Performance of Ceramic-Metal Composites as Potential Tool Materials for Friction Stir Welding of Aluminium, Copper and Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

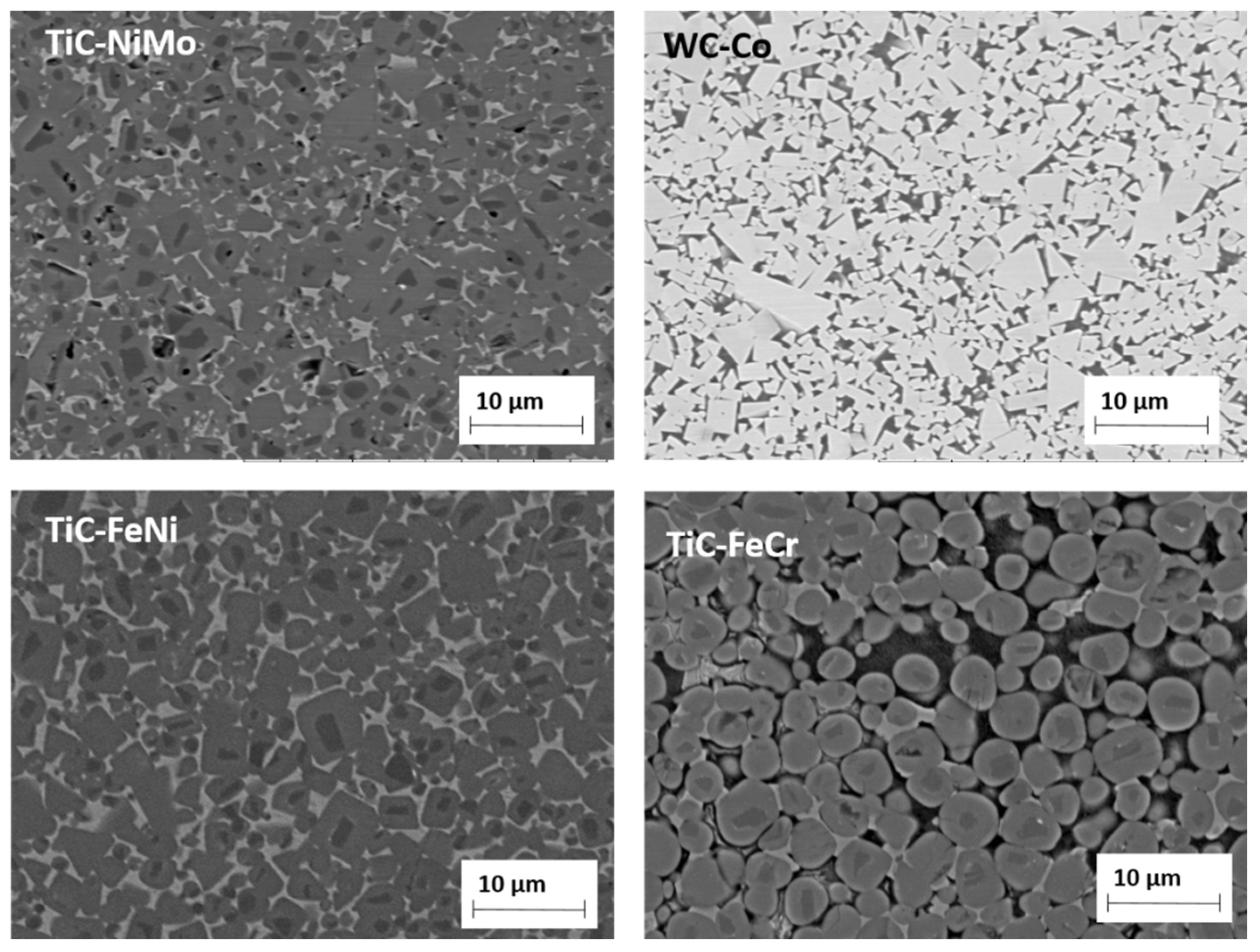

2.1. Material Specifications

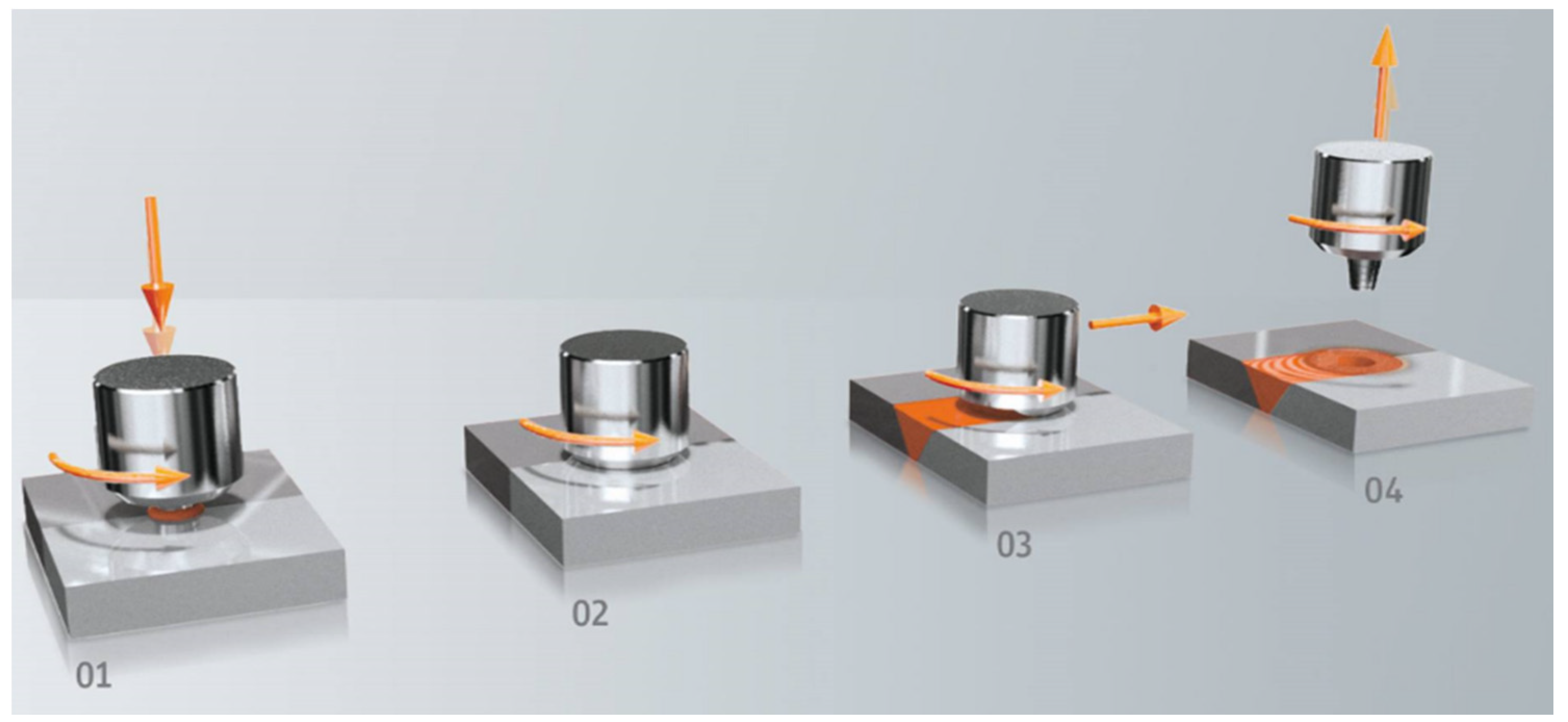

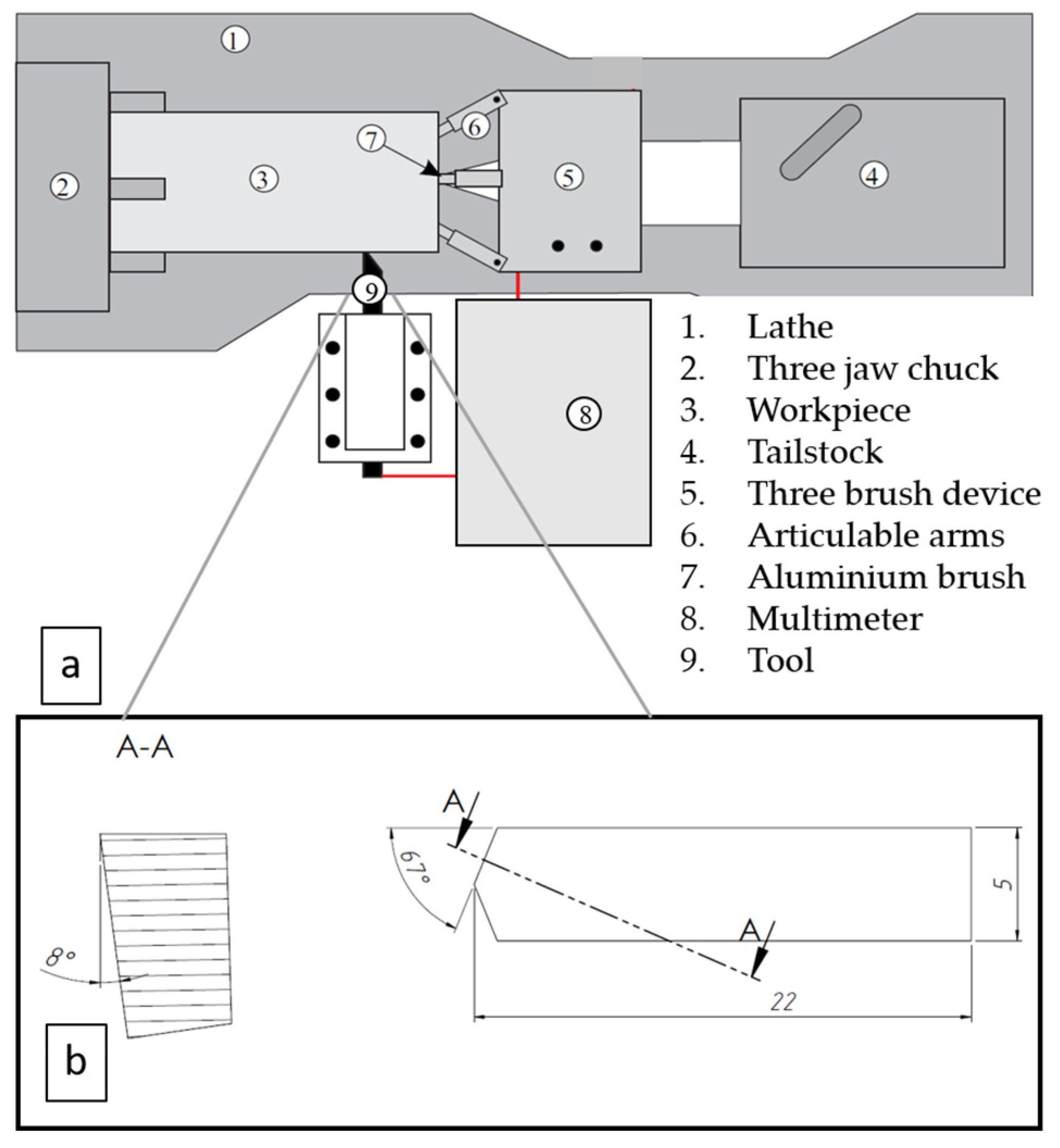

2.2. Experimental Details

