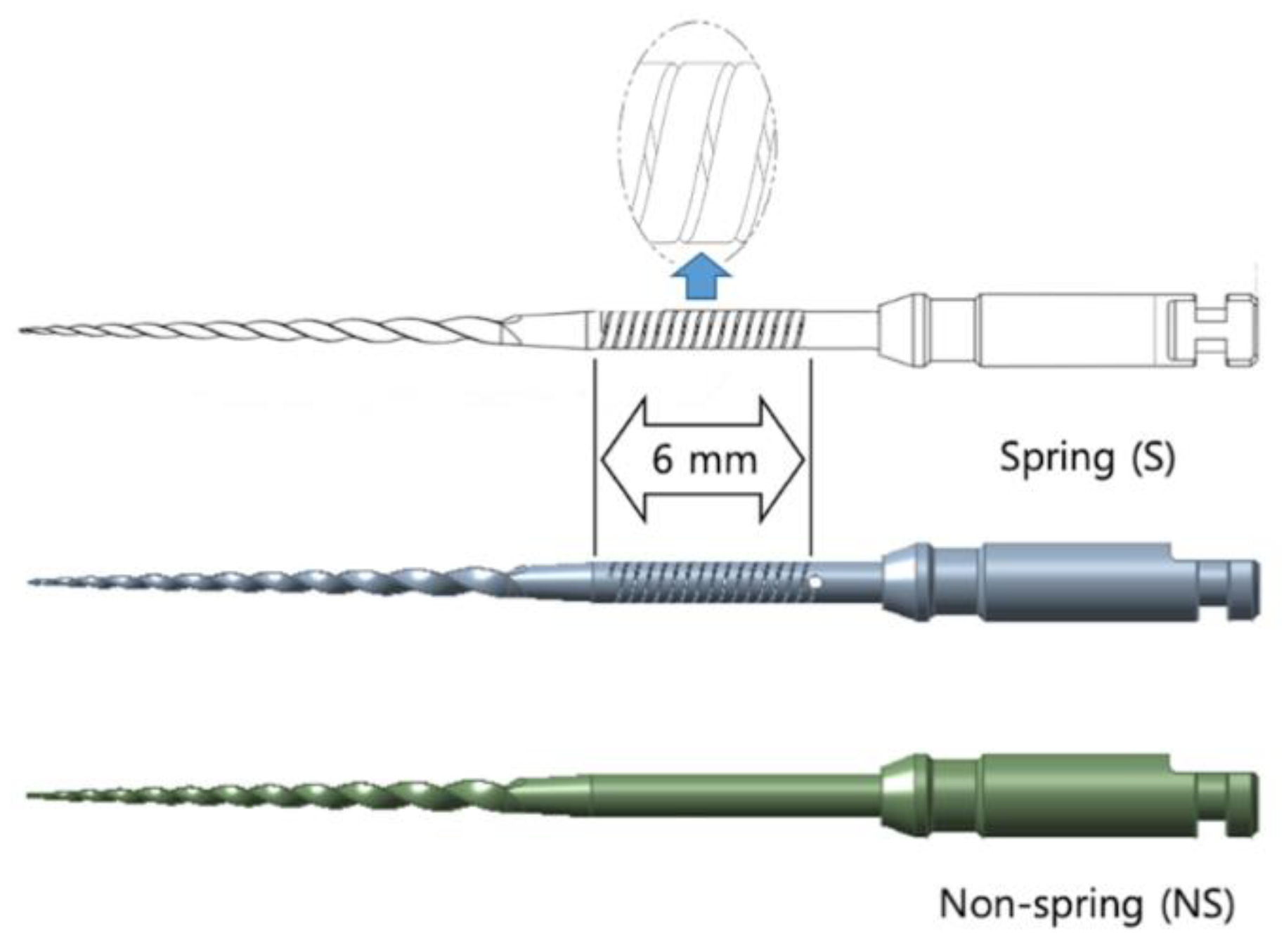

Advancement of Mechanical Properties of Nickel-Titanium Rotary Endodontic Instruments by Spring Machining on the File Shaft

