Simulation and Optimization of FEV Limit Discharge’s Heat Dissipation Based on Orthogonal Experiments

Abstract

1. Introduction

2. Preliminary Design and Thermal Simulation Analysis of FEV Battery System and Cooling System

2.1. FEV Battery System Parameter Design and Heat Dissipation Demand

2.1.1. Total Battery Capacity Requirement Design

2.1.2. Determination of the Number of Single Cells

2.1.3. Group Design of Power Battery Pack

2.1.4. Calculation of Heat Dissipation in Cyclic Durable Discharge Conditions

2.1.5. Calculation of Heat Dissipation in Large Current and Short-Time Discharge Conditions

2.1.6. Calculation of Air Volume of Cooling Fan

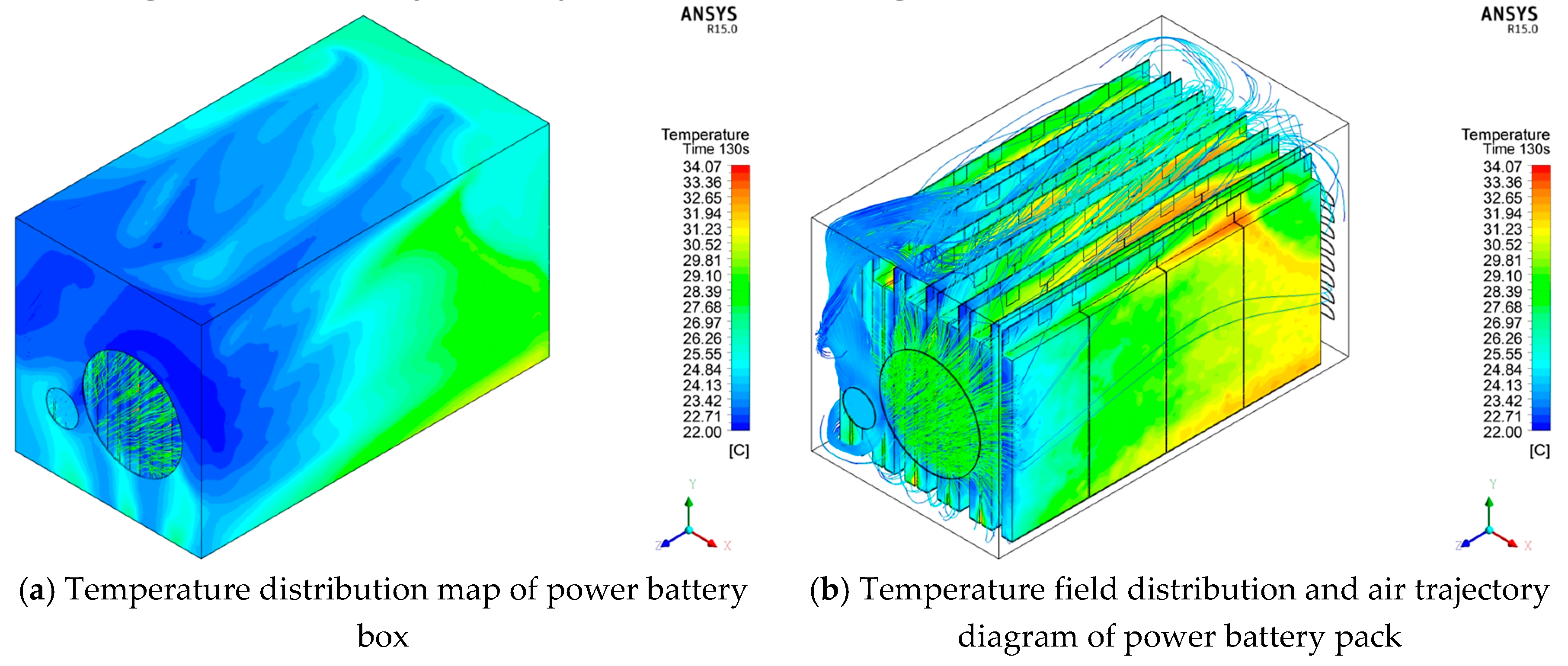

2.2. Preliminary Thermal Simulation of Power Battery Pack

2.2.1. Establishment of Finite Element Geometric Model

