Impact on Mechanical Properties and Microstructural Response of Nickel-Based Superalloy GH4169 Subjected to Warm Laser Shock Peening

Abstract

:1. Introduction

- Dislocation motion: Increase of temperature enhances thermal activation, and the concentration of vacancy defects is reduced in the crystalline grain. The edge dislocation begins climbing, which prompts the generation and annihilation of vacancy. The local equilibrium concentration of the dislocation is maintained, and the slippage movement of the screw dislocation also requires sufficient energy to activate.

- Critical shear stress: Higher temperature leads to critical shear stress, which results in material decrease and slip system increase. With the increase of temperature, atomic momentum becomes larger, and interatomic force is damaged, and then shear stress is reduced. There are more sliding positions, and the slip system is more active.

- Organization of metal materials: As temperature increases, the solubility of solute atoms increases, which results in the reduction of the resistance of the alloy. The material thermoplastic and atomic thermal vibration are reinforced, and atoms in the lattice become unstable. In this state, the atoms are easy to move along the gradient of the stress field under the action of external forces, and the plasticity becomes more strenuous.

2. Experiment Details

2.1. Materials and Microstructure Observation

2.2. Warm Laser Shock Peening Process

2.3. Measurements of Mechanical Properties and Microstructure

3. Results and Discussion

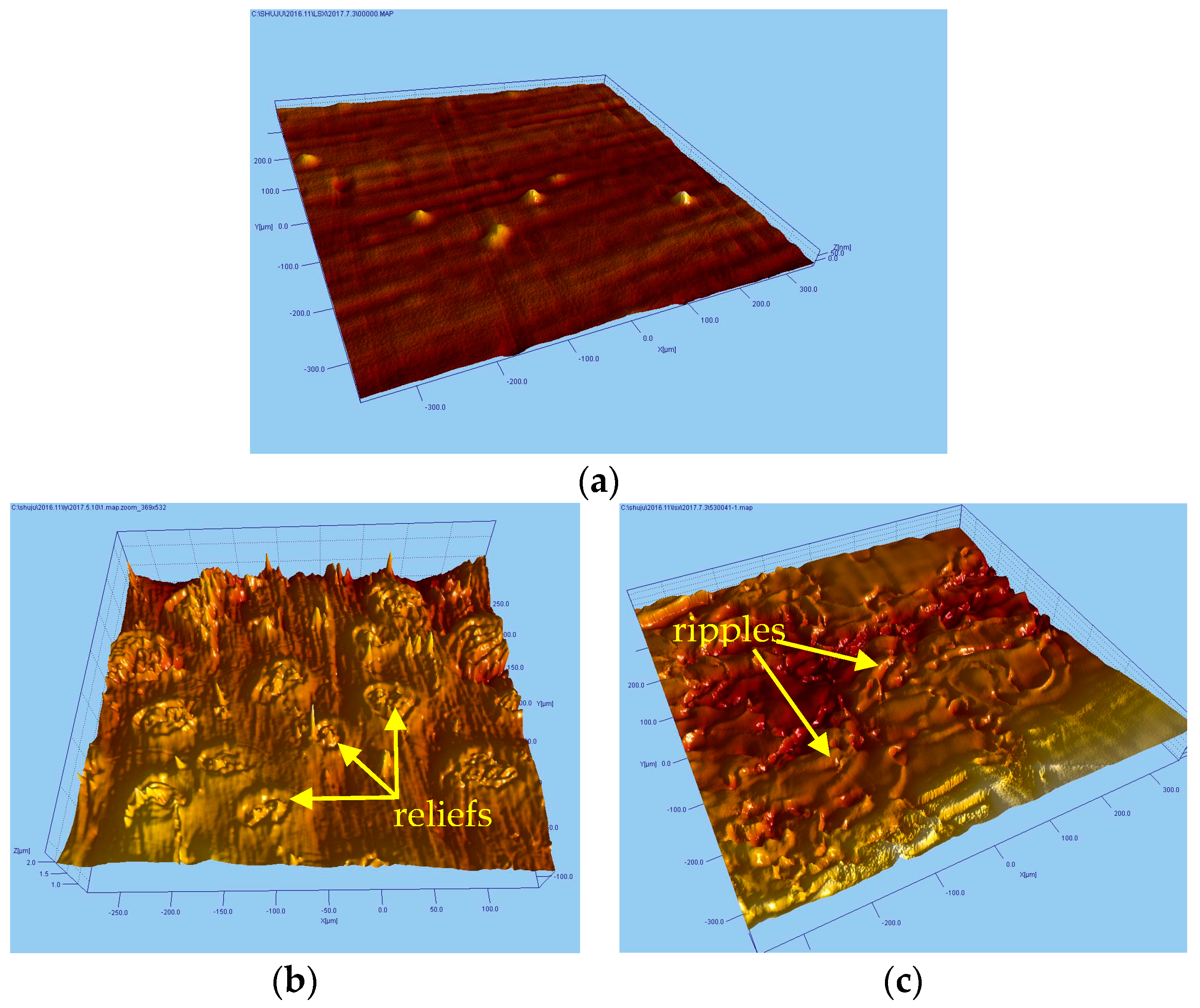

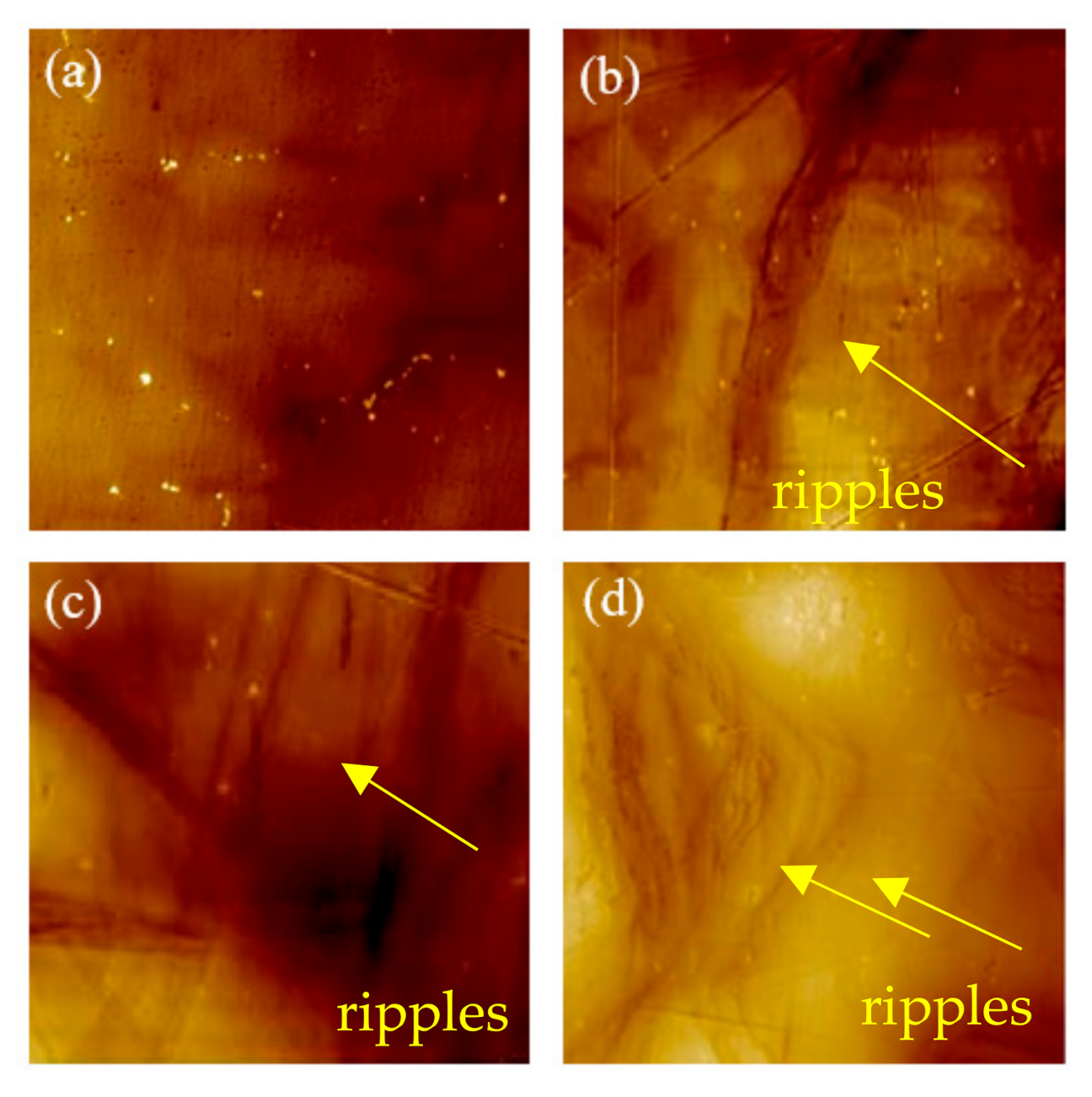

3.1. Surface Morphology

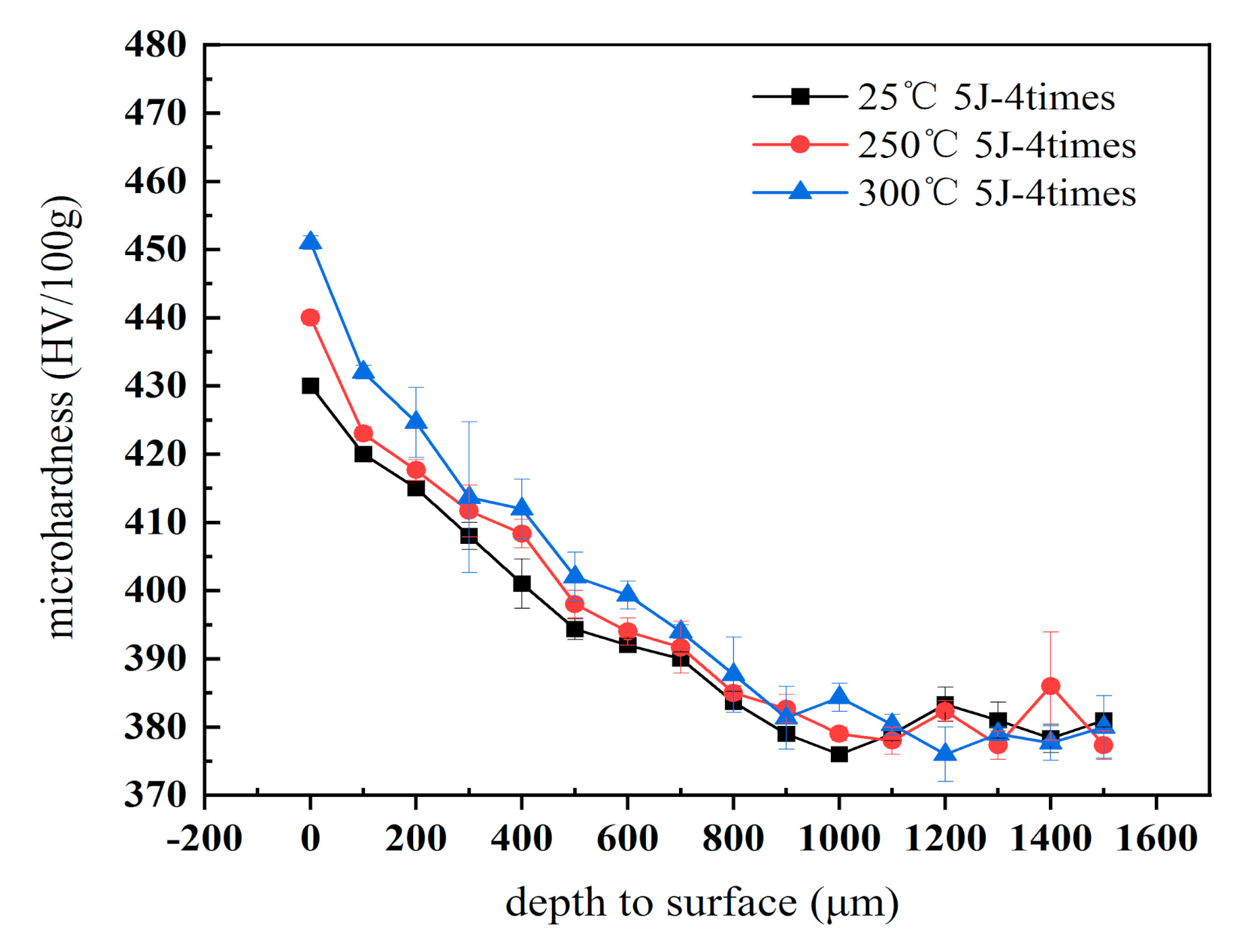

3.2. Microhardness Evaluation

3.3. Analysis of Residual Stress

- The surface residual stress shocked by WLSP was slightly lower than that shocked by LSP. However, the release of residual stress during the post-aging process induced by WLSP was less than that induced by LSP, indicating that the samples processed with WLSP were more stable than that processed with LSP.

- The relaxation effects of the residual stress on the surface increased gradually with the increase of the aging temperature. No significant change in the surface residual stress was observed during the aging process at a temperature of 600 °C. The residual stress induced by LSP released completely, while that induced by WLSP only decreased by 8% when the aging temperature increased to 650 °C. Moreover, when the aging temperature increased to 700 °C, the residual stress induced by LSP released soon, while that induced by WLSP only decreased by 50% after 100 h.

