The Study on the Whole Stress–Strain Curves of Coral Fly Ash-Slag Alkali-Activated Concrete under Uniaxial Compression

Abstract

1. Introduction

2. Experimental Program

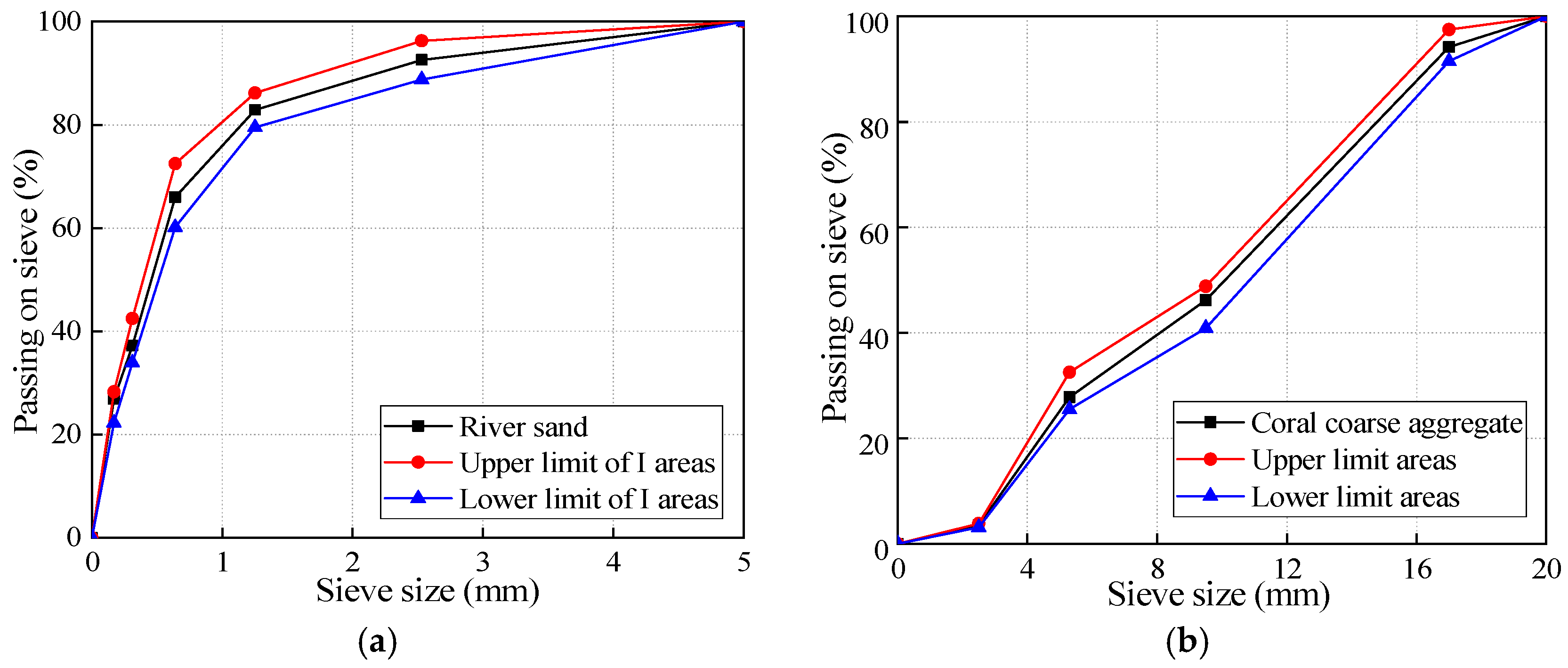

2.1. Materials

2.2. Mixture Proportions and Specimen Preparation

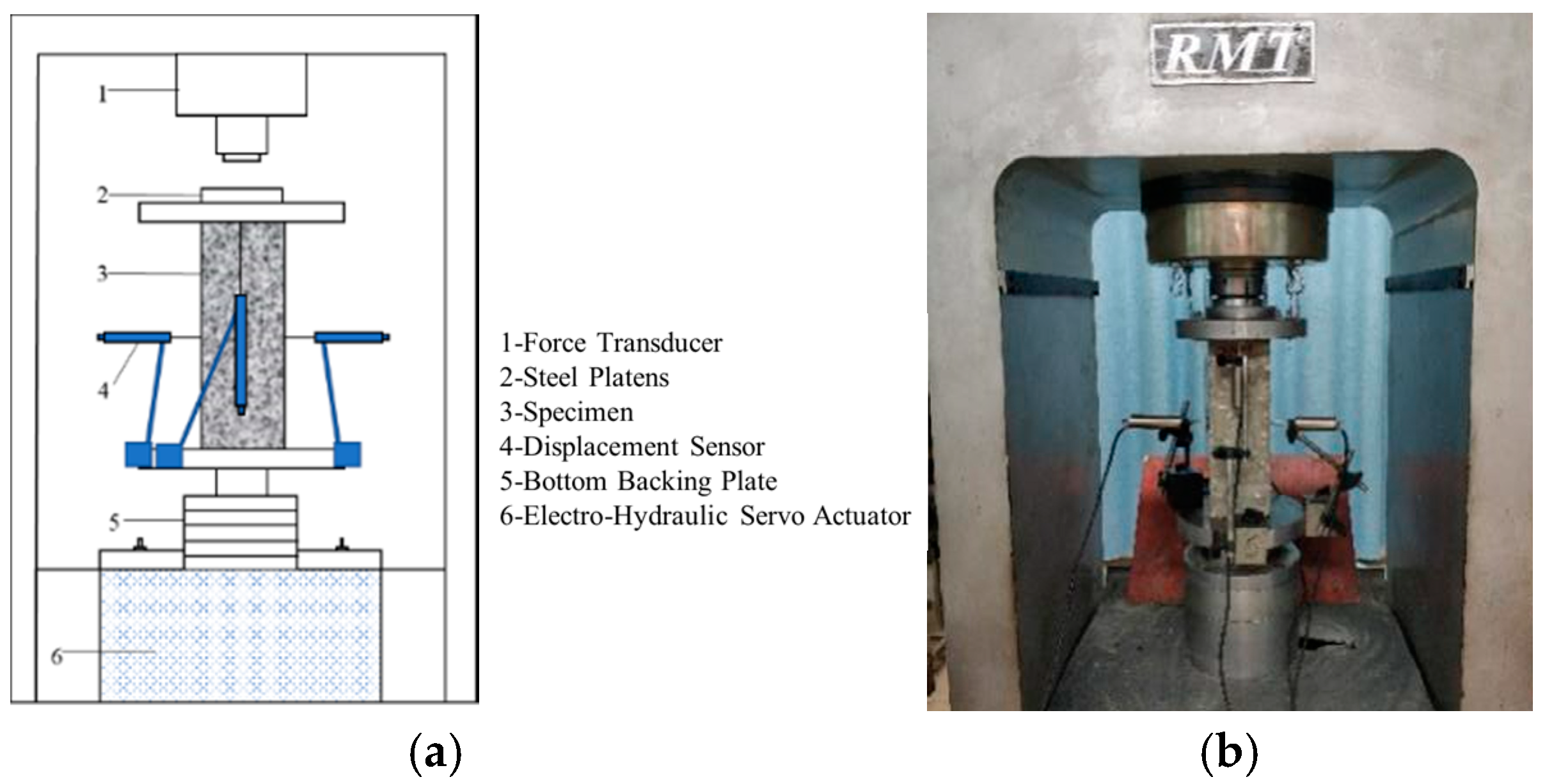

2.3. Test Methods

2.4. Elastic Modulus and Poisson’s Ratio

3. Test Results and Discussion

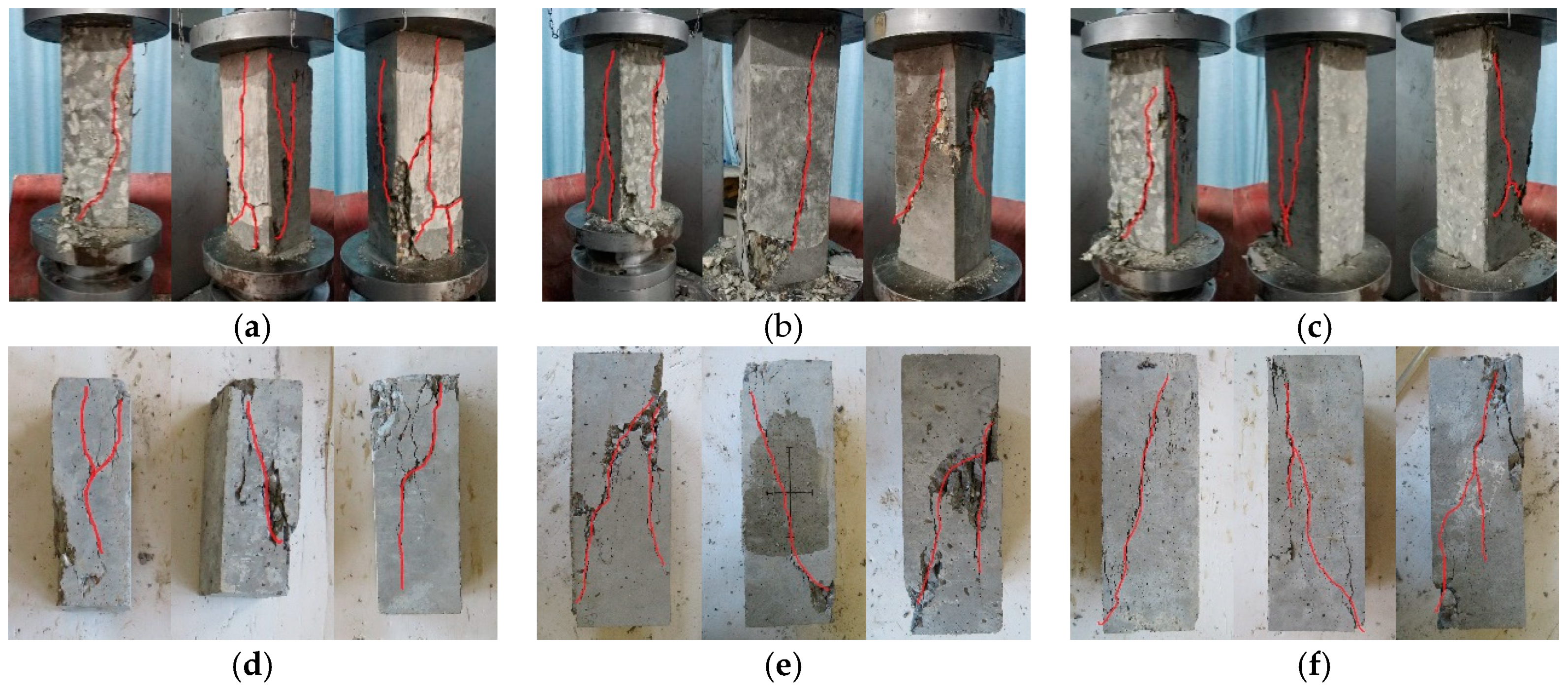

3.1. Compressive Failure Mode

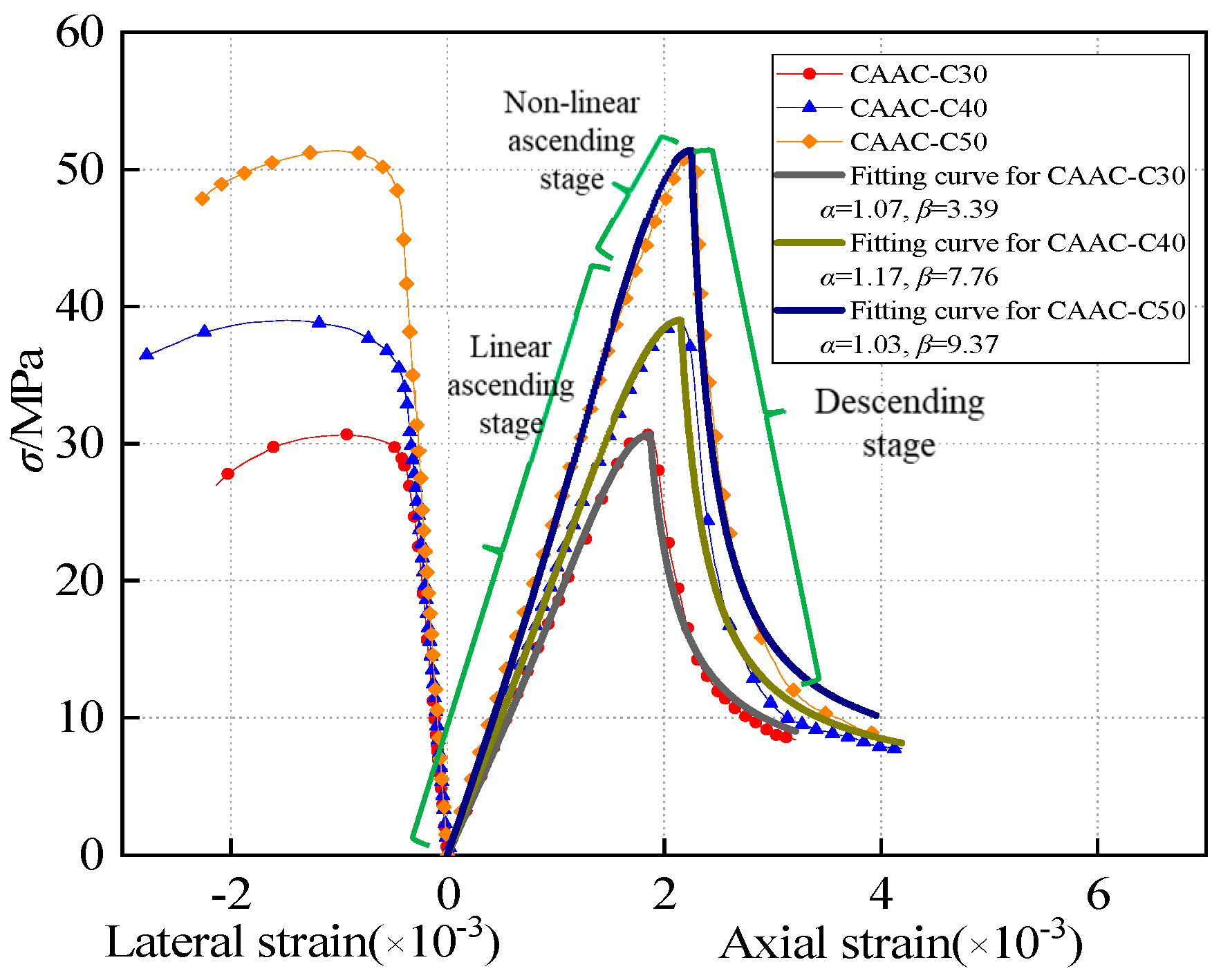

3.2. Measured Stress–Strain Curve

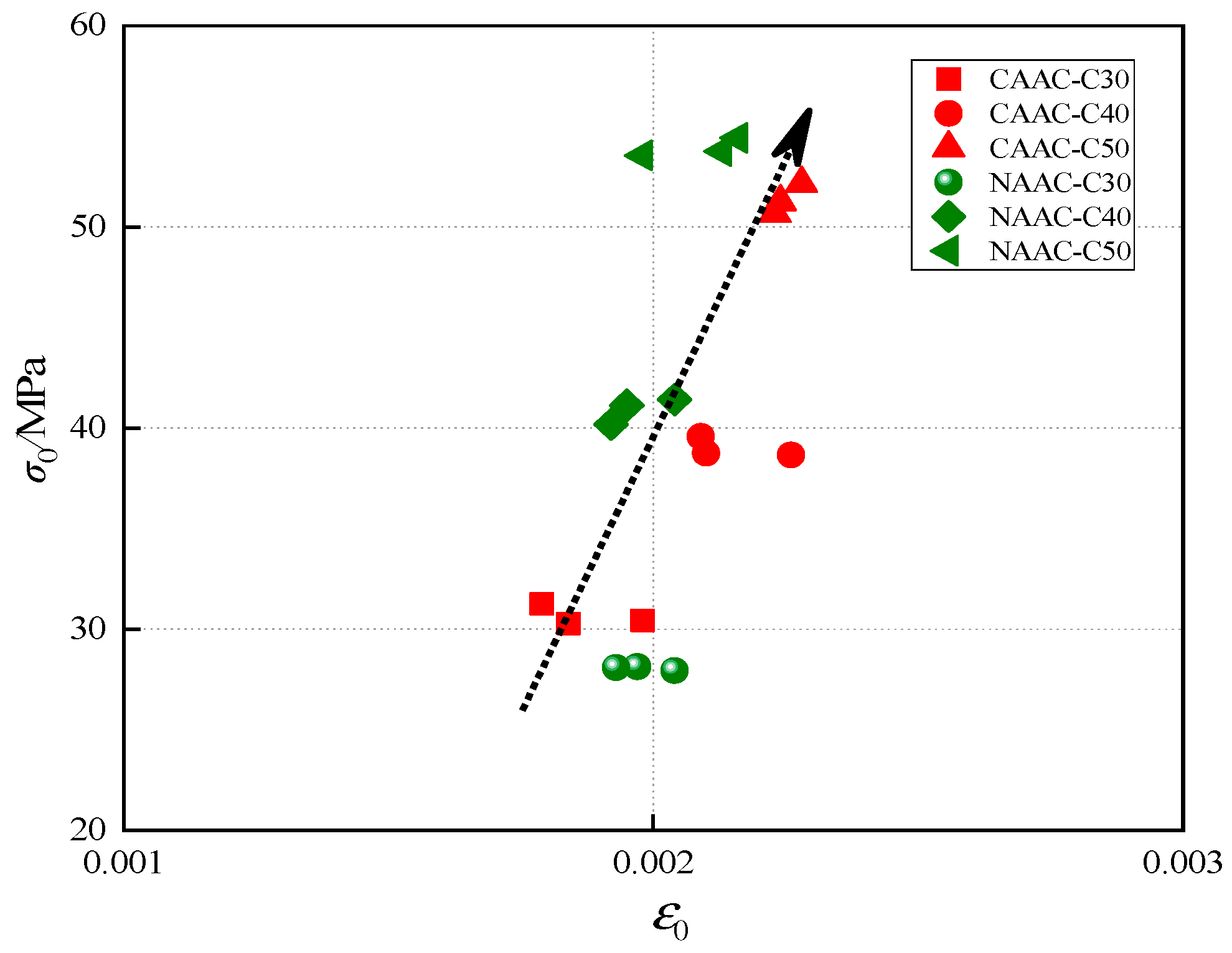

3.3. Mechanical Properties

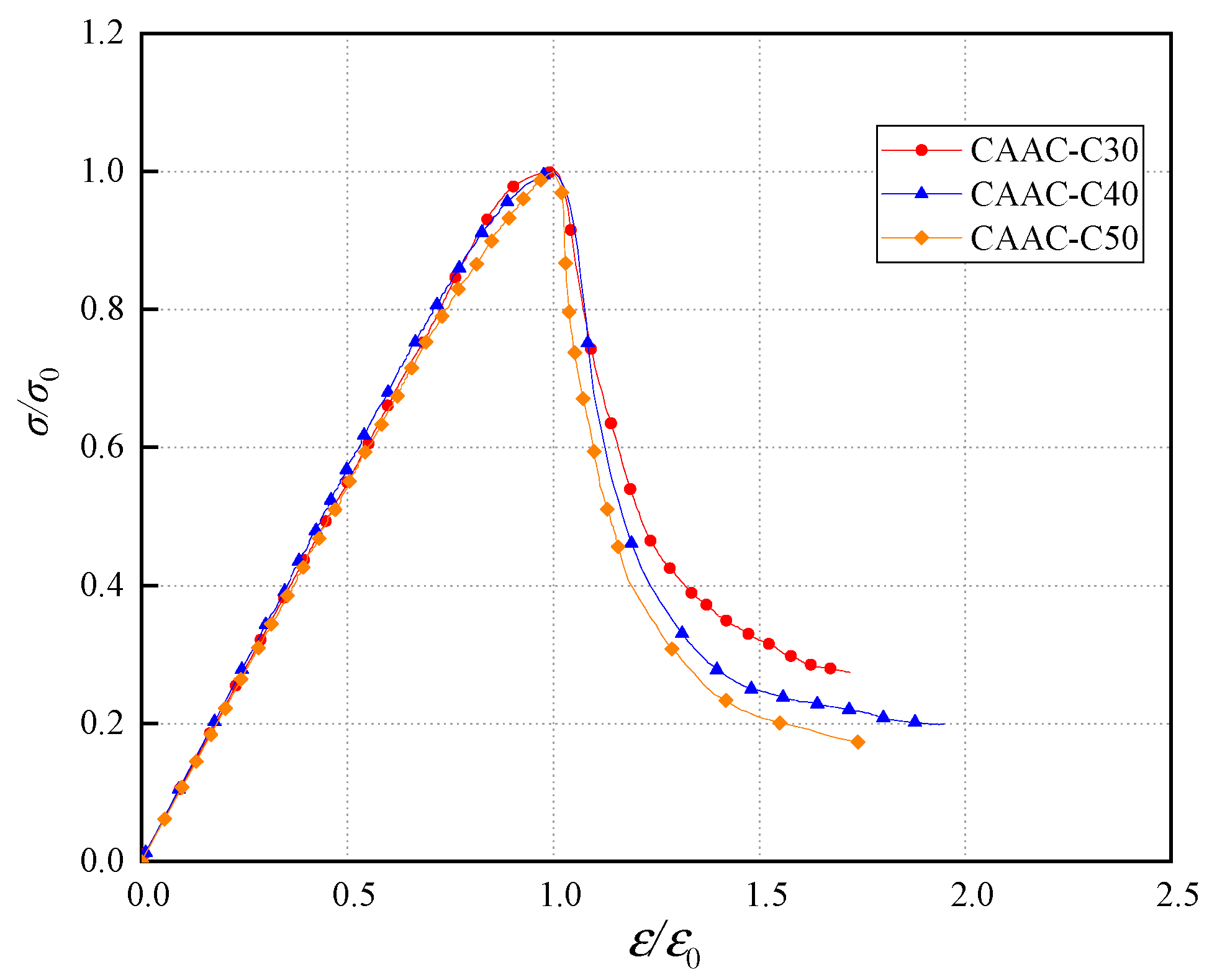

3.4. The Whole Stress–Strain Curve of CAAC

3.4.1. Establish the Whole Stress–Strain Curve of CAAC

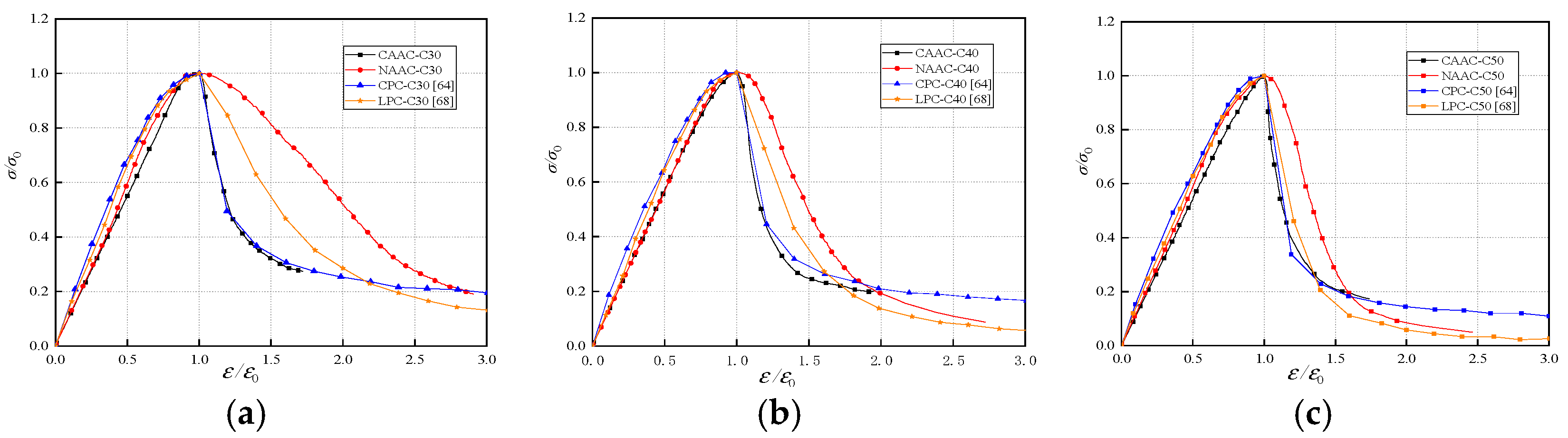

3.4.2. Comparison of Whole Stress–Strain Curve for Different Types of Concrete

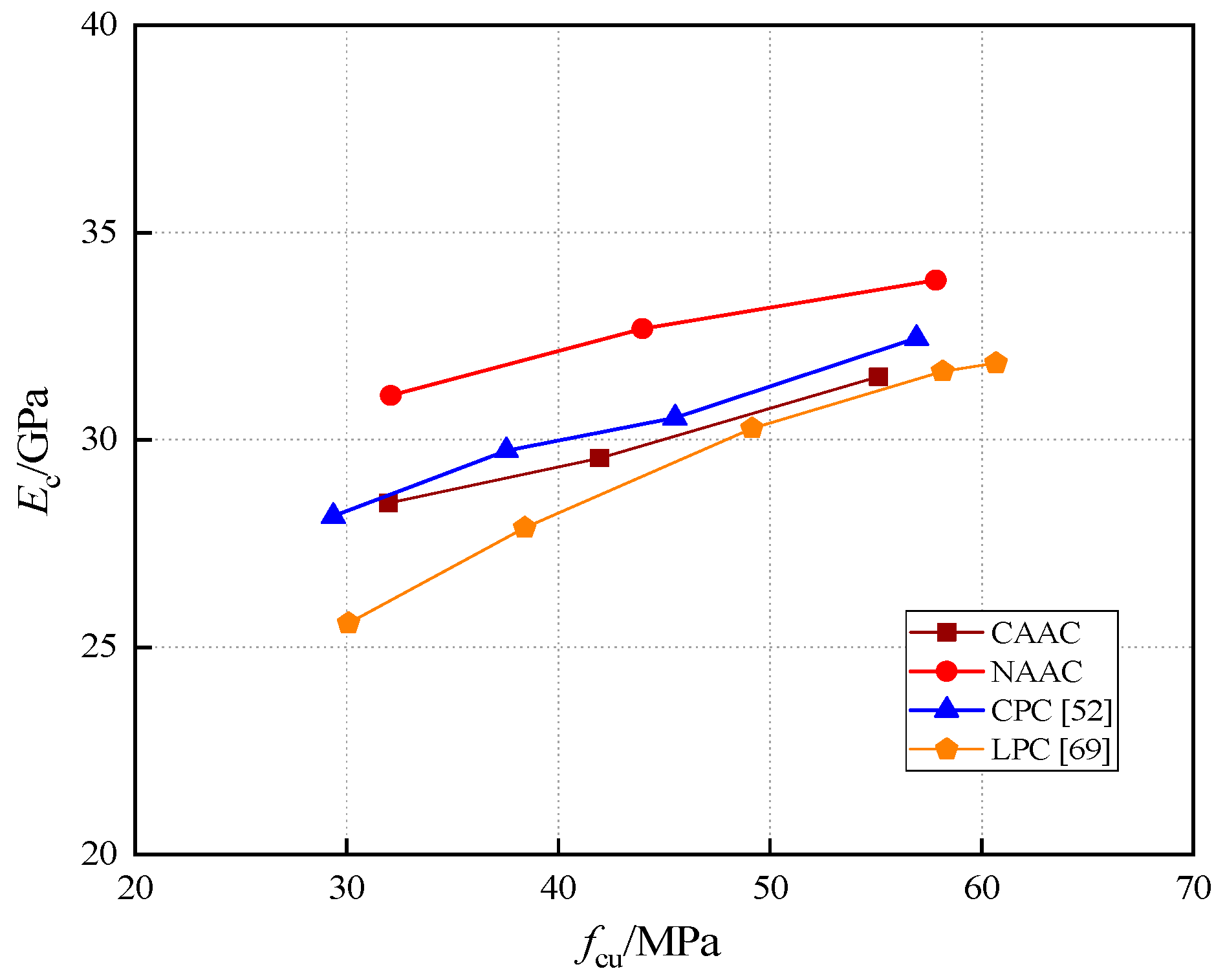

3.5. Elastic Modulus and Poisson’s Ratio of CAAC

3.6. Performance Comparison

3.7. Potential Application of CAAC

4. Conclusions