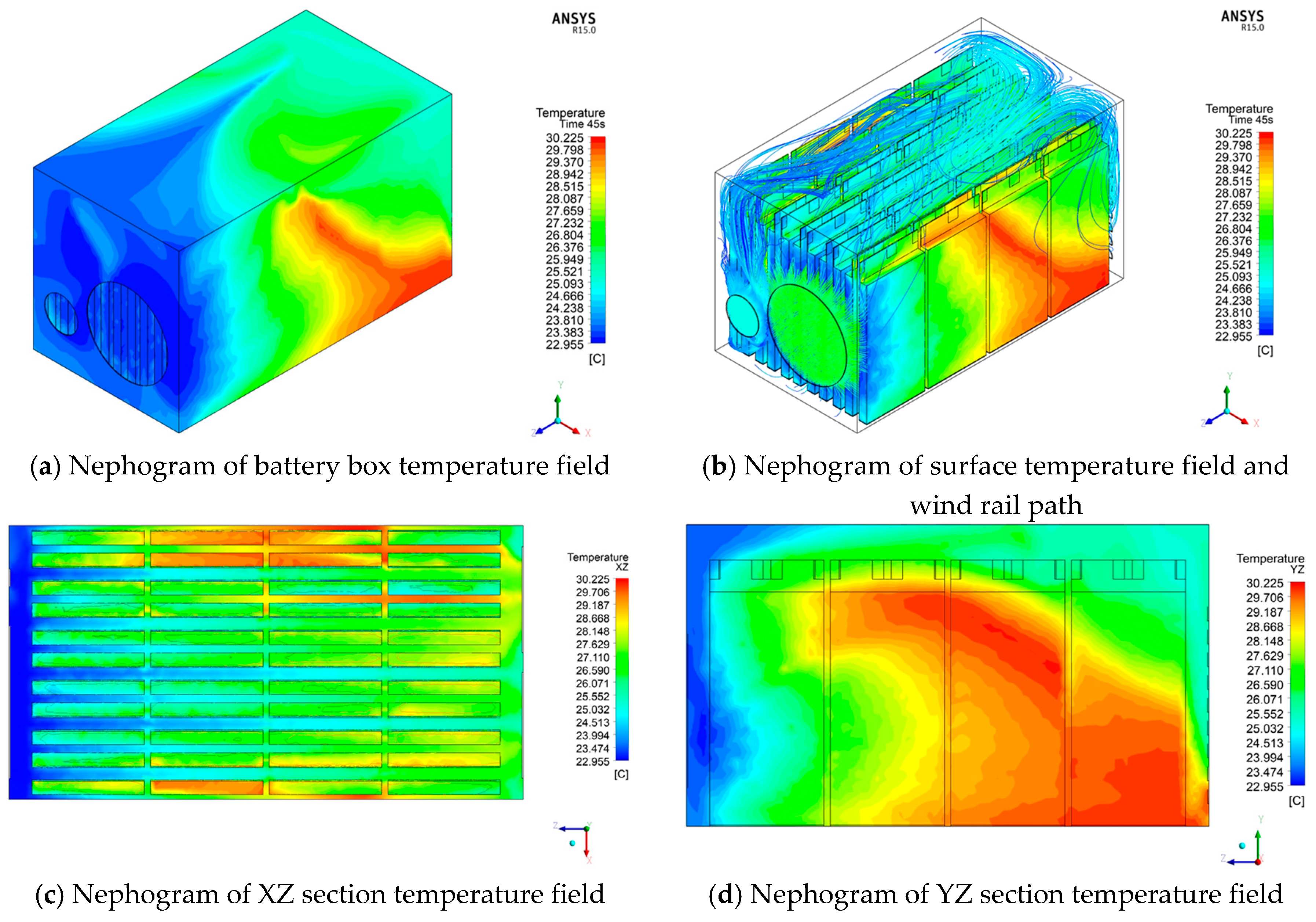

2.2.2. Analysis of Preliminary Thermal Simulation Results of Power Battery Pack

3. Design of Orthogonal Test Scheme for Heat Dissipation System

4. Evaluation Index Analysis of Heat Dissipation Simulation Results

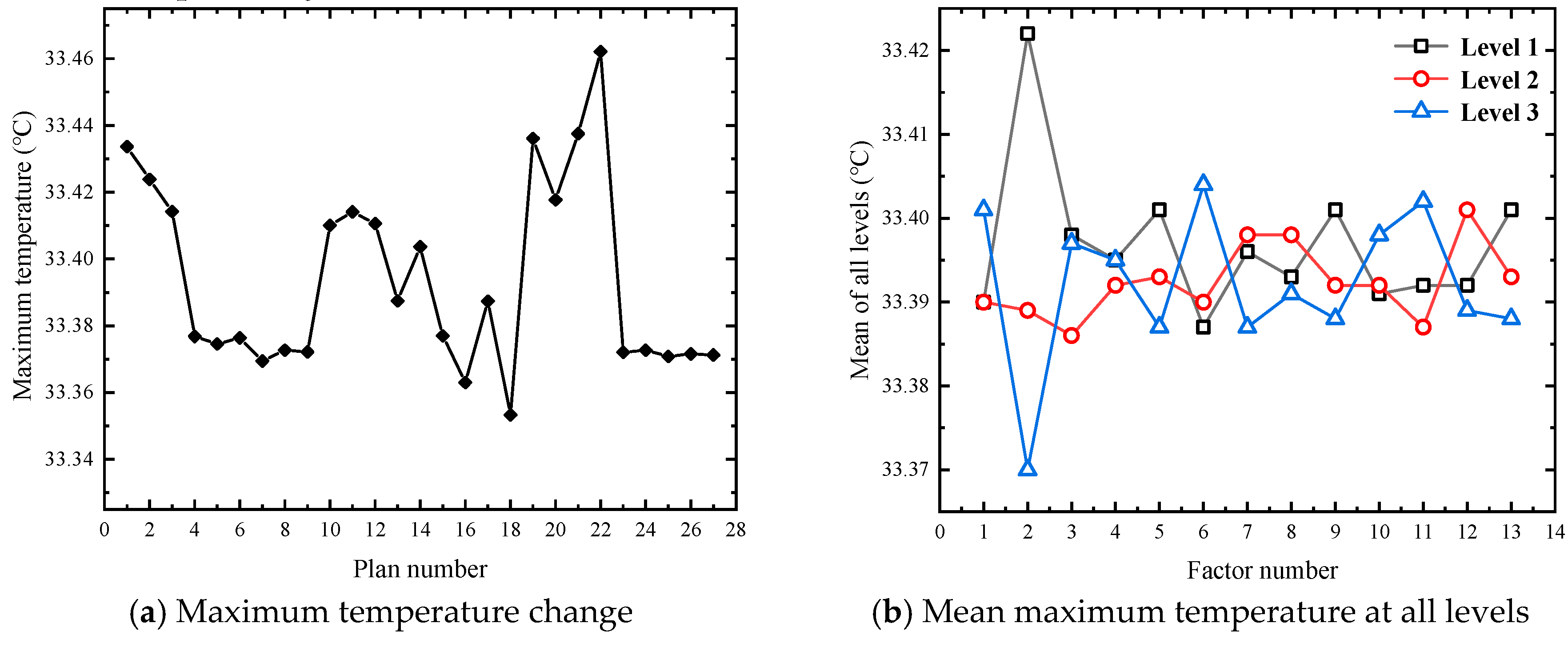

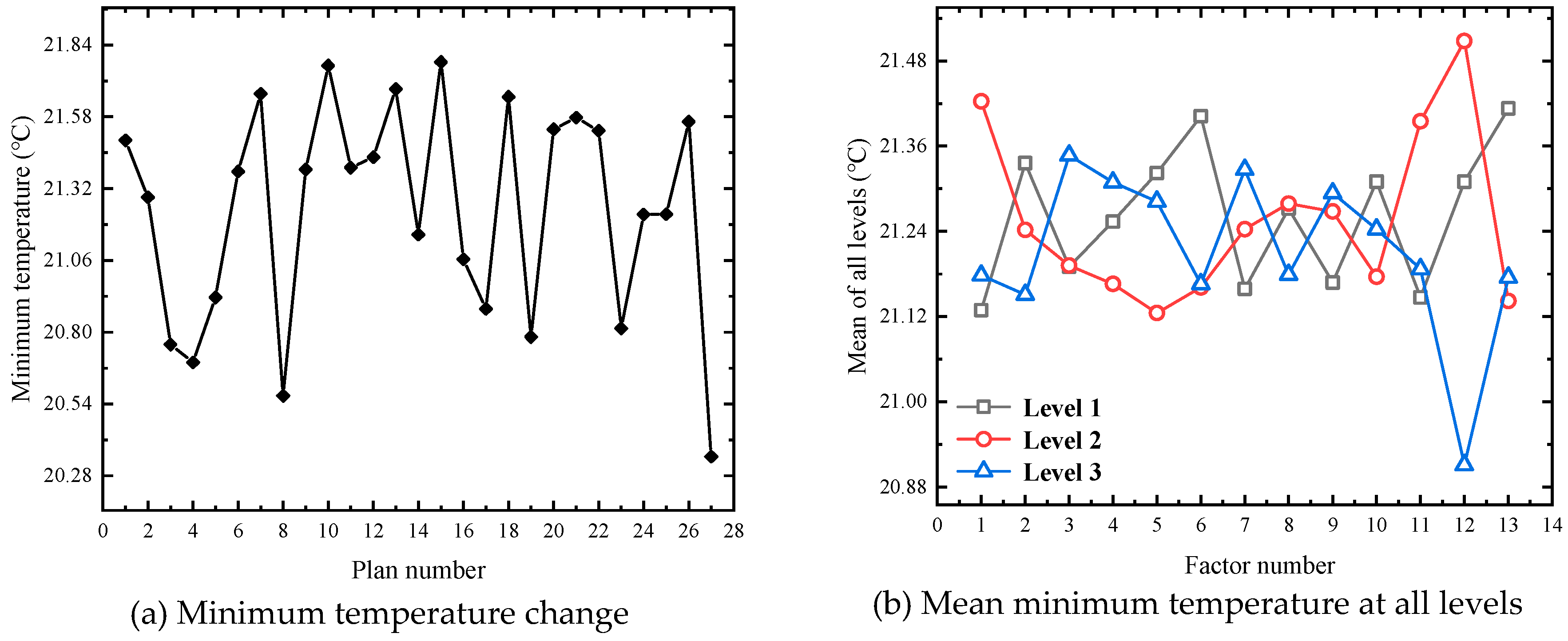

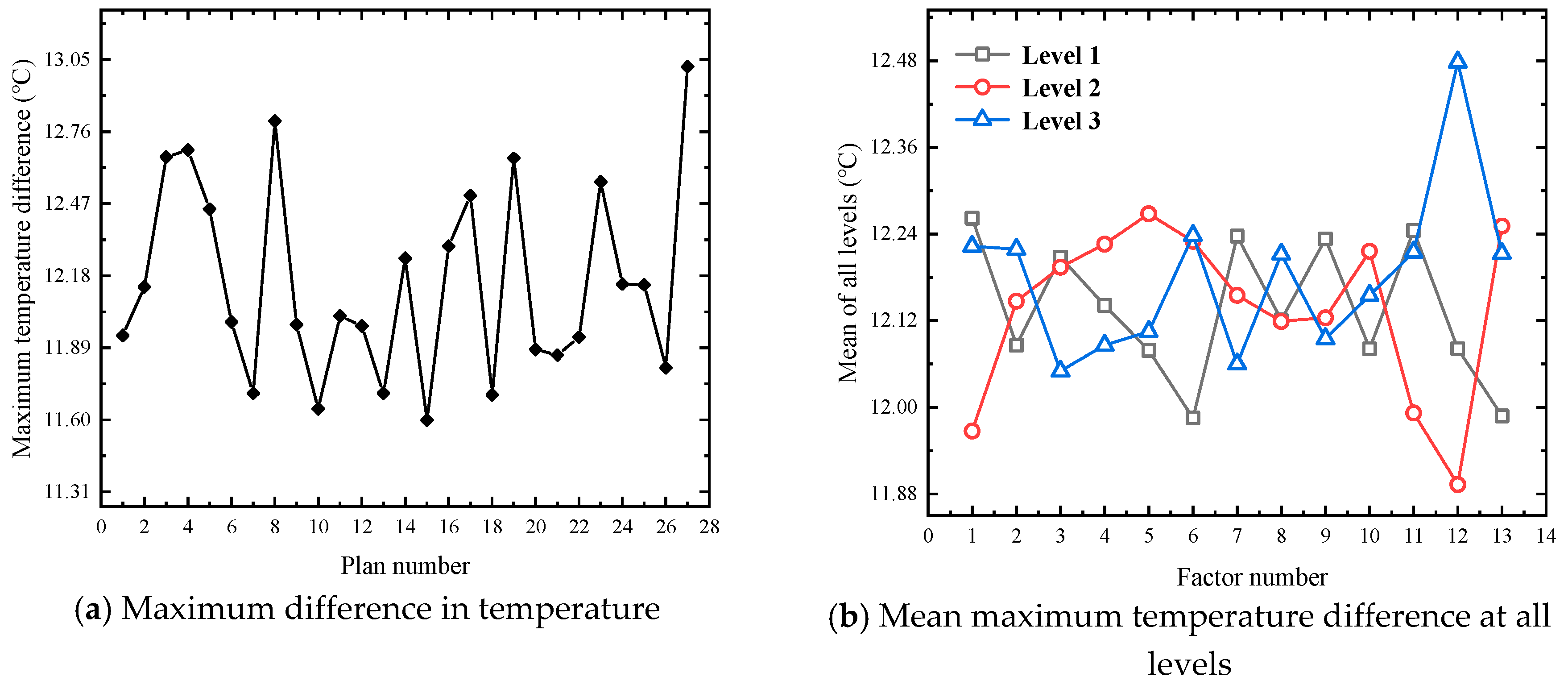

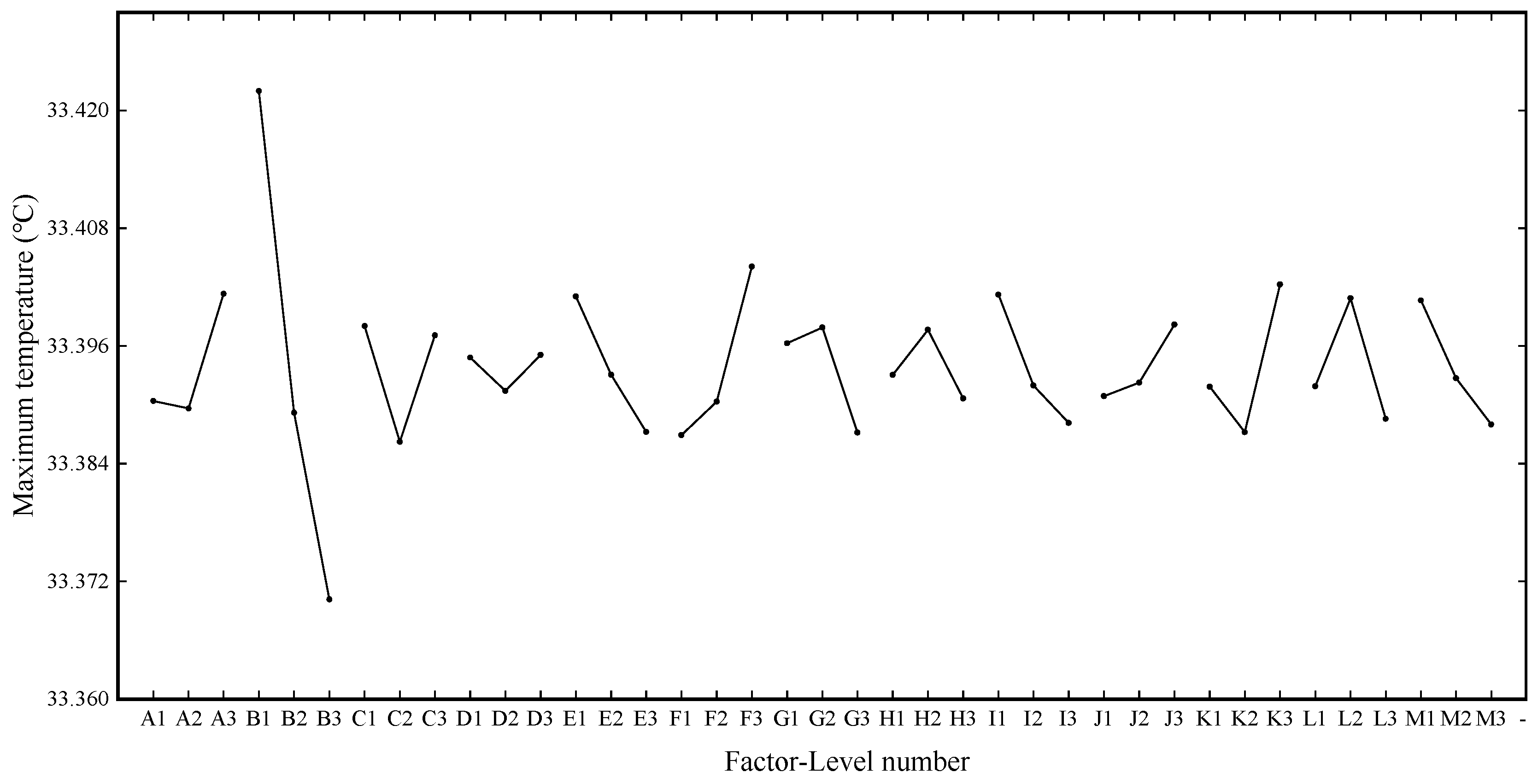

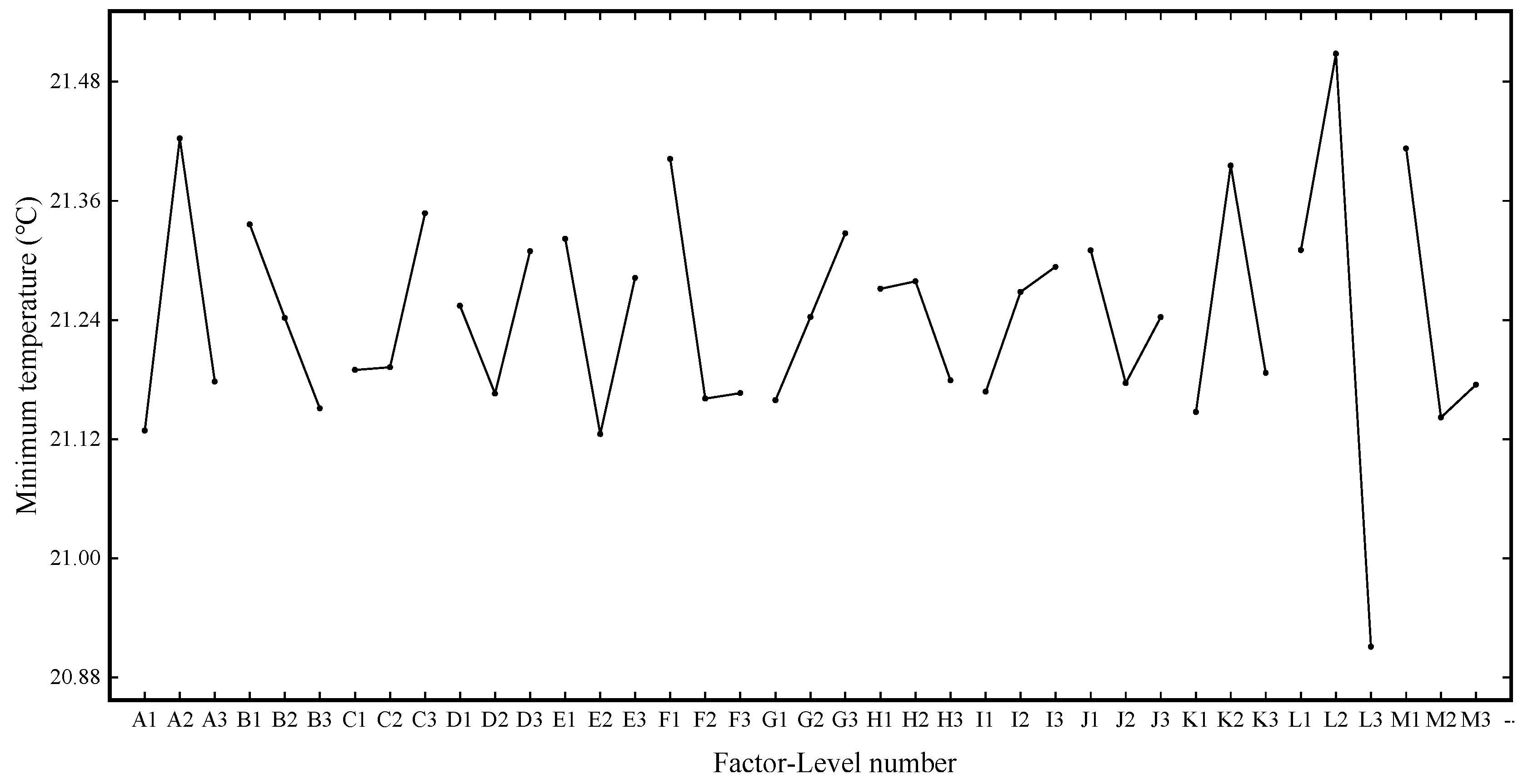

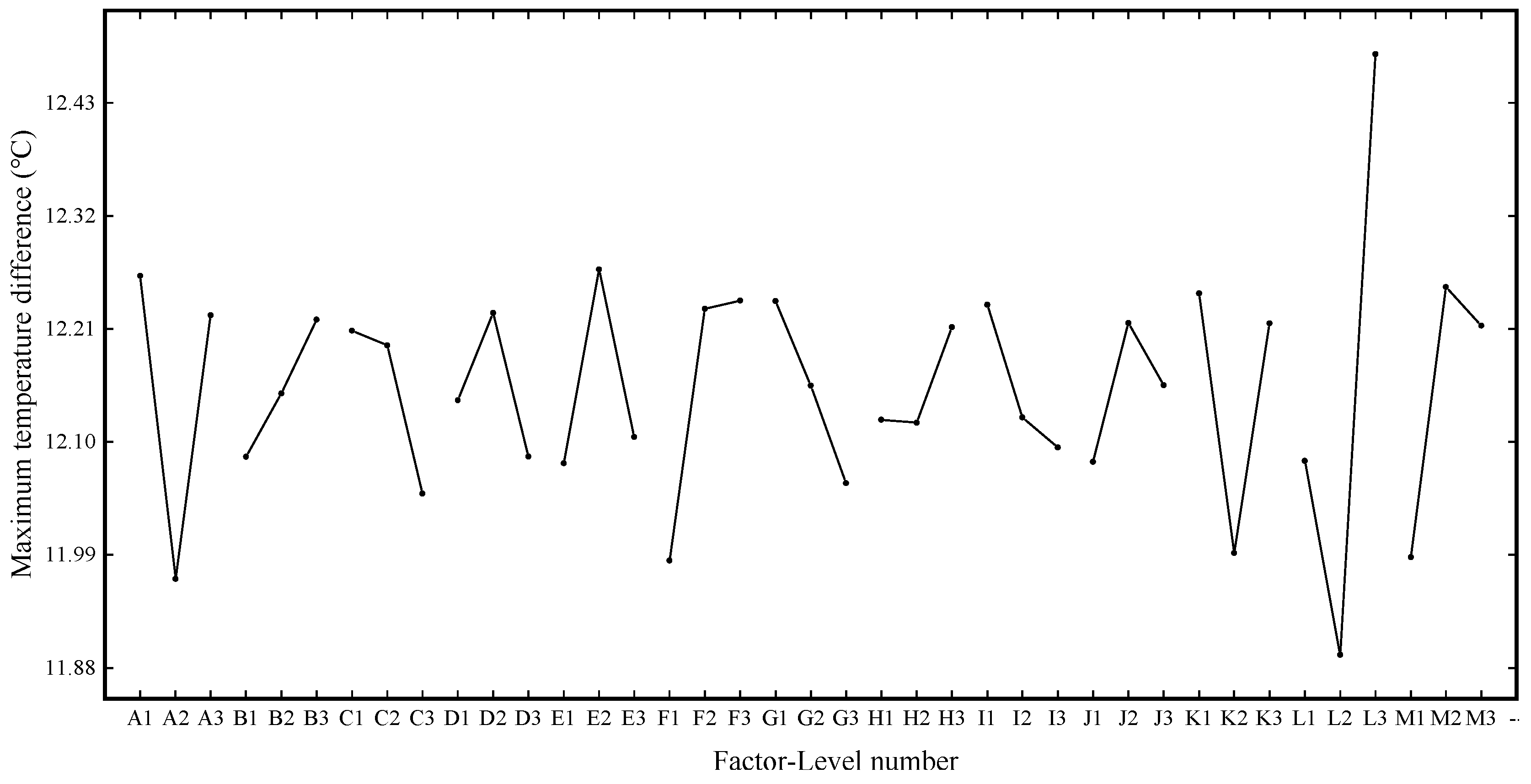

4.1. Analysis of FEV Orthogonal Test Scheme and Factor Results

4.2. Analysis of Thermal Simulation Temperature Effects

4.3. Analysis of Multiple Orthogonal Experiment Simulation Optimization Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Julien, C.; Mauger, A.; Vijh, A.; Zaghib, K. Safety