Ceramic Material Processing Towards Future Space Habitat: Electric Current-Assisted Sintering of Lunar Regolith Simulant

Abstract

1. Introduction

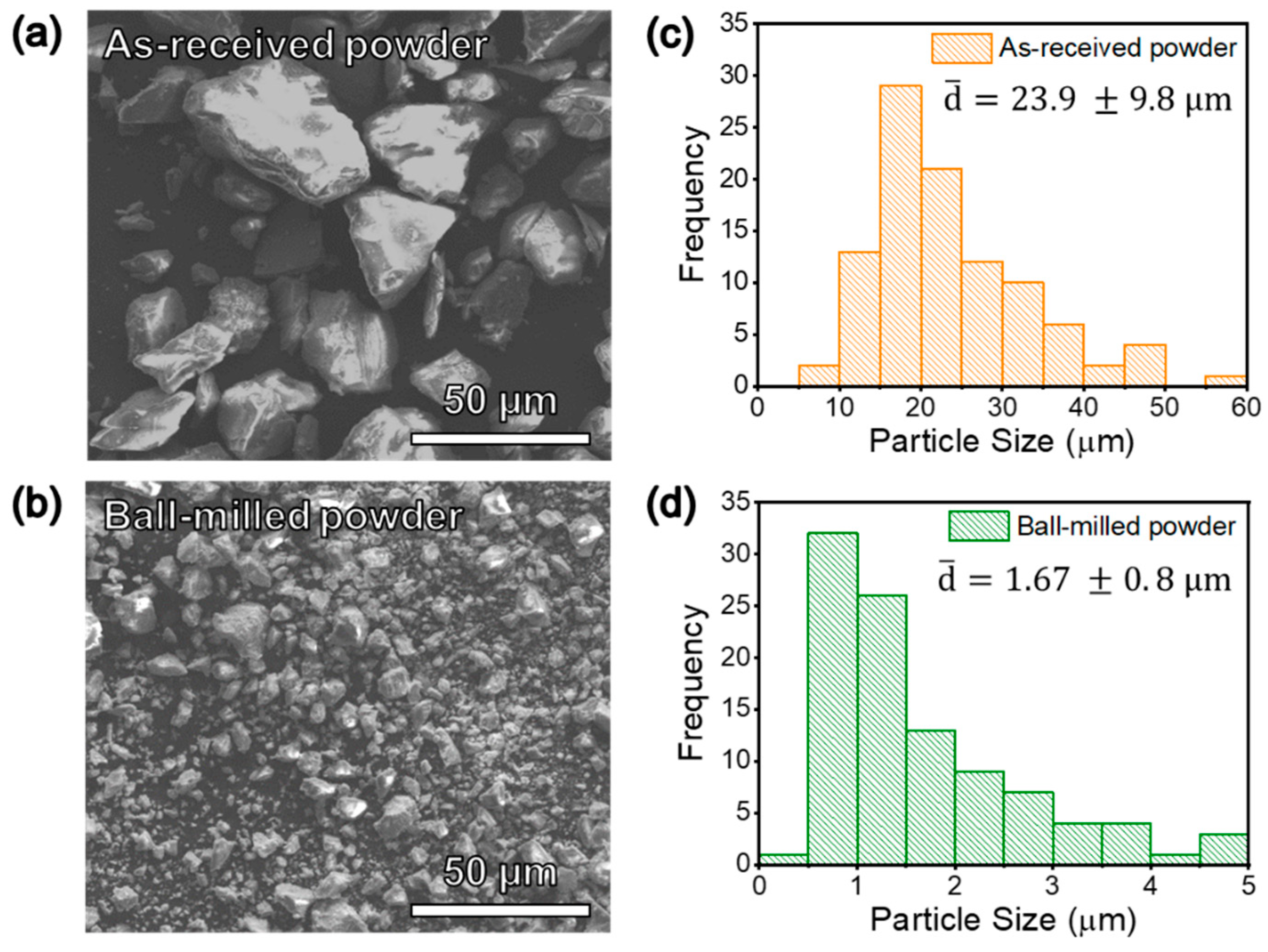

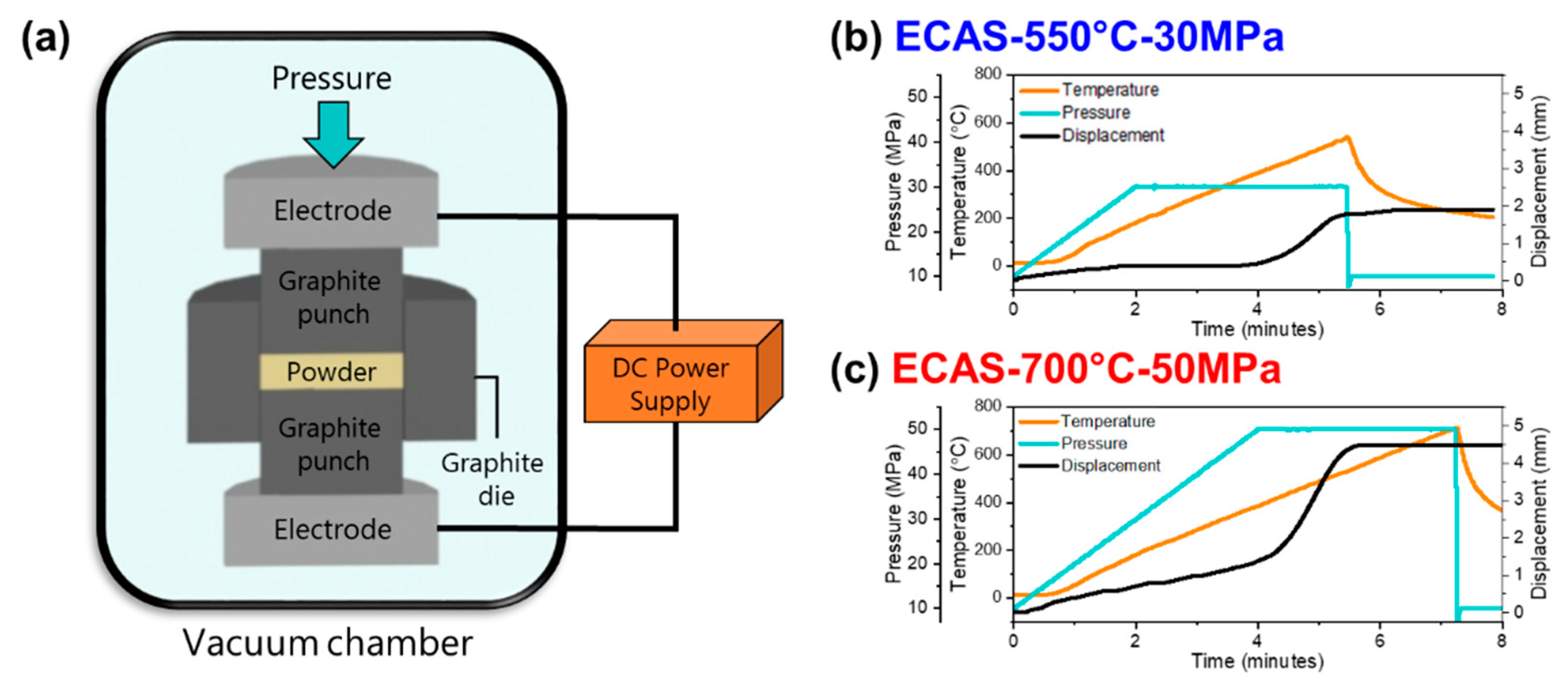

2. Materials and Methods

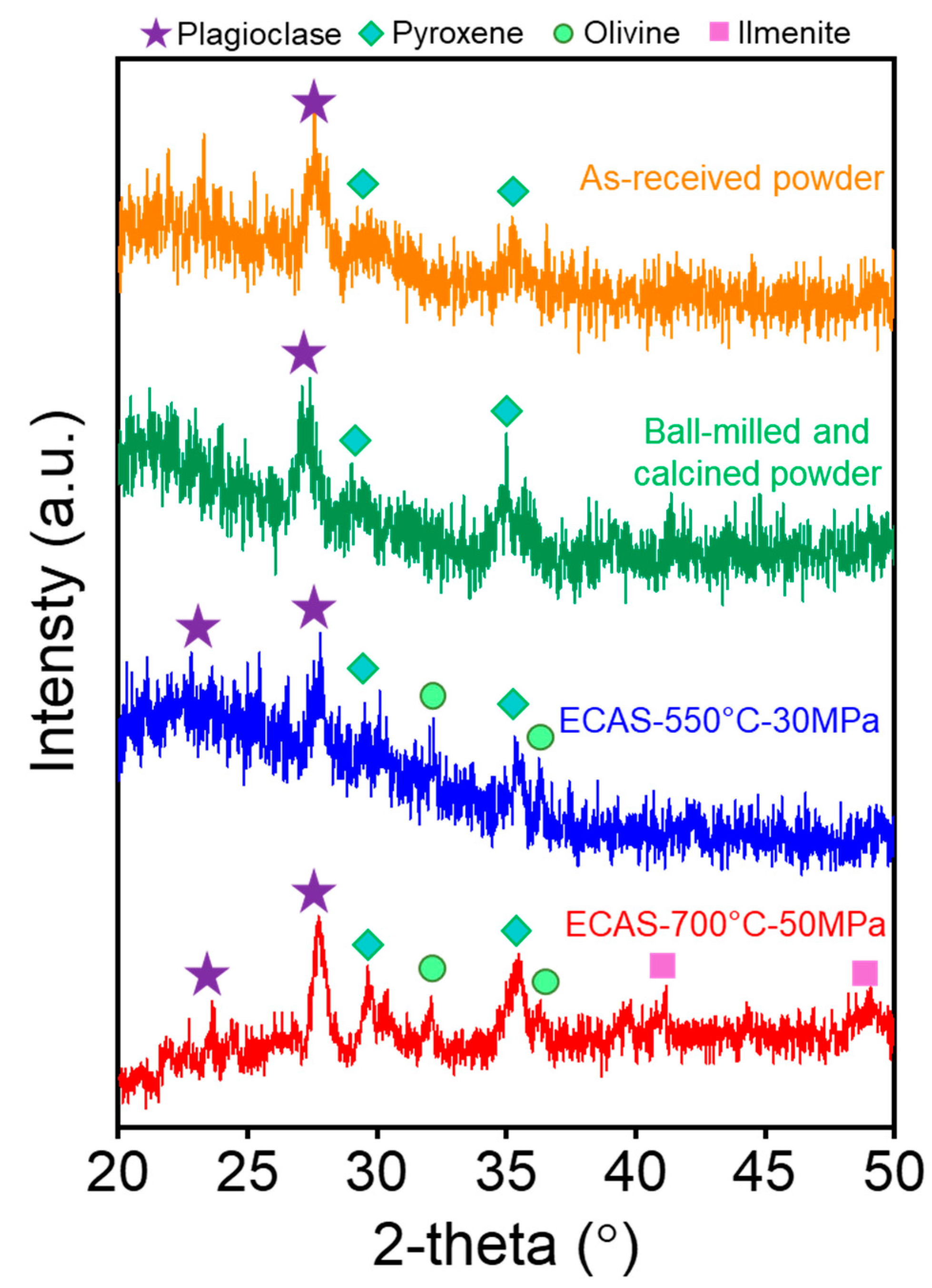

