Hot Deformation Behavior and Microstructure Evolution of Fe–5Mn–3Al–0.1C High-Strength Lightweight Steel for Automobiles

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Hot Deformation

2.3. Microstructure Characterization

3. Results and Discussion

3.1. Simulation in JMatPro

3.2. Physical Modeling on Gleeble

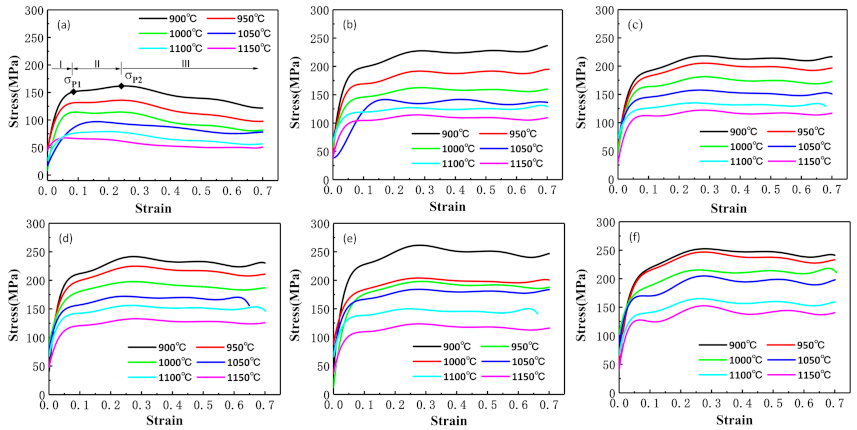

3.2.1. Flow Behavior

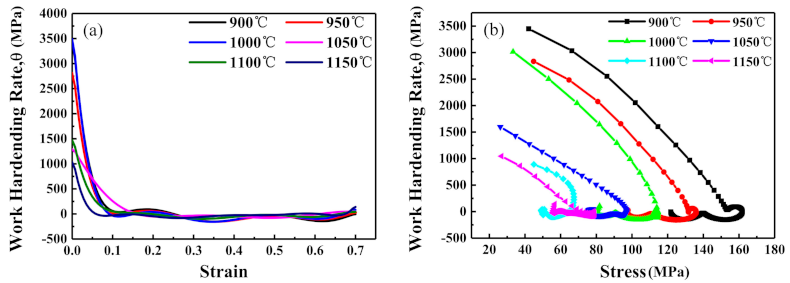

3.2.2. Determination of DRX Critical Stress and Strain

3.3. Processing Map and Microstructure Analysis

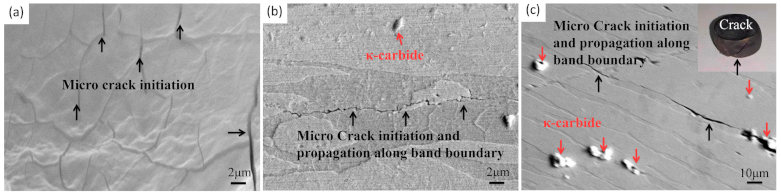

3.3.1. Region A

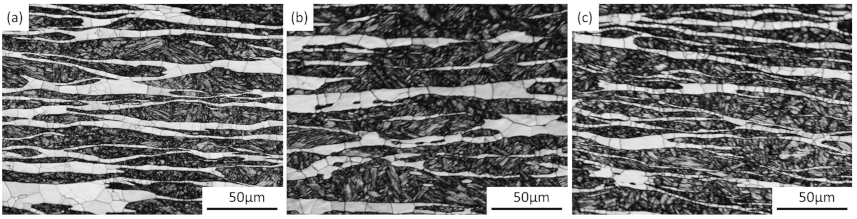

3.3.2. Region B

3.3.3. Region C