Aspects of Li-Ion Batteries. In Lithium Batteries; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Zhou, D.; Shanmukaraj, D.; Tkacheva, A.; Armand, M.; Wang, G. Polymer Electrolytes for Lithium-Based Batteries: Advances and Prospects. Chem 2019, 5, 2326–2352. [Google Scholar] [CrossRef]

- Ji, W.; Huang, H.; Zheng, D.; Zhang, X.; Ding, T.; Lambert, T.H.; Qu, D. A redox-active organic cation for safer metallic lithium-based batteries. Energy Storage Mater. 2020, 32, 185–190. [Google Scholar] [CrossRef]

- Zhu, Y.; Xie, J.; Pei, A.; Liu, B.; Wu, Y.; Lin, D.; Li, J.; Wang, H.; Chen, H.; Xu, J.; et al. Fast lithium growth and short circuit induced by localized-temperature hotspots in lithium batteries. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Chen, Y.; Li, Z.Y.; Yuan, F.; Wang, S.F. Design of the cell spacings of battery pack in parallel air-cooled battery thermal management system. Int. J. Heat Mass Transf. 2018, 127, 393–401. [Google Scholar] [CrossRef]

- Sun, H.G.; Dixon, R. Development of cooling strategy for an air cooled lithium-ion battery pack. J. Power Sources 2014, 272, 404–414. [Google Scholar] [CrossRef]

- Mahamud, R.; Park, C. Reciprocating air flow for Li-ion battery thermal management to improve temperature uniformity. J. Power Sources 2011, 196, 5685–5696. [Google Scholar] [CrossRef]

- Fathabadi, H. High thermal performance lithium-ion battery pack including hybrid active–passive thermal management system for using in hybrid/electric vehicles. Energy 2014, 70, 529–538. [Google Scholar] [CrossRef]