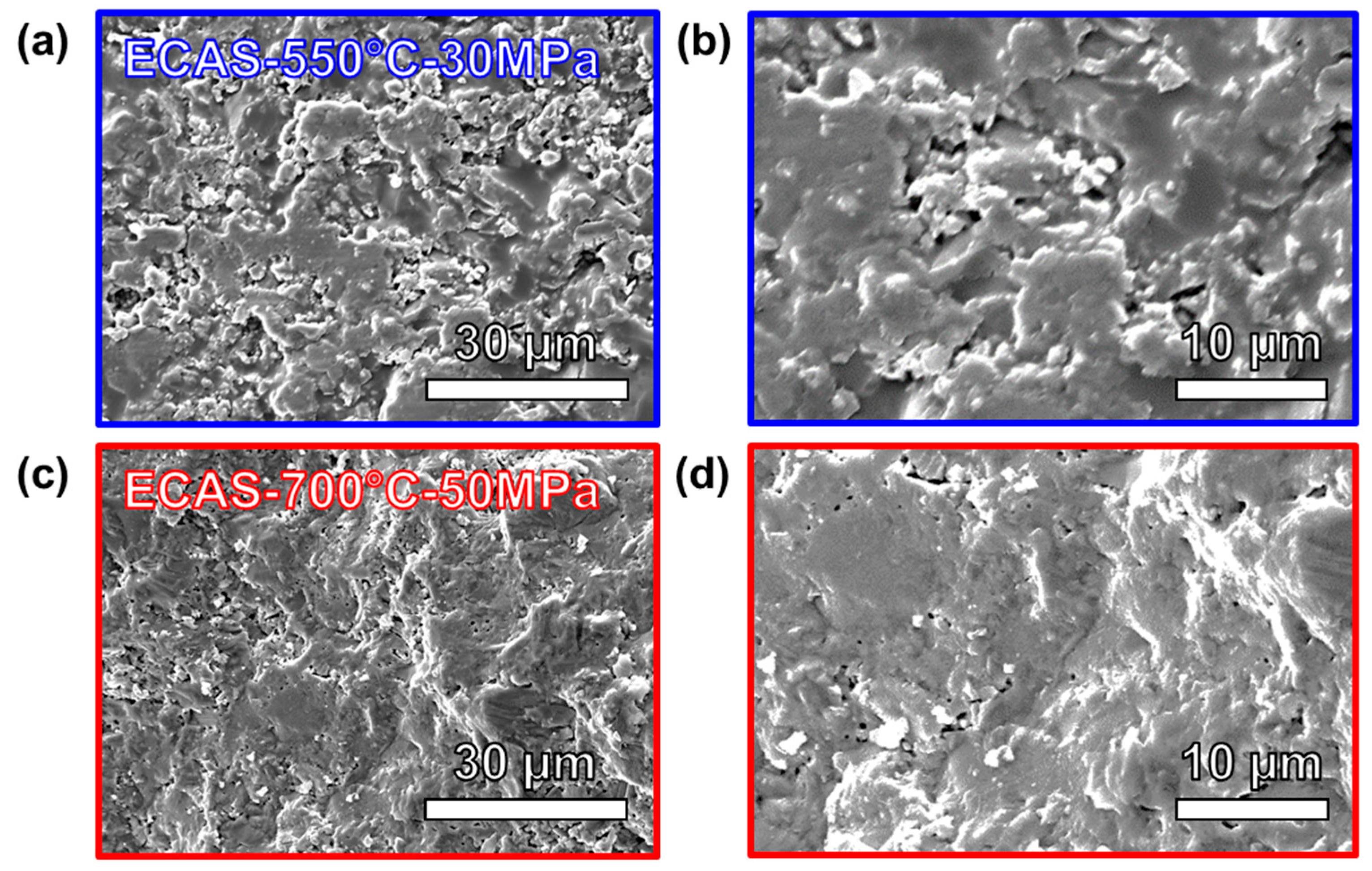

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Benaroya, H. Building Habitats on the Moon: Engineering Approaches to Lunar Settlements; Springer International Publishing: Cham, Switzerland, 2018; ISBN 9783319682426. [Google Scholar]

