Reinforcing Behaviors of Sulfur-Containing Silane Coupling Agent in Natural Rubber-Based Magnetorheological Elastomers with Various Vulcanization Systems

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Surface Modification of Carbonyl Iron (CI) Particles

2.3. Preparation of Magnetorheological Elastomer (MRE) Samples

2.4. Characterizations

2.4.1. Surface Hydrophobicity Behavior

2.4.2. Scanning Electron Microscopy

2.4.3. Crosslink Density

2.4.4. Dynamic Mechanical Properties

3. Results and Discussion

3.1. Surface Hydrophobicity of the CI Particles

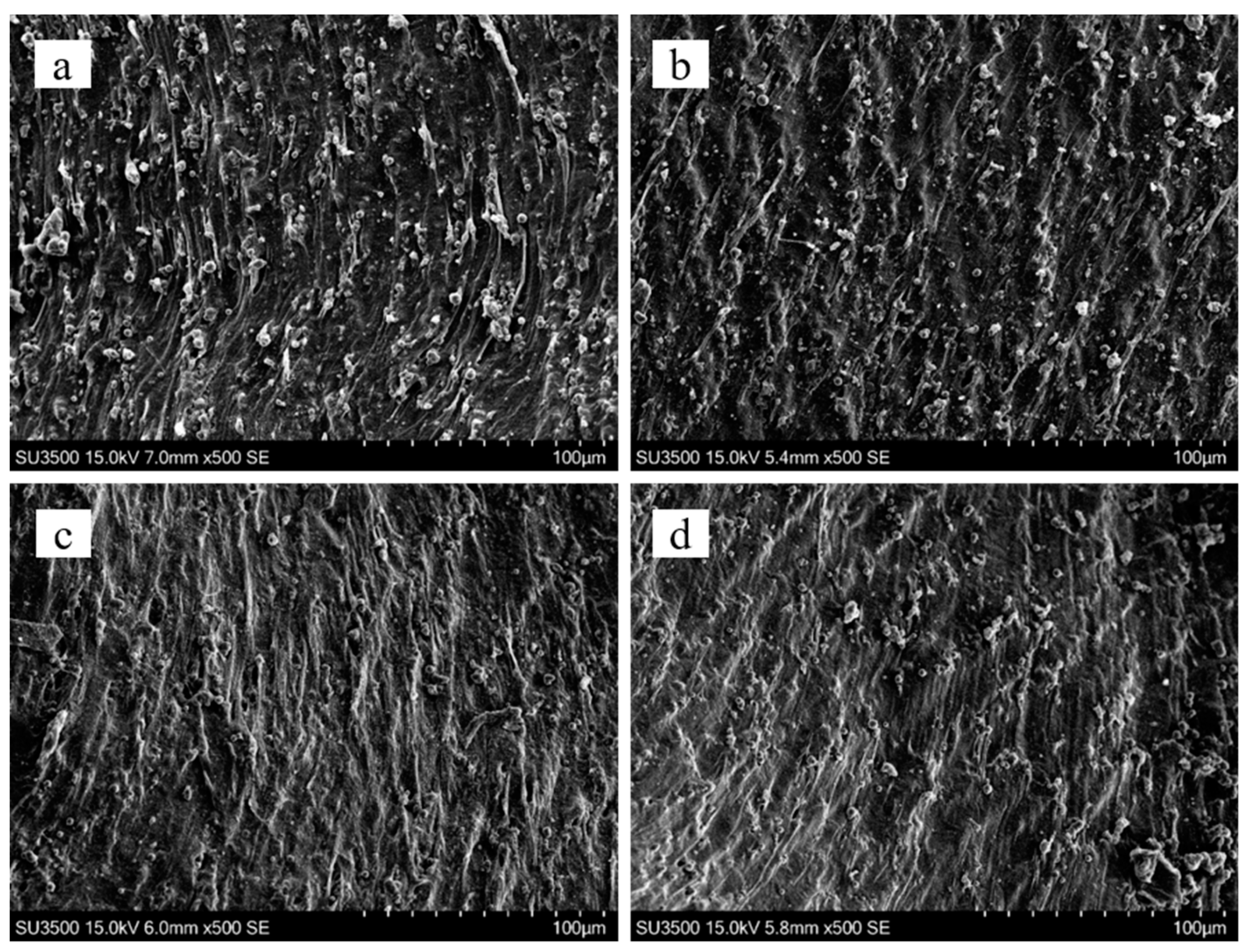

3.2. Morphology

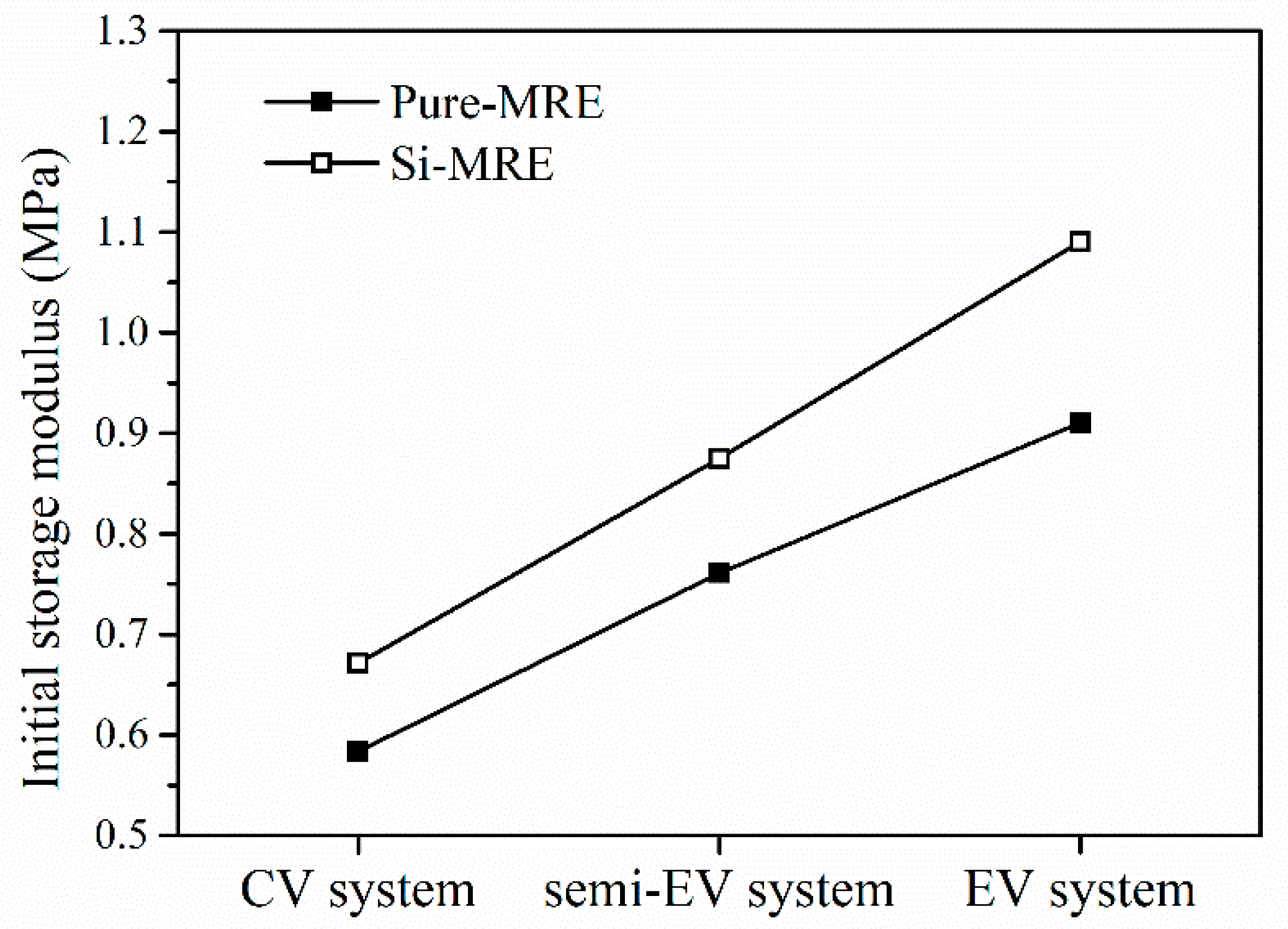

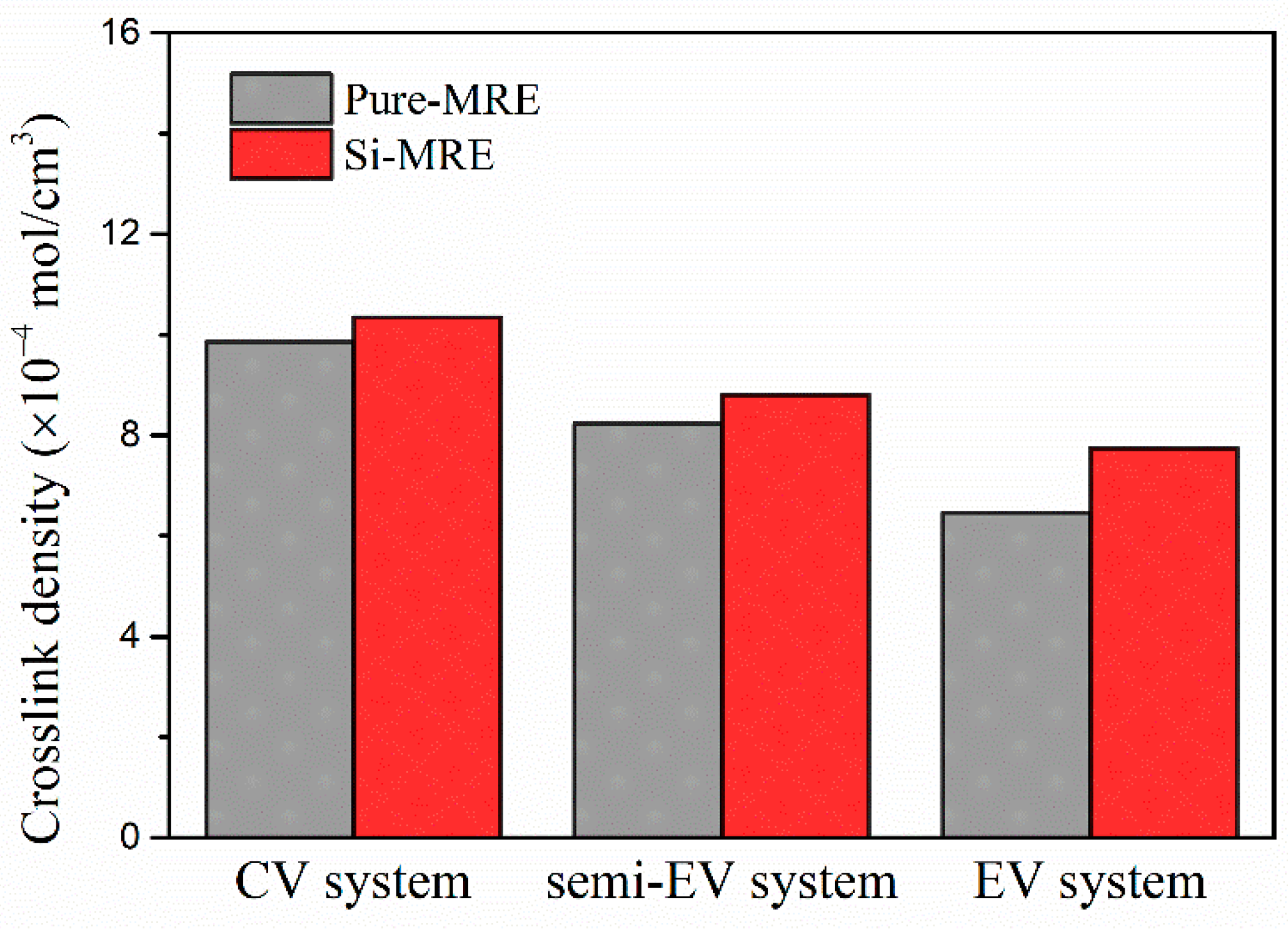

