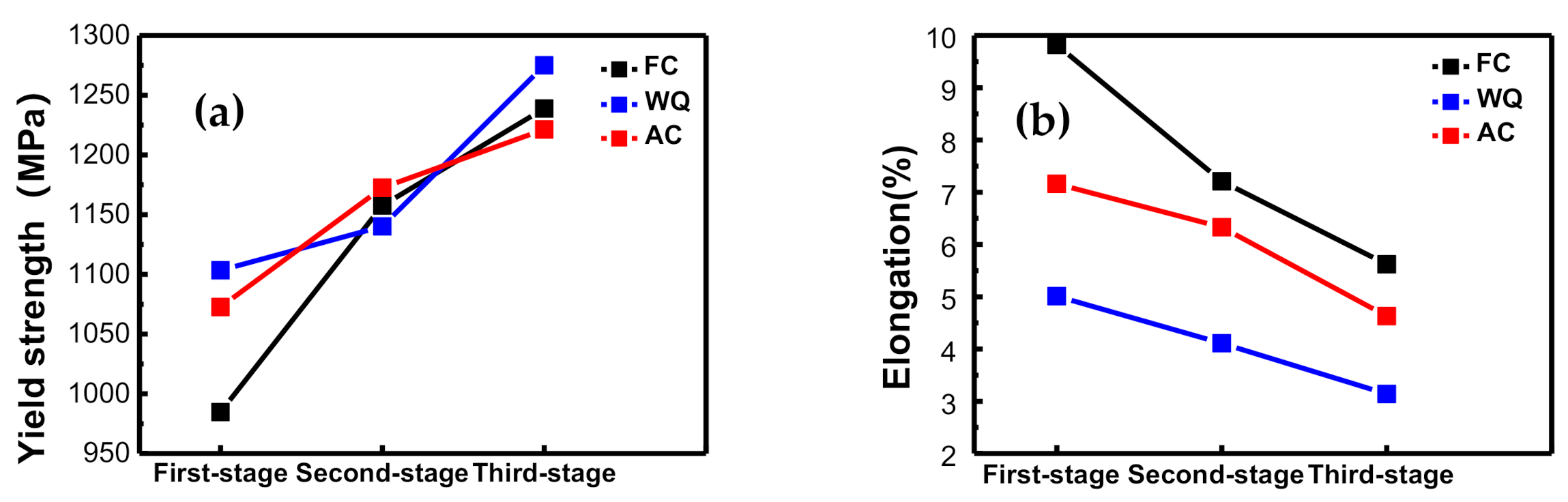

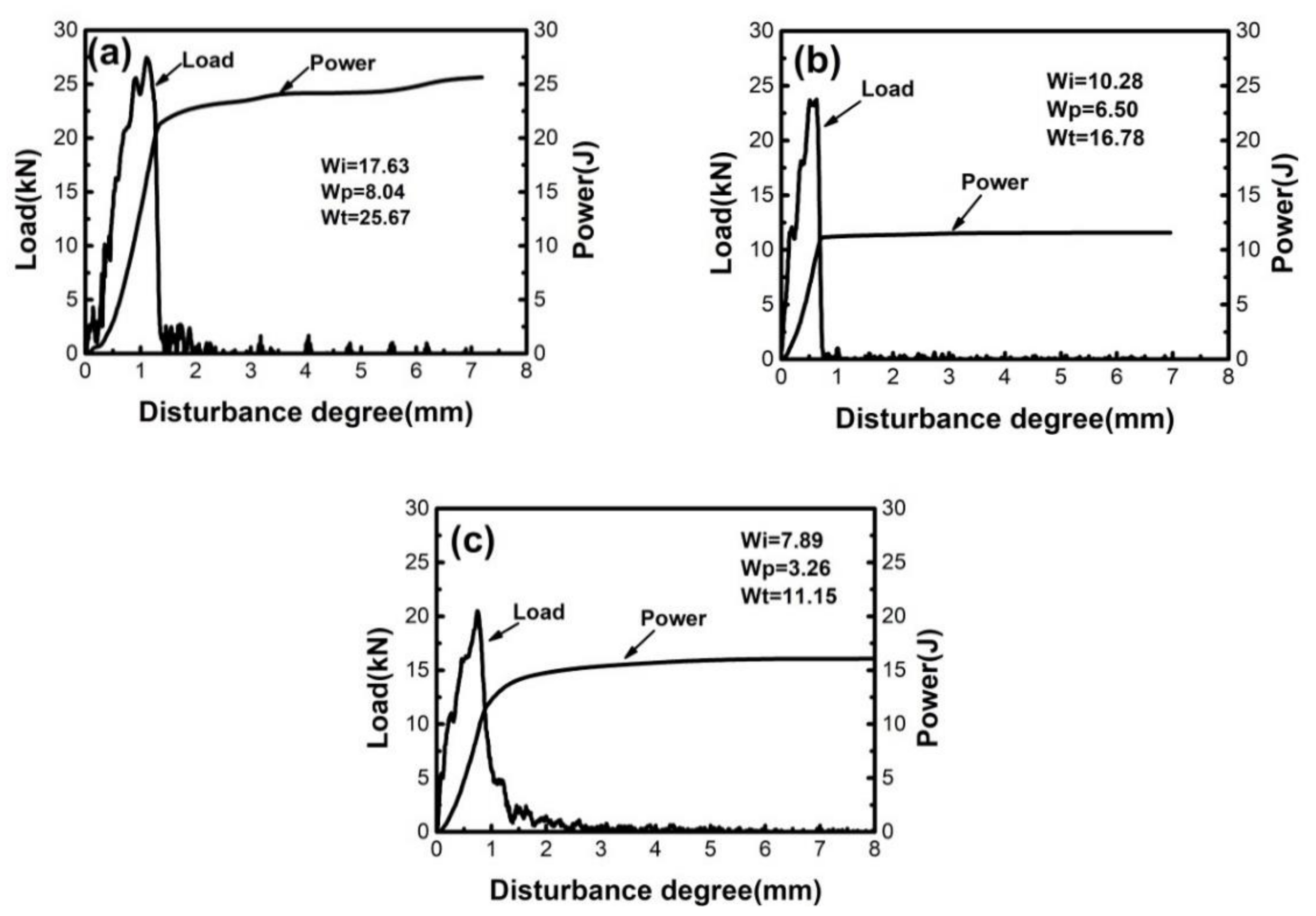

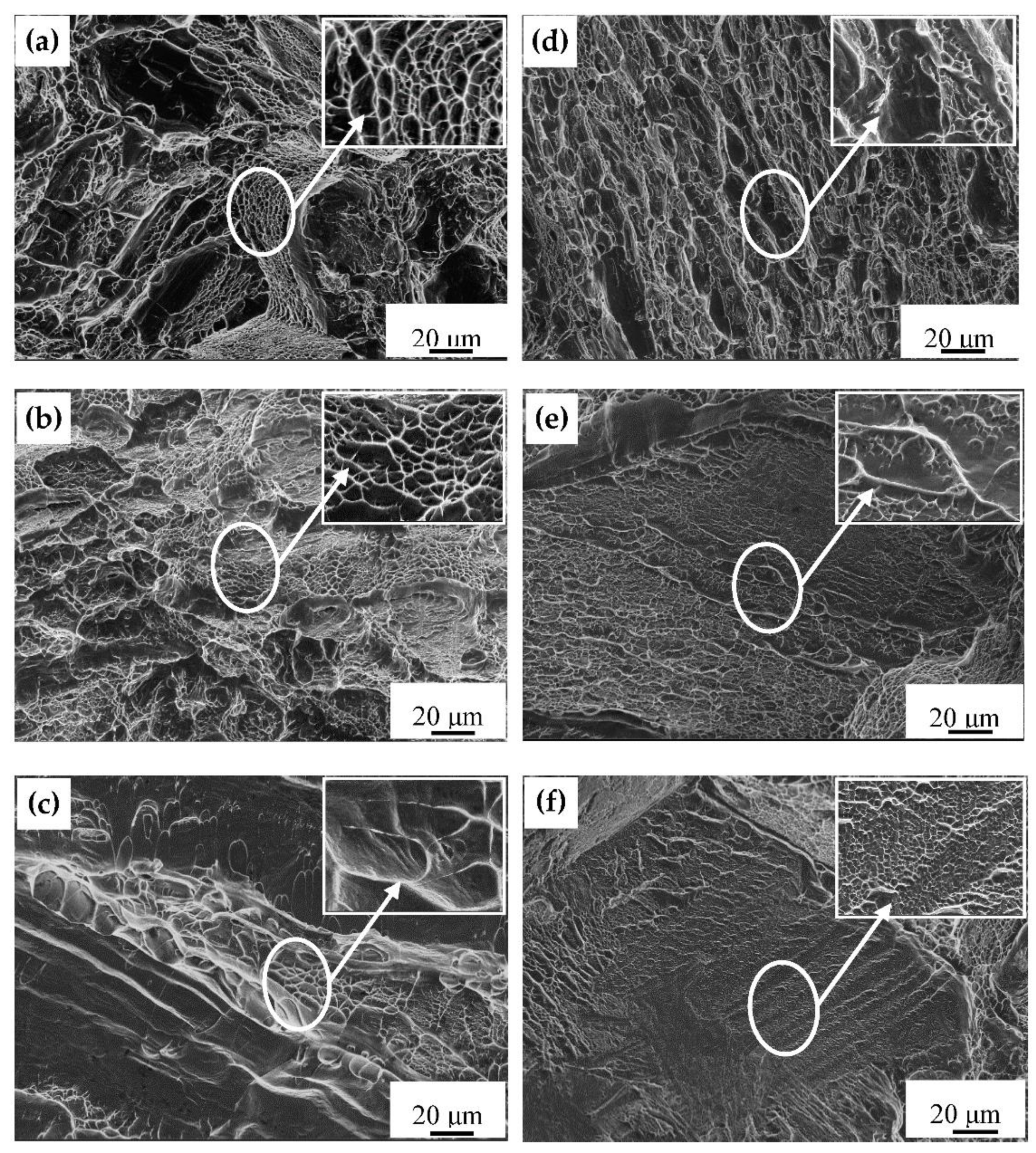

| Heat Treatment | Tensile Strength σb/MPa | Yield Strength σs/MPa | Reduction of Area Ψ/% | Elongation δ/% | Impact Energy A/J | |

|---|---|---|---|---|---|---|

| First solution stage (990 °C/30 min) | FC | 984.65 | 960.13 | 13.52 | 9.82 | 25.67 |

| AC | 1072.58 | 1059.45 | 8.63 | 7.66 | 16.78 | |

| WQ | 1103.37 | 1083.23 | 8.21 | 5.01 | 11.15 | |

| Second solution stage (900 °C/45 min/AC) | FC | 1157.66 | 1145.11 | 8.42 | 7.21 | - |

| AC | 1172.62 | 1158.45 | 7.65 | 6.83 | - | |

