About the Role of Interfaces on the Fatigue Crack Propagation in Laminated Metallic Composites

Abstract

1. Introduction

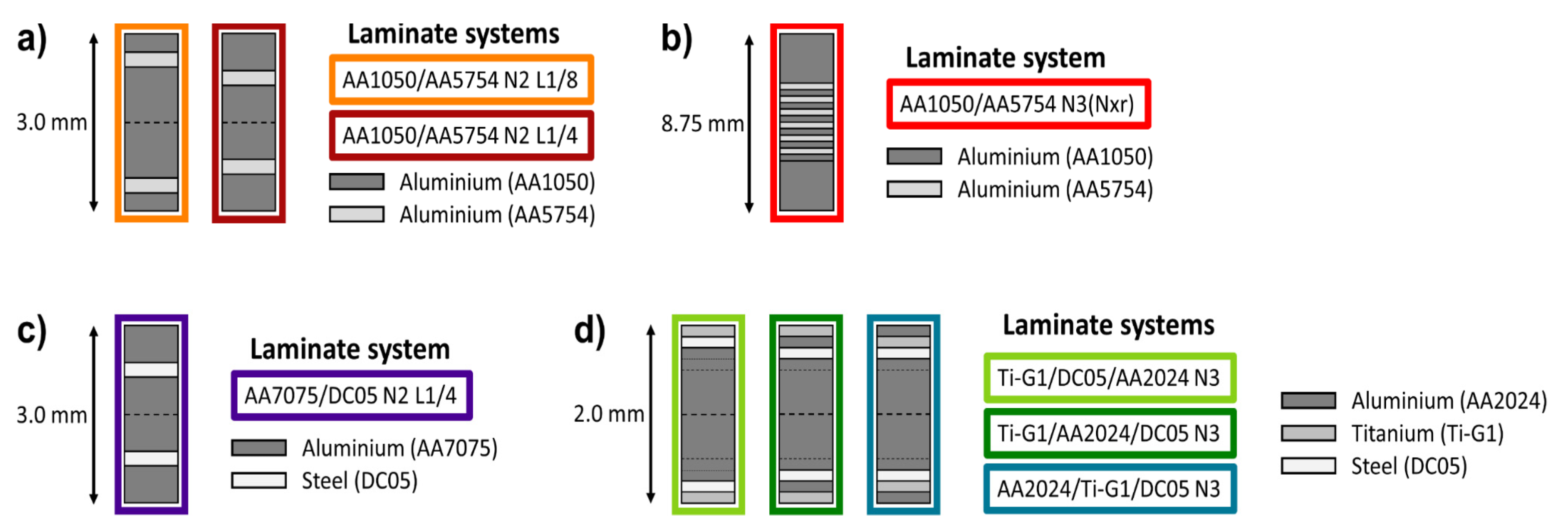

2. Materials and Methods

2.1. Processing of the Laminated Metal Composites and Monolithic Materials

2.2. Characterisation of Local Mechanical Properties