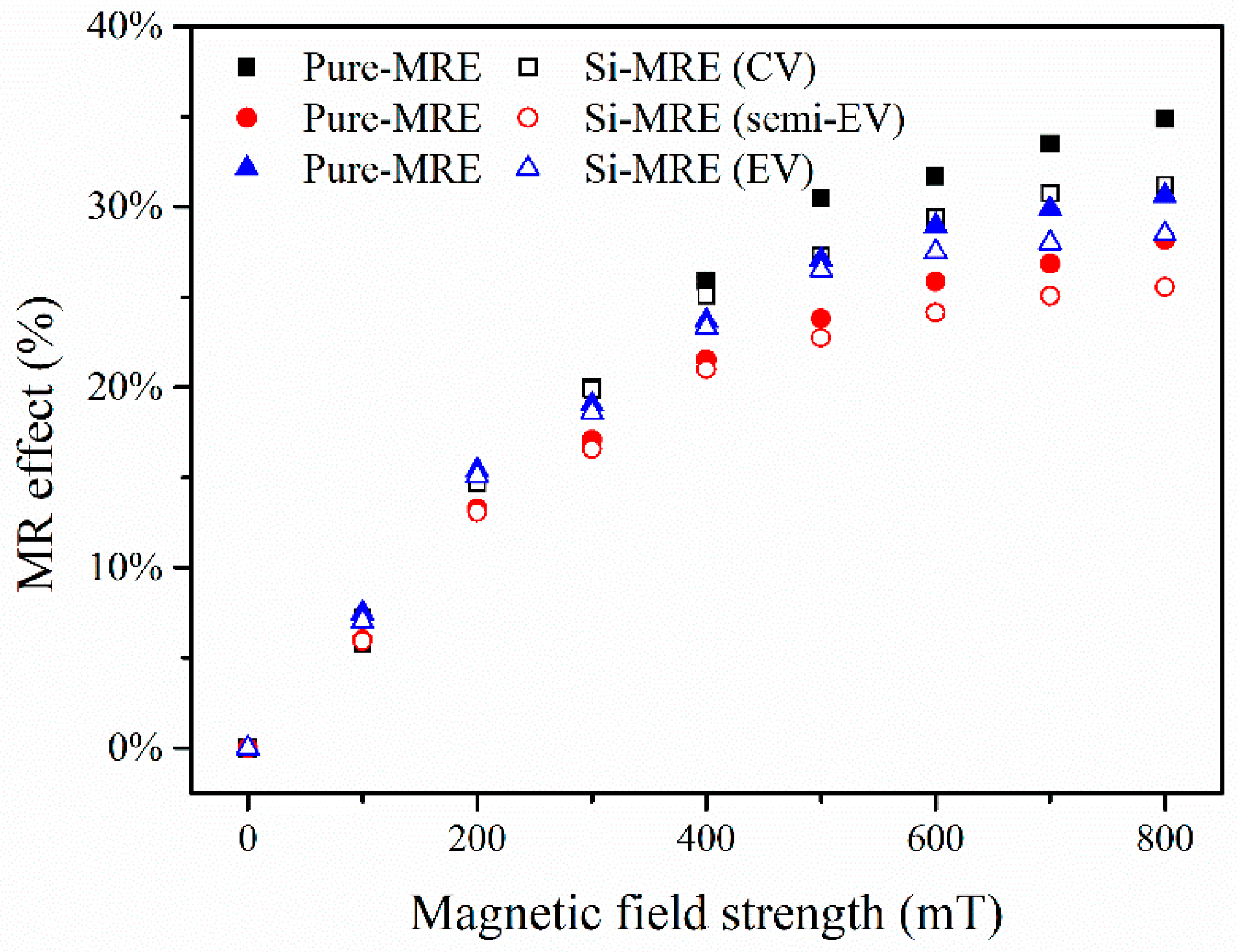

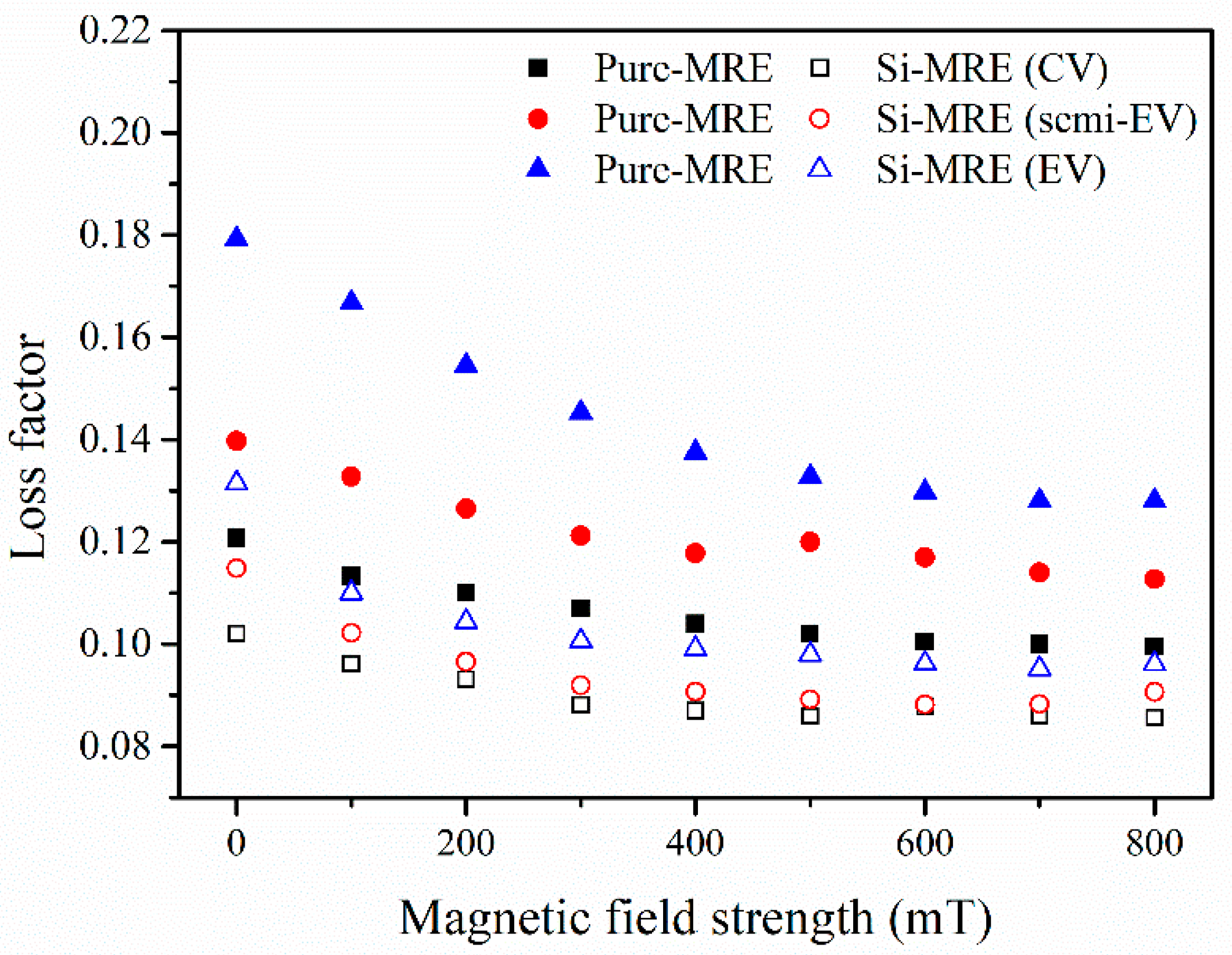

3.3. Dynamic Mechanical Analysis

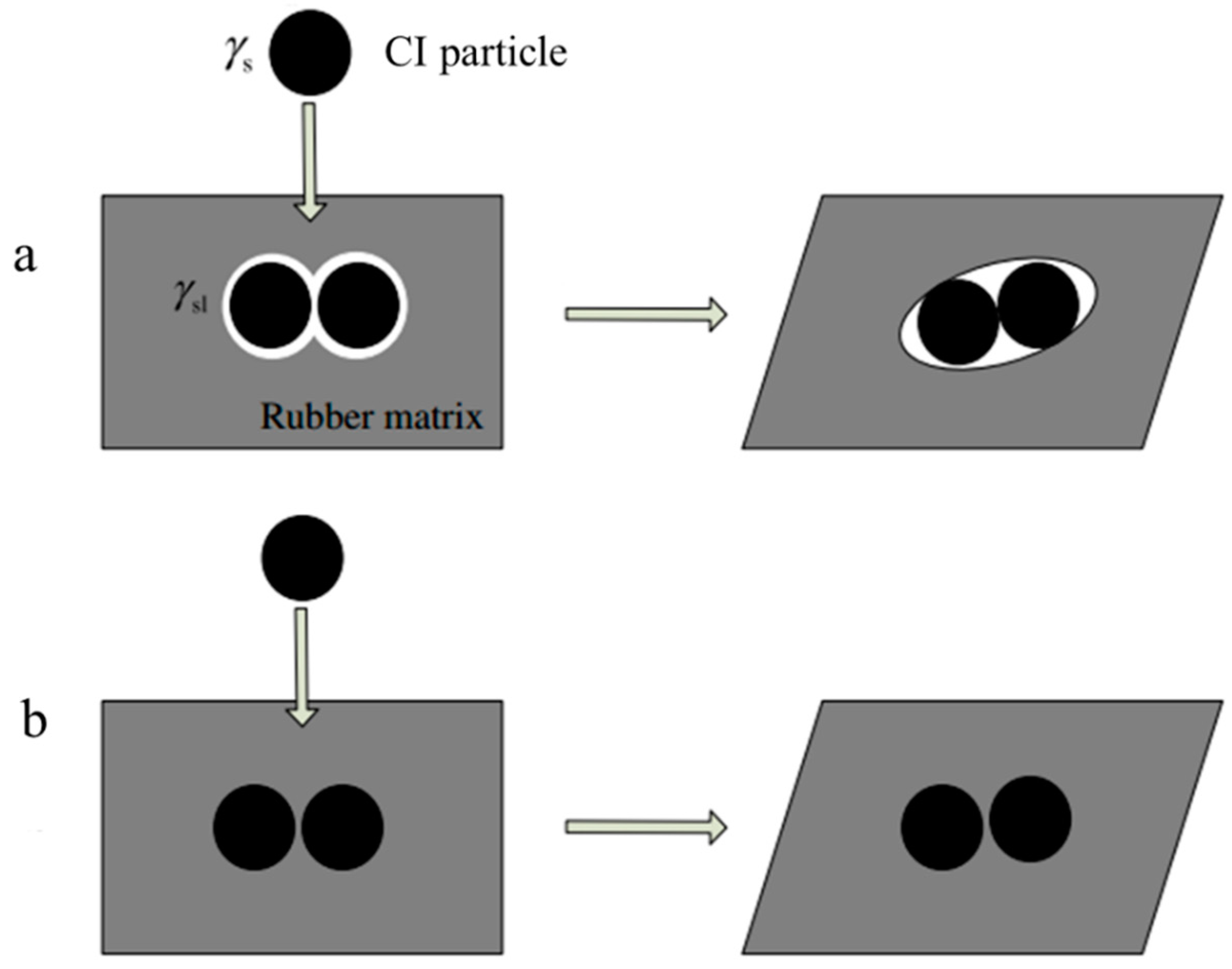

3.4. Enhancement Mechanism of Silane Coupling Agent Si69

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Norouzi, M.; Alehashem, S.M.S.; Vatandoost, H.; Ni, Y.Q.; Shahmardan, M.M. A New Approach for Modeling of Magnetorheological Elastomers. J. Intell. Mater. Syst. Struct. 2015, 27, 1121–1135. [Google Scholar] [CrossRef]

