Effect of sp3 Content on Adhesion and Tribological Properties of Non-Hydrogenated DLC Films

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

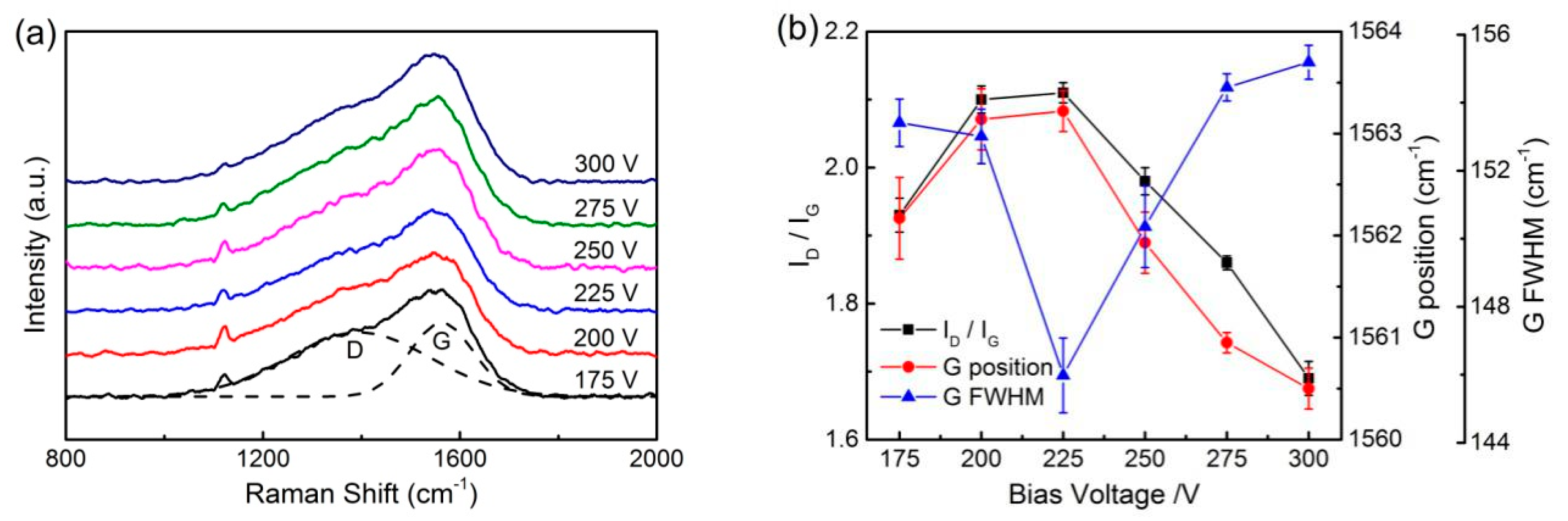

3.1. Raman and XPS Spectra

3.2. Adhesion Strength

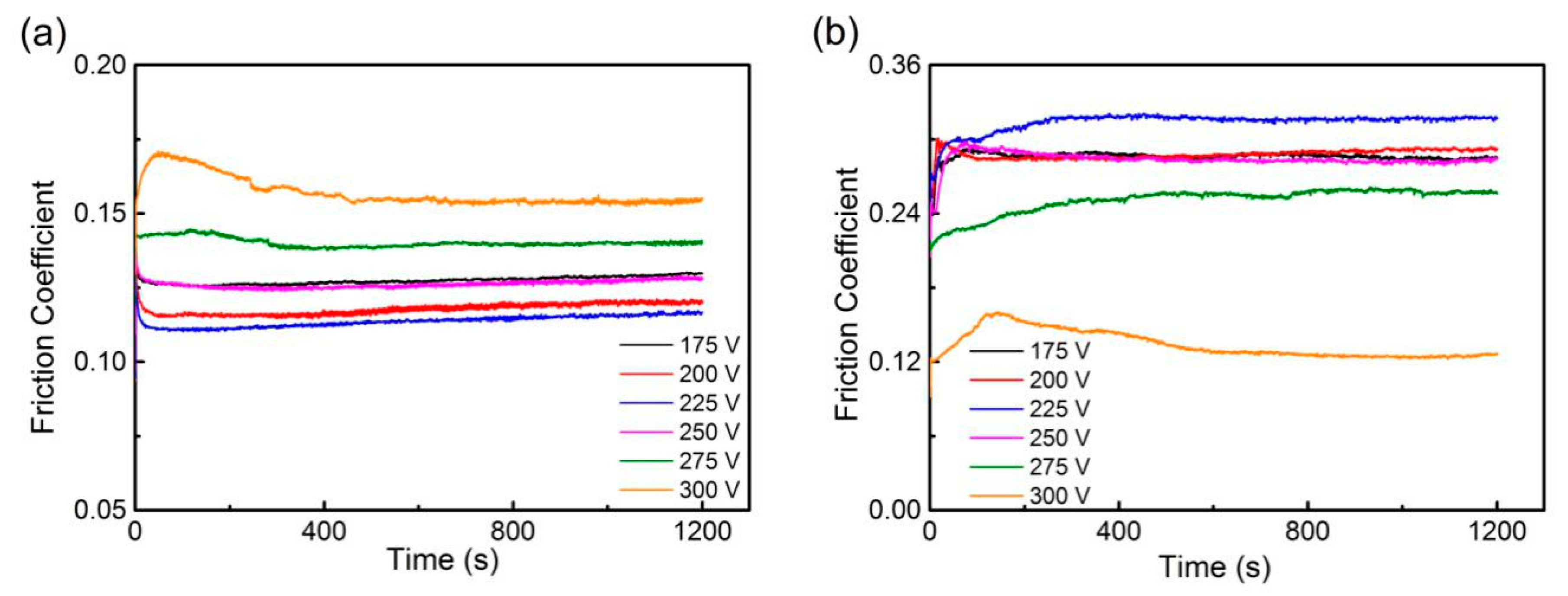

3.3. Tribological Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Donnet, C.; Erdemir, A. Historical developments and new trends in tribological and solid lubricant coatings. Surf. Coat. Technol. 2004, 180, 76–84. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Irmer, G.; Dorner-Reisel, A. Micro-Raman Studies on DLC coatings. Adv. Eng. Mater. 2010, 7, 694–705. [Google Scholar] [CrossRef]

- Cui, W.G.; Lai, Q.B.; Zhang, L.; Wang, F.M. Quantitative measurements of sp 3 content in DLC films with Raman spectroscopy. Surf. Coat. Technol. 2010, 205, 1995–1999. [Google Scholar] [CrossRef]

- Leung, T.Y.; Man, W.F.; Lim, P.K.; Chan, W.C.; Gaspari, F.; Zukotynski, S. Determination of the sp3/sp2 ratio of a-C:H by XPS and XAES. J. Non-Cryst. Solids 1999, 254, 156–160. [Google Scholar] [CrossRef]

- Dai, M.; Zhou, K.; Yuan, Z.; Ding, Q.; Fu, Z. The cutting performance of diamond and DLC-coated cutting tools. Diam. Relat. Mater. 2000, 9, 1753–1757. [Google Scholar] [CrossRef]