2.3. Determination of Fatigue Life

2.4. Determination of Fatigue Crack Growth

2.5. Characterisation of Damage Mechanisms

2.6. In-Situ Characterisation of Damage Mechanisms

3. Results

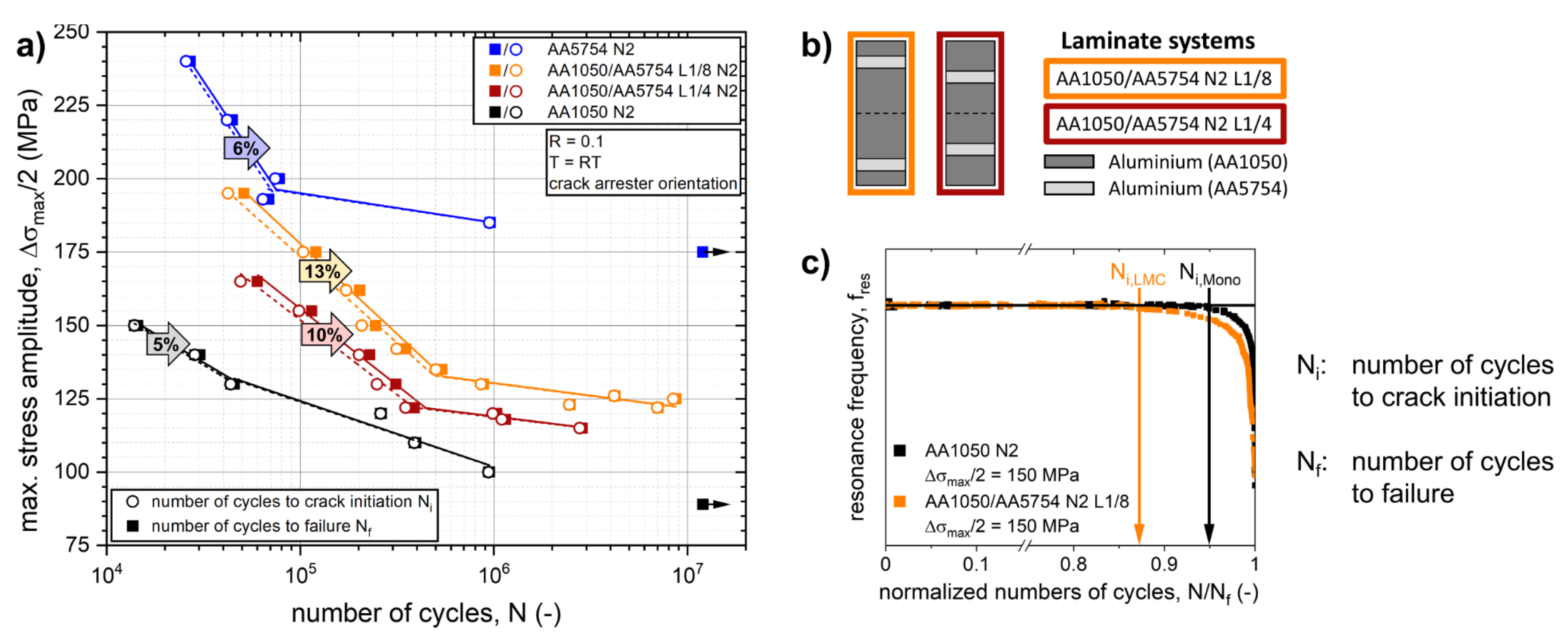

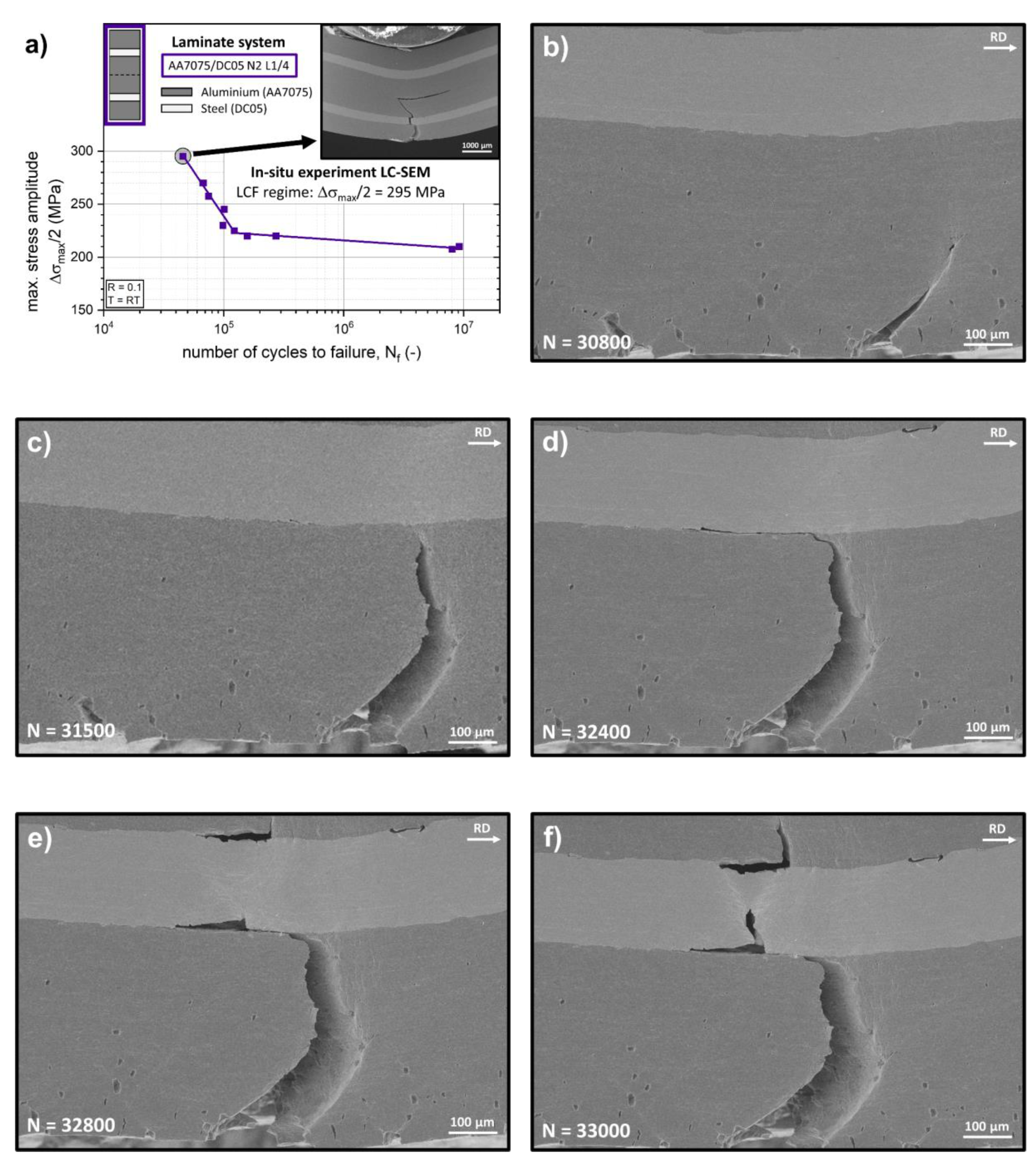

3.1. Effects of a Hardness Gradient at Interfaces on Fatigue Life and Crack Propagation in LMCs