- Yu, M.; Ju, B.; Fu, J.; Liu, X.; Yang, Q. Influence of Composition of Carbonyl Iron Particles on Dynamic Mechanical Properties of Magnetorheological Elastomers. J. Magn. Magn. Mater. 2012, 324, 2147–2152. [Google Scholar] [CrossRef]

- Gong, X.; Zhang, X.; Zhang, P. Fabrication and Characterization of Isotropic Magnetorheological Elastomers. Polym. Test. 2005, 24, 669–676. [Google Scholar] [CrossRef]

- Jolly, M.R.; Carlson, J.D.; Muñoz, B.C. A Model of the Behaviour of Magnetorheological Materials. Smart Mater. Struct. 1996, 5, 607–614. [Google Scholar] [CrossRef]

- Stepanov, G.; Abramchuk, S.; Grishin, D.; Nikitin, L.; Kramarenko, E.; Khokhlov, A.R. Effect of a Homogeneous Magnetic Field on the Viscoelastic Behavior of Magnetic Elastomers. Polymer 2007, 48, 488–495. [Google Scholar] [CrossRef]

- Liao, G.; Gong, X.; Xuan, S.; Guo, C.; Zong, L. Magnetic-Field-Induced Normal Force of Magnetorheological Elastomer under Compression Status. Ind. Eng. Chem. Res. 2012, 51, 3322–3328. [Google Scholar] [CrossRef]

- Lu, X.; Qiao, X.; Watanabe, H.; Gong, X.; Yang, T.; Li, W.; Sun, K.; Li, M.; Yang, K.; Xie, H.; et al. Mechanical and Structural Investigation of Isotropic and Anisotropic Thermoplastic Magnetorheological Elastomer Composites Based on Poly(Styrene-B-Ethylene-Co-Butylene-B-Styrene) (SEBS). Rheol. Acta 2011, 51, 37–50. [Google Scholar] [CrossRef]

- HuaXia, D.; XingLong, G.; LianHua, W. Development of an Adaptive Tuned Vibration Absorber With Magnetorheological Elastomer. Smart Mater. Struct. 2006, 15, N111. [Google Scholar]

- Majid, B.; Xiaojie, W.; Faramarz, G. Performance of a New Magnetorheological Elastomer Isolation System. Smart Mater. Struct. 2014, 23, 045014. [Google Scholar]

- Ladipo, I.L.; Fadly, J.; Faris, W.F. Characterization of Magnetorheological Elastomer (MRE) Engine Mounts. Mater. Today Proc. 2016, 3, 411–418. [Google Scholar] [CrossRef]

- Yu, M.; Qi, S.; Fu, J.; Zhu, M.; Chen, D. Understanding the Reinforcing Behaviors of Polyaniline-Modified Carbonyl Iron Particles in Magnetorheological Elastomer Based on Polyurethane/Epoxy Resin IPNs Matrix. Compos. Sci. Technol. 2017, 139, 36–46. [Google Scholar] [CrossRef]

- Martin, C.; Robert, M.; Michal, S.; Vladimir, P. Electromagnetic, Magnetorheological and Stability Properties of Polysiloxane Elastomers Based on Silane–Modified Carbonyl Iron Particles With Enhanced Wettability. Smart Mater. Struct. 2017, 26, 105003. [Google Scholar]

- Shuib, R.K.; Pickering, K. The Effect of Silane Coupling Agent on the Dynamic Mechanical Properties of Iron Sand/ Natural Rubber Magnetorheological Elastomers. Compos. Part B Eng. 2016, 90, 115–125. [Google Scholar] [CrossRef]

- Chen, D.; Yu, M.; Zhu, M.; Qi, S.; Fu, J. Carbonyl Iron Powder Surface Modification of Magnetorheological Elastomers for Vibration Absorbing Application. Smart Mater. Struct. 2016, 25, 115005. [Google Scholar] [CrossRef]

- Sun, Y.; Zhou, X.; Liu, Y.; Zhao, G.; Jiang, Y. Effect of Magnetic Nanoparticles on the Properties of Magnetic Rubber. Mater. Res. Bull. 2010, 45, 878–881. [Google Scholar] [CrossRef]