Abstract

1. Introduction

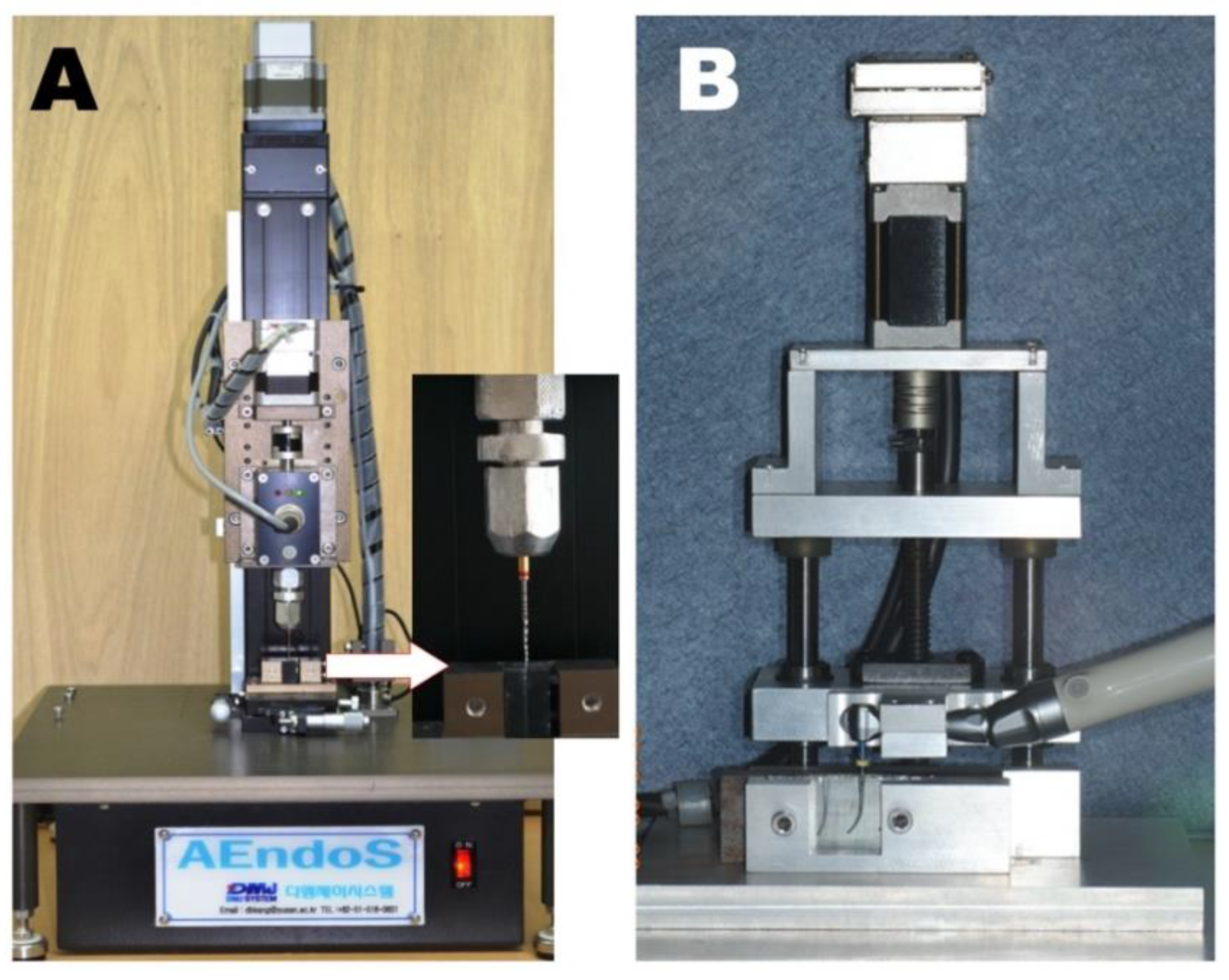

2. Materials and Methods

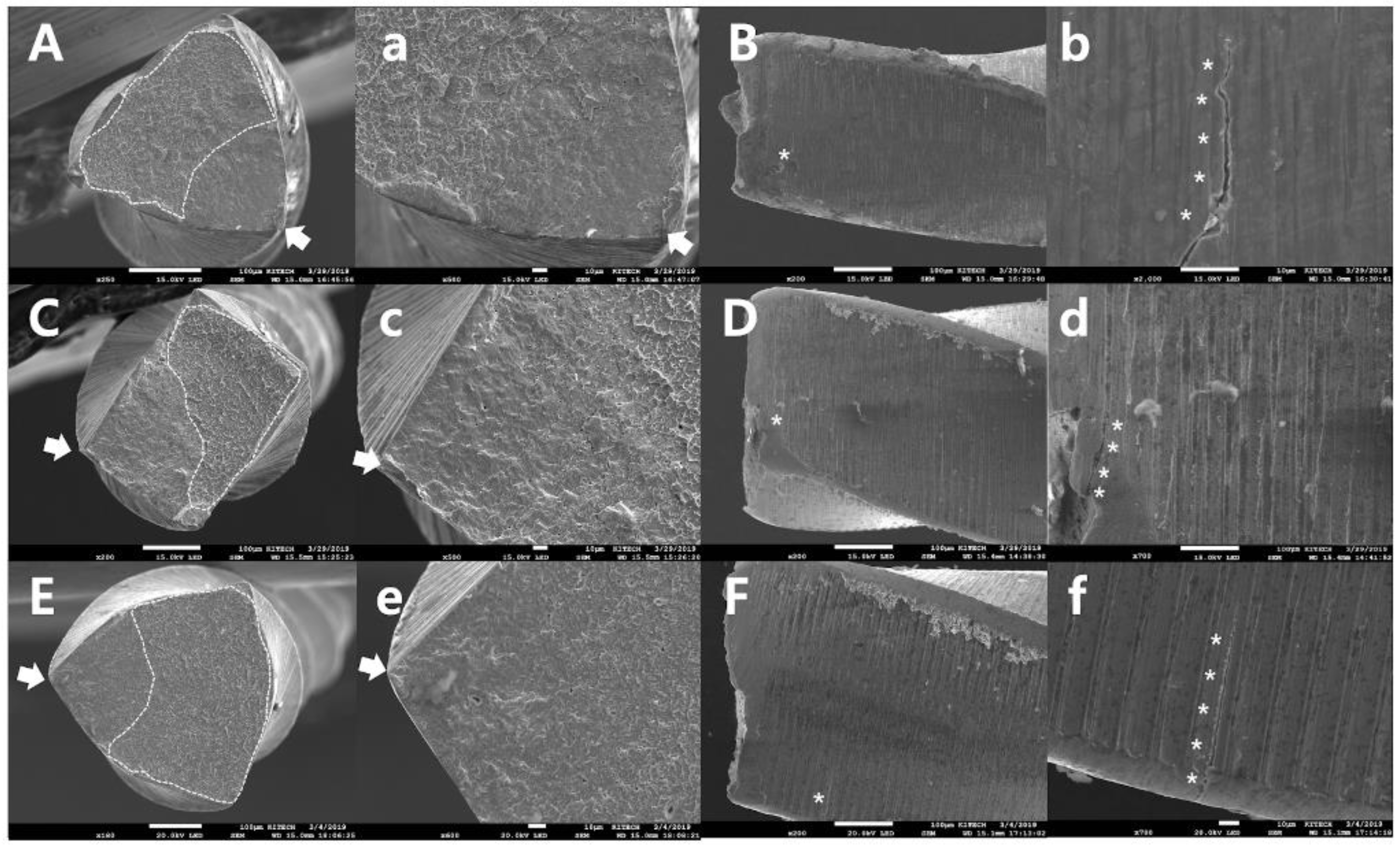