3. Results

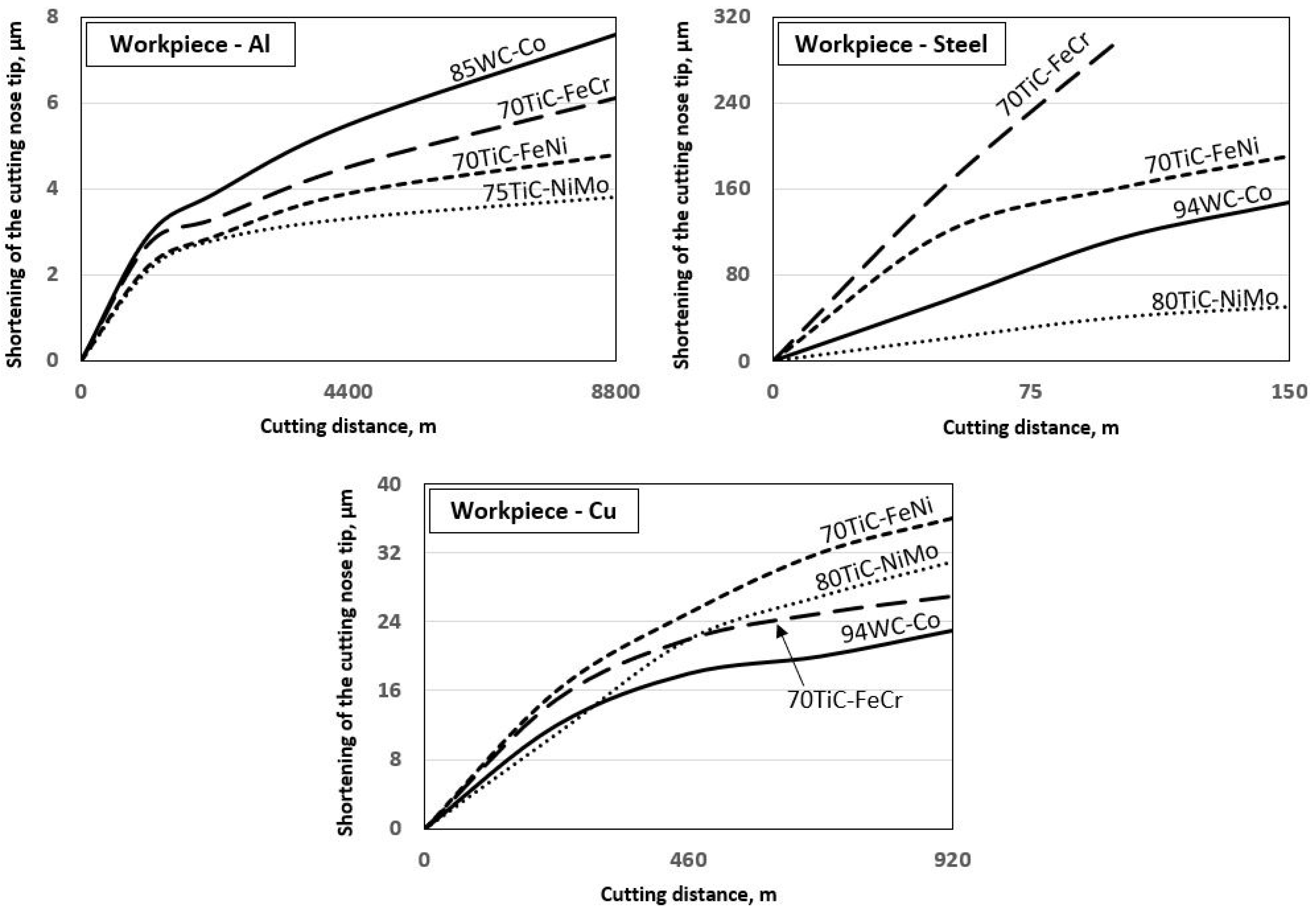

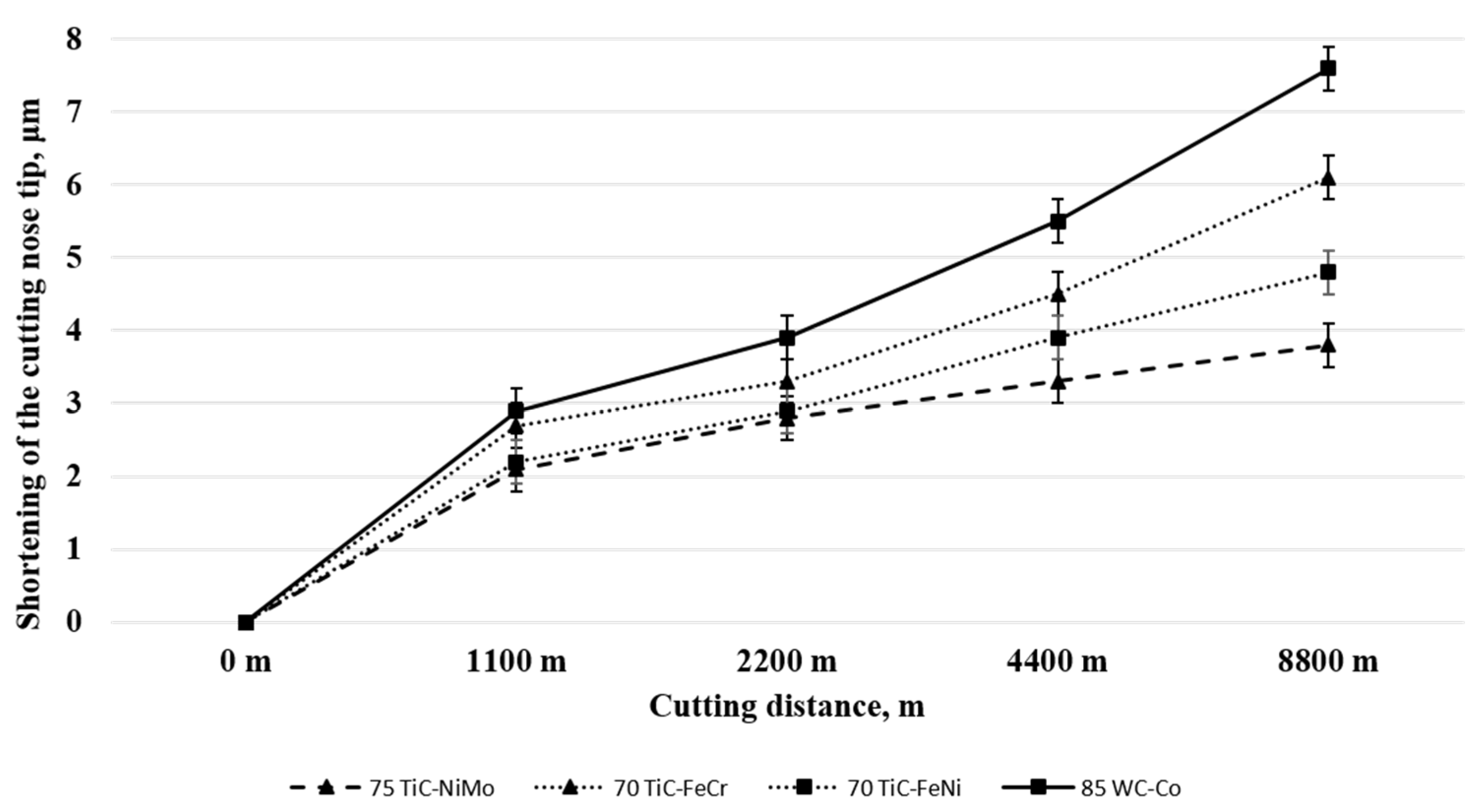

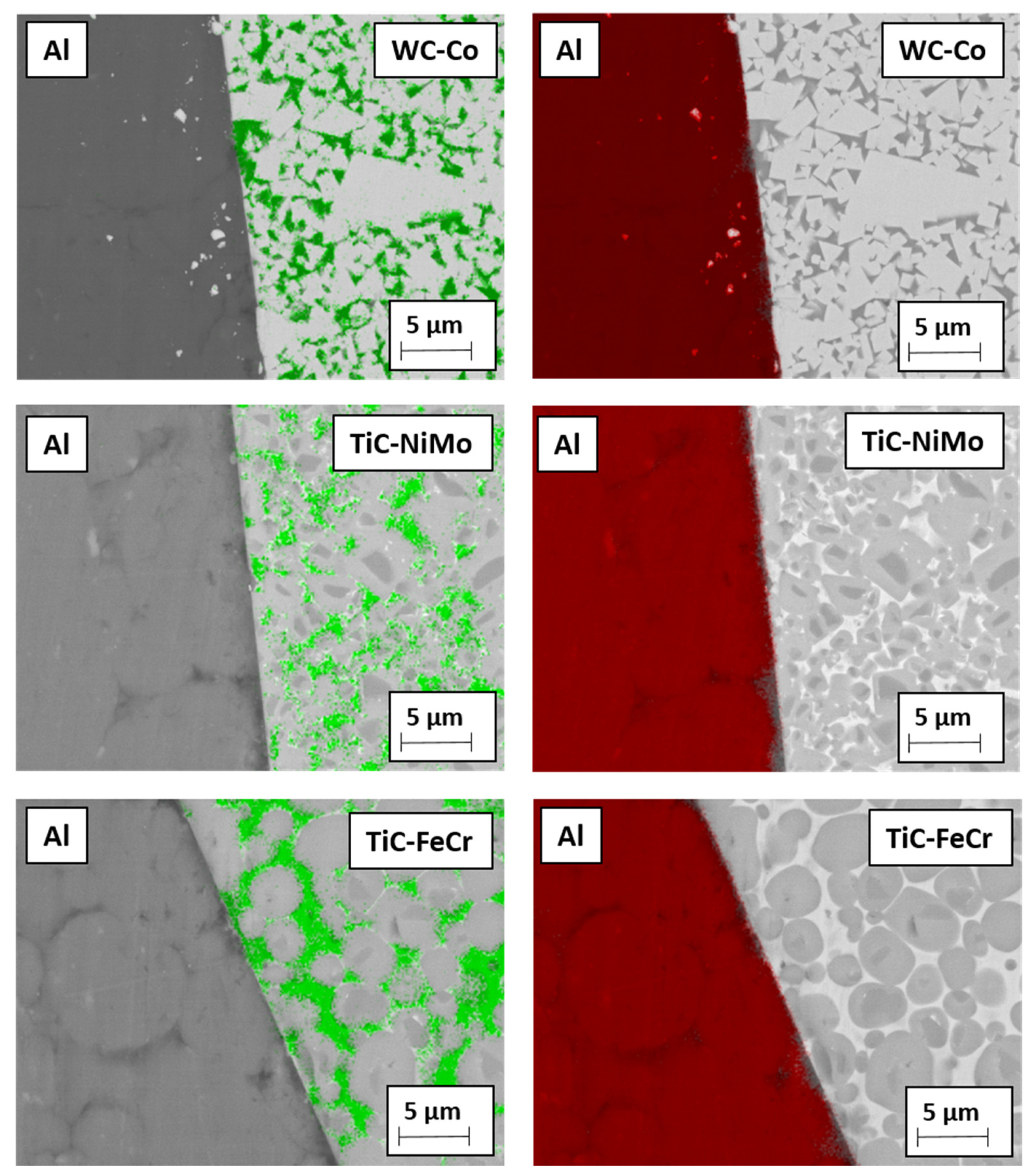

3.1. Working of Aluminium Alloy

