Intrinsic and Extrinsic Effects of Microstructure on Properties in Cast Al Alloys

Abstract

1. Introduction

- Pores are inevitable, i.e., intrinsic, in aluminum castings;

- Al–Cu alloys are difficult to cast because of their propensity for hot tears;

- The most important microstructural parameter is dendrite arm spacing, especially to control ductility;

- β–Al5FeSi platelets are weak and brittle, causing premature fracture in castings;

- In Al–Si alloys, Si eutectic particle size needs to be controlled (e.g., addition of modifiers such as Sr) because these particles fracture and debond in the early stages of plastic deformation, causing cracks to form, leading to premature fracture.

2. Intrinsic and Extrinsic Effects

2.1. Pores and Hot Tears

2.2. Dendrite Arm Spacing–Ductility Relationship

2.3. β–Al5FeSi Platelets

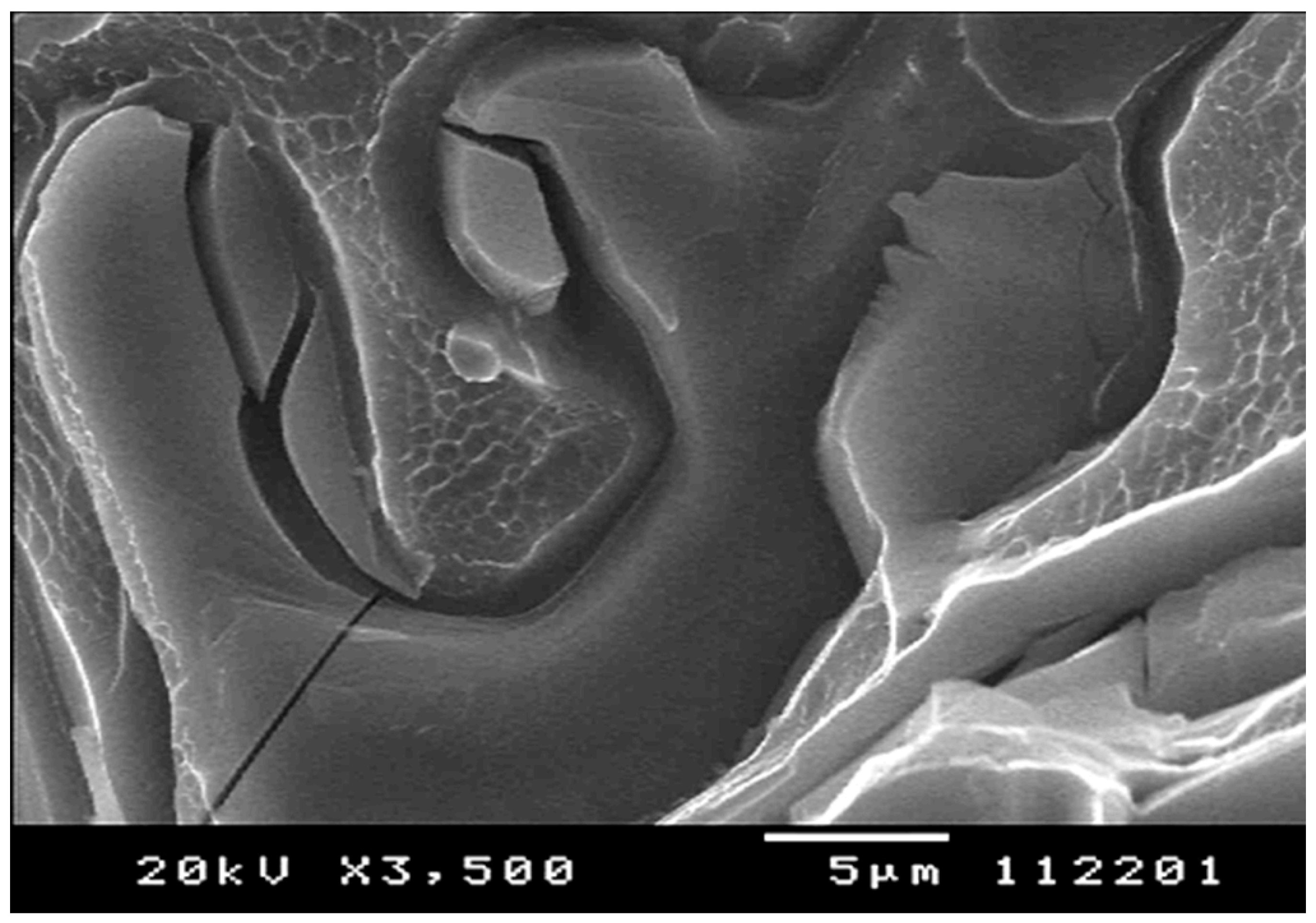

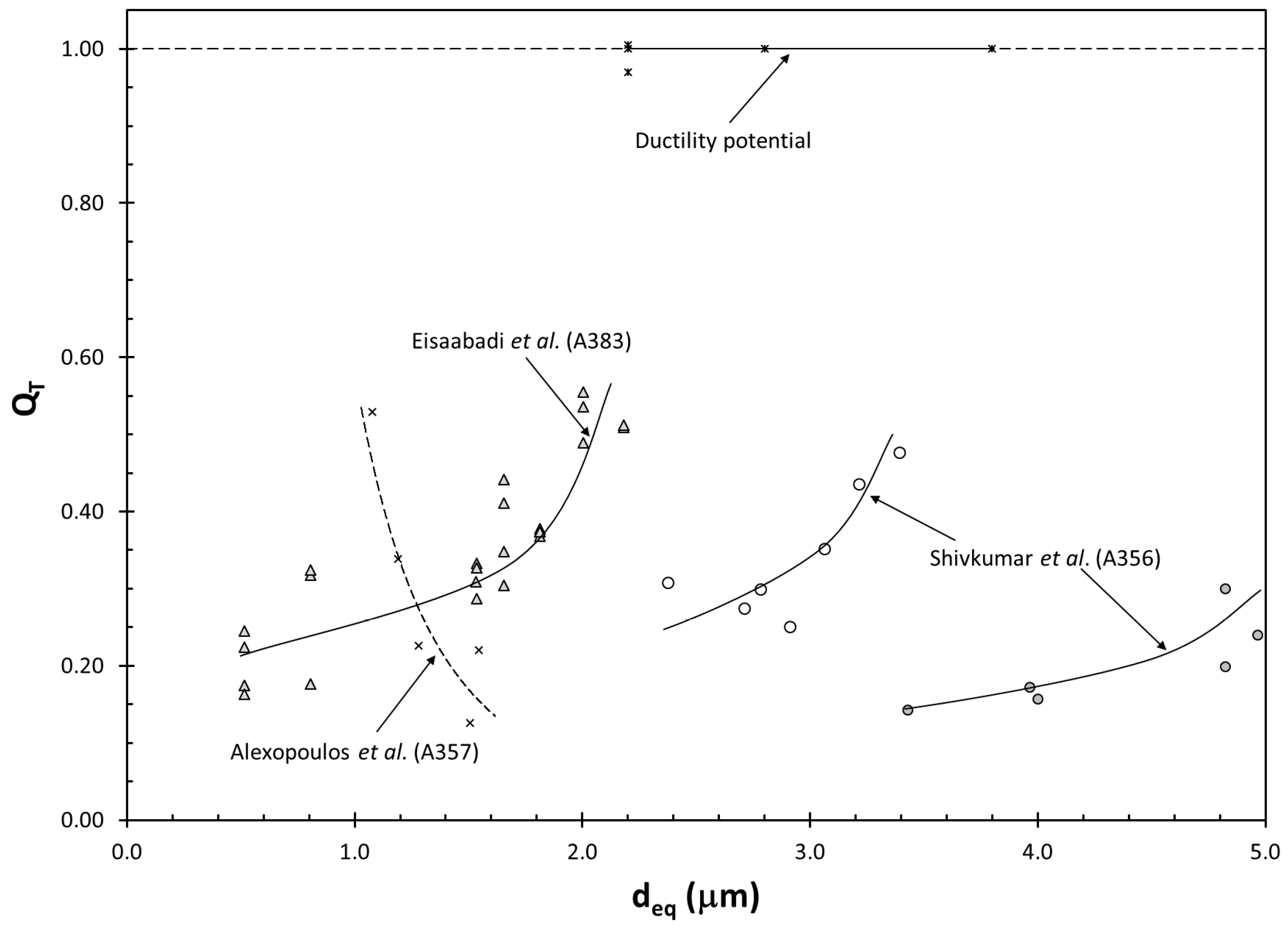

2.4. Si Particles in Al–Si Alloys

3. Epilogue

4. Conclusions

- Pores cannot nucleate, either homogeneously or heterogeneously in liquid aluminum. Therefore, nucleation is bypassed in pore formation because of the presence of bifilms in liquid aluminum, which represent the most significant, if not the only, weakening mechanism in liquid aluminum. Because pore formation is a necessary condition for the initiation of a hot tear, we can conclude that pores and hot tears are extrinsic defects and can be avoided.