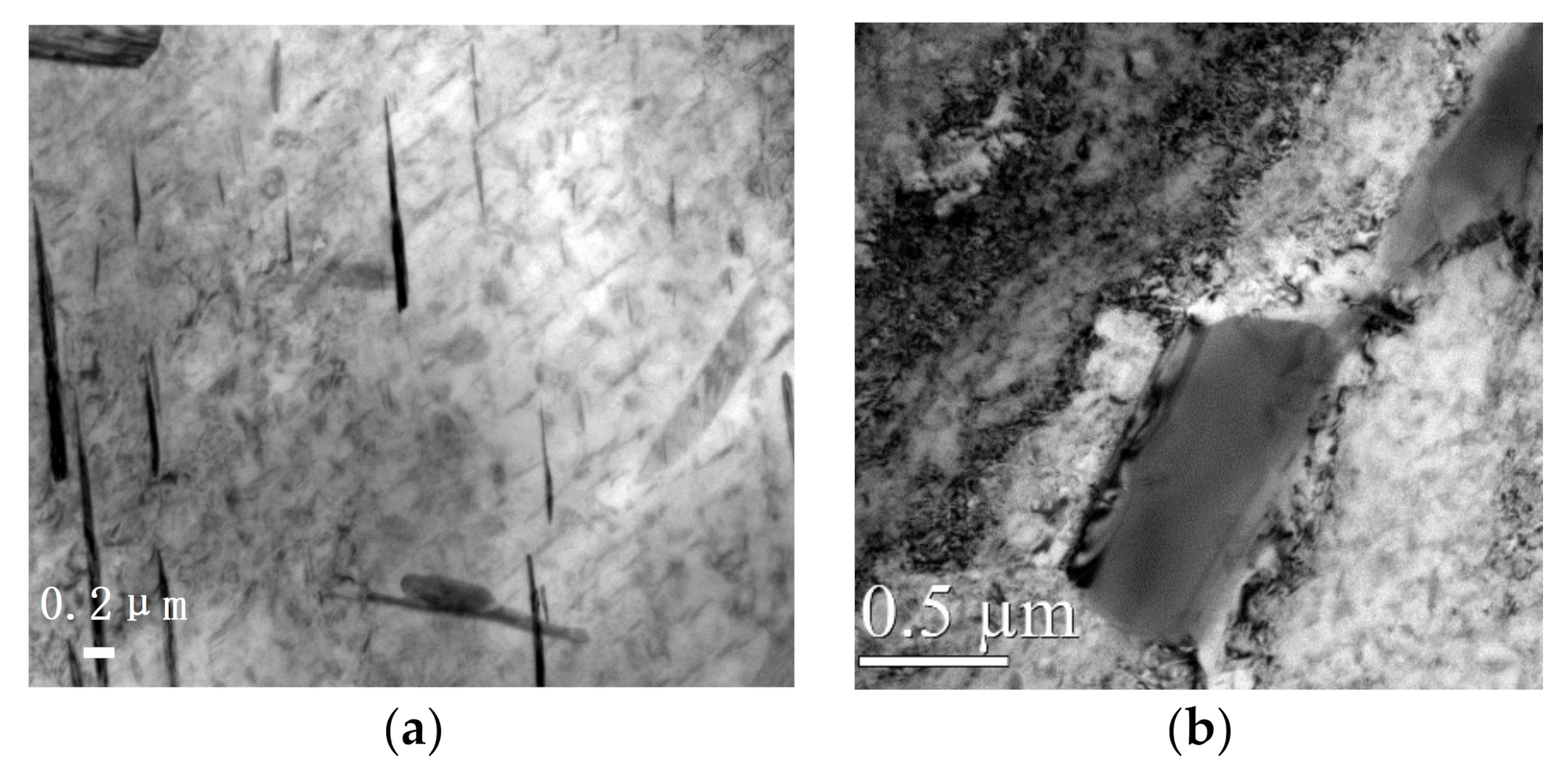

3.4. Microstructure Analysis

4. Conclusions

- (1)

