Densification of Bamboo: State of the Art

Abstract

1. Introduction

2. Densification Concept

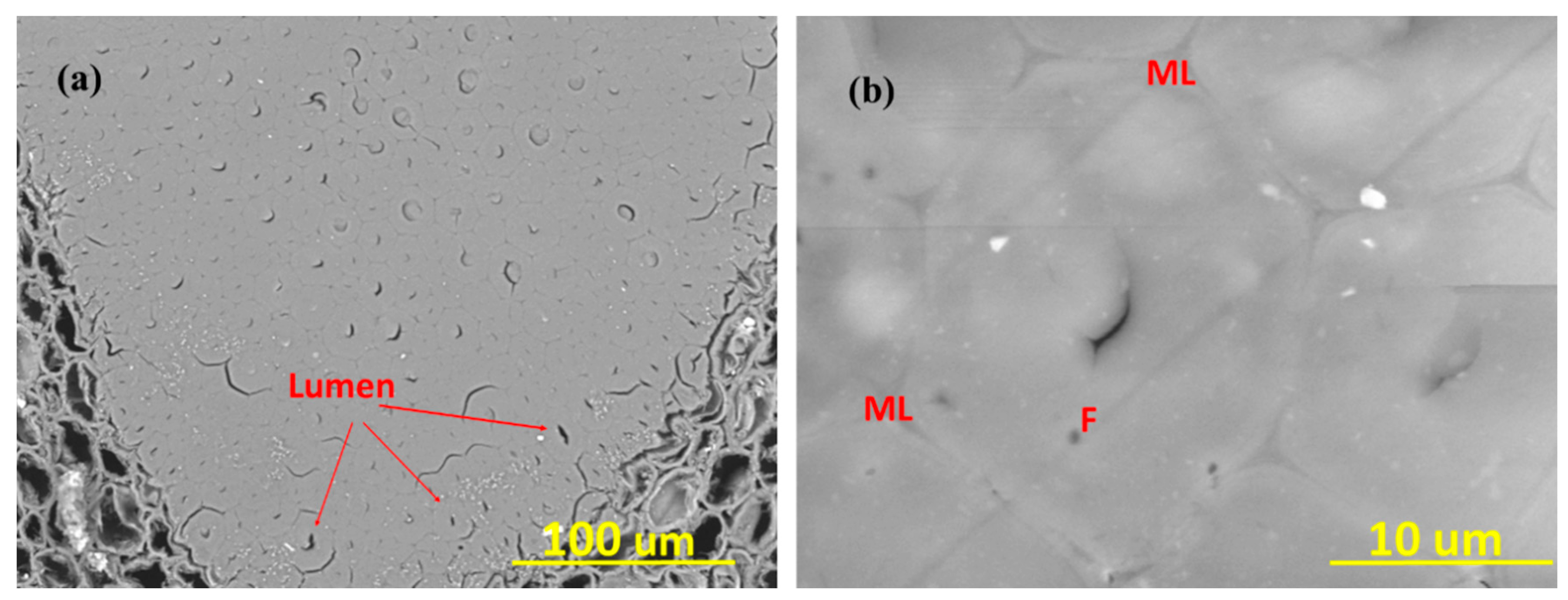

3. Bamboo

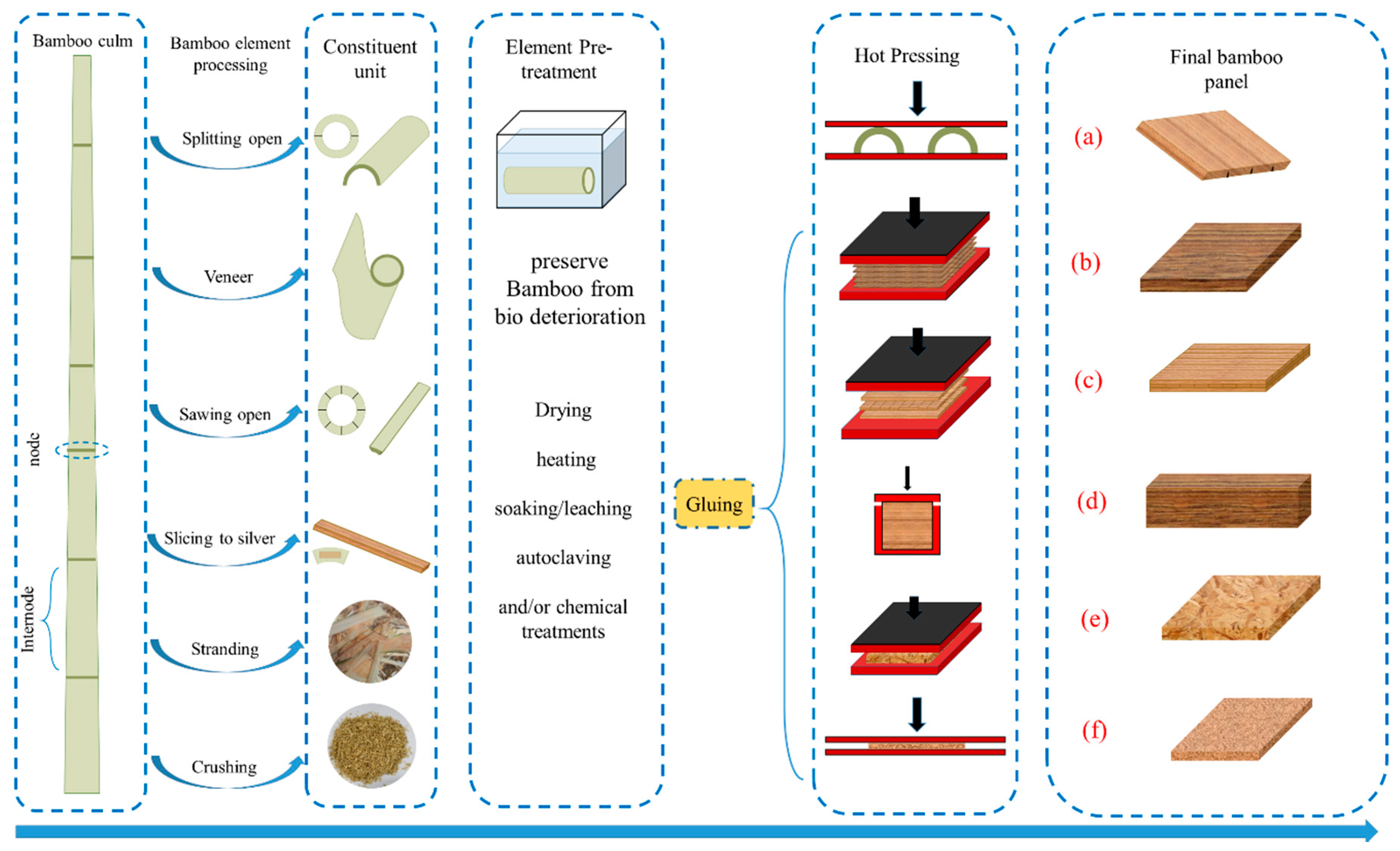

4. Densification in Bamboo-Based Panels

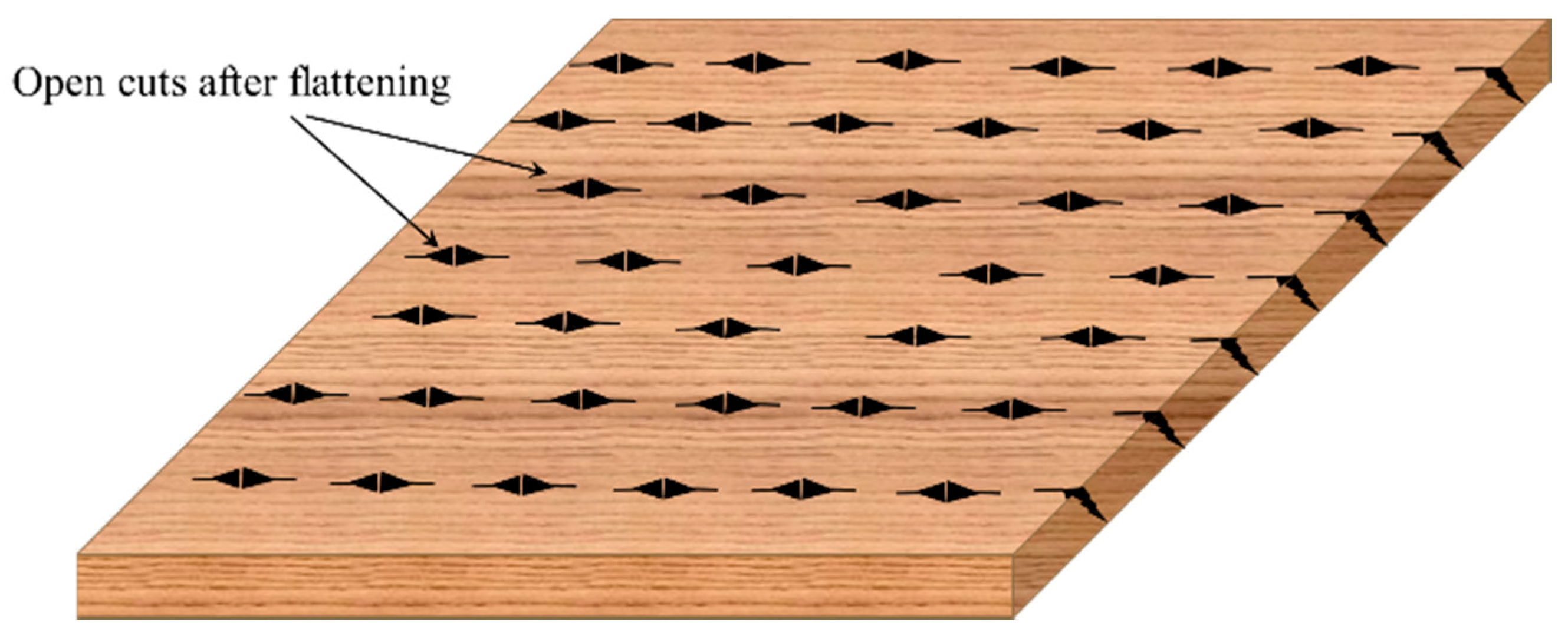

4.1. Densification in Flattened Bamboo Panels

4.2. Densification in BAMBOO Scrimber

5. Densified Bamboo

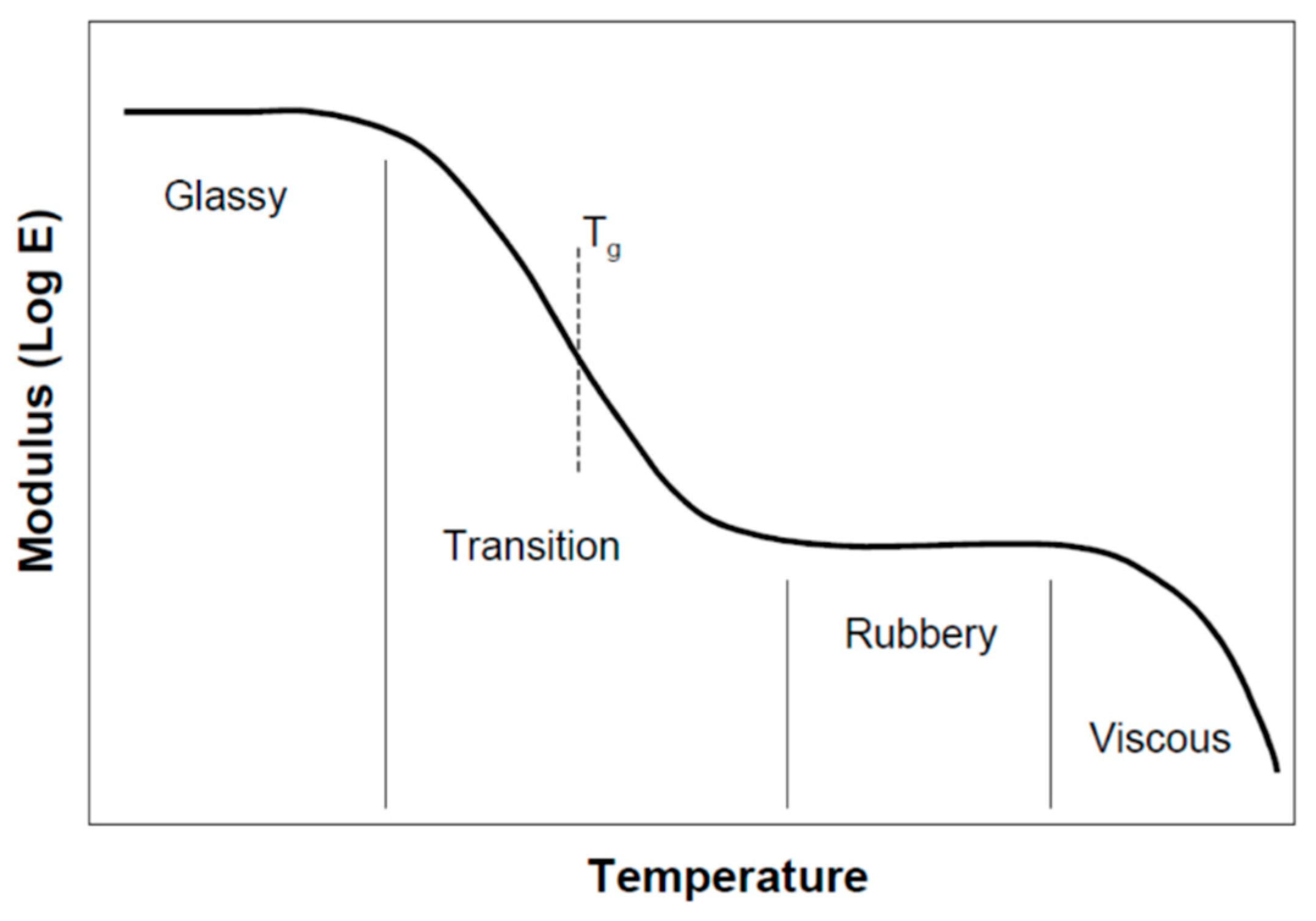

5.1. Softening Behavior of Bamboo

5.2. Densification Methods

5.2.1. Thermo-Mechanical (TM)

5.2.2. Viscoelastic-Thermal-Compression

- Elevating the temperature to exceed its glass transition temperature.

- Causing rapid steam decompression and removal of the bound water in the cell wall.

- Densification by compressing the material perpendicular to the grain.

- Relaxation of the remaining stresses. This step promotes the thermal degradation of the hemicelluloses in the material component.

- Cooling the material by conditioning that to the ambient temperature and humidity.

5.2.3. Mechanisms of Deformation

- Purely mechanical densification, mainly from rearrangement of fiber bundles, brittle crushing, cell wall buckling, and subsequent moisture content drainage during the compaction.