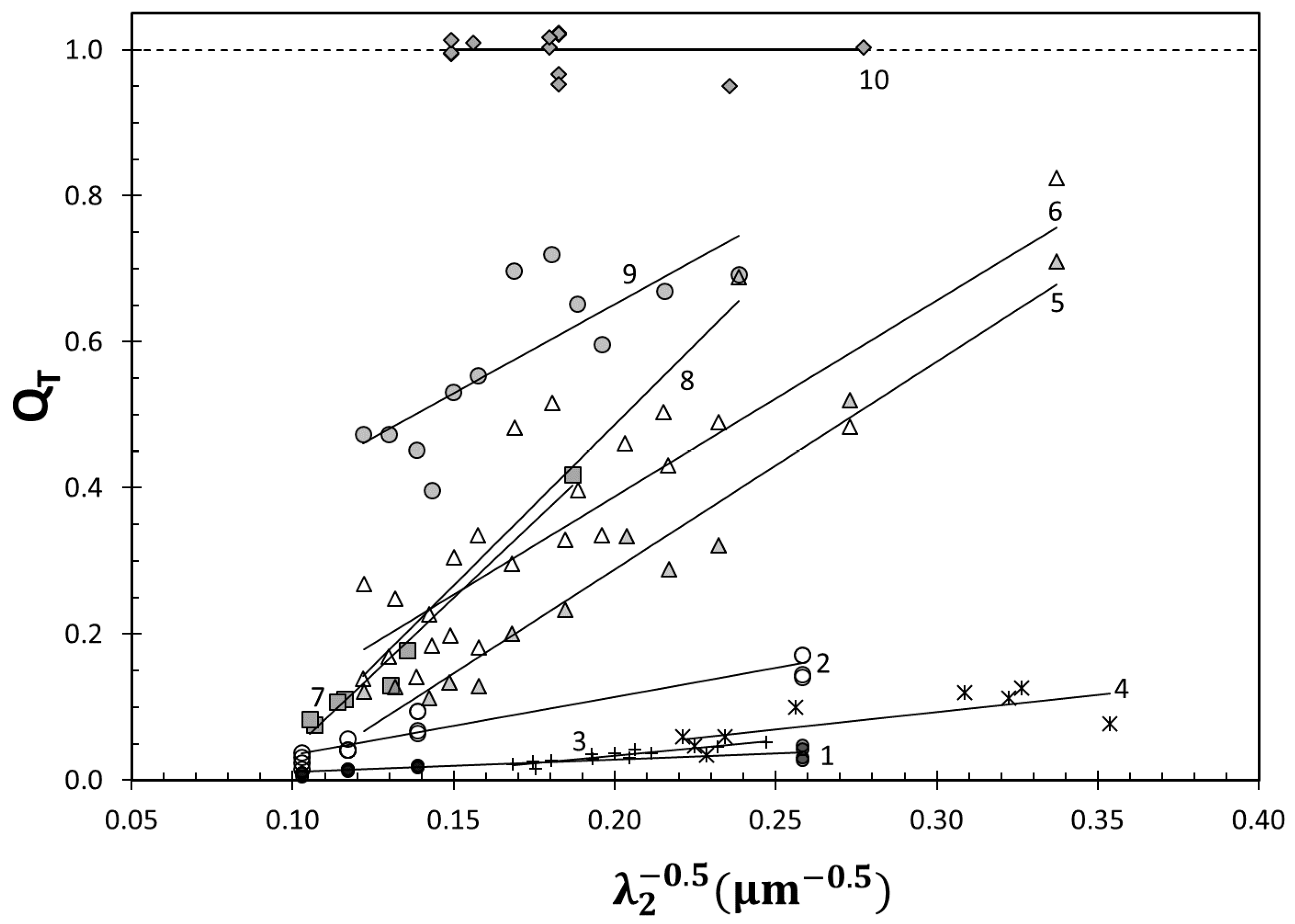

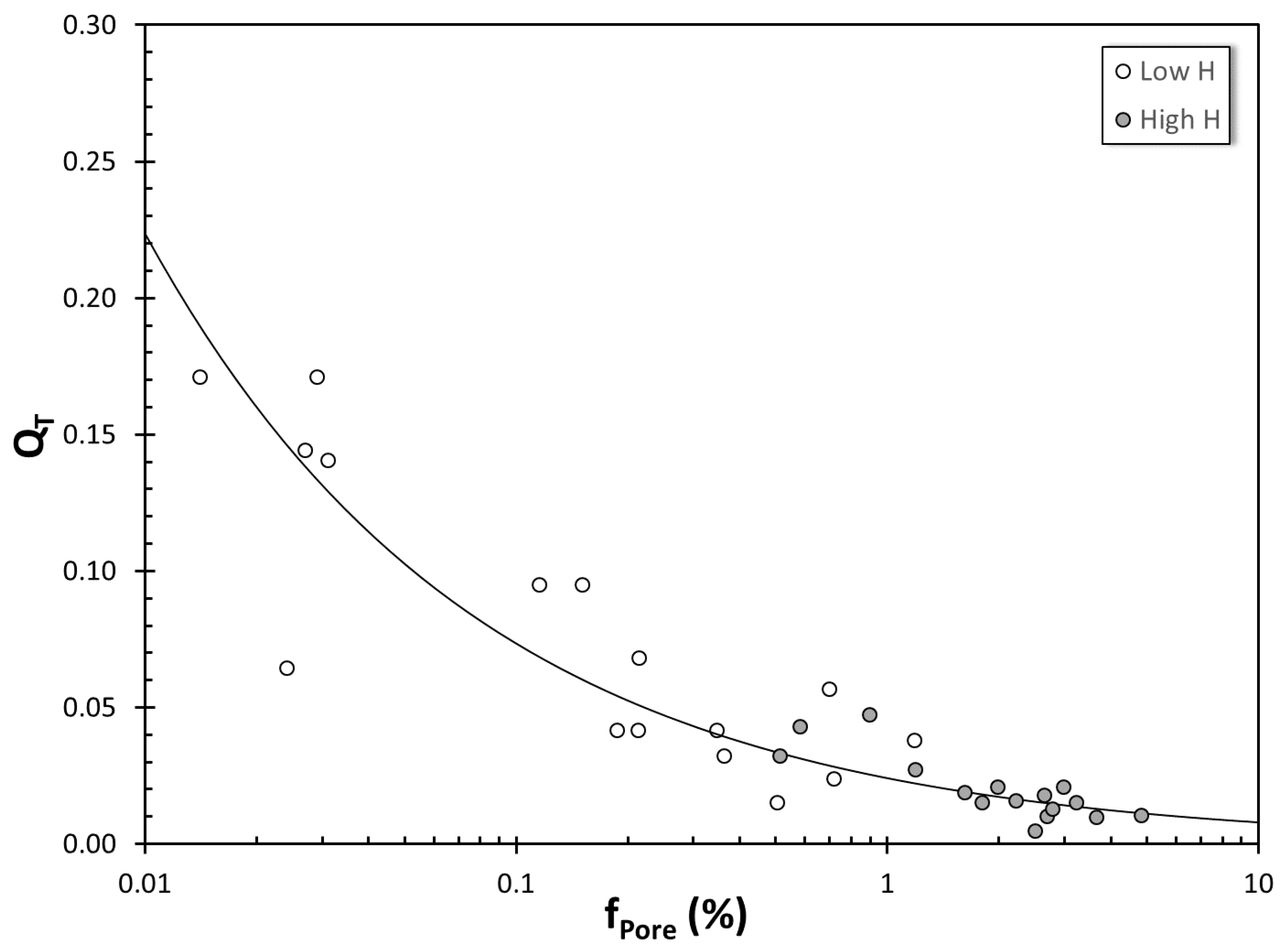

- Dendrite arm spacing has no intrinsic effect on ductility. A correlation is established between ductility and dendrite arm spacing only when bifilms are present in solid aluminum. The correlation is weak at very high and very low levels of bifilm density in aluminum. At intermediate levels, the strength of the correlation first increases, then decreases with bifilm content.

- In the absence of bifilms, Fe would be retained in solution during solidification and later precipitate as Al6Fe in the solid aluminum matrix. Therefore, the formation of the β–Al5FeSi platelets takes place intrinsically due to bifilms. These platelets are intrinsically strong and ductile, but extrinsically weakened by bifilms. Therefore, subsequent fracture of β–Al5FeSi platelets during deformation is also extrinsic.