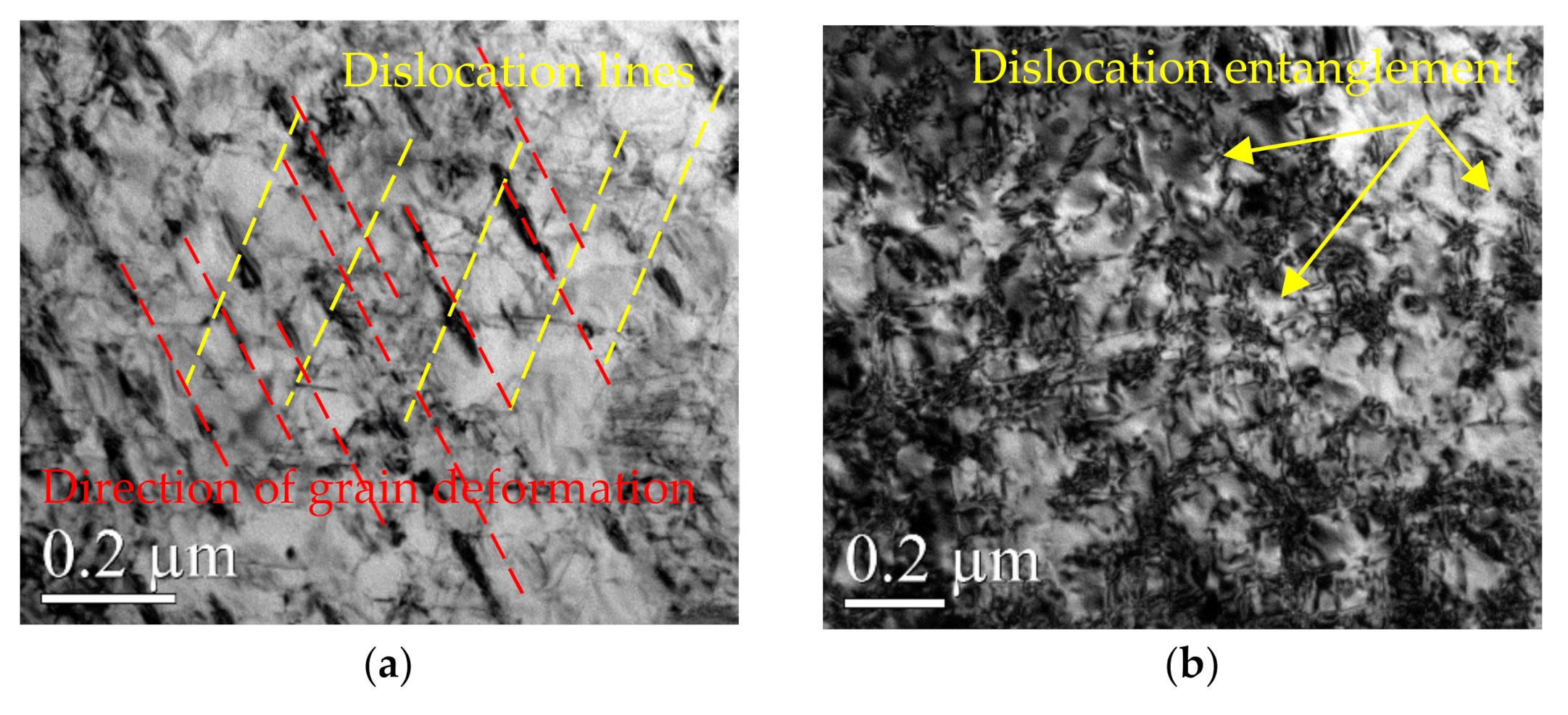

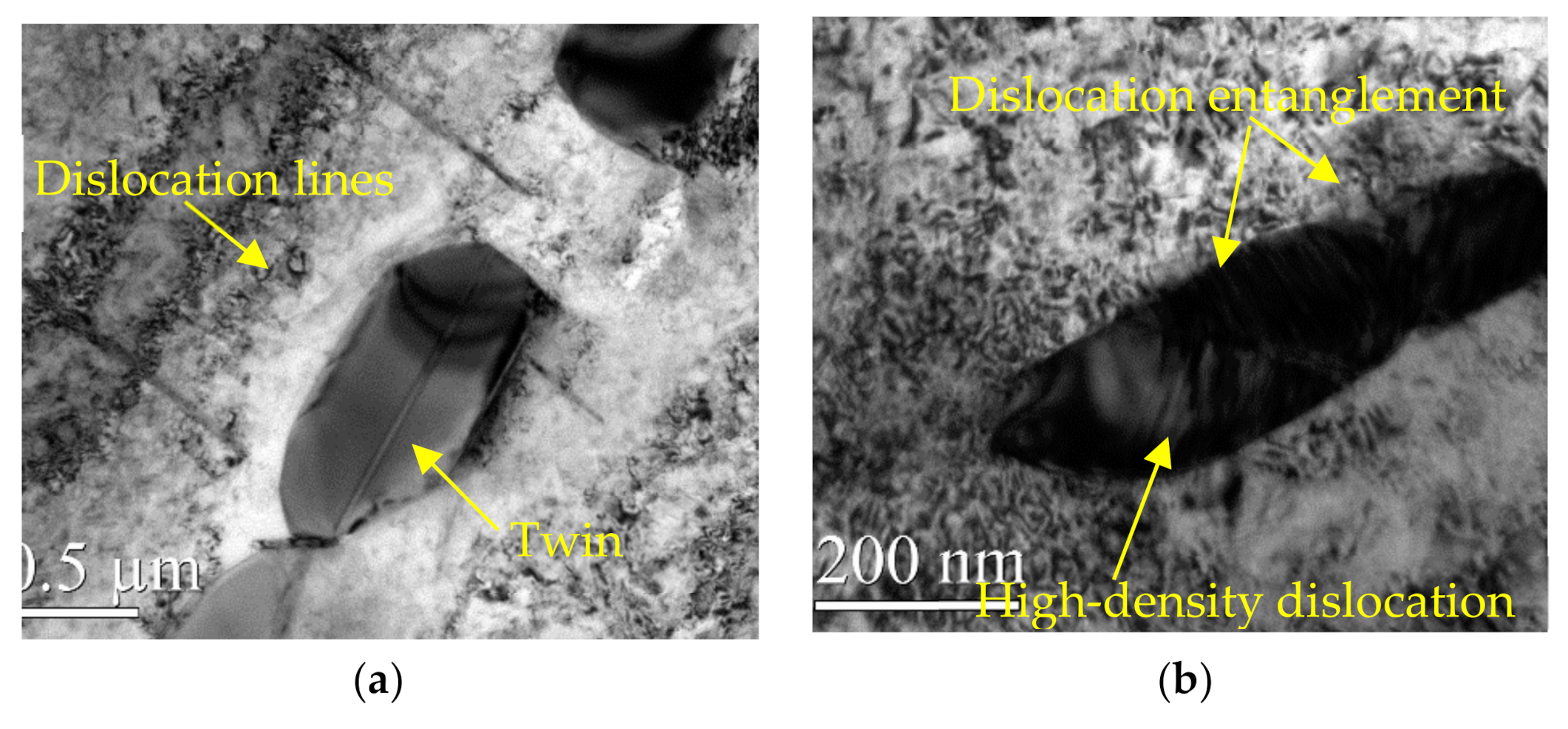

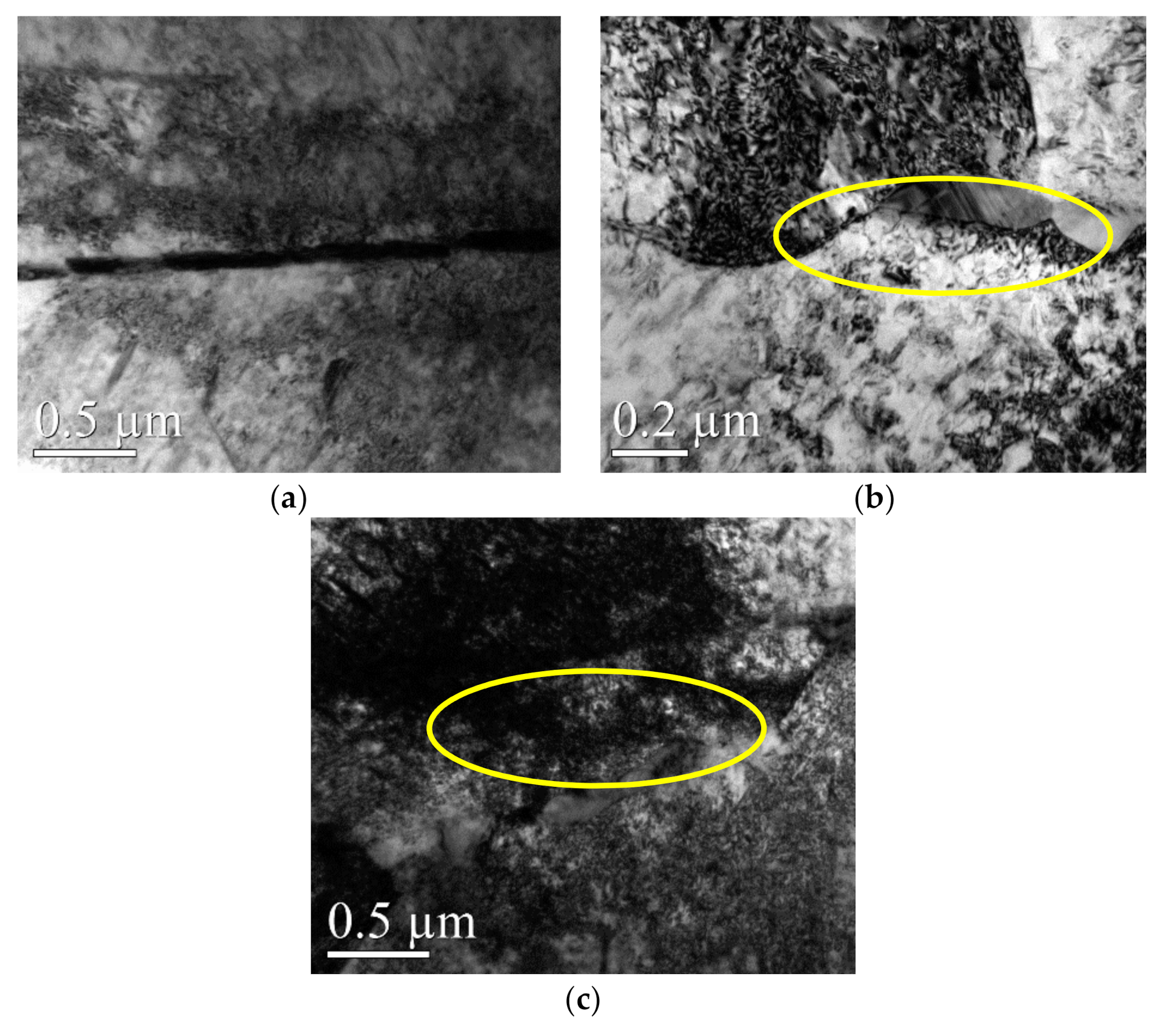

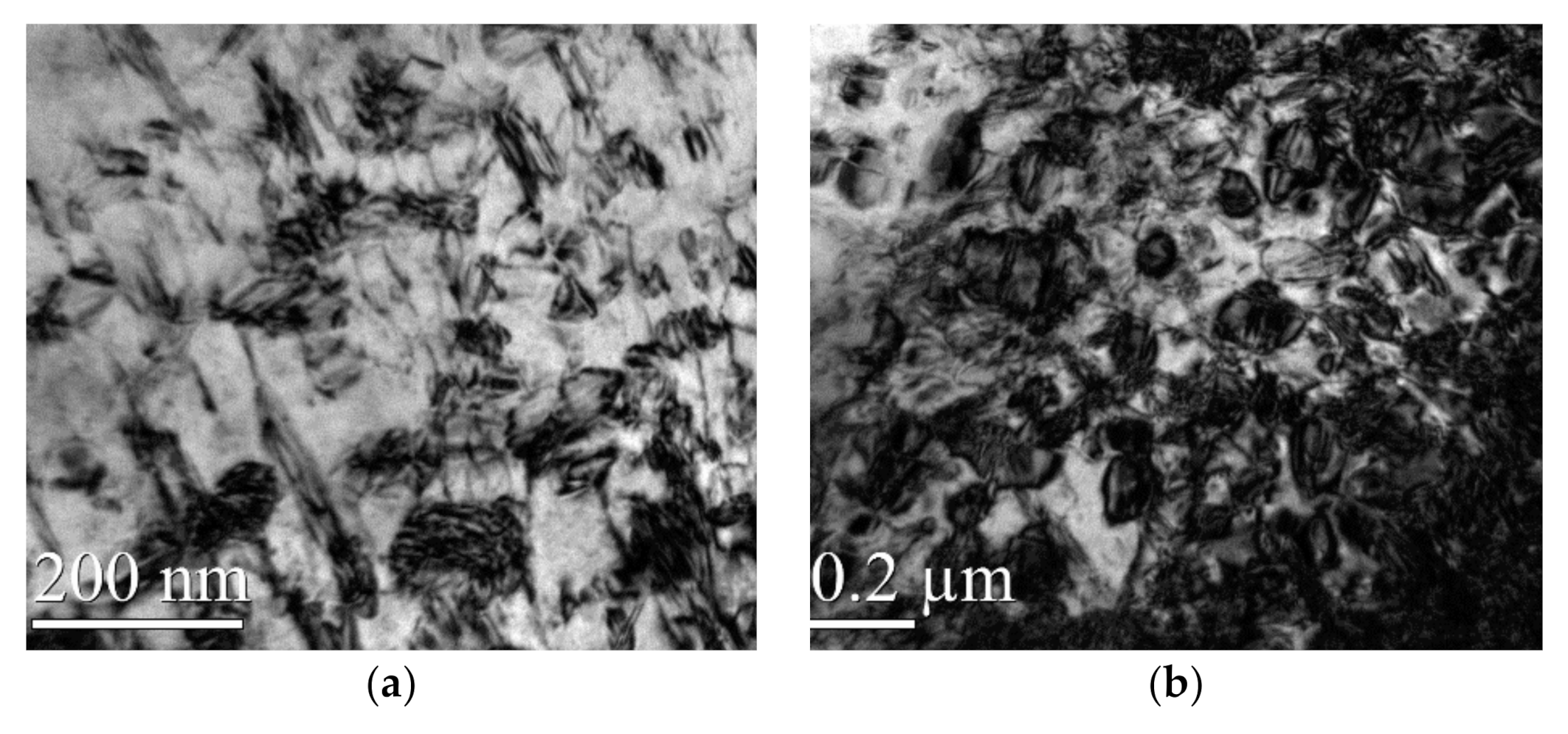

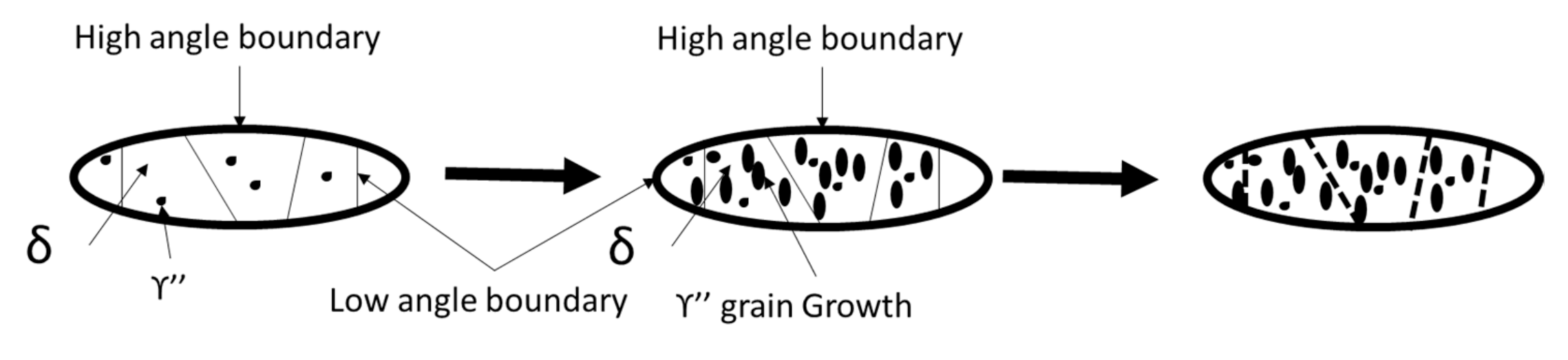

- Compared with LSP, WLSP could obtain a more complex dislocation structure. The dislocation promoted the precipitation of the enhanced phase, and this, in turn, enhanced the pinning effect of the dislocation. The effect of the dislocation on the grains or grain boundaries was more obvious, and a lot of dislocations gathered near the grain boundaries, especially when the temperature reached 150 °C, and the dislocation accumulation caused a significant deflection of the grain boundaries. When the samples were shocked at 200 °C, with the action of the dislocations, some of the crystal boundaries were blurred, and it was difficult to identify them. A large concentration of dislocation structures could provide nucleation sites for phase precipitation, which is beneficial to dynamic precipitation (DP).