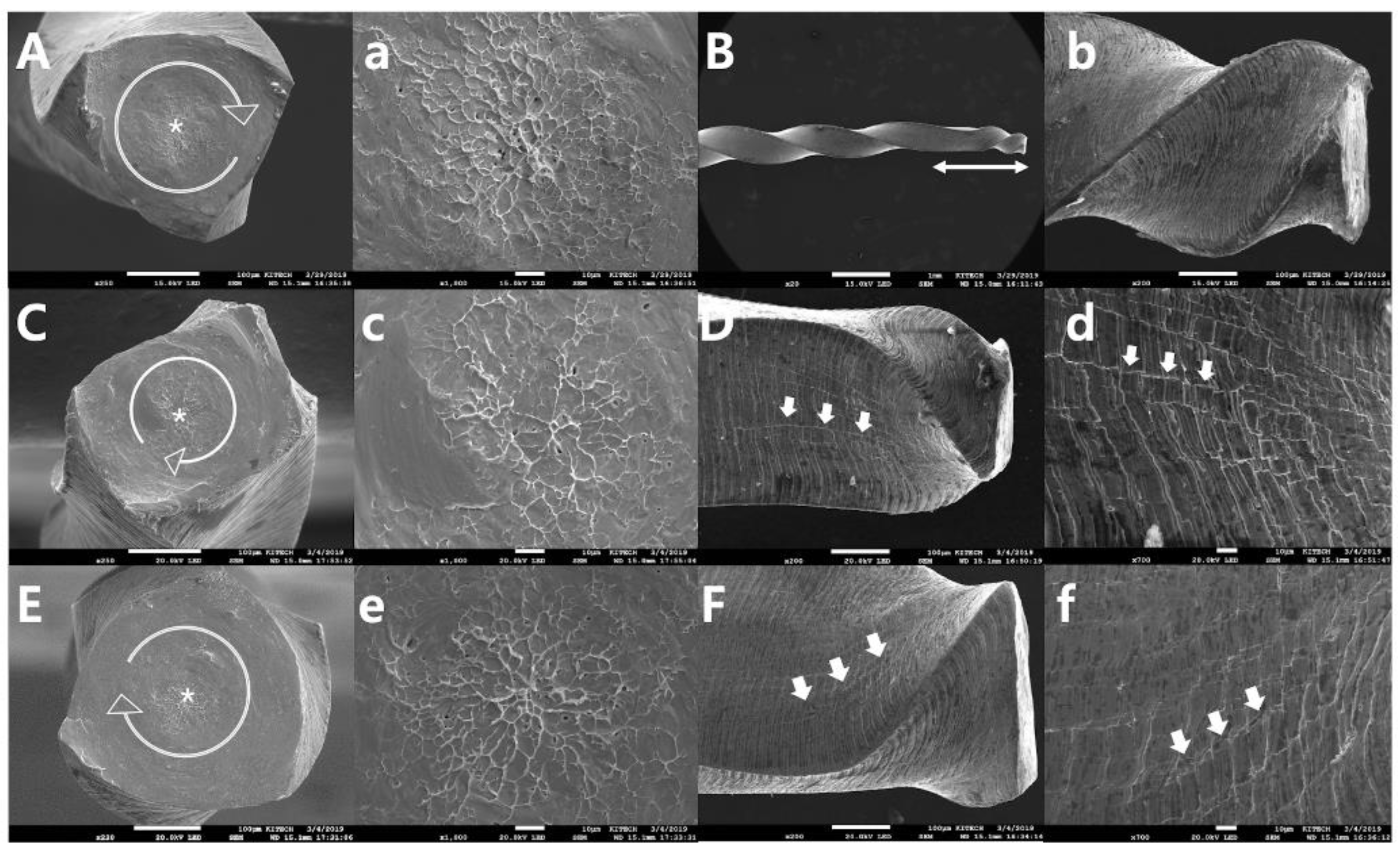

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Walia, H.; Brantley, W.A.; Gerstein, H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J. Endod. 1988, 14, 346–351. [Google Scholar] [CrossRef]

