Dynamic Recrystallization Critical Conditions and a Physically–Based Constitutive Model of Al–4.8Mg Alloy Under Hot Working Conditions

Abstract

1. Introduction

2. Materials and Experiments

3. Results and Discussion

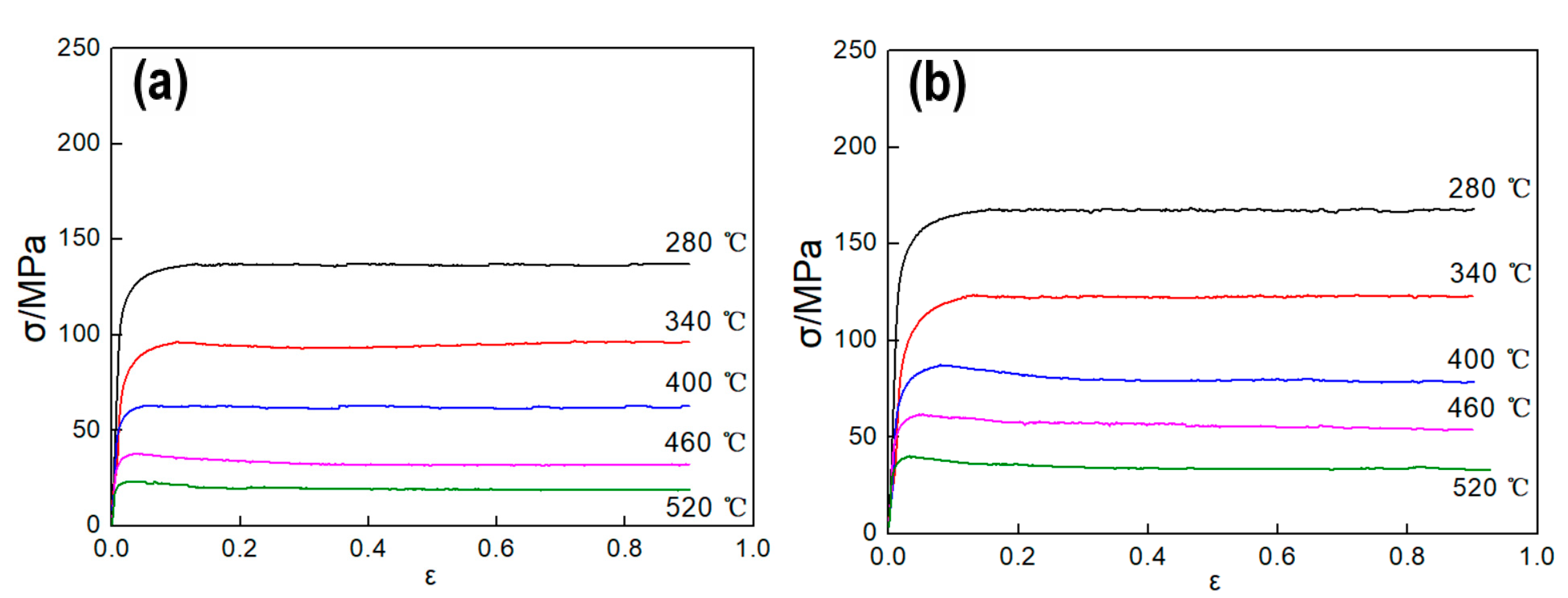

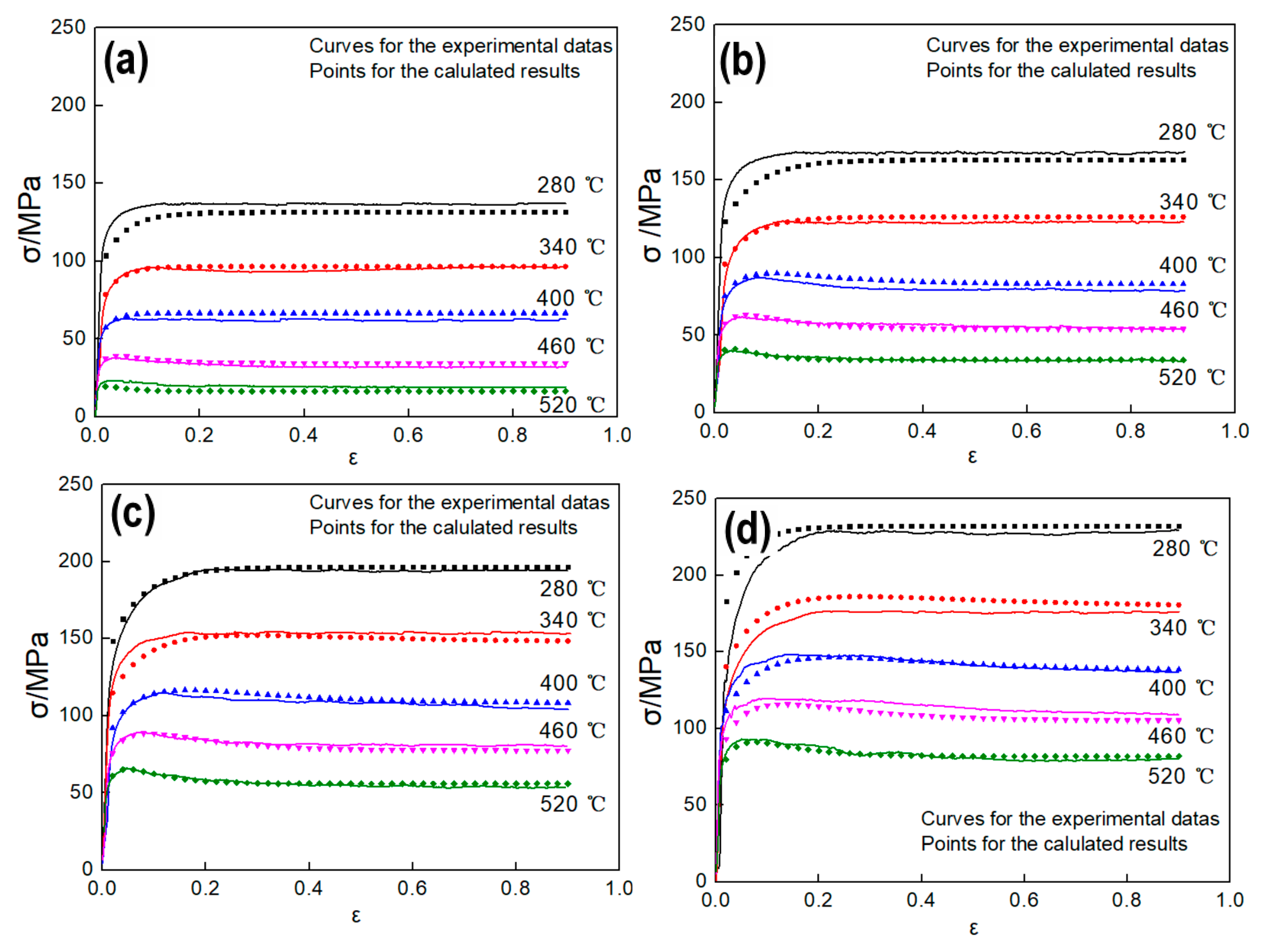

3.1. True Stress–Strain Curves

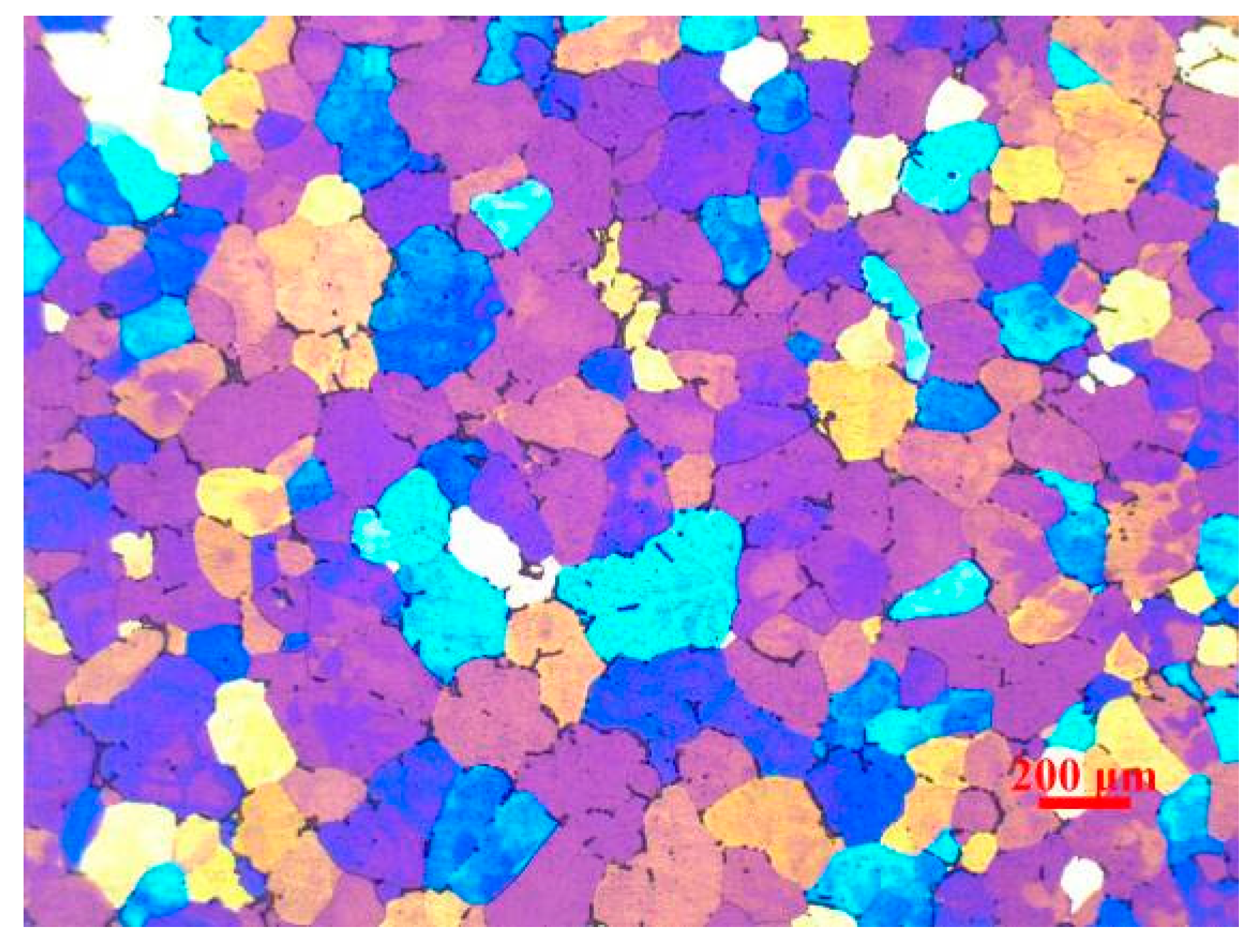

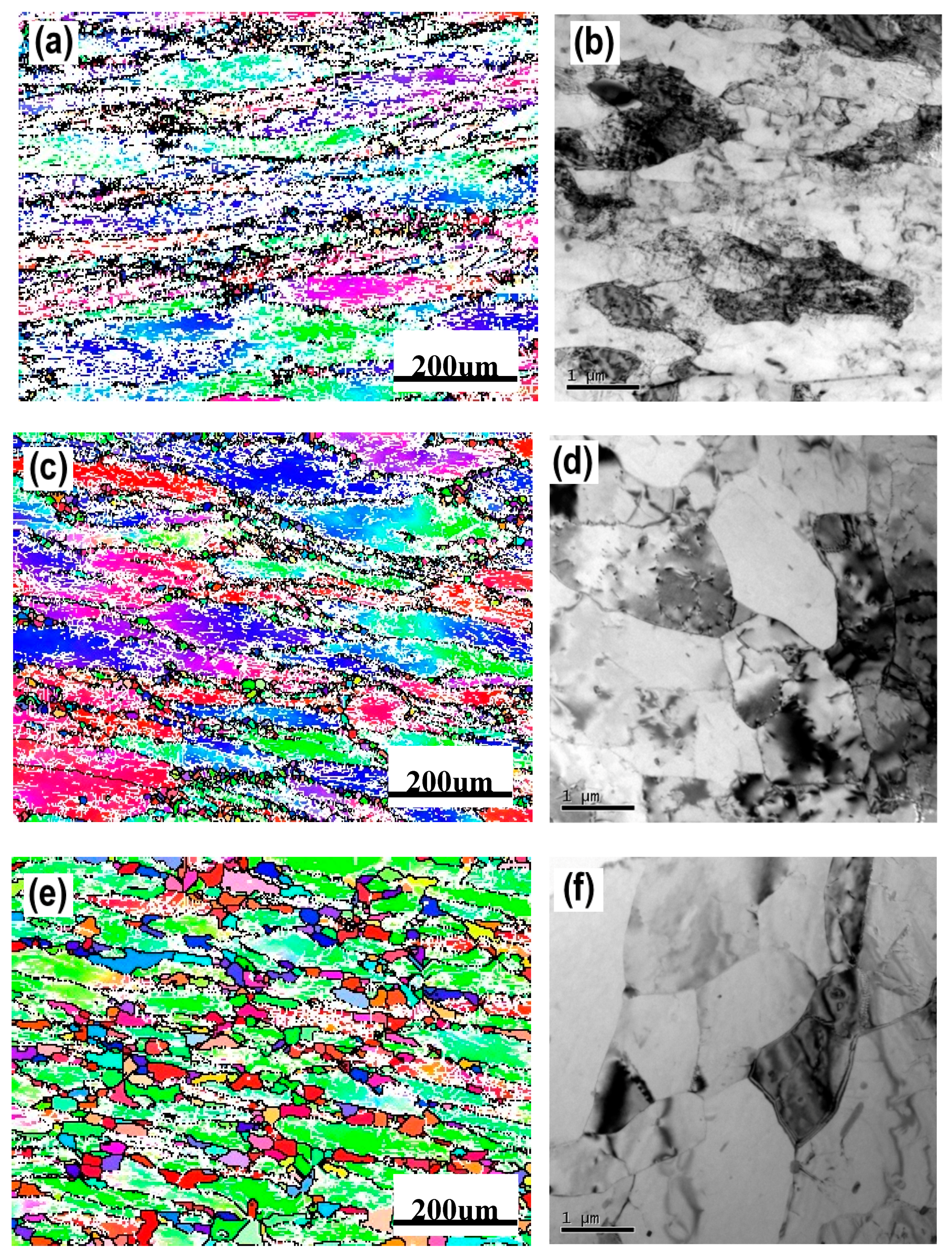

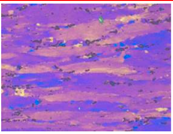

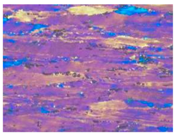

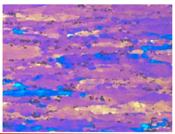

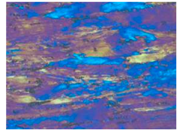

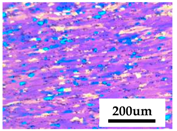

3.2. Microstructural Evolution

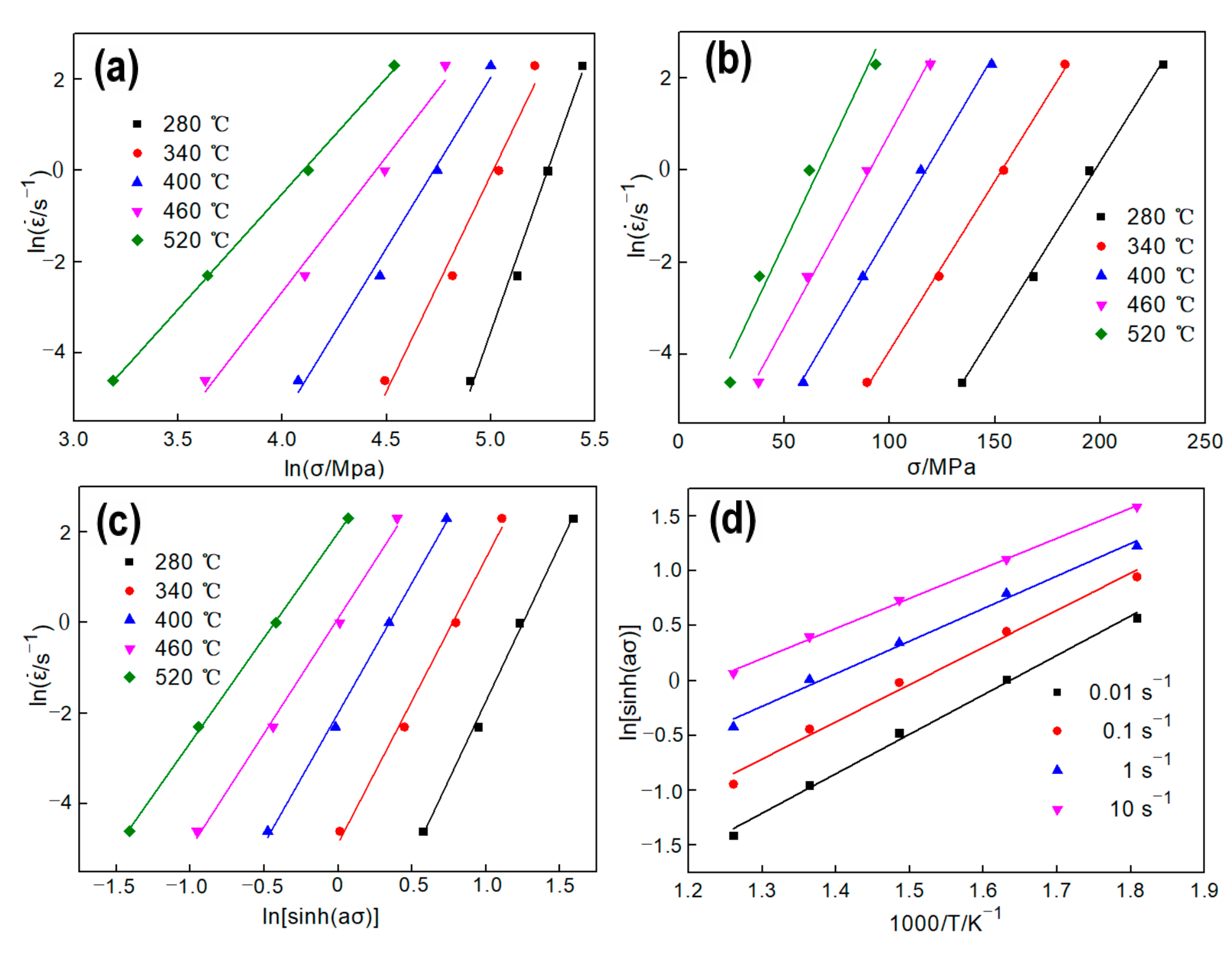