- (2)

- On the one hand, the surface plastic deformation of the material was strengthened, which promoted the appearance of super vacancy. The diffusion of the vacancy atom in the thermal insulation process reduced the system energy, which caused the nonequilibrium segregation of -Nb and increased the nucleation position of the γ” phase. Therefore, the nucleation rate of the γ” phase in the strengthening layer was increased. On the other hand, the uniform dislocations were rearranged as smaller-angle grain boundaries or subgrain boundaries perpendicular to the sliding surface, and the inhomogeneous dislocations were counteracted by each other, eventually increasing the size of the subgrain boundary area, which could lead to decreased grain size and increased surface hardness and yield strength.

- (3)

- The precipitated relative dislocation played a pinning role, and the accumulation of dislocations provided more nucleation sites for the precipitated phase. Thus, the finely dispersed and dispersed γ″ phase was interspersed with a large number of dislocations in the δ phase, forming a structure similar to reinforced concrete. This structure could be very stable at high temperatures, and with the high-temperature stress release process, the dislocations had an excellent pinning effect and effectively improved the softening resistance and creep resistance at high temperature.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nie, X.; He, W.; Zang, S.; Wang, X.; Zhao, J. Effect study and application to improve high cycle fatigue resistance of TC11 titanium alloy by laser shock peening with multiple impacts. Surf. Coat. Technol. 2014, 253, 68–75. [Google Scholar]

- Pant, B.; Sundar, R.; Kumar, H.; Kaul, R.; Pavan, A.; Prakash, R.V. Studies towards development of laser peening technology for martensitic stainless steel and titanium alloys for steam turbine applications. Mater. Sci. Eng. A 2013, 587, 352–358. [Google Scholar]