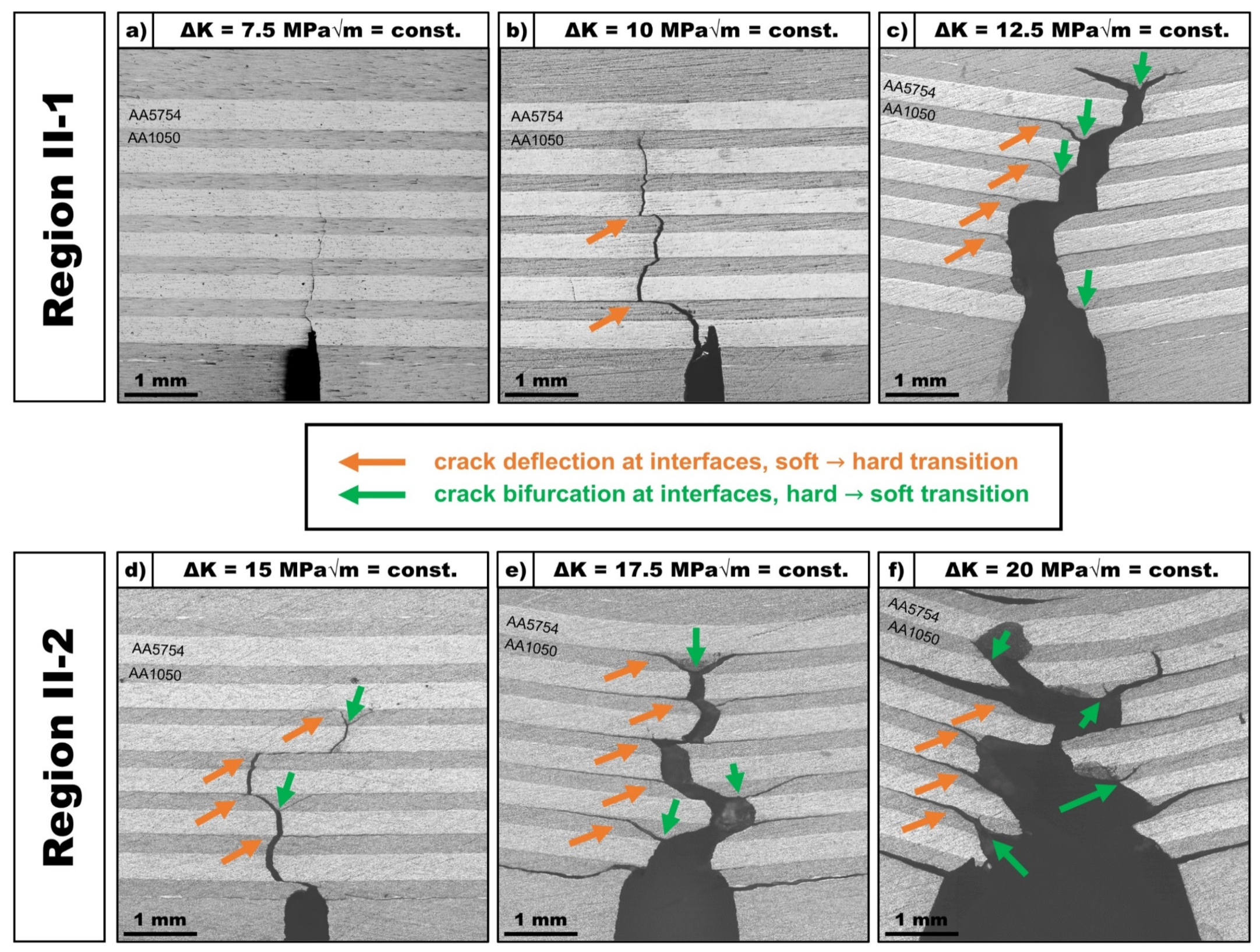

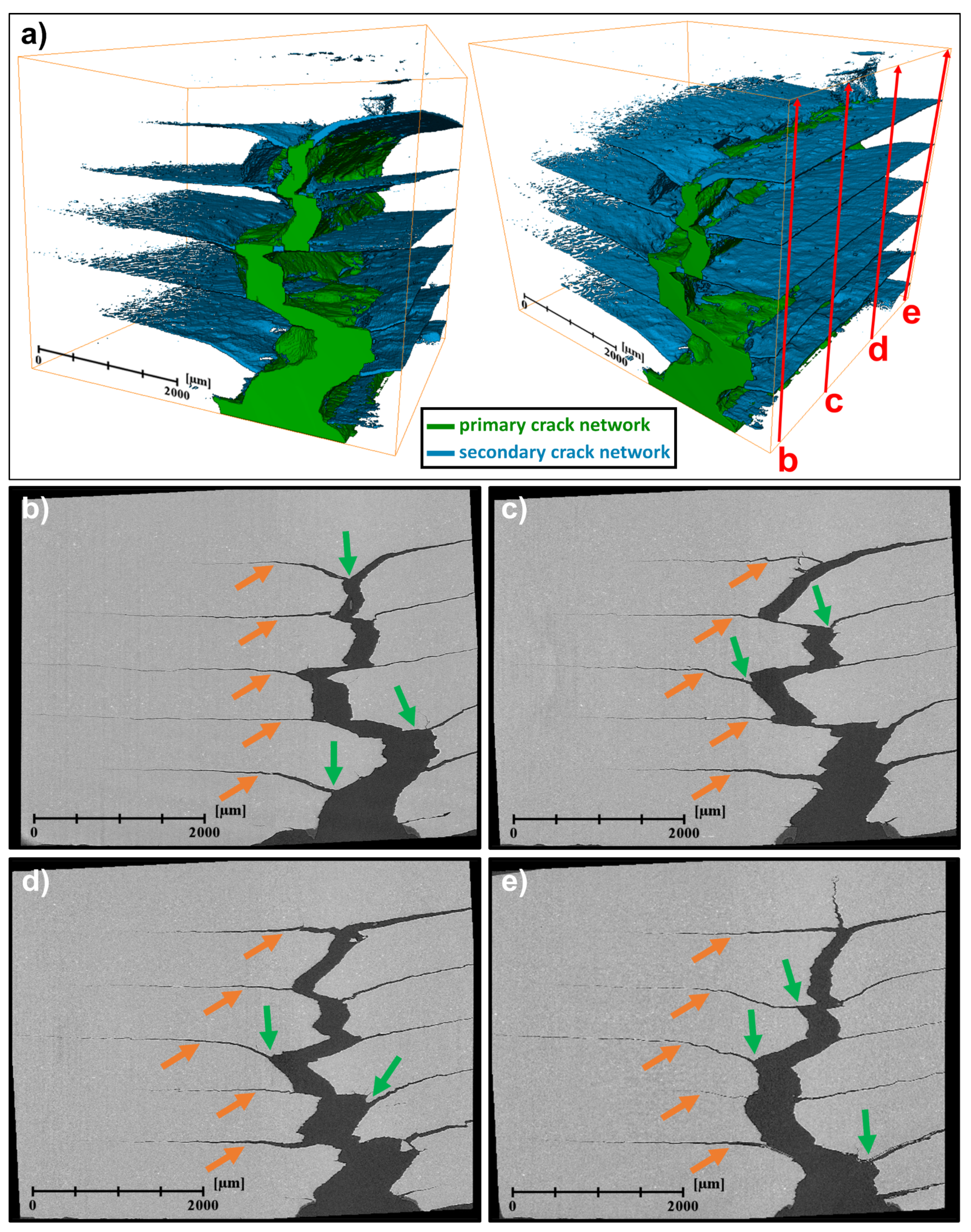

3.2. Effects of a Hardness Gradient at Interfaces on Fatigue Crack Growth (FCG) in LMCs

3.3. Effects of a Combined Gradient of Hardness and Elastic Properties at Interfaces on Fatigue Life and Crack Propagation in LMCs

