Improving the Mechanical Response of Al–Mg–Si 6082 Structural Alloys during High-Temperature Exposure through Dispersoid Strengthening

Abstract

:1. Introduction

2. Materials and Methods

3. Results

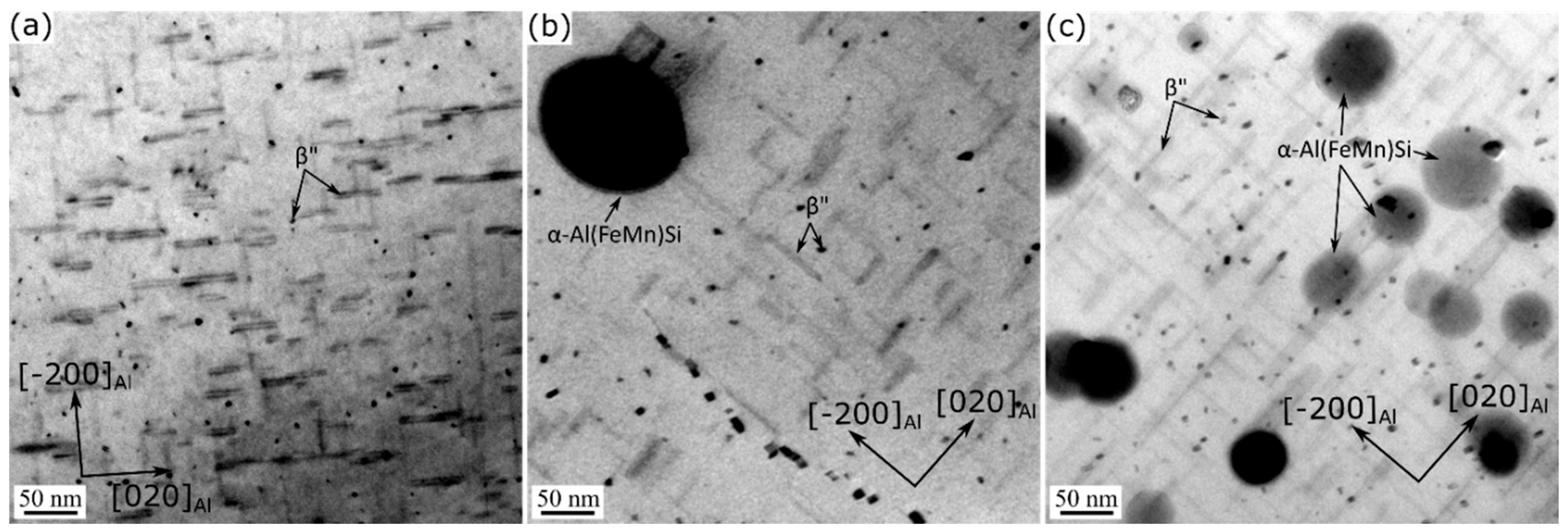

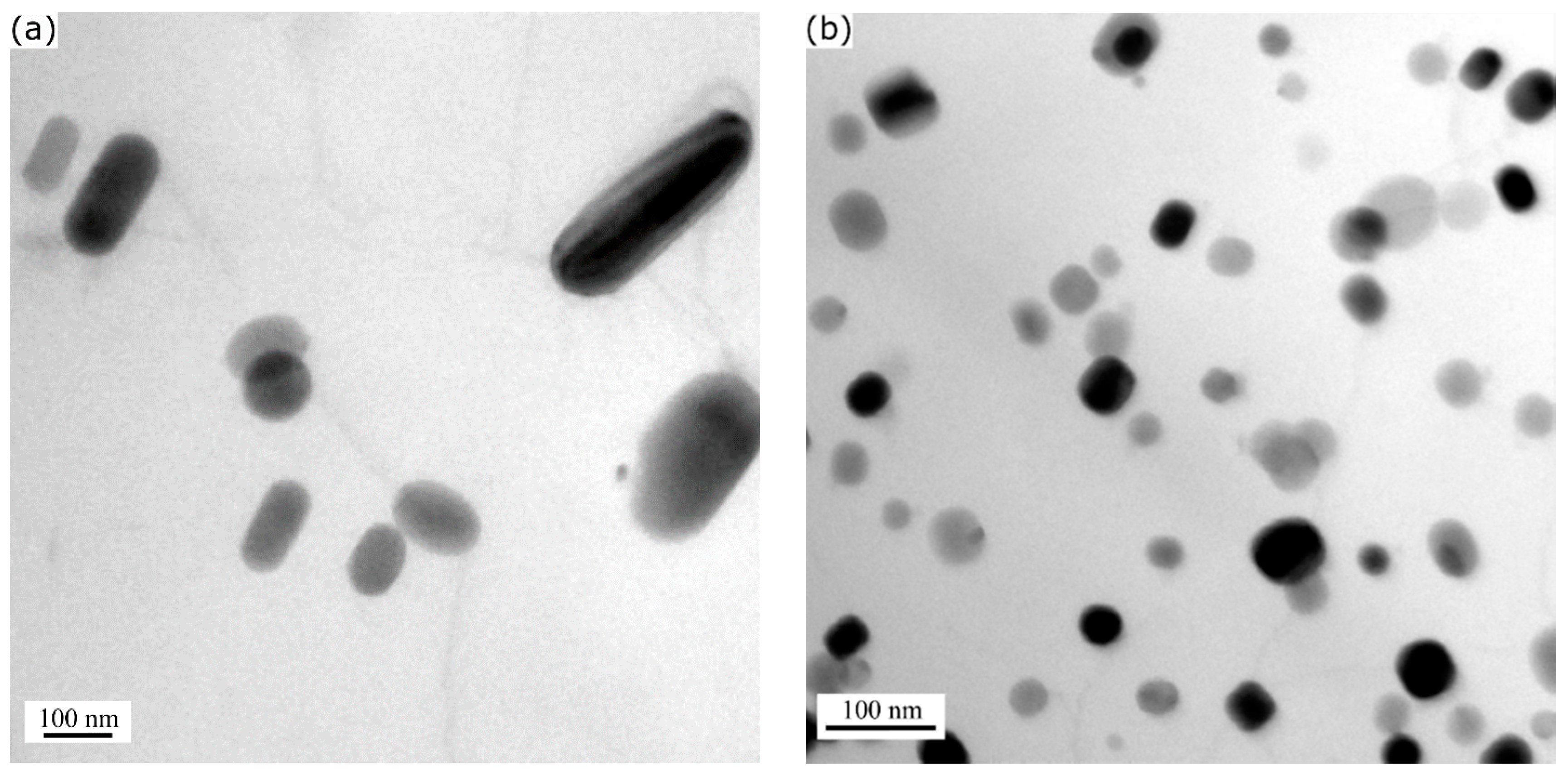

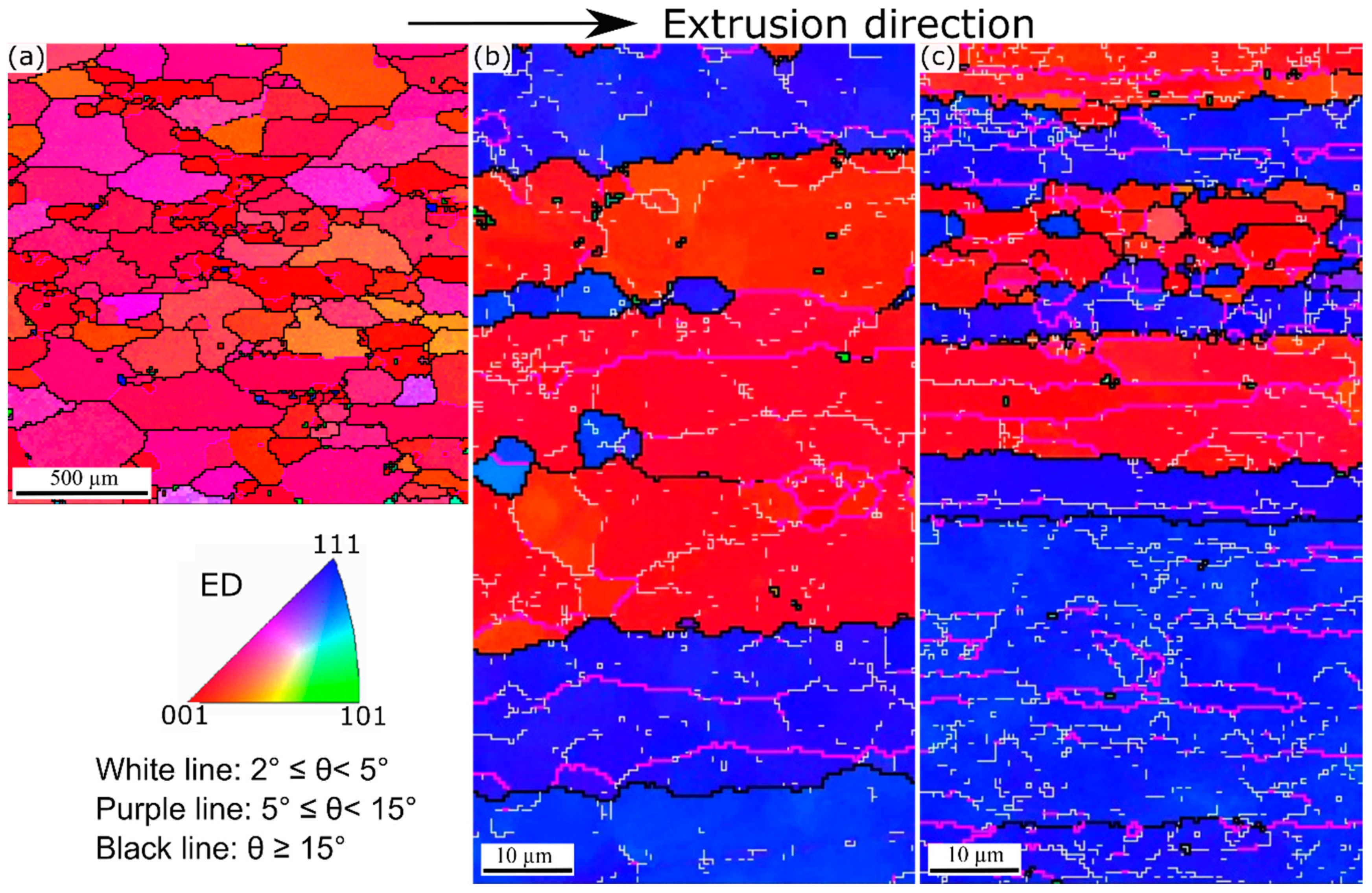

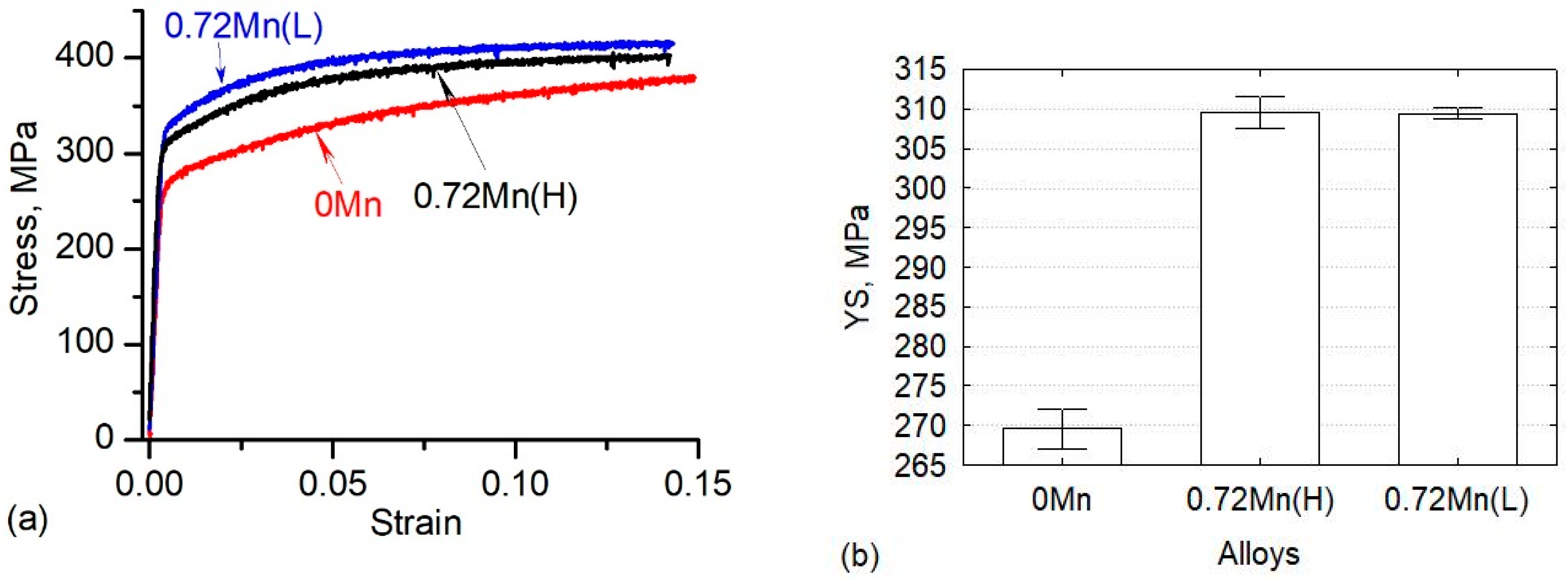

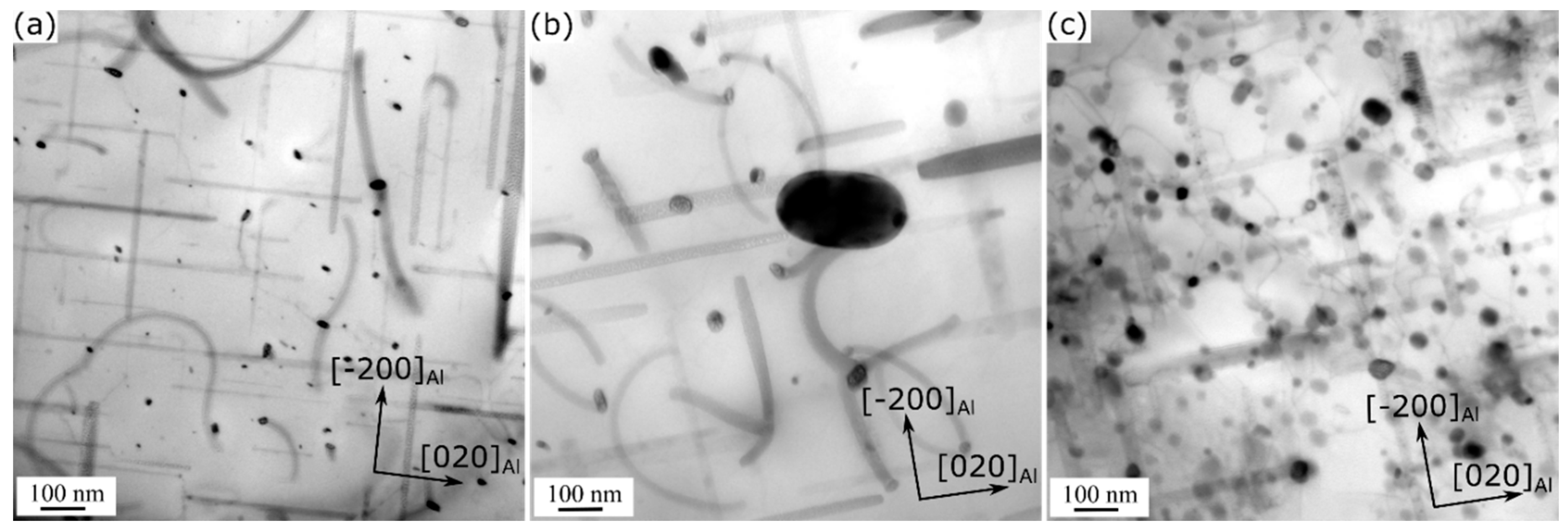