- Brittleness is the main cause of CAAC uniaxial compression damage. The CAAC would be divided into multiple cylinders as a splitting failure. The cracks of the specimen are mainly vertical cracks and inclined cracks. In addition, the failure of specimens usually occurs on the slope.

- According to the whole stress–strain curve of CAAC, the shapes and characteristics vary with different strength grades. As the strength grade increases, the Poisson’s ratio (μ) increases at first and then decreases. The reason is that the bond surface area between coral and cementing material decreases, which leads to the decrease of lateral restraint of concrete.

- For the whole stress–strain curves of CAAC, NAAC, CPC and LPC, there is no significant difference in the ascending stages, but there is a great difference in the descending stages. At the same strength grade, the descending stage of CAAC is the steepest compared with NAAC and CPC, which is basically consistent with CPC, indicating that CAAC is more brittle than NAAC and LPC. Superfine cement mortar and silicon mortar can be used to increase the strength of coral. It is recommended to add organic fiber to CAAC to improve the strength and toughness.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CAAC | coral fly ash-slag alkali-activated concrete |

| NAAC | normal weight alkali-activated concrete |

| CPC | coral concrete |

| OPC | ordinary concrete |

| LPC | lightweight aggregate concrete |

| AAC | alkali-activated concrete |

| FA | fly ash |

| GGBFS | ground granulated blast furnace slag |

References

- Malhotra, V.M. Making Concrete “Greener” with Fly Ash-Supplementary Cementing Materials Can Reduce Greenhouse Gas Emissions into the Environment. Concr. Int. 1999, 21, 61–66. [Google Scholar]

- Elchalakani, M.; Basarir, H.; Karrech, A. Green Concrete with High-Volume Fly Ash and Slag with Recycled Aggregate and Recycled Water to Build Future Sustainable Cities. J. Mater. Civ. Eng. 2016. [Google Scholar] [CrossRef]

- The European Cement Association. Key Facts & Figures: Global Cement Report. Available online: https://cembureau.eu/cement-101/key-facts-figures/2019 (accessed on 13 July 2019).

- The Cement Industry Federation (CIF). Federation cement industry, Australian Cement Production. Available online: http://www.cement.org.au (accessed on 25 September 2020).

- Hao, J.L.; Cheng, B.; Lu, W.; Xu, J.; Wang, J.; Bu, W.; Guo, Z. Carbon Emission Reduction in Prefabrication Construction during Materialization Stage: A BIM-Based Life-Cycle Assessment Approach. Sci. Total Environ. 2020, 723, 137870. [Google Scholar] [CrossRef] [PubMed]