- Ruess, F.; Schaenzlin, J.; Benaroya, H. Structural Design of a Lunar Habitat. J. Aerosp. Eng. 2006, 19, 133–157. [Google Scholar] [CrossRef]

- Bodiford, M.; Fiske, M.; Pope, R.; McGregor, W. In-Situ Resource-Based Lunar and Martian Habitat Structures Development at NASA/MSFC. In Proceedings of the AIAA 1st Exploration Conference, Orlando, FL, USA, 31 January–1 February 2005. [Google Scholar] [CrossRef]

- Khitab, A.; Anwar, W.; Mehmood, I.; Kazmi, S.M.S.; Munir, M.J. Lunar concrete: Prospects and challenges. Astron. Rep. 2016, 60, 306–312. [Google Scholar] [CrossRef]

- Okada, T.; Kanamore, H.; Ishikawa, N. The possibility of concrete production on the Moon. In Proceedings of the Second Conference on Lunar Bases and Space Activities of the 21st Century, NASA Johnson Space Center, Houston, TX, USA, 5–7 April 1988; Volume 2, pp. 489–491. [Google Scholar]

- Sik Lee, T.; Lee, J.; Yong Ann, K. Manufacture of polymeric concrete on the Moon. Acta Astronaut. 2015, 114, 60–64. [Google Scholar] [CrossRef]

- Freundlich, A.; Kubricht, T.; Ignatiev, A. Lunar regolith thin films: Vacuum evaporation and properties. AIP Conf. Proc. 2008, 660, 660–665. [Google Scholar] [CrossRef]

- Meurisse, A.; Beltzung, J.C.; Kolbe, M.; Cowley, A.; Sperl, M. Influence of Mineral Composition on Sintering Lunar Regolith. J. Aerosp. Eng. 2017, 30, 04017014. [Google Scholar] [CrossRef]

- Gualtieri, T.; Bandyopadhyay, A. Compressive deformation of porous lunar regolith. Mater. Lett. 2015, 143, 276–278. [Google Scholar] [CrossRef]

- Allan, S.M.; Merritt, B.J.; Griffin, B.F.; Hintze, P.E.; Shulman, H.S. High-Temperature Microwave Dielectric Properties and Processing of JSC-1AC Lunar Simulant. J. Aerosp. Eng. 2013, 26, 874–881. [Google Scholar] [CrossRef]

- Fateri, M.; Cowley, A.; Kolbe, M.; Garcia, O.; Sperl, M.; Cristoforetti, S. Localized Microwave Thermal Posttreatment of Sintered Samples of Lunar Simulant. J. Aerosp. Eng. 2019, 32, 04019051. [Google Scholar] [CrossRef]

- Taylor, L.A.; Meek, T.T. Microwave sintering of lunar soil: Properties, theory, and practice. J. Aerosp. Eng. 2005, 18, 188–196. [Google Scholar] [CrossRef]

- Fateri, M.; Meurisse, A.; Sperl, M.; Urbina, D.; Madakashira, H.K.; Govindaraj, S.; Gancet, J.; Imhof, B.; Hoheneder, W.; Waclavicek, R.; et al. Solar Sintering for Lunar Additive Manufacturing. J. Aerosp. Eng. 2019, 32, 04019051. [Google Scholar] [CrossRef]

- Meurisse, A.; Makaya, A.; Willsch, C.; Sperl, M. Solar 3D printing of lunar regolith. Acta Astronaut. 2018, 152, 800–810. [Google Scholar] [CrossRef]

- Taylor, S.L.; Jakus, A.E.; Koube, K.D.; Ibeh, A.J.; Geisendorfer, N.R.; Shah, R.N.; Dunand, D.C. Sintering of micro-trusses created by extrusion-3D-printing of lunar regolith inks. Acta Astronaut. 2018, 143, 1–8. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Zhang, J.; Fateri, M.; Xiao, Z. Ceramics 3D Printing by Selective Inhibition Sintering. In Proceedings of the Solid Freeform Symposium, Austin, TX, USA, 4–6 August 2014; Available online: http://utw10945.utweb.utexas.edu/sites/default/files/2014-015-Khoshnevis.pdf (accessed on 1 September 2020).