- Yu, X.L.; Lu, Z.; Zhang, L.Y.; Wei, L.C.; Cui, X.; Jin, L.W. Experimental study on transient thermal characteristics of stagger-arranged lithium-ion battery pack with air cooling strategy. Int. J. Heat Mass Transf. 2019, 143, 118576–118588. [Google Scholar] [CrossRef]

- Yang, N.X.; Zhang, X.W.; Li, G.J.; Hua, D. Assessment of the forced air-cooling performance for cylindrical lithium-ion battery packs: A comparative analysis between aligned and staggered cell arrangements. Appl. Therm. Eng. 2015, 80, 55–65. [Google Scholar] [CrossRef]

- Bargal, M.H.S.; Abdelkareem, M.A.A.; Tao, Q.; Li, J.; Shi, J.P.; Wang, Y.P. Liquid cooling techniques in proton exchange membrane fuel cell stacks: A detailed survey. Alex. Eng. J. 2020, 59, 635–655. [Google Scholar] [CrossRef]

- Wiriyasart, S.; Hommalee, C.; Sirikasemsuk, S.; Prurapark, R.; Naphon, P. Thermal management system with nanofluids for electric vehicle battery cooling modules. Case Stud. Therm. Eng. 2020, 18, 100583–100593. [Google Scholar] [CrossRef]

- Verma, A.; Shashidhara, S.; Rakshit, D. A comparative study on battery thermal management using phase change material (PCM). Therm. Sci. Eng. Prog. 2019, 11, 74–83. [Google Scholar] [CrossRef]

- Karimi, G.; Azizi, M.; Babapoor, A. Experimental study of a cylindrical lithium ion battery thermal management using phase change material composites. J. Energy Storage 2016, 8, 168–174. [Google Scholar] [CrossRef]

- Lv, Y.F.; Situ, W.F.; Yang, X.Q.; Zhang, G.Q.; Wang, Z.Y. A novel nanosilica-enhanced phase change material with anti-leakage and anti-volume-changes properties for battery thermal management. Energy Convers. Manag. 2018, 163, 250–259. [Google Scholar] [CrossRef]