3.3.4. Region D

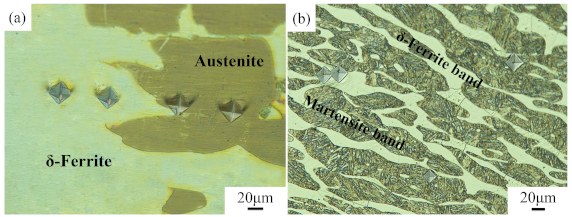

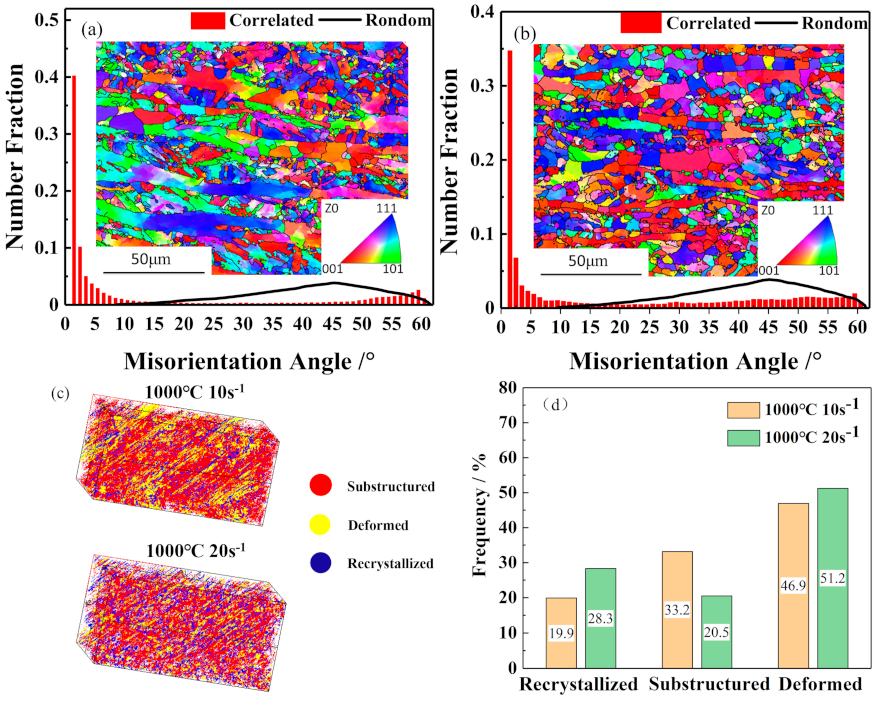

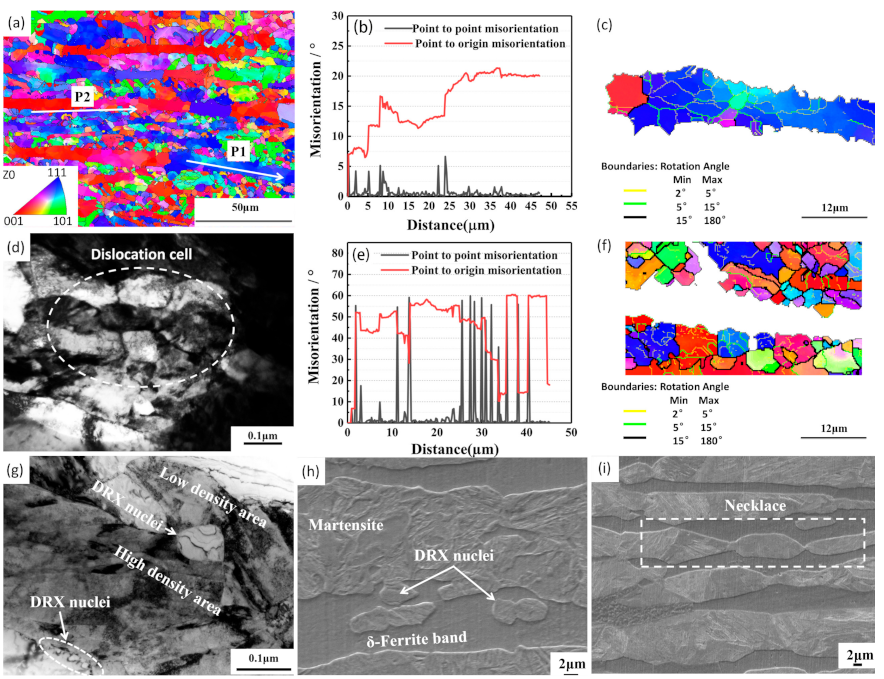

3.4. DRX Mechanism of Stable Regions

4. Conclusions

- The DRX critical strain (stress) predicting model, considering the Zener–Hollomon (Z) parameter and peak strain (stress), was established.

- 2.

- The processing maps of the newly designed Fe–5Mn–3Al–0.1C with different strains were constructed. With increasing strain, the low-dissipation region gradually becomes smaller, which means the processing region becomes larger. This occurs under the temperatures of 1000–1050 °C and the strain rate of 10–20 s−1.

- 3.