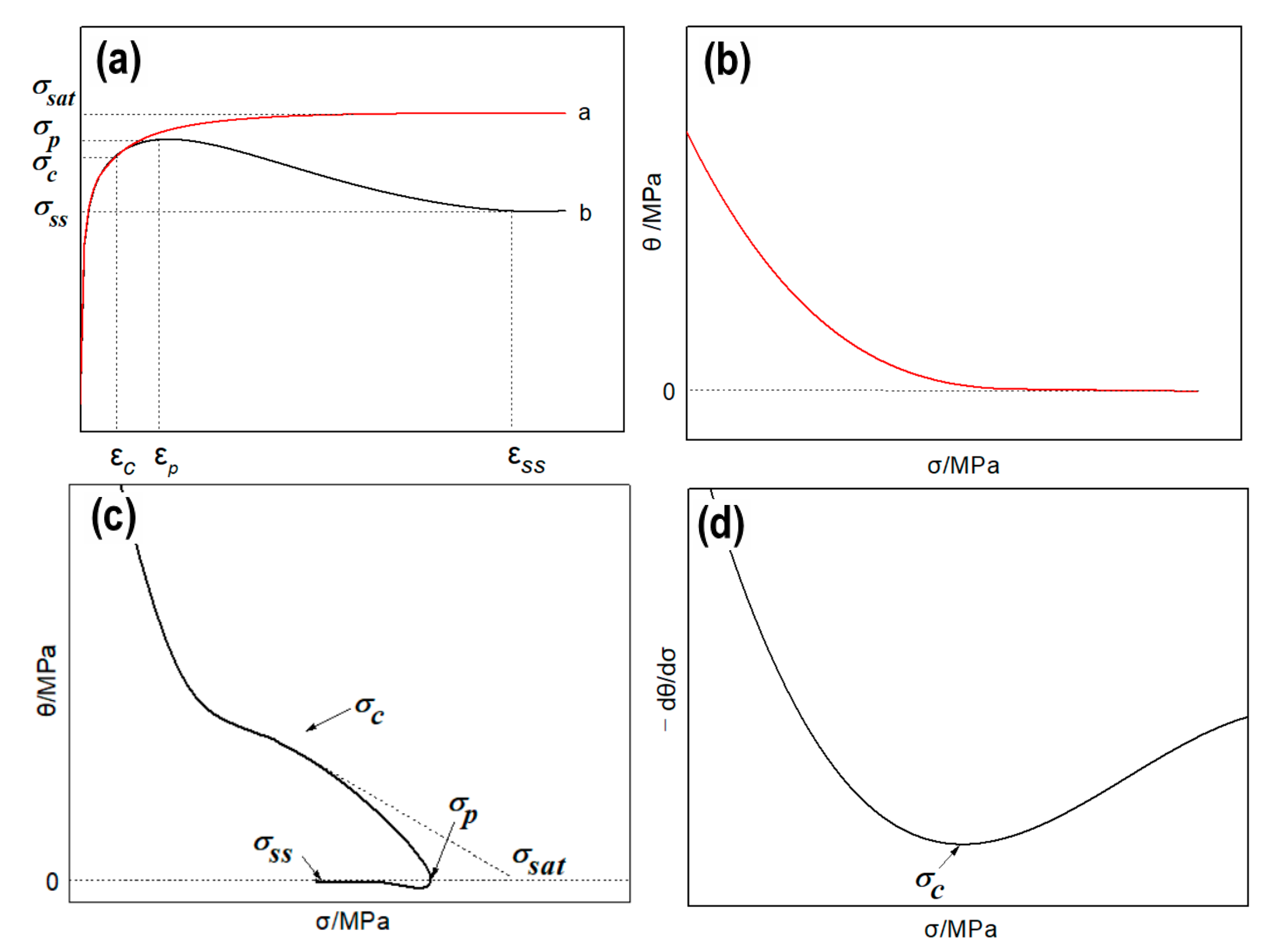

3.3. DRX Critical Conditions

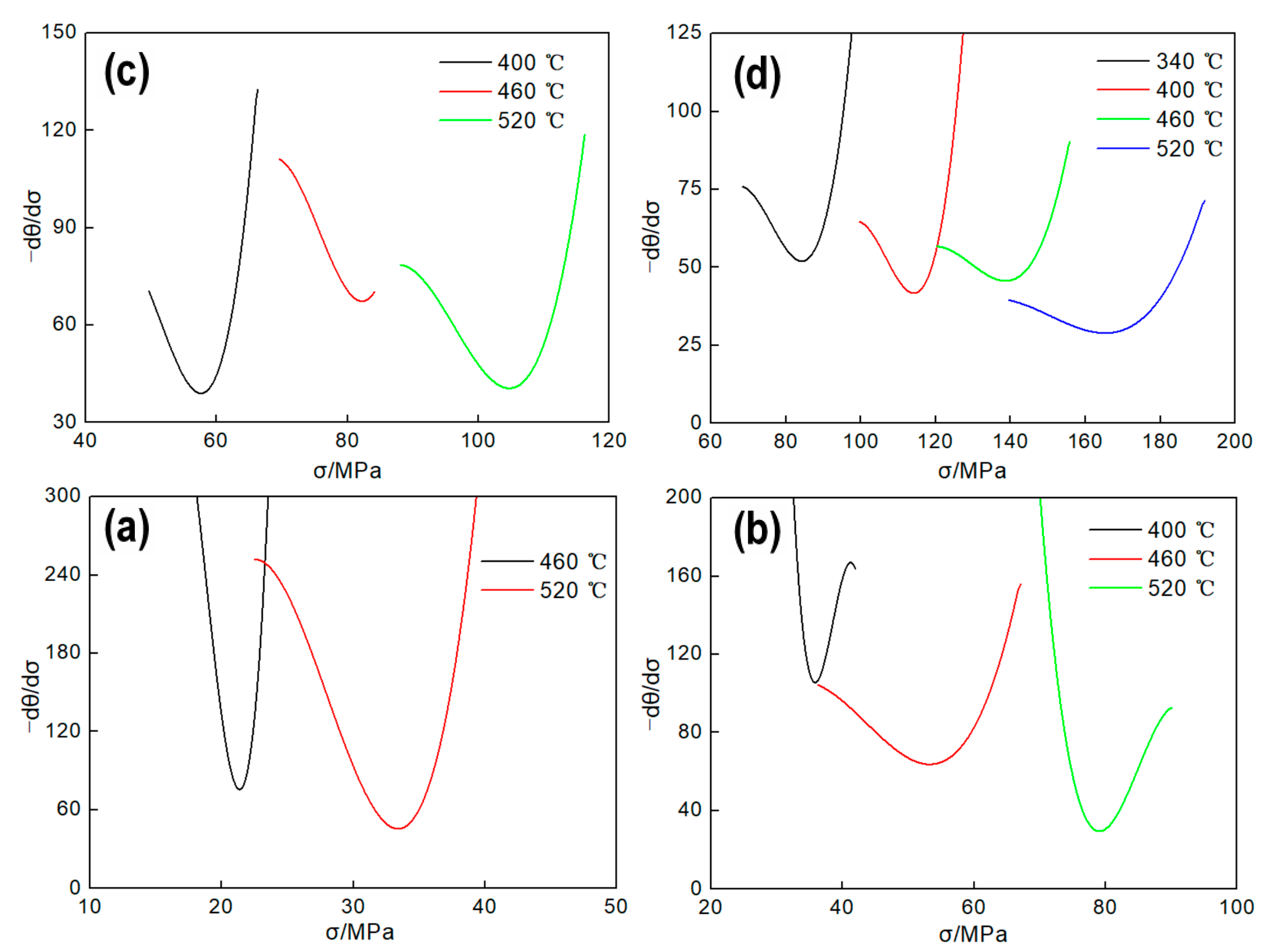

3.3.1. Determination of Critical Temperature and Strain Rate

3.3.2. Determination of Critical Strain

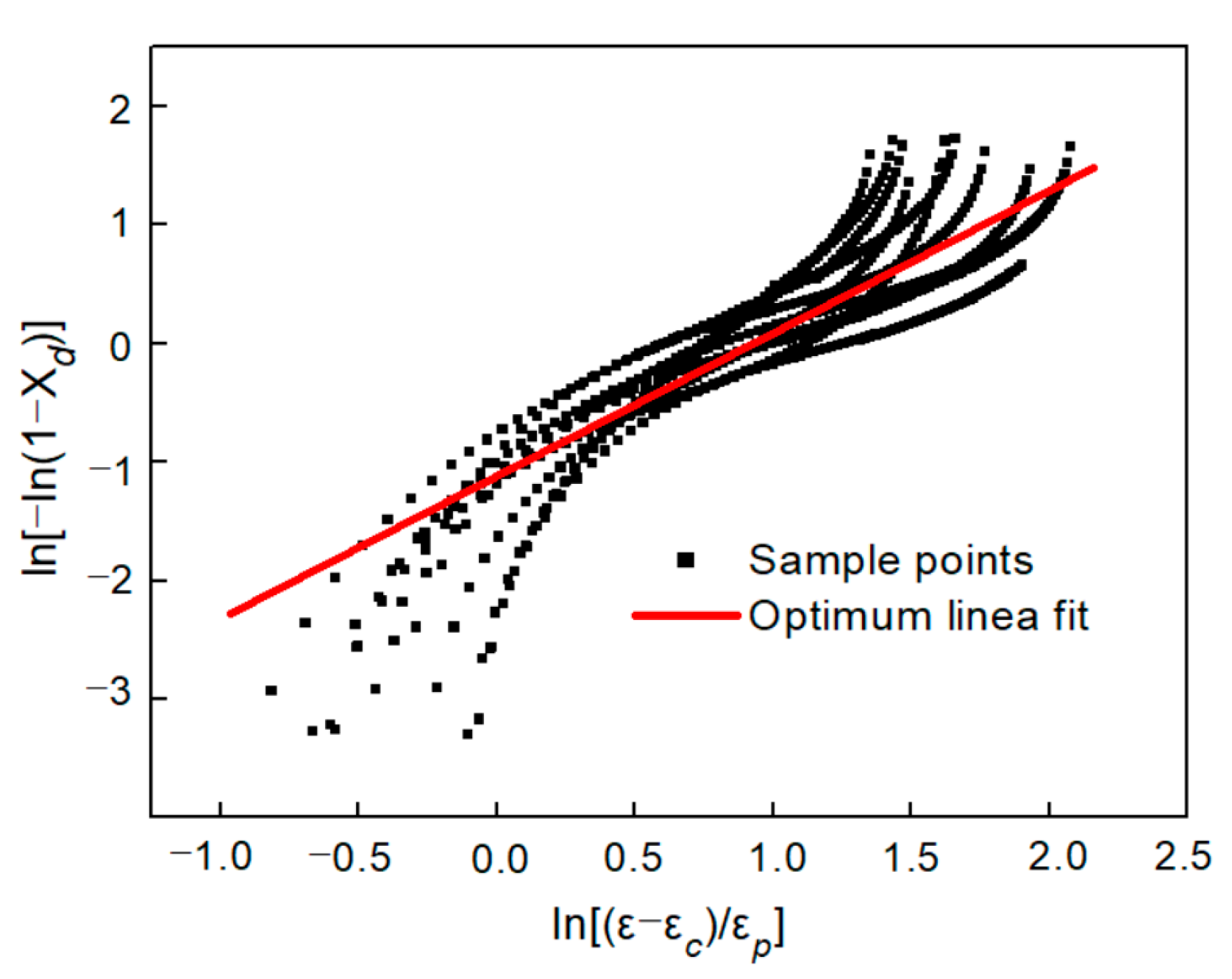

3.4. Physically–Based Constitutive Model of Flow Stress

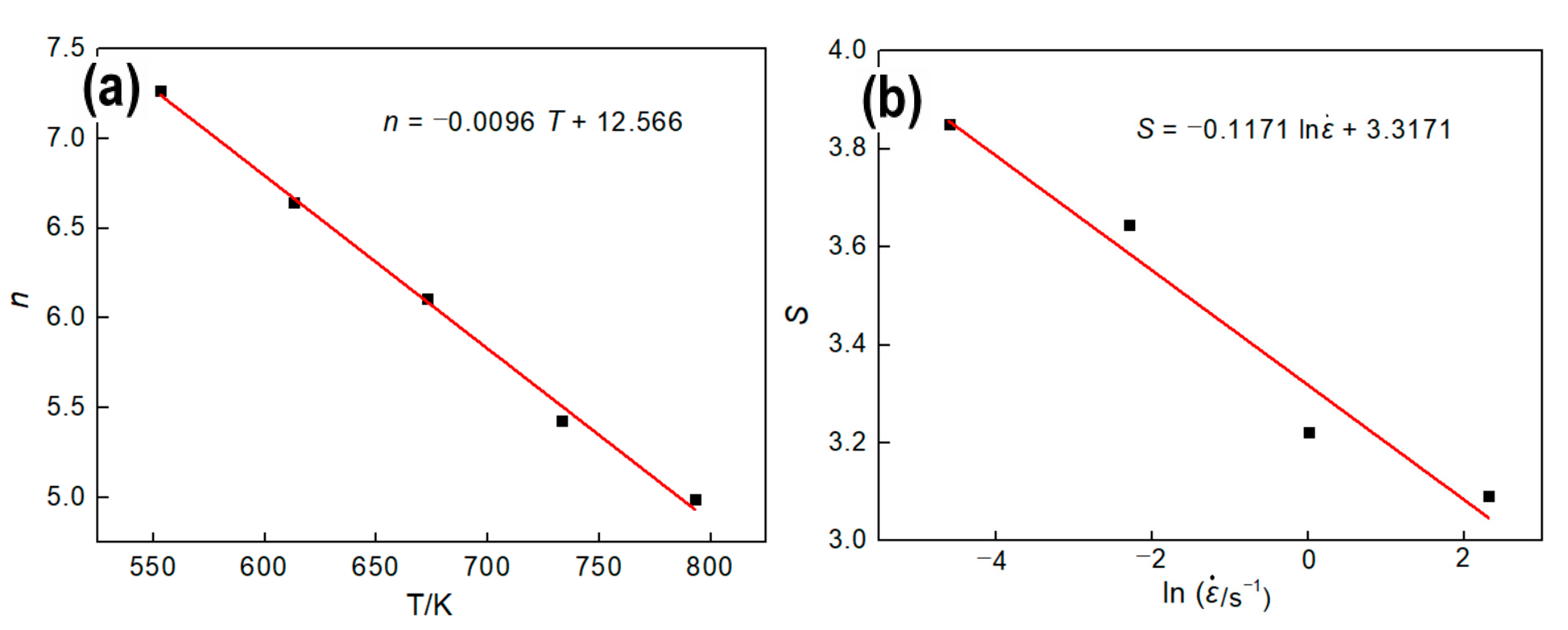

3.4.1. Part I. Constitutive Model Based on WH-DRV

3.4.2. Part II. Constitutive Model Based on DRX

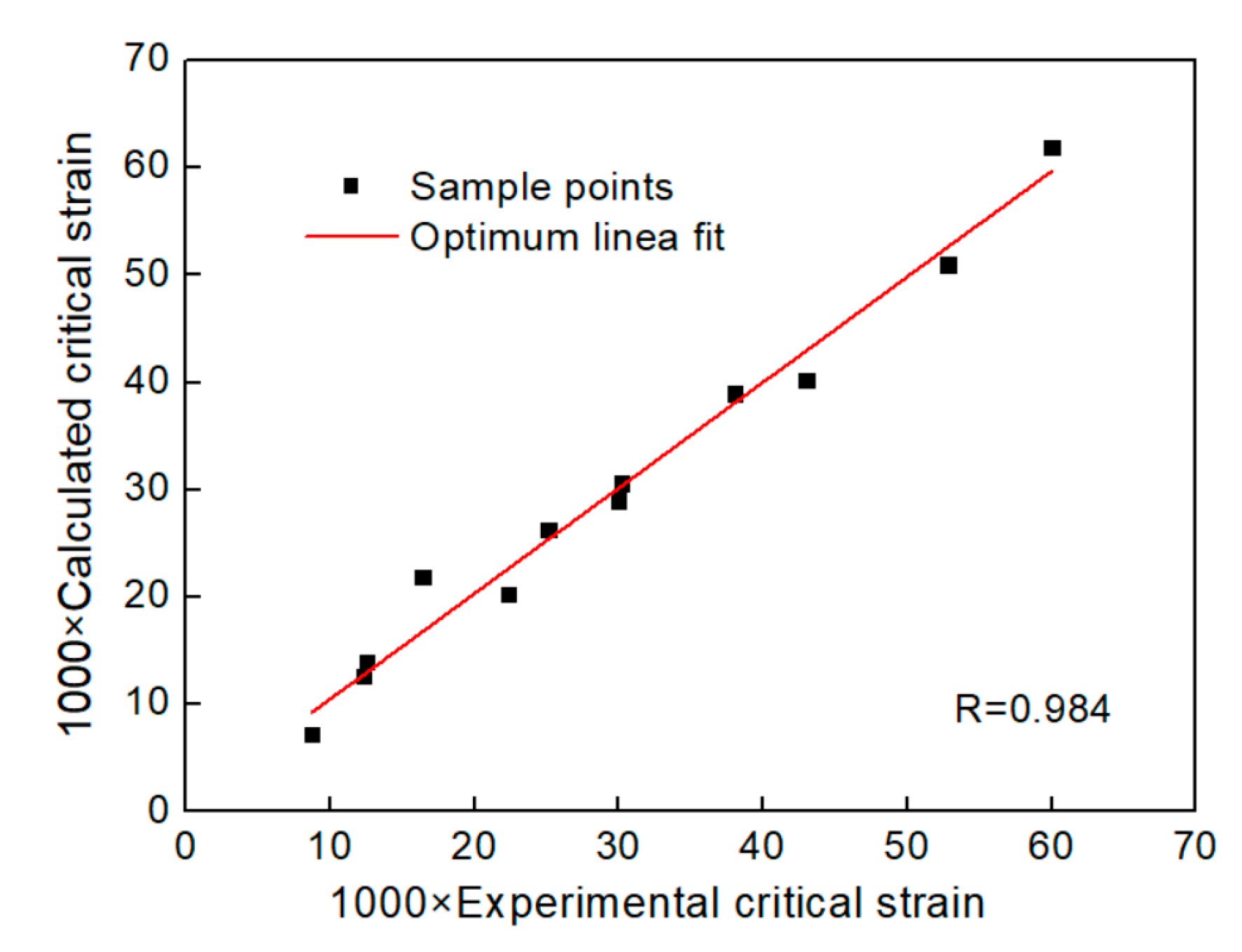

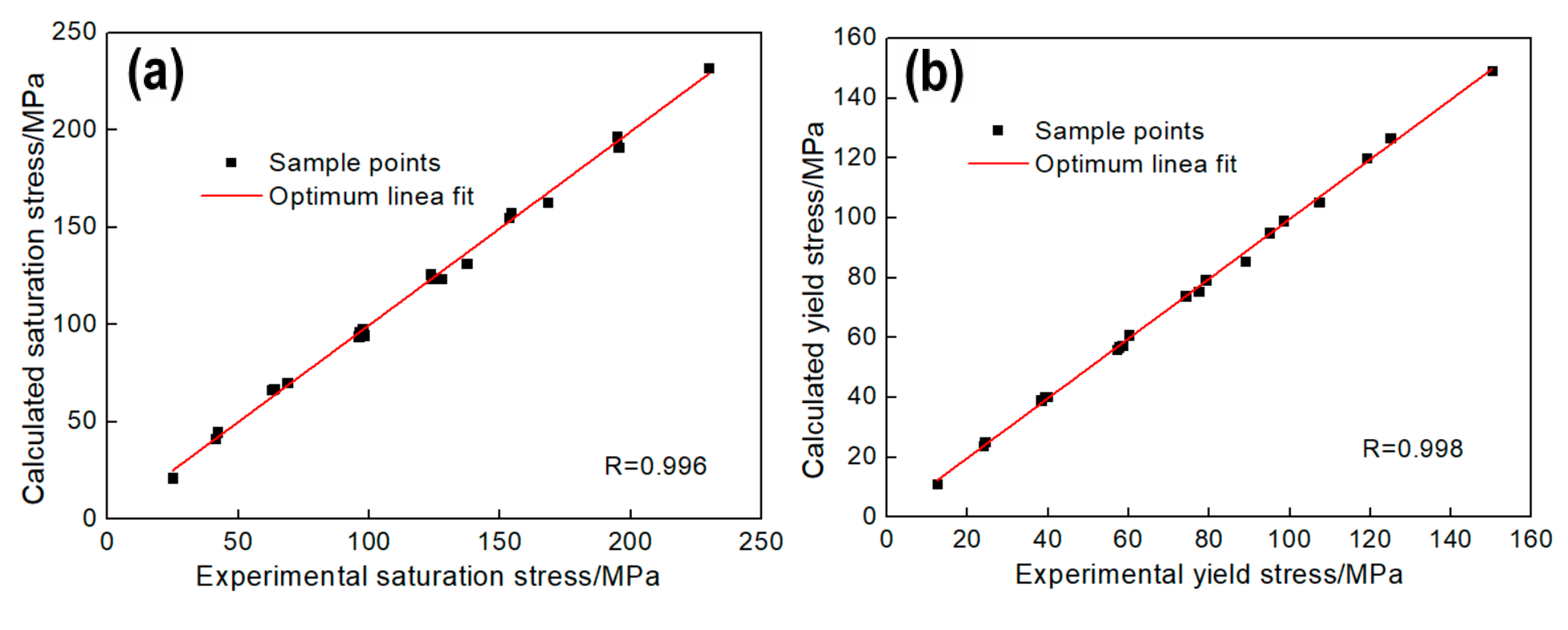

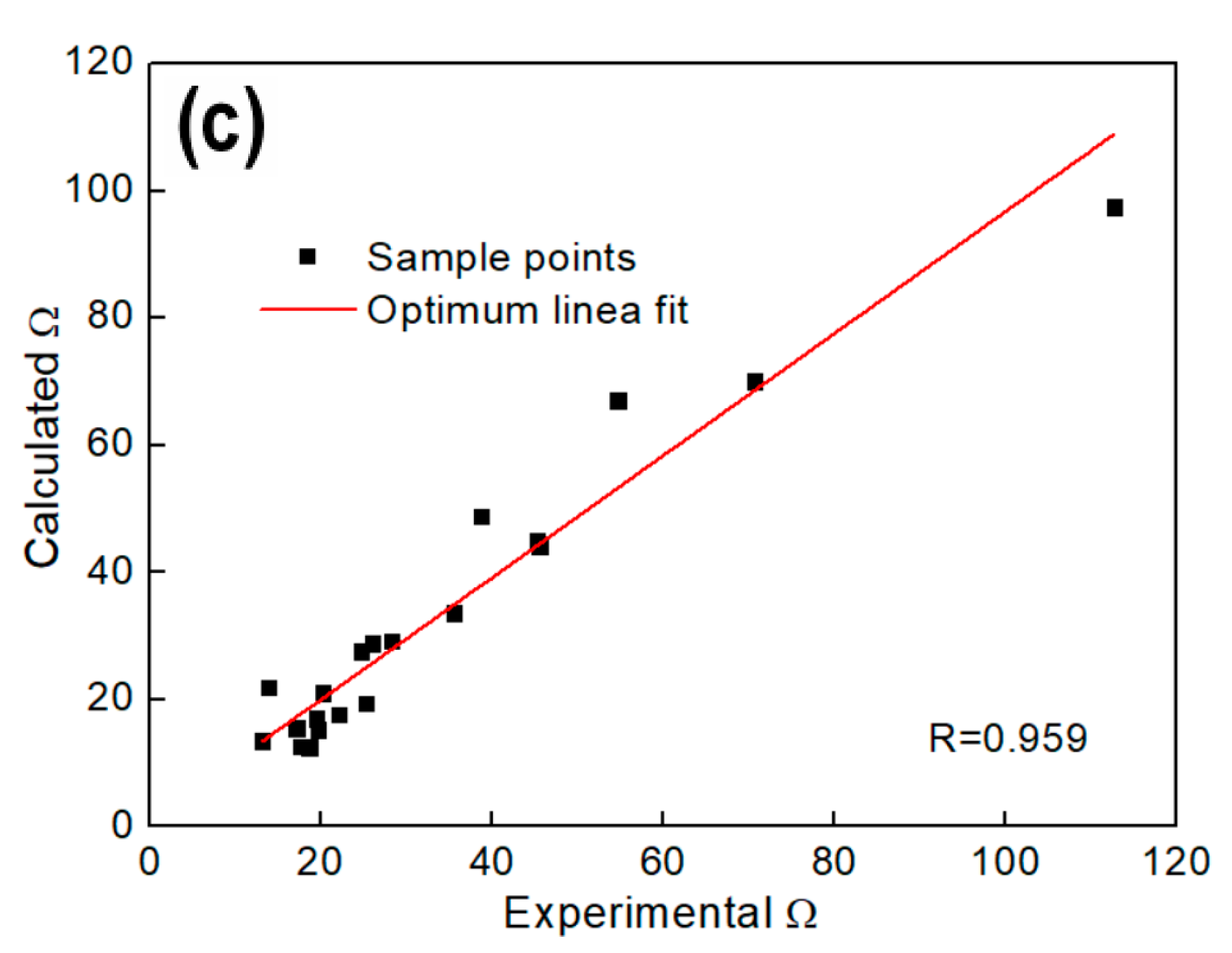

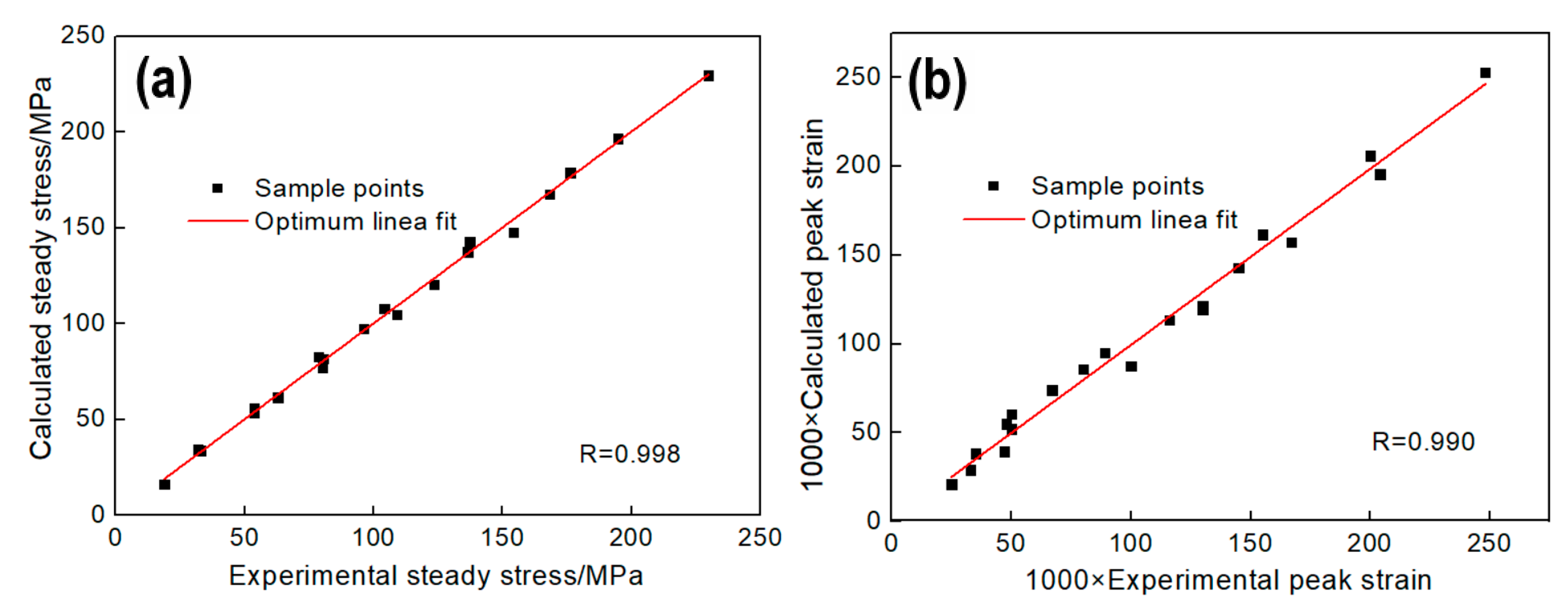

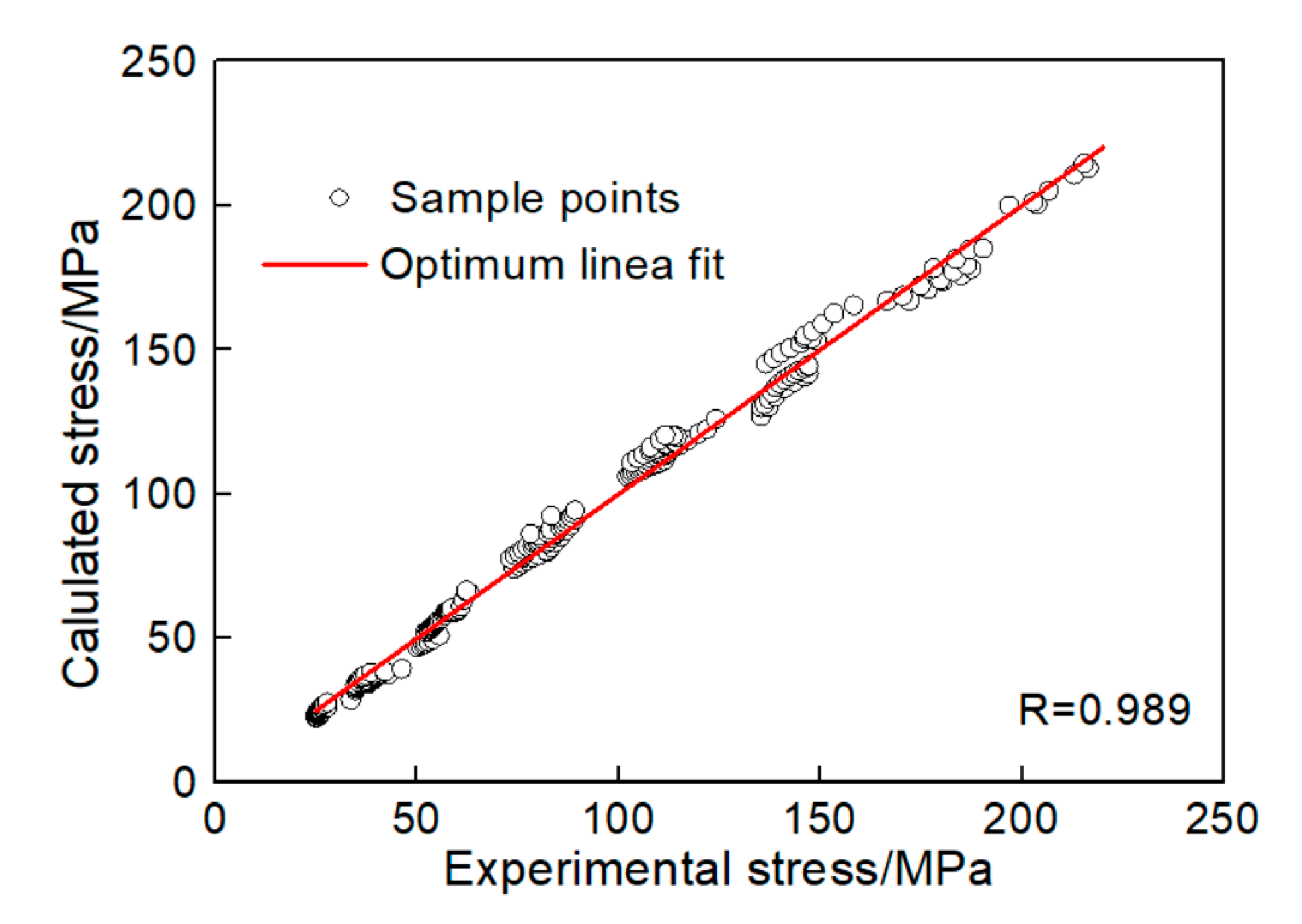

3.4.3. Verification of the Constitutive Model