- Luo, X.H.; Guo, Q.G.; Li, X.F.; Tao, Z.C.; Lei, S.W.; Liu, J.Q.; Kang, L.B.; Zheng, D.F.; Liu, Z.J. Experimental investigation on a novel phase change material composites coupled with graphite film used for thermal management of lithium-ion batteries. Renew. Energy 2020, 145, 2046–2055. [Google Scholar] [CrossRef]

- Smith, J.; Singh, R.; Hinterberger, M.; Mochizuki, M. Battery thermal management system for electric vehicle using heat pipes. Int. J. Therm. Sci. 2018, 134, 517–529. [Google Scholar] [CrossRef]

- Jouhara, H.; Serey, N.; Khordehgah, N.; Bennett, R.; Almahmoud, S.; Lester, S.P. Investigation, development and experimental analyses of a heat pipe based battery thermal management system. Int. J. Thermofluids 2020, 1–2, 100004–100019. [Google Scholar] [CrossRef]

- Wei, A.B.; Qu, J.; Qiu, H.H.; Wang, C.; Cao, G.H. Heat transfer characteristics of plug-in oscillating heat pipe with binary-fluid mixtures for electric vehicle battery thermal management. Int. J. Heat Mass Transf. 2019, 135, 746–760. [Google Scholar] [CrossRef]

- Zhao, R.; Gu, J.J.; Liu, J. Optimization of a phase change material based internal cooling system for cylindrical Li-ion battery pack and a hybrid cooling design. Energy 2017, 135, 811–822. [Google Scholar] [CrossRef]

- Kermani, M.M.; Houshfar, E.; Ashjaee, M. A novel hybrid thermal management for Li-ion batteries using phase change materials embedded in copper foams combined with forced-air convection. Int. J. Therm. Sci. 2019, 141, 47–61. [Google Scholar] [CrossRef]

- Ramadevi, B.; Kumar, K.A.; Sugunamma, V.; Sandeep, N. Influence of non-uniform heat source/sink on the three-dimensional magnetohydrodynamic Carreau fluid flow past a stretching surface with modified Fourier’ s law. Pramana J. Phys. 2019, 93, 86. [Google Scholar] [CrossRef]

- Zhang, J. Study on Heat Dissipation Structure Optimization of Power Electronic; Harbin Institute of Technology: Harbin, China, 2015. [Google Scholar]

| Item | Rated Parameters |

|---|---|

| Typical capacity/mAh | 22,000 |

| Cell resistance/mΩ | 3 |

| Cell thickness/mm | 11.8 |

| Cell length/mm | 194 |

| Cell weight/g | 420 |

| Cell width/mm | 91 |

| Nominal voltage/V | 3.7 |

| Charge cutoff voltage/V | 4.2 |

| Cathode width/mm | 35 |

| Anode width/mm | 25 |

| Maximum discharge current/A | 220 |

| Standard charging current/A | 22 |

| Standard discharge current/A | 22 |

| Discharge temperature/°C | −20~75 |

| Factors | Alpha Code | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| Single cell clearance/mm | A | 1 | 2 | 3 |

| Single battery pack clearance/mm | B | 2.5 | 3.5 | 4.5 |

| Battery pack clearance/mm | C | 10 | 11 | 12 |

| Number of outlet grilles/unit | D | 16 | 18 | 20 |

| Air outlet grille height/mm | E | 10 | 10.5 | 11 |

| X-direction spacing of outlet grille/mm | F | 17 | 18 | 19 |

| Y-direction spacing of outlet grille/mm | G | 6.5 | 7 | 7.5 |

| Air inlet size R1/mm | H | 59 | 60 | 61 |

| X-direction spacing of first air intake/mm | I | 28.5 | 26.5 | 24.5 |

| Y-direction spacing of first air intake/mm | J | 12.5 | 14.5 | 16.5 |

| Air inlet size R2/mm | K | 19 | 20 | 21 |

| X-direction spacing of second air intake/mm | L | 54.5 | 56.5 | 58.5 |

| Y-direction spacing of second air intake/mm | M | 48 | 46 | 44 |

| Number | A | B | C | D | E | F | G | H | I | J | K | L | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 2.5 | 10 | 16 | 10.0 | 17 | 6.5 | 59 | 28.5 | 12.5 | 19 | 54.5 | 48 |