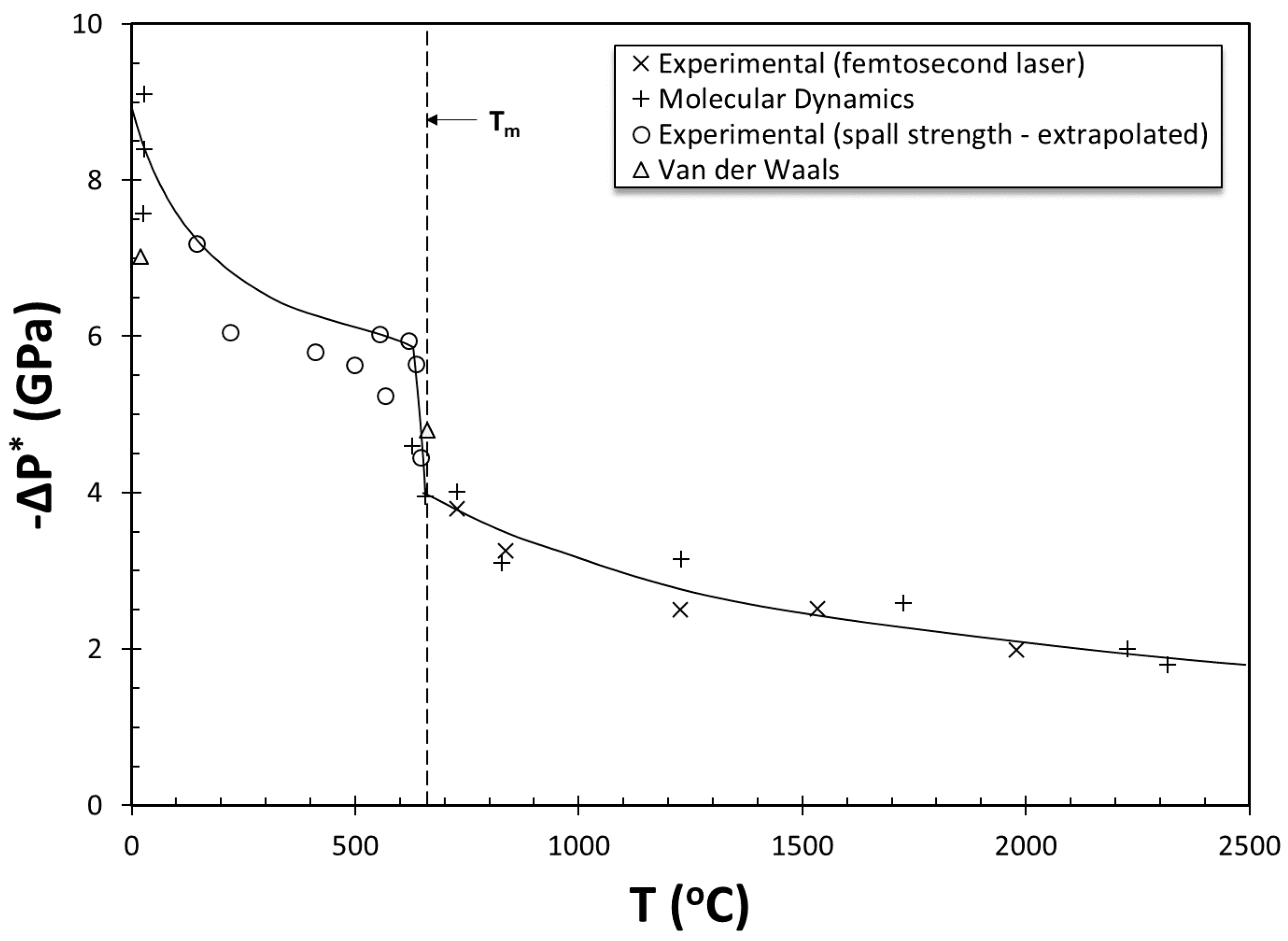

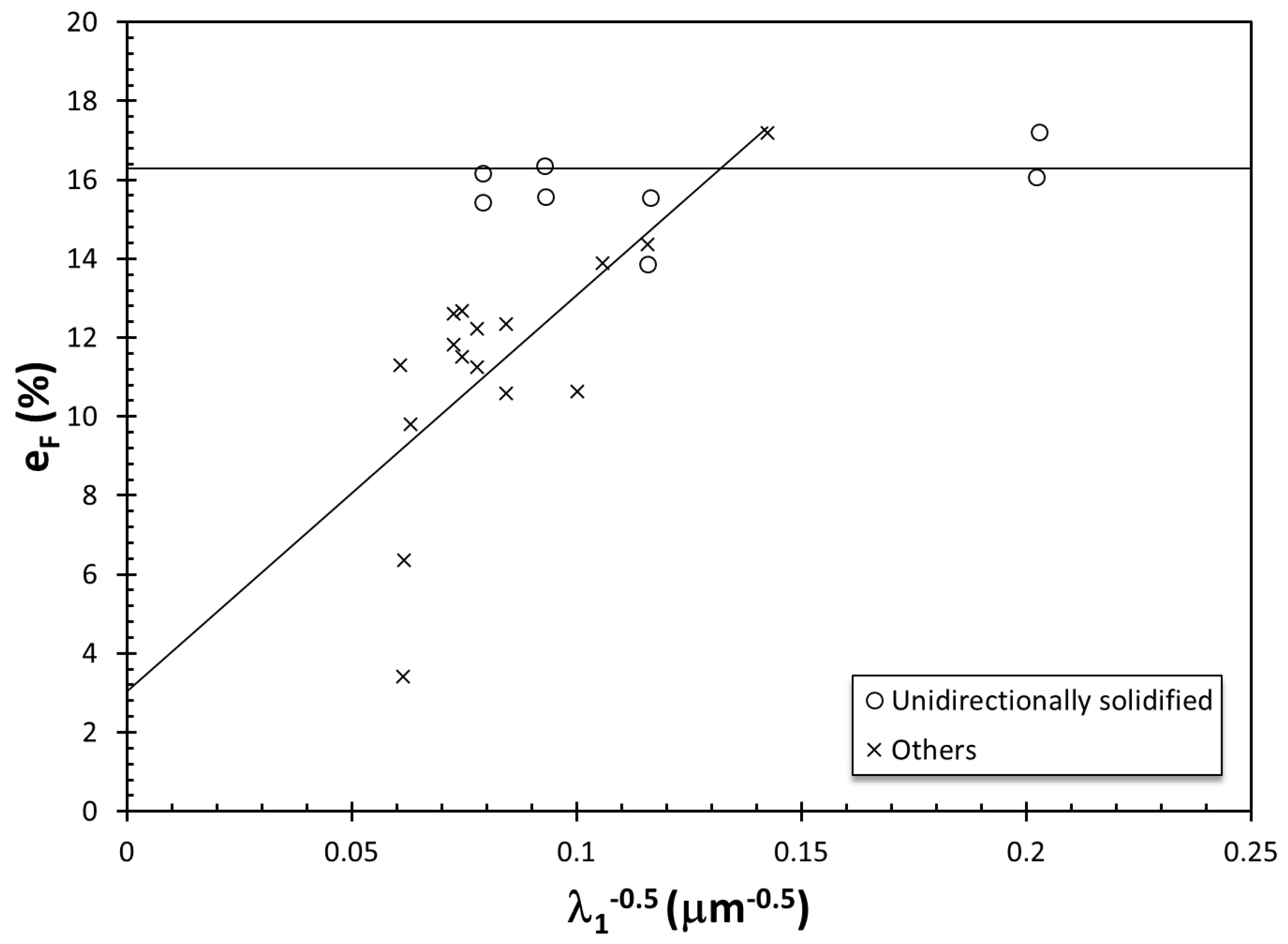

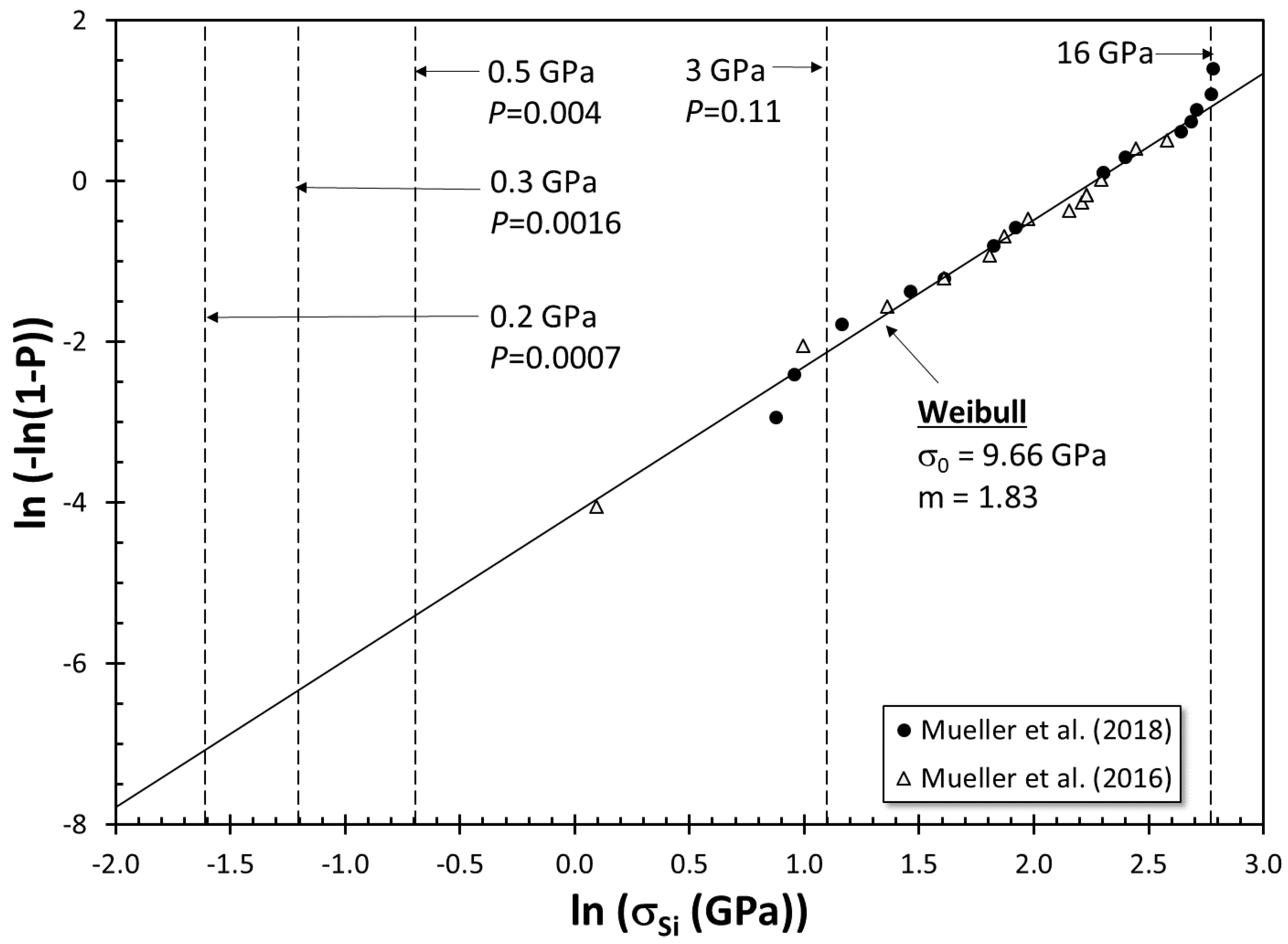

- Si eutectic particles are intrinsically strong and ductile, with a strength of 16 GPa as determined by molecular dynamics simulations and in situ micromechanical testing. Consequently, they should not fracture during tensile deformation unless they have precipitated on bifilms or other intermetallics. Therefore, damage to Si particles during tensile testing is extrinsic. Intrinsic debonding of Si from the aluminum matrix is possible only in very limited cases. The abundance of debonding observed in the literature suggests that extrinsic factors weaken the Al–Si interface.

- The duality in aluminum metallurgy, which is based on whether a product is cast or wrought, is a culmination of the strong, extrinsic correlations demonstrated in this paper. Even the alloys developed only for casting applications, such as the Al–Si alloys, are a result of this duality. The entire metallurgy of these alloys must be reevaluated and a new approach to the production of aluminum castings must be adopted, so that they can be produced at a lower cost and perform at much higher levels.

Author Contributions

Funding

Conflicts of Interest

References

- Metallic Materials and Elements for Aerospace Vehicle Structures; United States Department of Defense: Washington, DC, USA, 2003.