- Goulas, A.; Binner, J.G.P.; Harris, R.A.; Friel, R.J. Assessing extraterrestrial regolith material simulants for in-situ resource utilisation based 3D printing. Appl. Mater. Today 2017, 6, 54–61. [Google Scholar] [CrossRef]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Jakus, A.E.; Koube, K.D.; Geisendorfer, N.R.; Shah, R.N. Robust and Elastic Lunar and Martian Structures from 3D-Printed Regolith Inks. Sci. Rep. 2017, 7, 44931. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Tang, W.; Duan, W.; Li, S.; Dou, R.; Wang, G.; Liu, B.; Wang, L. Digital light processing of lunar regolith structures with high mechanical properties. Ceram. Int. 2019, 45, 5829–5836. [Google Scholar] [CrossRef]

- Dou, R.; Tang, W.Z.; Wang, L.; Li, S.; Duan, W.Y.; Liu, M.; Zhang, Y.B.; Wang, G. Sintering of lunar regolith structures fabricated via digital light processing. Ceram. Int. 2019, 45, 17210–17215. [Google Scholar] [CrossRef]

- Balla, V.K.; Roberson, L.B.; O’Connor, G.W.; Trigwell, S.; Bose, S.; Bandyopadhyay, A. First demonstration on direct laser fabrication of lunar regolith parts. Rapid Prototyp. J. 2012, 18, 451–457. [Google Scholar] [CrossRef]

- Fateri, M.; Gebhardt, A.; Khosravi, M. Experimental Investigation of Selective Laser Melting of Lunar Regolith for In-Situ Applications. In Proceedings of the ASME 2013 International Mechanical Engineering Congress and Exposition, San Diego, CA, USA, 15–21 November 2013. V02AT02A008. [Google Scholar] [CrossRef]

- Fateri, M.; Gebhardt, A. Process parameters development of selective Laser Melting of lunar regolith for on-site manufacturing applications. Int. J. Appl. Ceram. Technol. 2015, 12, 46–52. [Google Scholar] [CrossRef]

- Ray, C.S.; Reis, S.T.; Sen, S.; O’Dell, J.S. JSC-1A lunar soil simulant: Characterization, glass formation, and selected glass properties. J. Non. Cryst. Solids 2010, 356, 2369–2374. [Google Scholar] [CrossRef]

- Indyk, S.J.; Benaroya, H. A structural assessment of unrefined sintered lunar regolith simulant. Acta Astronaut. 2017, 140, 517–536. [Google Scholar] [CrossRef]

- Upadhyaya, A.; German, R.M. Gravitational effects during liquid phase sintering. Mater. Chem. Phys. 2001, 67, 25–31. [Google Scholar] [CrossRef]

- Fateri, M.; Pitikaris, S.; Sperl, M. Investigation on Wetting and Melting Behavior of Lunar Regolith Simulant for Additive Manufacturing Application. Microgravity Sci. Technol. 2019, 31, 161–167. [Google Scholar] [CrossRef]

- Song, L.; Xu, J.; Fan, S.; Tang, H.; Li, X.; Liu, J.; Duan, X. Vacuum sintered lunar regolith simulant: Pore-forming and thermal conductivity. Ceram. Int. 2019, 45, 3627–3633. [Google Scholar] [CrossRef]

- Munir, Z.A.; Quach, D.V.; Ohyanagi, M. Electric current activation of sintering: A review of the pulsed electric current sintering process. J. Am. Ceram. Soc. 2011, 94, 1–19. [Google Scholar] [CrossRef]

- Taggart, J.E. Analytical Methods for Chemical Analysis of Geologic and Other Materials, U.S. Geological Survey, Open-File Report 02-223, U.S. Department of the Interior. 2002. Available online: http://pubs.usgs.gov/of/2002/ofr-02-0223/ (accessed on 1 September 2020).