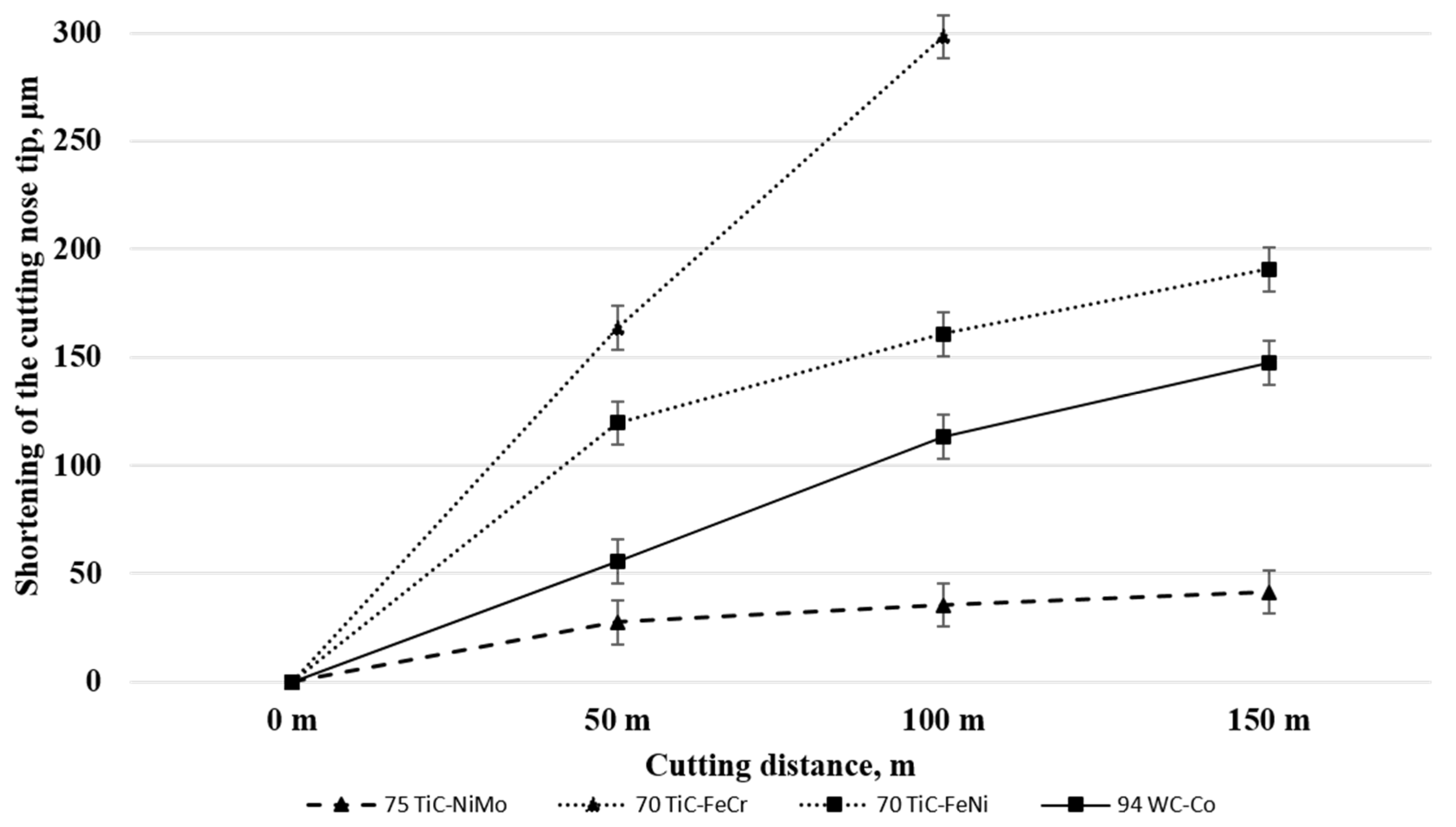

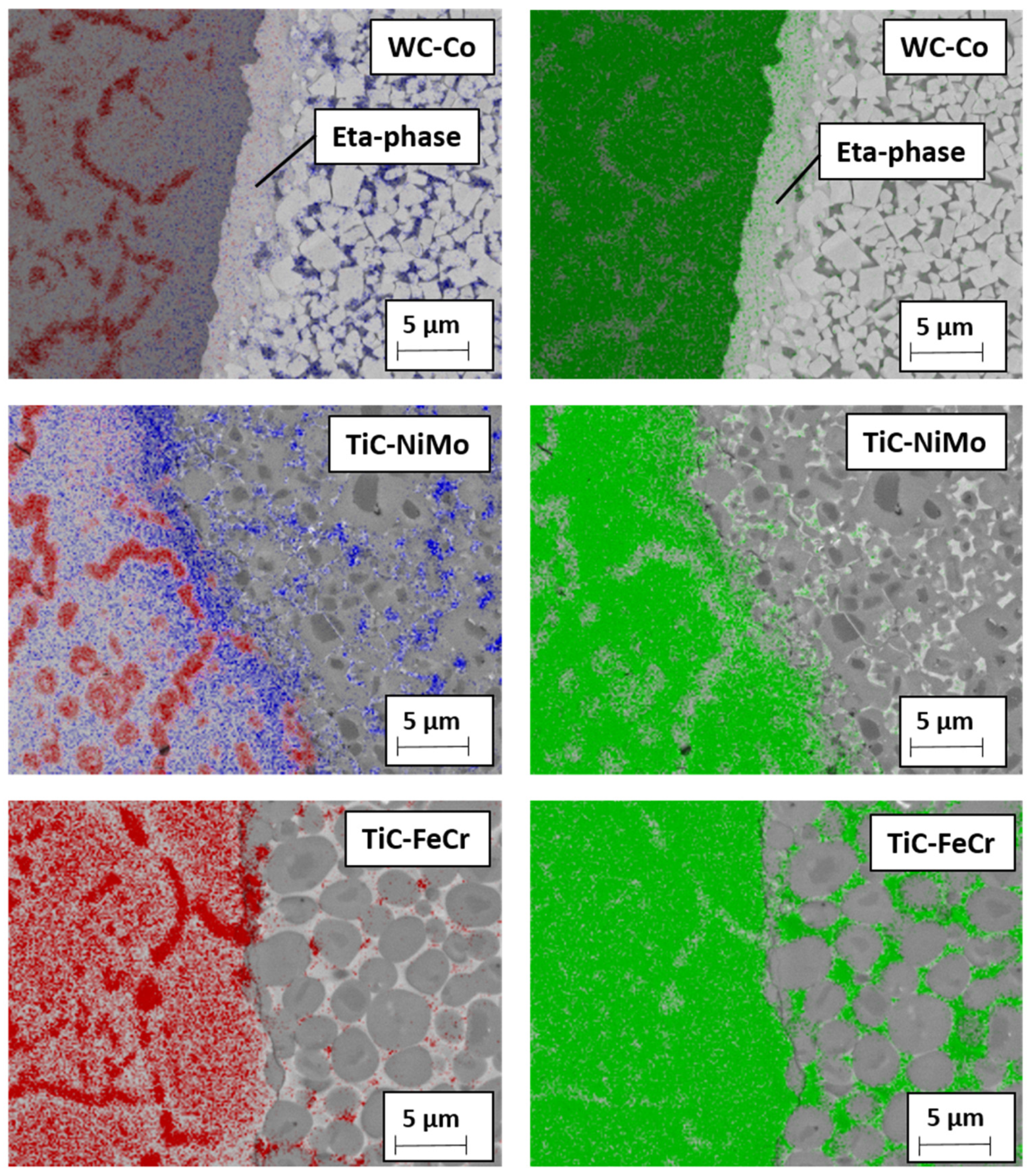

3.2. Working of Stainless Steel

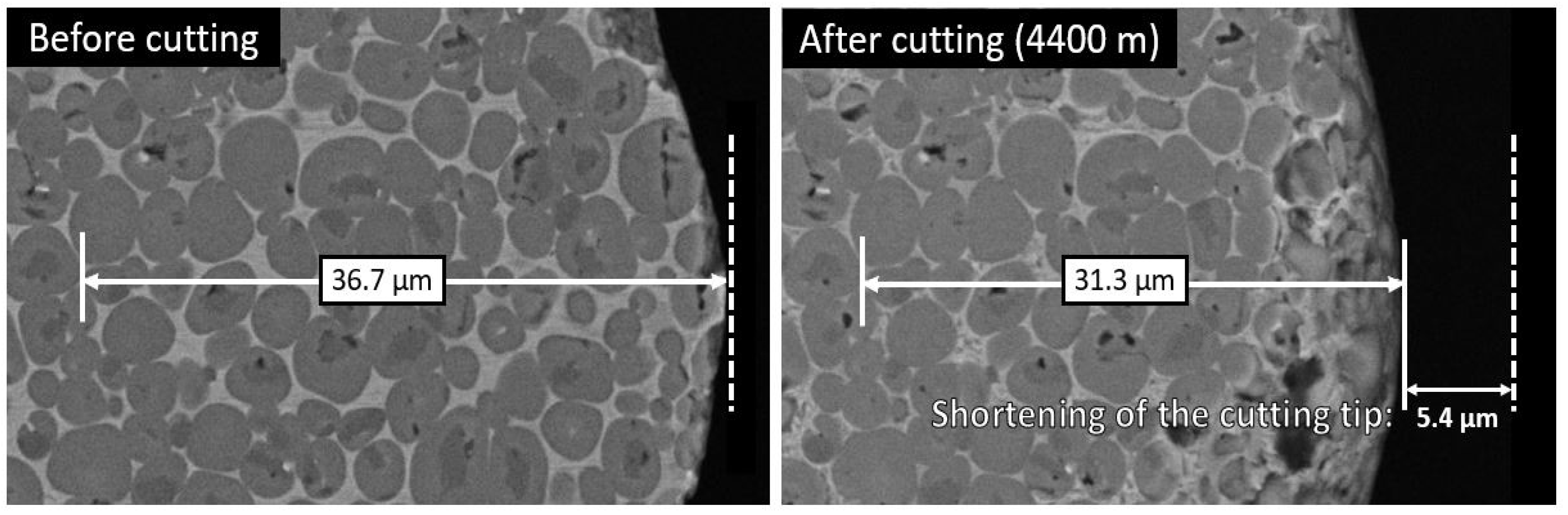