- Tiryakioglu, M. On the Intrinsic and Extrinsic Microstructure-Property Effects in Cast Aluminum Alloys. In TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings; Springer Science and Business Media LLC: Berlin, Germany, 2019; pp. 293–302. [Google Scholar]

- Staley, J. Microstructure and Toughness of High-Strength Aluminum Alloys. In Properties Related to Fracture Toughness; V. Weiss and W. Warke: West Conshohocken, PA, USA, 1976; pp. 71–103. [Google Scholar]

- Farup, I.; Drezet, J.-M.; Rappaz, M. In situ observation of hot tearing formation in succinonitrile-acetone. Acta Mater. 2001, 49, 1261–1269. [Google Scholar] [CrossRef]

- Lu, H.M.; Jiang, Q. Surface Tension and Its Temperature Coefficient for Liquid Metals. J. Phys. Chem. B 2005, 109, 15463–15468. [Google Scholar] [CrossRef] [PubMed]

- Yousefian, P.; Tiryakioglu, M. Pore Formation During Solidification of Aluminum: Reconciliation of Experimental Observations, Modeling Assumptions, and Classical Nucleation Theory. Met. Mater. Trans. A 2017, 49, 563–575. [Google Scholar] [CrossRef]

- Erzi, E.; Tiryakioḡlu, M. On the fracture pressure of liquid metals. Mater. Sci. Technol. 2019, 35, 1656–1659. [Google Scholar] [CrossRef]

- Tiryakioglu, M. On the Intrinsic Fracture Pressure of Liquid and Solid Aluminum Around Its Melting Temperature. Met. Mater. Trans. A 2018, 49, 5953–5955. [Google Scholar] [CrossRef]

- Campbell, J. Origin of Porosity in Cast Metals. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 1967. [Google Scholar]

- Campbell, J. Pore Nucleation in Solidifying Metals, Proceedings of the Conference on the Solidification of Metals, Brighton, UK, 1968; Institute of Metals Publication: London, UK, 1968; pp. 18–26. [Google Scholar]

- Shahani, H.; Fredriksson, H. On the mechanism of precipitation of pores in melts. Scand. J. Metall. 1985, 14, 316–320. [Google Scholar]

- Tiryakioğlu, M. submitted for publication. (under review).

- Campbell, J. Cavitation in liquid and solid metals: role of bifilms. Mater. Sci. Technol. 2014, 31, 565–572. [Google Scholar] [CrossRef]

- Campbell, J. The Origin of Griffith Cracks. Met. Mater. Trans. A 2011, 42, 1091–1097. [Google Scholar] [CrossRef]

- Campbell, J. Entrainment defects. Mater. Sci. Technol. 2006, 22, 127–145. [Google Scholar] [CrossRef]

- Campbell, J. An overview of the effects of bifilms on the structure and properties of cast alloys. Met. Mater. Trans. A 2006, 37, 857–863. [Google Scholar] [CrossRef]

- Staley, J.T.; Tiryakioglu, M.; Campbell, J., Jr. The effect of increased HIP temperatures on bifilms and tensile properties of A206–T71 aluminum castings. Mater. Sci. Eng. A 2007, 460, 324–334. [Google Scholar] [CrossRef]

- Dispinar, D.; Campbell, J. Porosity, hydrogen and bifilm content in Al alloy castings. Mater. Sci. Eng. A 2011, 528, 3860–3865. [Google Scholar] [CrossRef]

- Campbell, J. Metallurgy without Bifilms: No More Fractures, Proceedings of the Shape Casting: 5th International Symposium 2014; John Wiley and Sons Ltd: Hoboken, NJ, USA, 2014; pp. 161–170. [Google Scholar]

- El-Sayed, M.; Griffiths, W.D. Hydrogen, bifilms and mechanical properties of Al castings. Int. J. Cast Met. Res. 2014, 27, 282–287. [Google Scholar] [CrossRef]

- El-Sayed, M.A.; Hassanin, H.; Essa, K.; El-Sayed, M. Bifilm defects and porosity in Al cast alloys. Int. J. Adv. Manuf. Technol. 2016, 86, 1173–1179. [Google Scholar] [CrossRef]

- Tunçay, T.; Tekeli, S.; Özyürek, D.; Dişpinar, D. Microstructure–bifilm interaction and its relation with mechanical properties in A356. Int. J. Cast Met. Res. 2016, 30, 1–10. [Google Scholar] [CrossRef]

- Uludağ, M.; Çetin, R.; Dispinar, D.; Tiryakioglu, M. Characterization of the Effect of Melt Treatments on Melt Quality in Al–7wt %Si–Mg Alloys. Metals 2017, 7, 157. [Google Scholar] [CrossRef]

- Tiryakioglu, M.; Yousefian, P.; Eason, P.D. Quantification of Entrainment Damage in A356 Aluminum Alloy Castings. Met. Mater. Trans. A 2018, 49, 5815–5822. [Google Scholar] [CrossRef]

- Dispinar, D.; Campbell, J. Critical assessment of reduced pressure test. Part 1: Porosity phenomena. Int. J. Cast Met. Res. 2004, 17, 280–286. [Google Scholar] [CrossRef]

- Dispinar, D.; Campbell, J. Critical assessment of reduced pressure test. Part 2: Quantification. Int. J. Cast Met. Res. 2004, 17, 287–294. [Google Scholar] [CrossRef]

- Uludağ, M.; Çetin, R.; Dişpinar, D.; Tiryakioglu, M.; Tiryakioǧlu, M. The effects of degassing, grain refinement & Sr-addition on melt quality-hot tear sensitivity relationships in cast A380 aluminum alloy. Eng. Fail. Anal. 2018, 90, 90–102. [Google Scholar]

- Campbell, J. Complete Casting Handbook: Metal. Casting Processes, Metallurgy, Techniques and Design; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Campbell, J. “Stop Pouring, Start Casting”. Int. J. Met. 2012, 6, 7–18. [Google Scholar] [CrossRef]

- Tiryakioḡlu, M. The Effect of Hydrogen on Pore Formation in Aluminum Alloy Castings: Myth Versus Reality. Metals 2020, 10, 368. [Google Scholar] [CrossRef]

- Zhang, J.; Singer, R.F. Effect of grain-boundary characteristics on castability of nickel-base superalloys. Met. Mater. Trans. A 2004, 35, 939–946. [Google Scholar] [CrossRef]

- Lin, S.; Aliravci, C.; Pekguleryuz, M. Hot-Tear Susceptibility of Aluminum Wrought Alloys and the Effect of Grain Refining. Met. Mater. Trans. A 2007, 38, 1056–1068. [Google Scholar] [CrossRef]

- Easton, M.; Wang, H.; Grandfield, J.; St John, D.; Sweet, E. In An analysis of the effect of grain refinement on the hot tearing of aluminium alloys. Mater. Forum 2004, 28, 224–229. [Google Scholar]

- Schumacher, P.; Greer, A.L. Heterogeneously nucleated α–Al in amorphous aluminium alloys. Mater. Sci. Eng. A 1994, 178, 309–313. [Google Scholar] [CrossRef]

- Mohanty, P.; Gruzleski, J. Mechanism of grain refinement in aluminium. Acta Met. et Mater. 1995, 43, 2001–2012. [Google Scholar] [CrossRef]

- Schumacher, P.; Greer, A.L.; Worth, J.; Evans, P.V.; Kearns, M.A.; Fisher, P.; Green, A.H. New studies of nucleation mechanisms in aluminium alloys: Implications for grain refinement practice. Mater. Sci. Technol. 1998, 14, 394–404. [Google Scholar] [CrossRef]

- Easton, M.; StJohn, D. Grain refinement of aluminum alloys: Part II. Confirmation of, and a mechanism for, the solute paradigm. Met. Mater. Trans. A 1999, 30, 1625–1633. [Google Scholar] [CrossRef]