- Minaki, K.; Kitajima, K.; Nakahira, Y.; Ohnishi, M.; Sugimoto, T.; Kaminomura, S. Development of DLC Coated Tool For Cutting Of Aluminum Alloy: Influence Of Deposition Condition On Cutting Characteristic. Key Eng. Mater. 2009, 389–390, 163–168. [Google Scholar] [CrossRef]

- Horiuchi, T.; Yoshida, K.; Okuda, T.; Kano, M.; Kumagai, M.; Suzuki, T. Session 01: DLC coatings OA 01 P2009-245 evaluation of adhesion strength and wear resistance of DLC films. Surf. Coat. Technol. 2010, 205, S188–S195. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Volosova, M.A.; Batako, A.; Vereschaka, A.S.; Sitnikov, N.N.; Seleznev, A.E. Nano-scale multi-layered coatings for improved efficiency of ceramic cutting tools. Int. J. Adv. Manuf. Technol. 2017, 90, 1–17. [Google Scholar] [CrossRef]

- Ze, S.; Dejun, K. Effect of load on the friction-wear behavior of magnetron sputtered DLC film at high temperature. Mater. Res. Express 2017, 4, 016404. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Dasch, J.M.; Wagg, T.; Yamamoto, K.; Veldhuis, S.; Dosbaeva, G.K.; Tauhiduzzaman, M. Cutting performance of different coatings during minimum quantity lubrication drilling of aluminum silicon B319 cast alloy. Surf. Coat. Technol. 2011, 205, 4107–4116. [Google Scholar] [CrossRef]