- Parashos, P.; Messer, H.H. Rotary NiTi instrument fracture and its consequences. J. Endod. 2006, 32, 1031–1043. [Google Scholar] [CrossRef] [PubMed]

- Sattapan, B.; Nervo, G.J.; Palamara, J.E.; Messer, H.H. Defects in rotary nickel-titanium files after clinical use. J. Endod. 2000, 26, 161–165. [Google Scholar] [CrossRef]

- Yum, J.; Cheung, G.S.; Park, J.K.; Hur, B.; Kim, H.C. Torsional strength and toughness of nickel-titanium rotary files. J. Endod. 2011, 37, 382–386. [Google Scholar] [CrossRef]

- Cheung, G.S.P. Instrument fracture: Mechanisms, removal of fragments, and clinical outcomes. Endod. Top. 2009, 16, 1–26. [Google Scholar] [CrossRef]

- Ye, J.; Gao, Y. Metallurgical characterization of M-wire nickel-titanium shape memory alloy used for endodontic rotary instruments during low-cycle fatigue. J. Endod. 2012, 38, 105–107. [Google Scholar] [CrossRef]

- Ha, J.H.; Kim, S.K.; Cohenca, N.; Kim, H.C. Effect of R-phase heat treatment on torsional resistance and cyclic fatigue fracture. J. Endod. 2013, 39, 389–393. [Google Scholar] [CrossRef]

- Zhou, H.M.; Shen, Y.; Zheng, W.; Li, L.; Zheng, Y.F.; Haapasalo, M. Mechanical properties of controlled memory and superelastic nickel-titanium wires used in the manufacture of rotary endodontic instruments. J. Endod. 2012, 38, 1535–1540. [Google Scholar] [CrossRef]

- Goo, H.J.; Kwak, S.W.; Ha, J.H.; Pedullà, E.; Kim, H.C. Mechanical properties of various heat-treated nickel-titanium rotary instruments. J. Endod. 2017, 43, 1872–1877. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Qian, W.; Abtin, H.; Gao, Y.; Haapasalo, M. Fatigue testing of controlled memory wire nickel-titanium rotary instruments. J. Endod. 2011, 37, 997–1001. [Google Scholar] [CrossRef] [PubMed]

- Pedullà, E.; Lo Savio, F.; Boninelli, S.; Plotino, G.; Grande, N.M.; La Rosa, G.; Rapisarda, E. Torsional and cyclic fatigue resistance of a new nickel-titanium instrument manufactured by electrical discharge machining. J. Endod. 2016, 42, 156–159. [Google Scholar] [CrossRef] [PubMed]

- Cheung, G.S.; Darvell, B.W. Low-cycle fatigue of NiTi rotary instruments of various cross-sectional shapes. Int. Endod. J. 2007, 40, 626–632. [Google Scholar] [CrossRef] [PubMed]

- Isik, V.; Kwak, S.W.; Abu-Tahun, I.H.; Ha, J.H.; Kayahan, M.B.; Kim, H.C. Effect of shaft length on the torsional resistance of rotary nickel-titanium instruments. J. Endod. 2020, 46, 295–300. [Google Scholar] [CrossRef] [PubMed]

- Baek, S.H.; Lee, C.J.; Versluis, A.; Kim, B.M.; Lee, W.; Kim, H.C. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J. Endod. 2011, 37, 1283–1286. [Google Scholar] [CrossRef]