| 2 | 1 | 2.5 | 10 | 16 | 10.5 | 18 | 7.0 | 60 | 26.5 | 14.5 | 20 | 56.5 | 46 |

| 3 | 1 | 2.5 | 10 | 16 | 11.0 | 19 | 7.5 | 61 | 24.5 | 16.5 | 21 | 58.5 | 44 |

| 4 | 1 | 3.5 | 11 | 18 | 10.0 | 17 | 6.5 | 60 | 26.5 | 14.5 | 21 | 58.5 | 44 |

| 5 | 1 | 3.5 | 11 | 18 | 10.5 | 18 | 7.0 | 61 | 24.5 | 16.5 | 19 | 54.5 | 48 |

| 6 | 1 | 3.5 | 11 | 18 | 11.0 | 19 | 7.5 | 59 | 28.5 | 12.5 | 20 | 56.5 | 46 |

| 7 | 1 | 4.5 | 12 | 20 | 10.0 | 17 | 6.5 | 61 | 24.5 | 16.5 | 20 | 56.5 | 46 |

| 8 | 1 | 4.5 | 12 | 20 | 10.5 | 18 | 7.0 | 59 | 28.5 | 12.5 | 21 | 58.5 | 44 |

| 9 | 1 | 4.5 | 12 | 20 | 11.0 | 19 | 7.5 | 60 | 26.5 | 14.5 | 19 | 54.5 | 48 |

| 10 | 2 | 2.5 | 11 | 20 | 10.0 | 18 | 7.5 | 59 | 26.5 | 16.5 | 19 | 56.5 | 44 |

| 11 | 2 | 2.5 | 11 | 20 | 10.5 | 19 | 6.5 | 60 | 24.5 | 12.5 | 20 | 58.5 | 48 |

| 12 | 2 | 2.5 | 11 | 20 | 11.0 | 17 | 7.0 | 61 | 28.5 | 14.5 | 21 | 54.5 | 46 |

| 13 | 2 | 3.5 | 12 | 16 | 10.0 | 18 | 7.5 | 60 | 24.5 | 12.5 | 21 | 54.5 | 46 |

| 14 | 2 | 3.5 | 12 | 16 | 10.5 | 19 | 6.5 | 61 | 28.5 | 14.5 | 19 | 56.5 | 44 |

| 15 | 2 | 3.5 | 12 | 16 | 11.0 | 17 | 7.0 | 59 | 26.5 | 16.5 | 20 | 58.5 | 48 |

| 16 | 2 | 4.5 | 10 | 18 | 10.0 | 18 | 7.5 | 61 | 28.5 | 14.5 | 20 | 58.5 | 48 |

| 17 | 2 | 4.5 | 10 | 18 | 10.5 | 19 | 6.5 | 59 | 26.5 | 16.5 | 21 | 54.5 | 46 |

| 18 | 2 | 4.5 | 10 | 18 | 11.0 | 17 | 7.0 | 60 | 24.5 | 12.5 | 19 | 56.5 | 44 |

| 19 | 3 | 2.5 | 12 | 18 | 10.0 | 19 | 7.0 | 59 | 24.5 | 14.5 | 19 | 58.5 | 46 |

| 20 | 3 | 2.5 | 12 | 18 | 10.5 | 17 | 7.5 | 60 | 28.5 | 16.5 | 20 | 54.5 | 44 |

| 21 | 3 | 2.5 | 12 | 18 | 11.0 | 18 | 6.5 | 61 | 26.5 | 12.5 | 21 | 56.5 | 48 |

| 22 | 3 | 3.5 | 10 | 20 | 10.0 | 19 | 7.0 | 60 | 28.5 | 16.5 | 21 | 56.5 | 48 |

| 23 | 3 | 3.5 | 10 | 20 | 10.5 | 17 | 7.5 | 61 | 26.5 | 12.5 | 19 | 58.5 | 46 |

| 24 | 3 | 3.5 | 10 | 20 | 11.0 | 18 | 6.5 | 59 | 24.5 | 14.5 | 20 | 54.5 | 44 |

| 25 | 3 | 4.5 | 11 | 16 | 10.0 | 19 | 7.0 | 61 | 26.5 | 12.5 | 20 | 54.5 | 44 |

| 26 | 3 | 4.5 | 11 | 16 | 10.5 | 17 | 7.5 | 59 | 24.5 | 14.5 | 21 | 56.5 | 48 |

| 27 | 3 | 4.5 | 11 | 16 | 11.0 | 18 | 6.5 | 60 | 28.5 | 16.5 | 19 | 58.5 | 46 |

| Project Portfolio | Maximum Temperature/°C | Minimum Temperature/°C | Maximum Temperature Difference/K |

|---|---|---|---|

| B3F1K2E3I3M3L3C2A2G3J1H3D2 | 32.9656 | 21.9412 | 11.0244 |

| L3A1M2K1F2E2B3G1C1D2J2I1H3 | 32.0529 | 22.5172 | 9.5357 |

| L2A2M1F1K2E1G3C3D3I3J1B1H2 | 33.1124 | 21.2543 | 11.8581 |

| L2B1A3M1F3K3E1C1G2I1D3J3H2 | 32.4201 | 21.2689 | 11.1512 |

| Factors | Parameter |

|---|---|

| Single cell clearance/mm | 5 |

| Single battery pack clearance/mm | 6.5 |

| Battery pack clearance/mm | 10 |

| Number of outlet grilles/unit | 18 |

| Air outlet grille height/mm | 11 |

| X-direction spacing of outlet grille/mm | 17 |

| Y-direction spacing of outlet grille/mm | 7 |

| Air inlet size R1/mm | 61 |

| X-direction spacing of first air intake/mm | 32 |

| Y-direction spacing of first air intake/mm | 28 |

| Air inlet size R2/mm | 25 |

| X-direction spacing of second air intake/mm | 68 |

| Y-direction spacing of second air intake/mm | 52 |

| Project | Maximum Temperature/°C | Minimum Temperature/°C | Maximum Temperature Difference/K |

|---|---|---|---|

| Preliminary design | 33.4906 | 21.4007 | 12.0899 |

| Many optimization | 30.2254 | 22.9550 | 7.2704 |

| Percentage degree of optimization % | 9.7496 | 7.2628 | 39.8639 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Xu, Y.; Yang, Y.; Si, C. Simulation and Optimization of FEV Limit Discharge’s Heat Dissipation Based on Orthogonal Experiments. Materials 2020, 13, 5563. https://doi.org/10.3390/ma13235563

Li H, Xu Y, Yang Y, Si C. Simulation and Optimization of FEV Limit Discharge’s Heat Dissipation Based on Orthogonal Experiments. Materials. 2020; 13(23):5563. https://doi.org/10.3390/ma13235563

Chicago/Turabian StyleLi, Hong, Yilun Xu, Yong Yang, and Chenlong Si. 2020. "Simulation and Optimization of FEV Limit Discharge’s Heat Dissipation Based on Orthogonal Experiments" Materials 13, no. 23: 5563. https://doi.org/10.3390/ma13235563

APA StyleLi, H., Xu, Y., Yang, Y., & Si, C. (2020). Simulation and Optimization of FEV Limit Discharge’s Heat Dissipation Based on Orthogonal Experiments. Materials, 13(23), 5563. https://doi.org/10.3390/ma13235563