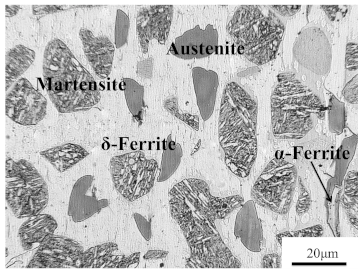

- The original microstructure of the steel consists of δ-ferrite and austenite. There is formation of DRX new grains within δ-ferrite grains and austenite grains during the hot compression test. The steel possesses unfavorable toughness at the deformation temperature of 900 °C, which is mainly due to the presence of coarse κ-carbides along grain boundaries, as well as the lower strengthening effect of grain boundaries.

- 4.

- The local misorientation (point-to-point) and the cumulative misorientation (point-to-origin) of EBSD and TEM image were analyzed in detail, there are two different DRX nucleation mechanisms that operate during the compression deformation process. DDRX is the primary nucleation mechanism of austenite, and DRX nuclei form due to the local bulging out of the original grain boundaries. The nucleation mechanism of CDRX was found in δ-ferrite, which is due to dislocation tangling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Zhang, X.-M.; Cai, Z.-H.; Ding, H.; Pan, M.-M.; Li, H.-S. Hot Deformation Behavior of a High-Mn Austenitic Steel for Cryogenic Liquified Natural Gas Applications. J. Mater. Eng. Perform. 2020, 29, 5503–5514. [Google Scholar] [CrossRef]

- Li, J.; Song, R.; Wang, Y.; Zhou, N. Decreasing yield ratio of 70 GPa.% grade hot-rolled medium Mn steel by weakening multi-strengthening effects. Vacuum 2019, 170. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Zhao, J.W.; Jiang, Z.Y. Thermomechanical processing of advanced high strength steels. Prog. Mater Sci. 2018, 94, 174–242. [Google Scholar] [CrossRef]

- De Meyer, M.; Vanderschueren, D.; De Cooman, B.C. The influence of the substitution of Si by Al on the properties of cold rolled C-Mn-Si TRIP steels. ISIJ Int. 1999, 39, 813–822. [Google Scholar] [CrossRef]

- Hu, B.; Luo, H.; Yang, F.; Dong, H. Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 2017, 33, 1457–1464. [Google Scholar] [CrossRef]

- Aydin, H.; Essadiqi, E.; Jung, I.-H.; Yue, S. Development of 3rd generation AHSS with medium Mn content alloying compositions. Mater. Sci. Eng. A 2013, 564, 501–508. [Google Scholar] [CrossRef]

- Grajcar, A.; Skrzypczyk, P.; Kuziak, R.; Gołombek, K. Effect of Finishing Hot-Working Temperature on Microstructure of Thermomechanically Processed Mn–Al Multiphase Steels. Steel Res. Int. 2014, 85, 1058–1069. [Google Scholar] [CrossRef]

- Grajcar, A.; Kuziak, R. Softening kinetics in Nb-microalloyed TRIP steels with increased Mn content. Adv. Mater. Res. 2011, 314–316, 119–122. [Google Scholar] [CrossRef]

- Poliak, E.I.; Bhattacharya, D. Aspects of thermomechanical processing of 3rd generation advanced high strength steels. Mater. Sci. Forum 2014, 783–786, 3–8. [Google Scholar] [CrossRef]

- Zhang, J.; Di, H.; Mao, K.; Wang, X.; Han, Z.; Ma, T. Processing maps for hot deformation of a high-Mn TWIP steel: A comparative study of various criteria based on dynamic materials model. Mater. Sci. Eng. A 2013, 587, 110–122. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Najafizadef, A. Hot Deformation and Dynamic Recrystallization of 17-4 PH Stainless Steel. ISIJ Int. 2013, 53, 680–689. [Google Scholar] [CrossRef]

- Saadatkia, S.; Mirzadeh, H.; Cabrera, J.M. Hot deformation behavior, dynamic recrystallization, and physically-based constitutive modeling of plain carbon steels. Mater. Sci. Eng. A 2015, 636, 196–202. [Google Scholar] [CrossRef]

- Gan, C.; Zheng, K.; Wang, H.; Qi, W.; Zhou, N. Flow Behavior of Lead-Free Machinable Brass during Hot Compression Deformation. Arab. J. Sci. Eng. 2014, 39, 9093–9100. [Google Scholar] [CrossRef]