4. Conclusions

- (1)

- There are three main dynamic softening mechanisms of samples within the range of experimental parameters: DRV, DRV + DRX and DRX, and the equiaxial DRX is more easily to form under higher deformation temperature and higher strain rate.

- (2)

- Based on the deformation activation energy and work-hardening rate, an improved DRX critical conditions model was proposed to describe the DRX conditions of Al-4.8Mg alloy under a wide range of hot deformation parameters.

- (3)

- According to the proposed DRX critical conditions model, a two–stage physically–based constitutive model including the WH-DRV stage and DRX stage was established. The 4.02% of AARE between the calculated values and experimental values indicates that the established physically–based constitutive model has a good prediction accuracy.

Author Contributions

Funding

Conflicts of Interest

References

- Mills, R.J.; Lattimer, B.Y.; Case, S.W.; Mouritz, A.P. The influence of sensitization and corrosion on creep of 5083–H116. Corros. Sci. 2018, 143, 1–9. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Yakovtseva, O.A.; Golovin, I.S.; Pozdniakov, A.V.; Portnoy, V.K. Superplastic deformation mechanisms in fine–grained Al–Mg based alloys. Mater. Sci. Eng. A 2015, 627, 31–41. [Google Scholar] [CrossRef]

- Olaf, E.; Simon, M.J. Control of second-phase particles in the Al-Mg-Mn alloy AA 5083. J. Alloys Comp. 2016, 689, 998–1010. [Google Scholar] [CrossRef]