- Cheng, B.; Li, J.; Tam, V.W.; Yang, M.; Chen, D. A BIM-LCA Approach for Estimating the Greenhouse Gas Emissions of Large-Scale Public Buildings: A Case Study. Sustainability 2020, 12, 685. [Google Scholar] [CrossRef]

- Chen, H.; Li, H.; Wang, Y.; Cheng, B. A Comprehensive Assessment Approach for Water-Soil Environmental Risk during Railway Construction in Ecological Fragile Region Based on AHP and MEA. Sustainability 2020, 12, 7910. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Rangan, B.V. Study on Engineering Properties of Fly Ash-Based Geopolymer Concrete. J. Australas. Ceram. Soc. 2002, 38, 44–47. [Google Scholar]

- Huntzinger, D.N.; Eatmon, T.D. A Life-Cycle Assessment of Portland cement Manufacturing: Comparing the Traditional Process with Alternative Technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Yuan, H.; Shen, L. Trend of the Research on Construction and Demolition Waste Management. Waste Manag. 2011, 31, 670–679. [Google Scholar] [CrossRef]

- Chen, J.; Hua, C.; Liu, C. Considerations for Better Construction and Demolition Waste Management: Identifying the Decision Behaviors of Contractors and Government Departments through a Game Theory Decision-Making Model. J. Clean. Prod. 2019, 212, 190–199. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An Overview of Study on Recycled Aggregate Concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Jorge Evangelista, A.C. A Review of Recycled Aggregate in Concrete Applications (2000–2017). Constr. Build. Mater. 2011, 72, 272–292. [Google Scholar] [CrossRef]

- Luo, Z.; Li, W.; Tam, V.W.; Xiao, J.; Shah, S.P. Current progress on nanotechnology application in recycled aggregate concrete. J. Sustain. Cem. Mater. 2018, 8, 1–18. [Google Scholar] [CrossRef]

- Nour, A.I.; Güneyisi, E.M. Prediction Model on Compressive Strength of Recycled Aggregate Concrete Filled Steel Tube Columns. Compos. Part B Eng. 2019, 173, 106938. [Google Scholar] [CrossRef]

- Shi, X.; Collins, F.; Zhao, X.; Wang, Q. Mechanical Properties and Microstructure Analysis of fly Ash Geopolymeric Recycled Concrete. J. Hazard. Mater. 2012, 237, 20–29. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Shi, C.; Zhang, Z.; Wang, H.; Liu, Y. A Review on Mixture Design Methods for Geopolymer Concrete. Compos. Part B Eng. 2019, 178, 107490. [Google Scholar] [CrossRef]