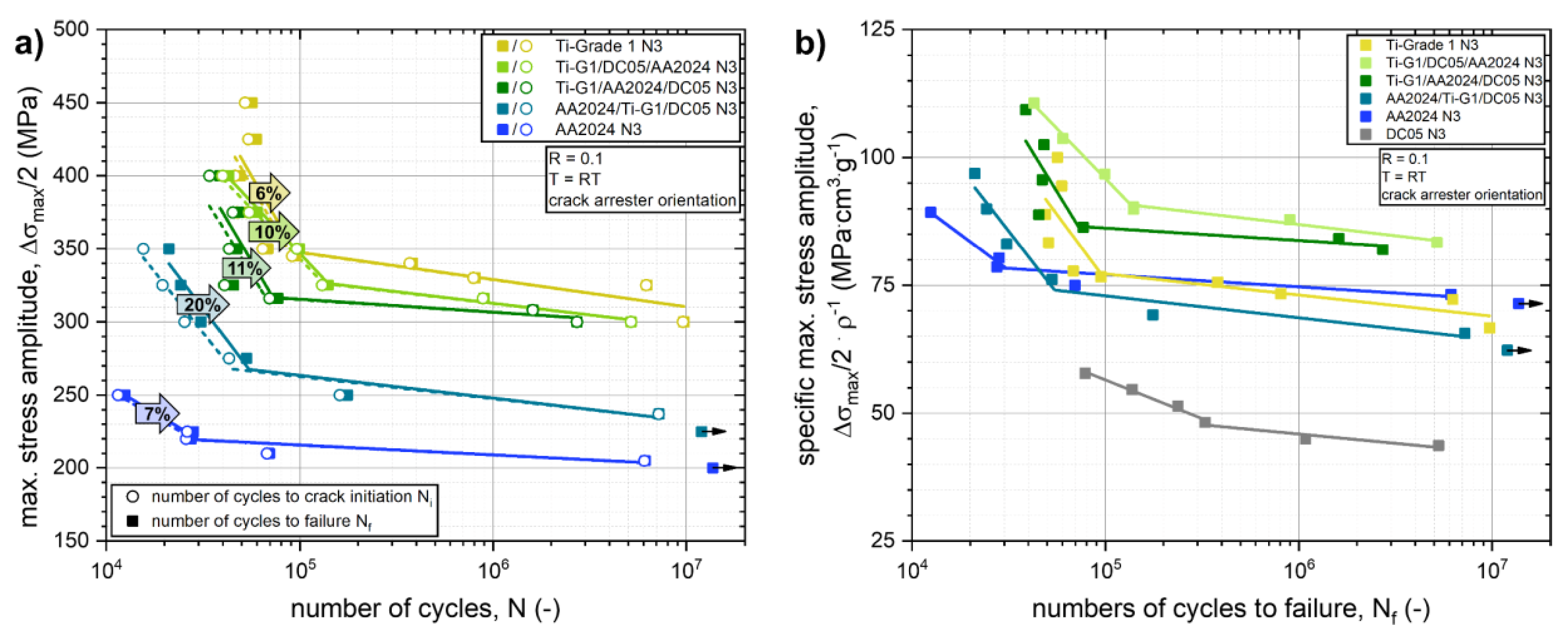

3.4. Effects of the LMC Architecture Combined with Gradients of Hardness and Elastic Properties at Interfaces on Fatigue Life and Crack Propagation

4. Discussion

4.1. Effects of Toughening Mechanisms on Crack Propagation and Crack Growth in LMCs with a Hardness Gradient at Interfaces

4.2. Effects of Toughening Mechanisms on Crack Propagation in LMCs with a Combined Gradient in Hardness and Elastic Properties at Interfaces

4.3. Optimization of LMC Architectures for Light Weight Applications Subjected to Cyclic Loading Cases

5. Conclusions

- The resistance against crack propagation in the LCF regime is improved in Al/Al-LMC systems by reinforcing the softer AA1050 matrix with thin and harder AA5754 layers compared to monolithic AA1050 due to the hardness gradient at the interface.

- The damage tolerant fatigue properties of dissimilar Al/Al-LMCs with an alternating layer structure are significantly enhanced in crack arrester orientation compared to both constituent monolithic AA1050 and AA5754 materials. Investigation of the surface and 3D-crack networks reveal the presence of two different toughening mechanisms at interfaces causing the reduction of crack growth in the LMCs. Crack deflection is observed when the crack approaches the interface from the softer towards the harder layers. Crack bifurcation happens in the opposite case. Both mechanisms appear to be more pronounced at higher remotely applied far-field stress intensity ranges. For the soft/hard transition at the interface in Al/Al-LMCs, a combination of the effects of crack tip shielding, deflection of the crack path and subsequent crack growth along the interfaces in both directions on multiple crack fronts contribute to the overall reduction of the local crack driving force at the vicinity of the interface. The local crack driving force at the vicinity of the hard/soft transition depends on the acceleration by anti-shielding effects and the superimposed reduction due to crack bifurcation and simultaneous crack growth along multiple crack fronts.