- Materials shrinkage and plastic yielding due to elevated temperature (at a temperature higher than 160 °C, the chemical changes also cause additional deformation).

- Compaction resulting from intercell steam pressure, generally induced by stress and heat, which causes intercell cracks (even in TM method, the moisture content and elevated temperature can generate steam).

6. Mechanical and Physical Performance of Densified Bamboo

7. Discussion of the Effective Parameters

7.1. The Influence of Bamboo Species

7.2. The Influence of Pressing Temperature

7.3. The Influence of Densification Degree

7.4. The Influence of Water and Initial Moisture Content

7.5. The Microstructure of Densified Bamboo

7.6. Best Practices

7.7. Gaps in Knowledge

8. Conclusions and Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Microstructure and mechanical properties of waste fibre-cement composites. Cem. Concr. Compos. 2005, 27, 583–592. [Google Scholar] [CrossRef]

- Vogtländer, J.; Van Der Lugt, P.; Brezet, H. The sustainability of bamboo products for local and Western European applications. LCAs and land-use. J. Clean. Prod. 2010, 18, 1260–1269. [Google Scholar] [CrossRef]

- Yu, D.; Tan, H.; Ruan, Y. A future bamboo-structure residential building prototype in China: Life cycle assessment of energy use and carbon emissi. Energy Build. 2011, 43, 2638–2646. [Google Scholar] [CrossRef]

- Agyekum, E.O.; Fortuin, K.P.J.K.; van der Harst, E. Environmental and social life cycle assessment of bamboo bicycle frames made in Ghana. J. Clean. Prod. 2017, 143, 1069–1080. [Google Scholar]

- Escamilla, E.Z.; Habert, G.; Daza, J.F.C.; Archilla, H.F.; Fernández, J.S.E.; Trujillo, D. Industrial or traditional bamboo construction? Comparative life cycle assessment (LCA) of bamboo-based buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef]

- Van Der Lugt, P.; Brezet, H. Bamboo, a Sustainable Solution for Western Europe Design Cases, LCAs and Land-Use; Centre for Indian Bamboo Resource and Technology: Gujarat, India, 2009; Volume 30, ISBN 9789051550474. [Google Scholar]

- Zea Escamilla, E.; Habert, G. Environmental impacts of bamboo-based construction materials representing global production diversity. J. Clean. Prod. 2014, 69, 117–127. [Google Scholar] [CrossRef]