- Easton, M.; StJohn, D. Grain refinement of aluminum alloys: Part I. the nucleant and solute paradigms—a review of the literature. Met. Mater. Trans. A 1999, 30, 1613–1623. [Google Scholar] [CrossRef]

- Greer, A.L.; Bunn, A.; Tronche, A.; Evans, P.; Bristow, D. Modelling of inoculation of metallic melts: application to grain refinement of aluminium by Al–Ti–B. Acta Mater. 2000, 48, 2823–2835. [Google Scholar] [CrossRef]

- Easton, M.; StJohn, D. An analysis of the relationship between grain size, solute content, and the potency and number density of nucleant particles. Met. Mater. Trans. A 2005, 36, 1911–1920. [Google Scholar] [CrossRef]

- Dahle, A.; StJohn, D. Rheological behaviour of the mushy zone and its effect on the formation of casting defects during solidification. Acta Mater. 1998, 47, 31–41. [Google Scholar] [CrossRef]

- Bishop, H.; Myskowski, E.; Pellini, W. Contribution of riser and casting end effects to the soundness of steel bars. AFS Trans. 1951, 59, 171. [Google Scholar]

- Bishop, H.; Pellini, W. The contribution of risers and chill-edge effects to soundness of cast steel plates. AFS Trans. 1950, 58, 185–197. [Google Scholar]

- Myskowski, E.; Bishop, H.; Pellini, W. Feeding range of joined sections. AFS Trans. 1953, 61, 302–308. [Google Scholar]

- Pellini, W.S. Factors which determine riser adequacy and feeding range. AFS Trans. 1953, 61, 61–80. [Google Scholar]

- Tiryakioglu, M. On intrinsic and extrinsic feeding distance calculations for aluminium alloys. Mater. Sci. Technol. 2019, 35, 738–741. [Google Scholar] [CrossRef]

- Erzi, E.; Tiryakioğlu, M. Feeding distance of tin bronze castings: intrinsic and extrinsic estimates. Mater. Sci. Technol. 2019, 35, 2211–2216. [Google Scholar] [CrossRef]

- Mikhailovskij, I.; Mazilova, T.I.; Voyevodin, V.N.; Mazilov, A. Inherent strength of grain boundaries in tungsten. Phys. Rev. B 2011, 83, 83. [Google Scholar] [CrossRef]

- Kotrechko, S.; Ovsjannikov, O.; Mazilova, T.; Mikhailovskij, I.; Sadanov, E.; Stetsenko, N. Inherent hydrostatic tensile strength of tungsten nanocrystals. Philos. Mag. 2017, 97, 930–943. [Google Scholar] [CrossRef]

- Fridman, V.Y. Strength and plasticity of submicron tungsten fibers. Sov. Phys. Solid State 1971, 12, 2461–2462. [Google Scholar]

- Rasool, H.I.; Ophus, C.; Klug, W.S.; Zettl, A.; Gimzewski, J.K. Measurement of the intrinsic strength of crystalline and polycrystalline graphene. Nat. Commun. 2013, 4, 2811. [Google Scholar] [CrossRef]

- Lee, G.-H.; Cooper, R.; An, S.J.; Lee, S.; Van Der Zande, A.M.; Petrone, N.; Hammerberg, A.G.; Lee, C.; Crawford, B.; Oliver, W.; et al. High-Strength Chemical-Vapor-Deposited Graphene and Grain Boundaries. Science 2013, 340, 1073–1076. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.-H.; Deng, S.; Wang, T.; Kohyama, M.; Yamamoto, R. Theoretical tensile strength of an Al grain boundary. Phys. Rev. B 2004, 69, 69. [Google Scholar] [CrossRef]

- Zhang, S.; Kontsevoi, O.Y.; Freeman, A.J.; Olson, G.B. Sodium-induced embrittlement of an aluminum grain boundary. Phys. Rev. B 2010, 82, 224107. [Google Scholar] [CrossRef]

- Lu, G.-H.; Zhang, Y.; Deng, S.; Wang, T.; Kohyama, M.; Yamamoto, R.; Liu, F.; Horikawa, K.; Kanno, M. Origin of intergranular embrittlement of Al alloys induced by Na and Ca segregation: Grain boundary weakening. Phys. Rev. B 2006, 73, 73. [Google Scholar] [CrossRef]

- Lu, G.-H.; Suzuki, A.; Ito, A.; Kohyama, M.; Yamamoto, R. Ab initio pseudopotential studies on an Al Σ = 9 grain boundary: Effects of Na and Ca impurities. Philos. Mag. Lett. 2001, 81, 757–766. [Google Scholar] [CrossRef]

- Flemings, M.C. Solidification processing. Met. Mater. Trans. A 1974, 5, 2121–2134. [Google Scholar] [CrossRef]

- Reyes, R.V.; Kakitani, R.; Costa, T.; Spinelli, J.E.; Cheung, N.; Garcia, A. Cooling thermal parameters, microstructural spacing and mechanical properties in a directionally solidified hypereutectic Al–Si alloy. Philos. Mag. Lett. 2016, 96, 1–10. [Google Scholar] [CrossRef]

- Reyes, R.V.; Bello, T.S.; Kakitani, R.; Costa, T.; Garcia, A.; Cheung, N.; Spinelli, J.E. Tensile properties and related microstructural aspects of hypereutectic Al–Si alloys directionally solidified under different melt superheats and transient heat flow conditions. Mater. Sci. Eng. A 2017, 685, 235–243. [Google Scholar] [CrossRef]

- Duarte, R.N.; Faria, J.D.; Brito, C.; Veríssimo, N.C.; Cheung, N.; Garcia, A. Length scale of the dendritic microstructure affecting tensile properties of Al–(Ag)–(Cu) alloys. Int. J. Mod. Phys. B 2016, 30, 1550261. [Google Scholar] [CrossRef]

- Canté, M.V.; Spinelli, J.E.; Cheung, N.; Garcia, A. The correlation between dendritic microstructure and mechanical properties of directionally solidified hypoeutectic Al–Ni alloys. Met. Mater. Int. 2010, 16, 39–49. [Google Scholar] [CrossRef]

- Tiryakioclu, M.; Campbell, J.; Tiryakioglu, M. Ductility, structural quality, and fracture toughness of Al–Cu–Mg–Ag (A201) alloy castings. Mater. Sci. Technol. 2009, 25, 784–789. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Campbell, J.; Alexopoulos, N.D. Quality Indices for Aluminum Alloy Castings: A Critical Review. Met. Mater. Trans. A 2009, 40, 802–811. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Campbell, J.; Alexopoulos, N.D. On the Ductility of Cast Al–7 Pct Si–Mg Alloys. Met. Mater. Trans. A 2009, 40, 1000–1007. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Campbell, J.; Alexopoulos, N.D. On the ductility potential of cast Al–Cu–Mg (206) alloys. Mater. Sci. Eng. A 2009, 506, 23–26. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Campbell, J. Quality Index for Aluminum Alloy Castings. Int. J. Met. 2014, 8, 39–42. [Google Scholar] [CrossRef]

- Samuel, A.M.; Samuel, F.H. Effect of melt treatment, solidification conditions and porosity level on the tensile properties of 319.2 endchill aluminium castings. J. Mater. Sci. 1995, 30, 4823–4833. [Google Scholar] [CrossRef]

- Grosselle, F.; Timelli, G.; Bonollo, F.; Molina, R. Correlation between microstructure and mechanical properties of Al–Si diecast engine blocks. Metall. Sci. Technol. 2009, 27, 2–10. [Google Scholar]