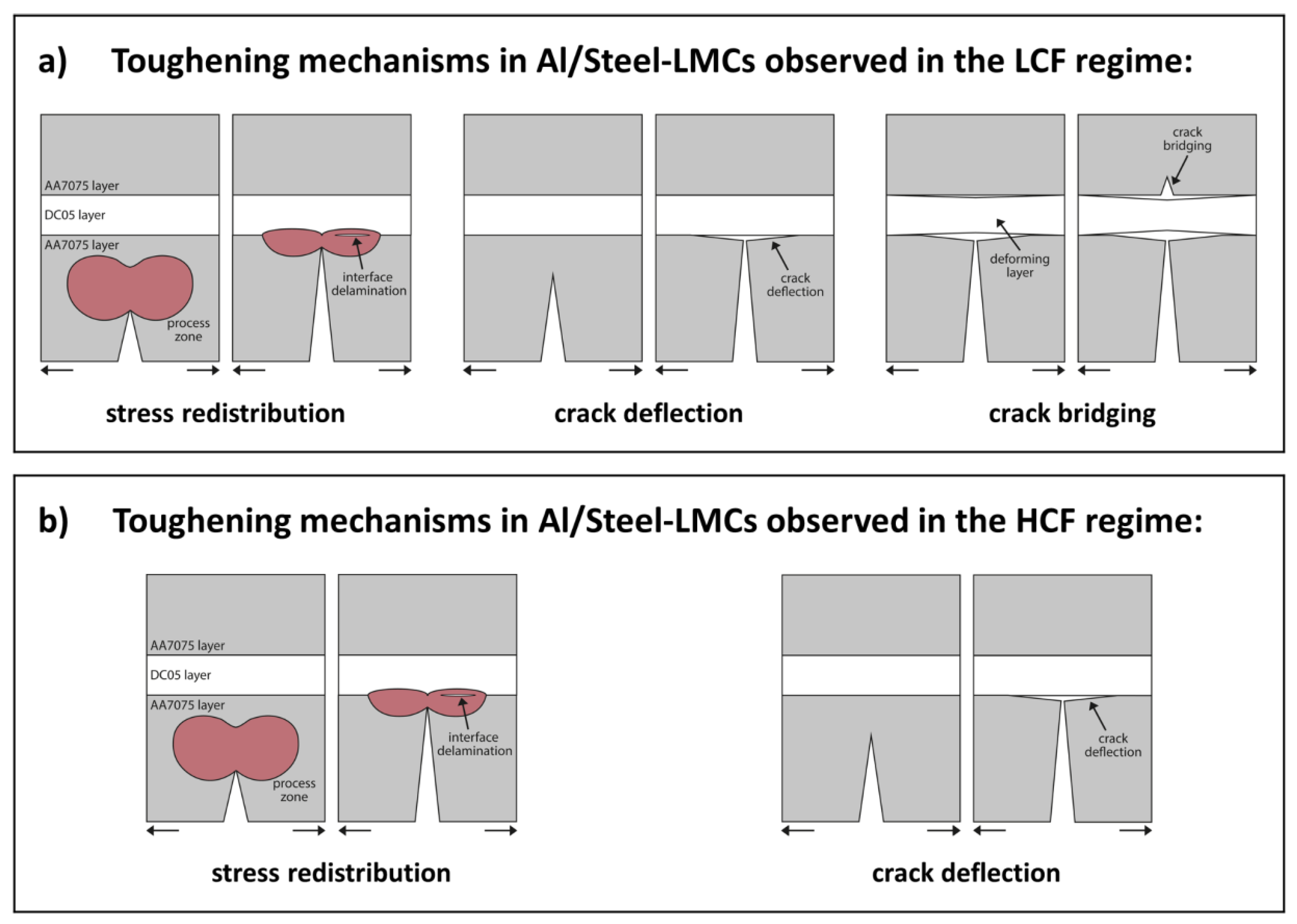

- Resistance against crack propagation in the LCF regime is enhanced significantly in an Al/Steel-LMC system by reinforcing the softer and more compliant AA7075 matrix material with harder and stiffer DC05 steel layers, utilizing gradient effects in hardness and elastic properties at the interfaces. The prevalent toughening mechanisms observed in-situ are stress redistribution, crack deflection and crack bridging in the LCF regime and stress redistribution and crack deflection in the HCF regime. In the LCF regime, the enhanced crack propagation phase is attributed mainly to the crack tip shielding effects at the soft/hard and compliant/stiff transition at the Al/Steel interface, resulting in stress redistribution and crack deflection. The crack bridging of the steel layer appears to be promoted by interface delamination occurring at the inner Steel/Al interface due to stress redistribution and a complex stress state of compressional stress in the steel layer and tensile stress in the aluminium layers due to the geometrically necessary co-deformation of these layers at the interface upon cyclic loading.

- The fatigue lives of Al/Ti/Steel tri-material laminated composites can be significantly improved compared to the monolithic AA2024 alloy by optimizing the laminate architecture, introducing thin Ti-G1 and DC05 layers. The specific fatigue properties of the LMC architectures containing Ti-G1 surface layers exceed those of the monolithic constituent materials significantly due to the lower density of the laminated composites. The effects of architecture optimization for laminated metal composites show promising potentials for LMCs in lightweight applications subjected to cyclic loading.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2021, 9, 1–31. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater. Res. Lett. 2019, 70, 393–398. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Misra, A.; Göken, M.; Mara, N.A.; Beyerlein, I.J. Hierarchical and heterogeneous multiphase metallic nanomaterials and laminates. MRS Bull. 2021, 46, 1–8. [Google Scholar] [CrossRef]

- Han, B.Q.; Huang, J.Y.; Zhu, Y.T.; Lavernia, E.J. Strain rate dependence of properties of cryomilled bimodal 5083 Al alloys. Acta Mater. 2006, 54, 3015–3024. [Google Scholar] [CrossRef]

- Zhao, Y.; Topping, T.; Bingert, J.F.; Thornton, J.J.; Dangelewicz, A.M.; Li, Y.; Liu, W.; Zhu, Y.; Zhou, Y.; Lavernia, E.J. High Tensile Ductility and Strength in Bulk Nanostructured Nickel. Adv. Mater. 2008, 20, 3028–3033. [Google Scholar] [CrossRef]

- Ruppert, M.; Schunk, C.; Hausmann, D.; Höppel, H.W.; Göken, M. Global and local strain rate sensitivity of bimodal Al-laminates produced by accumulative roll bonding. Acta Mater. 2016, 103, 643–650. [Google Scholar] [CrossRef]

- Höppel, H.W.; Westermeyer, M.; Kümmel, F.; Göken, M. The Role of Interfaces on the Deformation Mechanisms in Bimodal Al Laminates Produced by Accumulative Roll Bonding. Adv. Eng. Mater. 2020, 22, 2000145. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing Extraordinary Intrinsic Tensile Plasticity in Gradient Nano-Grained Copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, P.; Chen, L.; Yuan, F.; Zhu, Y.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, P.; Chen, L.; Zhang, J.F.; Yuan, F.P.; Zhu, Y.T. Synergetic Strengthening by Gradient Structure. Mater. Res. Lett. 2014, 2, 185–191. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Mara, N.A.; Carpenter, J.S.; Nizolek, T.; Mook, W.M.; Wynn, T.A.; McCabe, R.J.; Mayeur, J.R.; Kang, K.; Zheng, S.; et al. Interface-driven microstructure development and ultra high strength of bulk nanostructured Cu-Nb multilayers fabricated by severe plastic deformation. J. Mater. Res. 2013, 28, 1799–1812. [Google Scholar] [CrossRef]

- Ma, X.; Huang, C.; Moering, J.; Ruppert, M.; Höppel, H.W.; Göken, M.; Narayan, J.; Zhu, Y. Mechanical properties of copper/bronze laminates: Role of interfaces. Acta Mater. 2016, 116, 43–52. [Google Scholar] [CrossRef]

- Kümmel, F.; Diepold, B.; Sauer, K.F.; Schunk, C.; Prakash, A.; Höppel, H.W.; Göken, M. High Lightweight Potential of Ultrafine-Grained Aluminum/Steel Laminated Metal Composites Produced by Accumulative Roll Bonding. Adv. Eng. Mater. 2019, 21. [Google Scholar] [CrossRef]

- Kümmel, F.; Diepold, B.; Prakash, A.; Höppel, H.W.; Göken, M. Enhanced monotonic and cyclic mechanical properties of ultrafine-grained laminated metal composites with strong and stiff interlayers. Int. J. Fatigue 2018, 116, 379–387. [Google Scholar] [CrossRef]

- Misra, A.; Hirth, J.P.; Hoagland, R.G. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 2005, 53, 4817–4824. [Google Scholar] [CrossRef]

- Misra, A.; Hoagland, R.G. Plastic flow stability of metallic nanolaminate composites. J. Mater. Sci. 2007, 42, 1765–1771. [Google Scholar] [CrossRef]

- Bloyer, D.R.; Ritchie, R.O.; Rao, K.T. Fracture toughness and R-Curve behavior of laminated brittle-matrix composites. Metall. Mater. Trans. A 1998, 29, 2483–2496. [Google Scholar] [CrossRef]

- Osman, T.M.; Hassan, H.A.; Lewandowski, J.J. Interface Effects on the Quasi-Static and Impact Toughness of Discontinuously Reinforced Aluminum Laminates. Metall. Mater. Trans. A 2008, 39, 1993–2006. [Google Scholar] [CrossRef]