- Longhi, M.A.; Walkley, B.; Rodríguez, E.D.; Kirchheim, A.P.; Zhang, Z.; Wang, H. New Selective Dissolution Process to Quantify Reaction Extent and Product Stability in Metakaolin-Based Geopolymers. Compos. Part B Eng. 2019, 176, 107172. [Google Scholar] [CrossRef]

- Khodr, M.; Law, D.W.; Gunasekara, C.; Setunge, S.; Brkljaca, R. Compressive Strength and Microstructure Evolution of Low Calcium Brown Coal Fly Ash-Based Geopolymer. J. Sustain. Cem. Mater. 2019, 9, 17–34. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Alipour, P.; Tahmouresi, B.; Mohseni, E.; Saradar, A.; Sarker, P.K. Influence of Different Monomer Ratios and Recycled Concrete Aggregate on Mechanical Properties and Durability of Geopolymer Concretes. Constr. Build. Mater. 2019, 205, 519–528. [Google Scholar] [CrossRef]

- Posi, P.; Teerachanwit, C.; Tanutong, C.; Limkamoltip, S.; Chindaprasirt, P. Lightweight Geopolymer Concrete Containing Aggregate from Recycle Lightweight Block. Mater. Des. 2013, 52, 580–586. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Influence of Recycled Aggregate on Fly Ash Geopolymer Concrete Properties. J. Clean. Prod. 2016, 112, 2300–2307. [Google Scholar] [CrossRef]

- Davidovits, J. High-Alkali Cements for 21st Century Concretes. ACI 1994, 144, 383–398. [Google Scholar] [CrossRef]

- Li, Z.; Ding, Z.; Zhang, Y. Development of Sustainable Cementitious Materials. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004; pp. 55–76. Available online: http://publications.iowa.gov/2941/1/SustainableConcreteWorkshop.pdf#page=66 (accessed on 25 September 2020).

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Deventer, J.S.J.V. The Role of Inorganic Polymer Technology in the Development of ‘Green Concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Dong, M.; Feng, W.; Elchalakani, M.; Li, G.; Karrech, A.; May, E.F. Development of a High Strength Geopolymer by Novel Solar Curing. Ceram. Int. 2017, 43, 11233–11243. [Google Scholar] [CrossRef]

- Elchalakani, M.; Dong, M.; Karrech, A.; Li, G.; Ali, M.S.M.; Xie, T. Development of Fly-Ash and Slag-Based Geopolymer Concrete with Calcium Carbonate or Microsilica. J. Mater. Civ. Eng. 2018, 30, 04018325.1–04018325.14. [Google Scholar] [CrossRef]

- Atis, C.D.; Gorur, E.B.; Karahan, O.; Bilim, C.; Ilkentapar, S.; Luga, E. Very High Strength (120 MPa) Class F Fly Ash Geopolymer Mortar Activated at Different NaOH Amount, Heat Curing Temperature and Heat Curing Duration. Constr. Build. Mater. 2015, 96, 673–678. [Google Scholar] [CrossRef]

- Hosan, A.; Haque, S.; Shaikh, F. Compressive Behaviour of Sodium and Potassium Activators Synthetized Fly Ash Geopolymer at Elevated Temperatures: A Comparative Study. J. Build. Eng. 2016, 8, 123–130. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G. Stress-Strain Behaviour and Abrupt Loss of Stiffness of Geopolymer at Elevated Temperatures. Cem. Concr. Compos. 2010, 32, 657–664. [Google Scholar] [CrossRef]

- Bernal, S.A.; De Gutierrez, R.M.; Provis, J.L.; Rose, V. Effect of Silicate Modulus and Metakaolin Incorporation on the Carbonation of Alkali Silicate-Activated Slags. Cem. Concr. Res. 2010, 40, 898–907. [Google Scholar] [CrossRef]

- Bernal, S.A.; Gutierrez, R.M.D.; Provis, J.L. Engineering and Durability Properties of Concretes Based on Alkali-Activated Granulated Blast Furnace Slag/Metakaolin Blends. Constr. Build. Mater. 2012, 33, 99–108. [Google Scholar] [CrossRef]

- Monticelli, C.; Natali, M.E.; Balbo, A.; Chiavari, C.; Bignozzi, M.C. Corrosion Behavior of Steel in Alkali-Activated Fly Ash Mortars in the Light of Their Microstructural, Mechanical and Chemical Characterization. Cem. Concr. Res. 2016, 80, 60–68. [Google Scholar] [CrossRef]

- Babaee, M.; Castel, A. Chloride-Induced Corrosion of Reinforcement in Low-Calcium Fly Ash-Based Geopolymer Concrete. Cem. Concr. Res. 2016, 88, 96–107. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Lodeiro, I.G.; Palomo, A. Durability of Alkali-Activated Fly Ash Cementitious Materials. J. Mater. Sci. 2006, 42, 3055–3065. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J. Bond Strength between Blended Slag and Class F Fly Ash Geopolymer Concrete with Steel Reinforcement. Cem. Concr. Res. 2015, 72, 48–53. [Google Scholar] [CrossRef]

- Kim, J.S.; Park, J. An Experimental Evaluation of Development Length of Reinforcements Embedded in Geopolymer Concrete. Appl. Mech. Mater. 2014, 578, 441–444. [Google Scholar] [CrossRef]

- Moser, R.D.; Allison, P.G.; Williams, B.; Weiss, C.; Diaz, A.; Gore, E.; Malone, P. Improvement in the Geopolymer-To-Steel Bond Using A Reactive Vitreous Enamel Coating. Constr. Build. Mater. 2013, 49, 62–69. [Google Scholar] [CrossRef]

- Ganesan, N.; Indira, P.V.; Santhakumar, A. Bond Behaviour of Reinforcing Bars Embedded in Steel Fibre Reinforced Geopolymer Concrete. Mag. Concr. Res. 2014, 67, 9–16. [Google Scholar] [CrossRef]

- Dattatreya, J.K.; Rajamane, N.P.; Sabitha, D.; Ambily, P.S.; Nataraja, M.C. Flexural Behaviour of Reinforced Geopolymer Concrete Beams. Int. J. Compu. Civ. Struct. Eng. 2012, 2, 138–159. [Google Scholar]

- Yost, J.R.; Radlinska, A.; Ernst, S.; Salera, M.; Martignetti, N.J. Structural Behavior of alkali activated fly ash concrete. Part 2: Structural Testing and Experimental Findings. Mater. Struct. 2013, 46, 449–462. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Le, T.A.; Lee, K. Experimental Study on Flexural Strength of Reinforced Geopolymer Concrete Beams. Int. J. Civ. Environ. Eng. 2016, 10, 4. [Google Scholar]

- Cui, Y.; Gao, K.; Zhang, P. Experimental and Statistical Study on Mechanical Characteristics of Geopolymer Concrete. Materials 2020, 13, 1651. [Google Scholar] [CrossRef]