- Grosselle, F.; Timelli, G.; Bonollo, F.; Tiziani, A.; Della Corte, E. Correlation between microstructure and mechanical properties of Al–Si cast alloys. Metall. Ital. 2009, 101, 25–32. [Google Scholar]

- Wang, Q. Microstructural effects on the tensile and fracture behavior of aluminum casting alloys a356/357. Metall. Mater. Trans. A 2003, 34, 2887–2899. [Google Scholar] [CrossRef]

- Miguelucci, E. The aluminum association cast alloy test program: Interim report. AFS Trans. 1985, 93, 913–916. [Google Scholar]

- Doglione, R. In Situ Investigations on the Ductility of an Al–Si–Mg Casting Alloy. JOM 2012, 64, 51–57. [Google Scholar] [CrossRef]

- Ghassemali, E.; Riestra, M.; Bogdanoff, T.; Kumar, B.S.; Seifeddine, S. Hall-Petch equation in a hypoeutectic Al–Si cast alloy: grain size vs. secondary dendrite arm spacing. Procedia Eng. 2017, 207, 19–24. [Google Scholar] [CrossRef]

- Polich, R.; Flemings, M. Mechanical properties of unidirectional steel castings. AFS Trans. 1965, 73, 28–33. [Google Scholar]

- Zhang, B.; Chen, W.; Poirier, D.R. Effect of solidification cooling rate on the fatigue life of A356.2–T6 cast aluminium alloy. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 417–423. [Google Scholar] [CrossRef]

- Vorren, O.; Evensen, J.; Pedersen, T. Microstructure and mechanical properties of AlSi (Mg) casting alloys. AFS Trans. 1984, 92, 459–466. [Google Scholar]

- Samuel, A.M.; Samuel, F.H.; Doty, H.W. Observations on the formation of β–Al5FeSi phase in 319 type Al–Si alloys. J. Mater. Sci. 1996, 31, 5529–5539. [Google Scholar] [CrossRef]

- Kirkwood, D. A simple model for dendrite arm coarsening during solidification. Mater. Sci. Eng. 1985, 73, L1–L4. [Google Scholar] [CrossRef]

- Feurer, U.; Wunderlin, R. Einfluss der Zusammensetzung und der Erstarrungsbedingungen auf die Dendritenmorphologie binärer Al-Legierungen, Fachbericht der Deutschen Gesellschaft für Metallkunde; Fachbericht Der Deutschen Gesellschaft für Metallkunde: Oberursel, FRG, Germany, 1977. [Google Scholar]

- Tiryakioğlu, M. A Simple Model to Estimate Solidification Time–Dendrite Arm Spacing Relationships in Cast Aluminum Alloys with Two Major Alloying Additions: Application to the Al–Si–Cu System. Met. Mater. Trans. A 2019, 50, 3030–3032. [Google Scholar] [CrossRef]

- Saller, B.D.; Hu, T.; Ma, K.; Kurmanaeva, L.; Lavernia, E.; Schoenung, J. A comparative analysis of solubility, segregation, and phase formation in atomized and cryomilled Al–Fe alloy powders. J. Mater. Sci. 2015, 50, 4683–4697. [Google Scholar] [CrossRef]

- Saller, B.D.; Sha, G.; Yang, L.M.; Liu, F.; Ringer, S.; Schoenung, J.M. Iron in solution with aluminum matrix after non-equilibrium processing: an atom probe tomography study. Philos. Mag. Lett. 2017, 97, 1–7. [Google Scholar] [CrossRef]

- Nayak, S.; Wollgarten, M.; Banhart, J.; Pabi, S.K.; Murty, B. Nanocomposites and an extremely hard nanocrystalline intermetallic of Al–Fe alloys prepared by mechanical alloying. Mater. Sci. Eng. A 2010, 527, 2370–2378. [Google Scholar] [CrossRef]

- Shuey, R.T. Personal Communication, 2008.

- Puncreobutr, C.; Phillion, A.; Fife, J.; Rockett, P.; Horsfield, A.; Lee, P.D. In situ quantification of the nucleation and growth of Fe-rich intermetallics during Al alloy solidification. Acta Mater. 2014, 79, 292–303. [Google Scholar] [CrossRef]

- Liu, K.; Cao, X.; Chen, X.-G. Solidification of Iron-Rich Intermetallic Phases in Al–4.5Cu–0.3Fe Cast Alloy. Met. Mater. Trans. A 2010, 42, 2004–2016. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. The solidification characteristics of Fe-rich intermetallics in Al–11.5Si–0.4Mg cast alloys. Met. Mater. Trans. A 2004, 35, 1425–1435. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. The nucleation of Fe-Rich phases on oxide films in Al–11.5Si–0.4Mg cast alloys. Met. Mater. Trans. A 2003, 34, 1409–1420. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. Morphology of β–Al5FeSi Phase in Al–Si Cast Alloys. Mater. Trans. 2006, 47, 1303–1312. [Google Scholar] [CrossRef]

- Miller, D.N.; Lu, L.; Dahle, A.K. The role of oxides in the formation of primary iron intermetallics in an Al–11.6Si–0.37Mg alloy. Met. Mater. Trans. A 2006, 37, 873–878. [Google Scholar] [CrossRef]

- Bjurenstedt, A.; Ghassemali, E.; Seifeddine, S.; Dahle, A.K. The effect of Fe-rich intermetallics on crack initiation in cast Aluminium: An in-situ tensile study. Mater. Sci. Eng. A 2019, 756, 502–507. [Google Scholar] [CrossRef]

- Laz, P.J.; Hillberry, B. Fatigue life prediction from inclusion initiated cracks. Int. J. Fatigue 1998, 20, 263–270. [Google Scholar] [CrossRef]

- Li, T.; Morris, J.W.; Chrzan, D.C. Ab initio study of the ideal shear strength and elastic deformation behaviors of B2 FeAl and NiAl. Phys. Rev. B 2006, 73, 024105. [Google Scholar] [CrossRef]

- Li, T.; Morris, J.W.; Chrzan, D.C. Ideal tensile strength of B2 transition-metal aluminides. Phys. Rev. B 2004, 70, 054107. [Google Scholar] [CrossRef]

- Seifeddine, S.; Johansson, S.; Svensson, I.L. The influence of cooling rate and manganese content on the β–Al5FeSi phase formation and mechanical properties of Al–Si-based alloys. Mater. Sci. Eng. A 2008, 490, 385–390. [Google Scholar] [CrossRef]

- Zhu, T.; Li, J.; Ogata, S.; Yip, S. Mechanics of Ultra-Strength Materials. MRS Bull. 2009, 34, 167–172. [Google Scholar] [CrossRef]

- Gangulee, A.; Gurland, J. On the fracture of silicon particles in aluminum- silicon alloys. Trans. Metall. Soc. AIME 1967, 239, 269–272. [Google Scholar]

- Finlayson, T.; Griffiths, J.; Viano, D.; Fitzpatrick, M.; Oliver, E.; Wang, Q. In Stresses in the eutectic silicon particles of strontium-modified a356 castings loaded in tension. In Shape Casting: 2nd International Symposium, Proceedings of the Shape Casting: 2nd International Symposium, Warrendale, PA, USA, 2007; John Wiley and Sons Ltd: Hoboken, NJ, USA, 2007; pp. 127–134. [Google Scholar]

- Cáceres, C.; Griffiths, J. Damage by the cracking of silicon particles in an Al–7Si–0.4Mg casting alloy. Acta Mater. 1996, 44, 25–33. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Liu, W.-P. The cracking mechanism of silicon particles in an A357 aluminum alloy. Met. Mater. Trans. A 1996, 27, 3558–3568. [Google Scholar] [CrossRef]