- Lesuer, D.R.; Syn, C.K.; Riddle, R.A.; Sherby, O.D. Extrinsic Fracture Mechanisms in Two Laminated Metal Composites. In Intrinsic and Extrinsic Fracture Mechanisms in Inorganic Composite Systems; Lewandowski, J.J., Hunt, W.H., Eds.; TMS: Warrendale, PA, USA, 1995; pp. 93–102. [Google Scholar]

- Adharapurapu, R.R.; Vecchio, K.S.; Jiang, F.; Rohatgi, A. Fracture of Ti-Al3Ti metal-intermetallic laminate composites: Effects of lamination on resistance-curve behavior. Metall. Mater. Trans. A 2005, 36, 3217–3236. [Google Scholar] [CrossRef]

- Bloyer, D.R.; Ritchie, R.O.; Rao, K.T. Fatigue-crack propagation behavior of ductile/brittle laminated composites. Metall. Mater. Trans. A 1999, 30, 633–642. [Google Scholar] [CrossRef]

- Adharapurapu, R.R.; Vecchio, K.S.; Jiang, F.; Rohatgi, A. Effects of ductile laminate thickness, volume fraction, and orientation on fatigue-crack propagation in Ti-Al3Ti metal-intermetallic laminate composites. Metall. Mater. Trans. A 2005, 36, 1595–1608. [Google Scholar] [CrossRef]

- Hassan, H.A.; Lewandowski, J.J.; El-Latif, M.H. Effects of lamination and changes in layer thickness on fatigue-crack propagation of lightweight laminated metal composites. Metall. Mater. Trans. A 2004, 35, 45–52. [Google Scholar] [CrossRef]

- Hoffman, P.B.; Carpenter, R.D.; Gibeling, J.C. Fatigue Crack Growth in Aluminum Laminate Composites. Mater. Res. Soc. Symp. Proc. 1996, 434, 281–286. [Google Scholar] [CrossRef]

- Lesuer, D.R.; Syn, C.K.; Sherby, O.D.; Wadsworth, J.; Lewandowski, J.J.; Hunt, W.H. Mechanical behaviour of laminated metal composites. Int. Mater. Rev. 1996, 41, 169–197. [Google Scholar] [CrossRef]

- Ritchie, R.O. Mechanisms of fatigue crack propagation in metals, ceramics and composites: Role of crack tip shielding. Mater. Sci. Eng. A 1988, 103, 15–28. [Google Scholar] [CrossRef]

- Ritchie, R.O.; Yu, W. Short crack effects in fatigue: A consequence of crack tip shielding. In Small Fatigue Cracks; Ritchie, R.O., Lankford, J., Eds.; TMS-AIME: Warrendale, PA, USA, 1986; pp. 167–189. [Google Scholar]

- Pippan, R.; Flechsig, K.; Riemelmoser, F.O. Fatigue crack propagation behavior in the vicinity of an interface between materials with different yield stresses. Mater. Sci. Eng. A 2000, 283, 225–233. [Google Scholar] [CrossRef]

- Sugimura, Y.; Lim, P.G.; Shih, C.F.; Suresh, S. Fracture normal to a bimaterial interface: Effects of plasticity on crack-tip shielding and amplification. Acta Metall. Mater. 1995, 43, 1157–1169. [Google Scholar] [CrossRef]

- Kümmel, F.; Höppel, H.W.; Göken, M. Layer architecture and fatigue life of ultrafine-grained laminated metal composites consisting of different aluminum alloys. Mater. Sci. Eng. A 2017, 702, 406–413. [Google Scholar] [CrossRef]

- Ohashi, Y.; Wolfenstine, J.; Koch, R.; Sherby, O.D. Fracture behavior of a laminated steel-brass composite in bend tests. Mater. Sci. Eng. A 1992, 151, 37–44. [Google Scholar] [CrossRef]

- Kolednik, O.; Kasberger, R.; Sistaninia, M.; Predan, J.; Kegl, M. Development of Damage-Tolerant and Fracture-Resistant Materials by Utilizing the Material Inhomogeneity Effect. J. Appl. Mech. 2019, 86. [Google Scholar] [CrossRef]

- Kolednik, O. The yield stress gradient effect in inhomogeneous materials. Int. J. Solids Struct. 2000, 37, 781–808. [Google Scholar] [CrossRef]

- Simha, N.; Fischer, F.; Kolednik, O.; Chen, C. Inhomogeneity effects on the crack driving force in elastic and elastic–plastic materials. J. Mech. Phys. Solids 2003, 51, 209–240. [Google Scholar] [CrossRef]

- Fratzl, P.; Gupta, H.S.; Fischer, F.D.; Kolednik, O. Hindered Crack Propagation in Materials with Periodically Varying Young’s Modulus—Lessons from Biological Materials. Adv. Mater. 2007, 19, 2657–2661. [Google Scholar] [CrossRef]

- Fan, K.; Wang, G.Z.; Tu, S.-T.; Xuan, F.Z. Effects of Toughness Mismatch on Failure Behavior of Bi-Material Interfaces. Procedia Eng. 2015, 130, 754–762. [Google Scholar] [CrossRef]

- Sistaninia, M.; Kolednik, O. Improving strength and toughness of materials by utilizing spatial variations of the yield stress. Acta Mater. 2017, 122, 207–219. [Google Scholar] [CrossRef]

- Sistaninia, M.; Kasberger, R.; Kolednik, O. To the design of highly fracture-resistant composites by the application of the yield stress inhomogeneity effect. Compos. Struct. 2018, 185, 113–122. [Google Scholar] [CrossRef]

- Suresh, S.; Sugimura, Y.; Tschegg, E.K. The growth of a fatigue crack approaching a perpendicularly-oriented, bimaterial interface. Scr. Metall. Mater. 1992, 27, 1189–1194. [Google Scholar] [CrossRef]

- Kolednik, O.; Predan, J.; Fischer, F.D.; Fratzl, P. Improvements of strength and fracture resistance by spatial material property variations. Acta Mater. 2014, 68, 279–294. [Google Scholar] [CrossRef]

- Kolednik, O.; Predan, J.; Fischer, F.D.; Fratzl, P. Bioinspired Design Criteria for Damage-Resistant Materials with Periodically Varying Microstructure. Adv. Funct. Mater. 2011, 21, 3634–3641. [Google Scholar] [CrossRef]

- Funari, M.F.; Lonetti, P. Initiation and evolution of debonding phenomena in layered structures. Theor. Appl. Fract. Mech. 2017, 92, 133–145. [Google Scholar] [CrossRef]

- Martin, E.; Leguillon, D. A strain energy density criterion for the initiation of edge debonding. Theor. Appl. Fract. Mech. 2015, 79, 58–61. [Google Scholar] [CrossRef]