- Risdanareni, P.; Zaccardi, Y.V.; Schollbach, K.; Wang, J.; Belie, N.D. Properties of Alkali Activated Lightweight Aggregate Generated from Sidoarjo Volcanic Mud (Lusi), Fly Ash, and Municipal Solid Waste Incineration Bottom Ash. Materials 2020, 13, 2528. [Google Scholar] [CrossRef] [PubMed]

- Giergiczny, Z. Fly Ash and Slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Longo, F.; Cascardi, A.; Lassandro, P.; Aiello, M.A. A New Fabric Reinforced Geopolymer Mortar (FRGM) with Mechanical and Energy Benefits. Fibers 2020, 8, 49. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; Wei, M.; Wang, L.; Cheng, B. Hysteretic Behavior of Geopolymer Concrete with Active Confinement Subjected to Monotonic and Cyclic Axial Compression: An Experimental Study. Materials 2020, 13, 3997. [Google Scholar] [CrossRef]

- Nowoświat, A.; Golaszewski, J. Influence of the Variability of Calcareous Fly Ash Properties on Rheological Properties of Fresh Mortar with Its Addition. Materials 2019, 12, 1942. [Google Scholar] [CrossRef]

- Cevik, A.; Alzeebaree, R.; Humur, G.; Nis, A.; Gülşan, M.E. Effect of Nano-Silica on the Chemical Durability and Mechanical Performance of Fly Ash Based Geopolymer Concrete. Ceram. Int. 2018, 44, 12253–12264. [Google Scholar] [CrossRef]

- Li, L. Research on Basic Characteristics of Coral Concrete; Guangxi University: Nanning, China, 2012. [Google Scholar]

- Zhang, S.Z. Experimental Study on the Fatigue Property and Microscopic Mechanism of Coral Concrete; Guangxi University: Nanning, China, 2012. [Google Scholar]

- Dempsey, G. Coral and Salt Water as Concrete Materials. ACI Mater. 1951, 48, 157–166. [Google Scholar]

- Vines, F.R. Experience with Use of Coral Detritus as Concrete Aggregate in Western Samoa. Aust. Road Res. 1982, 12, 17–28. [Google Scholar]

- Chen, Z.L.; Chen, T.Y.; Qu, Z.M. A Feasibility Study of Application of Coral Reef Sand Concrete. Ocean Eng. 1991, 9, 67–80. [Google Scholar]

- Chen, Z.L.; Sun, G.F.; Tang, X.N. Study on Applications of Concretes from Coral Reef Sand Mixed with Seawater for Patching-Up in Reef Engineering. Coast. Eng. 2008, 27, 60–69. [Google Scholar]

- Wang, L.; Zhao, Y.L. The Comparison of Coral Concrete and Other Light Weight Aggregate Concrete on Mechanics Performance. Adv. Mater. Res. 2012, 446, 3369–3372. [Google Scholar] [CrossRef]

- Li, Y.T.; Zhou, L.; Zhang, Y.; Cui, J.W.; Shao, J. Study on Long-Term Performance of Concrete Based on Seawater, Sea Sand and Coral Sand. Adv. Mater. Res. 2013, 706–708, 512–515. [Google Scholar] [CrossRef]

- Kong, L.J.; Ge, Y.; Yuan, J.; Zhang, B.S. Stress-Strain Curves of Combined Aggregate Concrete. J. Wuhan Univ. Technol. 2007, 29, 18–21. [Google Scholar]

- Petersen, L.; Lohaus, L.; Polak, M.A. Influence of Freezing-and-Thawing Damage on Behavior of Reinforced Concrete Elements. ACI Mater. J. 2007, 104, 369–378. [Google Scholar]

- Hasan, M.; Ueda, T.; Sato, Y. Stress-Strain Relationship of Frost-Damaged Concrete Subjected to Fatigue Loading. J. Mater. Civ. Eng. 2008, 20, 37–45. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, H.; Jia, X.; Chen, H.; Yu, W. Experimental Investigation of Stress-Strain Curves of Cast-In-Situ Phosphogypsum. J. Build. Struct. 2015. [Google Scholar] [CrossRef]

- China MOCO. Light Aggregate and Test Method; China Architecture& Building Press: Beijing, China, 1998. [Google Scholar]

- Vora, P.R.; Dave, U.V. Parametric Studies on Compressive Strength of Geopolymer Concrete. Procedia Eng. 2013, 51, 210–219. [Google Scholar] [CrossRef]

- Yuan, Y.F. Mix Design and Property of Coral Aggregate Concrete; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2015. [Google Scholar]

- China MOCO. Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Architecture& Building Press: Beijing, China, 2002. [Google Scholar]

- Wang, Z.; Li, L.; Zhang, Y. Bond-Slip Model Considering Freeze-Thaw Damage Effect of Concrete and Its Application. Eng. Struct. 2019, 201, 109831. [Google Scholar] [CrossRef]

- Wang, Z.; Li, L.; Zhang, Y. Reinforcement Model Considering Slip Effect. Eng. Struct. 2019, 198, 109493. [Google Scholar] [CrossRef]

- Shi, G.; Cheng, B.; Li, A. A Mathematical Model for Calculating the “Brittleness-Ductility” Drop Coefficient of Sandstone in Mining Zones. Discrete Dyn. Nat. Soc. 2020, 2020, 2621672. [Google Scholar] [CrossRef]

- Chen, G.M.; Yang, H.; Lin, C.J.; Chen, J.F.; He, Y.H.; Zhang, H.Z. Fracture Behaviour of Steel Fibre Reinforced Recycled Aggregate Concrete after Exposure to Elevated Temperatures. Constr. Build. Mater. 2016, 128, 272–286. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.; Ma, H.; Tan, Y.; Mi, R.; Dou, X. Experimental Investigation of Whole Stress-Strain Curves of Coral Concrete. Constr. Build. Mater. 2016, 122, 81–89. [Google Scholar] [CrossRef]

- Zheng, W.; Li, H.; Wang, Y. Compressive Stress-Strain Relationship of Steel Fiber-Reinforced Reactive Powder Concrete after Exposure to Elevated Temperatures. Constr. Build. Mater. 2012, 35, 931–940. [Google Scholar] [CrossRef]

- Guo, Z. Strength and Constitutive Relationship of Concrete-Principle and Application; China Building Industry Press: Beijing, China, 2004. [Google Scholar]

- China MOCO. Code for Design of Concrete Structures; China Architecture& Building Press: Beijing, China, 2010. [Google Scholar]

- Wang, Z.Y.; Ding, J.T.; Guo, Y.S. Stress-Strain Curves of Structural Lightweight Aggregate Concretes. Concretes 2005, 27, 39–41. [Google Scholar]

- Ding, F.X.; Ying, X.Y.; Yu, Z.W. Unified Calculation Method of Uniaxial Mechanical Properties of Lightweight Aggregate Concrete. J. Cent. South Univ. Sci. Technol. 2010, 41, 1973–1979. [Google Scholar]