- Mrlik, M.; Ilcíková, M.; Cvek, M.; Pavlínek, V.; Zahoranova, A.; Kroneková, Z.; Kasak, P. Carbonyl Iron Coated With a Sulfobetaine Moiety as a Biocompatible System and the Magnetorheological Performance of Its Silicone Oil Suspensions. RSC Adv. 2016, 6, 32823–32830. [Google Scholar] [CrossRef]

- Choi, S.; Kim, I.-S.; Woo, C.-S. Influence of TESPT Content on Crosslink Types and Rheological Behaviors of Natural Rubber Compounds Reinforced With Silica. J. Appl. Polym. Sci. 2007, 106, 2753–2758. [Google Scholar] [CrossRef]

- Bose, S.; Mahanwar, P. Effect of Titanate Coupling Agent on the Mechanical, Thermal, Dielectric, Rheological, and Morphological Properties of Filled Nylon 6. J. Appl. Polym. Sci. 2006, 99, 266–272. [Google Scholar] [CrossRef]

- Jia, Q.; Wu, Y.-P.; Wang, Y.-Q.; Lu, M.; Zhang, L. Enhanced Interfacial Interaction of Rubber/Clay Nanocomposites by a Novel Two-Step Method. Compos. Sci. Technol. 2008, 68, 1050–1056. [Google Scholar] [CrossRef]

- Su, J.; Chen, S.; Zhang, J.; Xu, Z. Comparison of Cure, Mechanical, Electric Properties of EPDM Filled With Sm2O3 Treated by Different Coupling Agents. Polym. Test. 2009, 28, 235–242. [Google Scholar] [CrossRef]

- Mohammadi, A.; Barikani, M.; Barmar, M. Effect of Surface Modification of Fe3O4 Nanoparticles on Thermal and Mechanical Properties of Magnetic Polyurethane Elastomer Nanocomposites. J. Mater. Sci. 2013, 48, 7493–7502. [Google Scholar] [CrossRef]

- Salam, F.A.-E.; Salam, M.H.A.-E.; Mostafa, M.T.; Nagy, M.R.; Mohamed, M.I. Effect of the Vulcanizing System on the Mechanical Properties of Butyl Rubber/Ethylene Propylene Diene Monomer-Carbon Black Blends. J. Appl. Polym. Sci. 2003, 90, 1539–1544. [Google Scholar] [CrossRef]

- Kruželák, J.; Sykora, R.; Dosoudil, R.; Hudec, I. Relationship Between the Cross-Link Structure and Properties of Peroxide and Sulfur-Cured Magnetic Composites Based on NR and NBR. J. Elastomers Plast. 2016, 49, 459–480. [Google Scholar] [CrossRef]

- Akiba, M. Vulcanization and Crosslinking in Elastomers. Prog. Polym. Sci. 1997, 22, 475–521. [Google Scholar] [CrossRef]

- Santana, M.H.; Valentín, J.L.; Lopez-Manchado, M.A.; Šics, I. Influence of the Vulcanization System on the Dynamics and Structure of Natural Rubber: Comparative Study by Means of Broadband Dielectric Spectroscopy and Solid-State NMR Spectroscopy. Eur. Polym. J. 2015, 68, 90–103. [Google Scholar] [CrossRef]

- Ansarifar, A.; Azhar, A.; Ibrahim, N.; Shiah, S.; Lawton, J. The Use of a Silanised Silica Filler to Reinforce and Crosslink Natural Rubber. Int. J. Adhes. Adhes. 2005, 25, 77–86. [Google Scholar] [CrossRef]

- Cheng, G.; Tong, B.; Tang, Z.; Yu, X.; Wang, H.; Ding, G. Surface Functionalization of Coal Powder With Different Coupling Agents for Potential Applications in Organic Materials. Appl. Surf. Sci. 2014, 313, 954–960. [Google Scholar] [CrossRef]

- Lu, J.; Askeland, P.; Drzal, L.T. Surface Modification of Microfibrillated Cellulose for Epoxy Composite Applications. Polymer 2008, 49, 1285–1296. [Google Scholar] [CrossRef]

- An, J.S.; Kwon, S.H.; Choi, H.J.; Jung, J.H.; Gil Kim, Y. Modified Silane-Coated Carbonyl Iron/Natural Rubber Composite Elastomer and Its Magnetorheological Performance. Compos. Struct. 2017, 160, 1020–1026. [Google Scholar] [CrossRef]

- Fan, Y.; Gong, X.; Xuan, S.; Qin, L.; Li, X. Effect of Cross-Link Density of the Matrix on the Damping Properties of Magnetorheological Elastomers. Ind. Eng. Chem. Res. 2013, 52, 771–778. [Google Scholar] [CrossRef]

- Ismail, H.; Chia, H. The Effects of Multifunctional Additive and Vulcanization Systems on Silica Filled Epoxidized Natural Rubber Compounds. Eur. Polym. J. 1998, 34, 1857–1863. [Google Scholar] [CrossRef]