- Vandevelde, T.C.; Vandierendonck, K.; Van Stappen, M.; Du Mong, W.; Perremans, P. Cutting applications of DLC, hard carbon and diamond films 1. Surf. Coat. Technol. 1999, 113, 80–85. [Google Scholar] [CrossRef]

- Choi, J.; Kato, T. Self-assembled monolayers on ta-C surfaces: Effect of sp3/sp2 ratio on adsorption rate and friction. J. Appl. Phys. 2003, 93, 8722–8724. [Google Scholar] [CrossRef]

- Tang, J. Study on deposition of amorphous hydrogenate DLC films on germanium substrates by RF-PECVD. Proc. SPIE Int. Soc. Opt. Eng. 2009, 31, 622–626. [Google Scholar]

- Ji, X.W.; Xu, Z.H.; He, L.L.; He, L.M. Influences of substrate negative bias voltage on microstructure and performance of DLC coatings. J. Mater. Eng. 2015. [Google Scholar] [CrossRef]

- Mabuchi, Y.; Higuchi, T.; Weihnacht, V. Effect of sp2/sp3 bonding ratio and nitrogen content on friction properties of hydrogen-free DLC coatings. Tribol. Int. 2013, 62, 130–140. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Z.; Ji, Z.; Xie, Y. Friction and wear behavior of hydrogenated diamond-like carbon coating against titanium alloys under large normal load and variable velocity. Ind. Lubr. Tribol. 2017, 69, 199–207. [Google Scholar] [CrossRef]

- Konca, E.; Cheng, Y.T.; Alpas, A.T. Dry sliding behaviour of non-hydrogenated DLC coatings against Al, Cu and Ti in ambient air and argon. Diam. Relat. Mater. 2006, 15, 939–943. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Holmberg, K. Friction and wear properties in dry, water- and oil-lubricated DLC against alumina and DLC against steel contacts. Wear 1998, 222, 120–128. [Google Scholar] [CrossRef]

- Suzuki, M.; Saito, T.; Tanaka, A. Tribological properties of DLC films against different steels. Wear 2013, 304, 83–87. [Google Scholar] [CrossRef]

- Xia, L.; Li, G. The frictional behavior of DLC films against bearing steel balls and Si3N4 balls in different humid air and vacuum environments. Wear 2008, 264, 1077–1084. [Google Scholar] [CrossRef]

- Konca, E.; Cheng, Y.T.; Weiner, A.M.; Dasch, J.M.; Alpas, A.T. Effect of test atmosphere on the tribological behaviour of the non-hydrogenated diamond-like carbon coatings against 319 aluminum alloy and tungsten carbide. Surf. Coat. Technol. 2005, 200, 1783–1791. [Google Scholar] [CrossRef]

- Banerji, A.; Bhowmick, S.; Alpas, A.T. High temperature tribological behavior of W containing diamond-like carbon (DLC) coating against titanium alloys. Surf. Coat. Technol. 2014, 241, 93–104. [Google Scholar] [CrossRef]

- Gharam, A.A.; Lukitsch, M.J.; Qi, Y.; Alpas, A.T. Role of oxygen and humidity on the tribo-chemical behaviour of non-hydrogenated diamond-like carbon coatings. Wear 2011, 271, 2157–2163. [Google Scholar] [CrossRef]

- Huang, L.; Yuan, J.T.; Wang, Z.H.; Yu, B.B. Effect of the Temperature on Diamond-Like Carbon(DLC) Thin Film Based on LIS. Appl. Mech. Mater. 2013, 421, 212–216. [Google Scholar] [CrossRef]

- Nguyen, T.; Ulrich, S.; Bsul, J.; Beauvais, S.; Burger, W.; Albers, A.; Stüber, M.; Ye, J. Influence of argon gas pressure and target power on magnetron plasma parameters. Diam. Relat. Mater. 2009, 18, 995–998. [Google Scholar] [CrossRef]

- Choi, J.; Nakao, S.; Ikeyama, M.; Kato, T. Effect of deposition pressure on the properties of DLC coatings deposited by bipolar-type PBII&D. Surf. Interface Anal. 2008, 40, 806–809. [Google Scholar]

- Jiang, M.; Ning, Z. Structure evolution of fluorinated diamond-like carbon films prepared at varying source gas flow ratios. J. Non-Cryst. Solids 2005, 351, 2462–2467. [Google Scholar] [CrossRef]