- Michel, M.D.; Mikowski, A.; Lepienski, C.M.; Foerster, C.E.; Serbena, F.C. High temperature microhardness of soda-lime glass. J. Non. Cryst. Solids 2004, 348, 131–138. [Google Scholar] [CrossRef]

- Fateri, M.; Gebhardt, A. Selective Laser Melting of soda-lime glass powder. Int. J. Appl. Ceram. Technol. 2015, 12, 53–61. [Google Scholar] [CrossRef]

- Zeng, T.; Lou, Q.; Bai, Y.; Dong, X.; Wang, Y. The dielectric breakdown properties of porous PZT95/5 ferroelectric ceramics. Ferroelectrics 2015, 478, 118–126. [Google Scholar] [CrossRef]

- Bocchini, G.F. The influences of porosity on the characteristics of sintered materials. SAE Tech. Pap. 1986. [Google Scholar] [CrossRef]

- Jodlauk, S.; Becker, P.; Mydosh, J.A.; Khomskii, D.I.; Lorenz, T.; Streltsov, S.V.; Hezel, D.C.; Bohatý, L. Pyroxenes: A new class of multiferroics. J. Phys. Condens. Matter 2007, 19. [Google Scholar] [CrossRef]

- Mettout, B.; Tolédano, P.; Fiebig, M. Symmetry replication and toroidic effects in the multiferroic pyroxene NaFeSi2O6. Phys. Rev. B Condens. Matter Mater. Phys. 2010, 81. [Google Scholar] [CrossRef]

- Baker, P.J.; Lewtas, H.J.; Blundell, S.J.; Lancaster, T.; Franke, I.; Hayes, W.; Pratt, F.L.; Bohatý, L.; Becker, P. Muon-spin relaxation and heat capacity measurements on the magnetoelectric and multiferroic pyroxenes. Phys. Rev. B 2010, 81, 214403. [Google Scholar] [CrossRef]