| WQ | 1140.19 | 1121.9 | 8.30 | 4.11 | - | |

| Third aging stage (590 °C/4 h/AC) | FC | 1238.80 | 1236.35 | 6.13 | 5.62 | 14.50 |

| AC | 1221.34 | 1211.34 | 6.33 | 5.13 | 13.98 | |

| WQ | 1275.02 | 1214.87 | 6.72 | 3.14 | 11.52 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, X.; Ou, M.; Chen, D.; Yang, M.; Long, W. Effect of Third-Stage Heat Treatments on Microstructure and Properties of Dual-Phase Titanium Alloy. Materials 2021, 14, 2776. https://doi.org/10.3390/ma14112776

Mao X, Ou M, Chen D, Yang M, Long W. Effect of Third-Stage Heat Treatments on Microstructure and Properties of Dual-Phase Titanium Alloy. Materials. 2021; 14(11):2776. https://doi.org/10.3390/ma14112776

Chicago/Turabian StyleMao, Xiqin, Meigui Ou, Desong Chen, Ming Yang, and Wei Long. 2021. "Effect of Third-Stage Heat Treatments on Microstructure and Properties of Dual-Phase Titanium Alloy" Materials 14, no. 11: 2776. https://doi.org/10.3390/ma14112776

APA StyleMao, X., Ou, M., Chen, D., Yang, M., & Long, W. (2021). Effect of Third-Stage Heat Treatments on Microstructure and Properties of Dual-Phase Titanium Alloy. Materials, 14(11), 2776. https://doi.org/10.3390/ma14112776