- Huang, Y.C.; Li, Y.; Xiao, Z.B.; Liu, Y.; Huang, Y.T.; Ren, X.W. Effect of homogenization on the corrosion behavior of 5083–H321 aluminum alloy. J. Alloys Comp. 2016, 673, 73–79. [Google Scholar] [CrossRef]

- Tang, J.G.; Huang, X.X.; Zhang, X.M. Hot−compression behavior of Al alloy 5182. J. Cent. South Univ. 2012, 19, 2073–2080. [Google Scholar] [CrossRef]

- Ebrahimi, G.R.; Zarei, H.A.; Haghshenas, M.; Arabshahi, H. The effect of heat treatment on hot deformation behaviour of Al 2024. J. Mater. Process Tech. 2008, 206, 25–29. [Google Scholar] [CrossRef]

- Avramovic, C.G.; Perovic, D.D.; McQueen, H.J. Hot deformation mechanisms of a solution–treated Al–Li–Cu–Mg–Zr alloy. Metall. Mater. Trans. A 1996, 27, 3478–3490. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Gao, K.Y.; Wu, X.L.; Wang, W.; Nie, Z.R. Hot deformation behavior and processing map of a new type Al–Zn–Mg–Er–Zr alloy. J. Alloys Comp. 2016, 685, 869–880. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.X.; Yuan, D.; Peng, D.S. Hot deformation behavior of the new Al–Mg–Si–Cu aluminum alloy during compression at elevated temperatures. Mater. Charact. 2007, 58, 168–173. [Google Scholar] [CrossRef]

- Dai, Q.S.; Deng, Y.L.; Tang, J.G.; Wang, Y. Deformation characteristics and strain–compensated constitutive equation for AA5083 aluminum alloy under hot compression. Trans. Nonferrous Met. Soc. China 2019, 29, 2252–2261. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.Q.; Yu, J.Q. Hot deformation behavior and constitutive modeling of homogenized 6026 aluminum alloy. Mater. Des. 2015, 74, 25–35. [Google Scholar] [CrossRef]

- Li, J.; Li, F.G.; Cai, J.; Wang, R.T.; Yuan, Z.W.; Xue, F.M. Flow behavior modeling of the 7050 aluminum alloy at elevated temperatures considering the compensation of strain. Mater. Des. 2012, 42, 369–377. [Google Scholar] [CrossRef]

- Xiao, Z.B.; Huang, Y.C.; Liu, H.S.; Wang, X. Hot tensile and fracture behavior of 35CrMo steel at elevated temperature and strain rate. Metals 2016, 6, 210. [Google Scholar] [CrossRef]