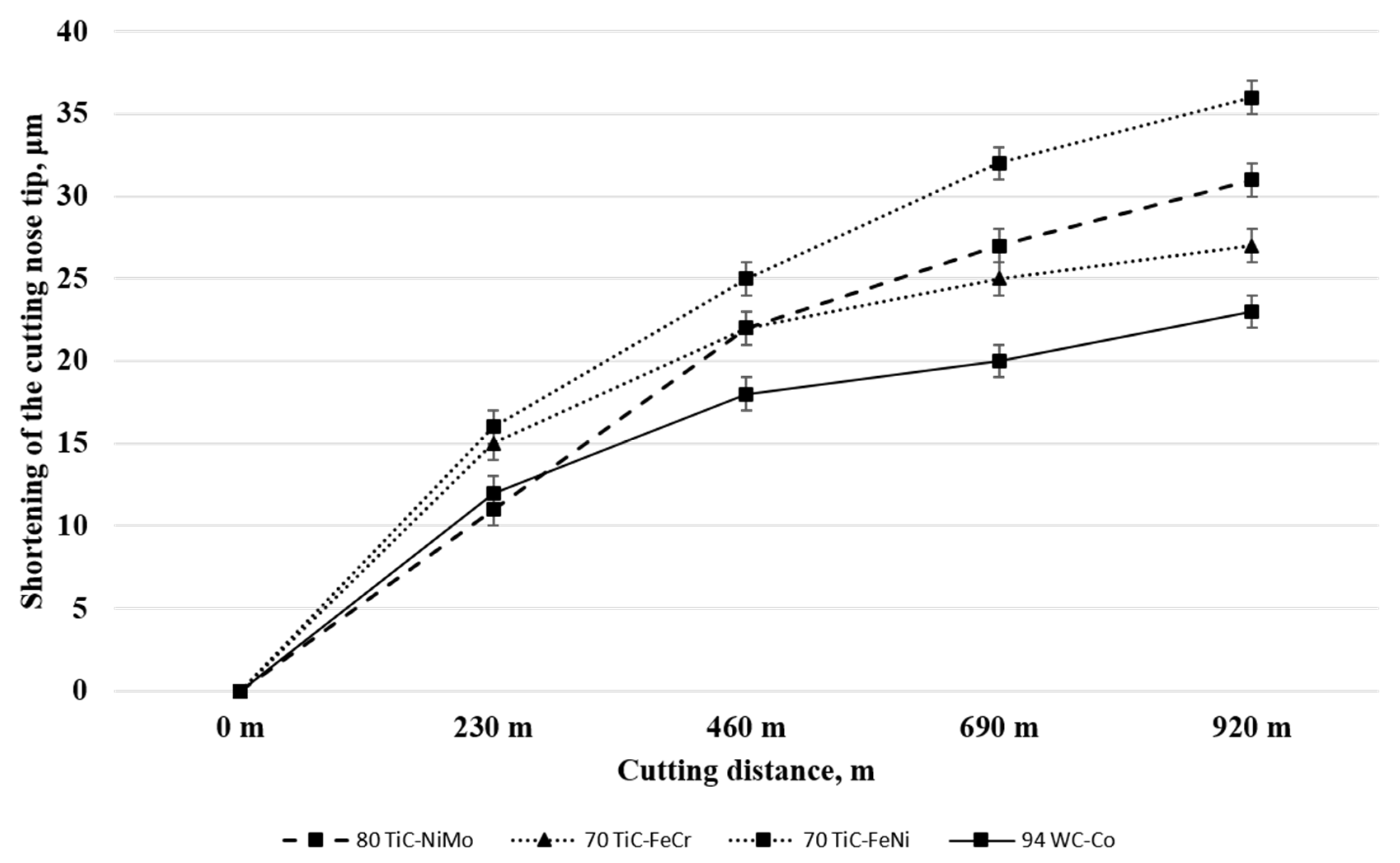

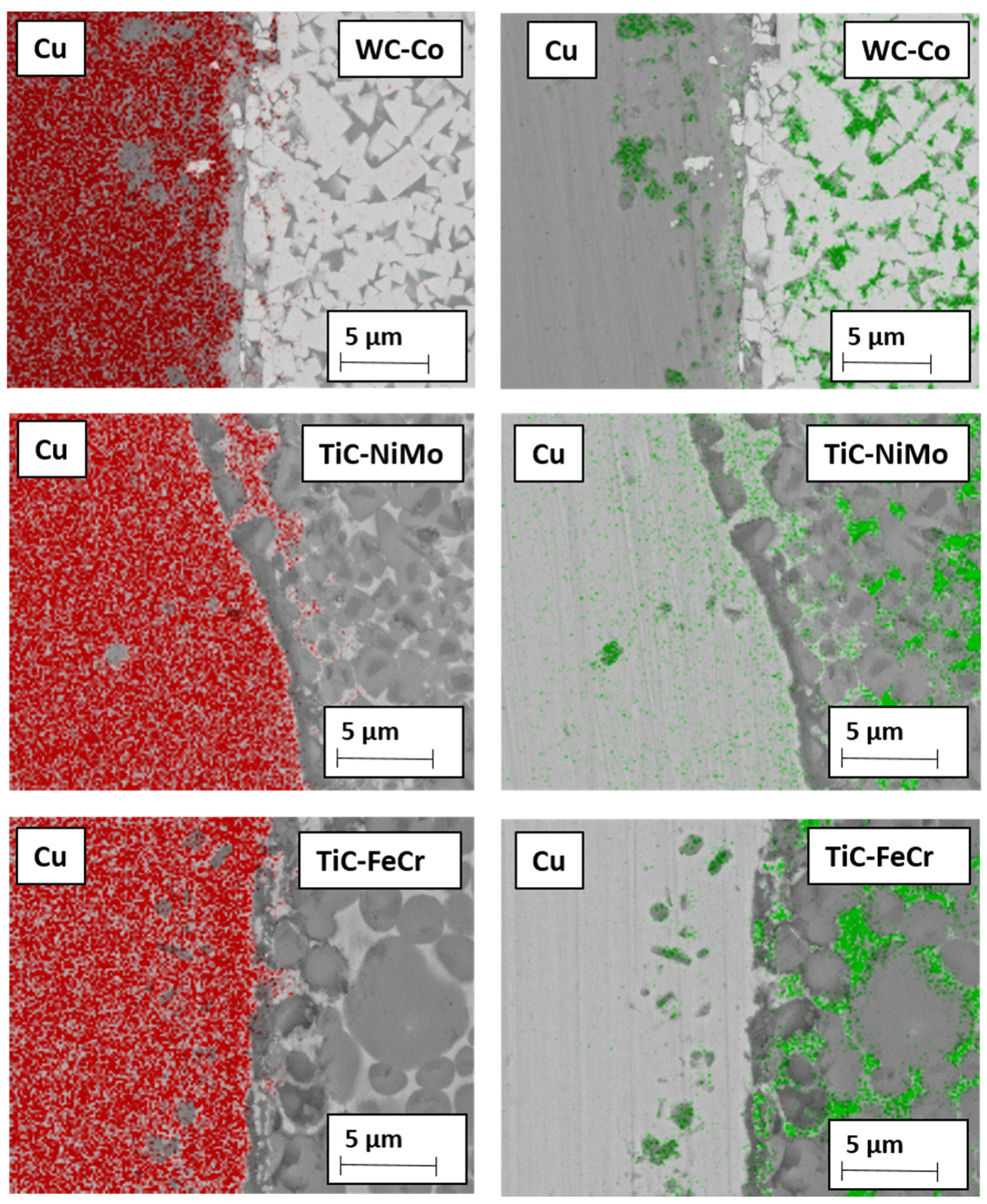

3.3. Working of Copper

4. Discussion

4.1. Working of Aluminium Alloy

4.2. Working of Stainless Steel

4.3. Working of Copper

5. Conclusions

- TiC-based cermets with Ni- and Fe- alloy binders show the highest performance in the model tests with workpiece from aluminium alloy.