| Oxide | Concentration (wt %) |

|---|---|

| SiO2 | 47.10 |

| TiO2 | 1.87 |

| Al2O3 | 17.10 |

| Fe2O3 | 3.41 |

| FeO | 7.57 |

| MnO | 0.18 |

| MgO | 6.90 |

| CaO | 10.30 |

| Na2O | 3.30 |

| K2O | 0.86 |

| P2O5 | 0.76 |

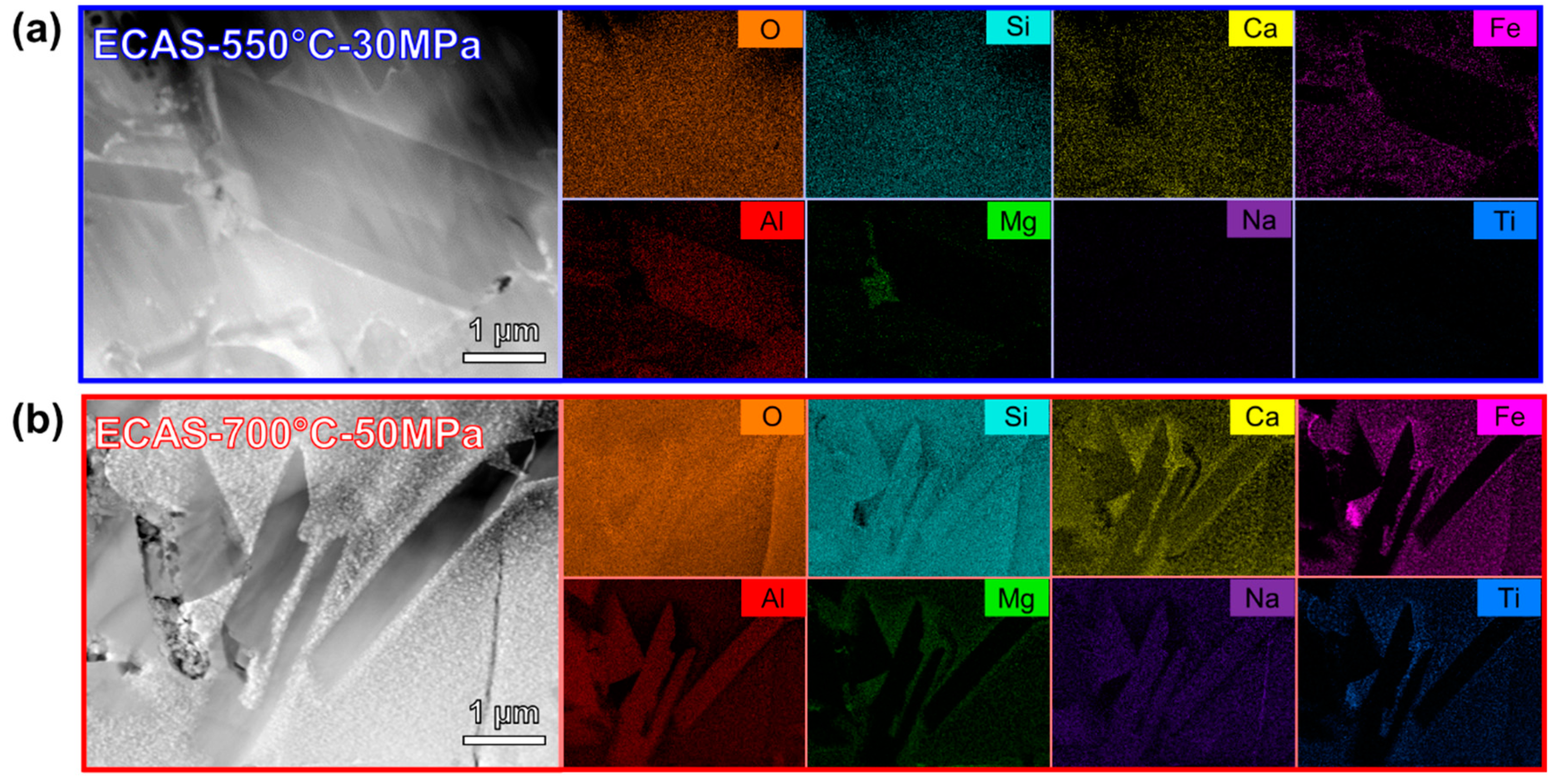

| Sample | Relative Density (%) | Hardness (GPa) |

|---|---|---|

| ECAS-550 °C-30 MPa | 95 | 5.49 ± 0.53 |

| ECAS-700 °C-50 MPa | 97 | 6.01 ± 0.66 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phuah, X.L.; Wang, H.; Zhang, B.; Cho, J.; Zhang, X.; Wang, H. Ceramic Material Processing Towards Future Space Habitat: Electric Current-Assisted Sintering of Lunar Regolith Simulant. Materials 2020, 13, 4128. https://doi.org/10.3390/ma13184128

Phuah XL, Wang H, Zhang B, Cho J, Zhang X, Wang H. Ceramic Material Processing Towards Future Space Habitat: Electric Current-Assisted Sintering of Lunar Regolith Simulant. Materials. 2020; 13(18):4128. https://doi.org/10.3390/ma13184128

Chicago/Turabian StylePhuah, Xin Li, Han Wang, Bruce Zhang, Jaehun Cho, Xinghang Zhang, and Haiyan Wang. 2020. "Ceramic Material Processing Towards Future Space Habitat: Electric Current-Assisted Sintering of Lunar Regolith Simulant" Materials 13, no. 18: 4128. https://doi.org/10.3390/ma13184128

APA StylePhuah, X. L., Wang, H., Zhang, B., Cho, J., Zhang, X., & Wang, H. (2020). Ceramic Material Processing Towards Future Space Habitat: Electric Current-Assisted Sintering of Lunar Regolith Simulant. Materials, 13(18), 4128. https://doi.org/10.3390/ma13184128