- Huang, Z.; Sun, Y.; Musso, F. Experimental study on bamboo hygrothermal properties and the impact of bamboo-based panel process. Constr. Build. Mater. 2017, 155, 1112–1125. [Google Scholar] [CrossRef]

- Li, Z.; Yang, G.S.; Zhou, Q.; Shan, B.; Xiao, Y. Bending performance of glubam beams made with different processes. Adv. Struct. Eng. 2019, 22, 535–546. [Google Scholar] [CrossRef]

- Esteves, B.; Ribeiro, F.; Cruz-Lopes, L.; Ferreira, J.; Domingos, I.; Duarte, M.; Duarte, S.; Nunes, L. Densification and heat treatment of maritime pine wood. Wood Res. 2017, 62, 373–388. [Google Scholar]

- Kutnar, A.; Šernek, M. Densification of wood. Zb. Gozdarstva Lesar. 2007, 82, 53–62. [Google Scholar]

- Li, L.; Gong, M.; Yuan, N.; Li, D. An Optimal Thermo-Hydro-Mechanical Densification (THM) Process for Densifying Balsam Fir Wood. BioResources 2013, 8, 3967–3981. [Google Scholar] [CrossRef][Green Version]

- Kúdela, J.; Rousek, R.; Rademacher, P.; Rešetka, M.; Dejmal, A. Influence of pressing parameters on dimensional stability and density of compressed beech wood. Eur. J. Wood Wood Prod. 2018, 76, 1241–1252. [Google Scholar] [CrossRef]

- Kutnar, A.; Sandberg, D.; Haller, P. Compressed and moulded wood from processing to products. Holzforschung 2015, 69, 885–897. [Google Scholar] [CrossRef]

- Gao, L.; Guo, W.; Luo, S. Investigation of changes in compressed moso bamboo (Phyllostachys pubescens) after hot-press molding. J. Wood Sci. 2018, 64, 557–565. [Google Scholar] [CrossRef]

- Dixon, P.G.; Semple, K.E.; Kutnar, A.; Kamke, F.A.; Smith, G.D.; Gibson, L.J. Comparison of the flexural behavior of natural and thermo-hydro-mechanically densified Moso bamboo. Eur. J. Wood Wood Prod. 2016, 74, 633–642. [Google Scholar] [CrossRef]

- Gibson, L.J. Biomechanics of cellular solids. J. Biomech. 2005, 38, 377–399. [Google Scholar] [CrossRef]

- BODIG, J. The effect of anatomy on the initial stress-strain relationship in transverse compression. For. Prod. J. 1965, 15, 197–202. [Google Scholar]

- Kennedy, R.W. Wood in transverse compression. For. Prod. J. 1968, l8, 36–40. [Google Scholar]

- Tabarsa, T. Compression Perpendicular-to-grain Behaviour of Wood. Ph.D. Thesis, The University of New Brunswick, Fredericton, NB, Canada, 1999. [Google Scholar]

- Gibson, L.J.; Ashby, M. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Wolcott, M.P. Formulation and process development of flat-pressed wood-polyethylene composites. For. Prod. J. 2003, 53, 25–32. [Google Scholar]

- Shangguan, W.; Gong, Y.; Zhao, R.; Ren, H. Efects of heat treatment on the properties of bamboo scrimber. J. Wood Sci. 2016, 62, 383–391. [Google Scholar]

- Zhao, J.-B.; Meng, Z.-X.; Jin, Z.; Chen, N.; Wu, Y.-S.; Zhang, W. Bending properties of bamboo scrimber with holes in different sizes and positions. Constr. Build. Mater. 2019, 200, 209–217. [Google Scholar] [CrossRef]

- Huang, Y.; Ji, Y.; Yu, W. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65, 25. [Google Scholar] [CrossRef]

- Zhong, W.; Rusinek, A.; Jankowiak, T.; Huang, X.; Abed, F. Experimental and numerical investigation on compression orthotropic properties of spruce wood in axial and transverse loading directions. Eng. Trans. 2014, 62, 381–401. [Google Scholar]

- Qisheng, Z.; Shenxue, J.; Yongyu, T. Industrial Utilization on Bamboo; International Network for Bamboo and Rattan: Beijing, China, 2002. [Google Scholar]

- Liese, W. The Anatomy of Bamboo Culms; Brill Publishers: Brill, UK, 1998; Volume 18. [Google Scholar]

- Chaowana, P.; Barbu, M.C. Bamboo: Potential Material for Biocomposites; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 9780081009666. [Google Scholar]

- Akinbade, Y.; Harries, K.A.; Flower, C.V.; Nettleship, I.; Papadopoulos, C.; Platt, S. Through-culm wall mechanical behaviour of bamboo. Constr. Build. Mater. 2019, 216, 485–495. [Google Scholar] [CrossRef]

- Li, S.H.; Fu, S.Y.; Zhou, B.L.; Zeng, Q.Y.; Bao, X.R. Reformed bamboo and reformed bamboo/aluminium composite—Part I Manufacturing technique, structure and static properties. J. Mater. Sci. 1994, 29, 5990–5996. [Google Scholar] [CrossRef]

- Ray, A.K.; Mondal, S.; Das, S.K.; Ramachandrarao, P. Bamboo—A functionally graded composite-correlation between microstructure and mechanical strength. J. Mater. Sci. 2005, 40, 5249–5253. [Google Scholar] [CrossRef]

- Chaowana, P.; Barbu, M.C.; Frühwald, A. Bamboo—A functionally graded composite material. For. Prod. J. 2015, 65, S48–S53. [Google Scholar]

- Osorio, L.; Trujillo, E.; Lens, F.; Ivens, J.; Verpoest, I.; Van Vuure, A. In-depth study of the microstructure of bamboo fibres and their relation to the mechanical properties. Reinf. Plast. Compos. 2018, 37, 1099–1113. [Google Scholar] [CrossRef]