- Li, Y.-P.; Song, R.-B.; Wen, E.-D.; Yang, F.-Q. Hot Deformation and Dynamic Recrystallization Behavior of Austenite-Based Low-Density Fe-Mn-Al-C Steel. Acta Metall. Sin. Engl. Lett. 2016, 29, 441–449. [Google Scholar] [CrossRef]

- Cai, Z.H.; Ding, H.; Misra, R.D.K.; Kong, H.; Wu, H.Y. Unique impact of ferrite in influencing austenite stability and deformation behavior in a hot-rolled Fe-Mn-Al-C steel. Mater. Sci. Eng. A 2014, 595, 86–91. [Google Scholar] [CrossRef]

- Wei, H.L.; Liu, G.Q.; Xiao, X.; Zhang, M.H. Dynamic recrystallization behavior of a medium carbon vanadium microalloyed steel. Mater. Sci. Eng. A 2013, 573, 215–221. [Google Scholar] [CrossRef]

- Rios, P.R.; Gottstein, G.; Shvindlerman, L.S. Application of the thermodynamic theory of irreversible processes to normal grain growth. Scr. Mater. 2001, 44, 893–897. [Google Scholar] [CrossRef]

- Momeni, A.; Ebrahimi, G.R.; Jahazi, M.; Bocher, P. Microstructure evolution at the onset of discontinuous dynamic recrystallization: A physics-based model of subgrain critical size. J. Alloys Compd. 2014, 587, 199–210. [Google Scholar] [CrossRef]

- Huang, K.; Loge, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Poliak, E.I.; Jonas, J.J. A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Mater. 1996, 44, 127–136. [Google Scholar] [CrossRef]

- Poliak, E.I.; Jonas, J.J. Initiation of Dynamic Recrystallization in Constant Strain Rate Hot Deformation. ISIJ Int. 2007, 43, 684–691. [Google Scholar] [CrossRef]

- Cai, Z.; Ji, H.; Pei, W.; Tang, X.; Huang, X.; Liu, J. Hot workability, constitutive model and processing map of 3Cr23Ni8Mn3N heat resistant steel. Vacuum 2019, 165, 324–336. [Google Scholar] [CrossRef]

- Wen, D.X.; Lin, Y.C.; Chen, J.; Chen, X.M.; Zhang, J.L.; Liang, Y.J.; Li, L.T. Work-hardening behaviors of typical solution-treated and aged Ni-based superalloys during hot deformation. J. Alloys Compd. 2015. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.G.; Lin, H.; Li, M.Q. The metadynamic recrystallization in the two-stage isothermal compression of 300M steel. Mater. Sci. Eng. A 2013, 565, 126–131. [Google Scholar] [CrossRef]

- Chen, X.M.; Lin, Y.C.; Wen, D.X.; Zhang, J.L.; He, M. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation. Mater. Des. 2014, 57, 568–577. [Google Scholar] [CrossRef]

- Jinbin, W.; Runyuan, H.; Huaying, L.; Guangming, L. Constitutive equation of Fe5Mn3Al medium-Mn automobile steel. J. Mater. Metall. 2019, 18, 65–71. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Mandal, S.; Athreya, C.N.; Babu, K.A.; de Boer, B.; Sarma, V.S. Influence of processing parameters on dynamic recrystallization and the associated annealing twin boundary evolution in a nickel base superalloy. Mater. Sci. Eng. A 2017, 700, 49–58. [Google Scholar] [CrossRef]

- Liu, Y.G.; Liu, J.; Li, M.Q.; Lin, H. The study on kinetics of static recrystallization in the two-stage isothermal compression of 300M steel. Comput. Mater. Sci. 2014, 84, 115–121. [Google Scholar] [CrossRef]

- Zhang, P.; Yi, C.; Chen, G.; Qin, H.Y.; Wang, C.J. Constitutive Model Based on Dynamic Recrystallization Behavior during Thermal Deformation of a Nickel-Based Superalloy. Metals 2016, 6, 161. [Google Scholar] [CrossRef]

- Lyszkowski, R.; Bystrzycki, J. Hot deformation and processing maps of a Fe-Al intermetallic alloy. Mater. Charact. 2014, 96, 196–205. [Google Scholar] [CrossRef]

- Prasad, Y.; Rao, K.; Sasidhar, S. Hot Working Guide: A Compendium of Processing Maps; ASM International: Geauga County, OH, USA, 2015; ISBN 978-1-62708-091-0. [Google Scholar] [CrossRef]