- Kim, W.J.; Kim, J.G.; Park, S.J.; Lee, K.R. Tribological and electrochemical characteristics of DLC coatings with bias voltage. Met. Mater. Int. 2005, 11, 473–480. [Google Scholar] [CrossRef]

- Seo, S.C.; Ingram, D.C.; Richardson, H.H. Effect of substrate bias on the properties of diamondlike carbon films deposited using unbalanced magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Film. 1995, 13, 2856–2862. [Google Scholar] [CrossRef]

- Cui, J.F.; Qiang, L.; Zhang, B.; Ling, X.; Zhang, J.Y. Effect of Substrate Bias Voltage on the Mechanical and Tribological Properties of Low Concentration Ti-Containing Diamond Like Carbon Films. Appl. Mech. Mater. 2012, 182–183, 232–236. [Google Scholar] [CrossRef]

- Nakao, S.; Yukimura, K.; Nakano, S.; Ogiso, H. DLC Coating by HiPIMS: The Influence of Substrate Bias Voltage. IEEE Trans. Plasma Sci. 2013, 41, 1819–1829. [Google Scholar] [CrossRef]

- Sheeja, D.; Tay, B.K.; Lau, S.P.; Shi, X. Tribological properties and adhesive strength of DLC coatings prepared under different substrate bias voltages. Wear 2001, 249, 433–439. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Kong, J.; Zhang, Y.; Zhang, W. Multilayer DLC coatings via alternating bias during magnetron sputtering. Thin Solid Film. 2011, 519, 4910–4916. [Google Scholar] [CrossRef]

- Lascovich, J.C.; Giorgi, R.; Scaglione, S. Evaluation of the sp2/sp3 ratio in amorphous carbon structure by XPS and XAES. Appl. Surf. Sci. 1991, 47, 17–21. [Google Scholar] [CrossRef]

- Cuomo, J.J.; Doyle, J.P.; Bruley, J.; Liu, J.C. Sputter deposition of dense diamond-like carbon films at low temperature. Appl. Phys. Lett. 1991, 58, 466. [Google Scholar] [CrossRef]

- Aijaz, A.; Sarakinos, K.; Lundin, D.; Brenning, N.; Helmersson, U. A strategy for increased carbon ionization in magnetron sputtering discharges. Diam. Relat. Mater. 2012, 23, 1–4. [Google Scholar] [CrossRef]

- Casiraghi, C.; Robertson, J.; Ferrari, A.C. Diamond-like carbon for data and beer storage. Mater. Today 2007, 10, 44–53. [Google Scholar] [CrossRef]

| Sample | Bias Voltage (V) | DLC Thickness (nm) | Surface Roughness (nm) | Ratio of sp3/sp2 Content |

|---|---|---|---|---|

| 1 | 175 | 645 | 14.82 | 0.77 |

| 2 | 200 | 611 | 18.63 | 0.75 |

| 3 | 225 | 559 | 15.97 | 0.74 |

| 4 | 250 | 472 | 17.28 | 0.79 |

| 5 | 275 | 378 | 18.17 | 0.83 |

| 6 | 300 | 337 | 20.70 | 0.98 |

| Wear Scratch on DLC (%) | Wear Mark on Balls (%) | Wear Debris (%) | |

|---|---|---|---|

| C | 87.86 | 22.93 | 75.46 |

| O | 10.35 | 45.65 | 16.90 |

| Al | 0.29 | 4.32 | 1.92 |

| Ti | 1.50 | 27.10 | 5.72 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Huang, L.; Yuan, J. Effect of sp3 Content on Adhesion and Tribological Properties of Non-Hydrogenated DLC Films. Materials 2020, 13, 1911. https://doi.org/10.3390/ma13081911

Li C, Huang L, Yuan J. Effect of sp3 Content on Adhesion and Tribological Properties of Non-Hydrogenated DLC Films. Materials. 2020; 13(8):1911. https://doi.org/10.3390/ma13081911

Chicago/Turabian StyleLi, Chao, Lei Huang, and Juntang Yuan. 2020. "Effect of sp3 Content on Adhesion and Tribological Properties of Non-Hydrogenated DLC Films" Materials 13, no. 8: 1911. https://doi.org/10.3390/ma13081911

APA StyleLi, C., Huang, L., & Yuan, J. (2020). Effect of sp3 Content on Adhesion and Tribological Properties of Non-Hydrogenated DLC Films. Materials, 13(8), 1911. https://doi.org/10.3390/ma13081911