- Versluis, A.; Kim, H.C.; Lee, W.; Kim, B.M.; Lee, C.J. Flexural stiffness and stresses in nickel-titanium rotary files for various pitch and cross-sectional geometries. J. Endod. 2012, 38, 1399–1403. [Google Scholar] [CrossRef]

- Palma, P.J.; Messias, A.; Cerqueira, A.R.; Tavares, L.D.; Caramelo, F.; Roseiro, L.; Santos, J.M. Cyclic fatigue resistance of three rotary file systems in a dynamic model after immersion in sodium hypochlorite. Odontology. 2019, 107, 324–332. [Google Scholar] [CrossRef]

- Webber, M.; Piasecki, L.; Jussiani, E.I.; Andrello, A.C.; Dos Reis, P.J.; Azim, K.A.; Azim, A.A. Higher speed and no glidepath: A new protocol to increase the efficiency of XP Shaper in curved canals—An in vitro study. J. Endod. 2020, 46, 103–109. [Google Scholar] [CrossRef]

- Gagliardi, J.; Versiani, M.A.; de Sousa-Neto, M.D.; Plazas-Garzon, A.; Basrani, B. Evaluation of the shaping characteristics of ProTaper Gold, ProTaper NEXT, and ProTaper Universal in curved canals. J. Endod. 2015, 41, 1718–1724. [Google Scholar] [CrossRef]

- Alqedairi, A.; Alfawaz, H.; Abualjadayel, B.; Alanazi, M.; Alkhalifah, A.; Jamleh, A. Torsional resistance of three ProTaper rotary systems. BMC Oral Health 2019, 19, 124. [Google Scholar] [CrossRef]

- American Dental Association Council on Dental Materials, Instruments and Equipment. Revised American National Standards Institute/American Dental Association Specification No. 28 for Root Canal Files and Reamers, Type K, and No. 58+ for Root Canal Files, Type H (Hedstrom). J. Am. Dent. Assoc. 1989, 118, 239–240. [Google Scholar] [CrossRef]

- ISO Standards ISO 3630-3631. Dentistry—Root-Canal Instruments: Part1—General Requirements and Test Methods; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- Pasqualini, D.; Mollo, L.; Scotti, N.; Cantatore, G.; Castellucci, A.; Migliaretti, G.; Berutti, E. Postoperative pain after manual and mechanical glide path: A randomized clinical trial. J. Endod. 2012, 38, 32–36. [Google Scholar] [CrossRef] [PubMed]

- Sonntag, D.; Guntermann, A.; Kim, S.K.; Stachniss, V. Root canal shaping with manual stainless steel files and rotary Ni-Ti files performed by students. Int. Endod. J. 2003, 36, 246–255. [Google Scholar] [CrossRef] [PubMed]

- Aydın, Z.U.; Keskin, N.B.; Özyürek, T.; Geneci, F.; Ocak, M.; Çelik, H.H. Microcomputed assessment of transportation, centering ratio, canal area, and volume increase after single-file rotary and reciprocating glide path instrumentation in curved root canals: A laboratory study. J. Endod. 2019, 45, 791–796. [Google Scholar] [CrossRef] [PubMed]

- Uygun, A.D.; Kol, E.; Topcu, M.K.; Seckin, F.; Ersoy, I.; Tanriver, M. Variations in cyclic fatigue resistance among ProTaper Gold, ProTaper Next and ProTaper Universal instruments at different levels. Int. Endod. J. 2016, 49, 494–499. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Peng, B.; Haapasalo, M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J. Endod. 2013, 39, 163–172. [Google Scholar] [CrossRef]

- Kwak, S.W.; Lee, C.J.; Kim, S.K.; Kim, H.C.; Ha, J.H. Comparison of screw-in forces during movement of endodontic files with different geometries, alloys, and kinetics. Materials 2019, 12, 1506. [Google Scholar] [CrossRef]