- Liese, W.; Kohl, M. Bamboo, the Plant and Its Uses; Springer: Berlin/Heidelberg, Germany, 1980; ISBN 9783319141329. [Google Scholar]

- Goh, Y.; Yap, S.P.; Tong, T.Y. Bamboo: The Emerging Renewable Material for Sustainable Construction; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; ISBN 9780128035818. [Google Scholar]

- Dixon, P.G.; Gibson, L.J. The structure and mechanics of Moso bamboo material. J. R. Soc. Interface 2014, 11, 20140321. [Google Scholar] [CrossRef]

- NFU. LY/T 1660-2006 Standard Terminology for Bamboo-Based Panels; Nanjing Forestry University, Standards Press China: Beijing, China, 2006. [Google Scholar]

- Liu, X.; Smith, G.D.; Jiang, Z.; Bock, M.C.D.; Boeck, F.; Frith, O.; Gatóo, A.; Liu, K.; Mulligan, H.; Semple, K.E.; et al. Engineered bamboo nomenclature. BioResources 2016, 11, 1141–1161. [Google Scholar] [CrossRef]

- Huang, Z. Application of Bamboo in Building Envelope. In Sustainable Development for Energy, Power, and Propulsion; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Fang, C.H.; Jiang, Z.H.; Sun, Z.J.; Liu, H.R.; Zhang, X.B.; Zhang, R.; Fei, B.H. An overview on bamboo culm flattening. Constr. Build. Mater. 2018, 171, 65–74. [Google Scholar] [CrossRef]

- Mahdavi, M.; Clouston, P.L.; Asce, A.M.; Arwade, S.R.; Asce, A.M. Development of Laminated Bamboo Lumber: Review of Processing, Performance, and Economical Considerations. J. Mater. Civ. Eng. 2011, 23, 1036–1042. [Google Scholar] [CrossRef]

- Anwar, U.; Hiziroglu, S.; Hamdan, H.; Latif, M.A. Effect of outdoor exposure on some properties of resin-treated plybamboo. Crop Prod. 2011, 33, 140–145. [Google Scholar] [CrossRef]

- Qisheng, Z.; Shenxue, J.; Hai, L.; Xufeng, X.; Hongzheng, L.; Bin, X.; Wen, H. A Recombined Bamboo Section Material and its Manufacturing Method. European Paten EP 2269788 B1, 18 February 2015. [Google Scholar]

- Biswas, D.; Bose, S.K.; Hossain, M.M. Physical and mechanical properties of urea formaldehyde-bonded particleboard made from bamboo waste. Int. J. Adhes. Adhes 2011, 31, 84–87. [Google Scholar] [CrossRef]

- Gauss, C.; De Araujo, V.; Gava, M.; Cortez-Barbosa, J.; Savastano Junior, H. Bamboo particleboards: Recent developments. Pesquisa Agropecuária Tropical 2019, 49, e55081. [Google Scholar] [CrossRef]

- Malanit, P.; Barbu, M.C.; Frühwald, A. Physical and mechanical properties of oriented strand lumber made from an Asian bamboo (Dendrocalamus asper Backer). Eur. J. Wood Wood Prod. 2011, 69, 27–36. [Google Scholar] [CrossRef]

- Tianxiang, Q. Oriented Structure Plate of Antiskid Filmed Bamboo Strip and Bamboo-Wood Strips. CN 201154506 Y, 26 November 2008. [Google Scholar]

- SUMARDI, I.; ONO, K.; SUZUKI, S. Effect of board density and layer structure on the mechanical properties of bamboo oriented strandboard. J. Wood Sci. 2007, 53, 510–515. [Google Scholar] [CrossRef]

- Liese, W.; Tang, T.K.H. Preservation and Drying of Bamboo. In Bamboo: The Plant and Its Uses; Liese, W., Köhl, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 257–297. ISBN 9783319141329. [Google Scholar]

- Available online: http://www.ecosmartworks.com/bamboo-material/bamboo-veneer/ (accessed on 23 August 2020).

- ZAFU. LY/T 2222-2013 Sliced Bamboo Veneers; Zhejiang Agriculture and Forestry University: Zhejiang, China; Standards Press China: Beijing, China, 2014. [Google Scholar]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- CAF. GB/T 265365-2011 Bamboo Strip, Chinese Academy of Forestry; Research Insititute of Wood Industry, Standards Press China: Beijing, China, 2011. [Google Scholar]

- Hidalgo-López, O. Bamboo the Gift of the Gods; D’Vinni Ltda: Bogotá, Colômbia, 2003. [Google Scholar]

- Chen, G.; Luo, H.; Wu, S.; Guan, J.; Luo, J.; Zhao, T. Flexural deformation and fracture behaviors of bamboo with gradient hierarchical fibrous structure and water content. Compos. Sci. Technol. 2018, 157, 126–133. [Google Scholar] [CrossRef]

- Widyorini, R.; Puspa Yudha, A.; Isnan, R.; Awaluddin, A.; Agus Prayitno, T.; Ngadianto, A.; Umemura, K. Improving the Physico-Mechanical Properties of Eco-Friendly Composite Made from Bamboo. Adv. Mater. Res. 2014, 896, 562–565. [Google Scholar] [CrossRef]

- Zaia, U.J.; Cortez-Barbosa, J.; Morales, U.J.; ZAIA, E.A.M.; Lahr, F.A.R.; Nascimento, M.F.D.; Araujo, V.A.D. Production of particleboards with bamboo (Dendrocalamus giganteus) reinforcement. BioResources 2015, 10, 1424–1433. [Google Scholar] [CrossRef]

- Zeng, Q.; Tang, Z.; Li, S.; Zhou, B. Investigation of the Impact Toughness of Normal Bamboo, Reformed Bamboo and Reformed Bamboo Composites. Sci. Eng. Compos. Mater. 1995, 4, 255–260. [Google Scholar] [CrossRef]