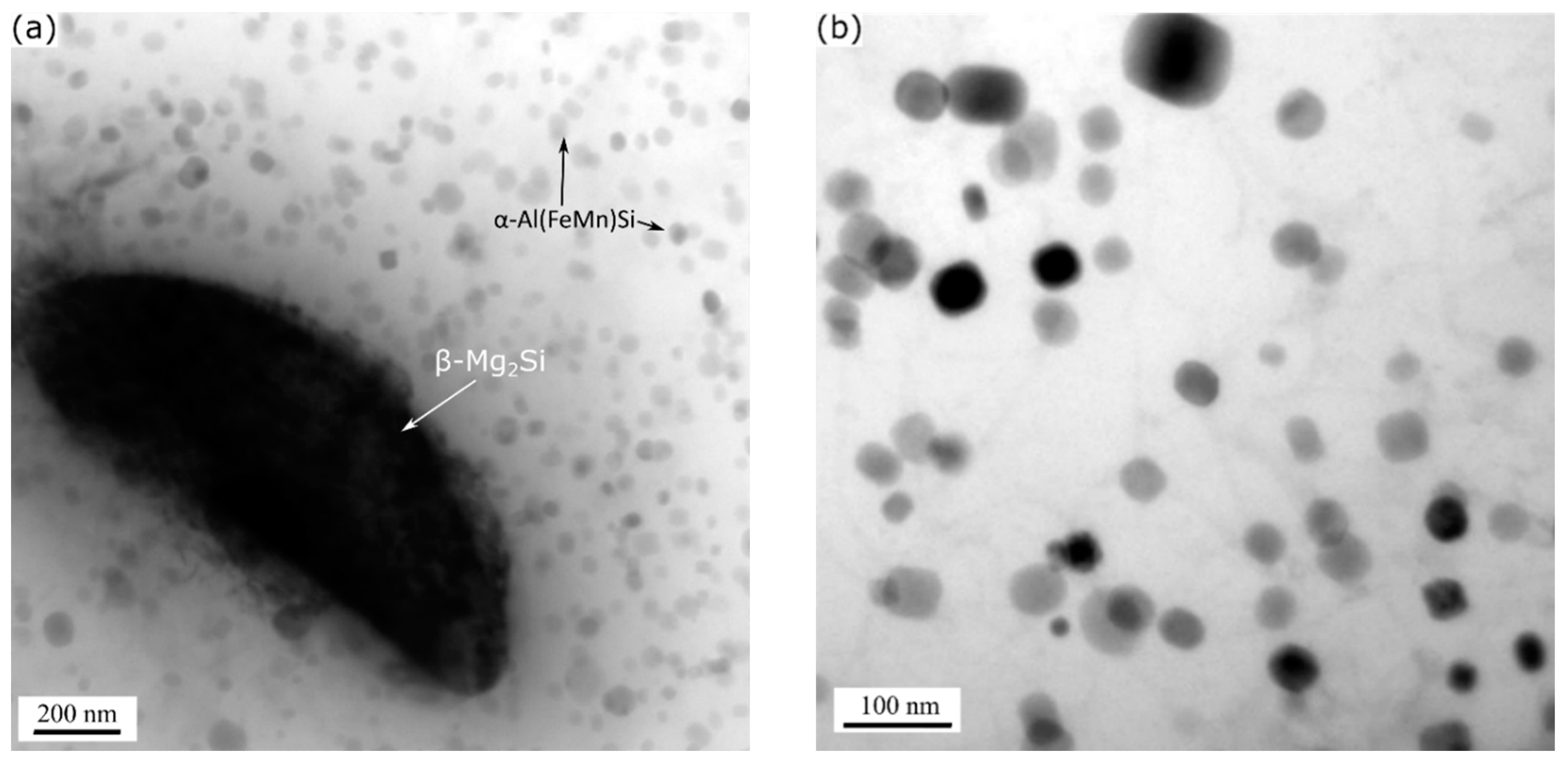

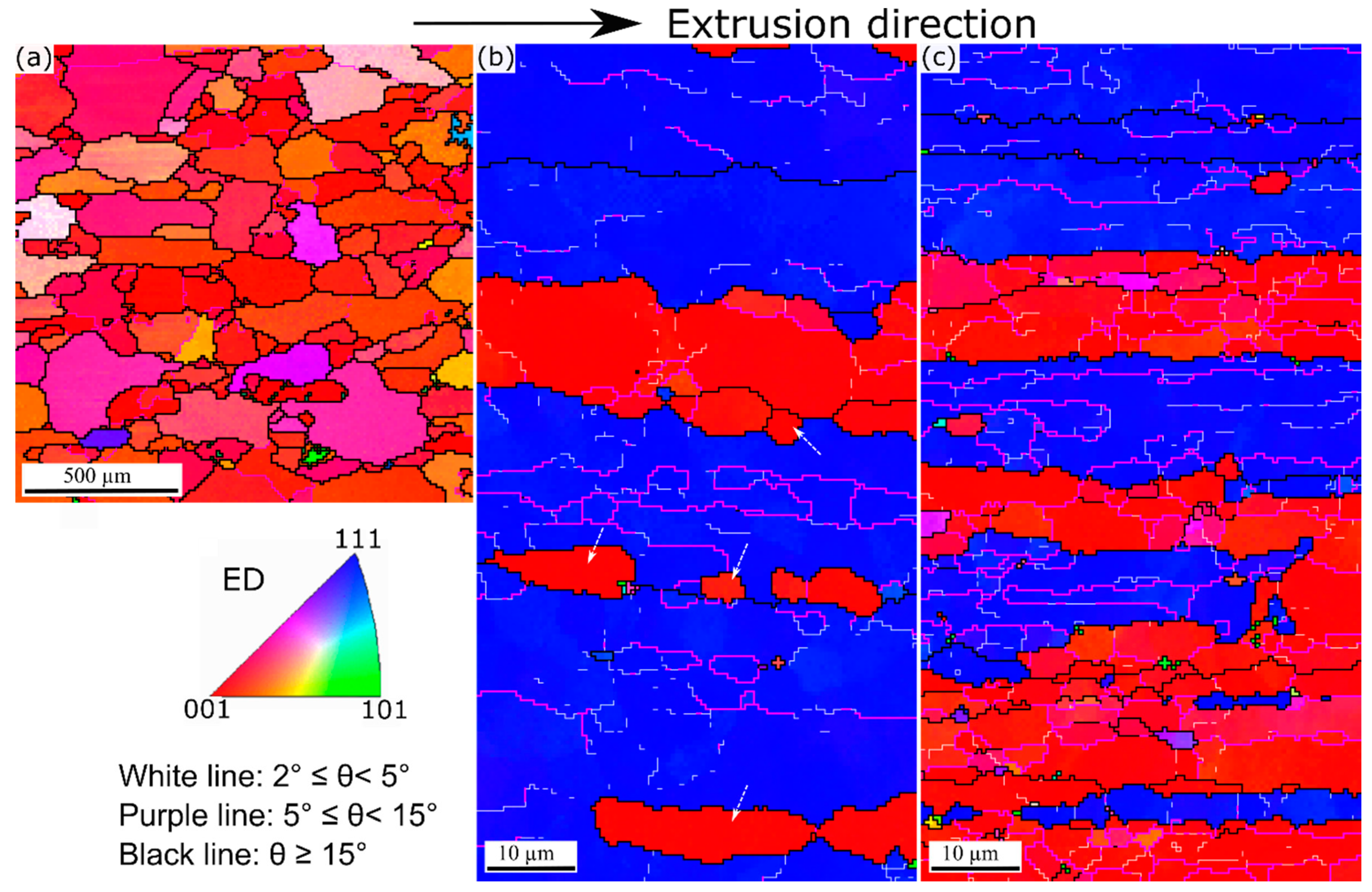

3.1. Microstructure and Mechanical Properties under T5 Conditions

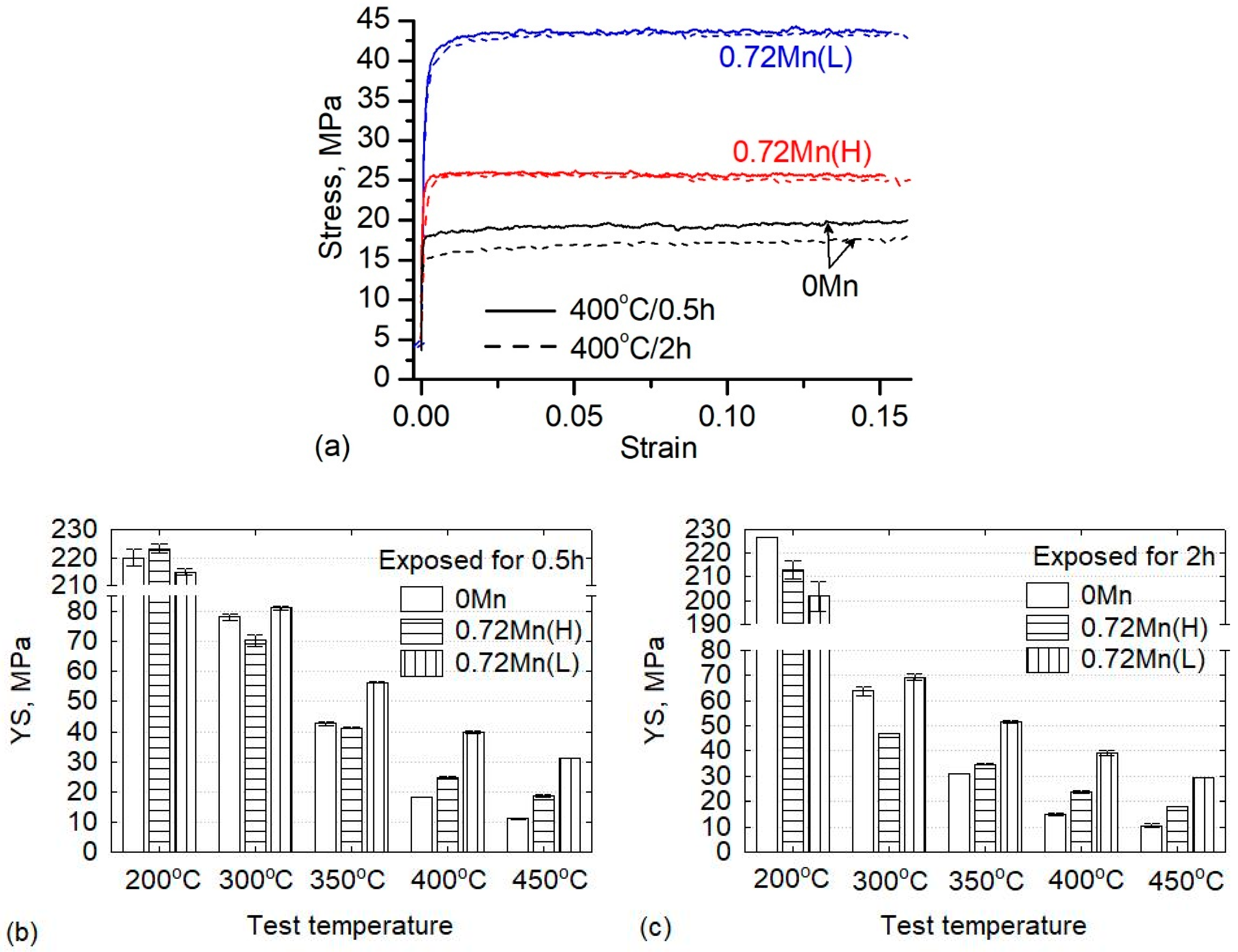

3.2. Instantaneous High-Temperature Strength during Thermal Exposure

3.3. Residual Room-Temperature Strength after Thermal Exposure

4. Discussion

5. Conclusions