- Poole, W.; Charras, N. An experimental study on the effect of damage on the stress–strain behaviour for Al–Si model composites. Mater. Sci. Eng. A 2005, 406, 300–308. [Google Scholar] [CrossRef]

- Tiryakioğlu, M. Tensile Deformation, Fracture and Hardness Characteristics of cast Al–7wt.%Si–Mg alloys. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2002. [Google Scholar]

- Harris, S.J.; O’Neill, A.; Boileau, J.; Donlon, W.; Su, X.; Majumdar, B. Application of the Raman technique to measure stress states in individual Si particles in a cast Al–Si alloy. Acta Mater. 2007, 55, 1681–1693. [Google Scholar] [CrossRef]

- Joseph, S.; Kumar, S.; Bhadram, V.S.; Narayana, C. Stress states in individual Si particles of a cast Al–Si alloy: Micro-Raman analysis and microstructure based modeling. J. Alloy. Compd. 2015, 625, 296–308. [Google Scholar] [CrossRef]

- Wang, Q.G.; Caceres, C.H.; Griffiths, J.R. Damage by eutectic particle cracking in aluminum casting alloys a356/357. Metall. Mater. Trans. A 2003, 34, 2901–2912. [Google Scholar] [CrossRef]

- Weibull, W. A statistical distribution function of wide applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar]

- Pierce, F. Tensile tests for cotton yarns: V. The “weakest link” theorems on the strength of long and of composite specimens. J. Text. Inst. 1926, 17, 355–368. [Google Scholar]

- Mueller, M.; Žagar, G.; Mortensen, A. In-situ strength of individual silicon particles within an aluminium casting alloy. Acta Mater. 2018, 143, 67–76. [Google Scholar] [CrossRef]

- Mueller, M.; Fornabaio, M.; Žagar, G.; Mortensen, A. Microscopic strength of silicon particles in an aluminium–silicon alloy. Acta Mater. 2016, 105, 165–175. [Google Scholar] [CrossRef]

- Mueller, M.; Fornabaio, M.; Mortensen, A. Silicon particle pinhole defects in aluminium–silicon alloys. J. Mater. Sci. 2016, 52, 858–868. [Google Scholar] [CrossRef]

- Umeno, Y.; Kushima, A.; Kitamura, T.; Gumbsch, P.; Li, J. Ab initiostudy of the surface properties and ideal strength of (100) silicon thin films. Phys. Rev. B 2005, 72, 72. [Google Scholar] [CrossRef]

- Dubois, S.M.-M.; Rignanese, G.-M.; Pardoen, T.; Charlier, J.-C. Ideal strength of silicon: An ab initio study. Phys. Rev. B 2006, 74, 235203. [Google Scholar] [CrossRef]

- Campbell, J.; Tiryakioğlu, M. Modelling Microstructure and Properties: The Contributions of Grain Size, DAS and Bifilms. Mater. Sci. Forum 2006, 519, 1453–1460. [Google Scholar] [CrossRef]

- Shankar, S.; Riddle, Y.W.; Makhlouf, M.M. Nucleation mechanism of the eutectic phases in aluminum–silicon hypoeutectic alloys. Acta Mater. 2004, 52, 4447–4460. [Google Scholar] [CrossRef]

- Shankar, S.; Riddle, Y.W.; Makhlouf, M.M. Eutectic solidification of aluminum-silicon alloys. Met. Mater. Trans. A 2004, 35, 3038–3043. [Google Scholar] [CrossRef]

- Xia, S.; Qi, Y.; Perry, T.; Kim, K.-S. Strength characterization of Al/Si interfaces: A hybrid method of nanoindentation and finite element analysis. Acta Mater. 2009, 57, 695–707. [Google Scholar] [CrossRef]

- Ward, D.; Curtin, W.; Qi, Y. Aluminum–silicon interfaces and nanocomposites: A molecular dynamics study. Compos. Sci. Technol. 2006, 66, 1151–1161. [Google Scholar] [CrossRef]

- Ward, N.K.; Curtin, W.; Qi, Y. Mechanical behavior of aluminum–silicon nanocomposites: A molecular dynamics study. Acta Mater. 2006, 54, 4441–4451. [Google Scholar] [CrossRef]

- Noreyan, A.; Qi, Y.; Stoilov, V. Critical shear stresses at aluminum–silicon interfaces. Acta Mater. 2008, 56, 3461–3469. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Tiryakioğlu, M.; Vasilakos, A.N.; Kourkoulis, S.K. The effect of Cu, Ag, Sm and Sr additions on the statistical distributions of Si particles and tensile properties in A357–T6 alloy castings. Mater. Sci. Eng. A 2014, 604, 40–45. [Google Scholar] [CrossRef]

- Yeom, G.Y.; Tiryakioğlu, M.; Netto, N.; Beygi, R.; Mehrizi, M.Z.; Kim, S.K. The effect of solution treatment time on the microstructure and ductility of naturally-aged A383 alloy die castings. Mater. Sci. Eng. A 2018, 722, 1–7. [Google Scholar] [CrossRef]

- Shivkumar, S.; Ricci, S.; Keller, C.; Apelian, D. Effect of solution treatment parameters on tensile properties of cast aluminum alloys. J. Heat Treat. 1990, 8, 63–70. [Google Scholar] [CrossRef]

- Tiryakioğlu, M. Si particle size and aspect ratio distributions in an Al–7%Si–0.6%Mg alloy during solution treatment. Mater. Sci. Eng. A 2008, 473, 1–6. [Google Scholar] [CrossRef]

- Rhines, F.N.; Aballe, M. Growth of silicon particles in an aluminum matrix. Met. Mater. Trans. A 1986, 17, 2139–2152. [Google Scholar] [CrossRef]

| Alloy | Dataset | Reference | Q0 | Λ0 (μm0.5) | Comments |

|---|---|---|---|---|---|

| 319 | 1 | [67] | −0.0062 | 0.1717 | High hydrogen content |

| 2 | [67] | −0.0445 | 0.7928 | Low hydrogen content | |

| A380 | 3 | [68] | −0.0490 | 0.4122 | High pressure die cast |

| 4 | [69] | −0.0496 | 0.4765 | Permanent mold | |

| A357 | 5 | [70] | −0.2803 | 2.8440 | No modification |

| 6 | [70] | −0.1504 | 2.6931 | Sr-modified | |

| A356 | 7 | [71] | −0.3759 | 4.1723 | Aluminum Association dataset |

| 8 | [70] | −0.3935 | 4.3961 | No modification | |

| 9 | [70] | 0.1626 | 2.4443 | Sr-modified | |

| Al–7%Si–Mg | 10 | [64] | 1.0000 | 0.0000 | Maximum points |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiryakioğlu, M. Intrinsic and Extrinsic Effects of Microstructure on Properties in Cast Al Alloys. Materials 2020, 13, 2019. https://doi.org/10.3390/ma13092019

Tiryakioğlu M. Intrinsic and Extrinsic Effects of Microstructure on Properties in Cast Al Alloys. Materials. 2020; 13(9):2019. https://doi.org/10.3390/ma13092019

Chicago/Turabian StyleTiryakioğlu, Murat. 2020. "Intrinsic and Extrinsic Effects of Microstructure on Properties in Cast Al Alloys" Materials 13, no. 9: 2019. https://doi.org/10.3390/ma13092019

APA StyleTiryakioğlu, M. (2020). Intrinsic and Extrinsic Effects of Microstructure on Properties in Cast Al Alloys. Materials, 13(9), 2019. https://doi.org/10.3390/ma13092019