- Hieawy, A.; Haapasalo, M.; Zhou, H.; Wang, Z.J.; Shen, Y. Phase transformation behavior and resistance to bending and cyclic fatigue of ProTaper Gold and ProTaper Universal instruments. J. Endod. 2015, 41, 1134–1138. [Google Scholar] [CrossRef]

- Peters, O.A.; Barbakow, F. Dynamic torque and apical forces of ProFile.04 rotary instruments during preparation of curved canals. Int. Endod. J. 2002, 35, 379–389. [Google Scholar] [CrossRef]

- Bahia, M.G.; Buono, V.T. Decrease in the fatigue resistance of nickel-titanium rotary instruments after clinical use in curved root canals. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2005, 100, 249–255. [Google Scholar] [CrossRef]

- Miyai, K.; Ebihara, A.; Hayashi, Y.; Doi, H.; Suda, H.; Yoneyama, T. Influence of phase transformation on the torsional and bending properties of nickel-titanium rotary endodontic instruments. Int. Endod. J. 2006, 39, 119–126. [Google Scholar] [CrossRef]

| Non-Spring (NS) | Spring (S) | ||

|---|---|---|---|

| NCF * | SPR * | 1348 ± 196 | 1810 ± 410 |

| PTN * | 1618 ± 283 | 2065 ± 239 | |

| PTG * | 2099 ± 147 | 2623 ± 284 | |

| Fracture Fragment Length (mm) | SPR | 1.87 ± 0.18 | 1.84 ± 0.21 |

| PTN | 3.59 ± 0.40 | 3.48 ± 0.25 | |

| PTG | 3.46 ± 0.62 | 3.20 ± 0.16 | |

| Non-Spring (NS) | Spring (S) | ||

|---|---|---|---|

| Toughness * (°·Ncm) | SPR * | 513.82 ± 45.86 | 565.29 ± 61.80 |

| PTN * | 217.37 ± 26.74 | 253.26 ± 26.11 | |

| PTG * | 544.41 ± 94.72 | 659.76 ± 100.97 | |

| Ultimate Strength (Ncm) | SPR | 1.11 ± 0.09 | 1.11 ± 0.09 |

| PTN | 0.84 ± 0.09 | 0.82 ± 0.05 | |

| PTG | 1.43 ± 0.12 | 1.48 ± 0.08 | |

| Distortion Angle * (°) | SPR * | 621.61 ± 28.00 | 676.23 ± 63.06 |

| PTN * | 359.36 ± 19.51 | 429.91 ± 26.44 | |

| PTG * | 507.76 ± 72.94 | 641.48 ± 117.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, S.; Ha, J.-H.; Kwak, S.W.; Kim, H.-C. Advancement of Mechanical Properties of Nickel-Titanium Rotary Endodontic Instruments by Spring Machining on the File Shaft. Materials 2020, 13, 5246. https://doi.org/10.3390/ma13225246

Ahn S, Ha J-H, Kwak SW, Kim H-C. Advancement of Mechanical Properties of Nickel-Titanium Rotary Endodontic Instruments by Spring Machining on the File Shaft. Materials. 2020; 13(22):5246. https://doi.org/10.3390/ma13225246

Chicago/Turabian StyleAhn, Sangmi, Jung-Hong Ha, Sang Won Kwak, and Hyeon-Cheol Kim. 2020. "Advancement of Mechanical Properties of Nickel-Titanium Rotary Endodontic Instruments by Spring Machining on the File Shaft" Materials 13, no. 22: 5246. https://doi.org/10.3390/ma13225246

APA StyleAhn, S., Ha, J.-H., Kwak, S. W., & Kim, H.-C. (2020). Advancement of Mechanical Properties of Nickel-Titanium Rotary Endodontic Instruments by Spring Machining on the File Shaft. Materials, 13(22), 5246. https://doi.org/10.3390/ma13225246