- The addition of Mn in a typical high-temperature homogenization treatment produced a number of α-Al(FeMn)Si dispersoids in the 0.72Mn(H) alloy, which improved the mechanical response during thermal exposure at 350–450 °C relative to that of the Mn-free base alloy. Moreover, the low-temperature homogenization treatment resulted in a high density of fine dispersoids in the 0.72Mn(L) alloy, which further improved the mechanical response substantially.

- At a low exposure temperature (200 °C), the instantaneous and residual YSs of the alloys were mainly governed by the β” precipitates, and the mechanical properties of the aluminum structural alloys were not markedly affected compared to their original strength under T5 condition.

- At a high exposure temperature of 300 °C, the β” precipitates transformed into coarse β’ precipitates, thereby resulting in a significant reduction in the alloy strength. The strength improvement due to the presence of fine and dense dispersoids became quite evident, because the instantaneous and residual strengths of the corresponding alloy (0.72Mn(L)) were higher than those of the alloys without dispersoids (0Mn) or with coarse dispersoids (0.72Mn(H)).

- At higher exposure temperatures (350–450 °C), the Mg2Si precursor precipitates transformed into coarse equilibrium β-Mg2Si particles and lost their strengthening effect, while the dispersoids resisted the coarsening and became the dominant strengthening contributor. The 0.72Mn(L) alloy containing fine and dense dispersoids displayed far superior instantaneous and residual YSs compared to the other two alloy variants and therefore the best mechanical response during high temperature exposure.