- Kümmel, F.; Höppel, H.W.; Göken, M. Ultrafine-grained laminated metal composites: A new material class for tailoring cyclicially stressed components. Adv. Eng. Mater. 2021, 2100070. [Google Scholar] [CrossRef]

- Bryzgalin, G.I.; Tsvetkov, D.I.; Kartashov, G.G.; Nagibin, V.P.; Pisarev, A.V. Evaluation of the quality of laminated metallic materials on the basis of high-frequency endurance and damping capacity. Strength Mater. 1989, 21, 1652–1658. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Rosochowski, A.; Olejnik, L. Severe plastic deformation for grain refinement and enhancement of properties. In Microstructure Evolution in Metal Forming Processes, 1st ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 114–141. [Google Scholar]

- Hausöl, T.; Maier, V.; Schmidt, C.W.; Winkler, M.; Höppel, H.W.; Göken, M. Tailoring Materials Properties by Accumulative Roll Bonding. Adv. Eng. Mater. 2010, 12, 740–746. [Google Scholar] [CrossRef]

- Ruppert, M.; Böhm, W.; Nguyen, H.; Höppel, H.W.; Merklein, M.; Göken, M. Influence of upscaling accumulative roll bonding on the homogeneity and mechanical properties of AA1050A. J. Mater. Sci. 2013, 48, 8377–8385. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Hay, J.L.; Pharr, G.M. Instrumented Indentation Testing. In ASM Handbook Volume 8-Mechanical Testing and Evaluation; ASM International: Almere, The Netherlands, 2000; pp. 232–243. [Google Scholar]

- ASTM International. ASTM E1820-11. In Standard Test Method for Measuring of Fracture Toughness; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar] [CrossRef]

- ISO. ISO 12135:2016. In Metallic Materials-Unified Method of Test for the Determination of Quasistatic Fracture Toughness; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Barsoum, I.; Chandran, K.S. Stress intensity factor solutions for cracks in finite-width three layer laminates with and without residual stress effects. Eng. Fract. Mech. 2003, 70, 2015–2031. [Google Scholar] [CrossRef]

- Yasniy, P.; Maruschak, P.; Lapusta, Y. Experimental study of crack growth in a bimetal under fatigue and fatigue-creep conditions. Int. J. Fract. 2006, 139, 545–552. [Google Scholar] [CrossRef]

- Maruschak, P.O.; Konovalenko, I.V.; Maruschak, E.V.; Sorochak, A.P. Automated Method for Stereometric Study of Fatigue Failure Mechanisms. Metallurgist 2014, 58, 43–47. [Google Scholar] [CrossRef]

- ASTM International. ASTM E1823-20b. In Standard Terminology Relating to Fatigue and Fracture Testing; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- ASTM International. ASTM E647-13a. In Standard Test Method for Measurement of Fatigue Crack Growth Rates; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar] [CrossRef]

- Görner, W.; Hentschel, M.P.; Müller, B.R.; Riesemeier, H.; Krumrey, M.; Ulm, G.; Diete, W.; Klein, U.; Frahm, R. BAMline: The first hard X-ray beamline at BESSY II. Nucl. Instrum. Methods Phys. Res. 2001, 467–468, 703–706. [Google Scholar] [CrossRef]

- Van Rossum, G.; Drake, F.L. Python 3 Reference Manual; CreateSpace: Scotts Valley, CA, USA, 2009. [Google Scholar]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Avizo Software, Thermo Fisher Scientific. Available online: https://www.fei.com/software/avizo (accessed on 31 March 2021).

- Höppel, H.W.; Göken, M.; Klein, M. Large Chamber Scanning Electron Microscopes: Challenges and Aspects for Materials Science. Imaging Microsc. 2004, 3, 2–3. [Google Scholar]

- Nolte, R.; Höppel, H.W.; Göken, M. Großkammer-Rasterelektronenmikroskopie—Neue Dimensionen der Materialforschung und Schadensanalyse. In Tagung Werkstoffprüfung—Fortschritte der Kennwertermittlung für Forschung und Praxis; Stahleisen: Düsseldorf, Germany, 2009; pp. 195–202. [Google Scholar]

- Nolte, R. Großkammer-Rasterelektronenmikroskopie: Inbetriebnahme, Optimierung und Experimentelle Methodik. Ph.D. Thesis, FAU Erlangen-Nürnberg, Erlangen/Nürnberg, Germany, 2011. [Google Scholar]

- Schunk, C.; Nitschky, M.; Höppel, H.W.; Göken, M. Superior Mechanical Properties of Aluminum-Titanium Laminates in Terms of Local Hardness and Strength. Adv. Eng. Mater. 2019, 21, 1800546. [Google Scholar] [CrossRef]

- Hausöl, T.; Höppel, H.W.; Göken, M. Tailoring materials properties of UFG aluminium alloys by accumulative roll bonded sandwich-like sheets. J. Mater. Sci. 2010, 45, 4733–4738. [Google Scholar] [CrossRef]

- Lee, S.; Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T. Role of shear strain in ultragrain refinement by accumulative roll-bonding (ARB) process. Scr. Mater. 2002, 46, 281–285. [Google Scholar] [CrossRef]

- Kümmel, F.; Hausöl, T.; Höppel, H.W.; Göken, M. Enhanced fatigue lives in AA1050A/AA5005 laminated metal composites produced by accumulative roll bonding. Acta Mater. 2016, 120, 150–158. [Google Scholar] [CrossRef]

- Paris, P.C.; Gomez, M.P.; Anderson, W.E. A Rational Analytic Theory of Fatigue. Trend Eng. 1961, 13, 9–14. [Google Scholar]

- Paris, P.; Erdogan, F. A Critical Analysis of Crack Propagation Laws. J. Basic Eng. 1963, 85, 528–533. [Google Scholar] [CrossRef]

- Villuendas, A.; Jorba, J.; Roca, A. The Role of Precipitates in the Behavior of Young’s Modulus in Aluminum Alloys. Metall. Mater. Trans. A 2014, 45, 3857–3865. [Google Scholar] [CrossRef]

- Luzin, V.; Banovic, S.; Gnäupel-Herold, T.; Prask, H.; Ricker, R.E. Measurement and Calculation of Elastic Properties in Low Carbon Steel Sheet. Mater. Sci. Forum 2005, 495–497, 1591–1596. [Google Scholar] [CrossRef]

- Harlow, D.G.; Nardiello, J.; Payne, J. The effect of constituent particles in aluminum alloys on fatigue damage evolution: Statistical observations. Int. J. Fatigue 2010, 32, 505–511. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Sistaninia, M.; Kolednik, O. Effect of a single soft interlayer on the crack driving force. Eng. Fract. Mech. 2014, 130, 21–41. [Google Scholar] [CrossRef]