- TiC-NiMo cermets demonstrate the highest while cermets with Fe-alloy binders the lowest wear performance in the model tests using counterpart from austenitic stainless steel. An excellent elevated temperature performance is behind the high degradation resistance of TiC-NiMo cermets.

- WC-Co hardmetals, in particular composites with 90–94 wt.% WC, outperform most of TiC-based cermet grades in the model tests with a workpiece from copper. Hardmetals show better performance if compared to cermets, in particular TiC-NiMo composites demonstrating high wear resistance during working of stainless steel, even if they compare unfavourably with hardness.

- Irrespective of workpiece metal (aluminium alloy, stainless steel, copper), the most common wear mechanisms of tools from ceramic-metal composites in the model tests are adhesion and diffusion.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brookes, K.J. World Directory and Handbook of Hardmetals and Hard Materials; Metal Powder Industry: London, UK, 1996. [Google Scholar]

- Choi, D.H.; Lee, C.W.; Ahn, B.W.; Choi, J.H.; Yeon, Y.M.; Song, K.; Park, H.S.; Kin, Y.J.; Yoo, C.D.; Jung, S.B. Frictional wear evaluation of WC-Co alloy tool in friction stir spot welding of low carbon steel plates. Int. J. Refract. Met. Hard 2009, 27, 931–936. [Google Scholar] [CrossRef]

- Siddiquee, A.N.; Pandey, S. Experimental investigation of deformation and wear of WC tool during friction stir welding (FSW) of stainless steel. Int. J. Adv. Manuf. Technol. 2014, 73, 479–486. [Google Scholar] [CrossRef]

- Liu, H.J.; Feng, J.C.; Fujii, H.; Nogi, K. Wear characteristics of a WC-Co tool in friction stir welding of AC4A + 30 vol% SiCp composite. Int. J. Mach. Tool Manu. 2005, 45, 1635–1639. [Google Scholar] [CrossRef]

- Hardmetals. Comprehensive Hard Materials, 1st ed.; Sarin, V.K., Ed.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Klaasen, J.; Kübarsepp, J. Wear of advanced cemented carbides for metalforming tool materials. Wear 2004, 256, 846–853. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J.G.B. Friction Welding. Patent 9,125,978.8, 6 December 1991. [Google Scholar]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Prasanna, P.; Rao, B.S.; Rao, G.K.M. Finite element modeling for maximum temperature in friction stir welding and its validation. Int. J. Adv. Manuf. Technol. 2010, 51, 925–933. [Google Scholar] [CrossRef]

- Nakata, K. Friction stir welding of copper and copper alloys. Weld. Int. 2005, 19, 929–933. [Google Scholar] [CrossRef]

- Kah, R.; Tajan, R.; Matrikainen, J.; Suoranta, R. Investigation of weld defects in friction-stir welding and fusion welding of aluminium alloys. Int. J. Mech. Mater. Eng. 2015, 10, 26. [Google Scholar] [CrossRef]

- Kumar, A.; Gautam, S.S.; Kumar, A. Heat input & joint efficiency of three welding processes TIG, MIG and FSW using AA6061. Int. J. Mech. Eng. Rob. Res. 2014, 1, 89–94. [Google Scholar]

- Strand, S. Joining plastics-can friction stir welding compete. In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Technology Conference, Indianapolis, IN, USA, 25–25 September 2003; pp. 321–326. [Google Scholar]

- Olson, D.L.; Siewert, T.A.; Liu, S.; Edwards, G.R. Welding, brazing and soldering. In ASM Handbook; ASM International: Cleveland, OH, USA, 1993; Volume 6. [Google Scholar]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Review: Friction stir welding tools. Sci. Technol. Weld. Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Jeganathan Arulmoni, V.; Ranganath, M.S.; Mishra, R.S. Friction stir processed copper: A review. Int. Res. J. Sustain. Sci. Eng. 2015, 3, 1–11. [Google Scholar]

- Mishra, R.; De, P.S.; Kumar, N. Friction Stir Welding and Processing; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Critical Raw Materials. Available online: https://europa.eu/growth/sectors/raw-materials/specificinterest/critical_et (accessed on 29 March 2020).

- REACH (Registration, Evaluation, Authorization and Restriction of Chemical Substances). Available online: http://ec.europa.eu/environment/chemicals/reach/reach_intro.htm (accessed on 29 March 2020).

- Kolnes, M.; Mere, A.; Kübarsepp, J.; Viljus, M.; Maaten, M.; Tarraste, M. Microstructure evolution of TiC cermets with ferritic AISI 430L steel binder. Powder Metall. 2018, 61, 197–209. [Google Scholar] [CrossRef]

- Santos, M.C., Jr.; Araujo Filho, J.S.; Barrozo, M.A.S.; Jackson, M.J.; Macchado, A.R. Development and application of temperature measurement device using the tool-workpiece thermocouple method in turning at high cutting speeds. Int. J. Adv. Manuf. Tech. 2017, 89, 2287–2298. [Google Scholar] [CrossRef]

- Kolnes, M.; Kübarsepp, J.; Sergejev, F.; Kolnes, M. Wear of potential tool materials for aluminium alloys friction stir welding at weld temperatures. Proc. Est. Acad. Sci. 2019, 68, 198–206. [Google Scholar] [CrossRef]

- Tarasov, S.Y.; Rubtsov, V.E.; Kolubaev, E.A. A proposed diffusion-controlled wear mechanism of alloy steel friction stir welding (FSW) tools used on an aluminum alloy. Wear 2014, 318, 130–134. [Google Scholar] [CrossRef]

- Thomson, B.T.; Babu, S.S.; Lolla, T. Application of diffusion models to predict FSW tool wear. In Proceedings of the Twenty-first International Offshore and Polar Engineering Conference, Maui, HI, USA, 19–24 June 2011; pp. 520–526. [Google Scholar]

- Evans, A.G.; Charles, E.A. Fracture toughness determinations by indentation. J. Am. Ceram. Soc. 1976, 59, 371–372. [Google Scholar] [CrossRef]

- Kübarsepp, J.; Klaasen, H.; Pirso, J. Behaviour of TiC-base cermets in different wear conditions. Wear 2001, 249, 229–234. [Google Scholar] [CrossRef]

- Klaasen, H.; Kübarsepp, J. Abrasive wear performance of carbide composites. Wear 2006, 261, 520–526. [Google Scholar] [CrossRef]

- Klaasen, H.; Kübarsepp, J.; Roosaar, T.; Viljus, M.; Traksmaa, R. Adhesive wear performance of hardmetals and cermets. Wear 2010, 268, 1122–1128. [Google Scholar] [CrossRef]

- Nabhani, F. Wear mechanisms of ultra-hard cutting tools materials. J. Mater. Process. Technol. 2001, 115, 402–412. [Google Scholar] [CrossRef]

- Lampman, S.; Zore, T.B. Properties and selection: Nonferrous alloys and special purpose materials. In ASM Handbook, 3rd ed.; ASM International: Cleveland, OH, USA, 1993; Volume 2, pp. 428–445. [Google Scholar]