- The presence of thermally stable dispersoids effectively retarded the recrystallization during high temperature exposure, which improved the high-temperature mechanical properties to a certain extent.

Author Contributions

Funding

Conflicts of Interest

References

- Summers, P.T.; Chen, Y.; Rippe, C.M.; Allen, B.; Mouritz, A.P.; Case, S.W.; Lattimer, B.Y. Overview of aluminum alloy mechanical properties during and after fires. Fire Sci. Rev. 2015, 4, 3. [Google Scholar]

- Chen, Z.H.; Lu, J.; Liu, H.B.; Liao, X.W. Experimental investigation on the post-fire mechanical properties of structural aluminum alloys 6061-T6 and 7075-T73. Thin Wall Struct. 2016, 106, 187–200. [Google Scholar]

- Maljaars, J.; Soetens, F.; Katgerman, L. Constitutive model for aluminum alloys exposed to fire conditions. Met. Mater. Trans. A 2008, 39A, 778–789. [Google Scholar]

- Fogle, E.J.; Lattimer, B.Y.; Feih, S.; Kandare, E.; Mouritz, A.P.; Case, S.W. Compression load failure of aluminum plates due to fire. Eng. Struct. 2012, 34, 155–162. [Google Scholar]

- Hu, J.; Zhang, W.; Fu, D.; Teng, J.; Zhang, H. Improvement of the mechanical properties of Al–Mg–Si alloys with nano-scale precipitates after repetitive continuous extrusion forming and T8 tempering. J. Mater. Res. Technol. 2019, 8, 5950–5960. [Google Scholar]

- Sekhar, A.P.; Mandal, A.B.; Das, D. Mechanical properties and corrosion behavior of artificially aged Al-Mg-Si alloy. J. Mater. Res. Technol. 2020, 9, 1005–1024. [Google Scholar]

- Kaufman, J.G. Fire Resistance of Aluminum and Aluminum Alloys: Measuring the Effects of Fire Exposure on the Properties of Aluminum Alloys; ASM International: Materials Park, OH, USA, 2016. [Google Scholar]

- European Center for Standardization. Design of Aluminium Structures. Part 1–2: Structural Fire Design; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- Sigli, C.; De Geuser, F.; Deschamps, A.; Lepinoux, J.; Perez, M. Recent advances in the metallurgy of aluminum alloys. Part II: Age hardening. Comptes Rendus Phys. 2018, 19, 688–709. [Google Scholar]

- Gupta, A.K.; Lloyd, D.J.; Court, S.A. Precipitation hardening in Al-Mg-Si alloys with and without excess Si. Mater. Sci. Eng. A 2001, 316, 11–17. [Google Scholar]

- Fang, X.; Song, M.; Li, K.; Du, Y. Precipitation Sequence of an Aged Al-Mg-Si Alloy. J. Min. Met. B 2010, 46, 171–180. [Google Scholar]

- Gross, C.T.; Isheim, D.; Vaynman, S.; Fine, M.E.; Chung, Y.W. Design and Development of Lightly Alloyed Ferritic Fire-Resistant Structural Steels. Met. Mater. Trans. A 2019, 50A, 209–219. [Google Scholar]

- Liu, K.; Ma, H.; Chen, X.G. Enhanced elevated-temperature properties via Mo addition in Al-Mn-Mg 3004 alloy. J. Alloys Compd. 2017, 694, 354–365. [Google Scholar]

- Liu, K.; Chen, X.G. Evolution of Intermetallics, Dispersoids, and Elevated Temperature Properties at Various Fe Contents in Al-Mn-Mg 3004 Alloys. Met. Mater. Trans. B 2016, 47, 3291–3300. [Google Scholar]

- Liu, K.; Chen, X.G. Development of Al–Mn–Mg 3004 alloy for applications at elevated temperature via dispersoid strengthening. Mater. Des. 2015, 84, 340–350. [Google Scholar]

- Li, Z.; Zhang, Z.; Chen, X.G. Microstructure, elevated-temperature mechanical properties and creep resistance of dispersoid-strengthened Al-Mn-Mg 3xxx alloys with varying Mg and Si contents. Mater. Sci. Eng. A 2017, 708, 383–394. [Google Scholar]

- Rakhmonov, J.; Timelli, G.; Fabrizi, A.; Bonollo, F. Effect of V and Zr microalloying, and heat treatment on microstructure and mechanical properties of secondary Al-7Si-3Cu-0.3Mg alloy. Int. J. Mater. Res. 2018, 109, 1099–1112. [Google Scholar]

- Du, Q.; Poole, W.J.; Wells, M.A.; Parson, N.C. Microstructure evolution during homogenization of Al-Mn-Fe-Si alloys: Modeling and experimental results. Acta Mater. 2013, 61, 4961–4973. [Google Scholar]