- Wang, B.; Siegmund, T. Simulation of fatigue crack growth at plastically mismatched bi-material interfaces. Int. J. Plast. 2006, 22, 1586–1609. [Google Scholar] [CrossRef]

- Tabiei, A.; Zhang, W. Composite Laminate Delamination Simulation and Experiment: A Review of Recent Development. Appl. Mech. Rev. 2018, 70, 1–23. [Google Scholar] [CrossRef]

- Pribe, J.D.; Siegmund, T.; Kruzic, J.J. The roles of yield strength mismatch, interface strength, and plastic strain gradients in fatigue crack growth across interfaces. Eng. Fract. Mech. 2020, 235, 107072. [Google Scholar] [CrossRef]

| Alloy | Chemical Composition (wt.%) 1 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | Fe | Mg | Zn | Cu | Ti | Si | Cr | Mn | C | O | Others | |

| AA1050 | 99.4 | 0.35 | - | - | - | - | 0.15 | - | - | - | - | 0.10 |

| AA2024 | 93.4 | 0.10 | 1.42 | - | 4.37 | - | 0.07 | - | 0.46 | - | - | 0.18 |

| AA5754 | 95.9 | 0.40 | 2.91 | - | - | - | 0.35 | - | 0.31 | - | - | 0.13 |

| AA7075 | 89.4 | 0.12 | 2.72 | 5.77 | 1.53 | - | 0.07 | 0.20 | - | - | - | 0.19 |

| DC05 | - | 99.7 | - | - | - | 0.07 | - | - | 0.10 | 0.01 | - | 0.12 |

| Ti-Grade1 | - | - | - | - | - | 99.8 | - | - | - | - | 0.06 | 0.14 |

| Material | AA1050/AA5754 N2 LMC Systems | ||

|---|---|---|---|

| AA1050 Layers | AA5754 Layers | Gradient (∆H) | |

| Hardness H/GPa | 0.79 ± 0.07 | 1.37 ± 0.11 | 0.58 ± 0.13 |

| Material | Monolithic Materials | ||

| AA1050 N2 Mono | AA5754 N2 Mono | Difference | |

| Yield stress/MPa | 152 ± 5 | 332 ± 5 | 180 ± 7 |

| Ultimate tensile stress/MPa | 172 ± 8 | 361 ± 2 | 189 ± 8 |

| Material | AA1050 N2(N1r) Mono | AA5754 N2(N1r) Mono | AA1050/AA5754 N3(Nxr) LMC | ||

|---|---|---|---|---|---|

| AA1050 Layers | AA5754 Layers | Gradient (∆H) | |||

| Hardness H/GPa | 0.71 ± 0.05 | 1.37 ± 0.10 | 0.73 ± 0.06 | 1.35 ± 0.12 | 0.62 ± 0.13 |

| Material | AA1050 N2(N1r) Mono | AA5754 N2(N1r) Mono | AA1050/AA5754 N3(Nxr) LMC | |

|---|---|---|---|---|

| Region II-1 | Region II-2 | |||

| Paris equation exponent m | 3.37 | 4.51 | 0.89 | 5.72 |

| Material | AA7075/DC05 N2 LMC System | ||

|---|---|---|---|

| AA7075 Layers | DC05 Layers | Gradients (∆H, ∆E) | |

| Hardness H/GPa | 1.55 ± 0.08 | 2.66 ± 0.12 | 1.11 ± 0.14 |

| Young’s modulus E/GPa | 70 1 | 210 2 | 140 |

| Material | Monolithic Materials | ||

| AA7075 N2 Mono | DC05 N2 Mono | Difference | |

| Yield stress/MPa | 308 ± 6 | 575 ± 8 | 267 ± 10 |

| Ultimate tensile stress/MPa | 385 ± 4 | 620 ± 7 | 235 ± 8 |

| Material | AA2024/Ti-G1/DC05 N3 LMC Systems | |||

|---|---|---|---|---|

| AA2024 Layers | Ti-G1 Layers | DC05 Layers | Gradients (∆H, ∆E) | |

| Hardness H/GPa | 2.58 ± 0.05 | 2.78 ± 0.15 | 3.20 ± 0.13 | Ti-Al: 0.20 ± 0.16 |

| Fe-Ti: 0.42 ± 0.20 | ||||

| Fe-Al: 0.62 ± 0.14 | ||||

| Young’s modulus E/GPa | 69 1 | 103 2 | 210 3 | Ti-Al: 64 |

| Fe-Ti: 107 | ||||

| Fe-Al: 141 | ||||

| Material | Monolithic Materials | |||

| AA2024 N3 Mono | Ti-G1 N3 Mono | DC05 N3 Mono | Difference | |

| Yield stress/MPa | 639 ± 10 | 538 ± 4 | 554 ± 1 | Al-Ti: 101 ± 11 |

| Fe-Ti: 16 ± 5 | ||||

| Al-Fe: 85 ± 10 | ||||

| Ultimate tensile stress/MPa | 654 ± 12 | 713 ± 2 | 704 ± 8 | Ti-Al: 59 ± 12 |

| Ti-Fe: 9 ± 8 | ||||

| Fe-Al: 50 ± 14 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pohl, P.M.; Kümmel, F.; Schunk, C.; Serrano-Munoz, I.; Markötter, H.; Göken, M.; Höppel, H.W. About the Role of Interfaces on the Fatigue Crack Propagation in Laminated Metallic Composites. Materials 2021, 14, 2564. https://doi.org/10.3390/ma14102564

Pohl PM, Kümmel F, Schunk C, Serrano-Munoz I, Markötter H, Göken M, Höppel HW. About the Role of Interfaces on the Fatigue Crack Propagation in Laminated Metallic Composites. Materials. 2021; 14(10):2564. https://doi.org/10.3390/ma14102564

Chicago/Turabian StylePohl, Philip Manuel, Frank Kümmel, Christopher Schunk, Itziar Serrano-Munoz, Henning Markötter, Mathias Göken, and Heinz Werner Höppel. 2021. "About the Role of Interfaces on the Fatigue Crack Propagation in Laminated Metallic Composites" Materials 14, no. 10: 2564. https://doi.org/10.3390/ma14102564

APA StylePohl, P. M., Kümmel, F., Schunk, C., Serrano-Munoz, I., Markötter, H., Göken, M., & Höppel, H. W. (2021). About the Role of Interfaces on the Fatigue Crack Propagation in Laminated Metallic Composites. Materials, 14(10), 2564. https://doi.org/10.3390/ma14102564