- Sae-oui, P.; Thepsuwan, U.; Hatthapanit, K. Effect of Curing System on Reinforcing Efficiency of Silane Coupling Agent. J. Polym. Test. 2004, 23, 397–403. [Google Scholar]

- Jung, H.S.; Kwon, S.H.; Choi, H.J.; Jung, J.H.; Gil Kim, Y. Magnetic Carbonyl Iron/Natural Rubber Composite Elastomer and Its Magnetorheology. Compos. Struct. 2016, 136, 106–112. [Google Scholar] [CrossRef]

- Gong, X.; Fan, Y.; Xuan, S.; Xu, Y.; Peng, C. Control of the Damping Properties of Magnetorheological Elastomers by Using Polycaprolactone as a Temperature-Controlling Component. Ind. Eng. Chem. Res. 2012, 51, 6395–6403. [Google Scholar] [CrossRef]

- Yu, M.; Zhu, M.; Fu, J.; Yang, P.A.; Qi, S. A Dimorphic Magnetorheological Elastomer Incorporated With Fe Nano-Flakes Modified Carbonyl Iron Particles: Preparation and Characterization. Smart Mater. Struct. 2015, 24, 115021. [Google Scholar] [CrossRef]

- Qiao, X.; Lu, X.; Li, W.; Chen, J.; Gong, X.; Yang, T.; Li, W.; Sun, K.; Chen, X. Microstructure and Magnetorheological Properties of the Thermoplastic Magnetorheological Elastomer Composites Containing Modified Carbonyl Iron Particles and Poly(Styrene-B-Ethylene-Ethylenepropylene-B-Styrene) Matrix. Smart Mater. Struct. 2012, 21. [Google Scholar] [CrossRef]

- Shuib, R.K.; Pickering, K.L.; Mace, B.R. Dynamic Properties of Magnetorheological Elastomers Based on Iron Sand and Natural Rubber. J. Appl. Polym. Sci. 2014, 132. [Google Scholar] [CrossRef]

| Materials | Vulcanization System | ||

|---|---|---|---|

| CV/phr | Semi-EV/phr | EV/phr | |

| NR | 100 | 100 | 100 |

| CI particles | 190 | 190 | 190 |

| S | 2.5 | 1.5 | 0.5 |

| CZ | 0.5 | 1.5 | 2.5 |

| ZnO | 5 | 5 | 5 |

| stearic acid | 1 | 1 | 1 |

| RD | 3 | 3 | 3 |

| 4010NA | 2 | 2 | 2 |

| cumarone | 12 | 12 | 12 |

| Si69/wt% | 0, 2 | 0, 2 | 0, 2 |

| Curing Characteristics | CV | Semi-EV | EV | |||

|---|---|---|---|---|---|---|

| Pure-MRE | Si-MRE | Pure-MRE | Si-MRE | Pure-MRE | Si-MRE | |

| t10/min | 5.88 | 4.50 | 7.10 | 7.89 | 9.83 | 9.02 |

| t90/min | 18.88 | 20.03 | 12.68 | 13.53 | 20.50 | 19.89 |

| ML/(N·m) | 0.03 | 0.021 | 0.03 | 0.016 | 0.028 | 0.02 |

| MH/(N·m) | 0.665 | 0.705 | 0.554 | 0.621 | 0.466 | 0.549 |

| ∆M = (MH−ML) | 0.635 | 0.684 | 0.524 | 0.605 | 0.438 | 0.529 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Hao, X.; Wang, W. Reinforcing Behaviors of Sulfur-Containing Silane Coupling Agent in Natural Rubber-Based Magnetorheological Elastomers with Various Vulcanization Systems. Materials 2020, 13, 5163. https://doi.org/10.3390/ma13225163

Wang M, Hao X, Wang W. Reinforcing Behaviors of Sulfur-Containing Silane Coupling Agent in Natural Rubber-Based Magnetorheological Elastomers with Various Vulcanization Systems. Materials. 2020; 13(22):5163. https://doi.org/10.3390/ma13225163

Chicago/Turabian StyleWang, Mengxin, Xiaoqian Hao, and Wenju Wang. 2020. "Reinforcing Behaviors of Sulfur-Containing Silane Coupling Agent in Natural Rubber-Based Magnetorheological Elastomers with Various Vulcanization Systems" Materials 13, no. 22: 5163. https://doi.org/10.3390/ma13225163

APA StyleWang, M., Hao, X., & Wang, W. (2020). Reinforcing Behaviors of Sulfur-Containing Silane Coupling Agent in Natural Rubber-Based Magnetorheological Elastomers with Various Vulcanization Systems. Materials, 13(22), 5163. https://doi.org/10.3390/ma13225163