- Altenberger, I.; Nalla, R.K.; Sano, Y.; Wagner, L.; Ritchie, R.O. On the effect of deep-rolling and laser-peening on the stress-controlled low- and high-cycle fatigue behavior of Ti-6Al-4V at elevated temperatures up to 550 °C. Int. J. Fatigue 2012, 44, 292–302. [Google Scholar]

- Ji, Y.; Wu, S. Study on microstructure and mechanical behavior of dissimilar Ti17 friction welds. Mater. Sci. Eng. A 2014, 596, 32–40. [Google Scholar]

- Hu, T.; Li, S.; Qiao, H.; Lu, Y.; Sun, B.; Wu, J. Effect of Warm Laser Shock Peening on Microstructure and Properties of GH4169 Superalloy. IOP Conf. Ser. Mater. Sci. Eng. A 2018, 423, 012054. [Google Scholar]

- Lu, Y.; Zhao, J.; Qiao, H.; Hu, T.; Sun, B.; Wu, J. A study on the surface morphology evolution of the GH4619 using warm laser shock peening. AIP Adv. 2019, 9, 085030. [Google Scholar]

- Zhou, J.S.; Huang, L.; Zuo, X.; Meng, J.; Sheng, Q.; Tian, Y.; Han, W.Z. Effects of laser peening on residual stresses and fatigue crack growth properties of Ti–6Al–4V titanium alloy. Opt. Lasers Eng. 2014, 52, 189–194. [Google Scholar]