- Cai, Z.W.; Chen, F.X.; Guo, J.Q. Constitutive model for elevated temperature flow stress of AZ41M magnesium alloy considering the compensation of strain. J. Alloys Comp. 2015, 648, 215–222. [Google Scholar] [CrossRef]

- Qu, F.S.; Reng, Z.Y.; Ma, R.R.; Chen, D.M. The research on the constitutive modeling and hot working characteristics of as–cast V–5Cr–5Ti alloy during hot. J. Alloys Comp. 2016, 663, 552–559. [Google Scholar] [CrossRef]

- Zhang, Y.; Chai, Z.; Volinsky, A.A.; Tang, B.H.; Sun, H.L.; Liu, P.; Liu, Y. Processing maps for the Cu–Cr–Zr–Y alloy hot deformation behavior. Mater. Sci. Eng. A 2016, 662, 320–329. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, X.M.; Liu, S.D.; Deng, Y.L. Constitutive equation and hot deformation behavior of homogenized Al–7.68Zn–2.12Mg–1.98Cu–0.12Zr alloy during compression at elevated temperature. Mater. Sci. Eng. A 2014, 608, 63–72. [Google Scholar] [CrossRef]

- Wu, B.; Li, M.Q.; Ma, D.W. The flow behavior and constitutive equations in isothermal compression of 7050 aluminum alloy. Mater. Sci. Eng. A 2012, 542, 79–87. [Google Scholar] [CrossRef]

- Ji, G.L.; Li, Q.; Li, L. A physical–based constitutive relation to predict flow stress for Cu–0.4Mg alloy during hot working. Mater. Sci. Eng. A 2014, 615, 247–254. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M.; Wen, D.X.; Chen, M.S. A physically–based constitutive model for a typical nickel–based superalloy. Comput. Mater. Sci. 2014, 83, 282–289. [Google Scholar] [CrossRef]

- Huang, C.Q.; Deng, J.; Wang, S.X.; Liu, L.L. A physical-based constitutive model to describe the strain-hardening and dynamic recovery behaviors of 5754 aluminum alloy. Mater. Sci. Eng. A 2017, 699, 106–113. [Google Scholar] [CrossRef]

- Zhu, R.H.; Liu, Q.; Li, J.F.; Xiang, S.; Chen, Y.L.; Zhang, X.H. Dynamic restoration mechanism and physically based constitutive model of 2050 Al–Li alloy during hot compression. J. Alloys Comp. 2015, 650, 75–85. [Google Scholar] [CrossRef]

- Jonas, J.J. The back stress in high temperature deformation. Acta Metall. 1969, 17, 397–405. [Google Scholar] [CrossRef]

- Liu, C.M.; Jiang, S.N.; Zhang, X.M. Continuous dynamic recrystallization and discontinuous dynamic recrystallization in 99.99% polycrystalline aluminum during hot compression. T. Nonferr. Metal. Soc. 2005, 15, 82–86. [Google Scholar] [CrossRef]

- Liu, W.Y.; Zhao, H.; Li, D.; Zhang, Z.Q.; Huang, G.J.; Liu, Q. Hot deformation behavior of AA7085 aluminum alloy during isothermal compression at elevated temperature. Mater. Sci. Eng. A 2014, 596, 176–182. [Google Scholar] [CrossRef]

- Zhang, P.; Yi, C.; Chen, G.; Qin, H.Y.; Wang, C.J. Constitutive Model Based on Dynamic Recrystallization Behavior during Thermal Deformation of a Nickel-Based Superalloy. Metals 2016, 6, 161–179. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Honeycombe, S.R. Modelling of Microstructure and Properties-14. Steels 2006, 13, 307–334. [Google Scholar] [CrossRef]

| Deformation Parameter | 280 °C | 340 °C | 400 °C | 460 °C | 520 °C |

|---|---|---|---|---|---|

| 0.01 s–1 |  |  |  |  |  |

| 0.1 s–1 |  |  |  |  |  |

| 1 s–1 |  |  |  |  |  |

| 10 s–1 |  |  |  |  |  |

| DRV | DRX | DRX + DRV | |||

| Deformation Parameter | 280 °C | 340 °C | 400 °C | 460 °C | 520 °C |

|---|---|---|---|---|---|

| 0.01 s–1 | 33.4 | 29.7 | 26.6 | 24.1 | 21.9 |

| 0.1 s–1 | 35.7 | 32.0 | 28.9 | 26.4 | 24.2 |

| 1 s–1 | 38.0 | 34.3 | 31.2 | 28.7 | 26.5 |

| 10 s–1 | 40.3 | 36.6 | 33.5 | 31.0 | 28.8 |

| Deformation Parameter | 280 °C | 340 °C | 400 °C | 460 °C | 520 °C |

|---|---|---|---|---|---|

| 0.01 s–1 | 232.7 | 214.2 | 195.7 | 183.4 | 158.8 |

| 0.1 s–1 | 216.4 | 199.2 | 182.1 | 170.6 | 147.7 |

| 1 s–1 | 200.1 | 184.3 | 168.4 | 157.8 | 136.6 |

| 10 s–1 | 183.9 | 169.3 | 154.7 | 145.0 | 125.5 |

| Deformation Parameter | 280 °C | 340 °C | 400 °C | 460 °C | 520 °C |

|---|---|---|---|---|---|

| 0.01 s–1 | 46.0 | 37.4 | 30.4 | 24.5 | 19.5 |

| 0.1 s–1 | 44.8 | 36.8 | 30.2 | 24.8 | 20.1 |

| 1 s–1 | 43.5 | 36.2 | 30.1 | 25.0 | 20.7 |

| 10 s–1 | 42.3 | 35.5 | 29.9 | 25.3 | 21.3 |

| Deformation Parameter | 280 °C | 340 °C | 400 °C | 460 °C | 520 °C |

|---|---|---|---|---|---|

| 0.01 s–1 | / | / | / | 0.0123 | 0.0087 |

| 0.1 s–1 | / | / | 0.0300 | 0.0164 | 0.0125 |

| 1 s–1 | / | / | 0.0430 | 0.0302 | 0.0223 |

| 10 s–1 | / | 0.0600 | 0.0528 | 0.0380 | 0.0251 |

| Y | E | F | G | H | I | J |

|---|---|---|---|---|---|---|

| 788.26028 | 23.02247 | −1.44929 | −0.01448 | 0.18729 | 0.00069 | |

| 568.86909 | 15.52260 | −1.10668 | −0.01087 | 0.12466 | 0.00056 | |

| 399.36983 | 23.03059 | −1.27480 | −0.03902 | 0.57730 | 0.00105 |

| Y | E | F | G | H | I | J |

|---|---|---|---|---|---|---|

| 879.62333 | 53.84443 | −1.58280 | −0.06159 | 0.21229 | 0.00066 | |

| 1073.28708 | 20.54150 | −2.28161 | −0.01285 | 0.38822 | 0.00126 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Q.; Deng, Y.; Wang, Y.; Huang, W. Dynamic Recrystallization Critical Conditions and a Physically–Based Constitutive Model of Al–4.8Mg Alloy Under Hot Working Conditions. Materials 2020, 13, 4982. https://doi.org/10.3390/ma13214982

Dai Q, Deng Y, Wang Y, Huang W. Dynamic Recrystallization Critical Conditions and a Physically–Based Constitutive Model of Al–4.8Mg Alloy Under Hot Working Conditions. Materials. 2020; 13(21):4982. https://doi.org/10.3390/ma13214982

Chicago/Turabian StyleDai, Qingsong, Yunlai Deng, Yu Wang, and Wenhui Huang. 2020. "Dynamic Recrystallization Critical Conditions and a Physically–Based Constitutive Model of Al–4.8Mg Alloy Under Hot Working Conditions" Materials 13, no. 21: 4982. https://doi.org/10.3390/ma13214982

APA StyleDai, Q., Deng, Y., Wang, Y., & Huang, W. (2020). Dynamic Recrystallization Critical Conditions and a Physically–Based Constitutive Model of Al–4.8Mg Alloy Under Hot Working Conditions. Materials, 13(21), 4982. https://doi.org/10.3390/ma13214982