- Li, Z.; Liu, C.-P.; Yu, T. Laminate of Reformed Bamboo and Extruded Fiber-Reinforced Cementitious Plate. J. Mater. Civ. Eng. 2002, 14, 359–365. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.; Chrusciel, L.; Na, B.; Lu, X. Study on a bamboo stressed flattening process. Eur. J. Wood Wood Prod. 2013, 71, 291–296. [Google Scholar] [CrossRef]

- Park, C.N. Flattening of Bamboo by Thermo mechanical Treatment. In Proceedings of the 10th World Bamboo Congress, Chonnam, Korea, 17–22 September 2015. [Google Scholar]

- Zhang, X.; Zhou, Z.; Zhu, Y.; Dai, J.; Yu, Y.; Song, P. High-pressure steam: A facile strategy for the scalable fabrication of flattened bamboo biomass. Ind. Crops Prod. 2019, 129, 97–104. [Google Scholar] [CrossRef]

- Archila-Santos, H.F.; Ansell, M.P.; Walker, P. Elastic Properties of Thermo-Hydro-Mechanically Modified Bamboo (Guadua angustifolia Kunth) Measured in Tension. Key Eng. Mater. 2014, 600, 111–120. [Google Scholar] [CrossRef]

- Kadivar, M.; Gauss, C.; Mármol, G.; de Sá, A.D.; Fioroni, C.; Ghavami, K.; Savastano, H. The influence of the initial moisture content on densification process of D. asper bamboo: Physical-chemical and bending characterization. Constr. Build. Mater. 2019, 229, 116896. [Google Scholar] [CrossRef]

- Chen, F.; Deng, J.; Cheng, H.; Li, H.; Jiang, Z.; Wang, G.; Zhao, Q.; Shi, S.Q. Impact properties of bamboo bundle laminated veneer lumber by preprocessing densification technology. J. Wood Sci. 2014, 60, 421–427. [Google Scholar] [CrossRef]

- Takagi, H.; Mizobuchi, A.; Kusano, K.; Okitsu, Y. Flexural properties of all bamboo green composites. WIT Trans. Built Environ. 2008, 97, 167–173. [Google Scholar]

- Tanaka, K.; Inoue, M.; Fujihara, H.; Adachi, H.; Goto, Y. Development of bamboo connector strengthened by densified technique. In Proceedings of the 9th World Conference on Timber Engineering, Portland, OR, USA, 6–10 August 2006; Volume 2, pp. 976–983. [Google Scholar]

- Maori, K.J.M. (Hyogo-ken. Industrial Research Inst., Process of flattening bamboo pieces utilizing microwave heating. Mokuzai Gakkai Shi. 1987, 33, 630–636. [Google Scholar]

- Qisheng, F.U.N.Z. Studies of bamboo plywood I. The softening and flattening of bamboo. J. Nanjing For. Univ. Sci. Ed. 1988, 4, 15–22. [Google Scholar]

- Parkkeeree, T.; Matan, N.; Kyokong, B. Mechanisms of bamboo flattening in hot linseed oil. Eur. J. Wood Wood Prod. 2015, 73, 209–217. [Google Scholar] [CrossRef]

- Sarula, Nakamura, S.; Yoshitani, K.; Tanahashi, M. Development of novel flattening method for bamboo cane by the high-pressure steam processing. Mokuzai Gakkai Shi 2012, 58, 193–200. [Google Scholar] [CrossRef]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J.; Hajek, P. Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Sharma, B.; Gatoo, A.; Bock, M.; Mulligan, H.; Ramage, M. Engineered bamboo: State of the art. Proc. Inst. Civ. Eng. Constr. Mater. 2015, 168, 57–67. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Zhu, R.; Zhang, Y.; Yu, W. Outdoor exposure tests of bamboo-fber reinforced composite: Evaluation of the physical and mechanical properties afer two years. Eur. J. Wood Wood Prod. 2015, 73, 275–278. [Google Scholar] [CrossRef]

- Kim, Y.; Roh, J.; Park, S. Effect of Zephyr Producing Method on Properties of Bamboo Zephyr Boards. J. Korean Wood Sci. Technol. 2003, 31, 24–30. [Google Scholar]

- Li, J.; Chen, Y.; Xu, J.; Ren, D.; Yu, H.; Guo, F.; Wu, Z. The Influence of Media Treatments on Color Changes, Dimensional Stability, and Cracking Behavior of Bamboo Scrimber. Int. J. Polym. Sci. 2018, 2018, 1–7. [Google Scholar] [CrossRef]

- Xie, J.Q.J.; Hu, T.; de Hoop, C.F.; Hse, C.Y.; Shupe, T. Efect of fabricated density and bamboo species on physical–mechanical properties of bamboo fber bundle reinforced composites. J. Mater. Sci. 2016, 51, 7480–7490. [Google Scholar] [CrossRef]

- Rao, F.; Chen, Y.; Li, N.; Zhao, X.; Bao, Y.; Wu, Z.; Ren, D.; Xu, J.; Cai, H. Preparation and characterization of outdoor bamboo-fiber-reinforced composites with different densities. BioResources 2017, 12, 6789–6811. [Google Scholar]

- Amada, S. and Lakes, R.S. Viscoelastic properties of bamboo. J. Mater. Sci. 1997, 32, 2693–2697. [Google Scholar] [CrossRef]

- Matan, N.; Kyokong, B.; Preechatiwong, W. Softening Behavior of Black Sweet-Bamboo (Dendrocalamus asper Backer) at Various Initial Moisture Contents. Walailak J. Sci. Tech. 2007, 4, 225–236. [Google Scholar]

- Glasser, W.G.; Rials, T.G.; Kelly, S.S.V. Dave Studies of the molecular interaction between cellulose and lignin as a model for the hierarchical structure of wood. Am. Chem. Soc. 1998, 19, 265–282. [Google Scholar]