- Spanrad, S.; Tong, J. Characterisation of foreign object damage (FOD) and early fatigue crack growth in laser shock peened Ti–6Al–4V aerofoil specimens. Mater. Sci. Eng. A 2011, 528, 2128–2136. [Google Scholar]

- Sano, Y.J.; Obata, M.; Kubo, T.; Mukai, N.; Yoda, M. Retardation of crack initiation and growth in austenitic stainless steels by laser peening without protective coating. Mater. Sci. Eng. A 2006, 417, 334–340. [Google Scholar]

- Zabeen, S.M.; Preuss, P.W. Evolution of a laser shock peened residual stress field locally with foreign object damage and subsequent fatigue crack growth. Acta Mater. 2015, 83, 216–226. [Google Scholar]

- Wu, B.J.; Zhang, L.; Zhang, Y.S.; Pyoun, Y.S.; Murakami, R. Effect of ultrasonic nanocrystal surface modification on surface and fatigue properties of quenching and tempering S45C steel. Appl. Surf. Sci. 2014, 321, 318–330. [Google Scholar]

- Wu, J.J.; Liu, X.J.; Zhao, J.B. The online monitoring method research of laser shock processing based on plasma acoustic wave signal energy. Optik 2019, 183, 1151–1159. [Google Scholar]

- Luo, K.Y.; Lin, T.; Dai, F.Z. Effects of overlapping rate on the uniformities of surface profile of LY2 Al alloy during massive laser shock peening impacts. Surf. Coat. Technol. 2015, 266, 49–56. [Google Scholar]

- Dai, F.Z.; Zhang, Z.D.; Ren, X.D. Effects of laser shock peening with contacting foil on micro laser texturing surface of Ti6Al4V. Opt. Laser. Eng. 2018, 101, 99–105. [Google Scholar]

- Li, K.M.; Wang, Y.F.; Cai, Y. Investigation on Residual Stress Loss during Laser Peen Texturing of 316L Stainless Steel. Appl. Sci. 2019, 9, 3511. [Google Scholar]

- Liao, Y.L.; Ye, C.; Cheng, G.J. Warm laser shock peening and related laser processing technique. Opt. Lasers Eng. 2016, 78, 15–24. [Google Scholar]

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Sun, G.F.; Gu, Y.Y.; Zhou, J.Z.; Ren, X.D. Grain refinement mechanism of multiple laser shock processing impacts on ANSI 304 stainless steel. Acta Mater. 2010, 58, 5354–5362. [Google Scholar]

- Ren, X.D.; Tong, Z.P.; Zhou, W.F. High temperature wear performance of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy subjected to laser shock peening. Mater. Sci. Technol. 2020, 34, 2294–2304. [Google Scholar]

- Lu, G.X.; Liu, J.D.; Zhou, Y.Z.; Jin, T.; Sun, X.F.; Hu, Z.Q. Differences in the micromechanical properties of dendrites and interdendritic regions in superalloys. Philos. Mag. Lett. 2016, 55, 1–8. [Google Scholar]

- Zhang, H.; Ren, Z.H.; Liu, J. Microstructure evolution and electroplasticity in Ti64 subjected to electropulsing-assisted laser shock peening. J. Alloys Compd. 2019, 802, 573–582. [Google Scholar]

- Hou, X.N.; Mankoci, S.; Walters, N. Hierarchical structures on nickel-titanium fabricated by ultrasonic nanocrystal surface modification. Mater. Sci. Technol. 2019, 98, 1307. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhou, J.; Feng, A.X. Twin formation and its strengthening mechanism of pure titanium processed by cryogenic laser peening. Opt. Lasers Eng. 2019, 120, 105763. [Google Scholar] [CrossRef]

| Ni | Cr | Fe | Mo | Nb | Ti | Si | |

|---|---|---|---|---|---|---|---|

| Composition (wt %) | 51.58 | 18.36 | 20.17 | 2.96 | 5.03 | 0.99 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Yang, Y.; Zhao, J.; Yang, Y.; Qiao, H.; Hu, X.; Wu, J.; Sun, B. Impact on Mechanical Properties and Microstructural Response of Nickel-Based Superalloy GH4169 Subjected to Warm Laser Shock Peening. Materials 2020, 13, 5172. https://doi.org/10.3390/ma13225172

Lu Y, Yang Y, Zhao J, Yang Y, Qiao H, Hu X, Wu J, Sun B. Impact on Mechanical Properties and Microstructural Response of Nickel-Based Superalloy GH4169 Subjected to Warm Laser Shock Peening. Materials. 2020; 13(22):5172. https://doi.org/10.3390/ma13225172

Chicago/Turabian StyleLu, Ying, Yuling Yang, Jibin Zhao, Yuqi Yang, Hongchao Qiao, Xianliang Hu, Jiajun Wu, and Boyu Sun. 2020. "Impact on Mechanical Properties and Microstructural Response of Nickel-Based Superalloy GH4169 Subjected to Warm Laser Shock Peening" Materials 13, no. 22: 5172. https://doi.org/10.3390/ma13225172

APA StyleLu, Y., Yang, Y., Zhao, J., Yang, Y., Qiao, H., Hu, X., Wu, J., & Sun, B. (2020). Impact on Mechanical Properties and Microstructural Response of Nickel-Based Superalloy GH4169 Subjected to Warm Laser Shock Peening. Materials, 13(22), 5172. https://doi.org/10.3390/ma13225172