- Li, Y.J.; Arnberg, L. Quantitative study on the precipitation behavior of dispersoids in DC-cast AA3003 alloy during heating and homogenization. Acta Mater. 2003, 51, 3415–3428. [Google Scholar]

- Li, Y.J.; Muggerud, A.M.F.; Olsen, A.; Furu, T. Precipitation of partially coherent α-Al(Mn,Fe)Si dispersoids and their strengthening effect in AA 3003 alloy. Acta Mater. 2012, 60, 1004–1014. [Google Scholar]

- Liu, Y.; Liu, H.B.; Chen, Z.H. Post-fire mechanical properties of aluminum alloy 6082-T6. Constr. Build. Mater. 2019, 196, 256–266. [Google Scholar]

- Engler, O.; Marioara, C.D.; Aruga, Y.; Kozuka, M.; Myhr, O.R. Effect of natural ageing or pre-ageing on the evolution of precipitate structure and strength during age hardening of Al–Mg–Si alloy AA 6016. Mater. Sci. Eng. A 2019, 759, 520–529. [Google Scholar]

- Qian, F.; Jin, S.B.; Sha, G.; Li, Y.J. Enhanced dispersoid precipitation and dispersion strengthening in an Al alloy by microalloying with Cd. Acta Mater. 2018, 157, 114–125. [Google Scholar]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The precipitation sequence in Al-Mg-Si alloys. Acta Mater. 1998, 46, 3893–3904. [Google Scholar]

- Mahmoodkhani, Y.; Wells, M.A.; Poole, W.J.; Grajales, L.; Parson, N. The Development of Grain Structure During Axisymmetric Extrusion of AA3003 Aluminum Alloys. Met. Mater. Trans. A 2015, 46, 5920–5932. [Google Scholar]

- Chen, J.Q.; Poole, W.J.; Parson, N.C. The effect of through thickness texture variation on the anisotropic mechanical response of an extruded Al-Mn-Fe-Si alloy. Mater. Sci. Eng. A 2018, 730, 24–35. [Google Scholar]

- Kaneko, S.; Murakami, K.; Sakai, T. Effect of the extrusion conditions on microstructure evolution of the extruded Al-Mg-Si-Cu alloy rods. Mater. Sci. Eng. A 2009, 500, 8–15. [Google Scholar]

- Roy, S.; Allard, L.F.; Rodriguez, A.; Porter, W.D.; Shyam, A. Comparative Evaluation of Cast Aluminum Alloys for Automotive Cylinder Heads: Part II-Mechanical and Thermal Properties. Met. Mater. Trans. A 2017, 48A, 2543–2562. [Google Scholar]

- Nie, J.F.; Muddle, B.C. Microstructural design of high-strength aluminum alloys. J. Phase Equilib. 1998, 19, 543–551. [Google Scholar]

| Alloys | Mg | Si | Mn | Fe | Ti | Al |

|---|---|---|---|---|---|---|

| 0Mn (base) | 0.83 | 1.01 | 0 | 0.22 | 0.018 | Bal. |

| 0.72Mn | 0.84 | 1.02 | 0.72 | 0.23 | 0.016 | Bal. |

| Alloy | β” Phase | α-Al(FeMn)Si Dispersoids | ||||

|---|---|---|---|---|---|---|

| 0Mn | 410 | 1.26 × 10−5 | 0.52 | - | - | - |

| 0.72Mn(H) | 459 | 1.40 × 10−5 | 0.62 | 146 | 11 | 0.91 |

| 0.72Mn(L) | 468 | 1.33 × 10−5 | 0.64 | 40 | 430 | 0.88 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakhmonov, J.; Liu, K.; Rometsch, P.; Parson, N.; Chen, X.-G. Improving the Mechanical Response of Al–Mg–Si 6082 Structural Alloys during High-Temperature Exposure through Dispersoid Strengthening. Materials 2020, 13, 5295. https://doi.org/10.3390/ma13225295

Rakhmonov J, Liu K, Rometsch P, Parson N, Chen X-G. Improving the Mechanical Response of Al–Mg–Si 6082 Structural Alloys during High-Temperature Exposure through Dispersoid Strengthening. Materials. 2020; 13(22):5295. https://doi.org/10.3390/ma13225295

Chicago/Turabian StyleRakhmonov, Jovid, Kun Liu, Paul Rometsch, Nick Parson, and X.-Grant Chen. 2020. "Improving the Mechanical Response of Al–Mg–Si 6082 Structural Alloys during High-Temperature Exposure through Dispersoid Strengthening" Materials 13, no. 22: 5295. https://doi.org/10.3390/ma13225295

APA StyleRakhmonov, J., Liu, K., Rometsch, P., Parson, N., & Chen, X.-G. (2020). Improving the Mechanical Response of Al–Mg–Si 6082 Structural Alloys during High-Temperature Exposure through Dispersoid Strengthening. Materials, 13(22), 5295. https://doi.org/10.3390/ma13225295