- Wolcott, M.P.; Kamke, F.A.; Dillard, D.A. Fundamentals of flake board manufacture: Viscoelastic behavior of the wood component. Wood Fiber Sci. 1990, 26, 345–361. [Google Scholar]

- Skyba, O. Durability and Physical Properties of Thermo-Hygro-Mechanically (Thm)-Densified Wood; ETH ZURICH: Zürich, Switzerland, 2008. [Google Scholar]

- Zhan, J.C.T.; Lu, J.; Zhang, H.; Jiang, J.; Peng, H. Changes of time dependent viscoelasticity of Chinese fir wood and its frequency-dependency during moisture desorption processes. Sci. Silvae Sin. 2017, 53, 155–162. [Google Scholar]

- Wang, J.; Wang, X.; Zhan, T.; Zhang, Y.; Lv, C.; He, Q.; Fang, L.; Lu, X. Preparation of hydro-thermal surface-densified plywood inspired by the stiffness difference in “sandwich structure” of wood. Constr. Build. Mater. 2018, 177, 83–90. [Google Scholar] [CrossRef]

- Lenth, C.A. Wood Material Behavior in Severe Environments; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 1999. [Google Scholar]

- Boonstra, M.J.; Blomberg, J. Semi-isostatic densification of heat-treated radiata pine. Wood Sci. Technol. 2007, 41, 607–617. [Google Scholar] [CrossRef]

- Ulker, O.; Imirzi, O.; Burdurlu, E. The Effect of Densification Temperature on Some. BioResources 2012, 7, 5581–5592. [Google Scholar]

- Kadivar, M.; Gauss, C.; Charca, S.; Ghavami, K.; Savastano, H. Physical Properties of Thermo-Hydro-Mechanically (Thm) Flattened and Densified Bamboo (Moso and Dendrocalamus Asper). In Proceedings of the XVIII Brazil MRS Meeting—Proceedings, Balneário Camboriú, SC, Brazil, 22–26 September 2019; ISBN 978-85-63273-40-6. [Google Scholar]

- Takao, F. JP2008173925A. 2008. Available online: https://patents.google.com/patent/JP2008173925A/en?oq=JP2008173925A (accessed on 23 August 2020).

- Fang, C.; Alan, K.; Jiang, Z.; Fei, B.; Sun, Z. CN106881755B: Hot Binding Steam Spraying Method Compacted Wood/Bamboo Wood Method and Compacted Wood/Bamboo Wood. Available online: https://patents.google.com/patent/CN106881755A/en?oq=CN106881755A (accessed on 23 June 2017).

- Semple, G.D.S.K.E.; Kamke, F.A.; Kutnar, A. Exploratory Thermal-Hydro-Mechanical Modification (THM) of Moso Bamboo (Phyllostachys pubescens Mazel). In Proceedings of the International workshop in Slovenia on Characterization of Modified Wood in Relation To Wood Bonding and Coating Performance, Rogla, Slovenia, 16–18 October 2013; pp. 220–227. [Google Scholar]

- Jis, Z. 2101 General Rules For Testing Wood; Japanese Standard Association: Tokyo, Japan, 1994. [Google Scholar]

- American Society for Testing and Materials International. ASTM D1037-06a. Standard Test Method for Evaluating Properties of Wood-?-Base Fiber and Particle Panel Materials; American Society for Testing and Materials International: West Conshohocken, PA, USA, 2006; p. 30. [Google Scholar]

- ISO-International Organization. ISO 22157-1:2004, Bamboo—Determination of Physical and Mechanical Properties—Part 1: Requirements; ISO-International Organization: Geneva, Switzerland, 2008. [Google Scholar]

- ISO-International Organization. Standardization ISO/TR 22157-2:2004, Bamboo—Determination of Physical and Mechanical Properties—Part 2: Laboratory Manual; ISO-International Organization: Geneva, Switzerland, 2009. [Google Scholar]

- American Society for Testing and Materials International. ASTM, D7264-15, Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials; American Society for Testing and Materials International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Heger, F.; Groux, M.; Girardet, F.; Welzbacher, C.; Rapp, A.O.; Navi, P. Mechanical and durability performance of THM-densified wood. In Proceedings of the Environmental Optimization of Wood Protection, Lisboa, Portugal, 22–23 March 2004. [Google Scholar]

- Seborg, R.M.; Millett, M.A.; Stamm, A.J. Heat-Stabilized Compressed Wood (Staypak). Mech. Eng. 1945, 67, 25–31. [Google Scholar]

- Tabarsa, T.; Chui, Y. Effects of hot-pressing on properties of white spruce. For. Prod. J. 1997, 47, 71. [Google Scholar]

- Gong, M.; Lamason, C. Improvement of Surface Properties of Low Density Wood: Mechanical Modification with Heat Treatment; University of New Brunswick: Fredericton, NB, Canada, 2007. [Google Scholar]

- Dubey, M.K. Improvements in Statility, Durability and Mechanical Properties of Radiata Pine Wood After Heat-Treatment in a Vegetable Oil. Ph.D.Thesis, Universidade de Canterbury, Christchurch, New Zealand, 2010. [Google Scholar]

- Şenol, S.; Budakçi, M. Mechanical Wood Modification Methods. Mugla J. Sci. Technol. 2016, 2, 53–59. [Google Scholar] [CrossRef][Green Version]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. IForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Lenth, C.A.; Kamke, F.A. Moisture dependent softening behavior of wood. Wood Fiber Sci. 2001, 33, 492–507. [Google Scholar]

- Yu, Y.; Zhang, F.; Zhu, S.; Li, H. Effects of high-pressure treatment on poplar wood: Density profile, mechanical properties, strength potential index, and microstructure. BioResources 2017, 12, 6283–6297. [Google Scholar] [CrossRef]

| Bamboo Element | Production Method | Size Range (mm) | Description | References |

|---|---|---|---|---|

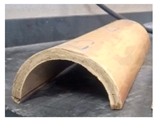

Half-split Culm (Half-Round Bamboo) | Dividing a culm into two equal splits and removing the nodes. | The size of half-split culm depends on the original culm dimension | It has been used for a variety of traditional applications such as roof tiles and drainage ducts. | [41,50] |