- Niu, D.; Su, L.; Luo, Y.; Huang, D.; Luo, D. Experimental Study on Mechanical Properties and Durability of Basalt Fiber Reinforced Coral Aggregate Concrete. Constr. Build. Mater. 2020, 237, 117628. [Google Scholar] [CrossRef]

| Sample | Chemical Composition (%) | Blaine Fineness (cm2/g) | Density (g/cm3) | LOI (%) | ||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | Fe2O3 | MgO | ||||

| FA | 49.10 | 26.70 | 6.96 | 9.67 | 1.37 | 3871 | 2.21 | 2.08 |

| GGBFS | 32.28 | 13.80 | 47.85 | 0.74 | 3.73 | 3862 | 2.86 | 1.30 |

| Aggregates | Particle Size (mm) | Specific Gravity | 24-h Water Absorption (%) | Fineness Modulus | Aggregates Crushing Value (%) | Cylinder Compressive Strength (MPa) |

|---|---|---|---|---|---|---|

| Natural river sand | ≤5 | 2.67 | 1.2 | 2.4 | - | - |

| Limestone aggregates | 5–20 | 2.64 | 0.83 | - | 23 | - |

| Coral aggregates | 4–20 | 1.24 | 14.2 | - | 30 | 2.12 |

| Mix ID | FA | GGBFS | Sodium Silicate | NaOH | River Sand | Normal Weight Aggregates | Coral Aggregates | Added Water | W/S | Superplasticizer |

|---|---|---|---|---|---|---|---|---|---|---|

| NAAC-C30 | 210 | 140 | 110 | 44 | 773 | 1094 | - | 23.1 | 0.29 | 0.9 |

| NAAC-C40 | 234 | 156 | 122 | 49 | 764 | 1023 | - | 11.5 | 0.25 | 1.4 |

| NAAC-C50 | 298 | 199 | 131 | 52 | 705 | 958 | - | 5.9 | 0.21 | 2.8 |

| CAAC-C30 | 216 | 144 | 110 | 44 | 868 | - | 605 | 13.1 | 0.26 | 2.1 |

| CAAC-C40 | 266 | 177 | 122 | 49 | 844 | - | 531 | 8.3 | 0.22 | 3.3 |

| CAAC-C50 | 339 | 226 | 124 | 50 | 790 | - | 462 | 5.5 | 0.18 | 4.8 |

| No. | σ0 | σ0i | S1 | σr | σri | S2 | σri/σ0i | ε0 | ε0i | P1 | εu | εui | P2 | εui/ε0i |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CAAC −30 | 30.29 | 30.66 | 0.52 | 8.52 | 8.41 | 0.10 | 0.28 | 0.00184 | 0.00187 | 0.00010 | 0.00318 | 0.00321 | 0.00006 | 1.72 |

| 31.25 | 8.38 | 0.00179 | 0.00328 | |||||||||||

| 30.44 | 8.33 | 0.00198 | 0.00317 | |||||||||||

| CAAC −40 | 38.75 | 39.00 | 0.50 | 7.57 | 7.76 | 0.28 | 0.20 | 0.00210 | 0.00215 | 0.00010 | 0.00416 | 0.00417 | 0.00005 | 1.94 |

| 38.67 | 7.63 | 0.00226 | 0.00422 | |||||||||||

| 39.58 | 8.08 | 0.00209 | 0.00413 | |||||||||||

| CAAC −50 | 51.25 | 51.37 | 0.75 | 8.93 | 8.89 | 0.11 | 0.17 | 0.00224 | 0.00225 | 0.00003 | 0.00387 | 0.0039 | 0.00007 | 1.76 |

| 52.17 | 8.76 | 0.00228 | 0.00398 | |||||||||||

| 50.69 | 8.97 | 0.00223 | 0.00400 | |||||||||||

| NAAC −30 | 28.14 | 28.06 | 0.10 | 5.35 | 5.41 | 0.07 | 0.19 | 0.00197 | 0.00198 | 0.00003 | 0.00542 | 0.00537 | 0.00006 | 2.71 |

| 27.95 | 5.40 | 0.00204 | 0.00538 | |||||||||||

| 28.09 | 5.48 | 0.00193 | 0.00531 | |||||||||||

| NAAC −40 | 41.42 | 40.90 | 0.65 | 3.69 | 3.61 | 0.11 | 0.088 | 0.00204 | 0.00201 | 0.00004 | 0.00569 | 0.00573 | 0.00005 | 2.85 |

| 40.18 | 3.49 | 0.00203 | 0.00579 | |||||||||||

| 41.13 | 3.65 | 0.00196 | 0.00571 | |||||||||||

| NAAC −50 | 54.42 | 53.91 | 0.45 | 2.52 | 2.63 | 0.11 | 0.049 | 0.00216 | 0.00209 | 0.00010 | 0.00509 | 0.00516 | 0.00006 | 2.46 |

| 53.76 | 2.64 | 0.00213 | 0.00518 | |||||||||||

| 53.55 | 2.73 | 0.00198 | 0.00521 |

| No. | α | β | ||

|---|---|---|---|---|

| CAAC-C30 | 1.07 | 0.998 | 3.39 | 0.958 |

| CAAC-C40 | 1.17 | 0.999 | 7.76 | 0.936 |

| CAAC-C50 | 1.03 | 0.997 | 9.37 | 0.969 |

| No. | fcu (MPa) | fc (MPa) | EC (GPa) | μ |

|---|---|---|---|---|

| CAAC-C30 | 31.97 | 30.66 | 28.48 | 0.211 |

| CAAC-C40 | 41.96 | 39.00 | 29.56 | 0.232 |

| CAAC-C50 | 55.13 | 51.37 | 31.82 | 0.224 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wang, L.; Li, L.; Cheng, B.; Zhang, Y.; Wei, Y. The Study on the Whole Stress–Strain Curves of Coral Fly Ash-Slag Alkali-Activated Concrete under Uniaxial Compression. Materials 2020, 13, 4291. https://doi.org/10.3390/ma13194291

Wang H, Wang L, Li L, Cheng B, Zhang Y, Wei Y. The Study on the Whole Stress–Strain Curves of Coral Fly Ash-Slag Alkali-Activated Concrete under Uniaxial Compression. Materials. 2020; 13(19):4291. https://doi.org/10.3390/ma13194291

Chicago/Turabian StyleWang, Huailiang, Lang Wang, Lei Li, Baoquan Cheng, Yonggang Zhang, and Yuhu Wei. 2020. "The Study on the Whole Stress–Strain Curves of Coral Fly Ash-Slag Alkali-Activated Concrete under Uniaxial Compression" Materials 13, no. 19: 4291. https://doi.org/10.3390/ma13194291

APA StyleWang, H., Wang, L., Li, L., Cheng, B., Zhang, Y., & Wei, Y. (2020). The Study on the Whole Stress–Strain Curves of Coral Fly Ash-Slag Alkali-Activated Concrete under Uniaxial Compression. Materials, 13(19), 4291. https://doi.org/10.3390/ma13194291