- Rao, K.; Prasad, Y.; Suresh, K. Hot working behavior and processing map of a γ-TiAl alloy synthesized by powder metallurgy. Mater. Des. 2011, 32, 4874–4881. [Google Scholar] [CrossRef]

- Latypov, M.I.; Shin, S.; De Cooman, B.C.; Kim, H.S. Micromechanical finite element analysis of strain partitioning in multiphase medium manganese TWIP plus TRIP steel. Acta Mater. 2016, 108, 219–228. [Google Scholar] [CrossRef]

- Han, S.Y.; Shin, S.Y.; Lee, S.; Kim, N.J.; Kwak, J.H.; Chin, K.G. Effect of Carbon Content on Cracking Phenomenon Occurring during Cold Rolling of Three Light-Weight Steel Plates. Metall. Mater. Trans. A 2011, 42A, 138–146. [Google Scholar] [CrossRef]

- Jeong, J.; Lee, C.-Y.; Park, I.-J.; Lee, Y.-K. Isothermal precipitation behavior of κ-carbide in the Fe–9Mn–6Al–0.15 C lightweight steel with a multiphase microstructure. J. Alloys Compd. 2013, 574, 299–304. [Google Scholar] [CrossRef]

- Li, Z.C.; Zhang, X.T.; Mou, Y.J.; Misra, R.D.K.; He, L.F.; Li, H.P. The impact of intercritical annealing in conjunction with warm deformation process on microstructure, mechanical properties and TRIP effect in medium-Mn TRIP steels. Mater. Sci. Eng. A 2019, 746, 363–371. [Google Scholar] [CrossRef]

- Kaar, S.; Krizan, D.; Schwabe, J.; Hofmann, H.; Hebesberger, T.; Commenda, C.; Samek, L. Influence of the Al and Mn content on the structure-property relationship in density reduced TRIP-assisted sheet steels. Mater. Sci. Eng. A 2018, 735, 475–486. [Google Scholar] [CrossRef]

- Xu, L.X.; Wu, H.B. Microstructural evolution and mechanical property optimization under solution treatment of an ultra-low carbon Fe-Mn-Al duplex steel. Mater. Sci. Eng. A 2018, 738, 163–173. [Google Scholar] [CrossRef]

- Liu, Y.; Geng, C.; Lin, Q.; Xiao, Y.; Xu, J.; Kang, W. Study on hot deformation behavior and intrinsic workability of 6063 aluminum alloys using 3D processing map. J. Alloys Compd. 2017, 713, 212–221. [Google Scholar] [CrossRef]

| Element | C | Mn | Al | Fe |

|---|---|---|---|---|

| Content (% wt.) | 0.13 | 5.50 | 3.10 | Bal. |

| Phases | Vickers Hardness (HV) |

|---|---|

| Initial δ-ferrite | 143 ± 5 |

| Initial austenite | 195 ± 8 |

| δ-ferrite band | 246 ± 6 |

| Martensite | 372 ± 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Wang, J.; Ji, Y.; Hao, R.; Li, H.; Li, Y.; Jiang, Z. Hot Deformation Behavior and Microstructure Evolution of Fe–5Mn–3Al–0.1C High-Strength Lightweight Steel for Automobiles. Materials 2021, 14, 2478. https://doi.org/10.3390/ma14102478

Liu G, Wang J, Ji Y, Hao R, Li H, Li Y, Jiang Z. Hot Deformation Behavior and Microstructure Evolution of Fe–5Mn–3Al–0.1C High-Strength Lightweight Steel for Automobiles. Materials. 2021; 14(10):2478. https://doi.org/10.3390/ma14102478

Chicago/Turabian StyleLiu, Guangming, Jinbin Wang, Yafeng Ji, Runyuan Hao, Huaying Li, Yugui Li, and Zhengyi Jiang. 2021. "Hot Deformation Behavior and Microstructure Evolution of Fe–5Mn–3Al–0.1C High-Strength Lightweight Steel for Automobiles" Materials 14, no. 10: 2478. https://doi.org/10.3390/ma14102478

APA StyleLiu, G., Wang, J., Ji, Y., Hao, R., Li, H., Li, Y., & Jiang, Z. (2021). Hot Deformation Behavior and Microstructure Evolution of Fe–5Mn–3Al–0.1C High-Strength Lightweight Steel for Automobiles. Materials, 14(10), 2478. https://doi.org/10.3390/ma14102478