Bamboo Veneer [51] | Rotary cutting of bamboo culms | T = 0.15–1.5 W = varied L = varied | A sheet-like folio which has the biggest bamboo industrial element size. | [39,50,51,52] |

Bamboo Strip | Cutting bamboo culm in longitudinal direction or by flattening half splits | T = 3–10 W = 15–25 L = varied | It is a long, thin piece of culm with uniform thickness and width. | [39,41,53,54] |

Bamboo Sliver | Cutting processSlicing to sliver | T = 0.5–3.5 W = 10–30 L = varied | Are also long bamboo elements consisting of flat surfaces, thinner than strips. | [27,29] |

Bamboo Strands | Produced by disk flaker | T: 0.3–0.8 W: 5–20 L: 50–90 | Are consisted of flat, long bundles of fibers having parallel surfaces and short slivers of bamboo. | [29,39,47,49,55,56] |

Bamboo Particles | Milling | T: 0.1–0.5 W: 1–5 L: 20–30 | [39,57,58] |

| Ref. | Bamboo Species | Size of Samples (mm) | Temperature (°C) | Pressing Time (min) | Method of Press | Pressure MPa | Densification Degree (DD) (%) |

|---|---|---|---|---|---|---|---|

| [68] | Phyllostachys edulis | I + M + O | 120 | - | Thermo-hydro-mechanical (THM) | 8 | - |

| P. bambusoides | I + M + O | ||||||

| [67] | P. bambusoides | 10 × 200 I + M + O | 25–220 | 10 | Thermo-mechanical (TM) | 50 | - |

| [94] | P. edulis | 5 × 20 × 150 M + I | 170 | 13.3 | Viscoelastic-thermal-compression (VTC) (steam pressure 775 kPa) | 20–67 | |

| [64] | Guadua angustifolia | M | 150 | 20 | TM | 6.2 | 42.51 |

| [16] | P. edulis | 90 ×20 × (3–5) | 170 | 13.3 | VTC (steam pressure 775 kPa) | - | 50 |

| [65] | Dendrocalamus asper | I+M+O | 140 | 20 | TM | 4.34 | 31.2 |

| Reference | Variable | Standard Method or Specimen Dimension | Apparent Density (kg/m−3) | Moisture Content (MC) (%) | Modulus of Elasticity (MOE) (GPa) | Ultimate Stress (MPa) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | Before | After | |||

| [68] | P. edulis | JIS Z2101. (1994) [95] | 680 | 1334 | 8.5–36.5 | - | 12.0 (T) | 32.0 (T) | 80 (T) | 310 (T) |

| P. bambusoides | 600 | 1100 | - | 8.5 (T) | 19.0 (T) | 170 (T) | 220 (T) | |||

| [67] (P. bambusoides) | 25 °C | (10 × 100 × (3–5)) mm | 714 | 1000 | 5 ± 3 | - | 6 (B) | 8.5 (B) | 117 (B) | 160 (B) |

| 160 °C | 1280 | 20.0 (B) | 320 (B) | |||||||

| 220 °C | 1380 | 27.0 (B) | 190 (B) | |||||||

| [94] (P. edulis) | 80% C. R | ASTM D1037-06a (2006) [96] | 653.9 | 780 | 9 | 6.8 | 8.21 (B) | 10.5 (B) | 109 (B) | 147 (B) |

| 66% C. R | 885 | 6.7 | 10.5 (B) | 160 (B) | ||||||

| 50% C. R | 1079 | 7.7 | 11.9 (B) | 187 (B) | ||||||

| 33% C. R | 1261 | 7.7 | 13.6 (B) | 219 (B) | ||||||

| [64] (G. angustifolia) | dry | ISO 22157 (2004) [97,98] | 540 (Oven dried) | 810 (OD) | - | - | 16.2 (T) | 22.8 (T) | - | - |

| Pre-soaked | 830 (OD) | - | - | 31.0 (T) | - | |||||

| [16] (P. edulis) | - | 70 × 5 × (1–3) mm | 450 to 600 | 800 to 1200 | 7 | 5 | 2.5–12.1 (B) | 5.4–23.0 (B) | 47–140 (B) | 74–296 (B) |

| [65] (D.Asper) | 0% MC | ASTM D7264—15 (2015) [99] | 790 | 890 | 0 | - | 19.6 (B) | 23.0 (B) | 203 (B) | 233 (B) |

| 5% MC | 1000 | 5 | 27.1 (B) | 308 (B) | ||||||

| 10% MC | 1020 | 10 | 27.8 (B) | 318 (B) | ||||||

| 20% MC | 1010 | 20 | 25.9 (B) | 272 (B) | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kadivar, M.; Gauss, C.; Ghavami, K.; Savastano, H., Jr. Densification of Bamboo: State of the Art. Materials 2020, 13, 4346. https://doi.org/10.3390/ma13194346

Kadivar M, Gauss C, Ghavami K, Savastano H Jr. Densification of Bamboo: State of the Art. Materials. 2020; 13(19):4346. https://doi.org/10.3390/ma13194346

Chicago/Turabian StyleKadivar, Marzieh, Christian Gauss, Khosrow Ghavami, and Holmer Savastano, Jr. 2020. "Densification of Bamboo: State of the Art" Materials 13, no. 19: 4346. https://doi.org/10.3390/ma13194346

APA StyleKadivar, M., Gauss, C., Ghavami, K., & Savastano, H., Jr. (2020). Densification of Bamboo: State of the Art. Materials, 13(19), 4346. https://doi.org/10.3390/ma13194346