- Brooks, C.R.; Spruiell, J.E.; Stansbury, E.E. Physical metallurgy of nickel-molybdenum alloys. Int. Met. Rev. 1984, 29, 210–248. [Google Scholar] [CrossRef]

- Lou, D.; Hellman, J.; Luhulima, D.; Liimatainen, J.; Lindroos, V.K. Interactions between tungsten carbide (WC) particulates and metal matrix in WC-reinforced composites. Mater. Sci. Eng. A 2003, 340, 155–162. [Google Scholar] [CrossRef]

- Sahlot, P.; Jha, K.; Dey, G.K.; Arora, A. Quantitative wear analysis of H13 steel tool during friction stir welding of Cu-0.8%Cr-0.1%Zr alloy. Wear 2017, 378–379, 82–89. [Google Scholar] [CrossRef]

- Sahlot, P.; Mishra, R.S.; Arora, A. Wear mechanism for H13 steel tool during friction stir welding of CuCrZr alloy. In Friction Stir Welding and Processing X; Springer: Cham, Switzerland, 2019; pp. 59–64. [Google Scholar]

| Welded Material | Aluminium Alloy | Copper and Copper Alloy | Stainless Steel |

|---|---|---|---|

| Tool materials | AISI H13 steel, high carbon steel, HSS steel | AISI H13 steel, tungsten carbide, HSS steel | pcBN, W alloy |

| Material | Chemical Composition (wt.%) | Powder Particle Size (µm) | Supplier |

|---|---|---|---|

| WC | W—base; C—6.13; oth. < 0.14 | D50 = 0.86 | Wolfram Bergbau und Hütten AG (Sankt Martin im Sulmtal, Austria) |

| TiC | Ti—base; Ctotal—19.12; Cfree—0.15; oth. < 0.31 | 2.0–3.0 | Pacific Particulate Materials Ltd. (New Westminster, BC, Canada) |

| Co | Co—99.5; oth.—0.5 | 5.0–6.0 | Pacific Particulate Materials Ltd. (New Westminster, BC, Canada) |

| Fe | Fe—99.72; Si—0.01; P—0.07; Mn—0,02; oth—C | 40–90 | Rio Tinto (London, UK) |

| Ni | Ni—99.8; oth.—0.2 | 3.0–5.0 | Pacific Particulate Materials Ltd. (New Westminster, BC, Canada) |

| Mo | Mo—99.8; oth.—0.2 | 1.0–3.0 | Pacific Particulate Materials Ltd. (New Westminster, BC, Canada) |

| AISI430L | Fe—base; Fe—16.8; Mn—0.69; Si—0.64; oth < 0.05 | 10–45 | Sandvik Osprey Ltd. (Neath, UK) |

| Designation | Initial Composition (wt.%) | Carbide Content after Sintering (vol.%) | Hardness HV30 | Fracture Toughness, (MPa∙m1/2) | Average Carbide Particle Size, (µm) | |

|---|---|---|---|---|---|---|

| Carbide | Binder | |||||

| 85WC-Co | 85WC | 15Co | 76.4 | 1150 ± 20 | 17.8 ± 0.5 | 0.91 |

| 90WC-Co | 90WC | 10Co | 83.7 | 1238 ± 6 | 16.7 ± 0.3 | 1.19 |

| 94WC-Co | 94WC | 6Co | 90.0 | 1765 ± 25 | 7.2 ± 0.3 | 0.48 |

| 70TiC-NiMo | 70TiC | 20Ni; 10Mo | 87.7 | 1340 ± 21 | 12.6 ± 0.3 | 1.21 |

| 75TiC-NiMo | 75TiC | 16.7Ni; 8.3Mo | 89.9 | 1403 ± 25 | 11.4 ± 0.4 | 1.14 |

| 80TiC-NiMo | 80TiC | 13.3Ni; 6.7Mo | 92.1 | 1492 ± 16 | 10.1 ± 0.4 | 1.60 |

| 70TiC-FeCr | 70TiC | 24.9Fe; 5.1Cr | 84.0 | 1352 ± 6 | 9.1 ± 0.7 | 1.99 |

| 70TiC-FeNi | 70TiC | 25.8Fe; 4.2Ni | 79.3 | 1379 ± 21 | 15.2 ± 0.5 | 1.60 |

| Workpiece Material | Chemical Composition (wt%) | |||||

|---|---|---|---|---|---|---|

| Aluminium alloy (AW6082-T6) | 96.9 Al | 1.1 Si | 0.5 Mn | 0.8 Mg | 0.7 Other | |

| Copper (Cu-ETP) | 99.9 Cu | 0.1 Other | ||||

| Stainless steel (AISI 304) | 70.7 Fe | 1.6 Mn | 18.0 Cr | 8.1 Ni | 0.3 Si | 1.3 Other |

| Workpiece Material | Tool Materials Wear Rate at Maximal Cutting Distances (Shortening of the Cutting Tool Nose Tip, μm) | |||||||

|---|---|---|---|---|---|---|---|---|

| 85WC-Co | 90WC-Co | 94WC-Co | 70TiC-NiMo | 75TiC-NiMo | 80TiC-NiMo | 70TiC-FeCr | 70TiC-FeNi | |

| Aluminium alloy (AW6082-T6) | 7.6 | - | fracture | - | 3.8 | - | 6.1 | 4.8 |

| Stainless steel (AISI 304) | 258 | 174 | 147 | 108 | 42 | 50 | 298 | 191 |

| Copper (Cu-ETP) | 28 | 26 | 23 | 37 | 38 | 31 | 27 | 36 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolnes, M.; Kübarsepp, J.; Sergejev, F.; Kolnes, M.; Tarraste, M.; Viljus, M. Performance of Ceramic-Metal Composites as Potential Tool Materials for Friction Stir Welding of Aluminium, Copper and Stainless Steel. Materials 2020, 13, 1994. https://doi.org/10.3390/ma13081994

Kolnes M, Kübarsepp J, Sergejev F, Kolnes M, Tarraste M, Viljus M. Performance of Ceramic-Metal Composites as Potential Tool Materials for Friction Stir Welding of Aluminium, Copper and Stainless Steel. Materials. 2020; 13(8):1994. https://doi.org/10.3390/ma13081994

Chicago/Turabian StyleKolnes, Mart, Jakob Kübarsepp, Fjodor Sergejev, Märt Kolnes, Marek Tarraste, and Mart Viljus. 2020. "Performance of Ceramic-Metal Composites as Potential Tool Materials for Friction Stir Welding of Aluminium, Copper and Stainless Steel" Materials 13, no. 8: 1994. https://doi.org/10.3390/ma13081994

APA StyleKolnes, M., Kübarsepp, J., Sergejev, F., Kolnes, M., Tarraste, M., & Viljus, M. (2020). Performance of Ceramic-Metal Composites as Potential Tool Materials for Friction Stir Welding of Aluminium, Copper and Stainless Steel. Materials, 13(8), 1994. https://doi.org/10.3390/ma13081994